Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Job shop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

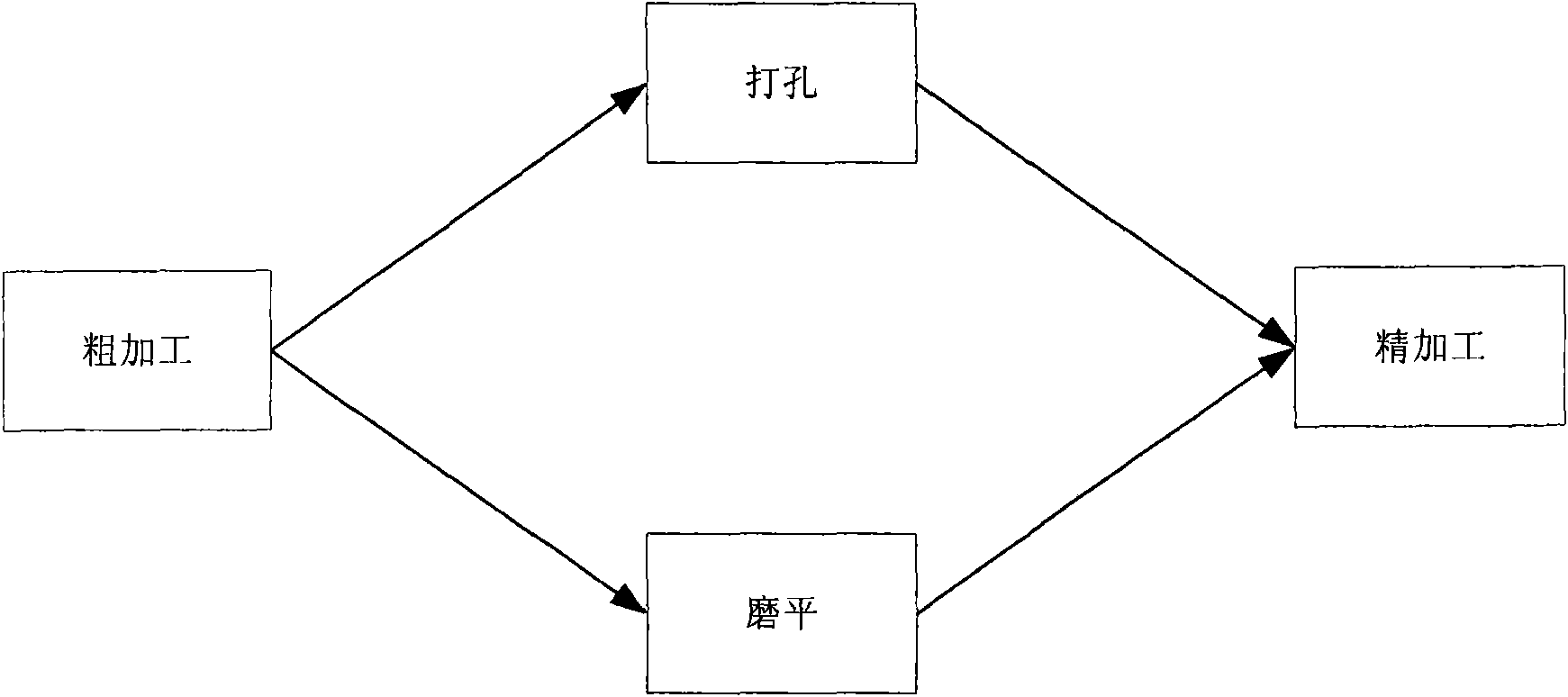

Job shops are typically small manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs. Job shops typically move on to different jobs (possibly with different customers) when each job is completed. Job shops machines are aggregated in shops by the nature of skills and technological processes involved, each shop therefore may contain different machines, which gives this production system processing flexibility, since jobs are not necessarily constrained to a single machine. In computer science the problem of job shop scheduling is considered strongly NP-hard.

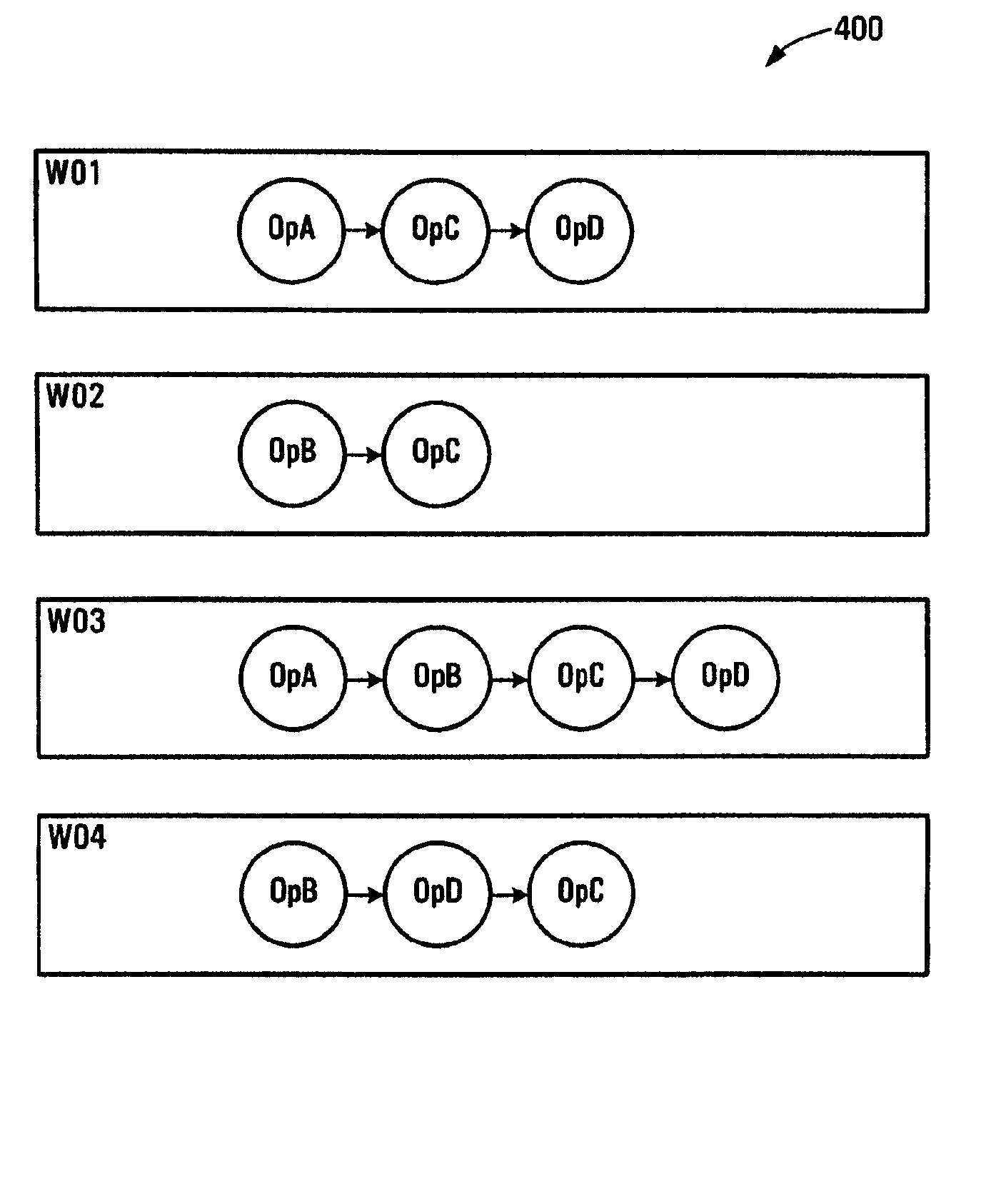

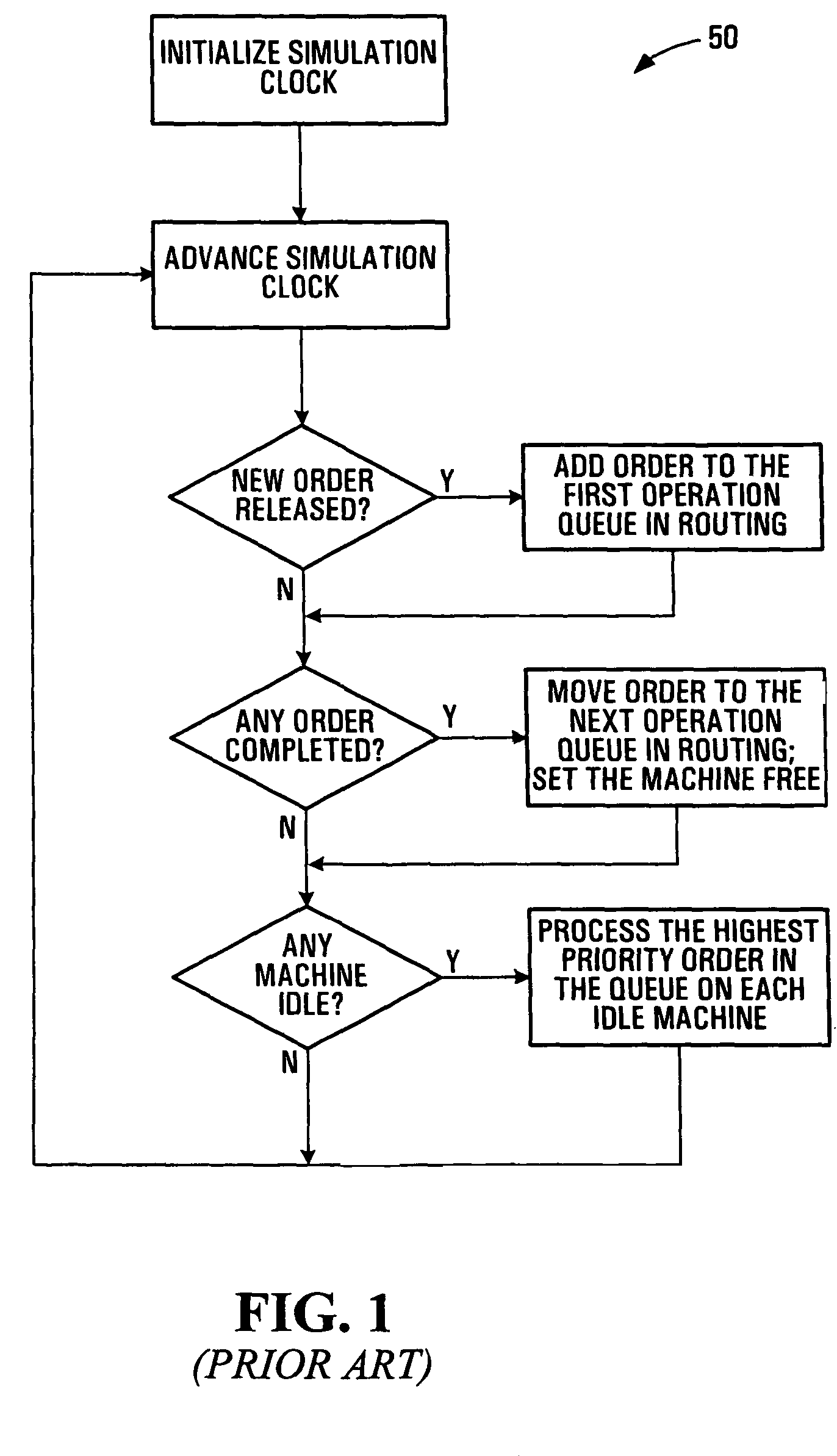

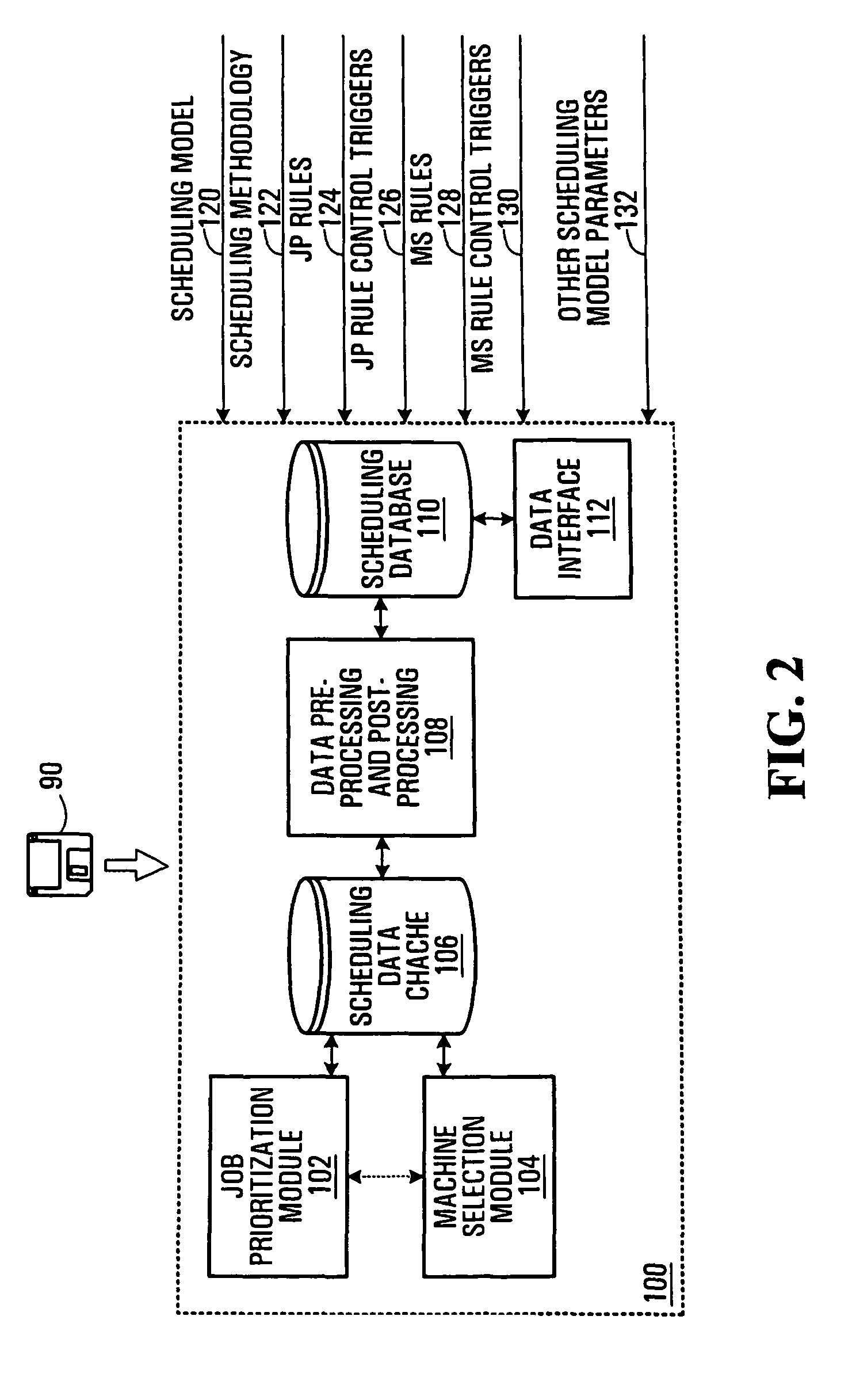

Finite capacity scheduling using job prioritization and machine selection

InactiveUS7904192B2Improve machine utilizationMultiprogramming arrangementsResourcesMachine selectionMachine utilization

Owner:AGENCY FOR SCI TECH & RES

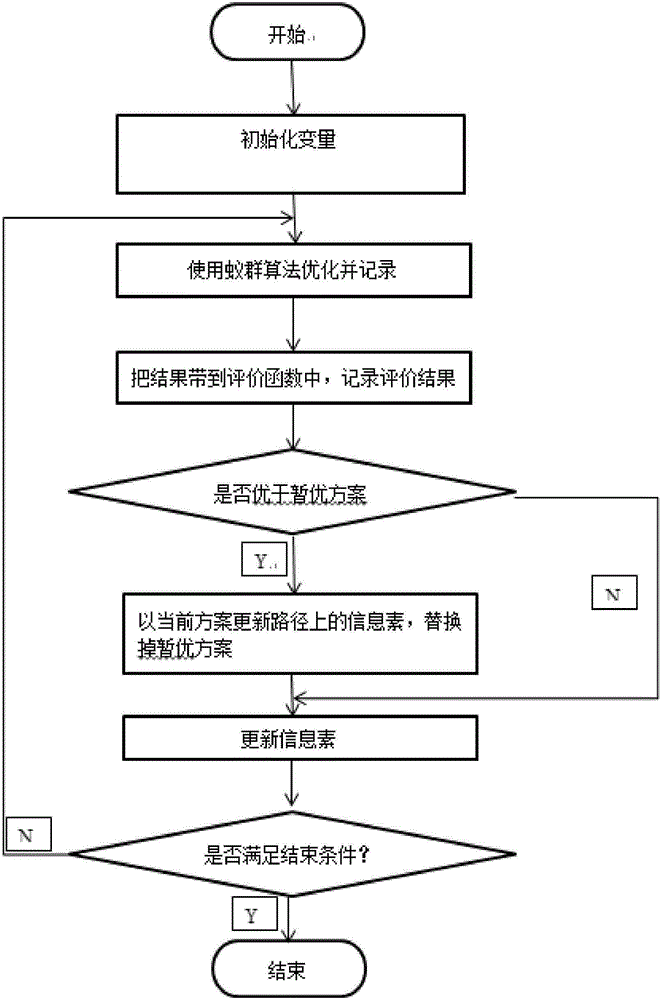

Flexible job-shop scheduling multi-objective method

InactiveCN104914835AReduce manufacturing costGood effectProgramme total factory controlJob shop schedulingJob shop scheduling problem

The invention discloses a flexible job-shop scheduling multi-objective method. The specific implementation procedures of the flexible job-shop scheduling multi-objective method are that: establishing a model for a multi-objective flexible job shop; optimizing the model by using an ant colony algorithm, and evaluating the result to check whether the scheme is the optimal scheme; and improving a pheromone updating rule according to the optimal scheme, and increasing convergence rate of the algorithm to obtain a Pareto optimal solution of a multi-objective flexible job shop scheduling problem. Compared with the prior art, the flexible job-shop scheduling multi-objective method effectively reduces workshop production cost, shortens the processing time, improves qualified rate of products, is high in practicability, and is easy to popularize.

Owner:QILU UNIV OF TECH

Flexible job shop order insertion dynamic scheduling optimization method

ActiveCN107831745AReduced delay periodImprove the individual population update methodInternal combustion piston enginesProgramme total factory controlMathematical modelParticle swarm algorithm

