Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272 results about "Smart factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smart factory-based multi-function data acquisition device, acquisition system and method

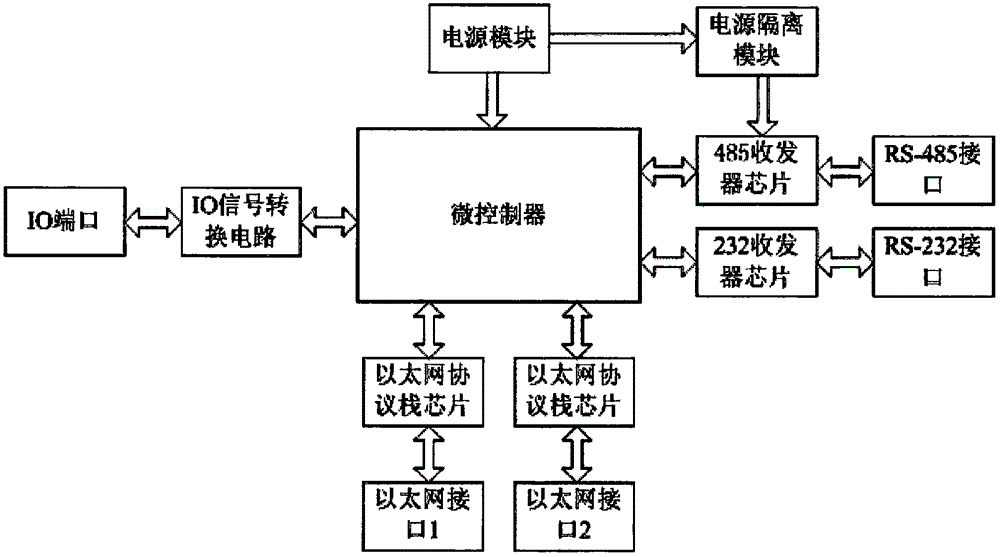

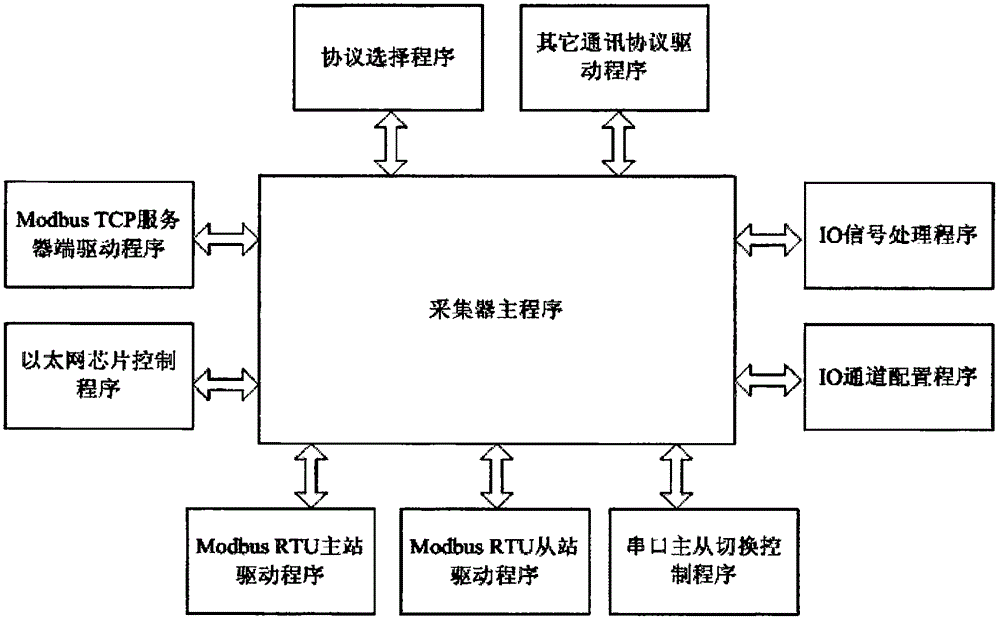

ActiveCN105785958AEasy to install on siteConvenient power supplyTotal factory controlProgramme total factory controlSmart factoryEthernet protocol

The invention discloses a smart factory-based multi-function data acquisition device, acquisition system and method. The acquisition device comprises a microprocessor as well as a power supply module, a 485 transceiver chip, a 232 transceiver chip, an IO signal conversion circuit and two Ethernet protocol stack chips which are connected with the microprocessor, wherein the 485 transceiver chip and the 232 transceiver chip are respectively provided with an RS-485 Interface and an RS-232 interface which are used for connecting external devices and acquiring device data, the Ethernet protocol stack chips are provided with Ethernet interfaces and are used for connecting upper computers or other acquisition devices and transmitting data, and the IO signal conversion circuit is provided with an IO port and is used for connecting external devices, acquiring signals or controlling the devices. The data acquisition device can be configured to a master station mode or a slave station mode, and is flexible in interfacing, and therefore, the data acquisition device can read data of field devices and scattered acquisition points more economically, conveniently and efficiently and provide complete and accurate bottom data for the establishment of a smart factory.

Owner:HANGZHOU JIKONG SOFTWARE CO LTD

Remote monitoring method and system for industrial production

PendingCN105357299AProduction management is more convenient and efficientHigh degree of digitizationSubstation equipmentTransmissionSmart factoryWireless data

The invention discloses a remote monitoring method and system for industrial production. The remote monitoring system mainly comprises a data acquisition module for performing data acquisition and data processing on the data generated by production stations, a wireless data receiving and sending base station for performing wireless receiving and sending on the data, a mobile terminal (mobile Internet equipment, such as a smart phone and the like) with a function of receiving and sending wireless data, and APP software mounted on the mobile terminal. The remote monitoring system adopts the wireless transmission technology; the mobile terminal is used as the terminal point and the source point of information for performing remote monitoring on the industrial production fields, so that the remote monitoring system is novel and creative; by adoption of the system, the real-time remote monitoring and control on production posts by industrial production administrators can be realized; and the remote monitoring system is an important production auxiliary management system of an industrial 4.0 system and is the important component of smart factories.

Owner:郑州弗曼智能设备科技有限公司

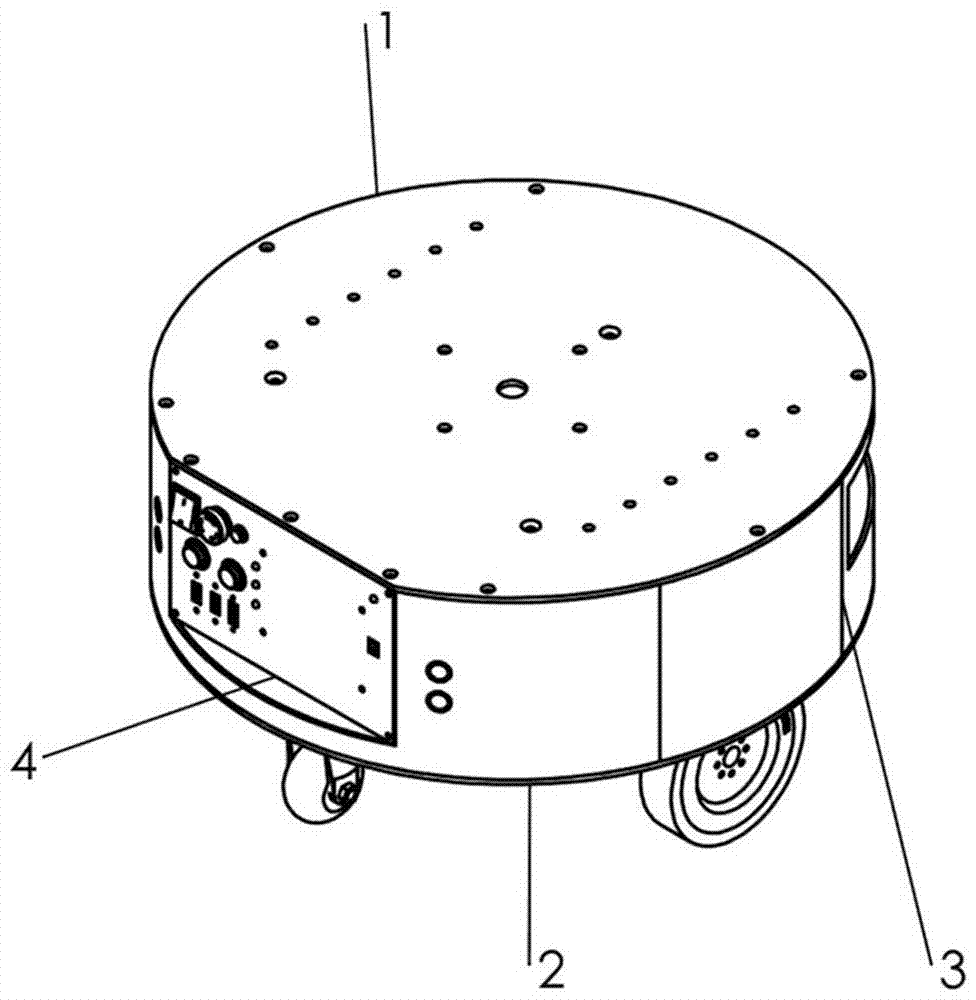

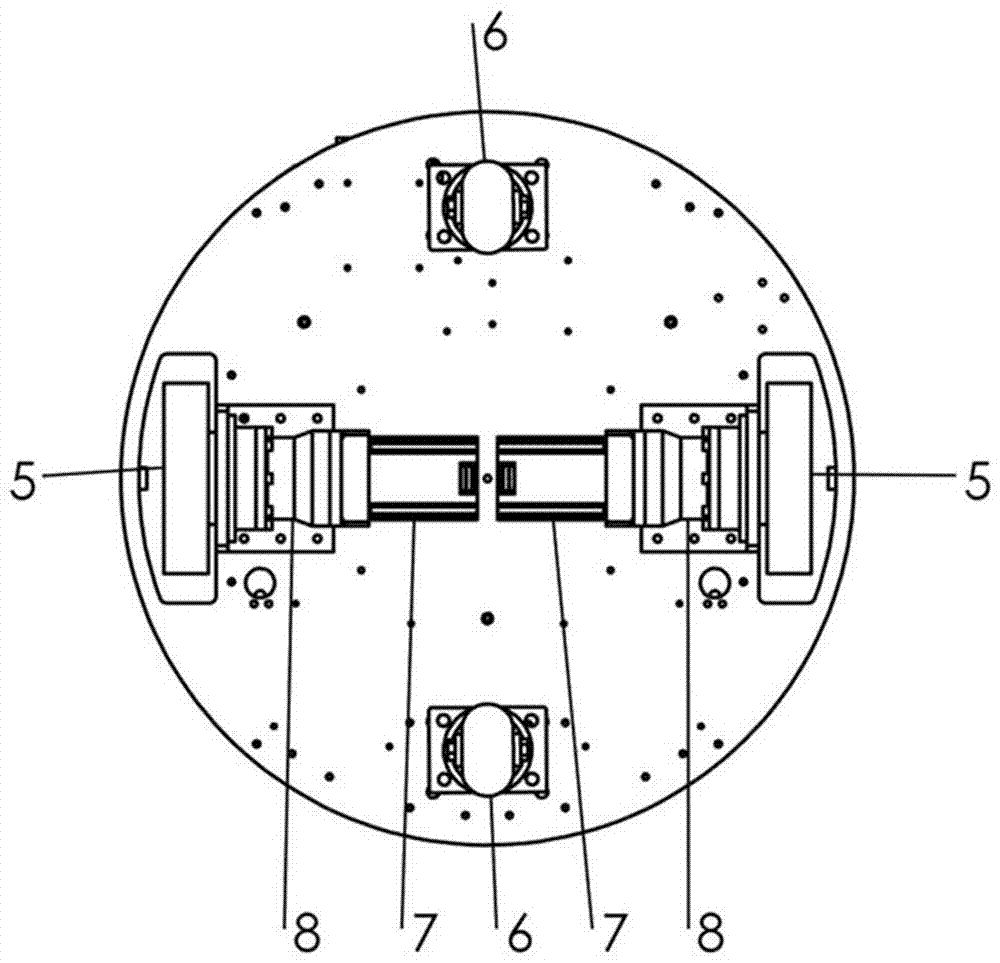

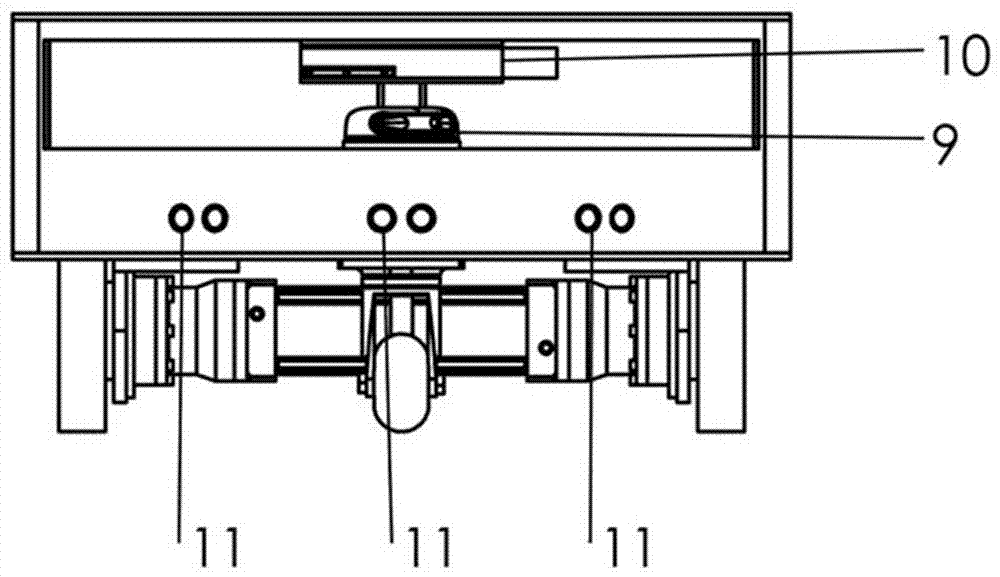

Autonomous navigation mobile robot and its operation method

PendingCN107193283ARealize interactionHigh degree of automationPosition/course control in two dimensionsVehiclesSensing dataSmart factory

The invention discloses an autonomous navigation mobile robot and its operation method. The robot includes a robot chassis frame, a host computer, a sensor system, an operation control panel, a power supply system, a driving system, a robot controller and a remote control device; the robot chassis frame is composed of a top plate, a bottom plate and a coaming, wherein the coaming surrounds the top plate and the bottom plate and is fixedly installed between the top plate and the bottom plate, the end opposite to the end provided with the operation control panel is provided with a groove, the sensing system includes a laser radar sensor and a stereo camera, the laser radar sensor and the stereo camera are fixedly installed in the groove, and the laser radar sensor and the stereo camera transmits obtained sensing data to the host computer connected with the laser radar sensor and the stereo camera in real time. The robot has the advantages of being high in degree of automation, short in deployment time, low in maintenance cost, widely applied and the like, can be widely applied in a dining room for food delivery, in a shopping mall for shopping guide, and in a smart factory for cargo transportation and conveying, and interaction between the robot and a user is effectively achieved.

Owner:青岛诺动软件有限公司

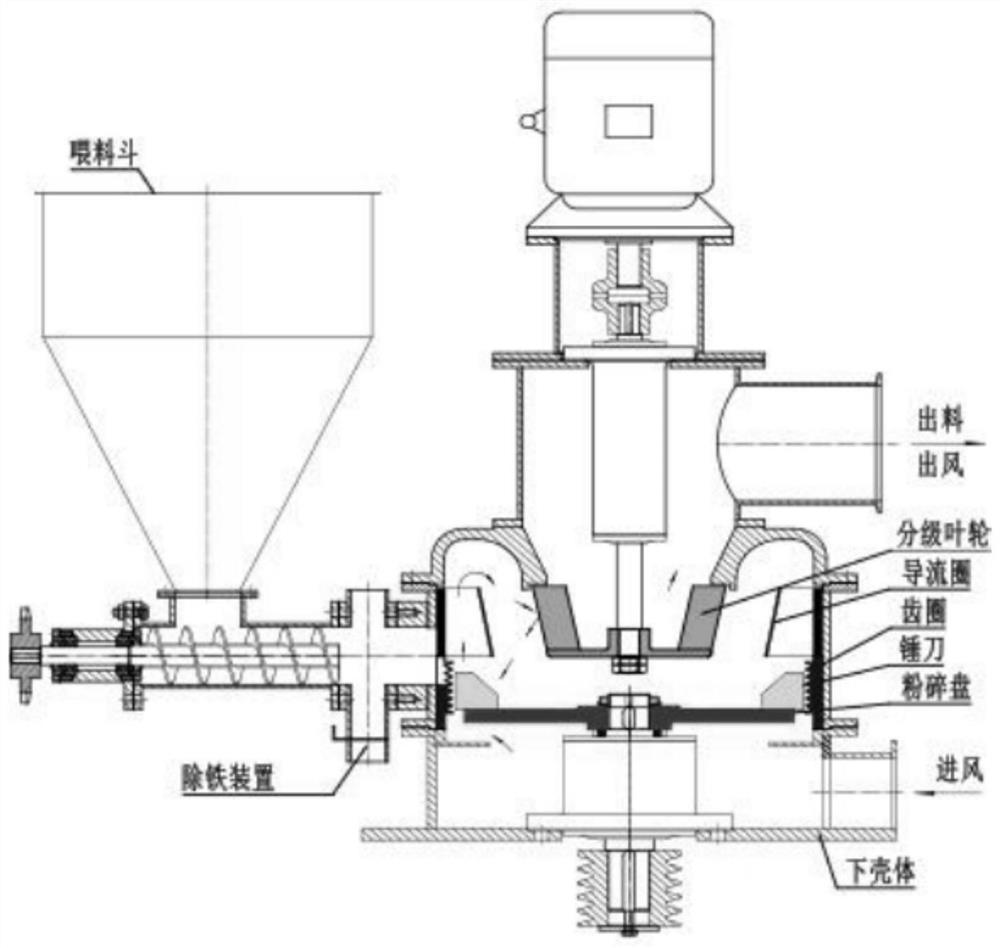

Multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and construction method

PendingCN112163688AIncrease productivityReduce operating costsForecastingResourcesInformation interoperabilitySmart factory

The invention provides a multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and a construction method. The invention breaks through a multi-dosage-form Chinese and western medicine product manufacturing process and a digital equipment technology. Advanced intelligent equipment such as intelligent equipment facilities, intelligent sensors, intelligent instruments and meters, industrial robots and the like are applied to implementation, and an advanced industrial control system, industrial control software and the like are integrated through technologies such as the Internet of Things technology, the big data technology, cloud computing, artificial intelligence, information security and the like. The information intercommunication between people and equipment, the information intercommunication between equipment and equipment, the information intercommunication between equipment and systems and the information intercommunication between systems are achieved. The full-life-cycle information integration of products from research and development design, planned purchasing, production and manufacturing, quality inspection, sales delivery,product tracing, after-sales service and the like is achieved.

Owner:CHONGQING PHARSCIN PHARM CO LTD

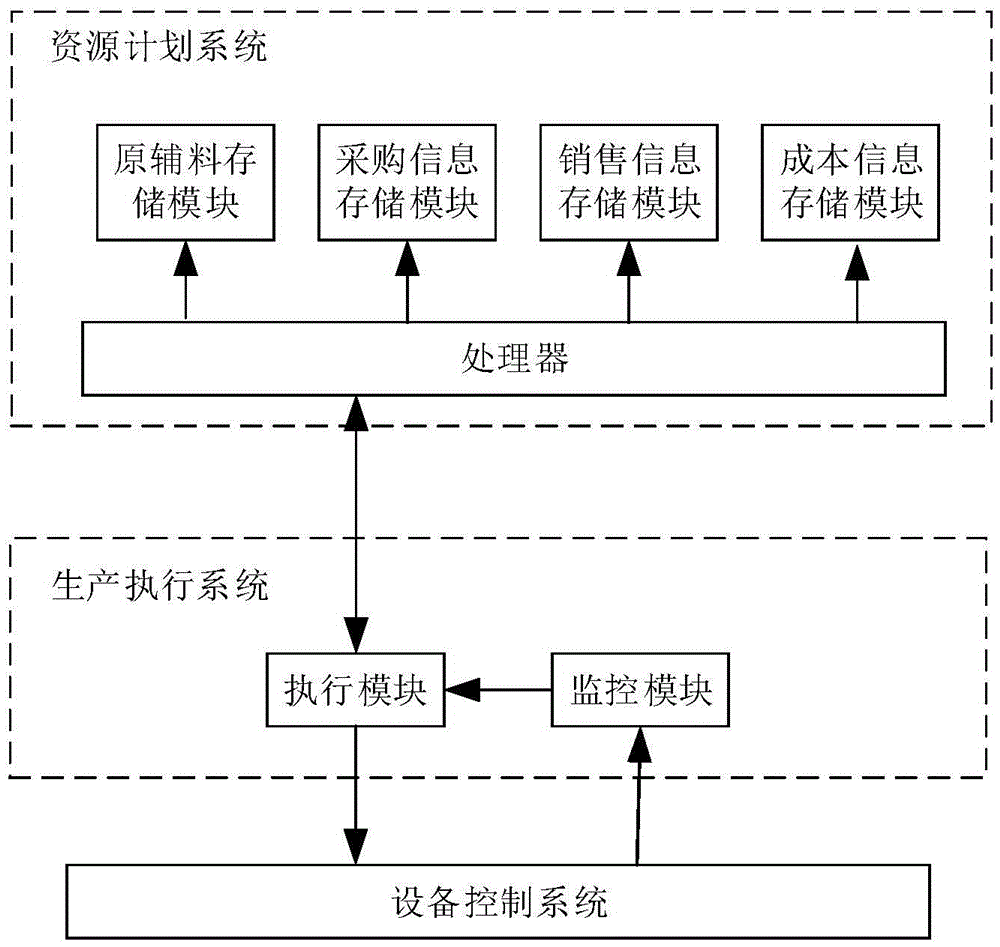

Traditional Chinese medicine smart factory integration system

InactiveCN105549570AAchieve sharingSolve the island problemProgramme total factory controlSmart factoryChinese herbology

