Conveying system of automatic yarn feeding equipment

A technology of conveying system and equipment, applied in the field of conveying system, can solve the problems of waste of resources and high cost, and achieve the effects of improving production efficiency, simple use and maintenance, and small changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

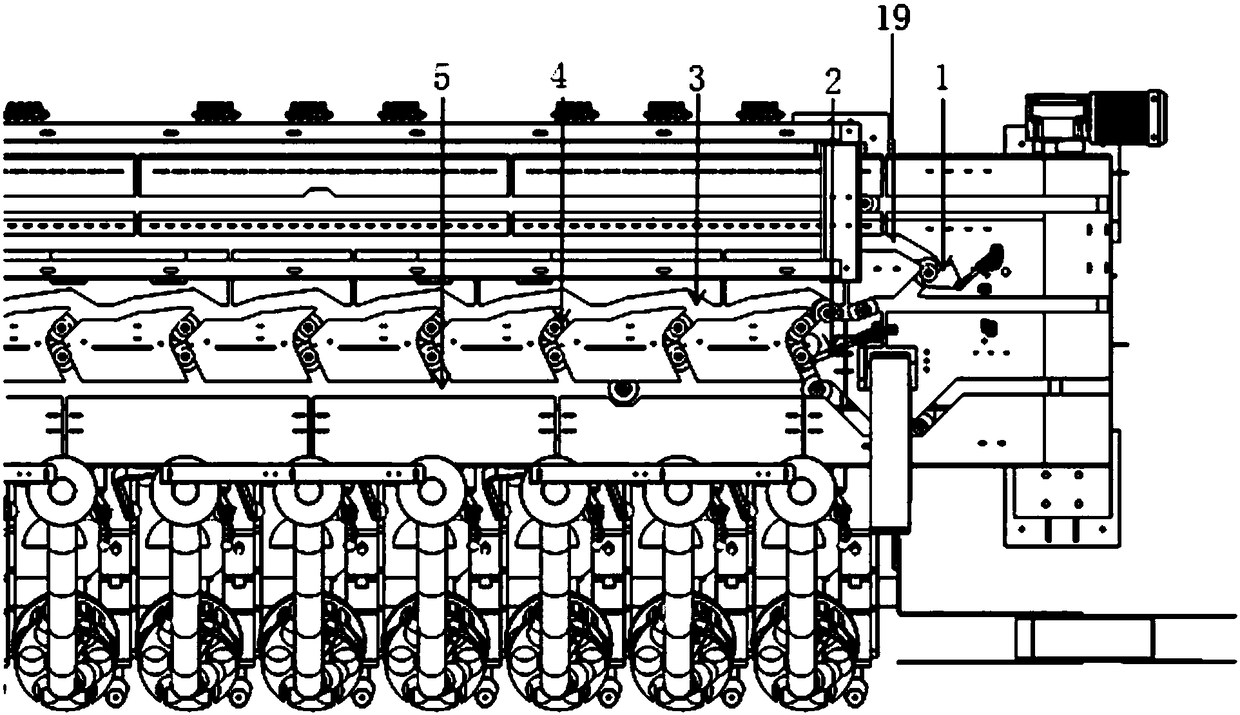

[0034] Such as figure 1 As shown, a conveying system of automatic yarn feeding equipment is erected above the automatic winder, and conveys the bobbin and bottom support to each winding station. Including feed channel 3, return channel 19 and base recovery channel 5.