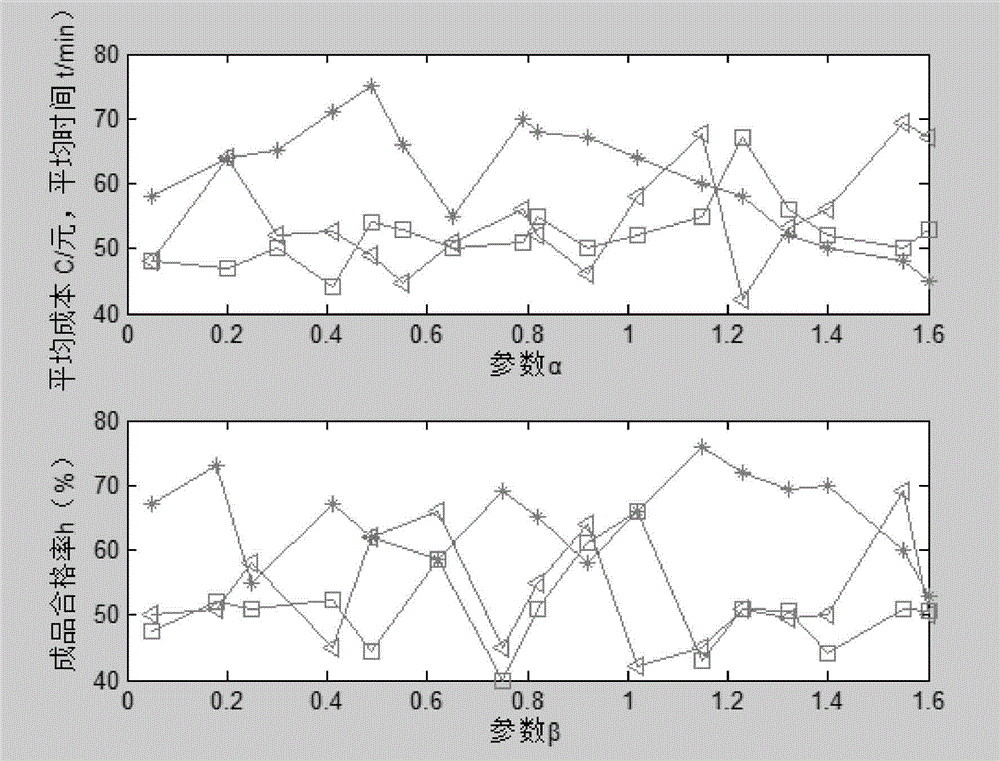

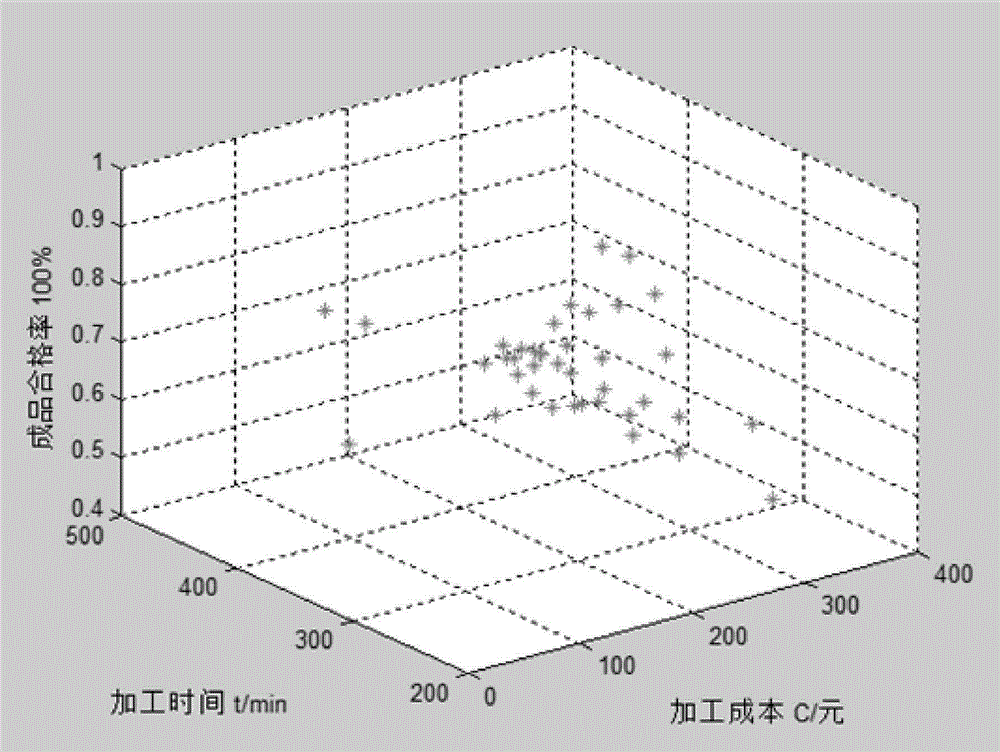

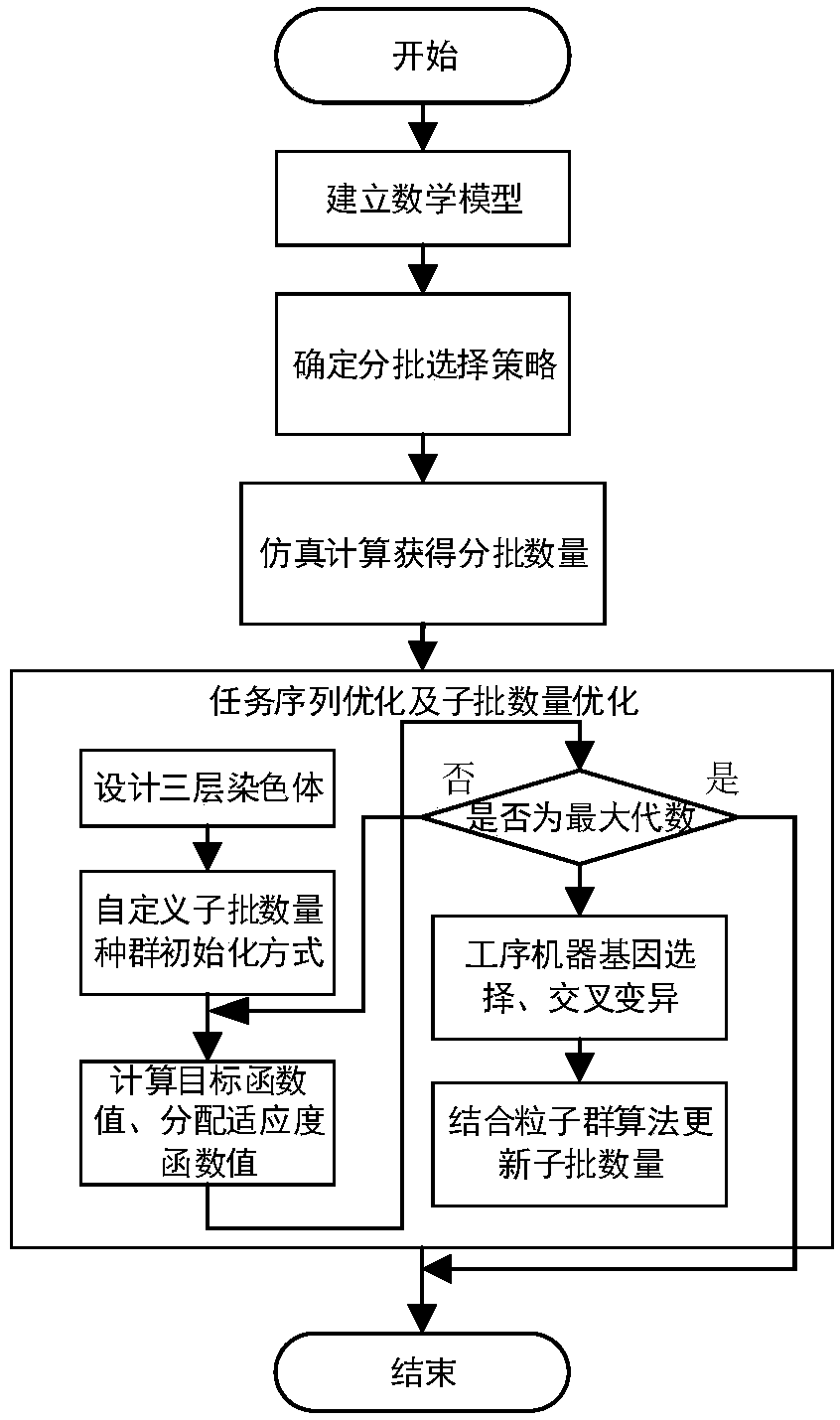

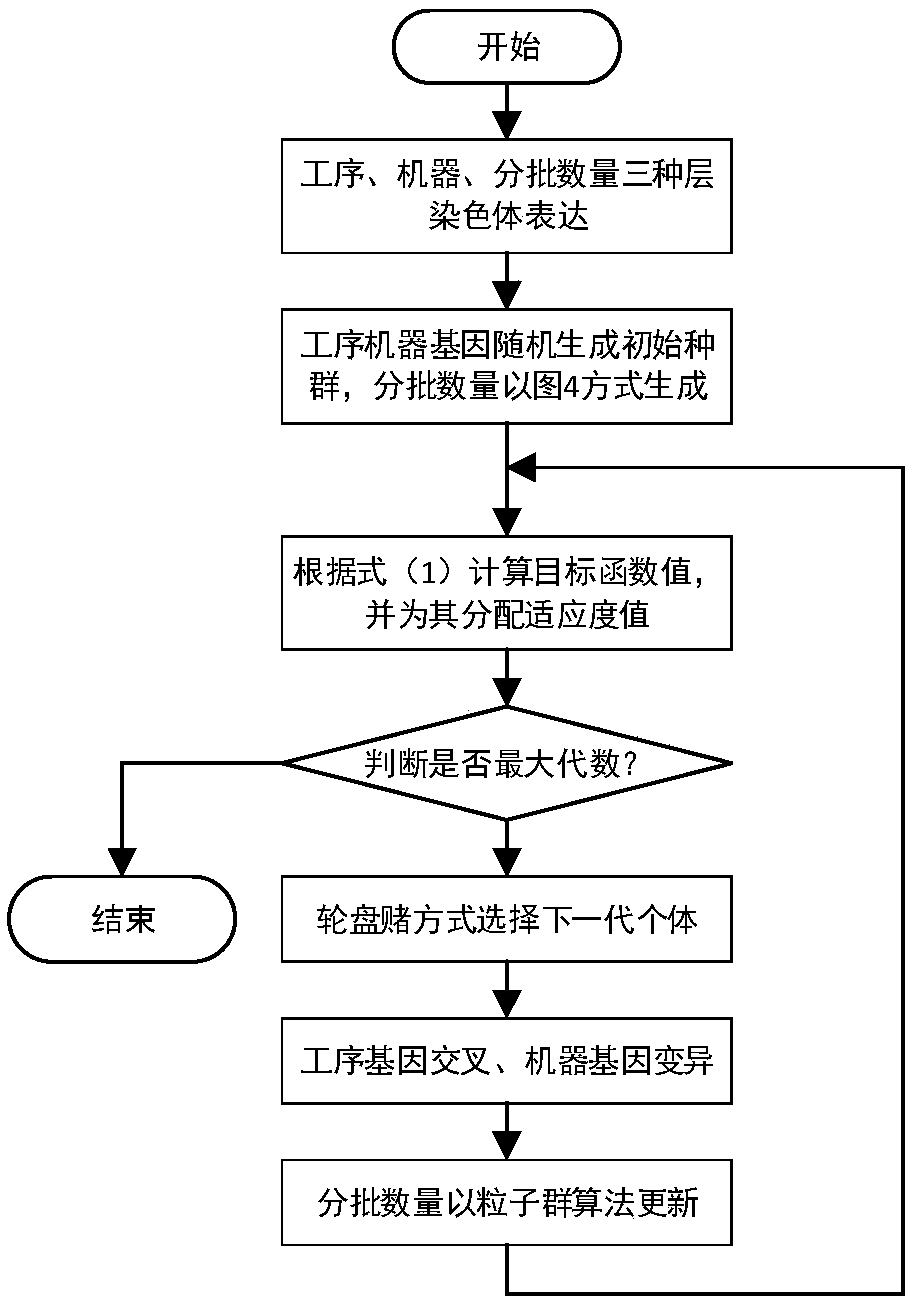

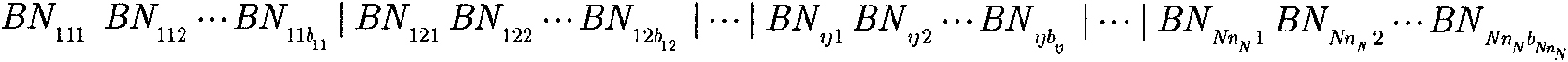

A flexible job shop order insertion dynamic scheduling optimization method is a solution method aiming at the delay problems caused by the order insertion in the job shop batch dynamic scheduling, andcomprises the steps of on the basis of establishing a mathematical model of the task sequence optimization and the order batch distribution, researching a batch selection strategy, adopting an example simulation mode to obtain the reasonable sub-batch number, at the same time, according to the simulation and calculation of the typical examples, giving a recommending value of the batch number; secondly, based on the three-layer gene chromosomes of the processes, the machines and the order distribution number, taking the minimum maximum time of completion and the delay period as the optimization targets; and finally, adopting a mixed algorithm of a particle swarm optimization algorithm and a genetic algorithm to improve the speed of evolution of the sub-batch number towards an optimal direction, thereby effectively reducing the tardiness quantity. The method is good at reducing the delay period in the job shop dynamic scheduling, and for the conventional genetic algorithm, enables the convergence speed and the stability to be improved substantially, at the same time, fully combines the actual production statuses of the intelligent job shops, greatly promotes the dynamic scheduling solution, and has the great application value in the engineering.

Owner:SOUTHWEST JIAOTONG UNIV

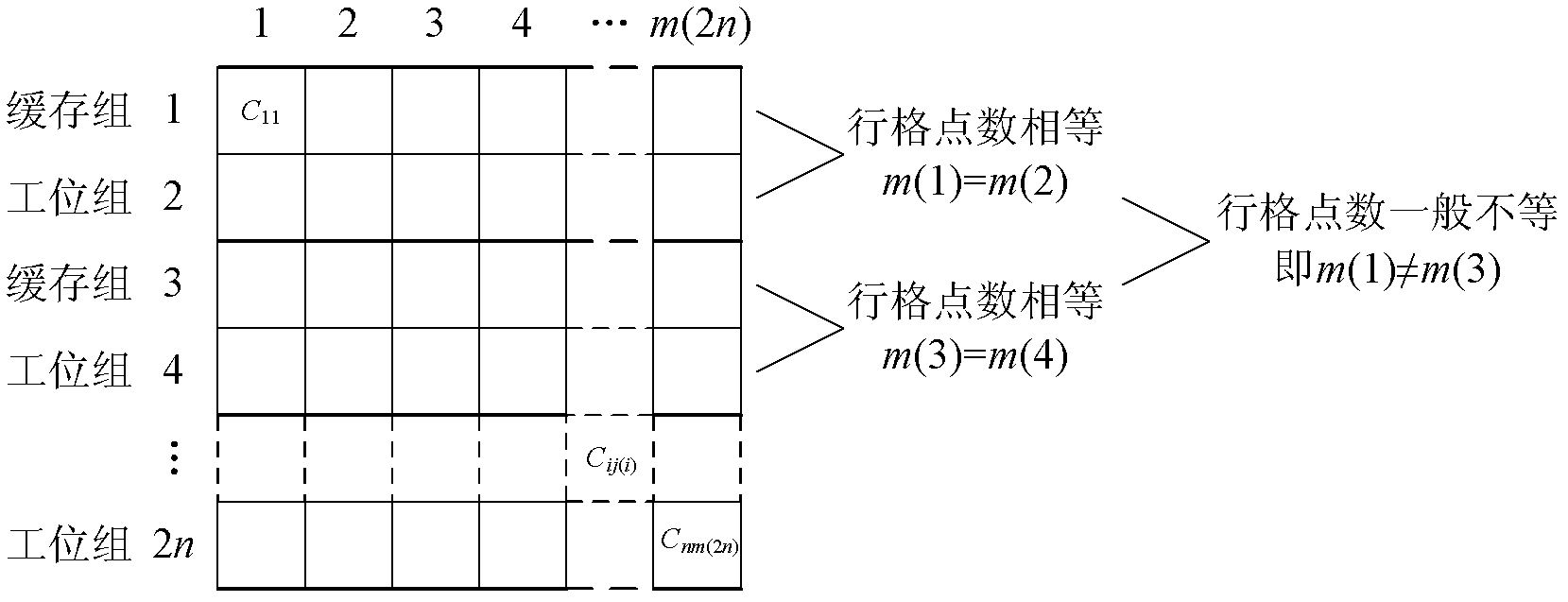

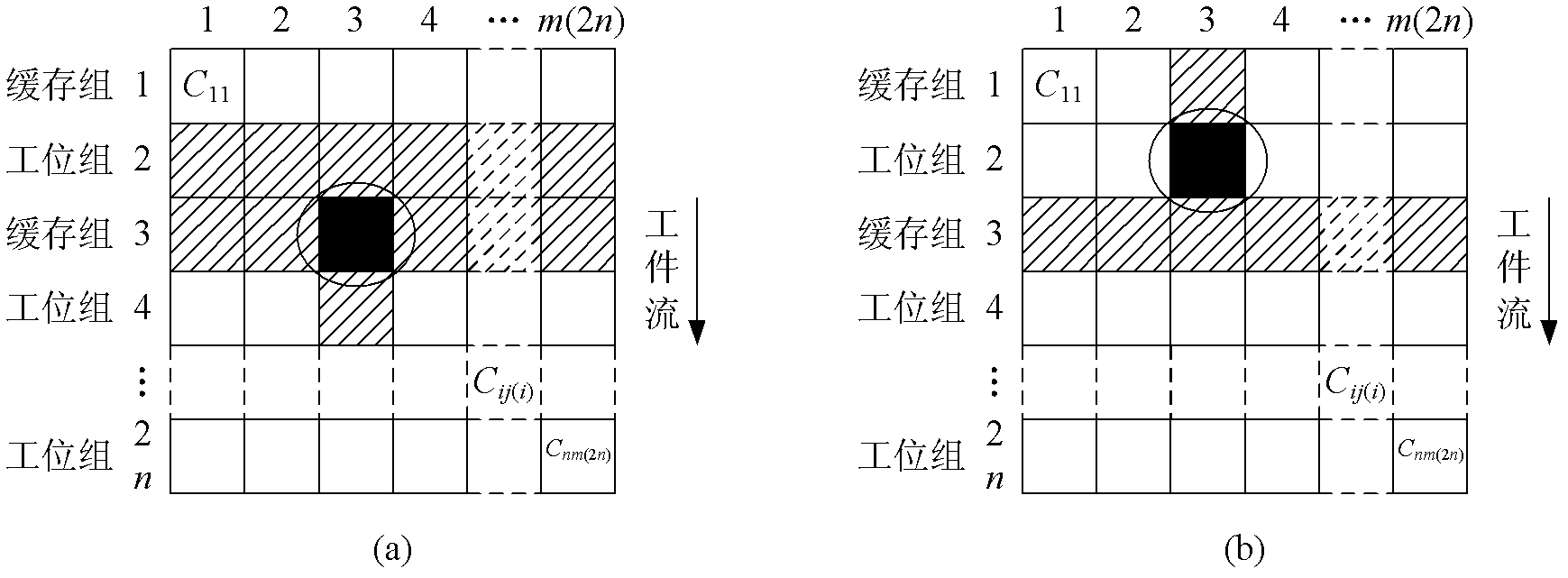

Cell-machine based dynamic scheduling method for large part flexible job shop

InactiveCN102608916AImprove operational efficiencyImprove stabilityAdaptive controlModel systemJob shop

The invention relates to a cell-machine based dynamic scheduling method for a large part flexible job shop, which comprises the steps of: 1) establishing a gridding model of a cell machine; 2) describing the cell state; 3) defining initial and entrance boundary conditions of a whole model system as beats of particles entering the system, wherein the exit boundary condition is reception capacity of a downriver factory of a supply chain on products; 4) determining the self-organized evolution rule of the model; and 5) for the work station selecting rule R[p--c], taking completion of the jth step as the start point and completion of the (j+1)th step as the finish point, taking the period (wq+w1 / pe) as a measuring standard, selecting the work station with minimum (wq+w1 / pe) as the processing work station of the (j+1)th step, wherein the work sequencing rule R[c--p] is determined according to a ''first come first serviced'' rule with the combination of workpiece processing priority. According to the cell-machine based dynamic scheduling method for the large part flexible job shop, the operating efficiency is improved and the stability of the device is enhanced.

Owner:ZHEJIANG UNIV OF TECH

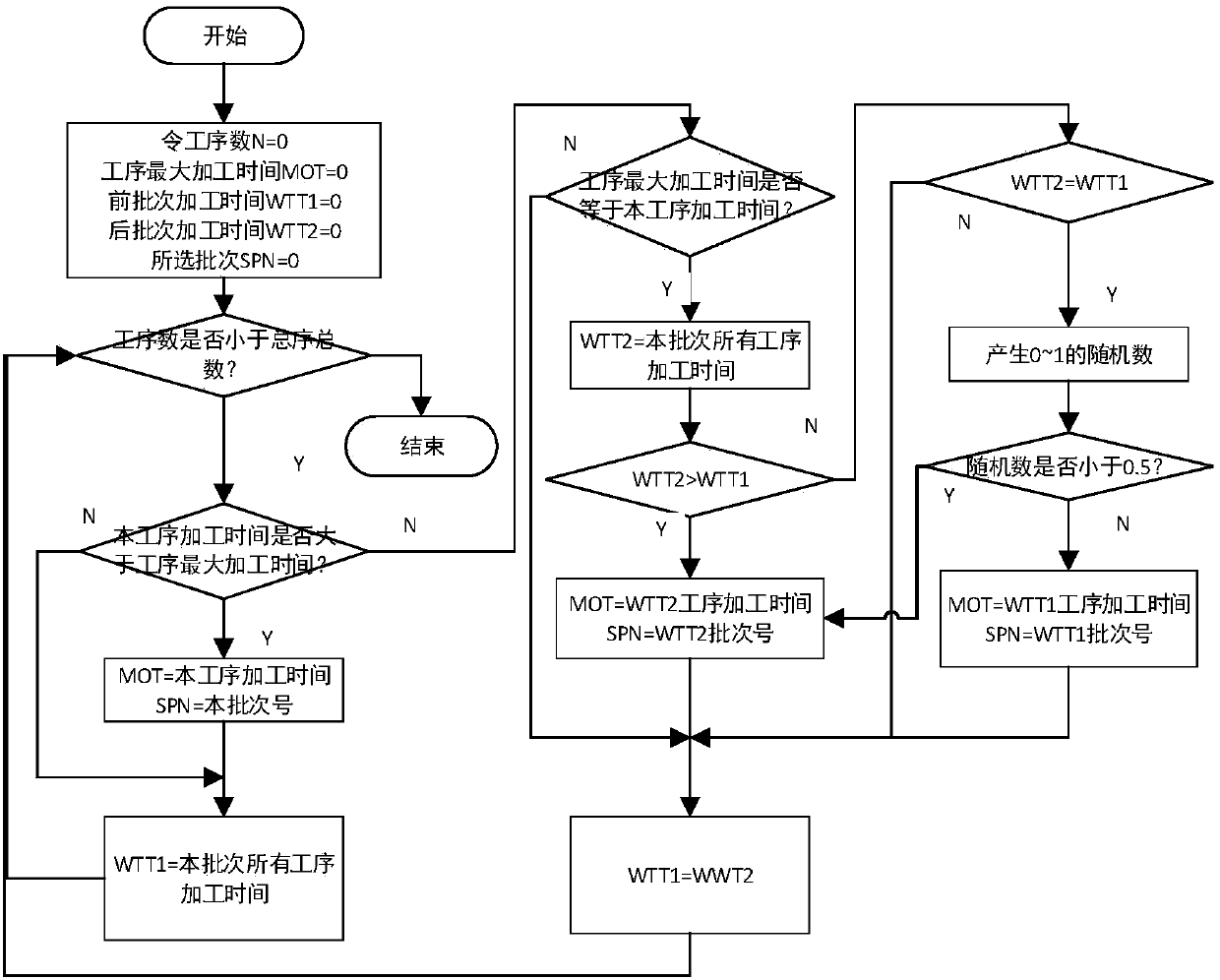

Method for dynamically re-dispatching job shop multi-process routes in batches based on two-stage differential evolution algorithm

InactiveCN101609334ASolve batch divisionSolving Scheduling Optimization ProblemsGenetic modelsTotal factory controlJob shopComputer science