The present invention discloses a traditional Chinese medicine smart factory integration system. The system comprises: a resource planning system consisting of an information storage module and a processor, wherein the information storage module is electrically connected with the input end of the processor; a device control system; a production execution system consisting of an execution module and a monitoring module which are electrically connected with each other, wherein one end of the execution module is connected with the processor, the other end of the execution module is connected with the device control system, and the information storage module consists of a raw auxiliary material storage module, a purchasing information storage module, a sale information storage module and a cost information storage module. The resource planning system, the device control system and the production execution module are connected through a TCP / IP wireless local area network. The traditional Chinese medicine smart factory integration system is able to realize the automation of a production process, the visualization of a production monitoring process, the process control optimization and the integration technology of a management system and a control system, so that the quality of products is guaranteed.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH +1

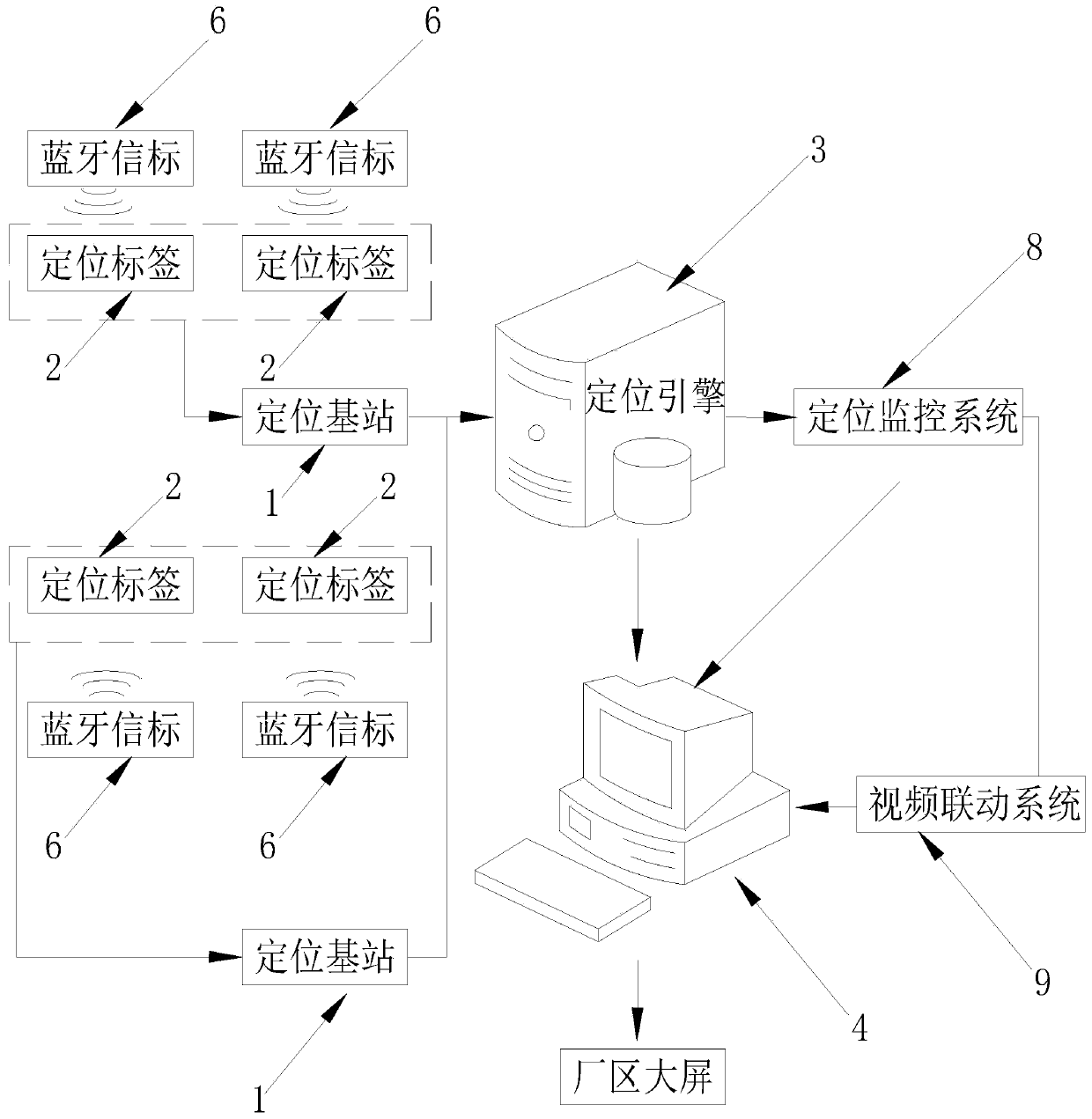

Intelligent factory area positioning and identifying system

InactiveCN111163420AEasy to operateComprehensive real-time dynamic controlParticular environment based servicesAlarmsInformation processingSmart factory

The invention relates to an intelligent factory area positioning and identifying system, which comprises an information processing system, a positioning engine, a plurality of Bluetooth beacons, a plurality of positioning tags and a plurality of positioning base stations, wherein the plurality of positioning base stations are deployed in a factory area at intervals, the Bluetooth beacons are deployed in the factory area at interval, and the Bluetooth beacons are used for sending positioning data to the positioning tags moving in the factory area at a certain frequency; a plurality of positioning tags are pasted on the target object and are in binding connection with the target object, the positioning tags receive Bluetooth signals sent by the Bluetooth beacons, and the current position ofthe target object is calculated according to the intensity information of the Bluetooth signals of the Bluetooth beacons; the positioning tags are used for adjusting the sending state of a Bluetooth signal in the Bluetooth beacons according to the current motion state. The positioning and identifying system is light, practical and easy to operate; through an accurate positioning technology, comprehensive real-time dynamic management and control are carried out on enterprise production personnel, and a safety management blind area is eliminated.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Digital twin management and control platform based on micro service

PendingCN113011837AImprove operational management efficiencyReduce the burden onGeometric CADDesign optimisation/simulationVideo monitoringData display

A digital twin management and control platform based on micro-service integrates park and factory resources depending on advanced technologies such as a three-dimensional model, big data analysis, virtual simulation and the like, and is a visual, intelligent and multi-dimensional comprehensive management and control platform which is oriented to a smart park and a smart factory and integrates comprehensive management and control and auxiliary decision analysis. The platform is provided with an equipment layer, a network layer, a service layer, an application layer and a display layer from bottom to top. According to the platform, the whole park is mapped to the three-dimensional visual management and control platform through the technologies of system integration, three-dimensional visual data display and the like and the TCP / IP and IOT technologies, and the application of a three-dimensional visual scene enables the content viewing of subsystems such as video monitoring, intrusion alarm, access control state and the like not to be limited in a data list mode. Instead, the position of the equipment is directly positioned through three-dimensional scene linkage, and the operation state and related records of the equipment are intelligently displayed, so that the operation management efficiency of the park is greatly improved, and the burden of operation and maintenance personnel is reduced.

Owner:江苏杰瑞信息科技有限公司

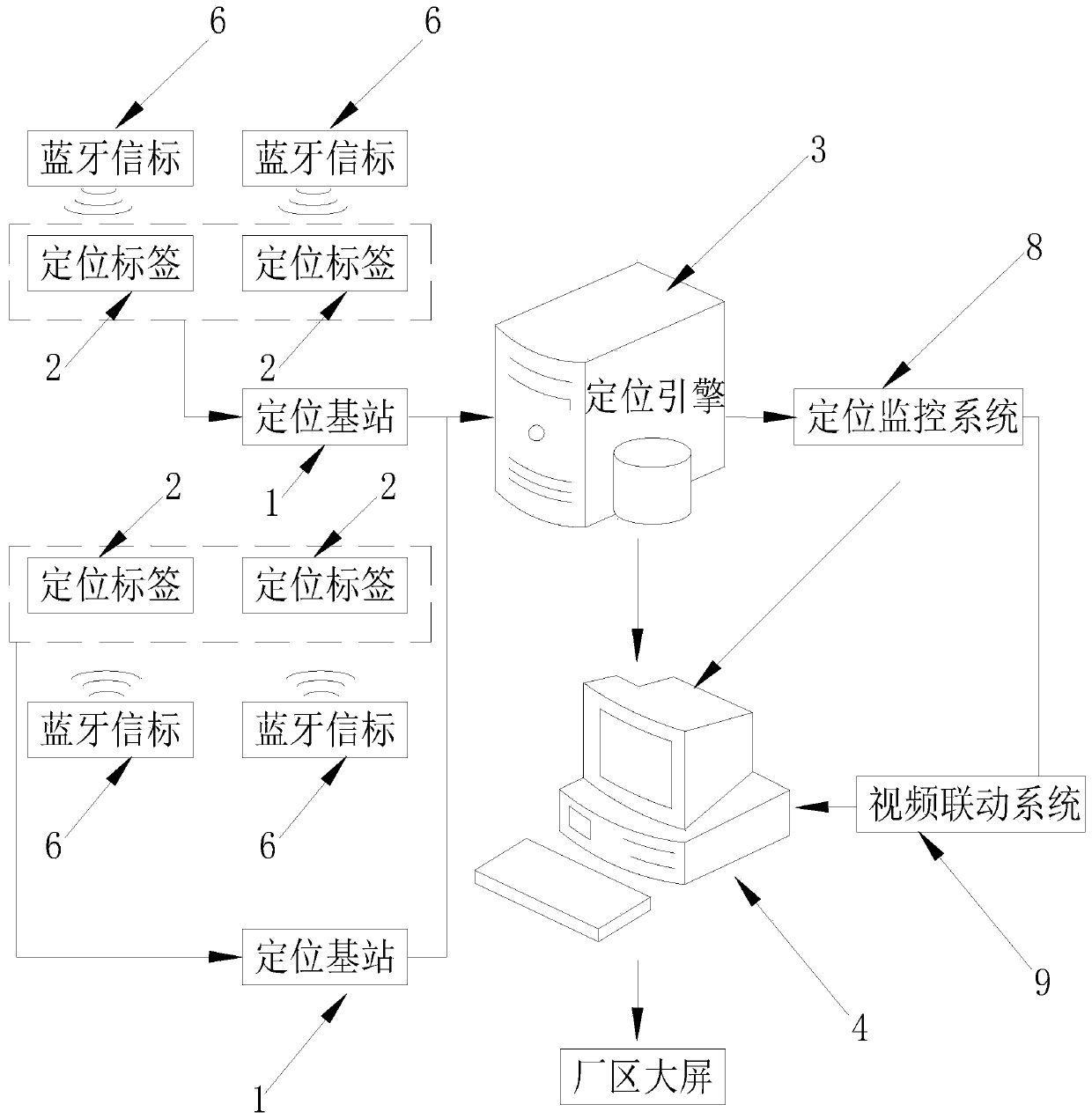

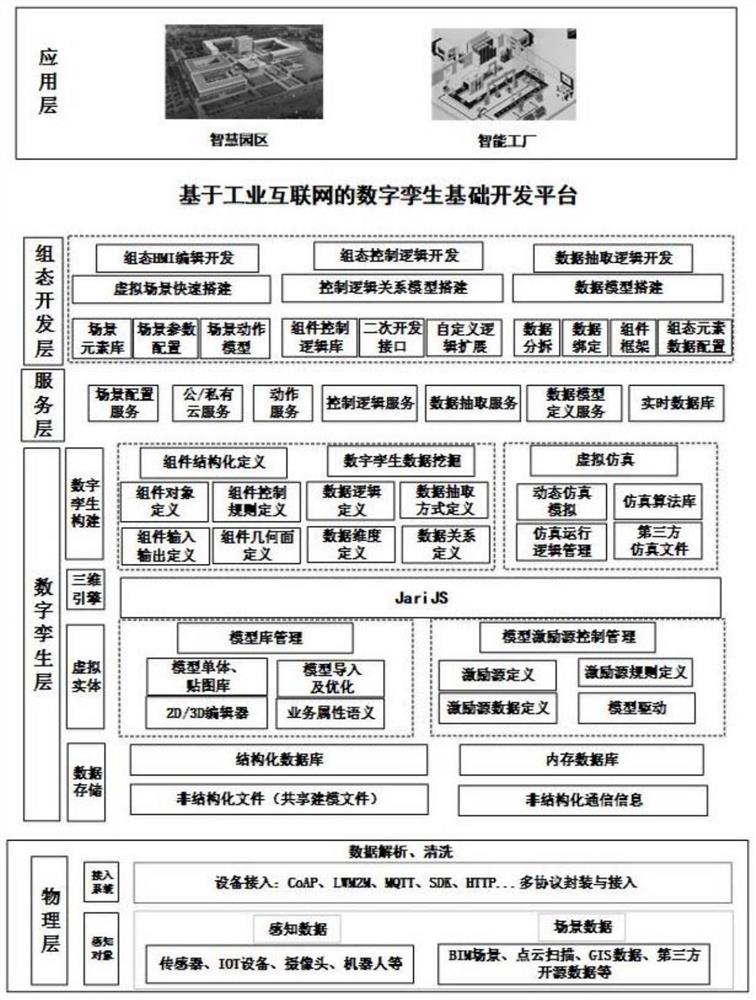

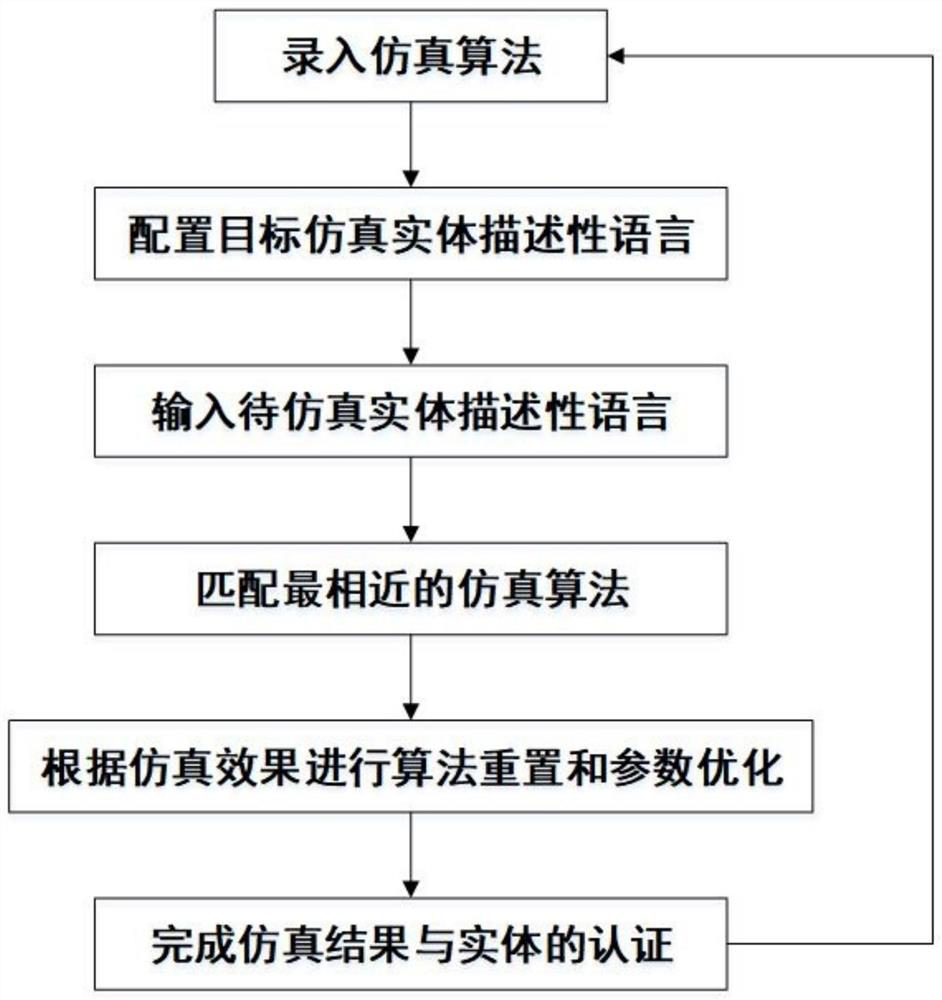

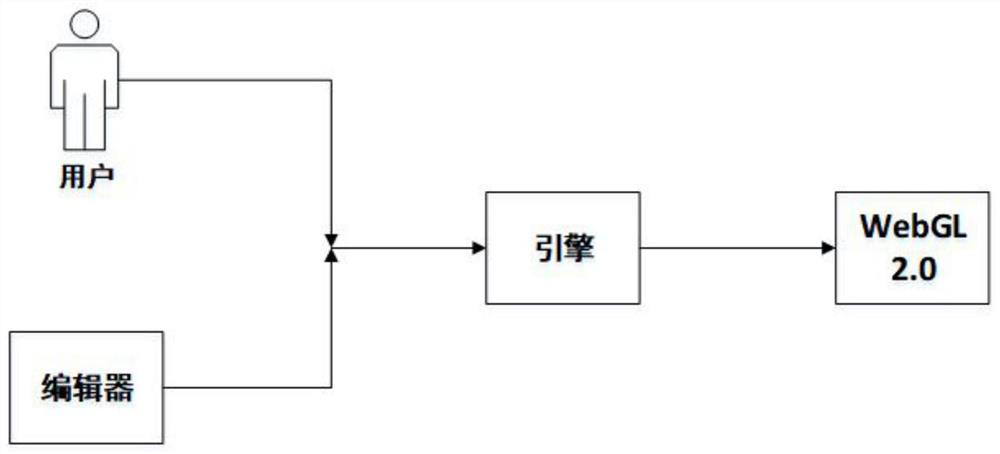

Digital twin basic development platform based on industrial internet

PendingCN113673948AImprove service capabilitiesImprove the ability to optimize configurationCAD network environmentSoftware designSmart factoryThe Internet

The invention relates to a digital twin basic development platform based on an industrial internet. Based on advanced technologies such as digital twinning development platform architecture construction, digital twinning rapid configuration engine and digital twinning simulation resource library construction, the problems of low process management and control visualization degree, insufficient virtual simulation construction capability, low system-level digital twinning scene construction and development efficiency and the like of typical industrial application scenes such as intelligent factories and the like are mainly solved. The invention is a set of visual, low-code and configurable digital twinning development platform based on the industrial internet technology, and management and control elements can be digitalized and modeled. Intelligent production service oriented to a global view angle is provided for industrial users, more intelligent data analysis capability is provided, and full-dimension and full-link process intelligent management is realized.

Owner:江苏杰瑞信息科技有限公司

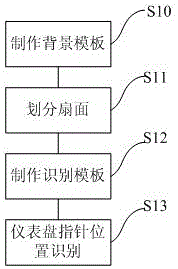

Intelligent factory supervision method

PendingCN111653023AHigh degree of intelligenceImprove regulatory efficiencyCharacter and pattern recognitionIndividual entry/exit registersData criteriaMachine vision

The invention relates to an intelligent factory supervision method, and the method comprises the steps: carrying out the classification of workers according to the organization structure or professional posts of an enterprise, and achieving the recognition of employees, outdoor workers and visitors when the pepole enter a factory; carrying out human face recognition through machine vision, and then counting attendance information of employees; detecting on-duty, off-duty and off-duty conditions of the employees and recording corresponding time through machine vision; carrying out detection anddata statistics on good products and inferior-quality products in the products through machine vision, and meanwhile, carrying out calculation to obtain productivity data; detecting violation behaviors of personnel in a plant area through machine vision; and carrying out positioning detection on the real-time position of each person in the factory. The intelligent factory supervision method is high in intelligent degree, high in supervision efficiency, low in labor cost, unified in data standard and low in management difficulty, and can timely discover various problems existing in the factoryoperation process so as to conveniently and timely eliminate various hidden dangers and improve the safety of various aspects of production.

Owner:深圳欧依云科技有限公司

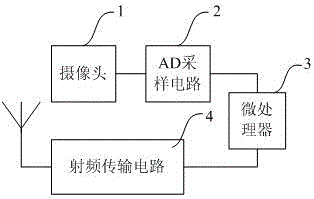

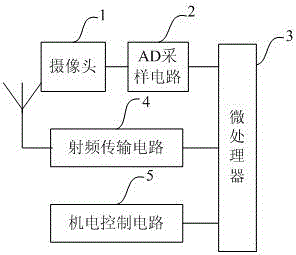

Production equipment data acquisition apparatus and method for smart factory

InactiveCN106444648AWide adaptabilityEasy to installTotal factory controlProgramme total factory controlCMOSSmart factory

The invention relates to a production equipment data acquisition apparatus for a smart factory. The production equipment data acquisition apparatus includes a camera, an AD sampling circuit, a microprocessor and a radio frequency transmission circuit, wherein the camera is used for acquiring the displayed images of an equipment meter or a display; the AD sampling circuit is used for converting analog signals into digital signals; the microprocessor is used for processing and analyzing the images of the meter or the display; the radio frequency transmission circuit is used for uploading the analyzed data to a server background system; and after the CMOS camera acquires the images of a meter panel or a display screen, the images are processed and analyzed, and the analyzed data is uploaded to the server background system through the radio frequency transmission circuit. The data acquisition apparatus can accurately acquire the data information displayed by old-fashioned equipment with a meter panel or novel equipment with a display screen and transmit the data information to the background system, and does not need to decode and analyze different interfaces and protocols of different pieces of equipment and also does not need to mount a sensor in production equipment while the sensor may influence normal operation of the production equipment. Therefore, the production equipment data acquisition apparatus for a smart factory has the advantages of being wide in adaptability, being simple and convenient for installation, and being lower in deployment difficulty and cost, compared with the original technology.