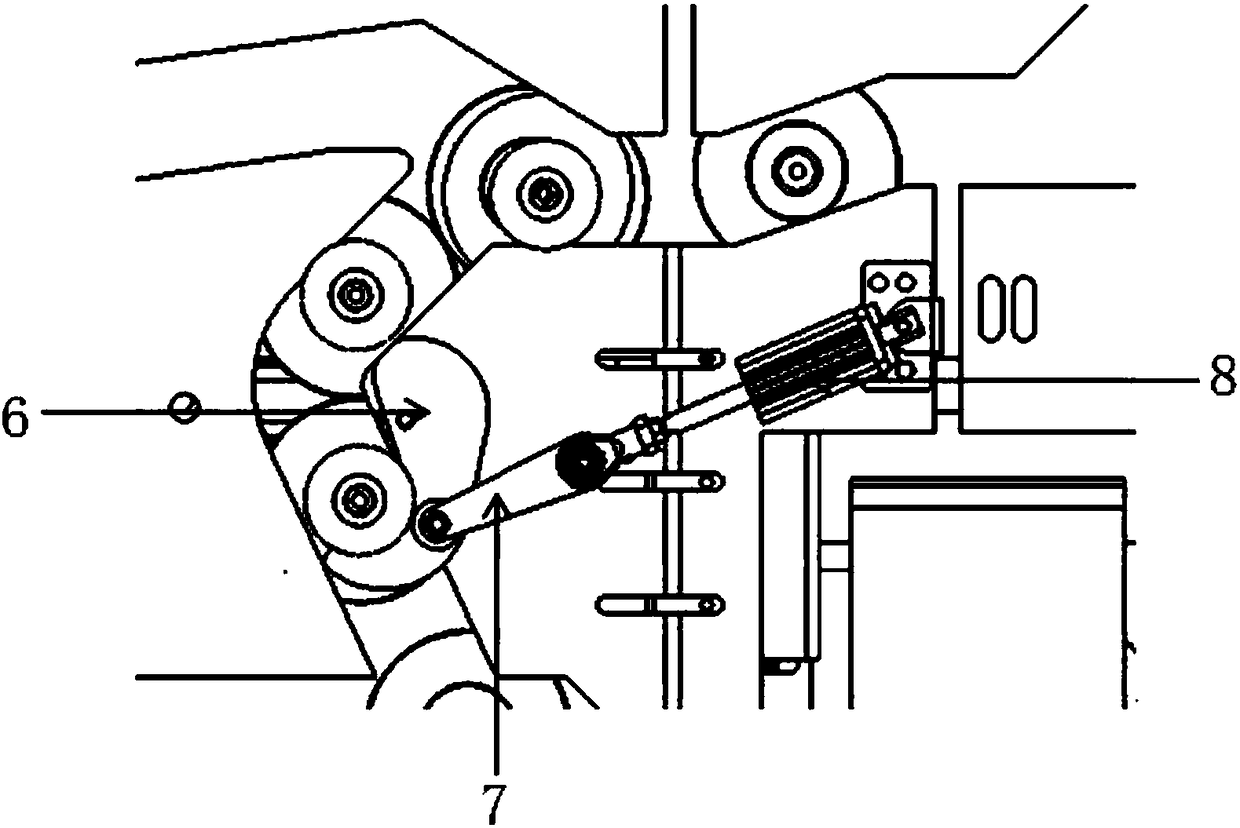

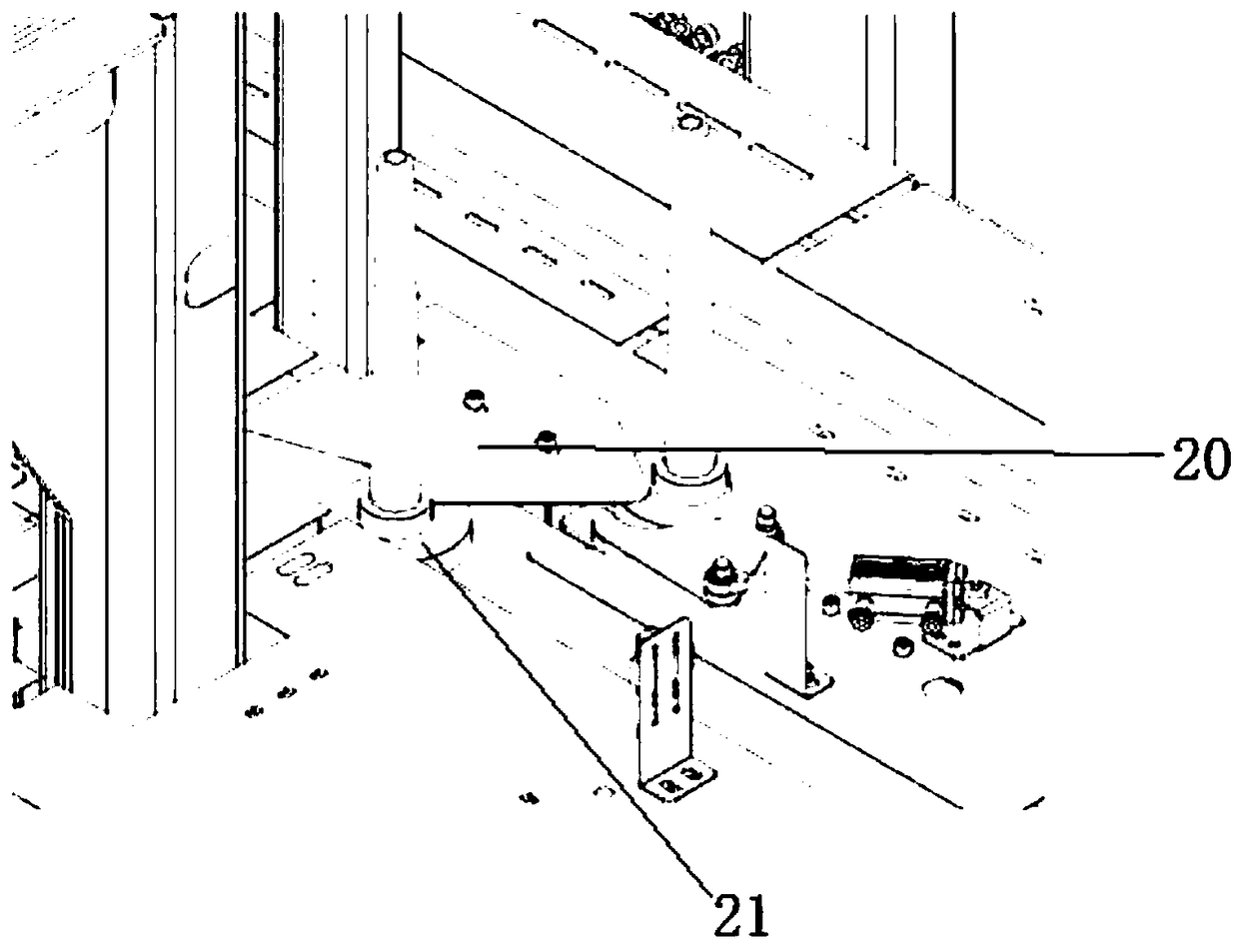

[0035] The feeding channel 3 is arranged along the direction of the winding station, and each winding station is branched by the bottom support to guide the cover plate 20 to have a waiting channel 4, and the waiting channel 4 is sequentially provided with queuing stations and The station to be grasped is provided with a photoelectric switch capable of detecting whether there is a bobbin on the station to be grasped, and the station to be grasped is provided with a shift fork capable of blocking the bottom bracket 21 and a single release bottom bracket Institution 2.

[0036] The feeding channel 3 uti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com