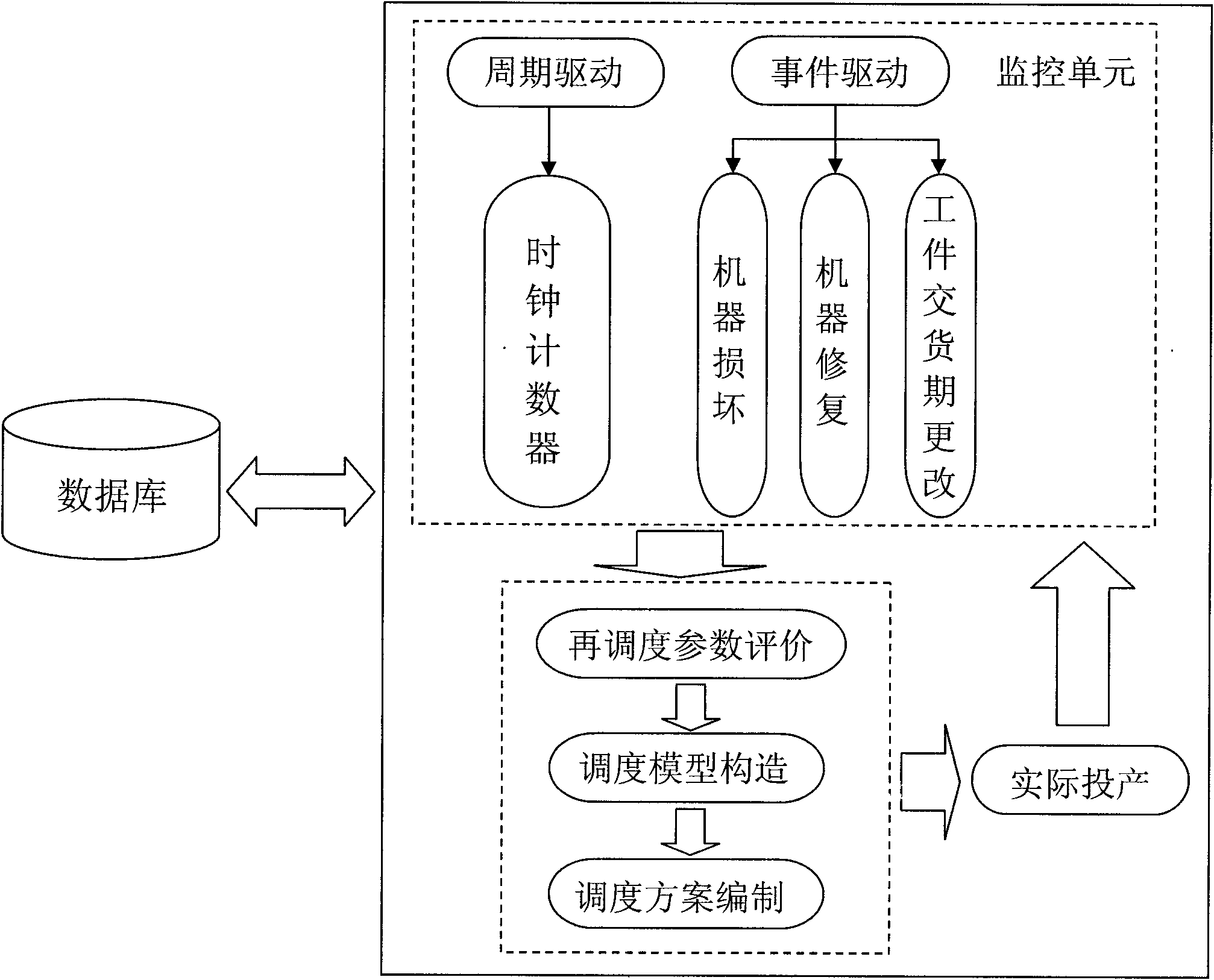

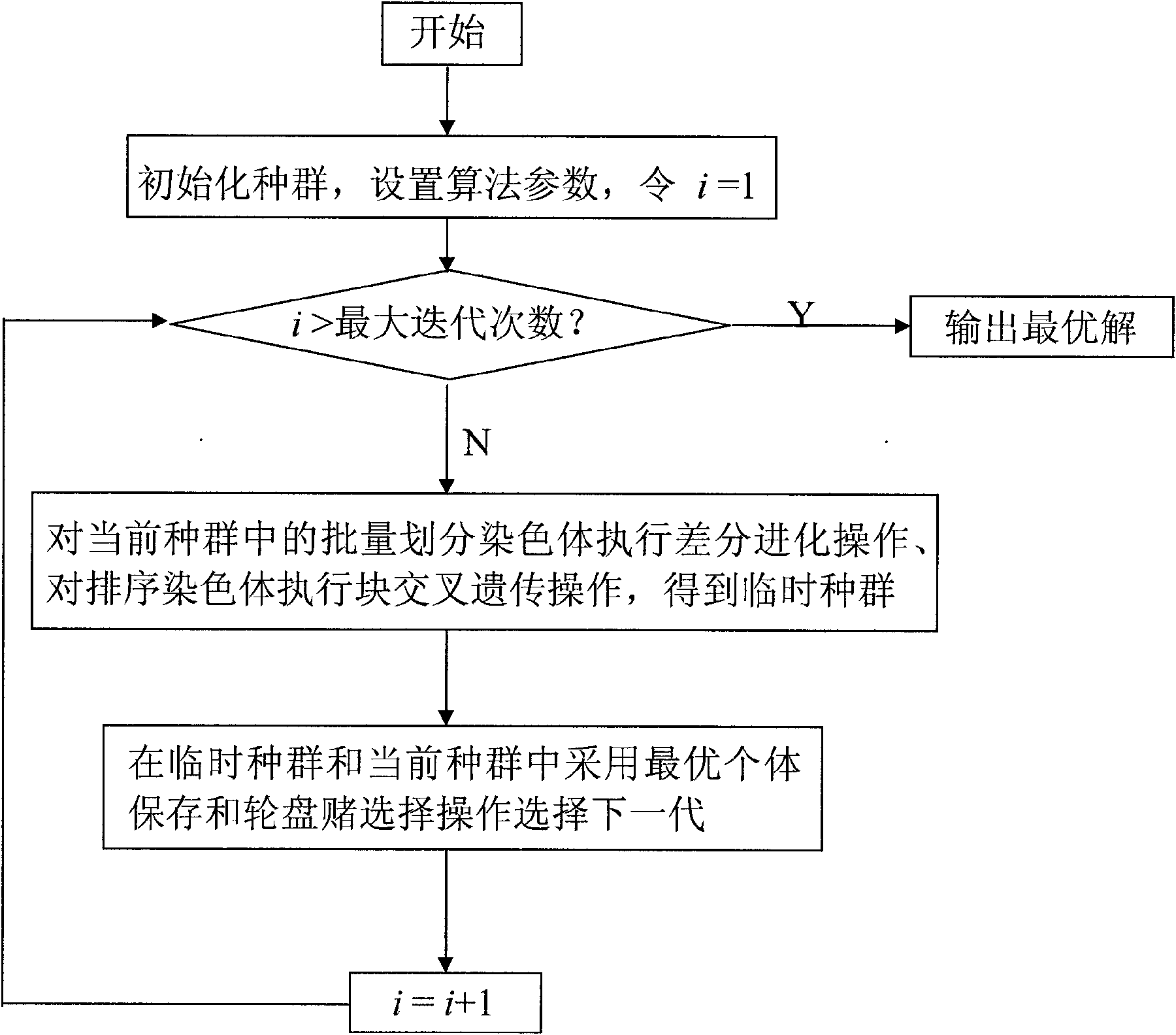

The invention provides a method for dynamically re-dispatching job shop multi-process routes in batches based on a two-stage differential evolution algorithm, relating to the evaluation of a re-dispatching parameter, the construction of a dispatching model and the compilation of a dispatching proposal. The method comprises the following steps: setting up a multi-process routes batching dispatching model based on a period and event driven re-dispatching strategy, and providing the two-stage differential evolution algorithm to solve the model, so as to solve the problems of batching dividing and dispatching optimizing. Considering the condition that each work procedure of work pieces possibly has uneven capability in real environment, the method divides the each work piece in batches at the each work procedure, and the designed two-stage differential evolution algorithm solves the problems of batching dividing and dispatching optimizing, so as to effectively reduce the free time of a machine, shorten a production period, and be completely suitable for complex environment change in the process of machining and real-time treatment.

Owner:ZHEJIANG UNIV OF TECH

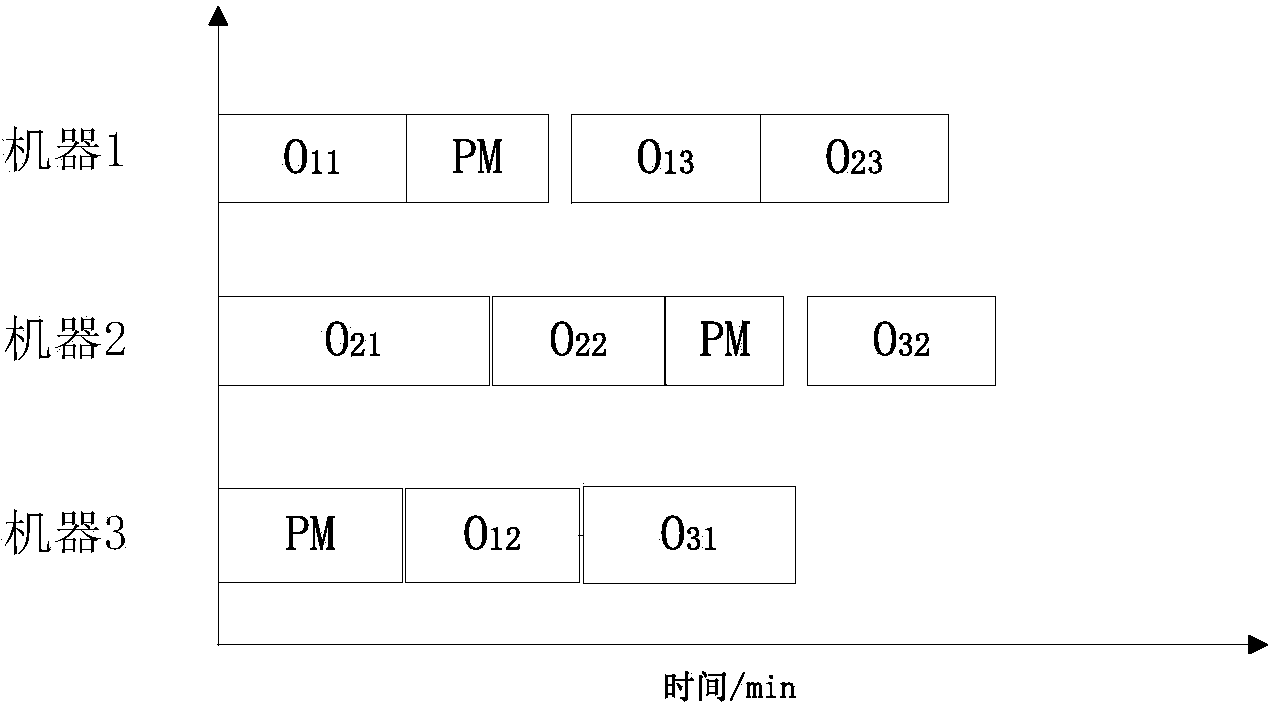

Equipment preventive maintenance and flexible job shop scheduling integrated optimization method

InactiveCN104111642AAbundant means of dynamic exchangeExpand your searchTechnology managementProgramme total factory controlCompletion timeChemical reaction

The invention discloses an equipment preventive maintenance and flexible job shop scheduling integrated optimization method. The method is characterized by specifically comprising: first of all, according to an operation sequence, an equipment maintenance period, and a constraint condition of uninterrupted production process of each operation and non-conflict production process and equipment maintenance process of a flexible job shop scheduling problem, establishing an integrated optimization model of a flexible job shop scheduling and equipment maintenance plan, which takes cost and efficiency into consideration; secondary, optimizing multiple targets by use of a hybrid multi-objective chemical-reaction optimization method, the multiple targets comprising maximum completion time, total production cost and total equipment preventive maintenance cost; and finally, obtaining an optimization solving result, such that a flexible job shop scheduling plan can be obtained. The method can realize the goals of reducing the maximum completion time, the production cost and the equipment maintenance cost and can obtain an optimal flexible job shop scheduling scheme.

Owner:HUAZHONG UNIV OF SCI & TECH

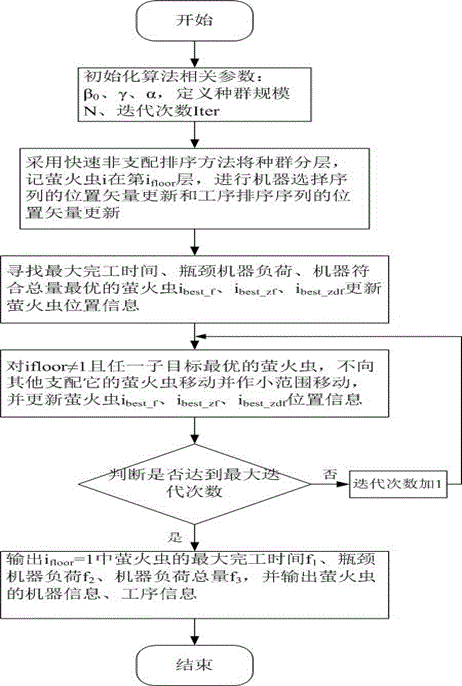

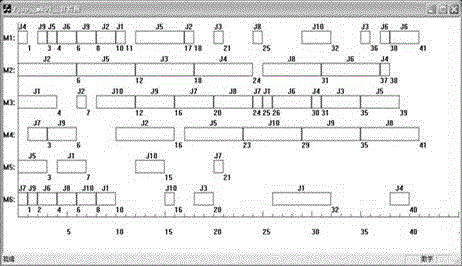

Multi-objective flexible job shop scheduling method based on discrete firefly algorithm

The invention provides a multi-objective flexible job shop scheduling method based on a discrete firefly algorithm. The method comprises the steps that a mathematical model is established for a multi-objective flexible job shop scheduling problem; a segment coding method is used to code a firefly, and a machine selection part and a process sorting part are divided; the discrete firefly algorithm is used to optimize the model to acquire a Pareto optimal solution set; and a solution corresponding to the actual need is selected from the Pareto optimal solution set, and decoding is carried out to output machine selection position information and process sorting position information. Compared with the existing method, the multi-objective flexible job shop scheduling problem optimizing method has the advantages that the global optimization ability of the algorithm is improved; the overall processing time is shortened; the job shop production cost is reduced; and the method meets actual production needs.

Owner:XIANGTAN UNIV

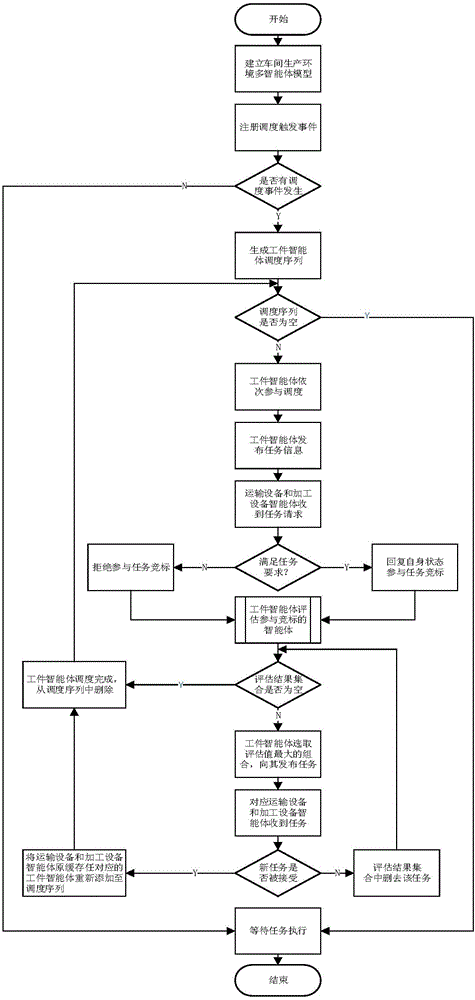

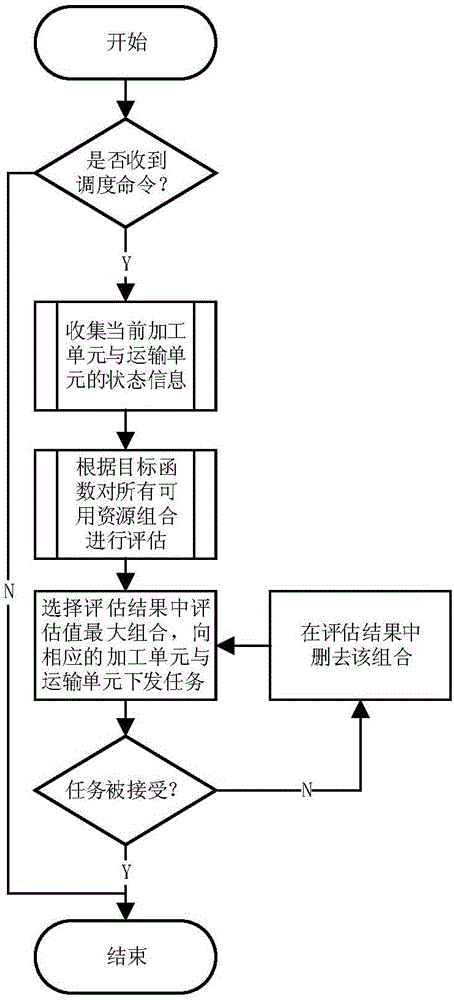

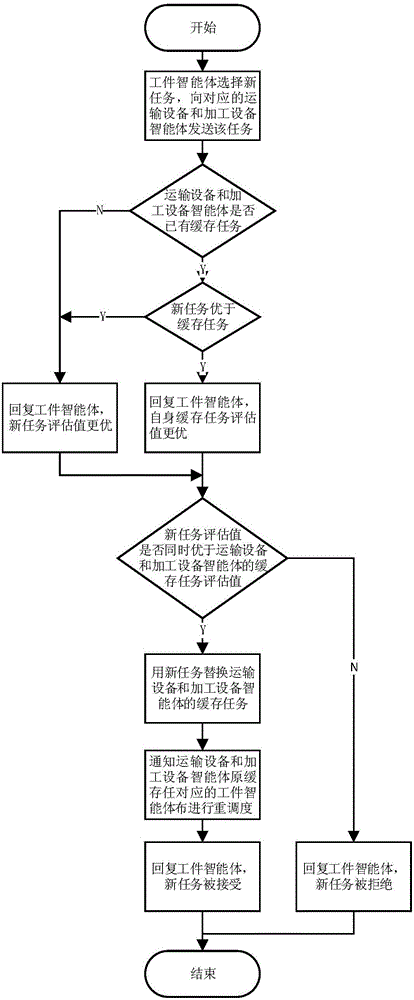

Real-time job shop scheduling control method in complicated production environment

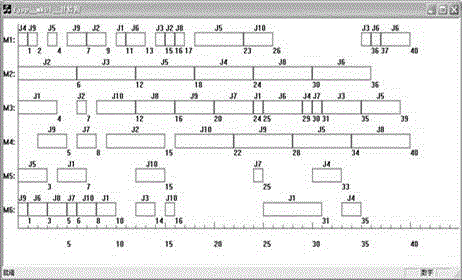

ActiveCN106094759AReduce invalid scheduling calculationsReduce error accumulationProgramme total factory controlEvent triggerJob shop scheduling