Owner:HUIZHOU IOT MICROELECTRONICS CO LTD

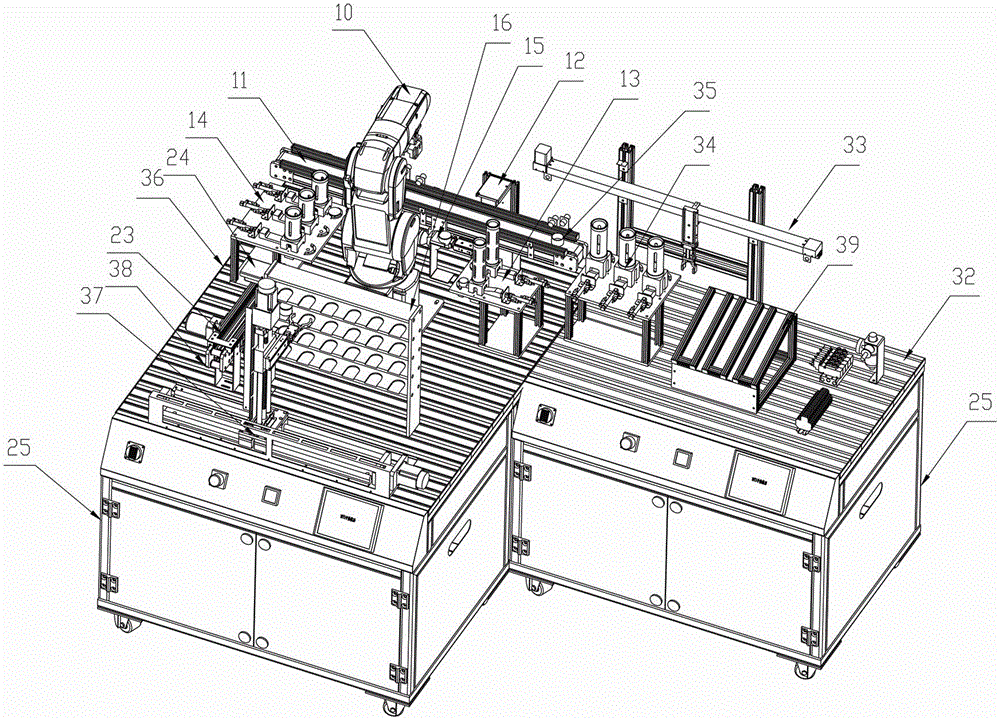

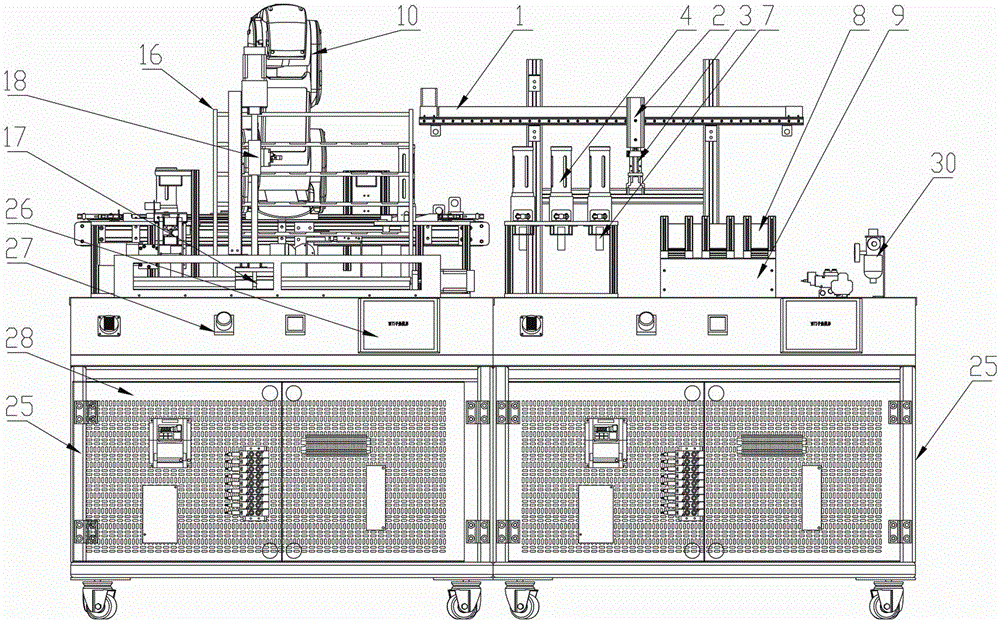

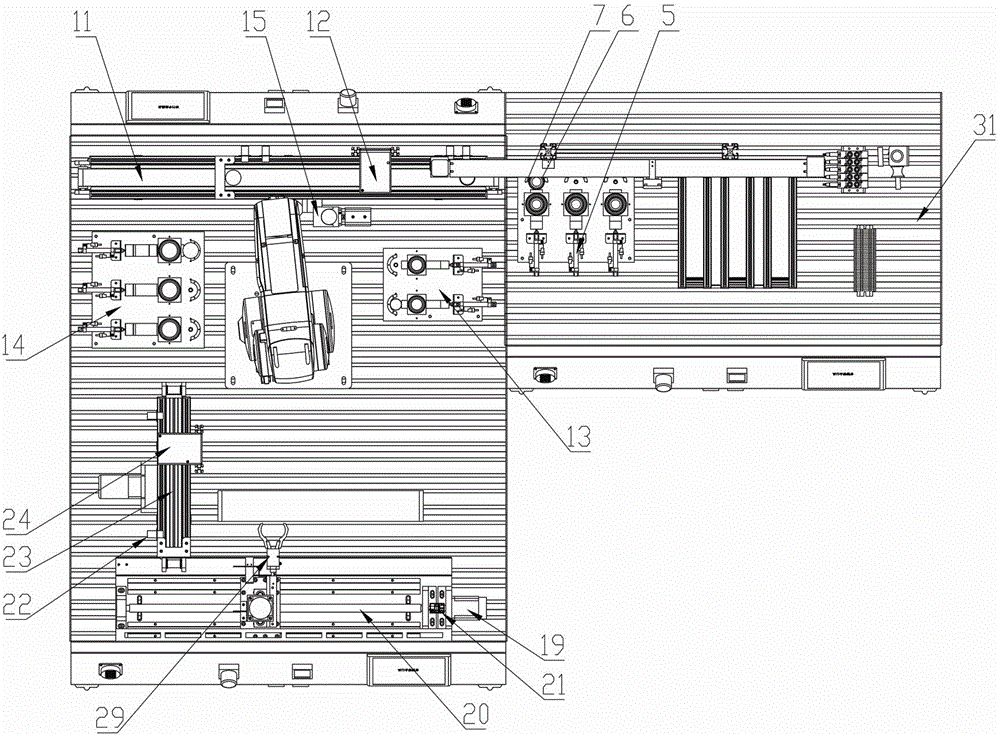

Production line information integration and control practice platform of intelligent manufacture

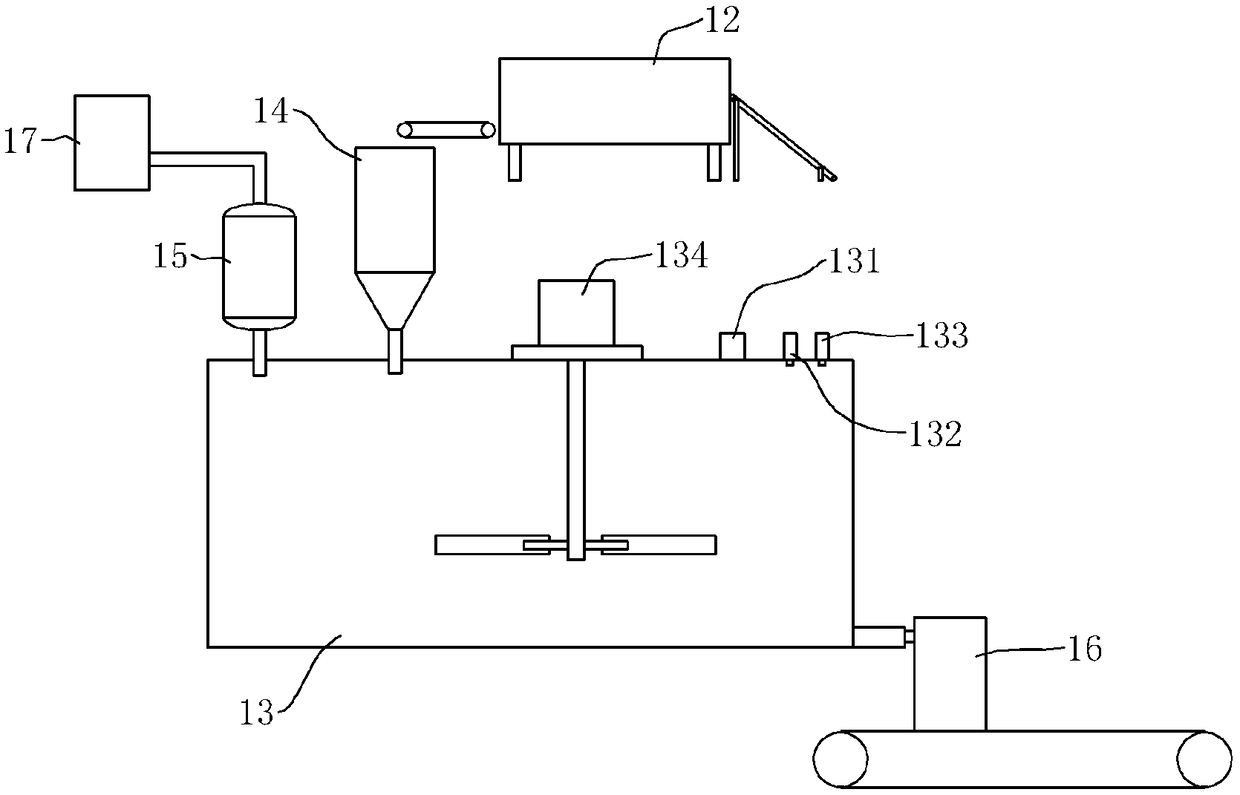

The invention relates to a production line information integration and control practice platform of intelligent manufacture. The practice platform is characterized by comprising a feeding and sorting integrated workstation, an industrial robot workstation, a multifunctional storage workstation and an intelligent production and manufacture management system. According to the technical scheme provided by the invention, the practical platform enables students to follow the development trends in intelligent manufacture and application of new technology, convenience is provided for optimization of teaching schemes, the platform can also help students develop learning interests and develop thinking, and thus, high-quality skill-orientated talents suitable for production line information integration and control, urgently needed by enterprises, and meeting requirements for intelligent factories and intelligent production in China manufacture 2025 plans in industry 4.0 can be cultivated.

Owner:ZHEJIANG TIANHUANG TECH INDAL

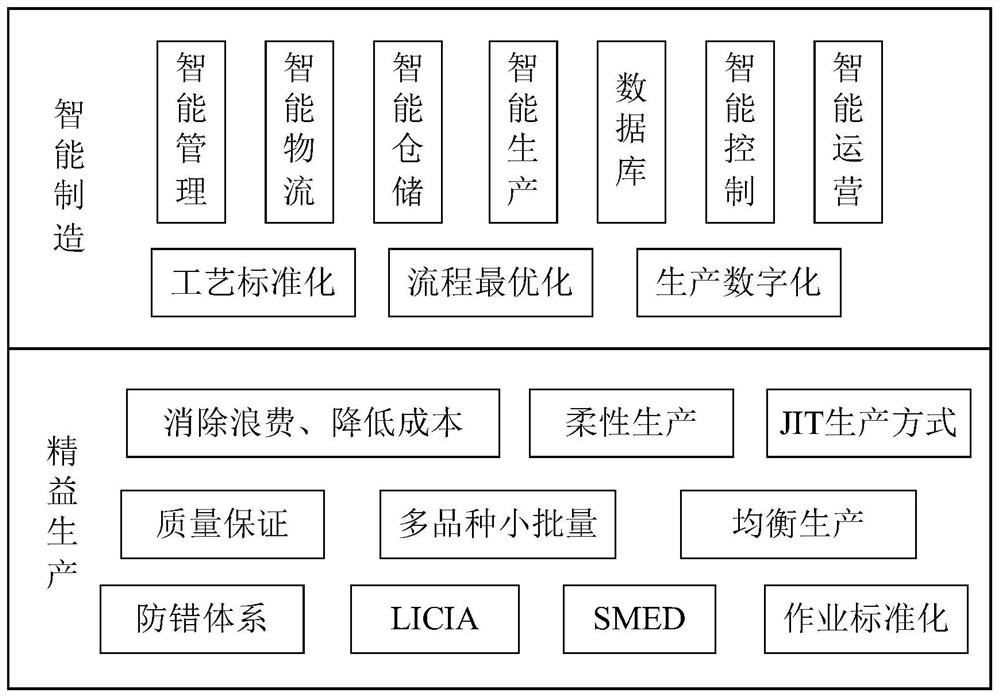

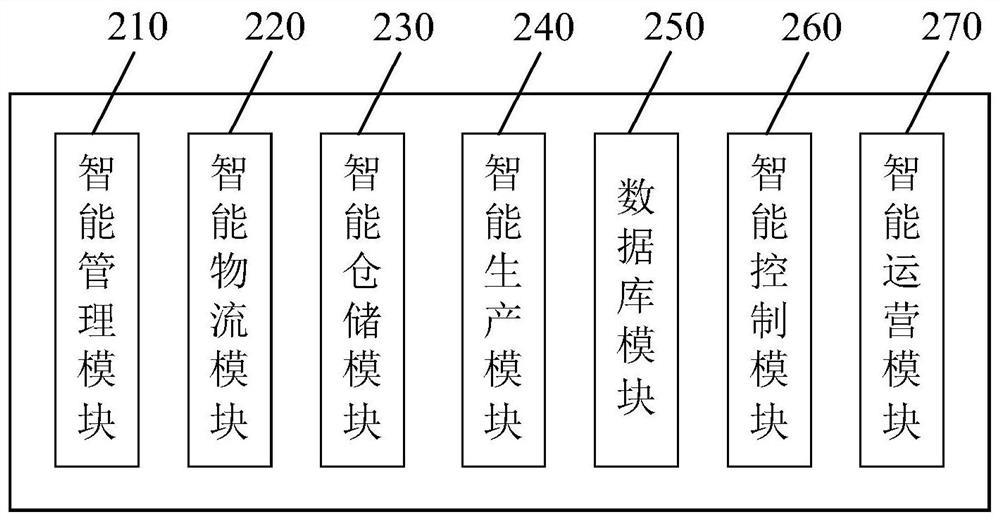

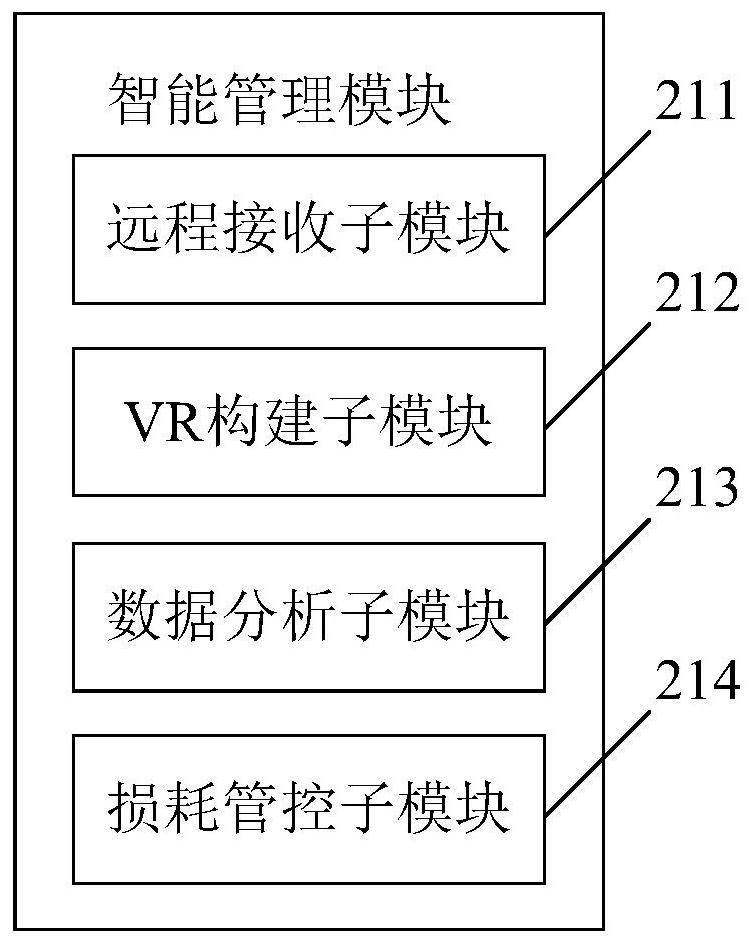

Intelligent factory control system and method based on big data

PendingCN112462698AImprove regulatory capacityReduce operating costsResourcesLogisticsSmart factoryService efficiency

The invention relates to an intelligent factory control system and method based on big data. The system comprises an intelligent management module used for obtaining equipment operation data and actual production data to obtain a control instruction, an intelligent logistics module used for dynamically tracking and acquiring external logistics data and internal logistics data in factory internal material assembly, an intelligent storage module used for distributing storage arrangements of the materials to obtain storage data, an intelligent production module used for carrying out intelligent production scheduling to obtain production scheduling data, a database module used for acquiring and storing the data, an intelligent control module used for formulating and adjusting scheduling shifttime, and an intelligent operation module used for arranging monitoring equipment in a factory and on a logistics vehicle. Through the seven modules of the system, cross-department, multi-system and full-process systematic operation can be realized, the comprehensive supervision capability of a factory park is improved, the enterprise operation cost is effectively reduced, and management refinement, decision scientization and high service efficiency are realized.

Owner:深圳市益鸿智能科技有限公司

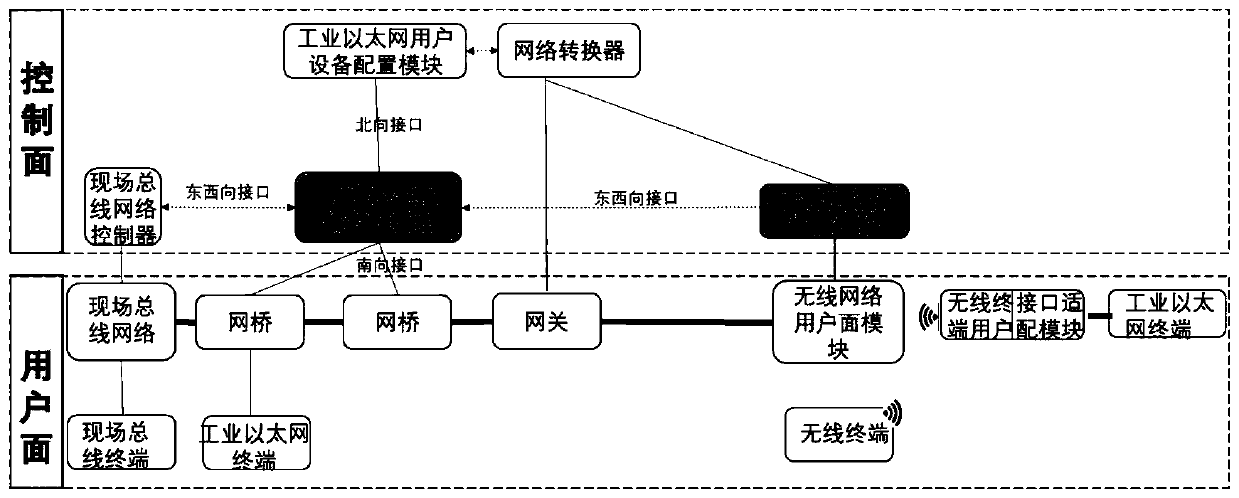

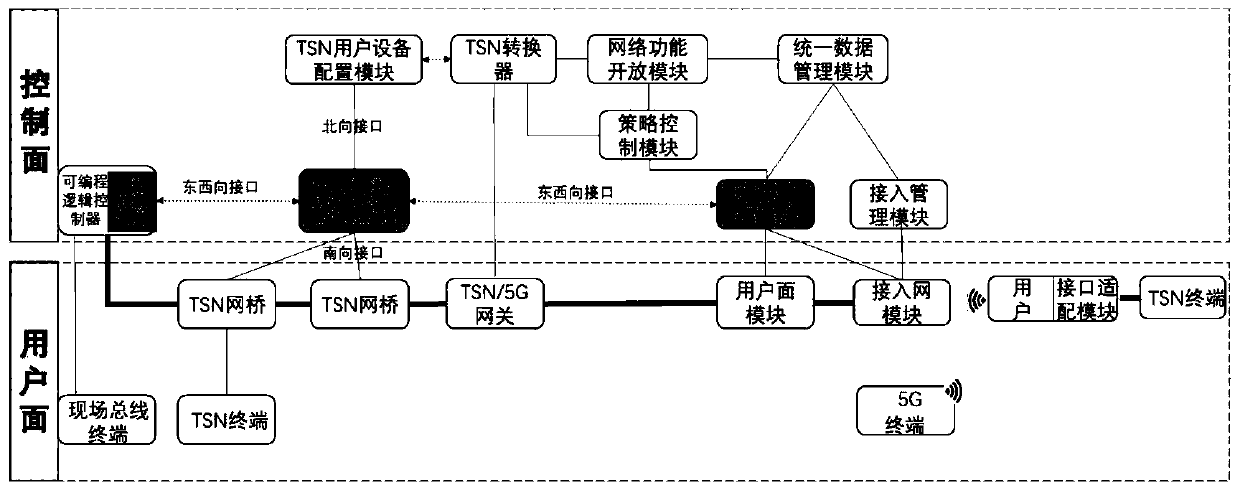

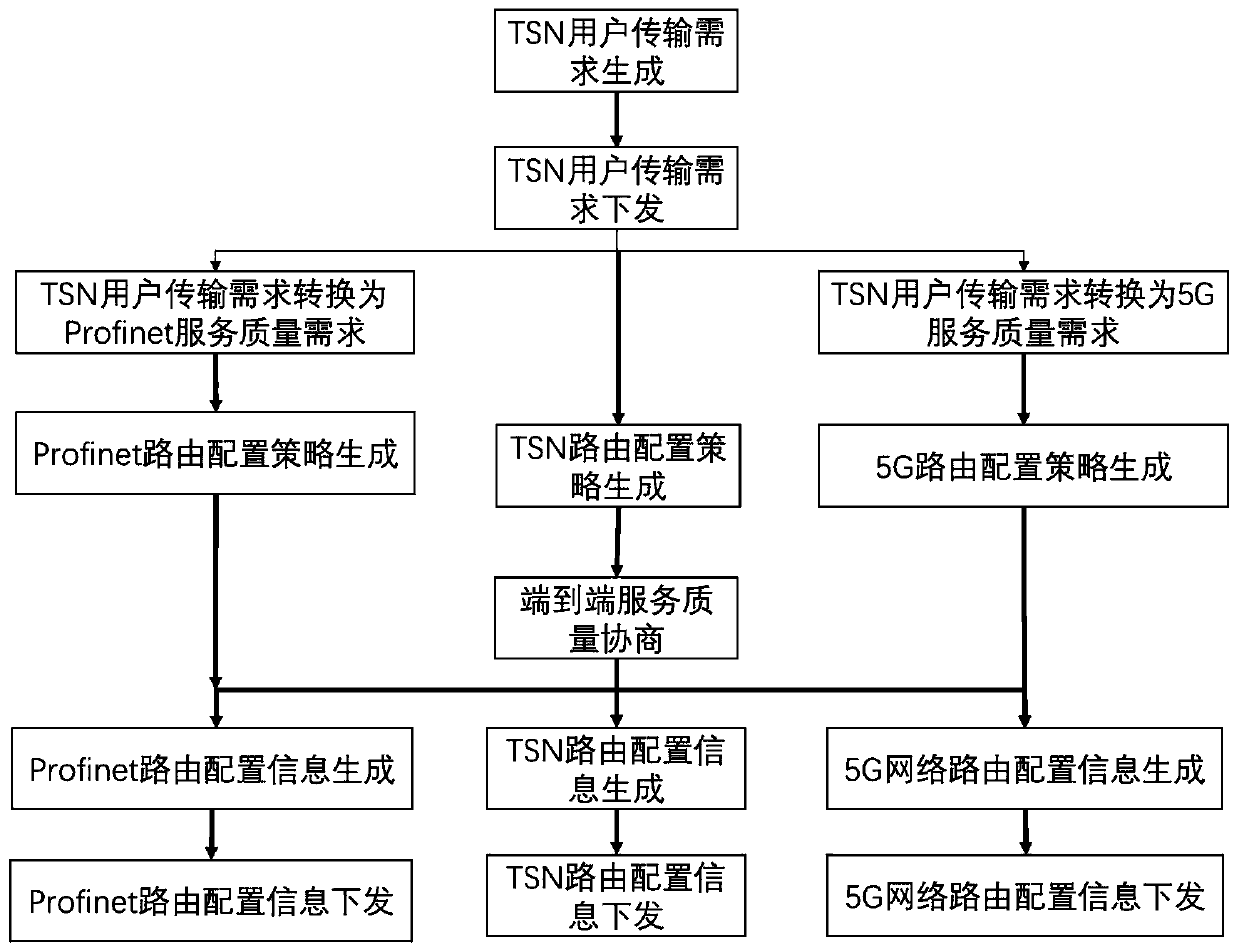

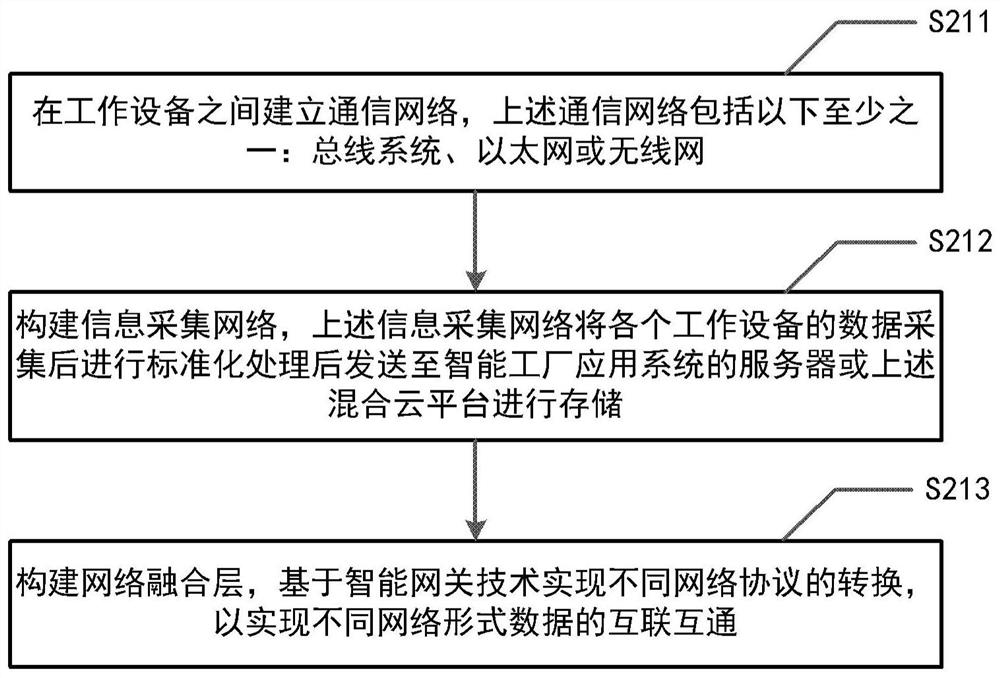

Heterogeneous convergence network architecture applied to intelligent factory and route configuration method

ActiveCN110996368ASupport interconnectionAccurately Control LatencyData processing applicationsParticular environment based servicesSmart factoryNetwork architecture

The invention relates to a heterogeneous convergence network architecture applied to an intelligent factory and a route configuration method. The network architecture comprises a field bus network, anindustrial Ethernet and a wireless network, wherein the fieldbus network mainly comprises a fieldbus network controller, a fieldbus network and a fieldbus terminal; the industrial Ethernet mainly comprises an industrial Ethernet user equipment configuration module, an industrial Ethernet network control module and a network bridge. The wireless network mainly comprises a network converter, a gateway, a wireless network control plane module, a wireless network user plane module, an access network module, a wireless terminal and an industrial Ethernet terminal supporting wireless transmission.According to the invention, effective interconnection and intercommunication between field devices based on different network technologies can be realized, and end-to-end time delay limitation of industrial control services can be ensured.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

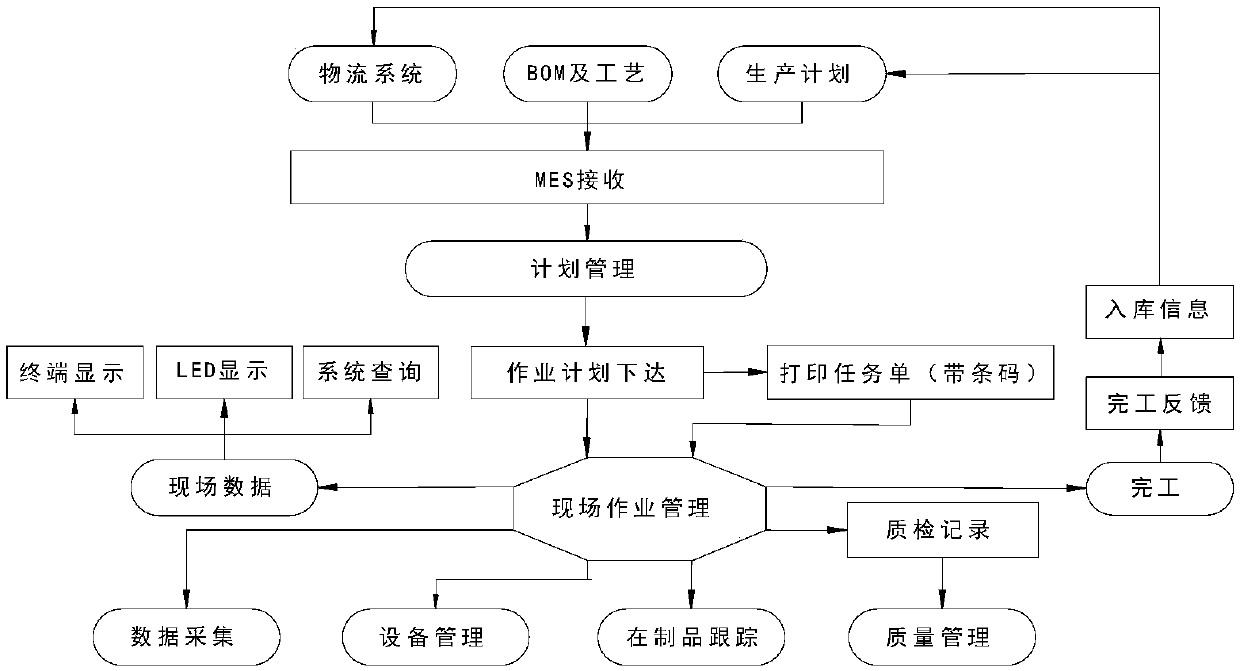

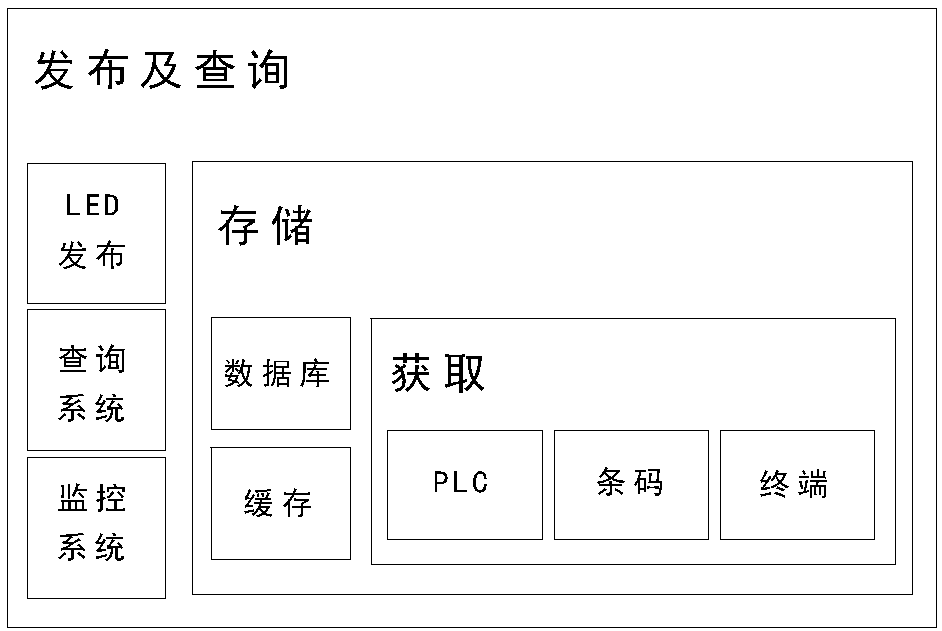

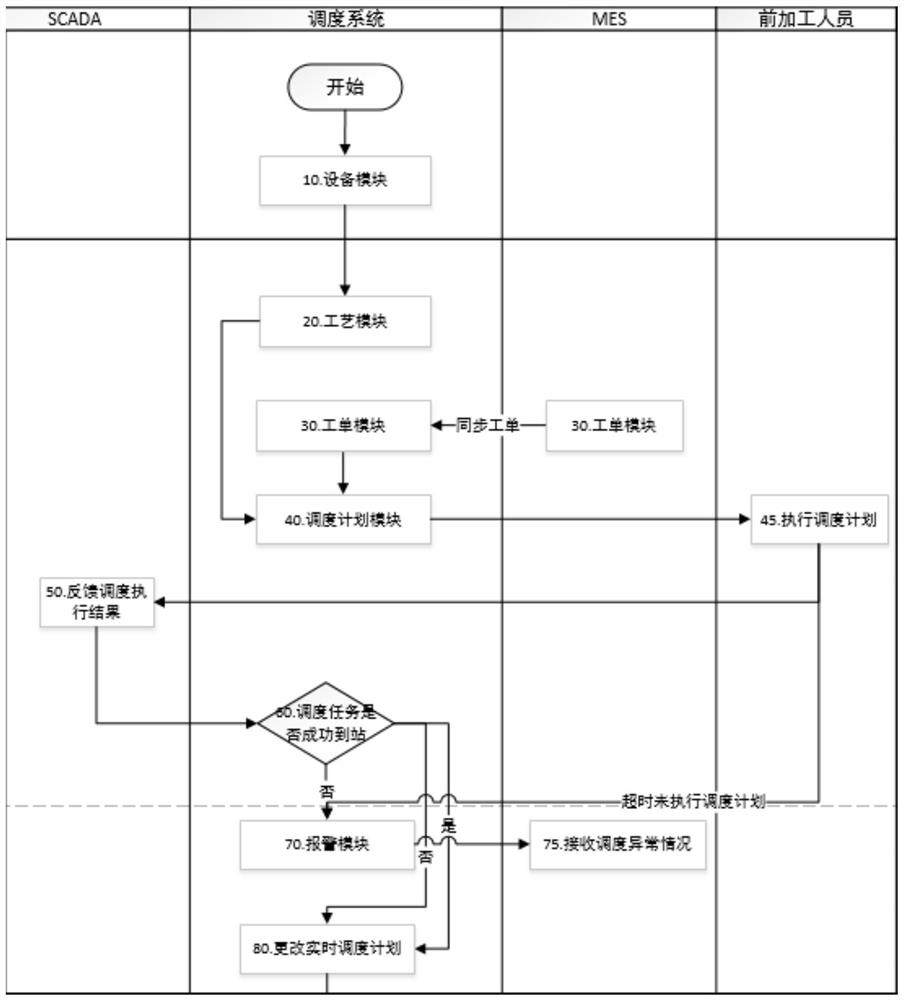

Production line data collection and kanban management system and method for smart factory

InactiveCN108681878AIncrease competitivenessAdjust production balanceOffice automationResourcesSmart factoryData acquisition

The invention provides a production line data collection and kanban management system for a smart factory. The system includes a production line data acquisition system and a kanban management systemthat are connected through an Ethernet; a production line data collection and kanban management method for the smart factory is also put forward and includes an MES receiving process and an on-site operation management process; an MES receives logistics system information, BOM and technique information, production plan information; plan management is carried out, an operation plan in plan management is issued, and on-site operation management is performed; the on-site operation management process includes data collection, equipment management, work-in-progress tracking and quality inspection records; quality management is carried out after the quality inspection records are gathered, and field data is formed during the on-site operation management; terminal display, LED display and systemquery of field data are performed, warehousing information is formed during completion feedback processes, and an MES receiving process is carried out after the warehousing information merges with theproduction plan information and the logistics system information.

Owner:浙江优勝科技有限公司

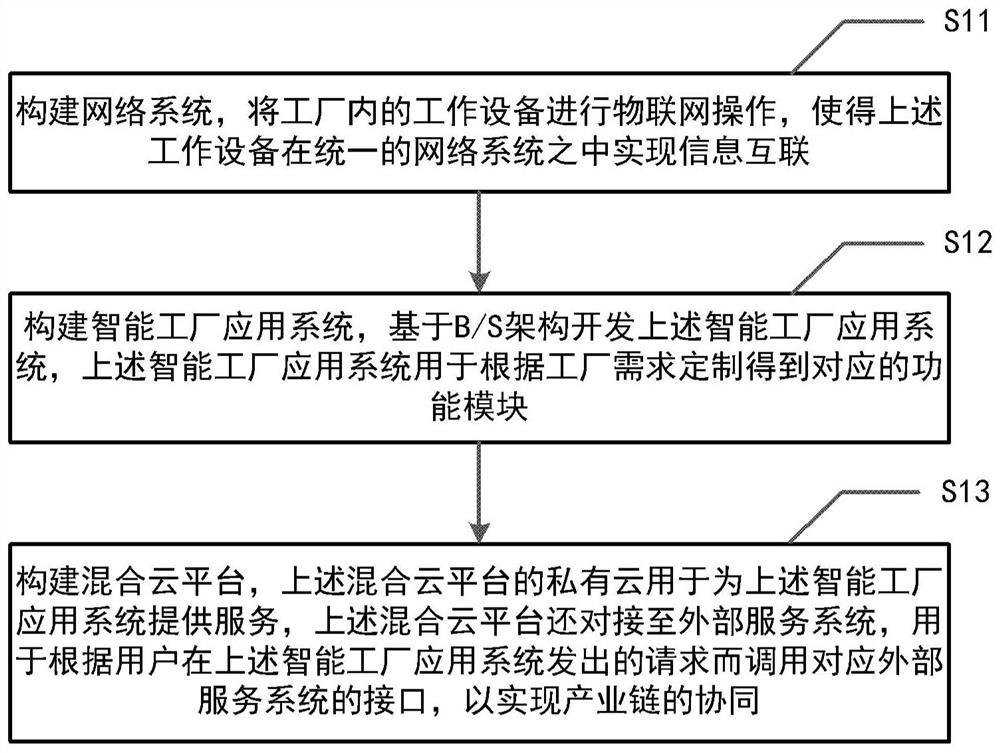

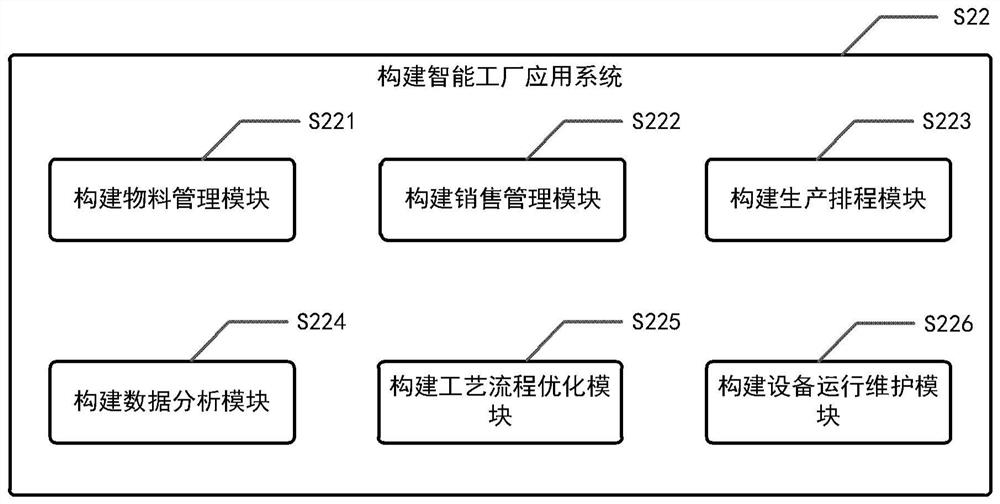

Intelligent factory based on industrial internet and construction method thereof

PendingCN113035376ARealize interconnectionRealize dockingOffice automationResourcesSmart factoryConstruction engineering

The invention provides an industrial internet-based intelligent factory and a construction method thereof, and the construction method comprises the steps: constructing a network system, carrying out the Internet of Things operation of working equipment in the factory, and enabling the working equipment to achieve the information interconnection in the unified network system; constructing an intelligent factory application system, developing the intelligent factory application system based on a B / S architecture, wherein the intelligent factory application system is used for obtaining corresponding function modules through customization according to factory requirements; and constructing a hybrid cloud platform, wherein a private cloud of the hybrid cloud platform is used for providing services for the intelligent factory application system, and the hybrid cloud platform is further in butt joint with an external service system and is used for calling an interface corresponding to the external service system according to a request sent by a user in the intelligent factory application system so as to achieve collaboration of industrial chains. Systematized, efficient and modularized construction of the intelligent factory is achieved.