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

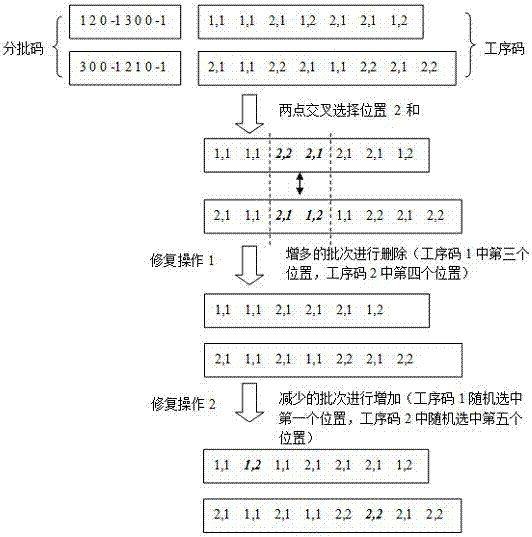

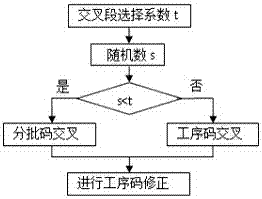

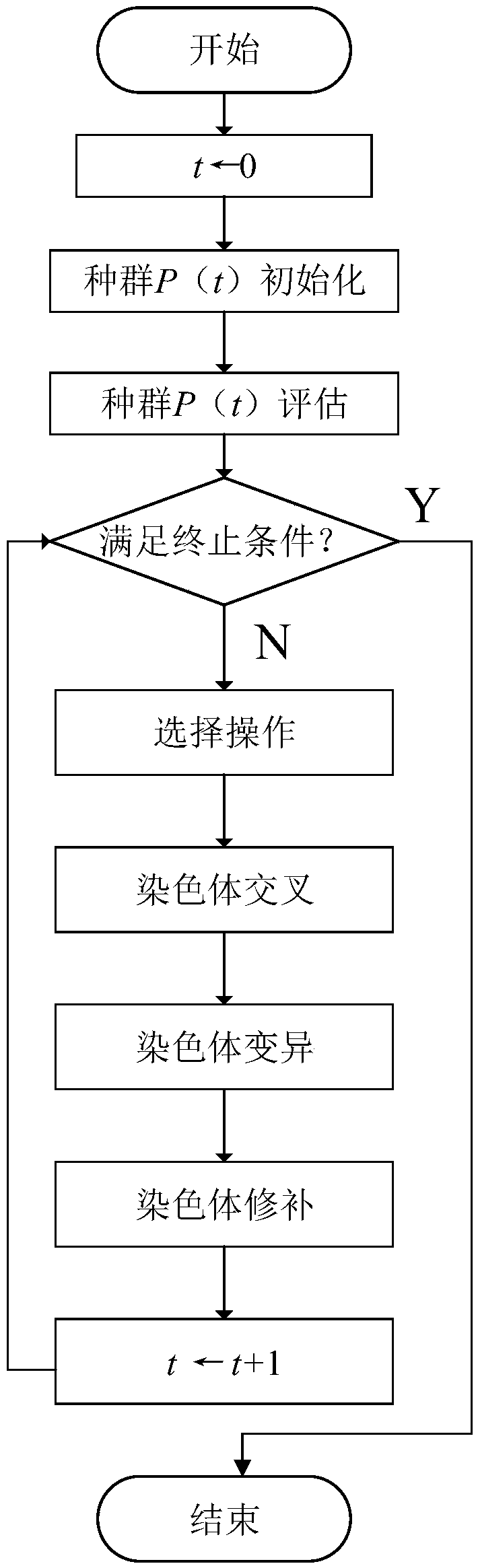

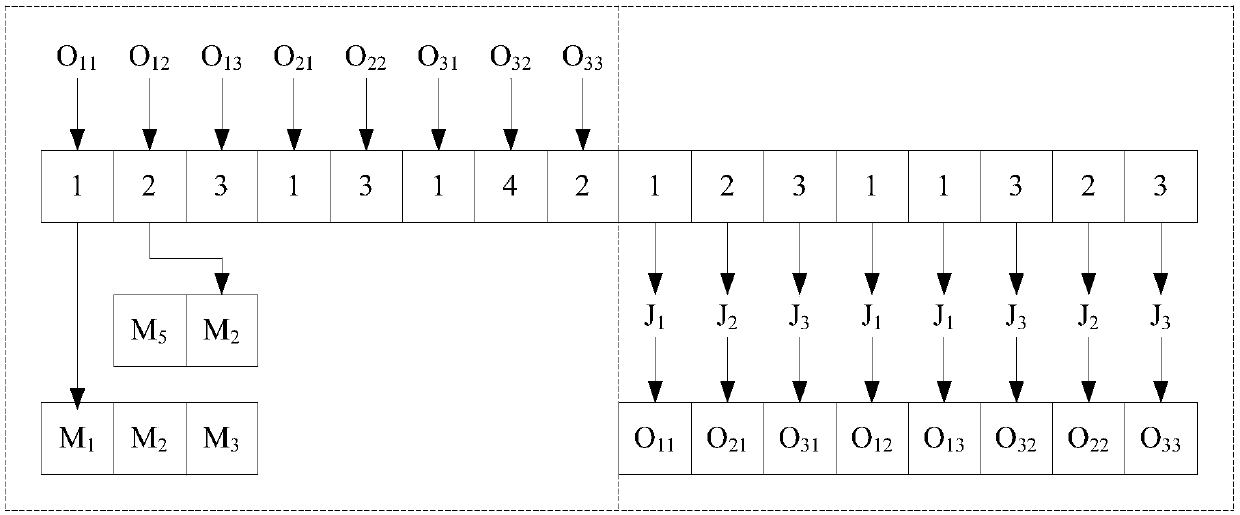

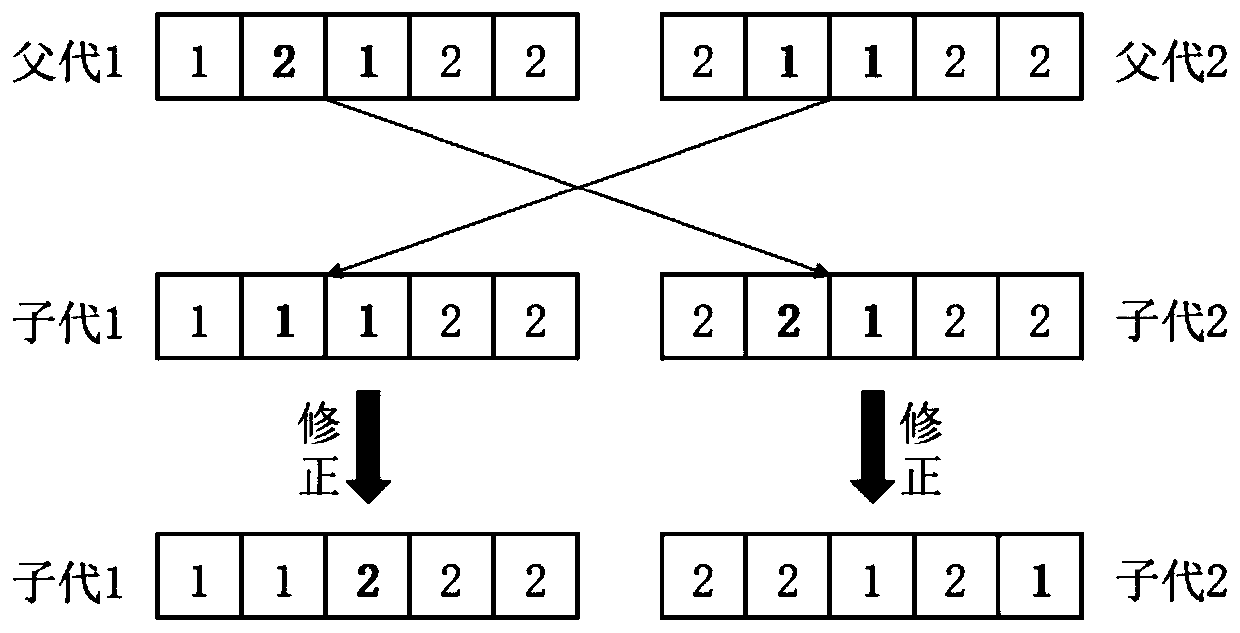

Flexible job shop batch scheduling method based on genetic algorithm

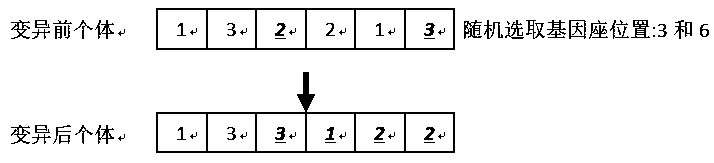

The invention discloses a batch scheduling method for flexible job shops based on genetic algorithms. The steps of the method are: (1) Determine the operating parameters, including population size M, crossover probability P C , the mutation probability P M , the number of iterations T; (2) Initial population generation, using segmented coding method to generate batch codes and process codes; (3) Individual fitness calculation, taking the reciprocal of the individual’s total completion time as its fitness value; (4) Select Operation, using the roulette selection operator; (5) crossover operation, setting crossover execution criteria, performing crossover on batch codes or process codes according to the criteria, and repairing after crossover; (6) mutation operation, using multiple Point mutation, using reverse sequence mutation for the process code; (7) Termination discrimination, judging whether the number of generations meets the termination condition, stop if it is satisfied, and output the optimal scheduling plan, otherwise go to (3). The invention can optimize the production operation of the flexible workshop, effectively shorten the production cycle, has strong applicability and is easy to popularize.

Owner:SHANGHAI UNIV

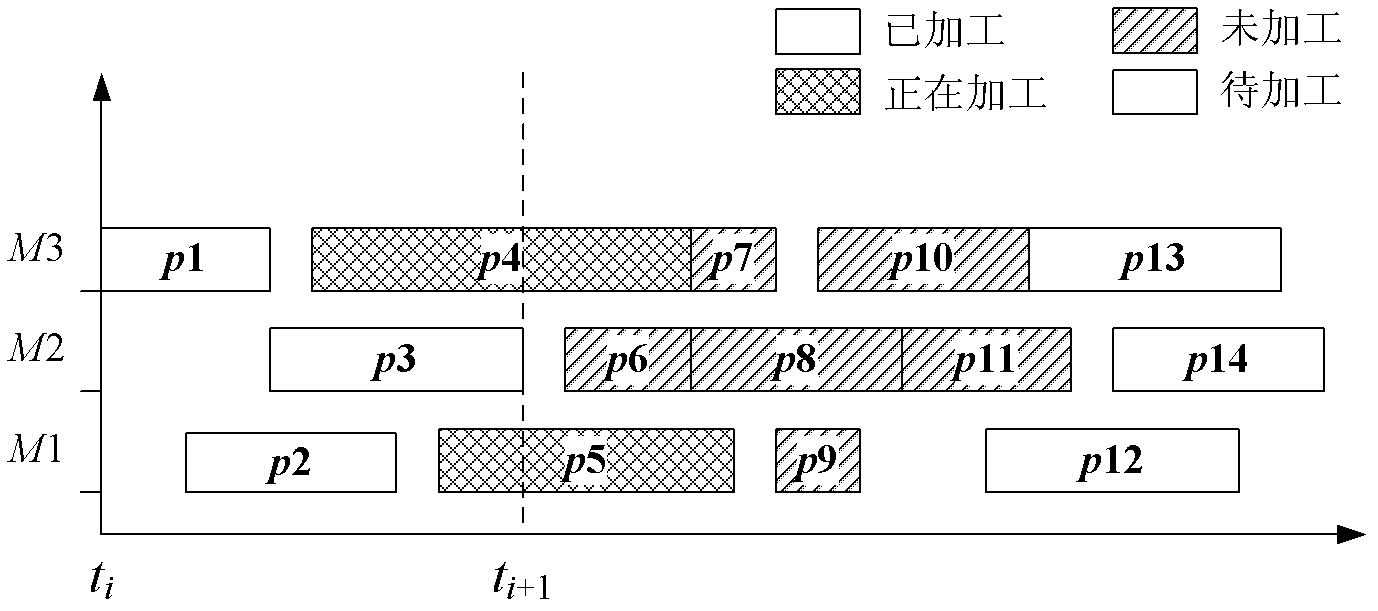

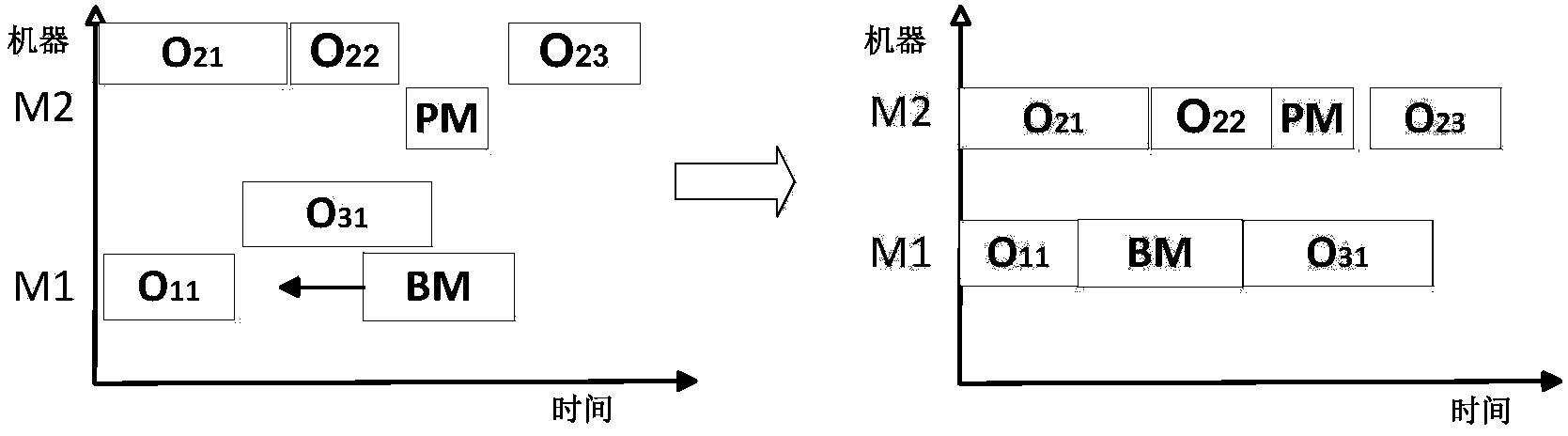

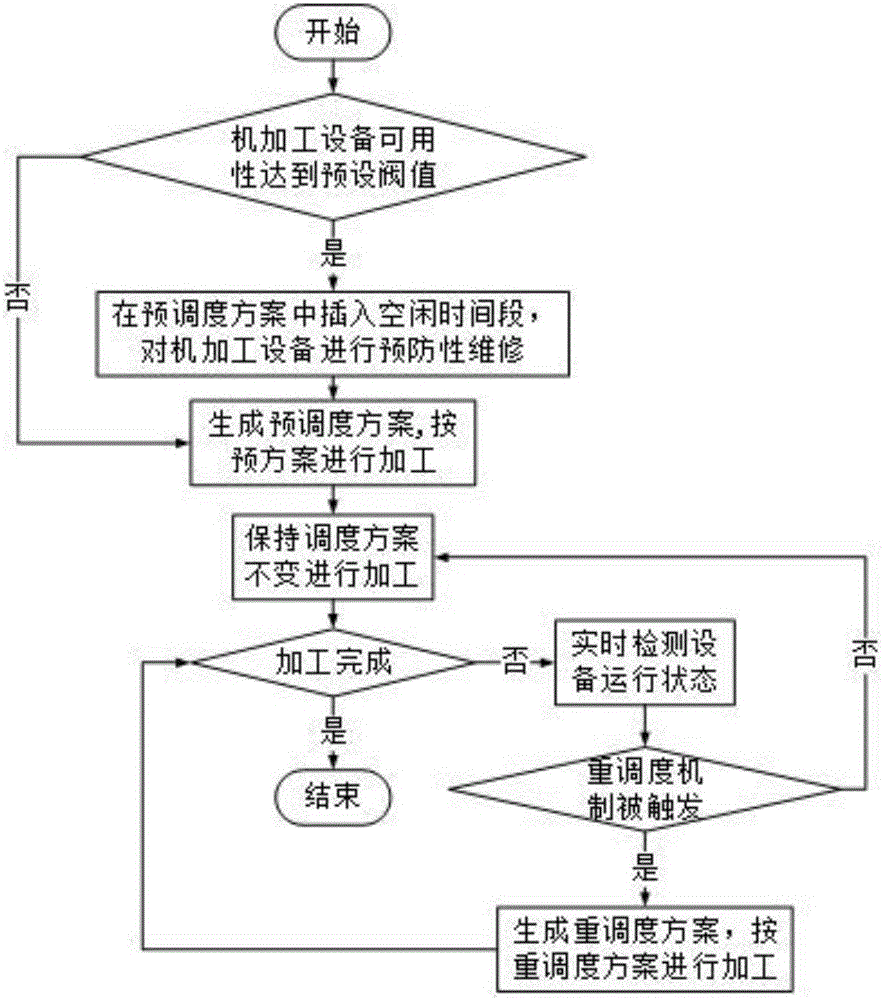

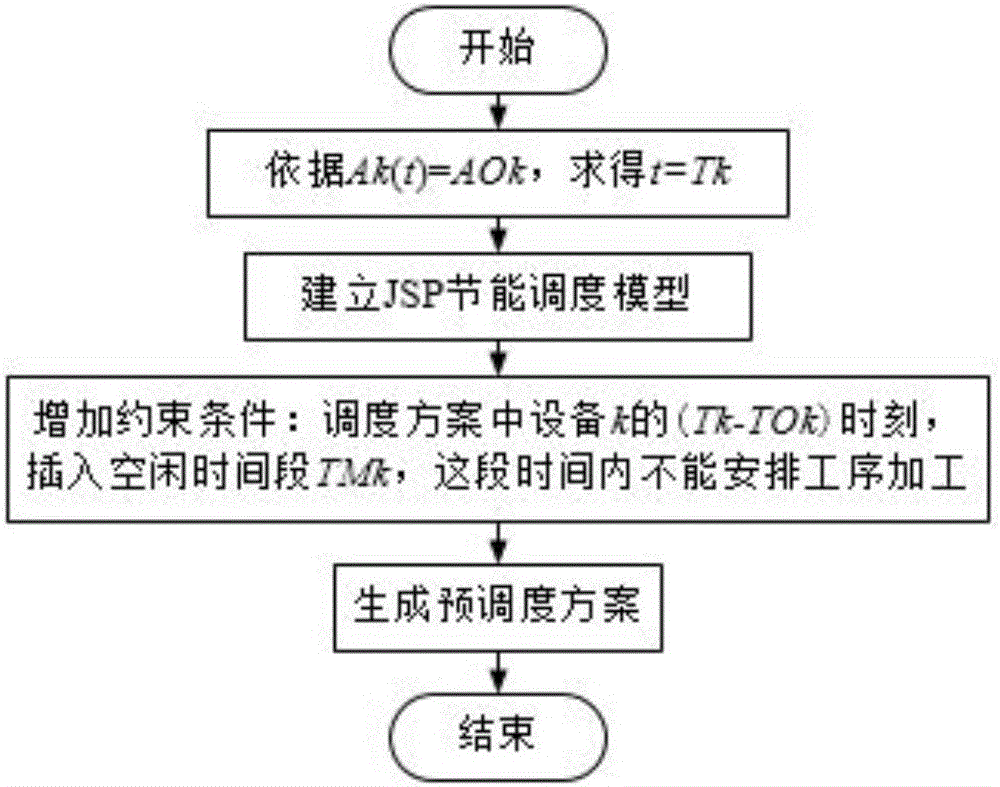

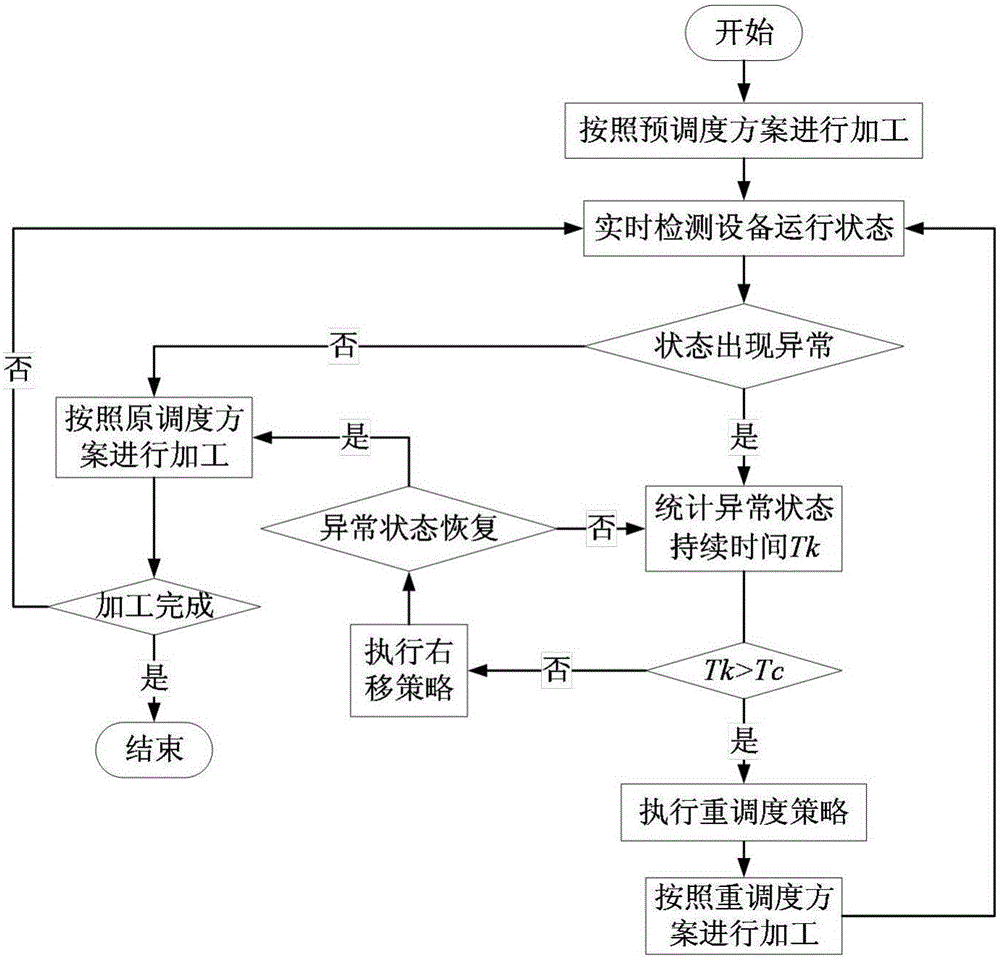

Flexible job shop dynamic scheduling method taking availability of machining equipment into consideration

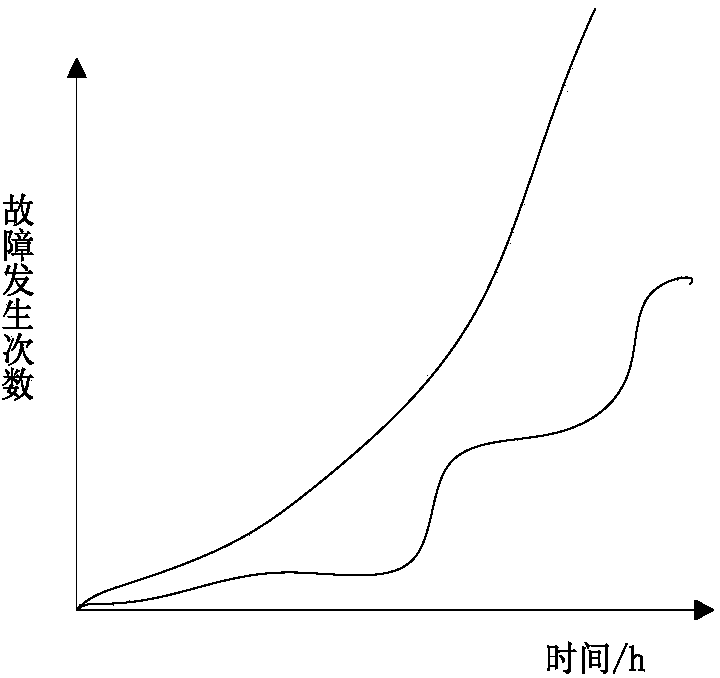

InactiveCN105824304AImprove dispatching operation efficiencyImprove responsivenessProgramme total factory controlIdle timeJob shop

The invention provides a flexible job shop dynamic scheduling method taking the availability of machining equipment into consideration, belonging to the technical field of shop scheduling. When the availability of machining equipment is decreased to a certain threshold, the machining equipment is preventively maintained, and a pre-scheduling scheme is generated in order to reduce the probability that the machining equipment is abnormal in the machining process; and then, the running status of the equipment is detected in real time in the machining process. When that the status of the equipment is abnormal is detected, whether to take a rightward shifting strategy or to execute a rescheduling strategy is judged by analyzing the influence degree of the duration of the abnormal status on the maximum time of completion. Based on the availability of machining equipment, the machining equipment is preventively maintained by inserting idle time, so the probability that the machining equipment is abnormal is reduced. Meanwhile, by detecting the running status of equipment in real time, the rescheduling response ability when there is an abnormality is improved, and the stability and timeliness of job shop dynamic scheduling are improved.