Owner:TSINGHUA UNIV

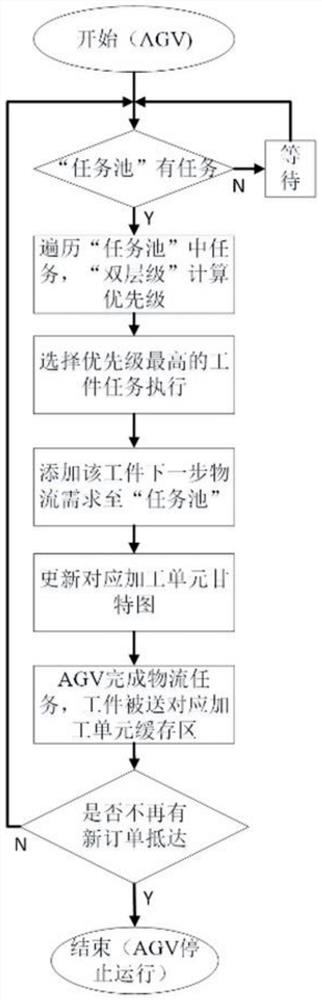

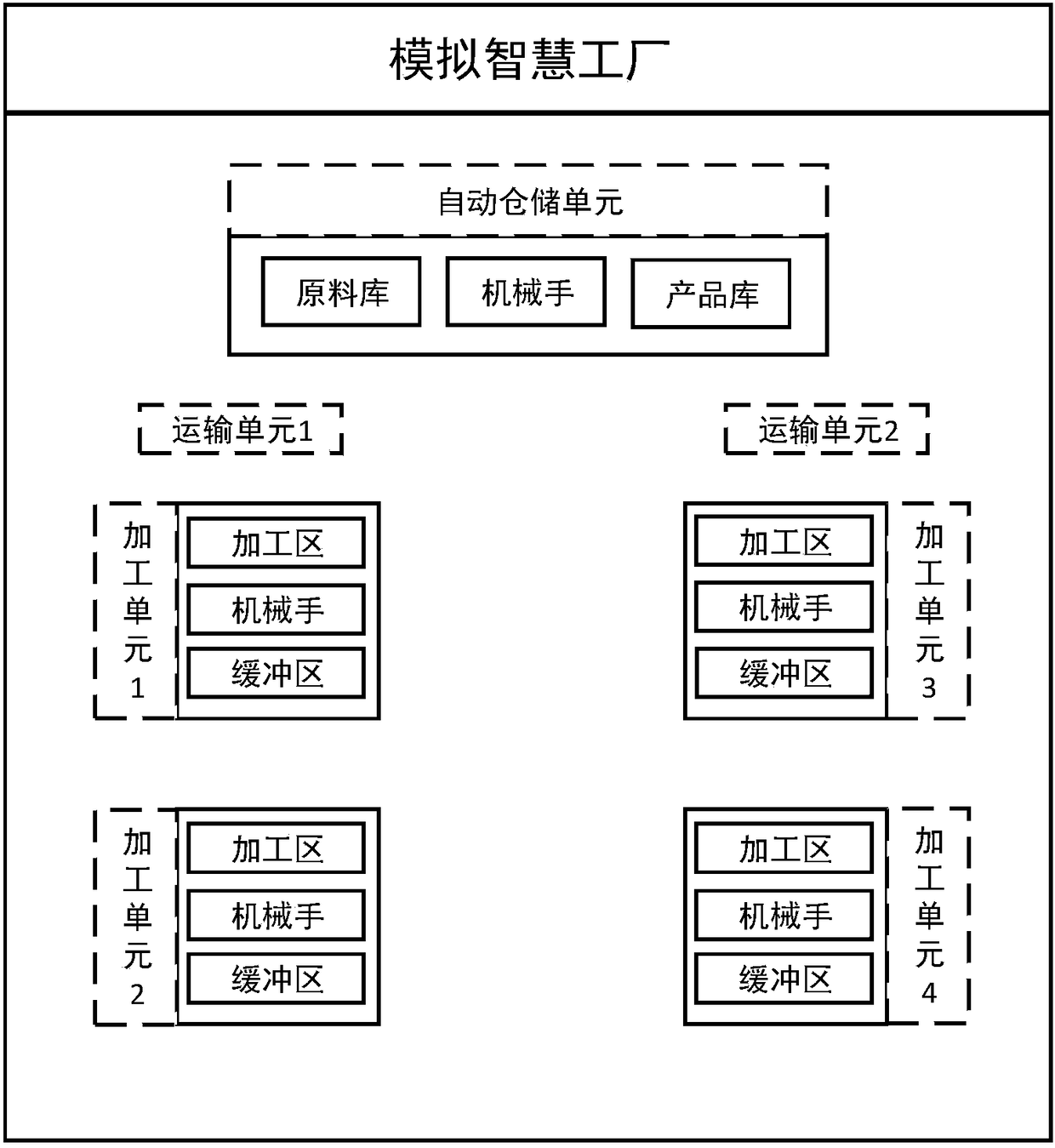

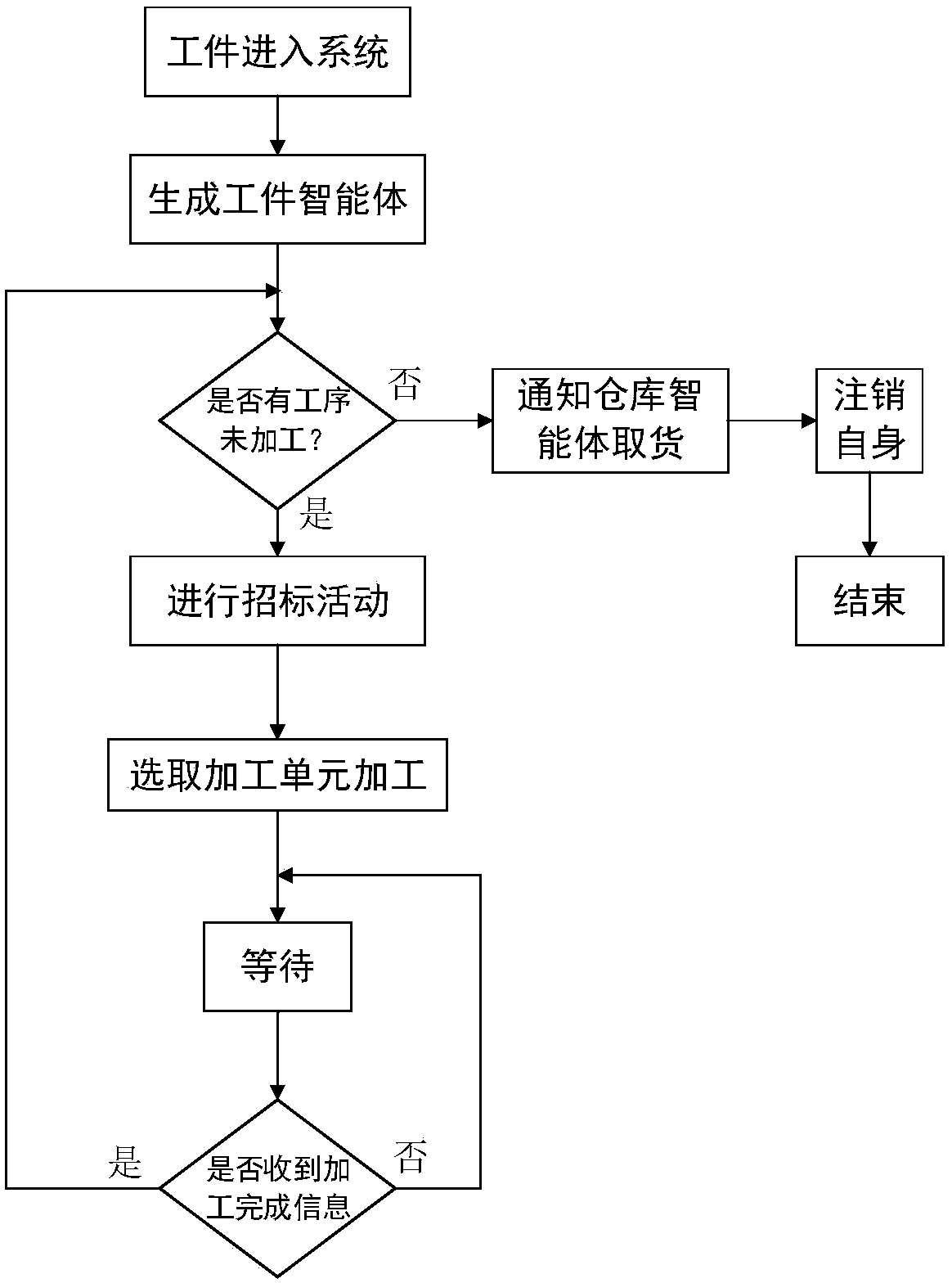

AGV-containing personalized customization flexible job shop scheduling method

The invention relates to an AGV-containing personalized customization flexible job shop scheduling method. The method comprises the steps that: an AGV-containing personalized customization flexible job shop industrial Internet of Things framework is established; a scheduling target and parameters are set; in the production process, a workpiece produced by a workshop sends a logistics demand instruction to a cloud computing platform, and an AGV receives the logistics demand instruction forwarded by the cloud computing platform, selects the logistics demand instruction with the highest priorityaccording to a priority rule, and plans a production plan corresponding to the workpiece; and a machining unit carries out workpiece machining according to the production plan, the machined workpieceis placed in a workpiece buffer area, and the AGV extracts the workpiece from the buffer area according to the plan. According to the invention, construction of an unmanned intelligent factory is facilitated; an efficient cooperation method of production equipment and logistics equipment is realized; AGV-containing personalized customization flexible job shop scheduling requirements can be met, and the AGV-containing personalized customization flexible job shop scheduling method has certain advantages in the aspects of advance / delay cost, equipment utilization rate and energy consumption compared with a traditional scheduling rule.

Owner:WUHAN UNIV OF TECH

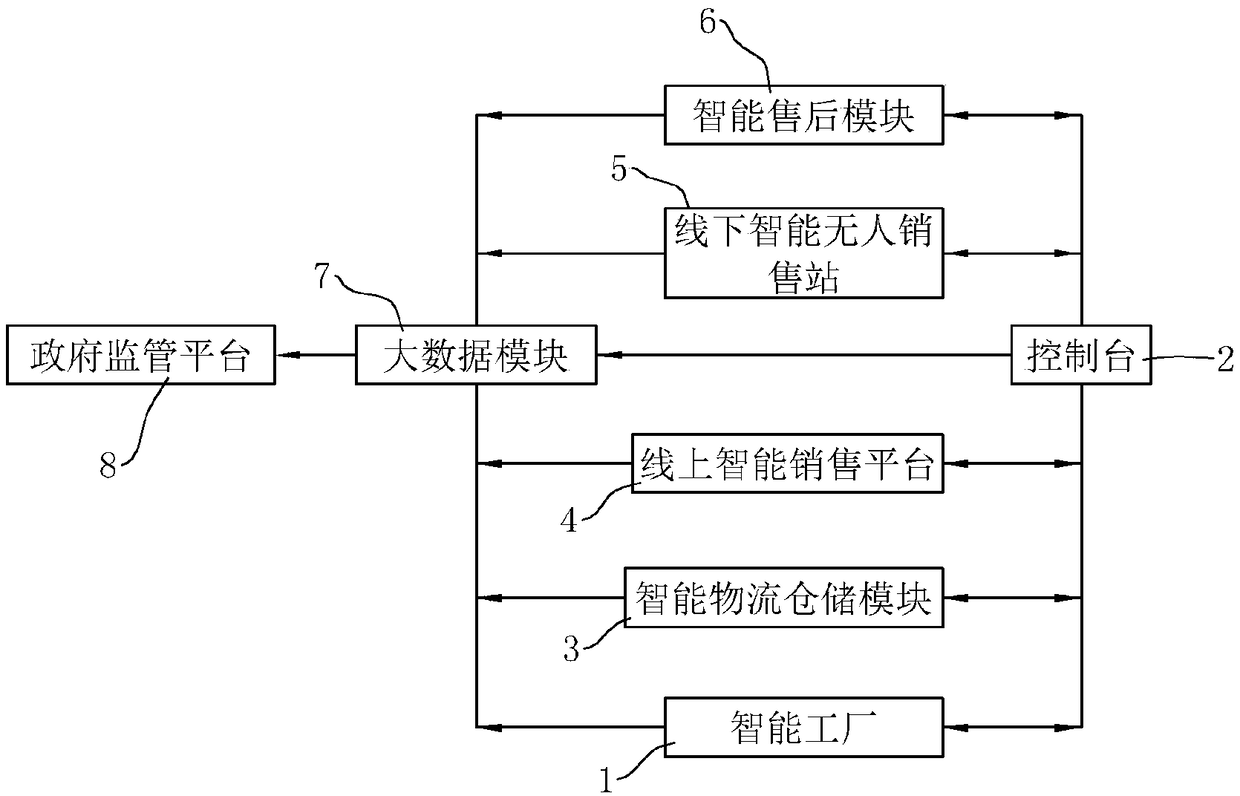

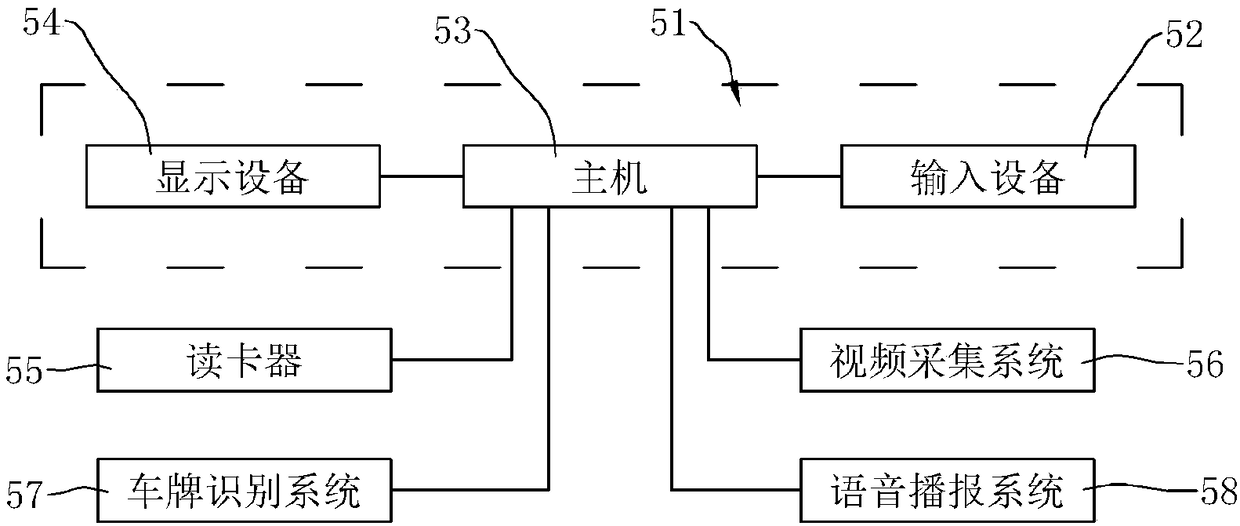

An NOx reducing agent whole industry chain intelligent production and operation monitoring management platform

InactiveCN109376973AImprove liquidityImprove experienceBuying/selling/leasing transactionsResourcesLogistics managementSmart factory

The invention discloses a NOx reducing agent whole industry chain intelligent production and operation monitoring management platform, comprising a console, and an intelligent factory, an intelligentlogistics storage module, an online intelligent sales platform, an offline intelligent unmanned sales station, an intelligent after-sale module, a big data module and a government supervision platformwhich are communicatively connected with the console. The big data module establishes communication connection with the government supervision platform; The invention intelligently produces nitrogenoxide reducing agent products, intelligent logistics storage, online and offline intelligent sales and after-sales links through the Internet of Things, Big data and artificial intelligence are closely related to each other, realizes the intelligent production and operation monitoring and management of the whole industry chain, improves the information circulation and sharing between each link, improves the operation efficiency, guarantee the quality, anti-counterfeit monitoring, reduce the cost, guarantee the use effect, serve the users, enterprises and the government, standardize the development of the industry, and support the government supervision and decision-making.

Owner:中车节能环保科技(天津)有限公司

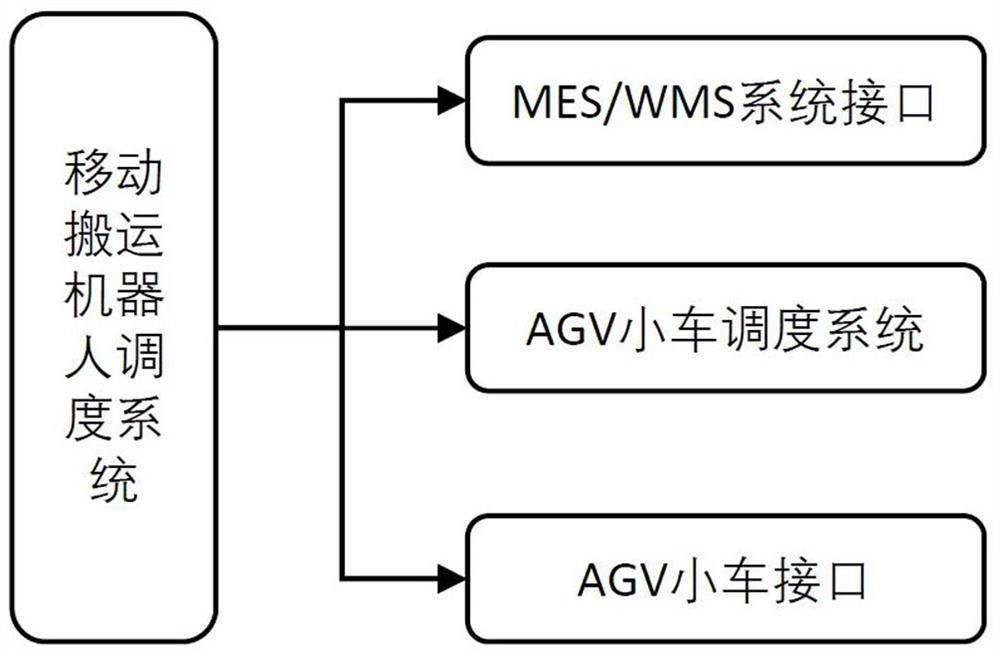

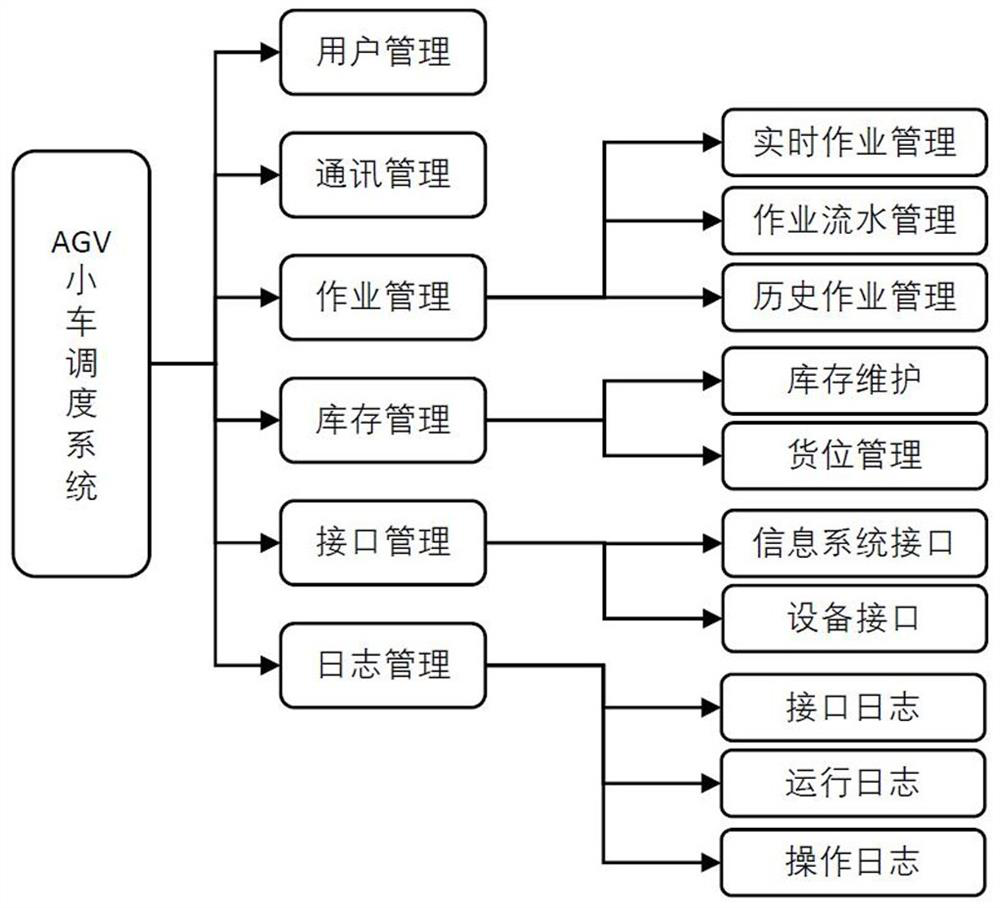

Mobile transfer robot scheduling system and scheduling method

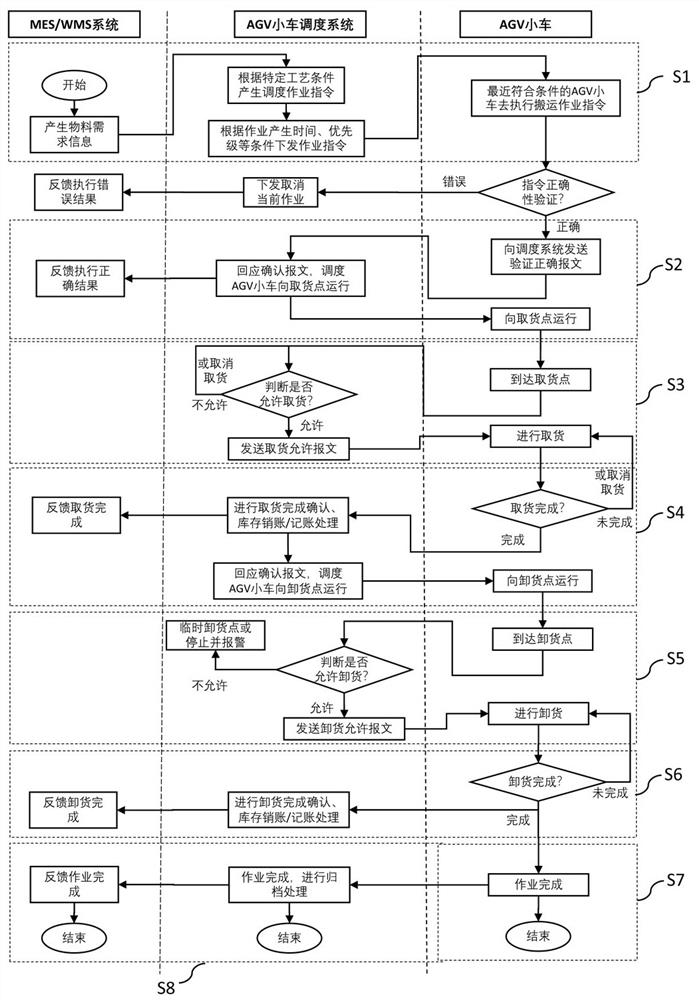

PendingCN113934189AIncrease productivityImprove work efficiencyElectric/hybrid propulsionTotal factory controlSocial benefitsSmart factory

The invention discloses a mobile transfer robot scheduling system and scheduling method, and the system comprises an MES / WMS system interface which is configured to be connected with an MES / WMS system and an AGV scheduling system, and is used for the communication connection of the MES / WMS system and the AGV scheduling system; an AGV interface which is configured to be connected with the AGV and the AGV dispatching system and used for communication connection between the AGV and the AGV dispatching system; and an AGV scheduling system which is configured to be connected with the MES / WMS system interface and the AGV interface, and is used for receiving the material demand information issued by the MES / WMS system, generating a scheduling operation instruction according to a specific condition, and issuing the scheduling operation instruction to the AGV according to a specific rule. The mobile transfer robot scheduling system provided by the invention has a good boosting effect on improving the overall operation efficiency of an AGV system, and can be widely applied to complete logistics equipment of digital workshops / intelligent factory workshops in different industry fields, so that the production efficiency of the whole factory is improved, and the mobile transfer robot scheduling system has remarkable economic and social benefits.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

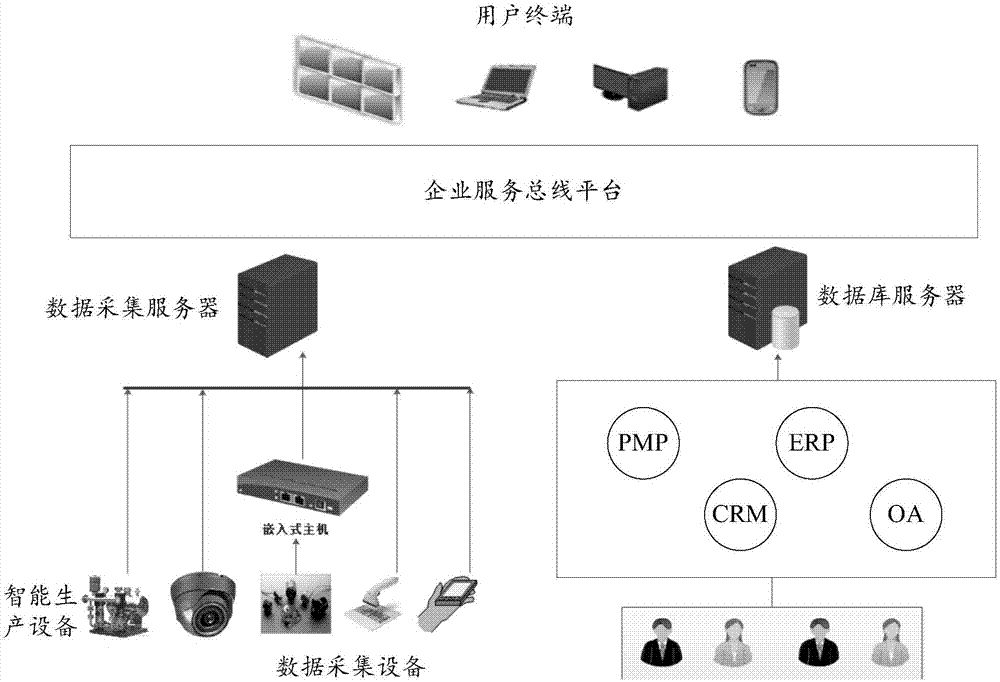

Data share system for intelligent factory

An embodiment of the invention discloses a data share system for an intelligent factory. The data share system comprises an enterprise service bus platform. The enterprise service bus platform establishes communication connections with a user terminal, a data collection server and a database server that are in the intelligent factory. The data collection server establishes communication connections with an intelligent production device and department data collection devise in the intelligent factory. The database server establishes communication connections with an enterprise resource planning system, a project management professional system, a client relationship management system and an office automation system in the intelligent factory. Through adoption of the data share system for the intelligent factory, data of all departments in the intelligent factory can be shared.