Owner:CHONGQING UNIV

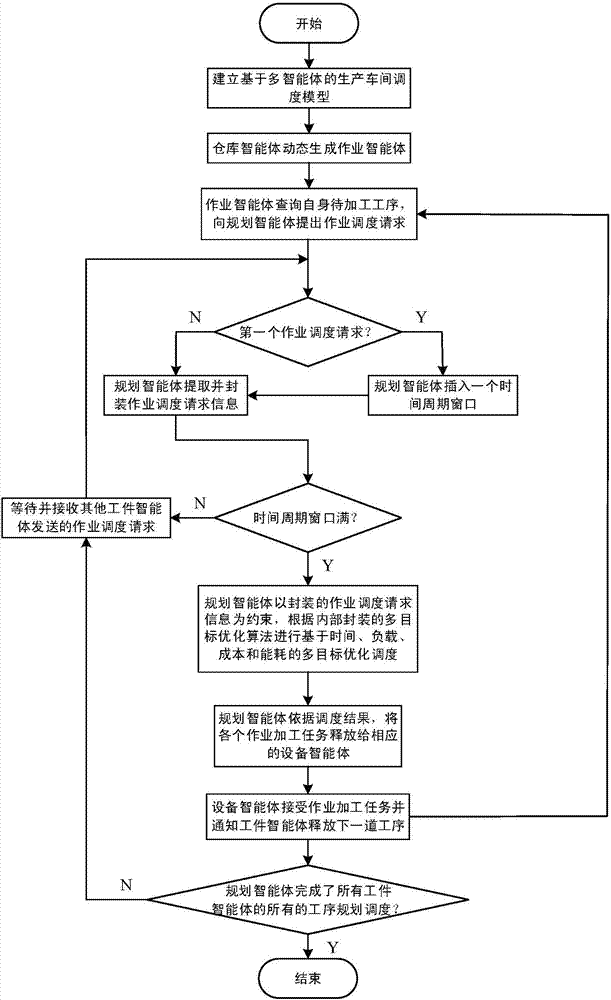

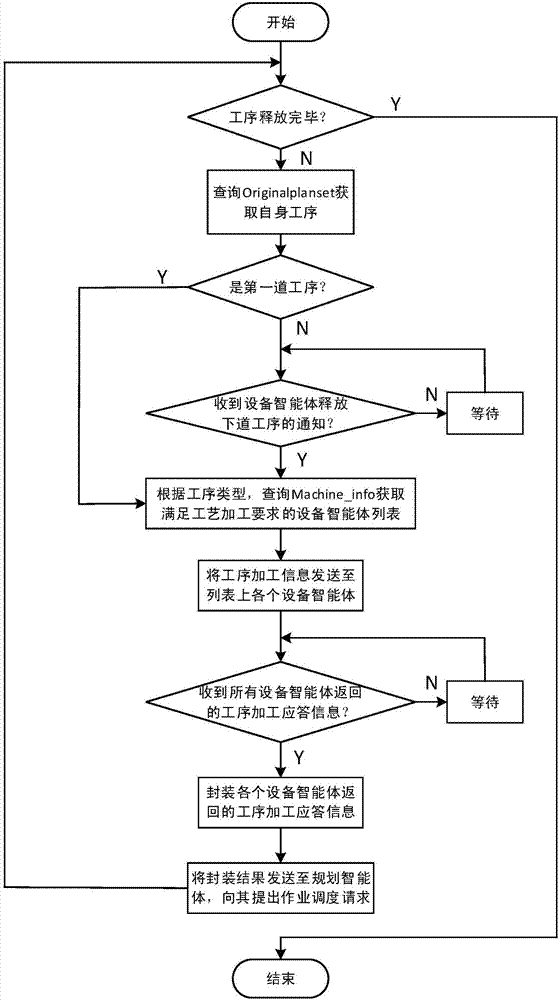

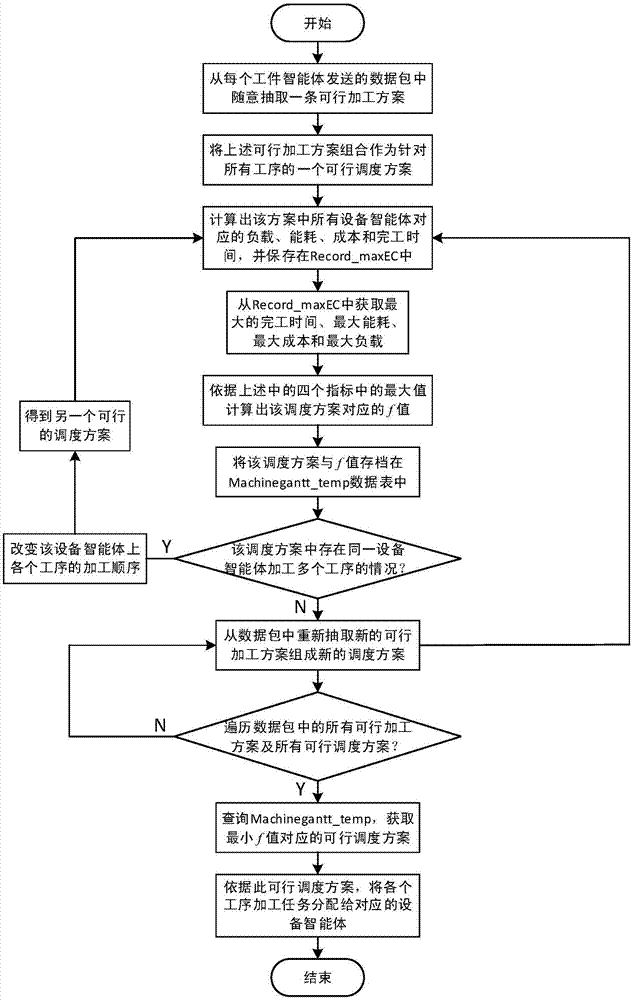

Multi-agent-based job-shop multi-objective collaborative optimization scheduling method

The invention discloses a multi-agent-based job-shop multi-objective collaborative optimization scheduling method, which comprises the following steps: a multi-agent-based production workshop scheduling model is established; a workpiece agent proposes a job scheduling request to a planning agent according to a processing task of itself; the planning agent inserts a time cycle window, and carries out multi-objective optimization scheduling based on time, load, cost and energy consumption on a plurality of job scheduling requests received in the window; and the planning agent releases a scheduling result to a device agent, and the device agent finishes the processing task and informs the workpiece agent to release a next process. By inserting the time window, arranging the planning agent and packaging a multi-objective optimization algorithm, optimization range is expanded, overall scheduling performance of the system is improved, multi-objective optimization scheduling is realized, and the defects of single-step optimization and single-objective optimization of a conventional multi-agent method are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

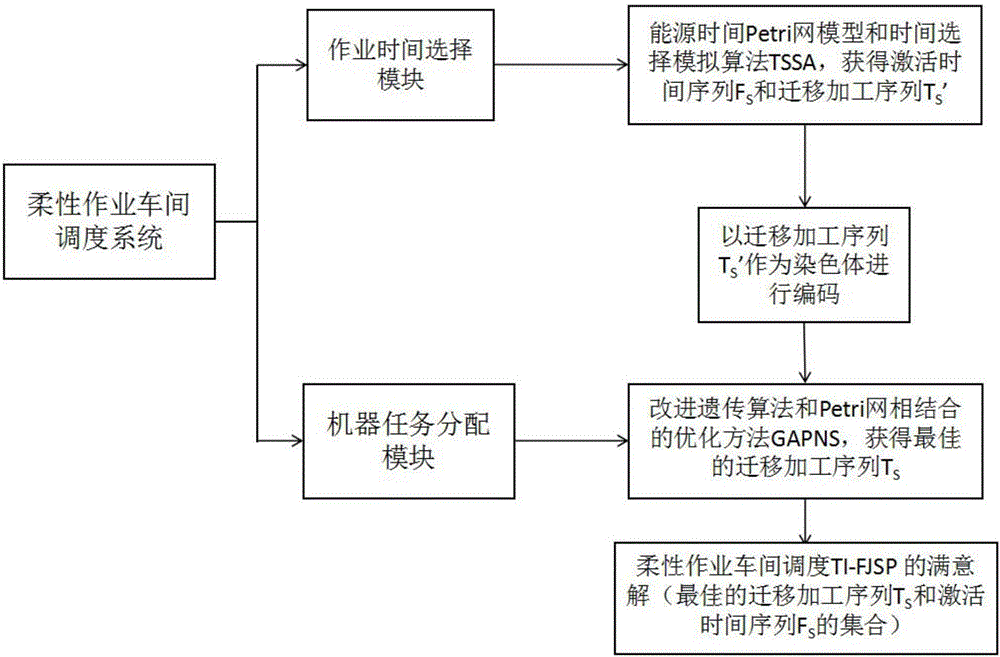

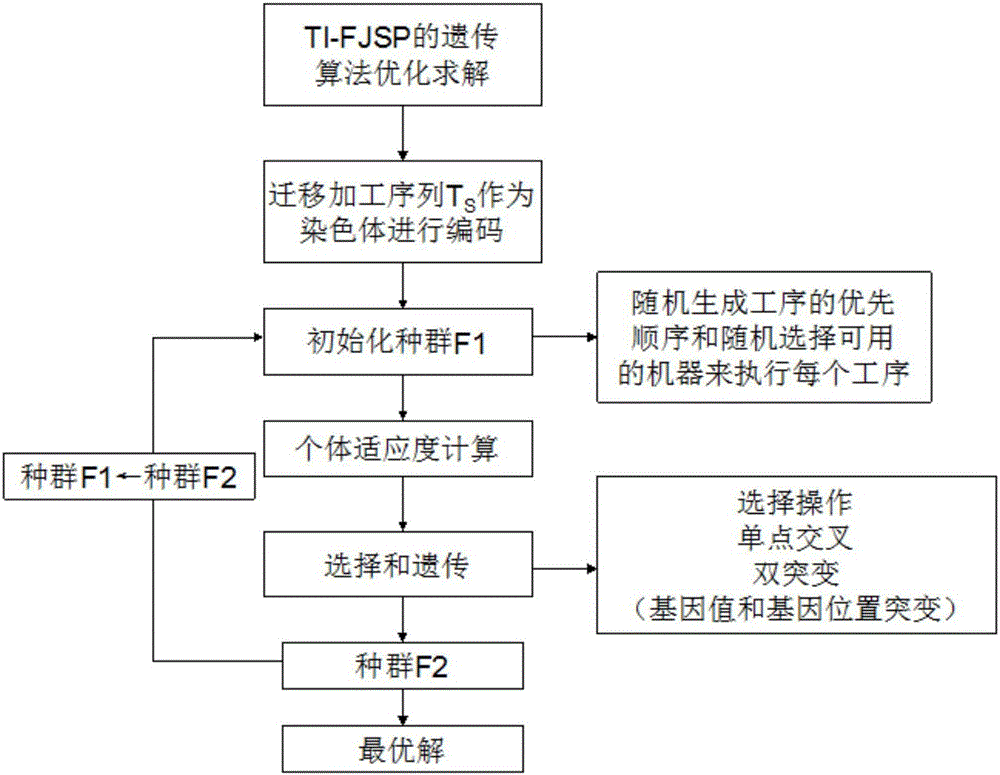

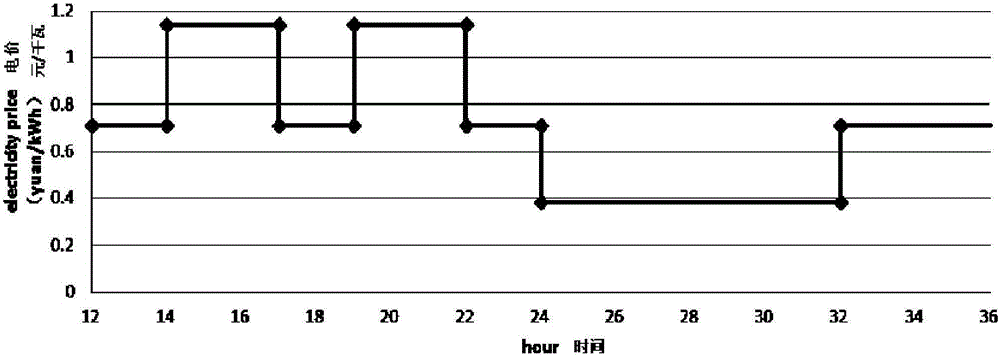

Flexible job shop scheduling system based on Petri network and improved genetic algorithm

The invention discloses a flexible job shop scheduling system based on a Petri network and an improved genetic algorithm. The flexible job shop scheduling system is a system for minimizing completion time and power consumption according to peak-valley electricity price and indirect energy consumption, and comprises a job time selection module and a machine task assigning module, wherein the job time selection module is used for obtaining a migration activation time sequence FS and a migration processing sequence TS' by establishing an energy time Petri network model and a time selection simulation algorithm TSSA; the machine task assigning module is used for simulating by combination of improved genetic algorithm and the Petri network, finding out an optimal migration processing sequence TS, and obtaining a satisfactory solution of flexible job shop scheduling TI-FJSP. By adopting the flexible job shop scheduling system disclosed by the invention, making and implementation of a production plan can be effectively optimized, and a production mode with the lowest cost is provided for a company according to the peak-valley electricity price, so that the production cost of the company can be lowered, the utilization rate of energy can be increased, energy allocation can be optimized, resources can be saved, the environment can be protected, the economic benefits of the company can be optimized, and the industrial competitiveness of the company can be improved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

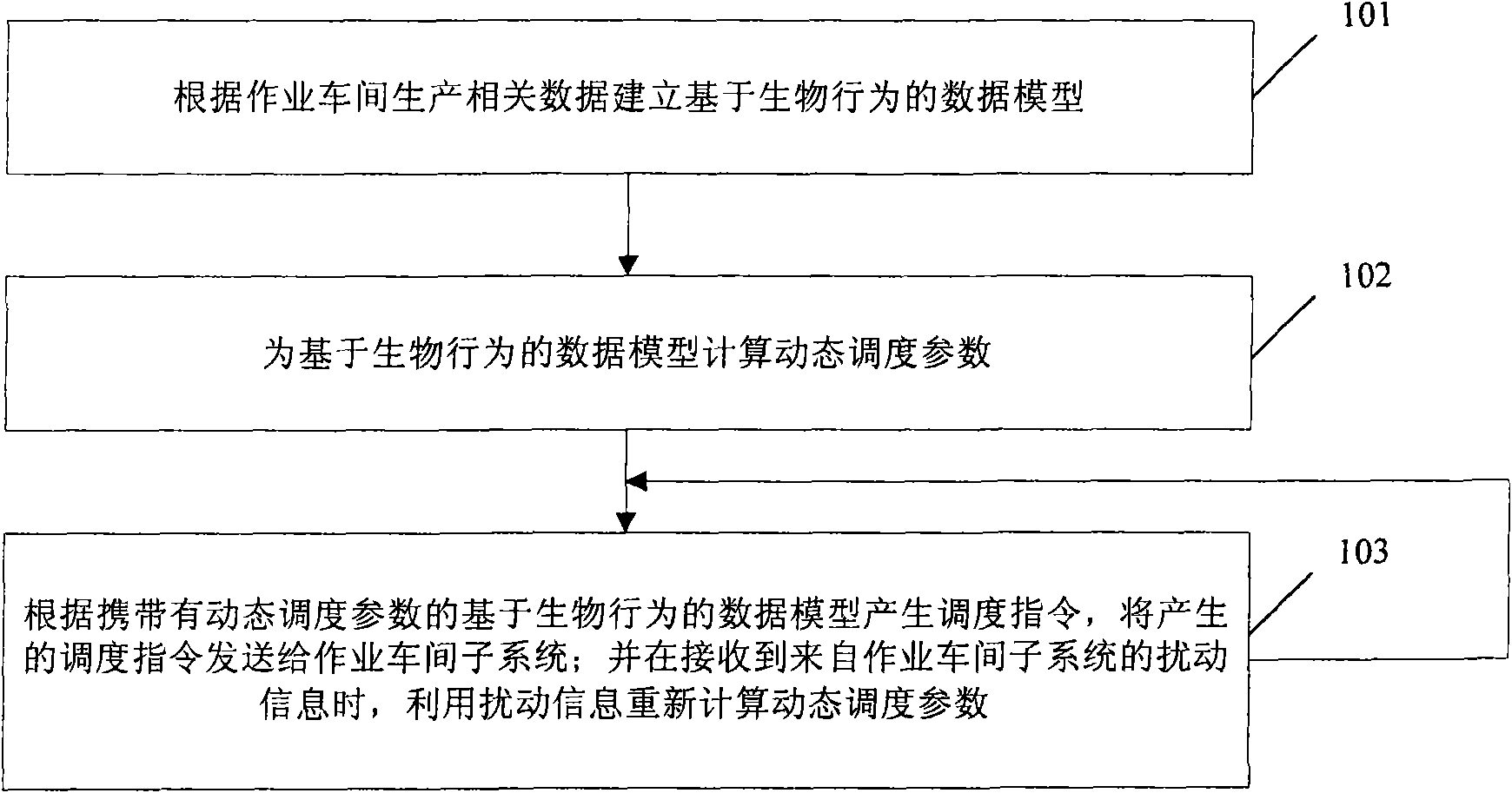

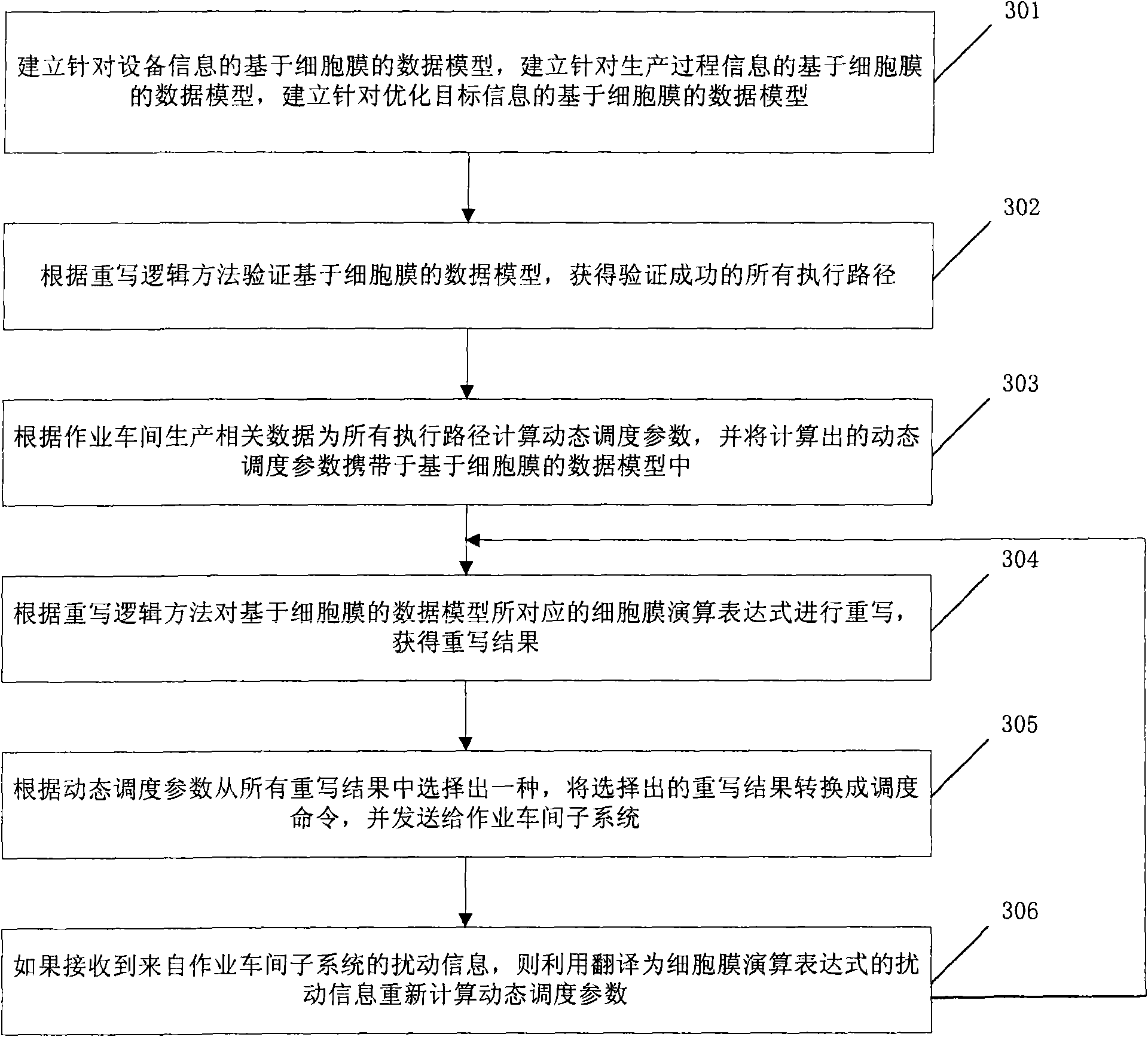

Method and system for realizing real-time scheduling of job shop

InactiveCN101556474AQuick responseIncrease productivitySimulator controlProgramme total factory controlJob shopReaction speed

The invention provides a method and a system for realizing the real-time scheduling of a job shop. The method for realizing the real-time scheduling of the job shop comprises the following steps: A, establishing a data model based on biological behaviors according to input related production data of the job shop; B, utilizing the related production data of the job shop to calculating a dynamic scheduling parameter of the data model based on the biological behaviors; C, generating a scheduling command according to the data model which is based on the biological behaviors and carries the dynamic scheduling parameter, sending the generated scheduling command to a job shop subsystem and recalculating the dynamic scheduling parameter by disturbance information when the disturbance information from the job shop subsystem is received; and repeatedly carrying out the step C till the scheduling of the job shop is completed. Because only the dynamic scheduling parameter is calculated during disturbance, the reaction speed of the system to disturbance situation is increased, the requirement of the real-time scheduling is met and the production efficiency of enterprises is improved.

Owner:SIEMENS CHINA

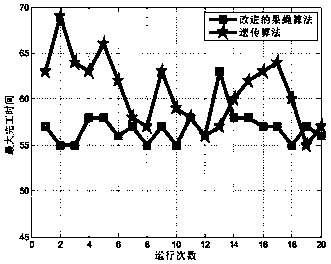

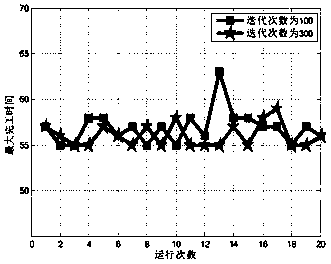

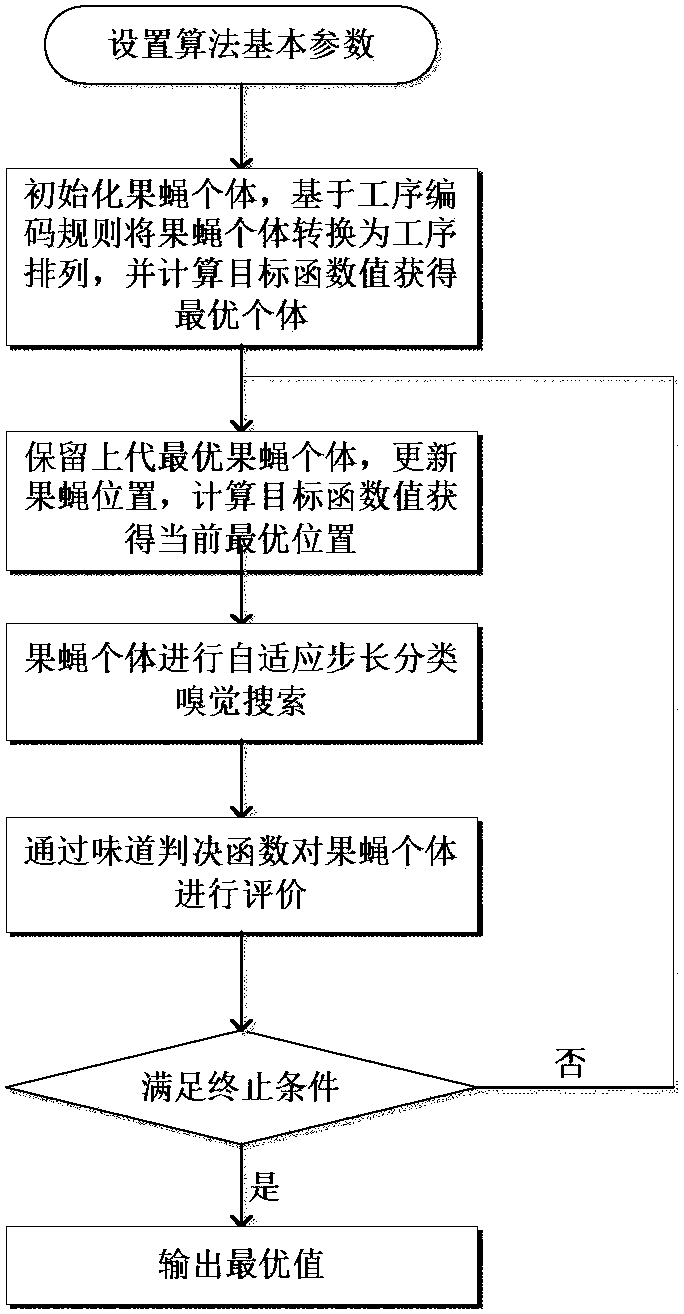

Job shop scheduling method based on improved fruit fly optimization algorithm

InactiveCN108108829AReduce settingsStrong global optimization abilityForecastingResourcesCompletion timeMathematical model

The invention presents a job shop scheduling method based on an improved fruit fly optimization algorithm. The method comprises the following steps: establishing a mathematical model of a job shop according to the characteristics of the job shop, and constructing the constraint conditions for the processing order of different working procedures of each work piece and the constraint conditions forthe processing order of the working procedures of different work pieces on each machine; and establishing a job shop scheduling objective function based on minimum maximum completion time, forming individual fruit flies through a coding method based on working procedures, enabling the fruit fly colony to quickly find the minimum value of a taste concentration determination function through a classification olfactory random search method based on adaptive step size, and obtaining an optimal solution of job shop scheduling, namely, an optimal scheme of job shop scheduling. The algorithm is simple to implement, and requires only two parameters. Moreover, the algorithm has strong global optimization ability, and can be used to solve the job shop scheduling problem.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD +1

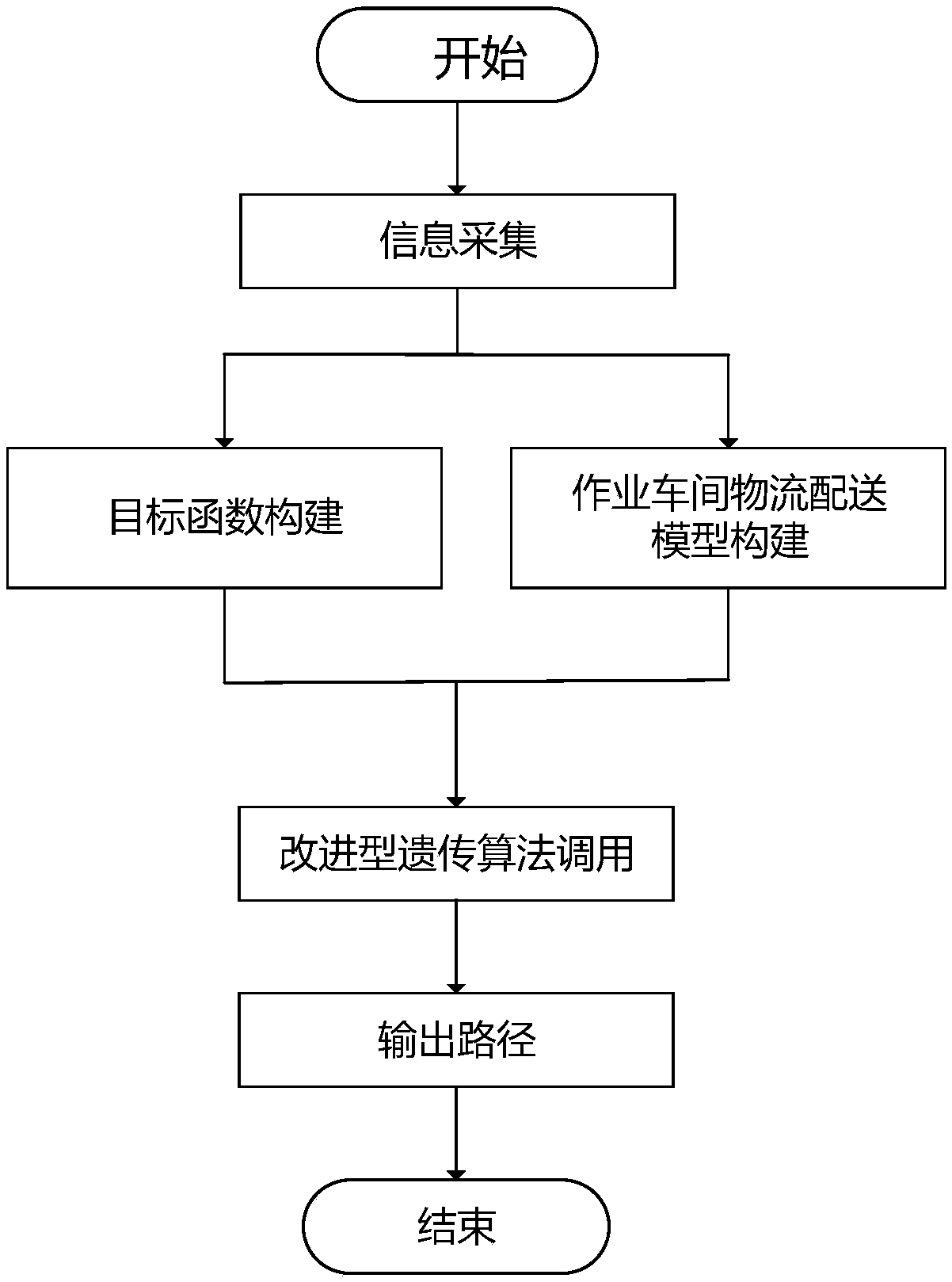

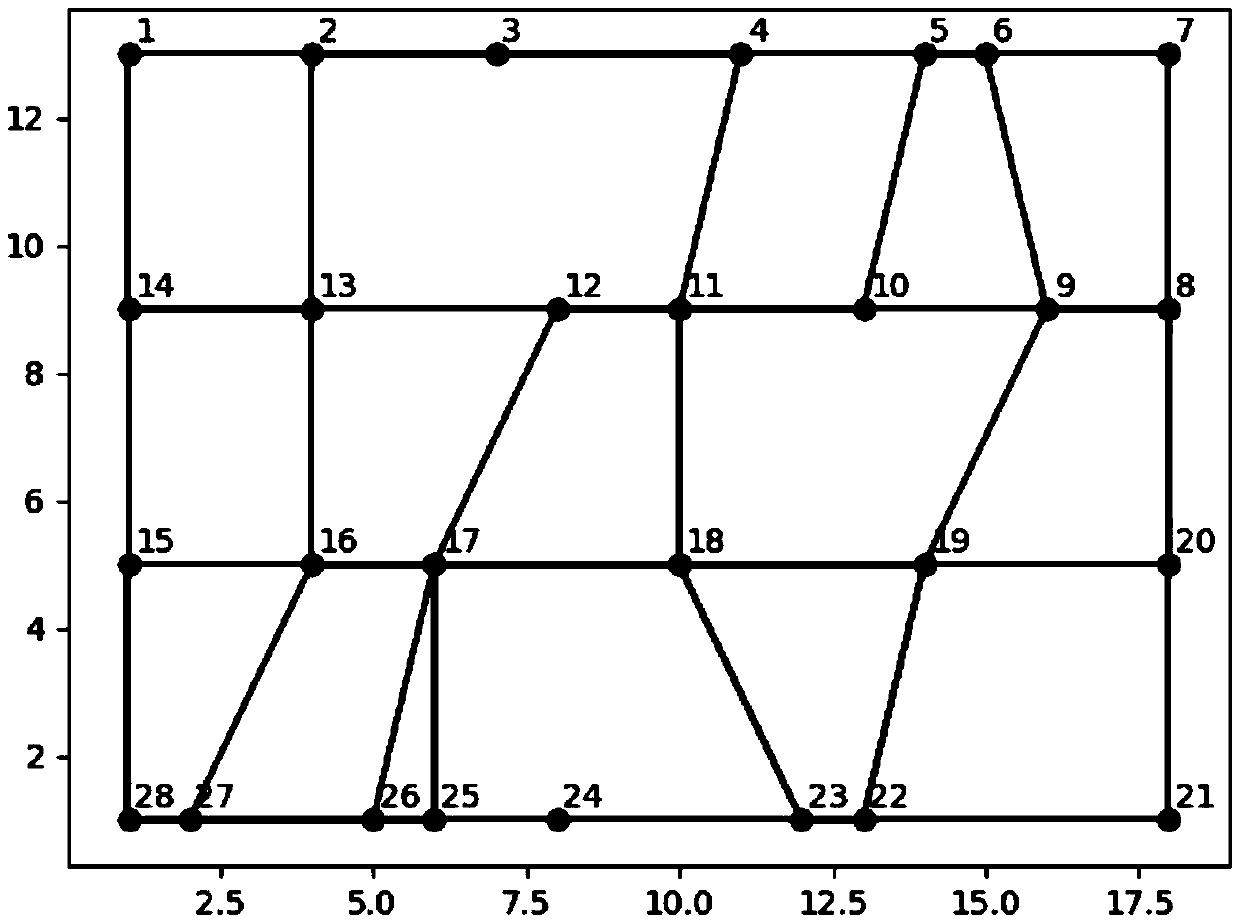

A job shop logistics distribution path optimization method based on a genetic algorithm

ActiveCN109685243AImprove adaptabilityFast convergenceForecastingLogisticsLocal optimumMutation operator

The invention discloses a workshop logistics distribution path optimization method based on a genetic algorithm. The workshop logistics distribution path optimization method is used for effectively planning multi-target node logistics distribution paths with priorities in discrete workshops. And on the basis of the layout diagram and the adjacency matrix of the job shop, an algorithm is applied tooptimize the logistics distribution path of the shop, and the objective function is optimized. In traditional multi-target path planning, path planning is divided into a plurality of single target nodes and a path planning problem of a single starting node, but the path planning problem generally can only obtain local optimum rather than global optimum. And a multi-target node path optimization model is established, and a proposed cross operator and a proposed mutation operator are applied from the perspective of global optimization, so that the solving speed is increased, and the solving precision is improved. By the adoption of the method, the path distance of logistics distribution in the workshops can be effectively reduced, the logistics distribution operation efficiency in the workshops can be improved, and conditions are created for improving the production efficiency in the workshops and improving the enterprise income.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Operation shop bottleneck recognition method based on cluster analysis and multiple attribute decision making

ActiveCN102789599ASolve the unsolvable multi-bottleneck identification problemForecastingStructure chartMultiple attribute

The invention provides an operation shop bottleneck recognition method based on a cluster analysis concept and a multiple attribute decision making theory. The method comprises the following steps of 1, utilizing dispatching optimization scheme as input of bottleneck recognition, determining feature attributes of a bottleneck recognition device and calculating the feature attribute values of the device according to the dispatching optimization result; 2, acquiring clustering clusters of the device under different distances and a parent-child relationship dendritic structure chart thereof on the basis of the similarity of a characteristic attribute excavating machine of the device by utilizing a hierarchical clustering method; 3, determining cluster centers of two sub-clusters of a final clustering cluster, comparing the attribute values of the cluster centers on the basis of a TOPSIS method and determining bottleneck clusters containing few device members; and 4, sequentially comparing sub-clusters of the bottleneck clusters and gradually obtaining main bottleneck clusters of different orders. According to the embodiment of the invention, the method provided by the invention can be used for solving the multi-bottleneck recognition problem which cannot be solved by the existing method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hybrid heuristic shifting bottleneck procedure for solving parallel-machine job-shop scheduling

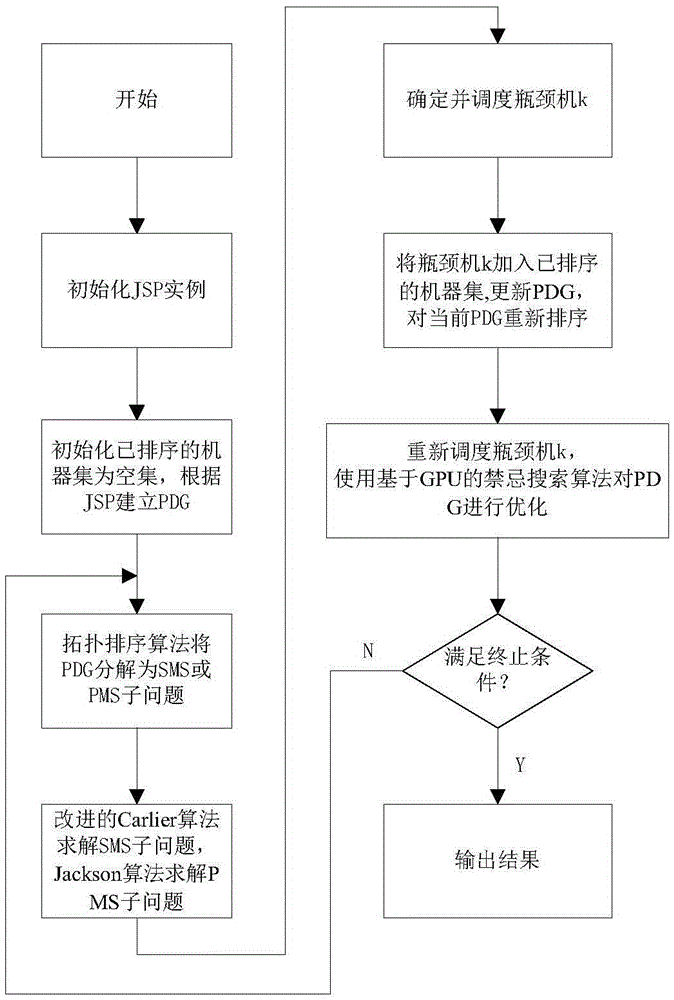

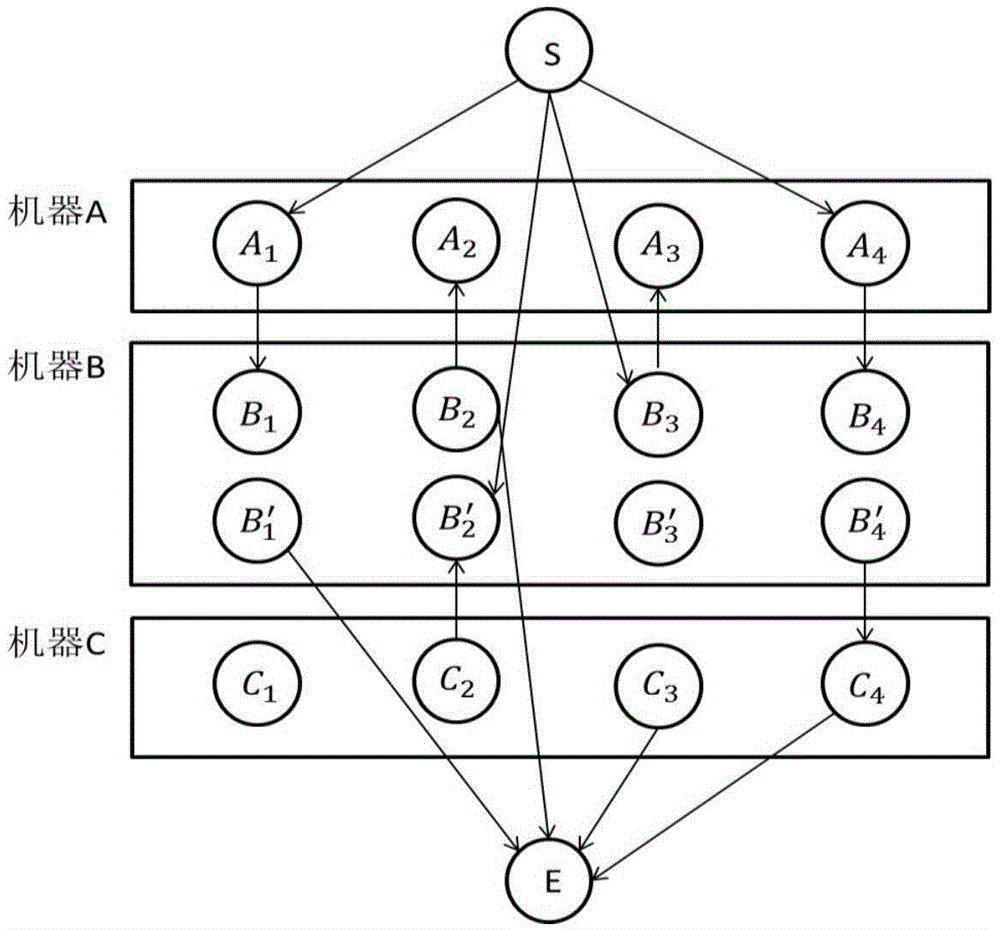

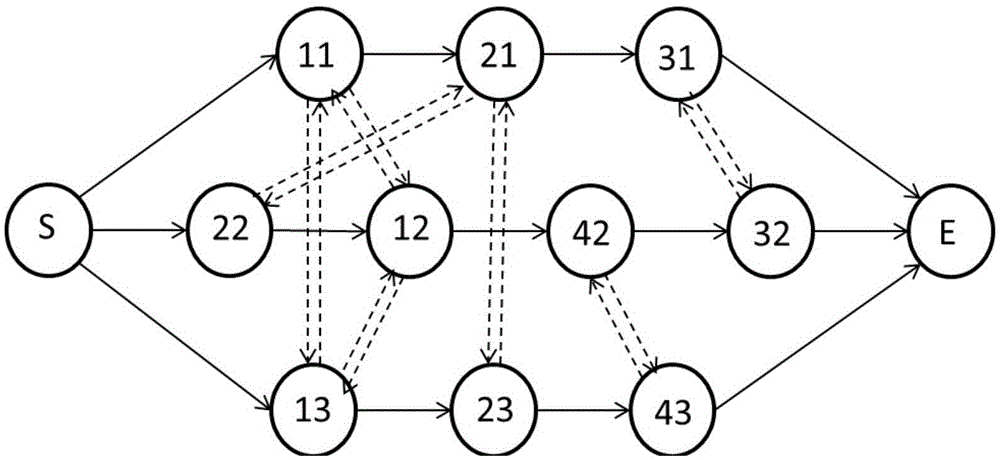

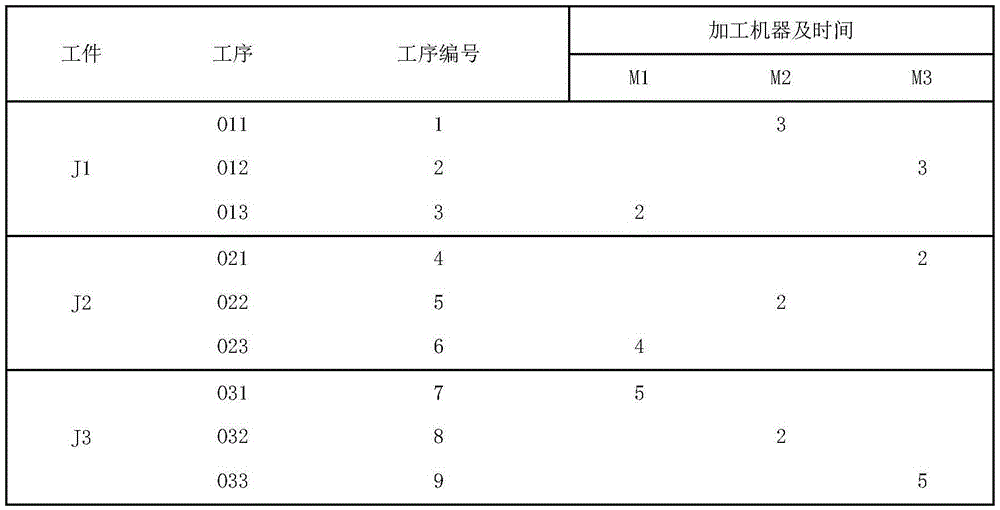

The invention provides a hybrid heuristic shifting bottleneck procedure for solving parallel-machine job-shop scheduling. According to the procedure, a hybrid shifting bottleneck procedure is provided by combining a shifting bottleneck procedure and a heuristic tabu search method, and a GPU is further utilized to achieve a parallel tabu search algorithm. The hybrid shifting bottleneck procedure comprises the following solving processes of (1) decomposing a PDG of a parallel-machine job shop into a series of single-machine scheduling (SMS) sub-problems and parallel-machine scheduling (PMS) sub-problems; (2) solving each SMS sub-problem and PMS sub-problem; (3) determining and scheduling bottleneck machines; and (4) carrying out reordering and optimization on the current PDG during each iteration and rescheduling the scheduled bottleneck machines. According to the hybrid procedure, an unstable search result is avoided, an optimal solution can be found out and the calculation time of finding the optimal solution is shortened.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