Owner:广州德为信息技术有限公司

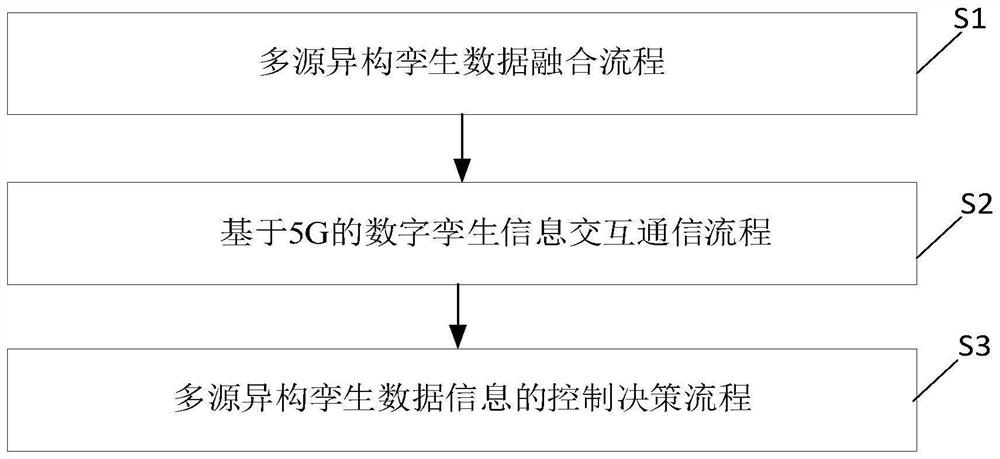

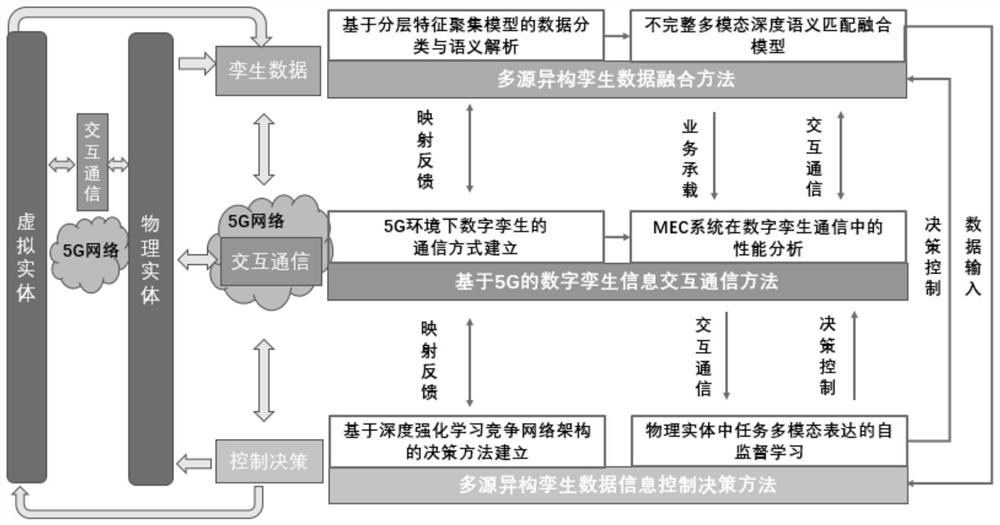

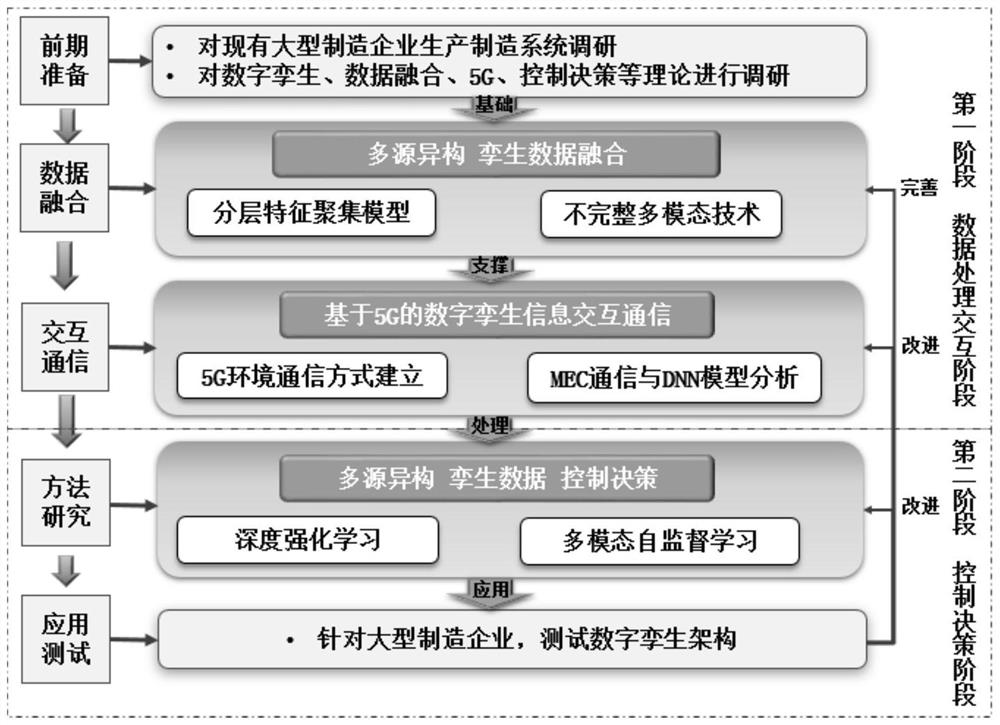

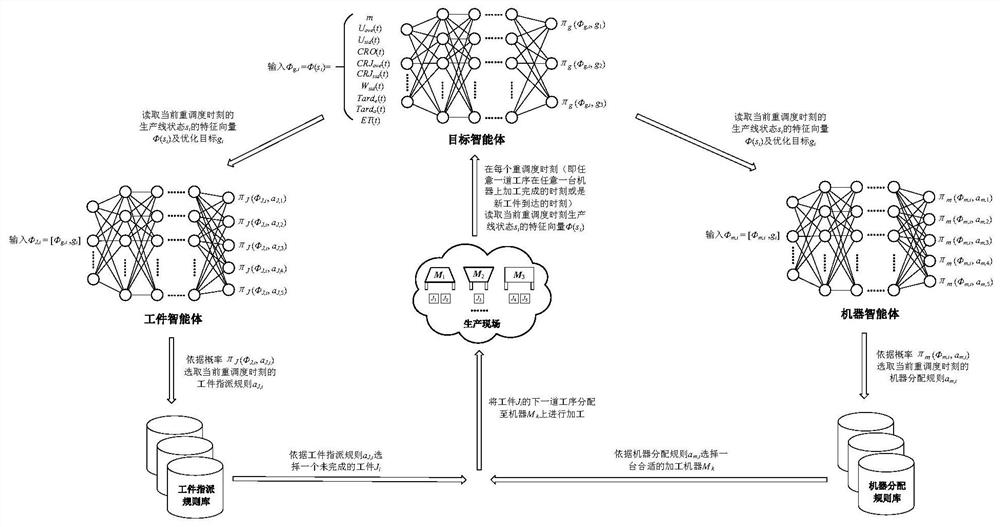

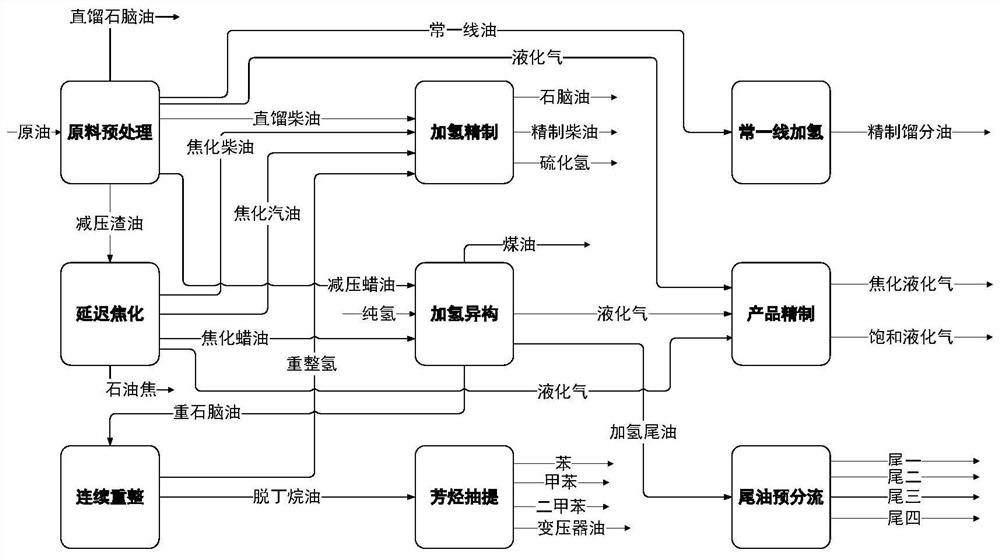

Decision control method and system for digital twin information of intelligent factory based on 5G driving

ActiveCN114637262ARealize online simulationRealize virtual reality mappingTotal factory controlProgramme total factory controlSmart factoryDecision control

The invention discloses a decision control method for intelligent factory digital twin information based on 5G driving. The method comprises the following steps: S1, carrying out a multi-source heterogeneous twin data fusion process; s2, a digital twin information interaction communication process based on 5G; and S3, a control decision process of the multi-source heterogeneous twin data information. According to the invention, a 5G-based digital twinning communication mode can be constructed, real-time twinning data-driven online simulation is realized, virtual-real mapping and interaction are really realized, the real-time performance of decision-making and control to terminals and applications and the autonomy and intellectualization of reaction are ensured, the upstream and downstream cooperation of an industrial chain of the manufacturing industry is promoted, and the development of the industrial chain of the manufacturing industry is promoted. And in an actual production environment, a reinforcement learning method and a self-supervised learning method are utilized to learn compact and multi-modal representation of data in an input network, so that decision-making and control efficiency of resource configuration, production planning, real-time scheduling, supply chains, logistics and the like is improved, and the method adapts to production management and control under dynamic factor disturbance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

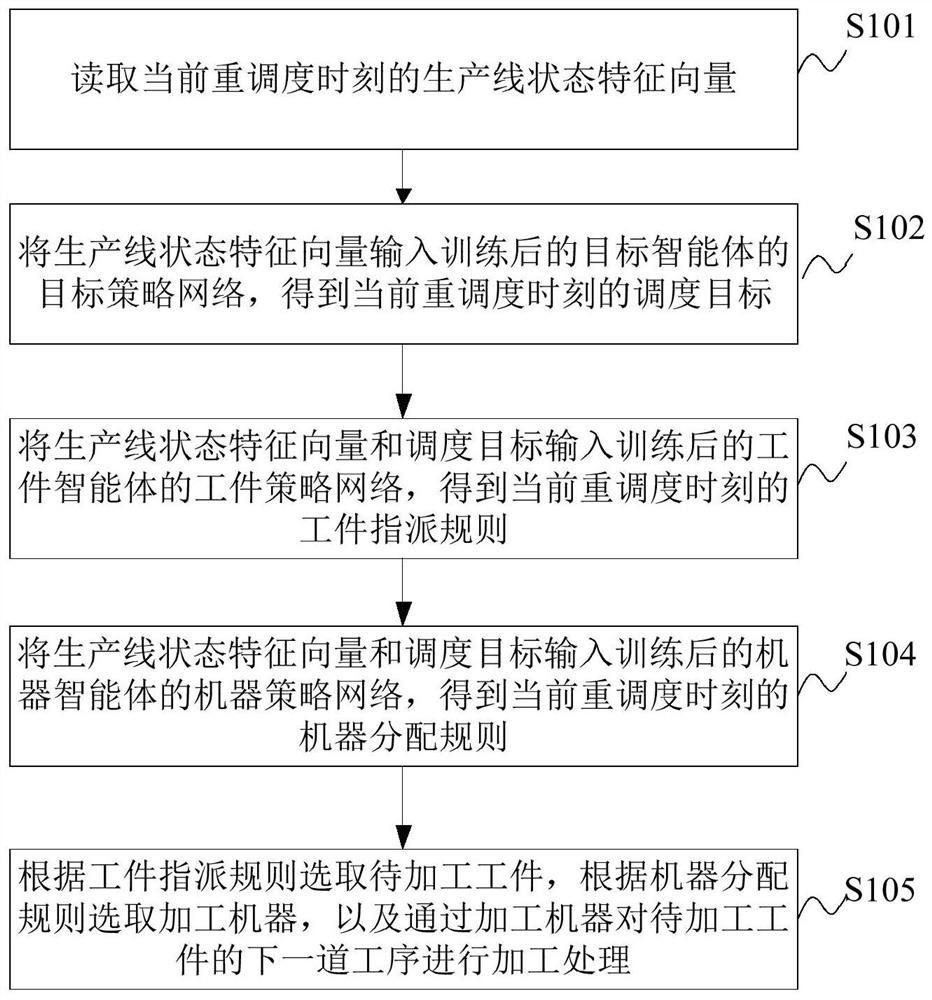

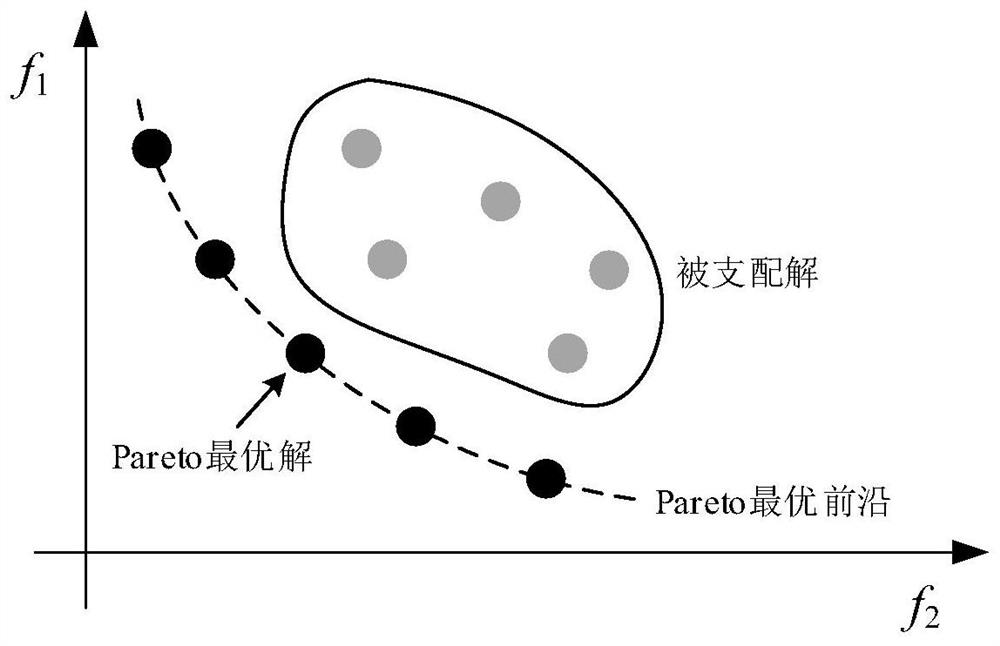

Multi-target flexible job shop scheduling method and device based on deep reinforcement learning

PendingCN112149987AFully real-timeAchieve autonomyNeural architecturesResourcesSmart factoryJob shop scheduling

The invention discloses a multi-target flexible job shop scheduling method and device based on deep reinforcement learning, and relates to the technical field of dynamic scheduling. The method comprises the steps: reading a production line state feature vector at a current rescheduling moment, and inputting the production line state feature vector into a trained target strategy network of a targetintelligent agent to obtain a scheduling target; inputting the production line state feature vector and the scheduling target into the workpiece strategy network of the trained workpiece intelligentagent to obtain a workpiece assignment rule, and inputting the workpiece assignment rule into the machine strategy network of the trained machine intelligent agent to obtain a machine distribution rule; selecting a to-be-machined workpiece according to the workpiece assignment rule, selecting a machining machine according to the machine allocation rule, and machining the next procedure of the to-be-machined workpiece through the machining machine. Therefore, different optimization objectives, workpiece assignment rules and machine allocation rules are intelligently selected according to the state of the production line at different rescheduling moments, and multi-objective collaborative optimization and complete real-time, autonomous and unmanned intelligent factories are realized.

Owner:TSINGHUA UNIV

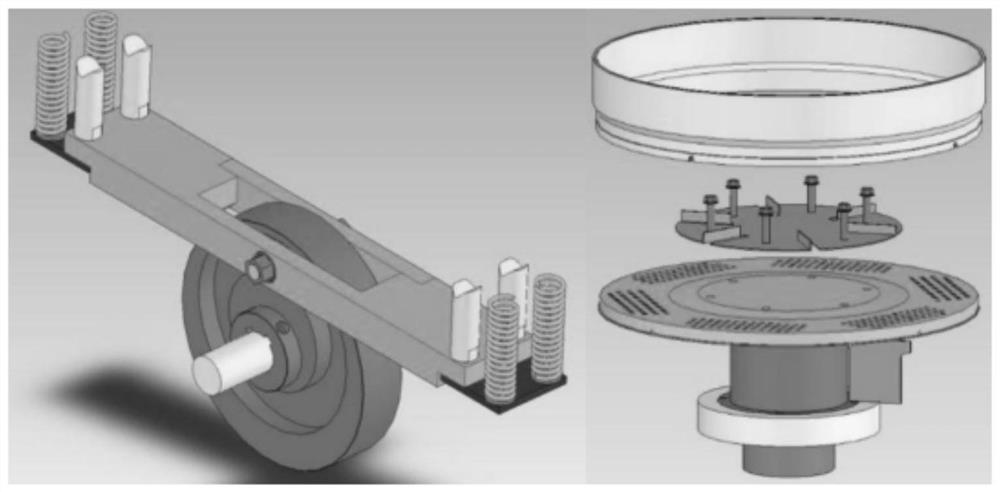

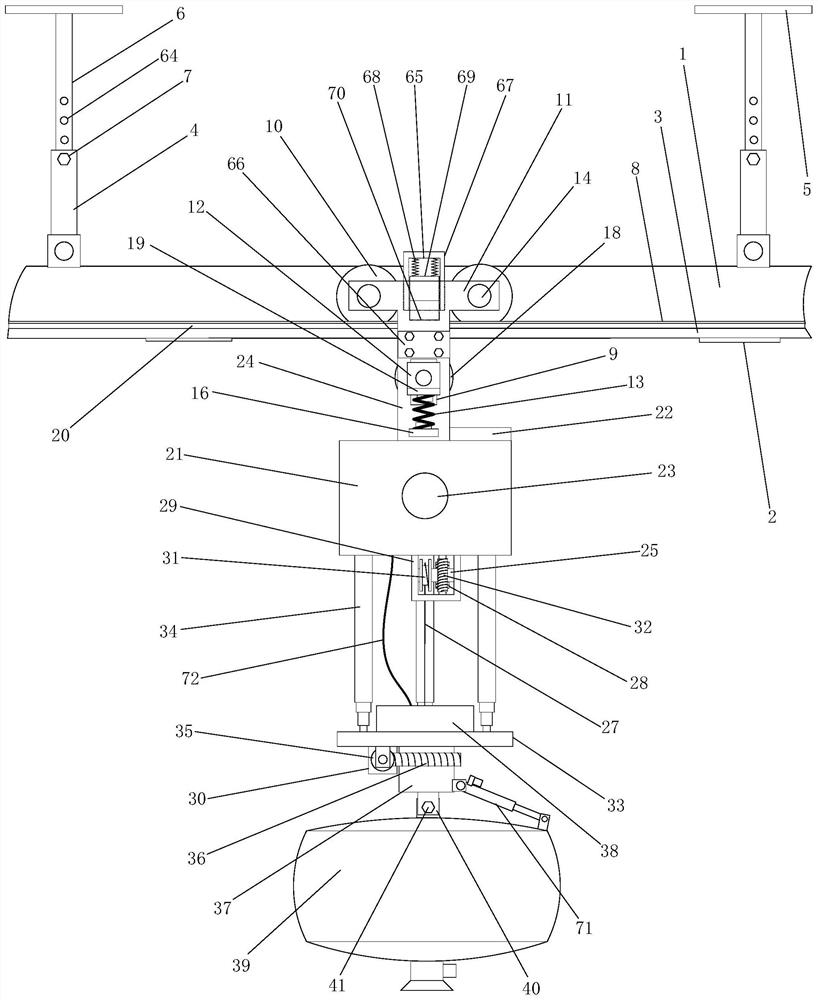

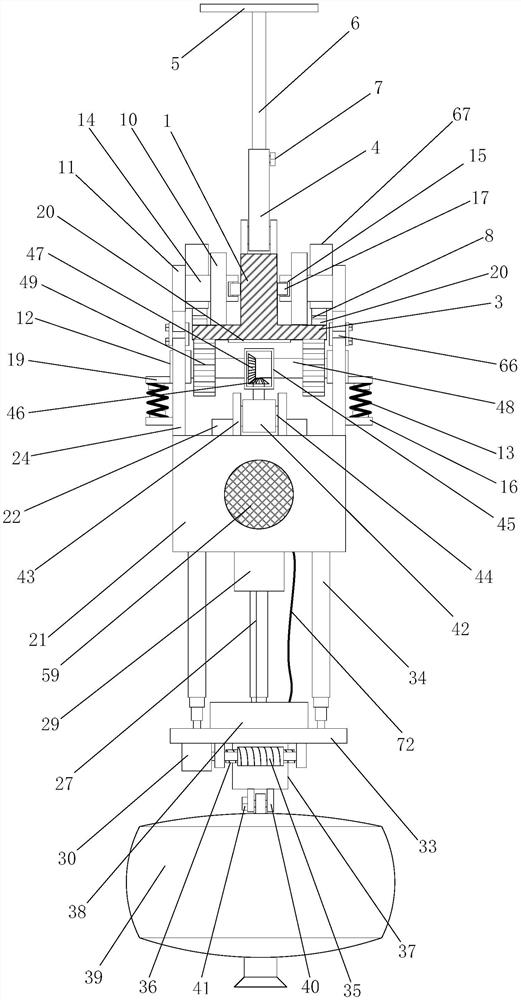

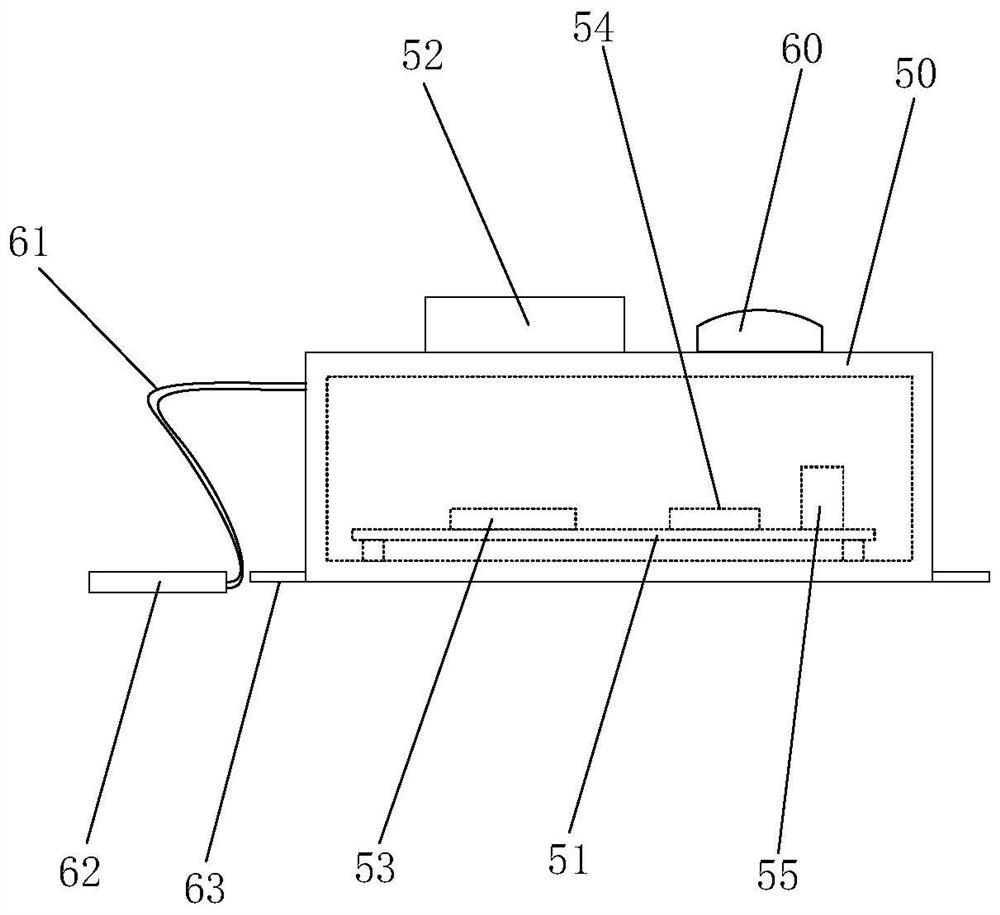

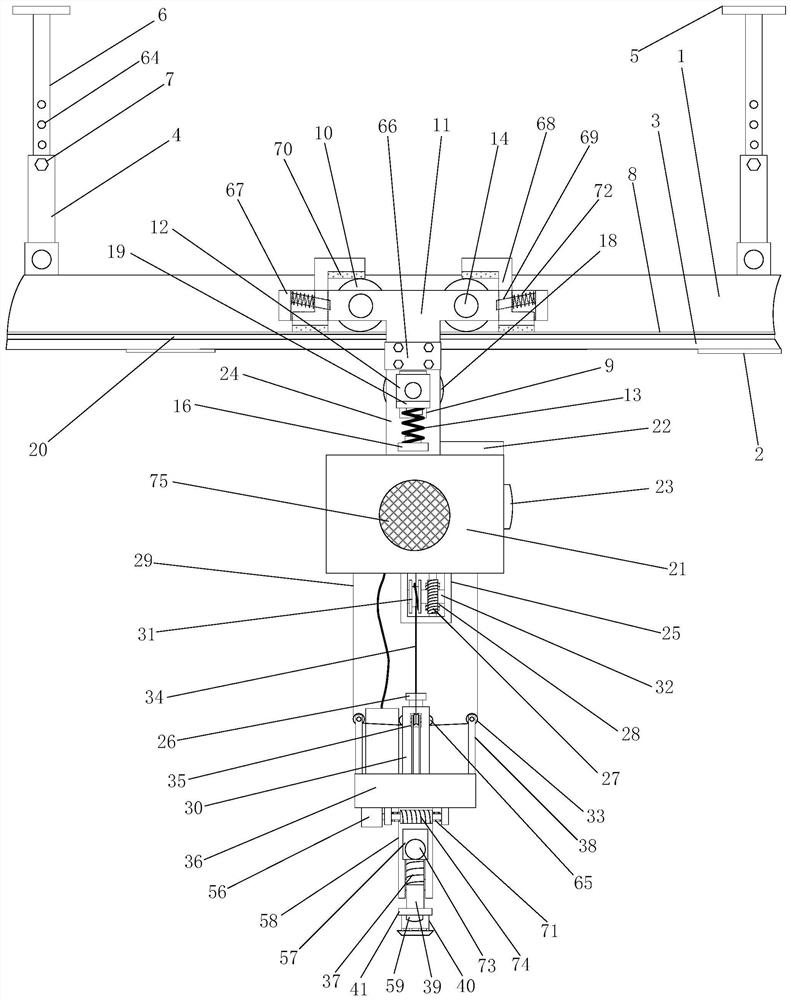

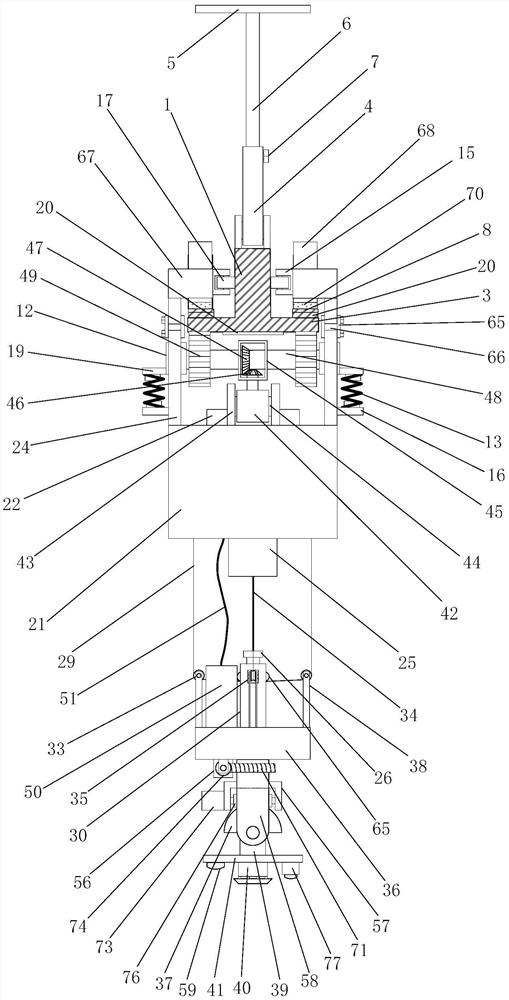

Smart factory fire-fighting inspection system

InactiveCN112402850AAchieve precise positioningContinuous and reliable operationFire rescueFire alarm smoke/gas actuationSmart factoryFire extinguisher

The invention discloses a smart factory fire-fighting inspection system. The system involves a walking track, a mobile fire-fighting device and alarm sensing nodes used for being installed at all detection points; and the movable fire-fighting device is composed of a movable mounting mechanism, a control box, a steel rope lifting mechanism, an angle adjusting mechanism and an electric control drypowder extinguisher. According to the smart factory fire-fighting inspection system, the uninterrupted external power supply of all electrical equipment in the control box can be realized by using twopower taking mechanisms so that the continuous and reliable operation of the mobile mounting mechanism can be ensured; and the spraying angle of the electric control dry powder extinguisher can be adjusted through the angle adjusting mechanism so that accurate fire extinguishing can be conducted on a monitoring point according to the preset angle.

Owner:苏州南师大科技园投资管理有限公司 +1

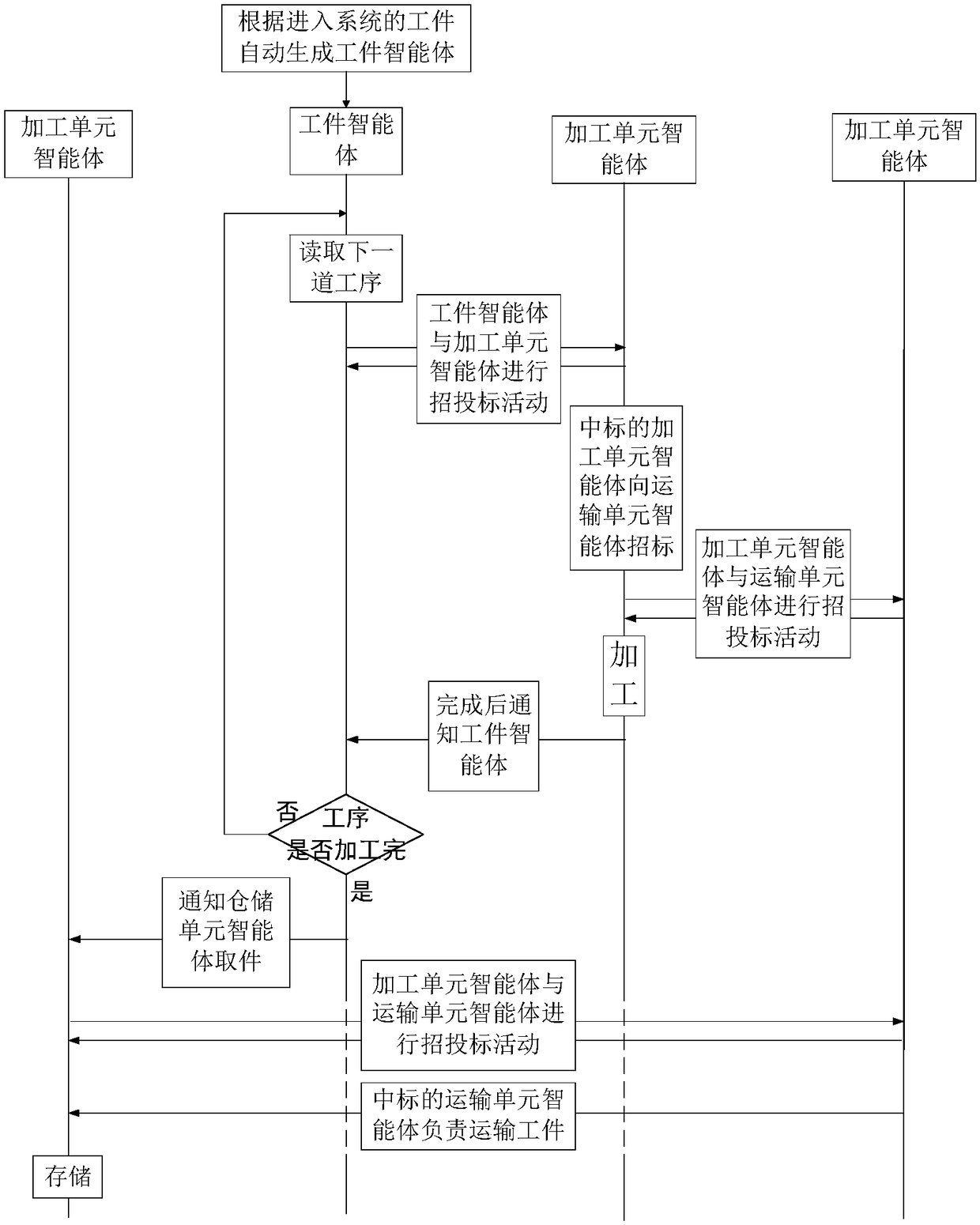

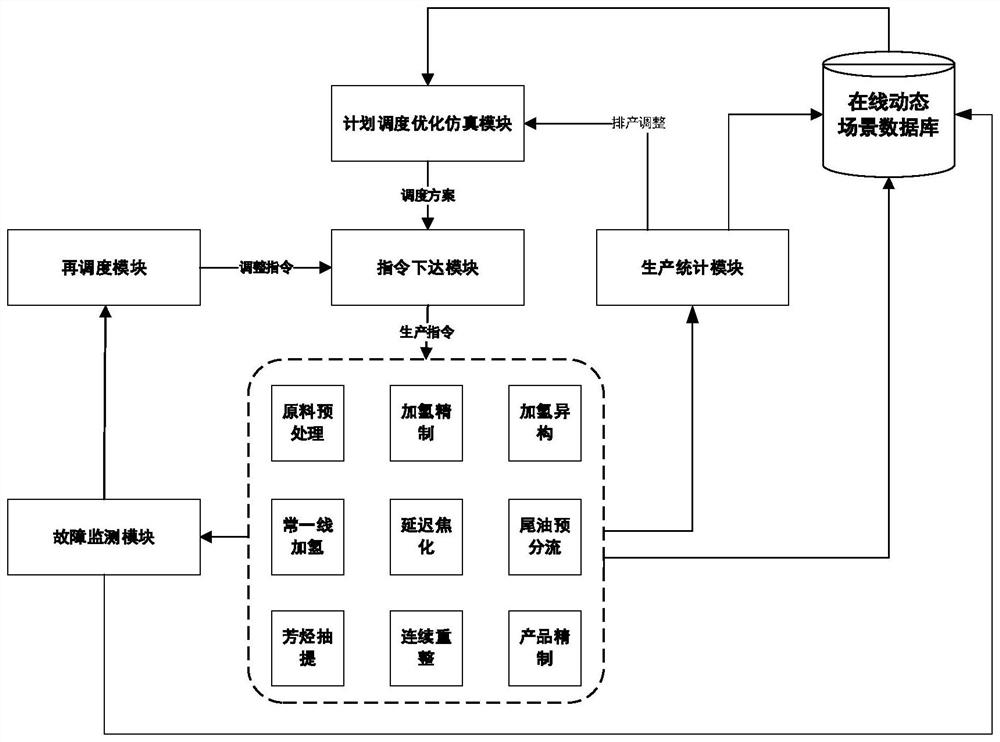

Smart factory dynamic collaborative scheduling method based on static scheduling prediction

ActiveCN108229853AOvercome the problems of lack of vision and lack of overall conceptImprove visionForecastingResourcesSmart factoryStatic dispatch

Disclosed is a smart factory dynamic collaborative scheduling method based on static scheduling prediction. After a workpiece enters into a production system, a corresponding workpiece agent is generated; every time after the workpiece agent enters into the production system or any of a processing procedure is completed, a processing unit agent is selected by the workpiece agent to perform processing procedures, a transportation unit agent is selected by the processing unit agent to transport workpiece, and if all of the procedures are completed, the transportation unit agent is selected by awarehouse unit agent to transport products to a warehouse. By means of the method, the problem of foresight lacking and overall concept lacking of a single agent of an existing multi-agent method is overcome, the foresight and overall concept of the single agent are improved through an experience summarizing mechanism and a global environment prediction mechanism, and the overall performance of the production system is optimized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

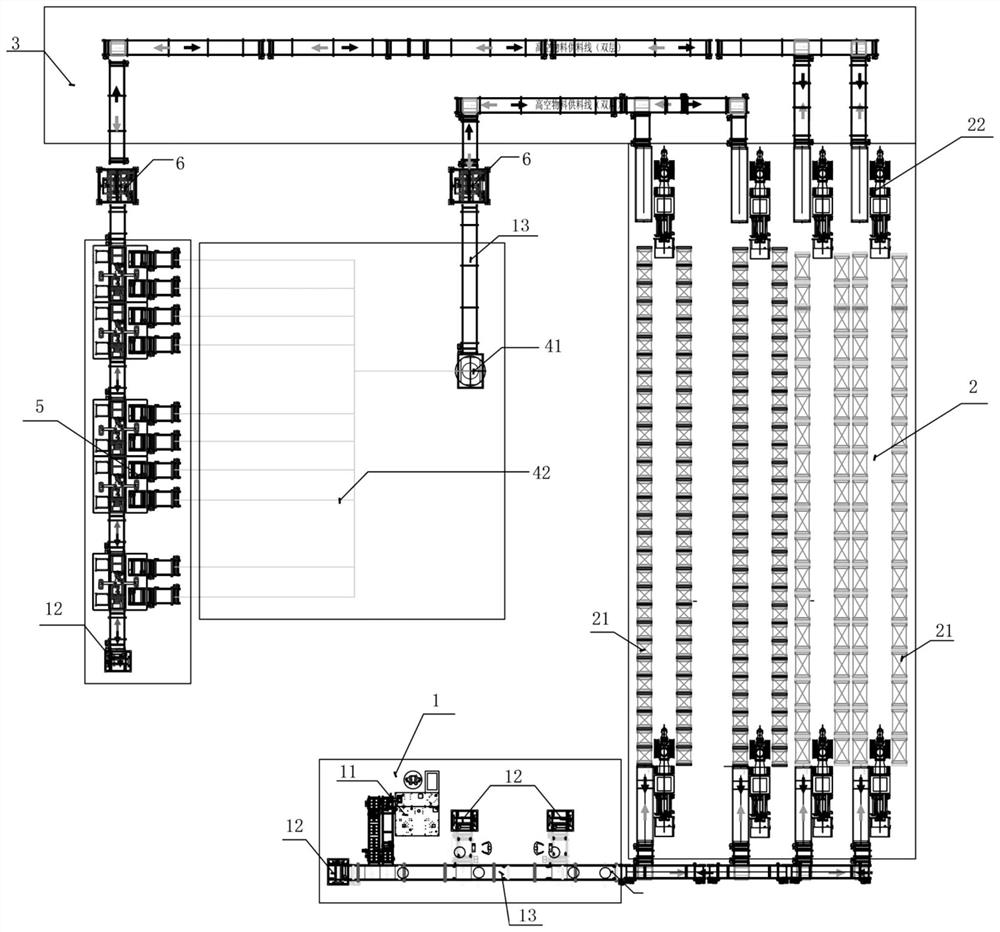

Intelligent factory logistics scheduling system

PendingCN111695789AGuaranteed uninterruptedImprove efficiencyForecastingResourcesLogistics managementSmart factory

The invention discloses an intelligent factory logistics scheduling system. The intelligent factory logistics scheduling system comprises an intelligent batching area, an intelligent storage area, anintelligent logistics conveying line area, an AGV distribution area, an intelligent manufacturing assembly line area and an intelligent scheduling system installed on a computer. The intelligent storage area is connected with the intelligent batching area, the intelligent logistics conveying line area is connected with the intelligent storage area, the AGV distribution area and the intelligent manufacturing assembly line area, and the intelligent dispatching system is connected with the intelligent storage area and the AGV distribution area. The intelligent factory logistics scheduling systemhas the advantages that the efficiency and accuracy of factory logistics scheduling can be effectively improved, and the intelligent factory logistics scheduling system is simple and easy to implement.

Owner:深圳载德激光自动化科技有限公司

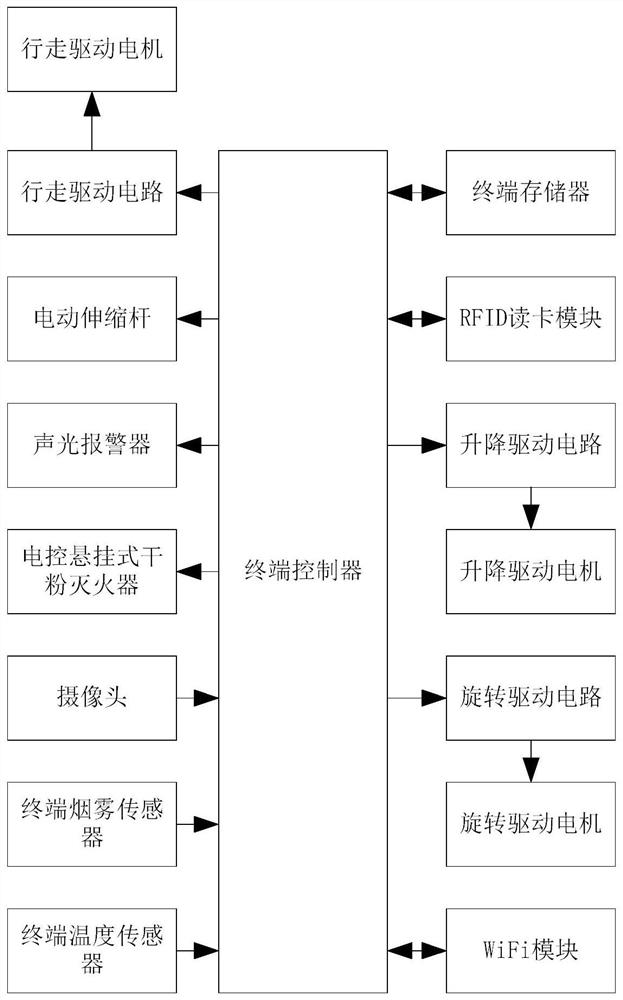

Production line inspection system for smart factory

InactiveCN112446977ARealize real-time monitoringAchieve precise positioningChecking time patrolsParticular environment based servicesProduction lineMonitoring site

The invention discloses a production line inspection system for a smart factory. The production line inspection system comprises a walking track, a movable mounting mechanism, a control box, a steel rope lifting mechanism, an angle adjusting mechanism, a terminal smoke sensor, a camera and a terminal temperature sensor. According to the production line inspection system for the smart factory, smoke signals, images and temperature collected by the terminal smoke sensor, the camera and the terminal temperature sensor can be transmitted to the upper computer to be displayed through a WiFi module,and real-time monitoring of the environment along the line in the moving process of a movable monitor is achieved; the heights of the terminal smoke sensor, the camera and the terminal temperature sensor can be adjusted as required by utilizing the mobile mounting mechanism and the steel rope lifting mechanism, so that approaching monitoring is carried out on a suspicious position; and the anglesof the terminal smoke sensor, the camera and the terminal temperature sensor can be adjusted by utilizing the angle adjusting mechanism, so that the monitoring point is accurately measured and shot according to a preset angle.