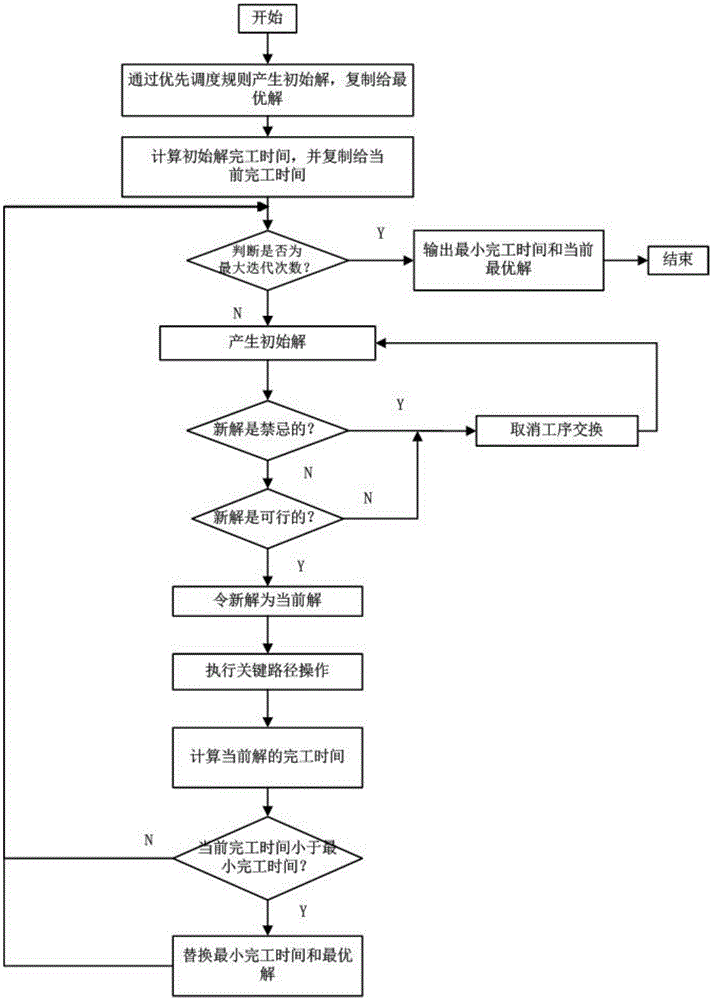

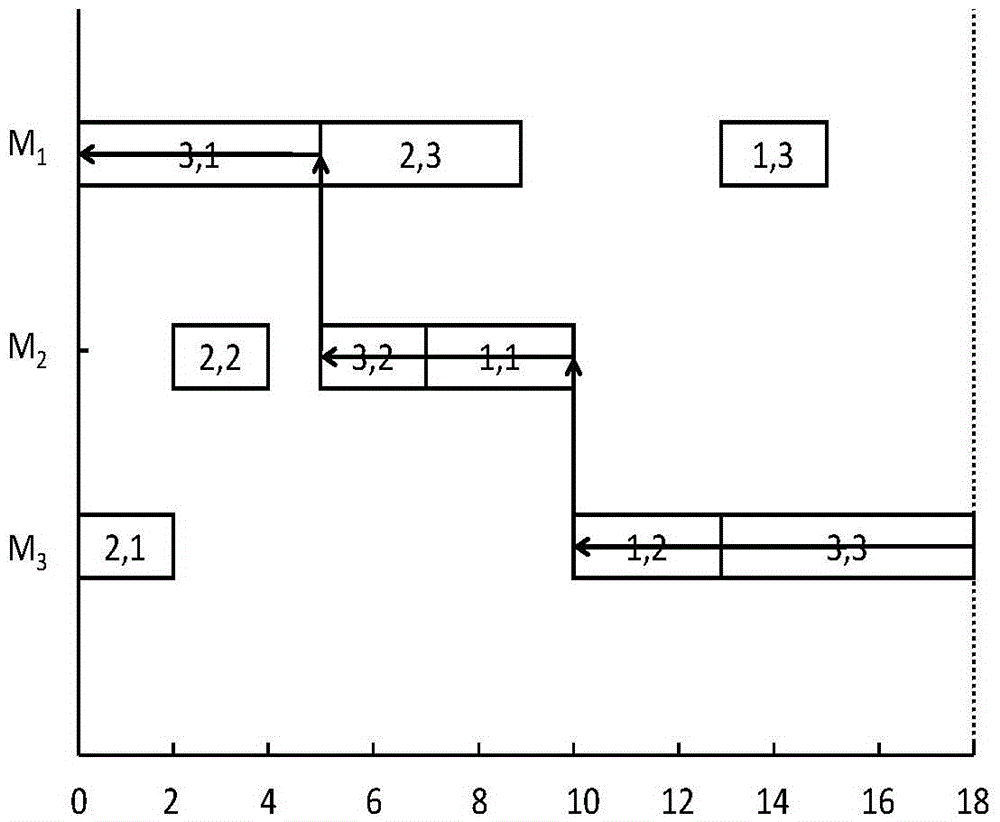

Critical path-combined hybrid neighborhood search algorithm for job-shop scheduling

InactiveCN106611377AAvoid repeated searchesSave time and costData processing applicationsManufacturing computing systemsNeighborhood searchJob shop

The invention provides a critical path-combined hybrid neighborhood search algorithm for job-shop scheduling. The algorithm comprises the contents of generating an initial solution by adopting a priority scheduling rule; combining a critical path, a key block and a tabu list and generating a new solution by adopting multiple neighborhood structures; carrying out infeasible estimation on the new solution; and mining a solution with a deeper range in a search space by adopting an improved critical path. A critical path-combined hybrid heuristic neighborhood search algorithm is provided, balancing of the advantages of various heuristic algorithms is achieved, and the problem of complicated shop scheduling combination optimization of an actual job shop is better solved.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

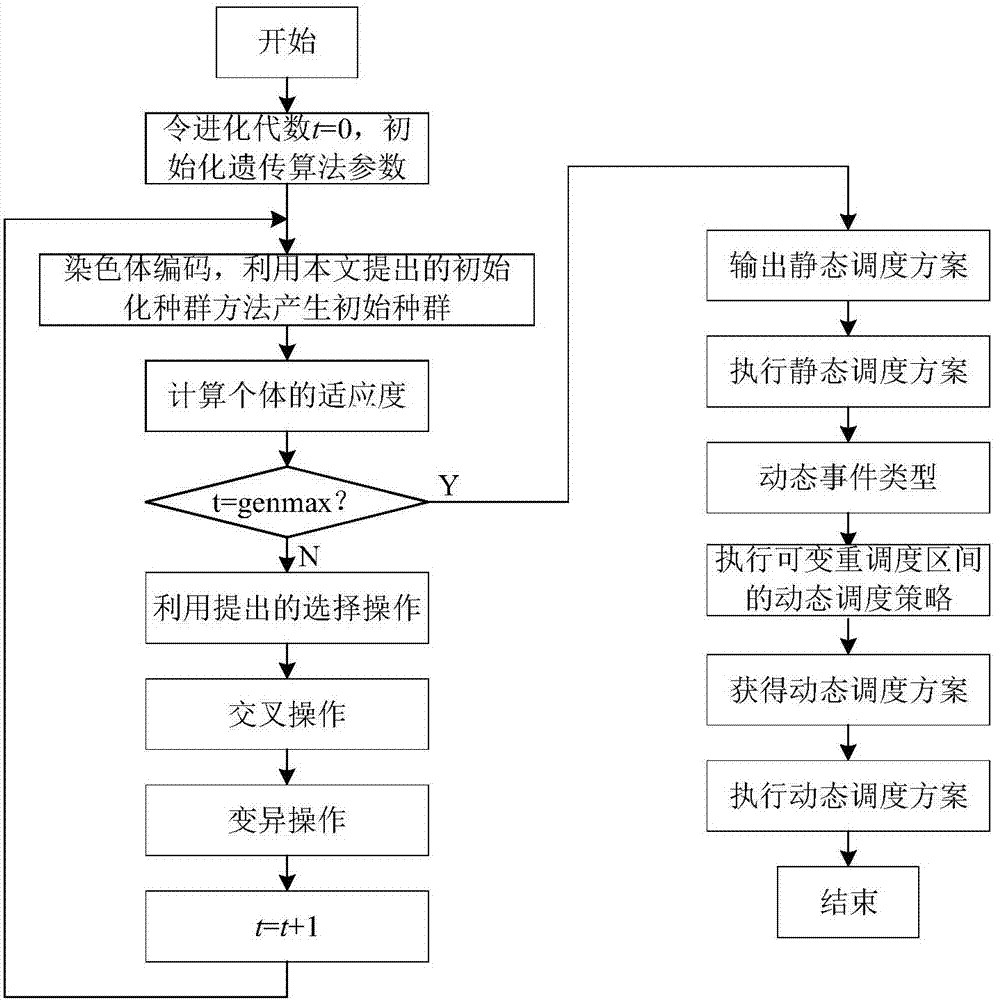

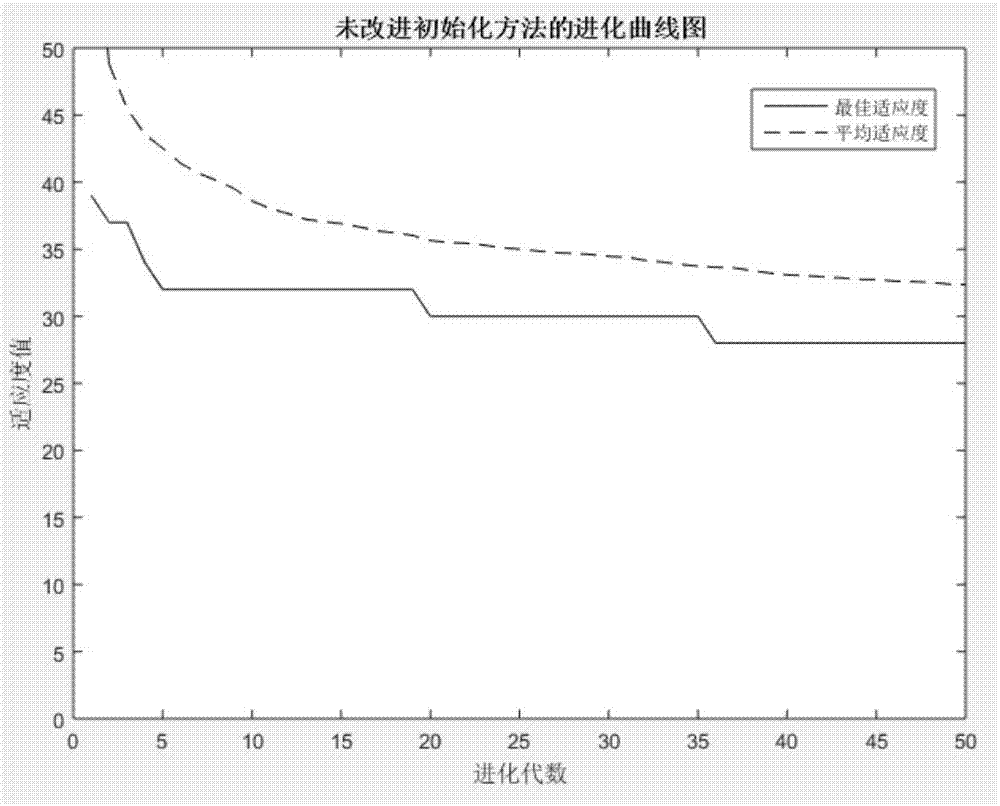

Flexible job-shop dynamic scheduling method based on variable weight scheduling range

ActiveCN107065803AQuality improvementImprove efficiencyProgramme total factory controlCompletion timeDirect effects

The invention discloses a flexible job-shop dynamic scheduling method based on variable weight scheduling range, and the method belongs to the technical field of workshop scheduling field and comprises the following steps: 1) using the improved genetic algorithm to initialize the data for a static flexible job shop scheduling scheme and implementing the scheme; 2) determining the type of dynamic events when dynamic events occur; and 3) implementing the dynamic scheduling method for the variable rescheduling range to regenerate a new scheduling scheme, and implementing the dynamic scheduling scheme. After the dynamic events occur, only the workpieces within the range are rescheduled, and the size of the range is determined by the workpieces directly influenced by the dynamic events. According to the invention, through the establishment of a flexible job-shop scheduling model featuring the goal of minimizing the work completion time, a cluster initialization and selection method and a dynamic scheduling strategy based on variable weight scheduling range are proposed, which solves the scheduling problem of a dynamic flexible job-shop and increases the quality of weight scheduling solution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

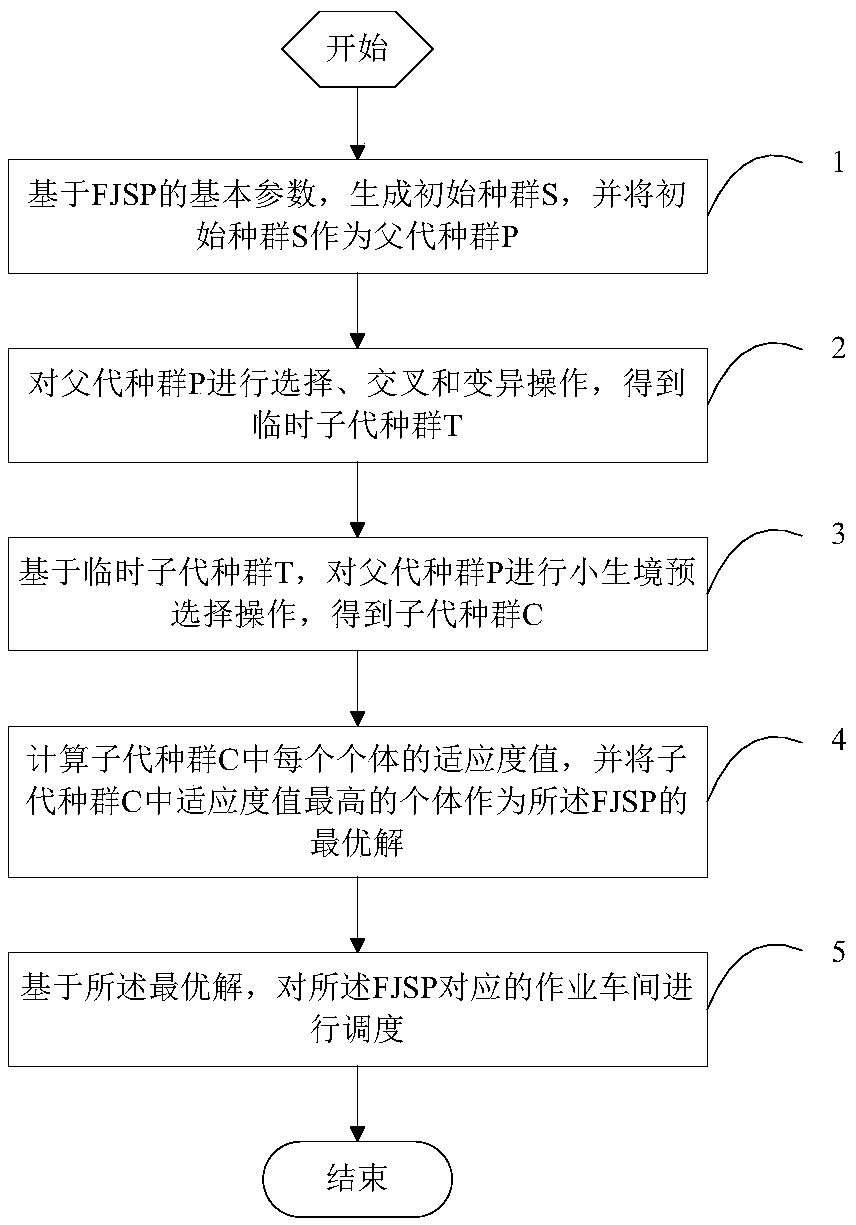

Flexible job shop scheduling method and system

InactiveCN108776461AImprove scheduling abilityMaintain population diversityProgramme total factory controlJob shop schedulingJob shop

The invention provides a flexible job shop scheduling method and system. The method comprises steps that S1, the initial population S is generated based on basic parameters of a flexible job shop scheduling problem FJSP, and the initial population S is taken as a parent population P; S2, the parent population P is selected, crossed and mutated to obtain a temporary progeny population T; S3, basedon the temporary progeny population T, the parent population P is subjected to niche pre-selection operation to obtain a progeny population C; S4, a fitness value of each individual in the progeny population C is calculated, and the individual with the highest fitness value in the progeny population C is taken as the optimal solution of the FJSP; and S5, based on the optimal solution, a job shop corresponding to the FJSP is scheduled. The method is advantaged in that the solution search space can be made to maintain population diversity, the obtained solution can be guaranteed to converge to the global optimum, and thereby the job shop scheduling effect can be improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

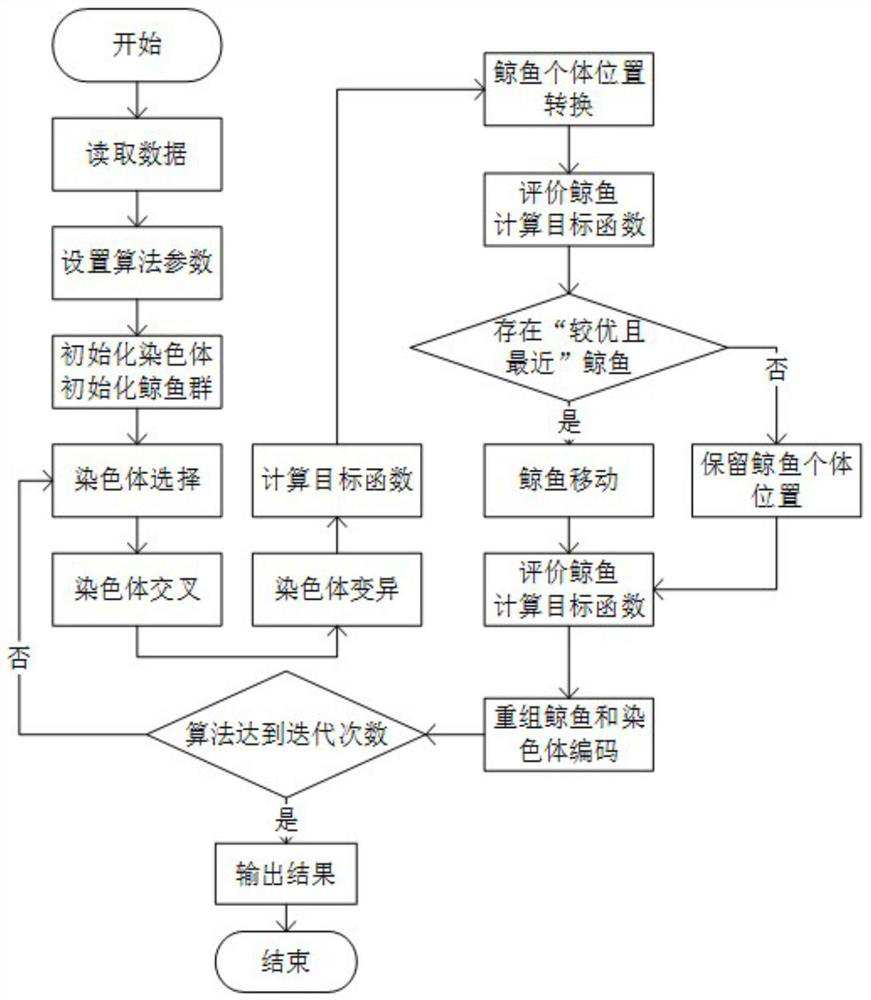

Method for solving flexible job shop scheduling based on hybrid genetic algorithm

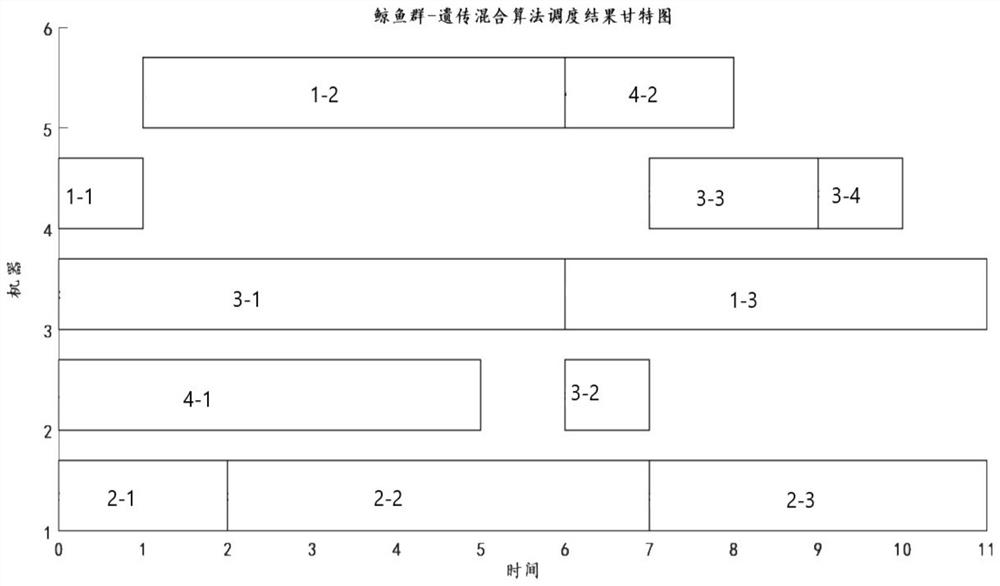

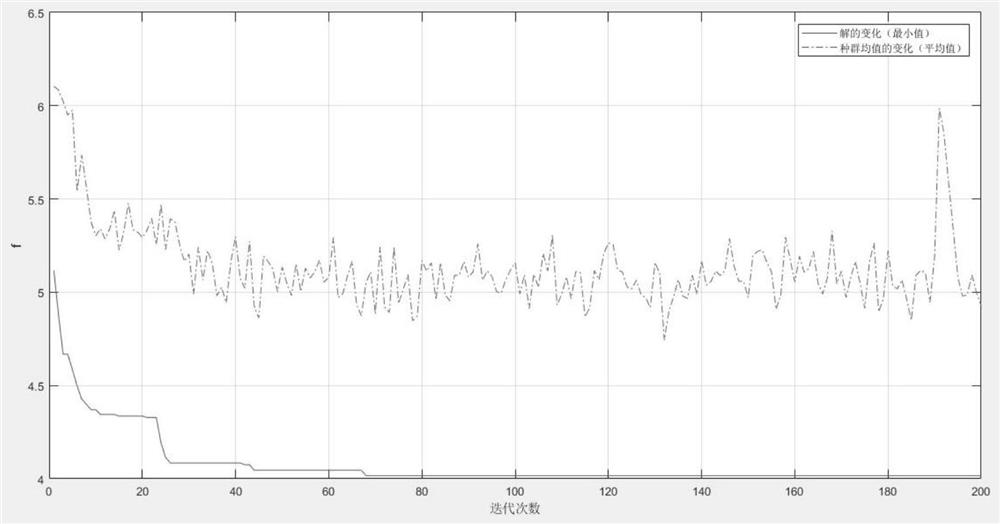

PendingCN111967654AIncrease search depthImprove the shortcoming that it is easy to fall into local optimumForecastingArtificial lifeOptimal schedulingTheoretical computer science

The invention discloses a method for solving flexible job-shop scheduling based on a hybrid genetic algorithm. The method is specifically implemented according to the following steps of 1, defining aflexible job-shop scheduling coding mode as a double-layer coding mode; 2, defining a fitness function, and taking the shortest time for solving and finishing machining as an optimization target; 3, initializing parameters and populations in a flexible workshop scheduling problem by adopting a genetic algorithm and a whale swarm algorithm, and randomly generating an initial population; 4, solvingflexible job shop scheduling through a genetic algorithm; 5, solving flexible job shop scheduling through a whale swarm algorithm; and 6, realizing iterative optimization of the whale swarm algorithmon the genetic algorithm through coding recombination, and outputting an optimal scheduling scheme. According to the method, the search depth of the algorithm is increased, and solving precision and solving stability are enhanced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