Owner:苏州南师大科技园投资管理有限公司 +1

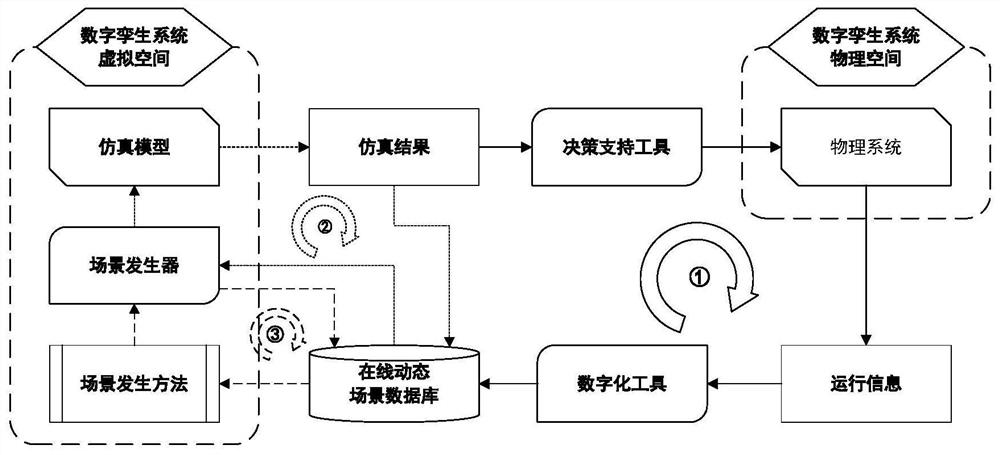

Multi-loop intelligent factory edge side digital twin scene coupling device

The invention discloses a multi-loop intelligent factory edge side digital twin scene coupling device. The device comprises a virtual space and a physical space of a production line edge side digitaltwin system, a decision support tool, a digitization tool and an online dynamic scene database; the virtual space comprises a Conditional WGAN dynamic scene generation method based on a Wasserstein generative adversarial network, a scene generator and a simulation model; wherein the physical space comprises a physical system; and the loop comprises a digital twin simulation decision loop, a scenesimulation loop and a dynamic scene generation loop. The coupling device can serve as a service to be embedded into an intelligent algorithm system on the edge side of an intelligent factory to be used for coupling generation of a digital twin production scene, reliable original data and training samples can be provided for other experiments and researches, and targeted research is carried out.

Owner:ZHEJIANG UNIV

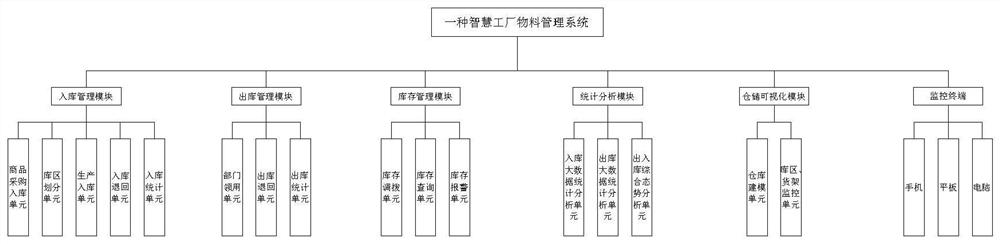

Smart factory material management system

PendingCN112132501AEasy accessWide applicabilityLogistics3D modellingSmart factoryStatistical analysis

The invention discloses a smart factory material management system which comprises a warehouse-in management module, a warehouse-out management module, an inventory management module, a counting analysis module, a warehouse visualization module and a monitoring terminal. The warehouse-in management module comprises a commodity purchasing warehouse-in single person, a warehouse area division unit,a production warehouse-in unit, a warehouse-in returning unit and a warehouse-in counting unit. The warehouse-out management module comprises a department receiving unit, a warehouse-out returning unit and a warehouse-out counting unit; the inventory management module comprises an inventory allocation unit, an inventory query unit and an inventory alarm unit; the counting analysis module comprisesa warehouse-in big data counting analysis unit, a warehouse-out big data counting analysis unit and a warehouse-in and warehouse-out comprehensive situation analysis unit; the warehouse visualizationmodule comprises a warehouse modeling unit, a warehouse area and a shelf monitoring unit; according to the invention, factory materials can be scientifically and systematically managed, the number and the state of current warehouse-in and warehouse-out products can be conveniently mastered, and the materials are greatly convenient to take.

Owner:上海有间建筑科技有限公司

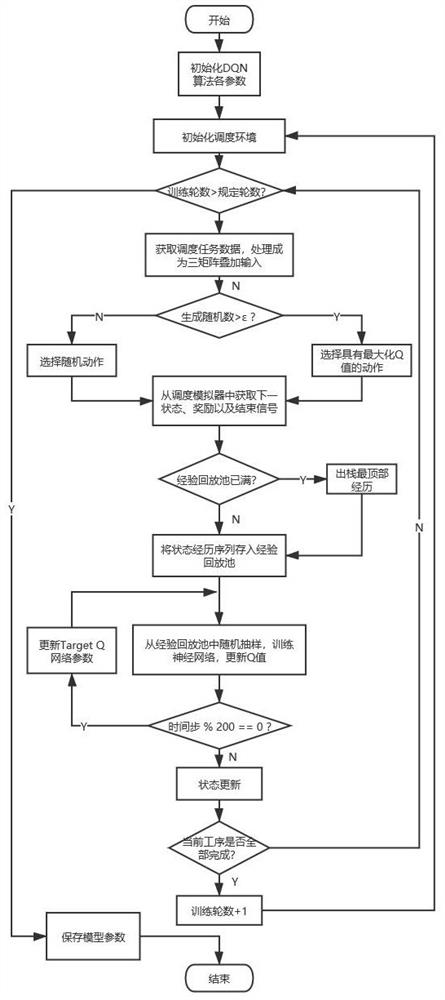

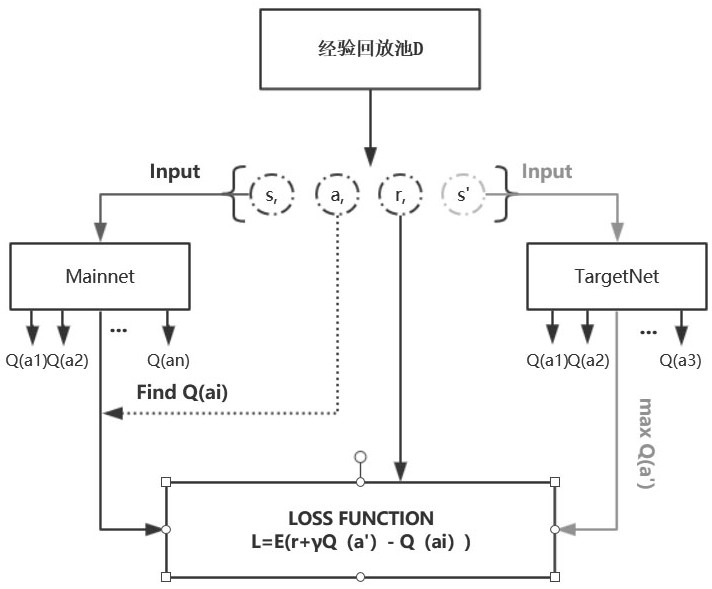

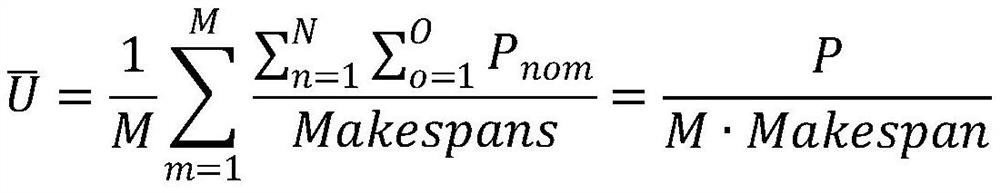

Intelligent factory production job scheduling method and system based on deep reinforcement learning

PendingCN113487165AEfficient schedulingMaximize Average UtilizationResourcesMachine learningOperation schedulingSmart factory

The invention relates to an intelligent factory production job scheduling method based on deep reinforcement learning, and the method comprises the following steps: S1, obtaining processing data of each process of each task on a corresponding machine, and carrying out preprocessing of the data, and forming a training set; S2, constructing a deep reinforcement learning DQN model, wherein the deep reinforcement learning DQN model comprises a DQN deep learning network structure and a DQN reinforcement learning module; S3, training the deep reinforcement learning DQN model to obtain a trained deep reinforcement learning DQN model; and S4, pre-processing to-be-produced task scheduling data, and inputting the pre-processed to-be-produced task scheduling data into the trained deep reinforcement learning DQN model to obtain a scheduling arrangement of a production task process. According to the invention, rapid and efficient scheduling of the current production operation can be realized.

Owner:FUZHOU UNIV

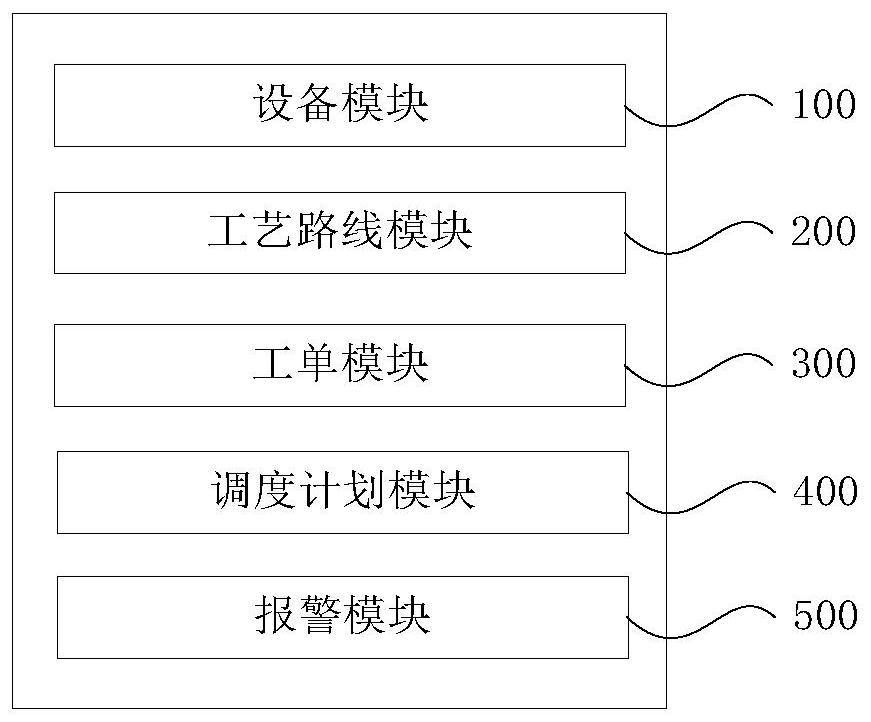

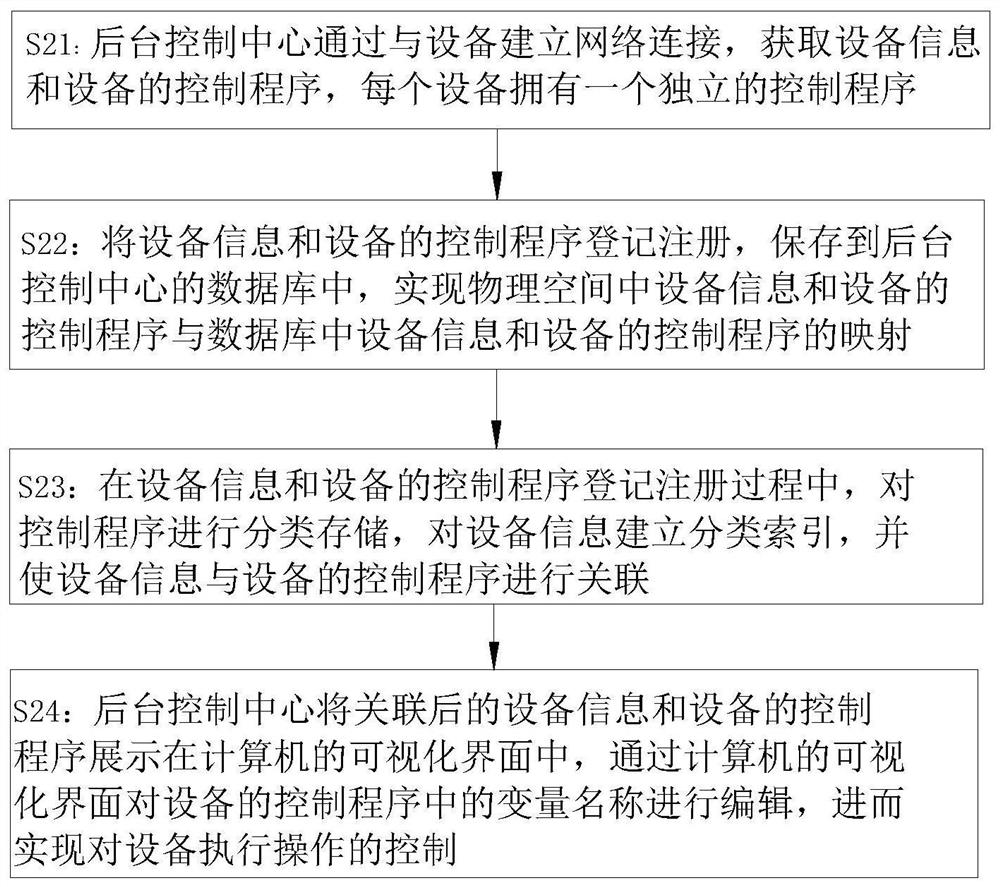

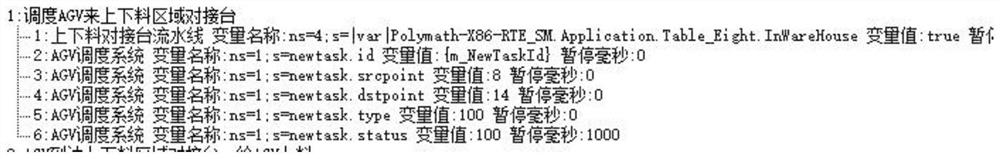

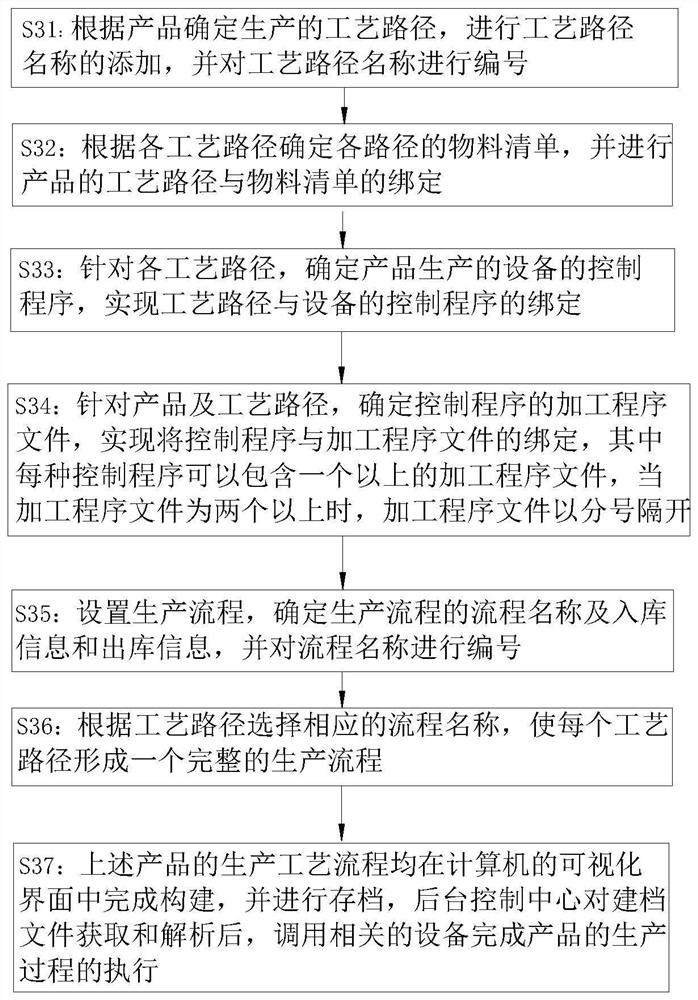

Management and control method for production equipment of smart factory

PendingCN111754087AEasy to controlSatisfy productivityResourcesTotal factory controlSmart factoryProcess engineering

The invention relates to a management and control method for production equipment of a smart factory. The method comprises the following steps that data mapping between equipment information and a background control center is established; association and management and control of the background control center on the equipment information are realized; a production process flow of a product is archived; a production process flow in the archiving file is associated with the equipment through an identification code or a functional parameter; the background control center can schedule the associated equipment according to the filing file; the execution of the production process of the product is realized; in a filing process of a production process flow of a product, a process path, a controlprogram, a processing program file and the like are modified and edited, the establishment of the production process of different products can be realized, after the background control center acquiresand analyzes the archiving file, the different products are processed according to the archiving file, and the process meets the production and processing requirements of the different products and dynamically configures specific production equipment for the product process.

Owner:SHENZHEN QIANHAI WELL SELL TECH CO LTD

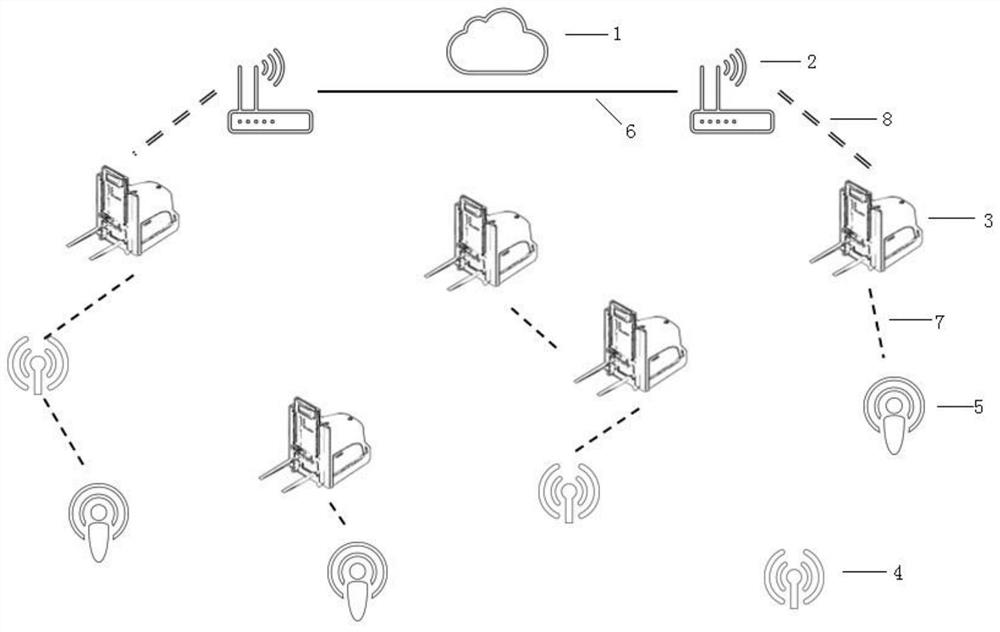

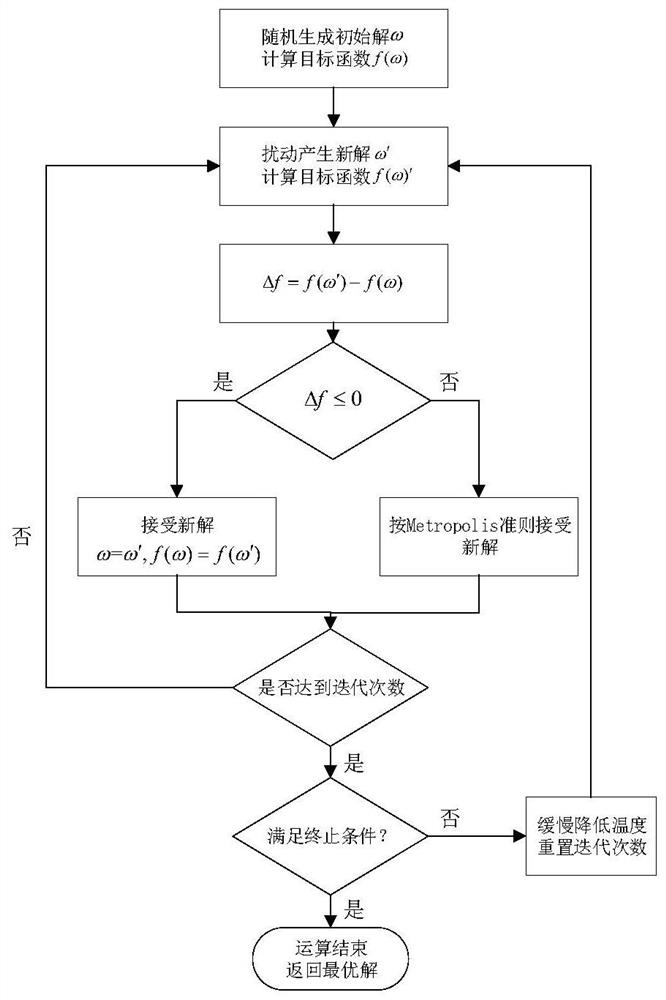

End-side-cloud cooperative data transmission method for AGV scene movement of intelligent factory

ActiveCN112153595AReduce computing and storage pressureReduce task response timeParticular environment based servicesTransmissionSmart factoryData transmission time

The invention discloses an end-side cloud cooperative data transmission method for AGV scene movement of an intelligent factory, and relates to the technical field of AGVs of intelligent factories. The method comprises the following steps: establishing a mobile terminal side cloud collaborative architecture for a delay tolerant mobile sensor network DTMSN composed of a wireless sensor, an AGV andan AGV scheduling system AGVS in an intelligent factory; fusing AGV, end-side cloud collaboration and DTMSN technologies; considering the influence of the movement of an end (wireless sensor) and an edge (AGV) on an end-edge cloud architecture network structure and a data transmission effect; improving an existing DTMSN algorithm, and using an idea that simulated quenching accepts inferior solutions according to probabilities for replacing a staged method to select intermediate nodes; combining data transmission task characteristics, node density, node speed, node type and other factors into autility function. Therefore, the data transmission quality is improved, the data transmission time delay and energy consumption are reduced, the feasibility and effectiveness of mobile terminal sidecloud cooperation are ensured, the computing resources of the AGV are fully utilized, and the task response time and the computing storage pressure of the cloud are reduced.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com