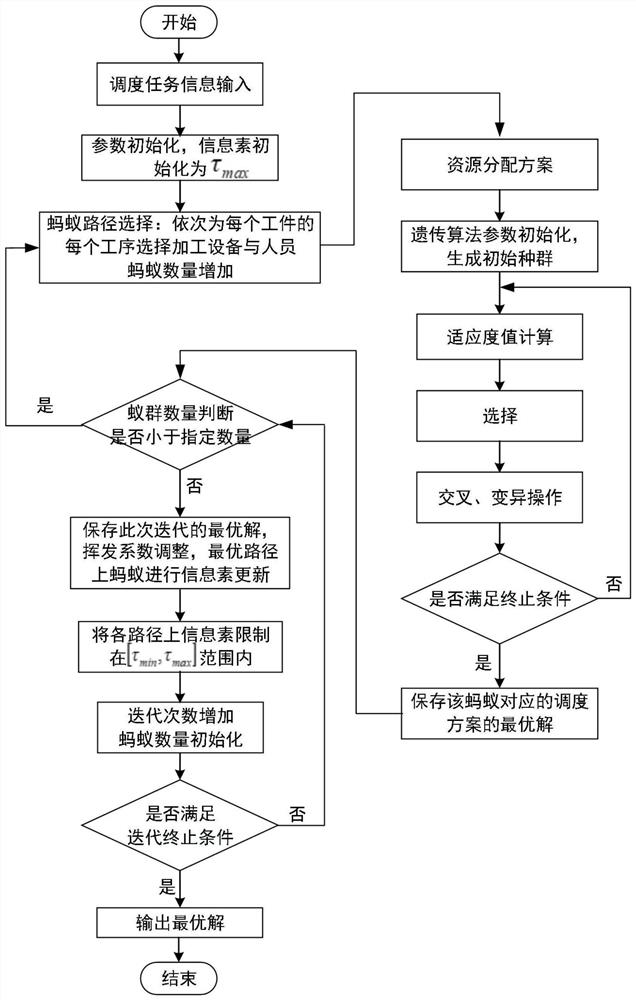

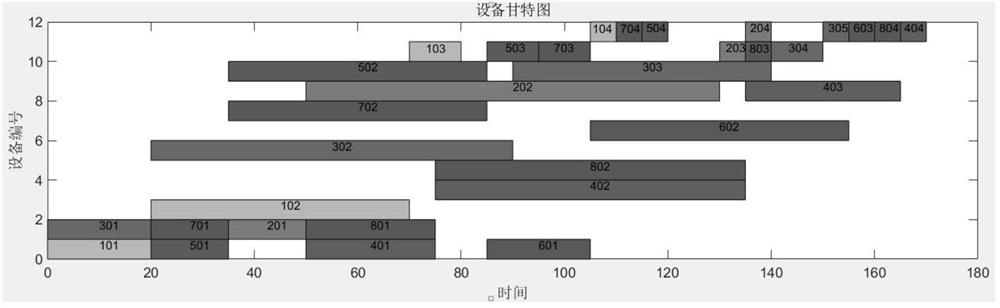

Double-resource die job shop scheduling optimization method based on AMAS-GA nested algorithm

ActiveCN111966050AIncrease productivityUniform loadProgramme total factory controlCompletion timeGenetics algorithms

The invention discloses a double-resource die job shop scheduling optimization method based on an AMAS-GA nested algorithm. On the basis of comprehensively analyzing energy consumption, completion time and equipment and personnel load conditions of a workshop, a double-resource job shop multi-target scheduling problem model is established, wherein the load balance condition of equipment and personnel is measured by calculating the standard deviation of the accumulated load of the equipment and personnel, and the energy consumption of the shop considers the energy consumption of the equipment in standby and processing states; secondly, an AMMS-GA nested algorithm is designed to carry out scheduling model optimization solution, and procedure sorting is carried out by adopting a genetic algorithm by an inner layer according to a resource selection result as a constraint; and finally, a scheduling scheme result is fed back to an outer layer algorithm to influence selection of ants on resources. The method can be used for workshop scheduling and production scheduling, the workshop production efficiency is improved, energy consumption is reduced, green and energy-saving production is promoted, and meanwhile equipment and personnel load balance in production can be met.

Owner:BEIJING UNIV OF TECH

Flexible production line for framework machining

InactiveCN113182935AIncrease productivityLow costAutomatic control devicesFeeding apparatusNumerical controlMachine

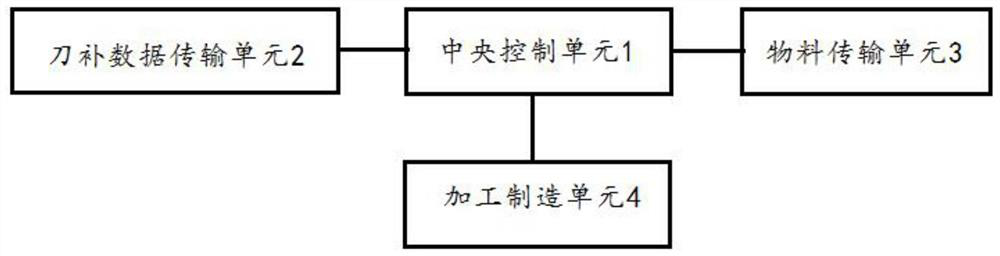

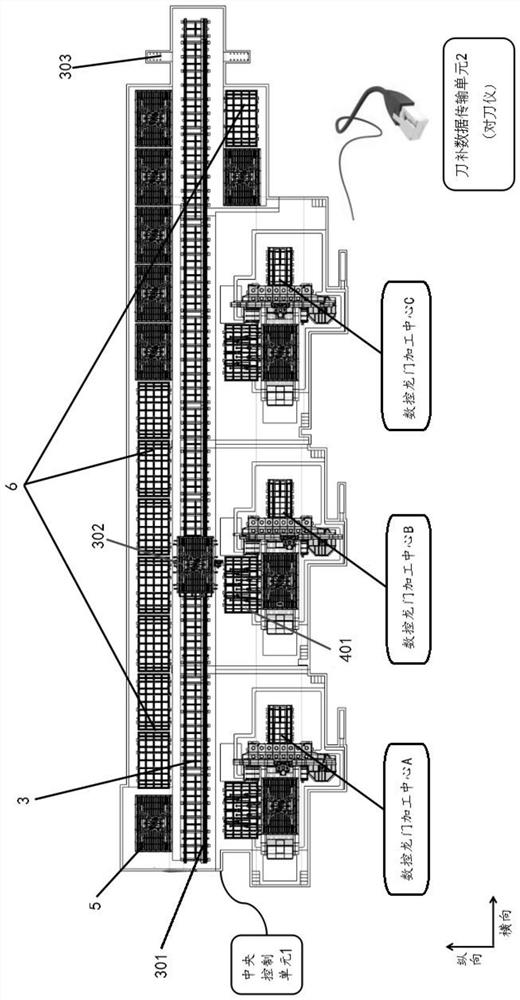

The invention relates to a flexible production line for framework machining. The flexible production line comprises a central control unit, a cutter compensation data transmission unit, a material transfer unit and a machining and manufacturing unit, wherein the cutter compensation data transmission unit, the material transfer unit and the machining and manufacturing unit are connected with the central control unit; the cutter compensation data transmission unit is used for transmitting cutter compensation data to the central control unit; the central control unit is used for assigning the cutter compensation data to the corresponding machining and manufacturing unit; the material transfer unit is used for carrying materials to a specified position and posture according to a carrying command of the central control unit; and the machining and manufacturing unit comprises three numerical control gantry machining centers and is used for machining the materials according to the cutter compensation data. The production capacity obtained by the three numerical control gantry machining centers of the flexible production line for framework machining is 1.5-2 times that obtained by using the same number of machine tools in a single machine operation workshop environment; and the machine tool operation is scheduled by the central control unit, and when one certain machine tool is idle, the central control unit adjusts a part to the machine tool, so that the production efficiency can be greatly improved.

Owner:河北京车轨道交通车辆装备有限公司

Single job shop scheduling method for multi-Agent deep reinforcement learning

ActiveCN111985672ASolve scheduling problemsImprove the method systemForecastingNeural architecturesData setAlgorithms performance

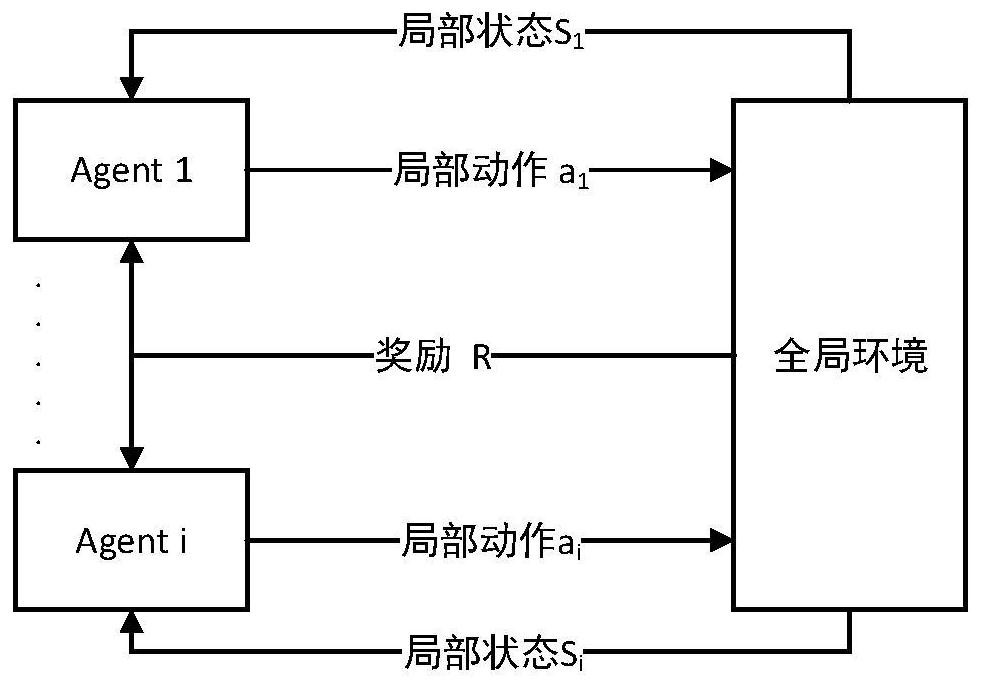

The invention provides a single-piece job-shop scheduling method based on multi-Agent deep reinforcement learning, aiming at the characteristics that the single-piece job-shop scheduling problem is complex in constraint and various in solution space types, and the traditional mathematical programming algorithm and meta-heuristic algorithm cannot meet the quick solution of the large-scale job-shopscheduling problem. The method comprises the following steps: firstly, designing a communication mechanism among multiple Agents, and carrying out reinforcement learning modeling on a single job shopscheduling problem by adopting a multi-Agent method; secondly, constructing a deep neural network to extract a workshop state, and designing an operation workshop action selection mechanism on the basis of the deep neural network to realize interaction between a workshop processing workpiece and a workshop environment; thirdly, designing a reward function to evaluate the whole scheduling decision,and updating the scheduling decision by using a PolicyGraphic algorithm to obtain a more excellent scheduling result; and finally, performing performance evaluation and verification on the algorithmperformance by using the standard data set. The job shop scheduling problem can be solved, and the method system of the job shop scheduling problem is enriched.

Owner:DONGHUA UNIV

AGV-containing personalized customization flexible job shop scheduling method

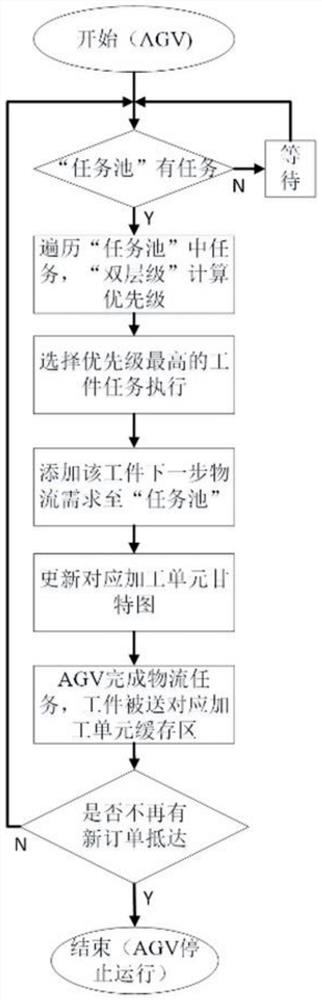

The invention relates to an AGV-containing personalized customization flexible job shop scheduling method. The method comprises the steps that: an AGV-containing personalized customization flexible job shop industrial Internet of Things framework is established; a scheduling target and parameters are set; in the production process, a workpiece produced by a workshop sends a logistics demand instruction to a cloud computing platform, and an AGV receives the logistics demand instruction forwarded by the cloud computing platform, selects the logistics demand instruction with the highest priorityaccording to a priority rule, and plans a production plan corresponding to the workpiece; and a machining unit carries out workpiece machining according to the production plan, the machined workpieceis placed in a workpiece buffer area, and the AGV extracts the workpiece from the buffer area according to the plan. According to the invention, construction of an unmanned intelligent factory is facilitated; an efficient cooperation method of production equipment and logistics equipment is realized; AGV-containing personalized customization flexible job shop scheduling requirements can be met, and the AGV-containing personalized customization flexible job shop scheduling method has certain advantages in the aspects of advance / delay cost, equipment utilization rate and energy consumption compared with a traditional scheduling rule.

Owner:WUHAN UNIV OF TECH

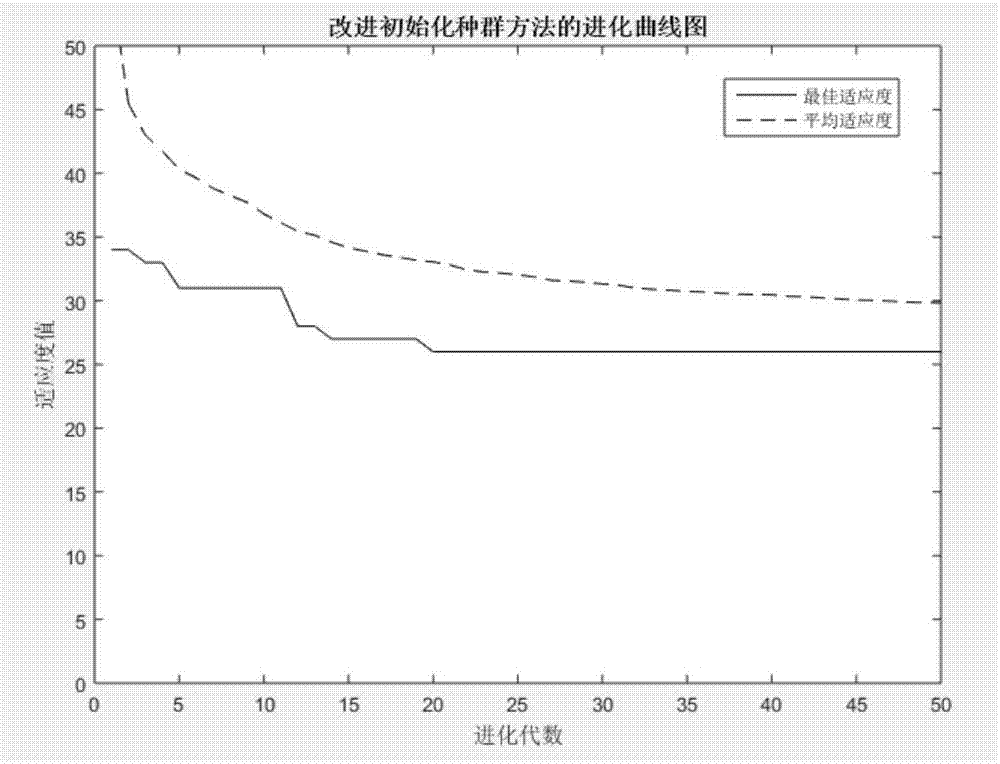

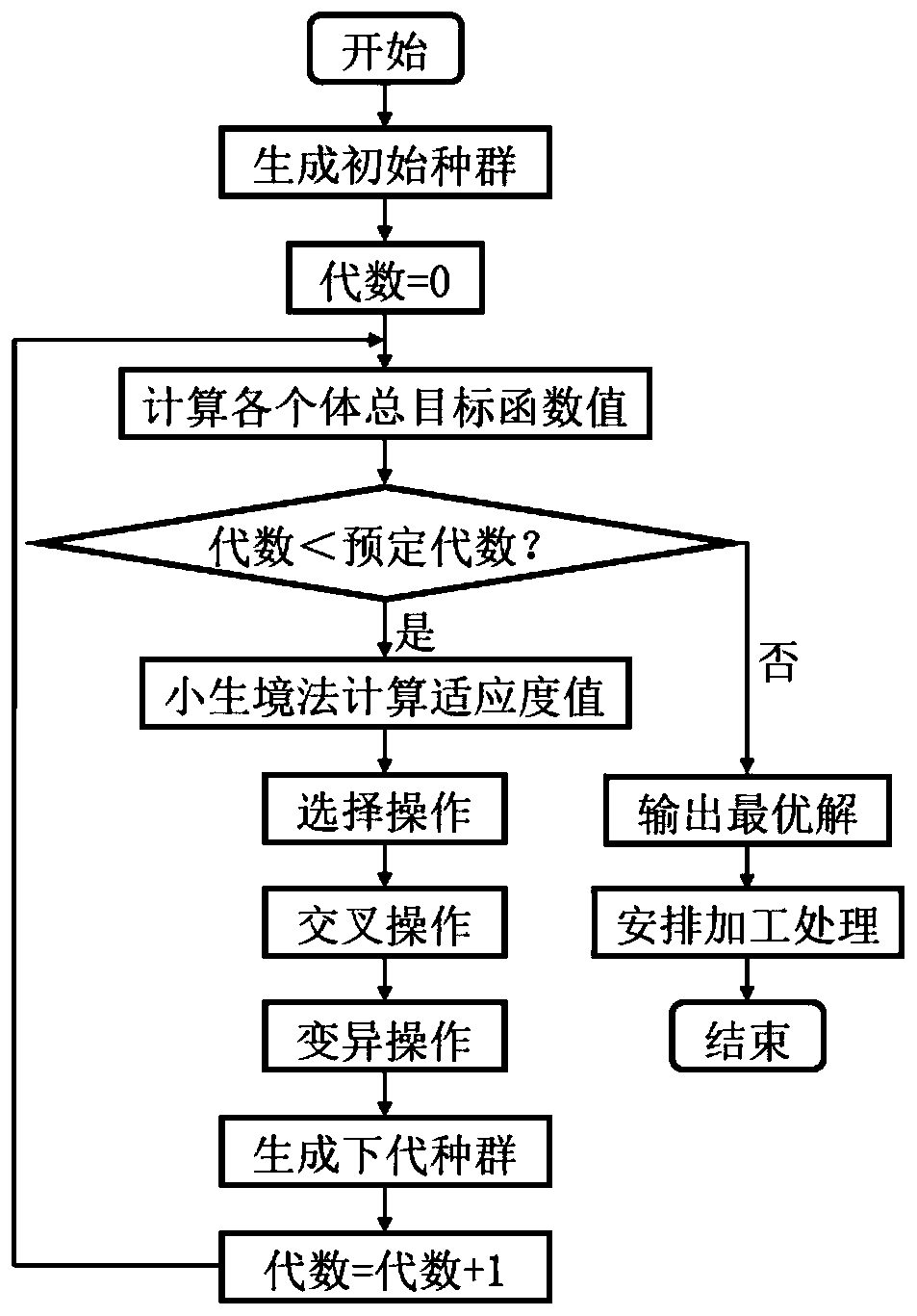

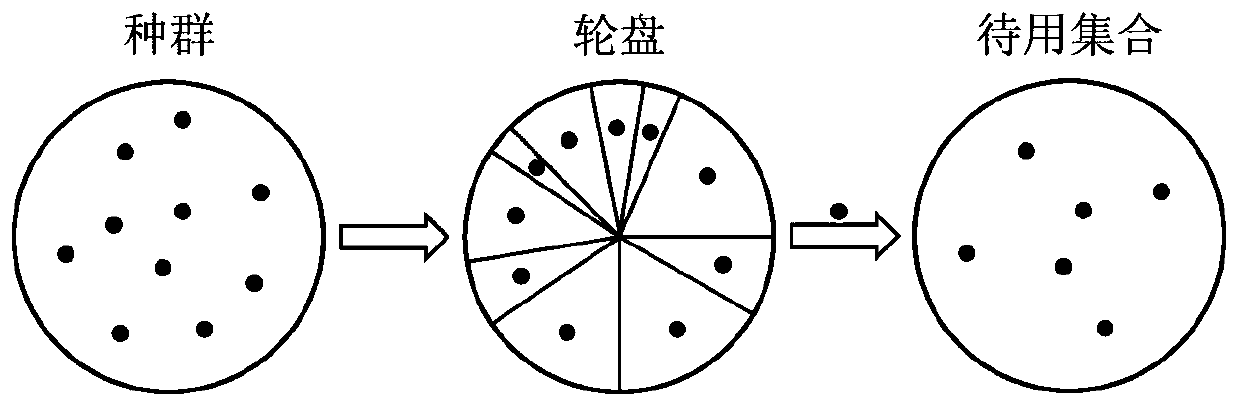

Multi-target flexible job shop scheduling method based on improved ecological niche genetic algorithm

ActiveCN111222642AImplement schedulingSolve fitResourcesManufacturing computing systemsAlgorithmGenetics algorithms

The invention discloses a multi-target flexible job shop scheduling method based on an improved niche genetic algorithm. Constructing a production scheduling sequence according to the process data ofall the workpieces in the multi-target flexible job shop, taking the production scheduling sequence as an individual, and generating a primary population; calculating a total objective function valueof the individual, and calculating a fitness value of the individual by using an improved niche method; selecting an individual set in a roulette mode according to the fitness value; implementing crossover operation and mutation operation of the genetic algorithm; forming a new population by the obtained individuals and the individuals with the highest fitness value in the generation population; repeating the steps until a termination condition is met, outputting an optimal individual in the last generation population, and arranging processing treatment by adopting a scheduling sequence of theoptimal individual, so as to realize multi-target flexible job shop scheduling. The improved ecological niche genetic algorithm is adopted to solve the scheduling problem in the production process, ahigh-quality scheduling result can be stably obtained, workshop resource allocation is optimized, and therefore the production efficiency of a workshop is improved.

Owner:ZHEJIANG UNIV +1

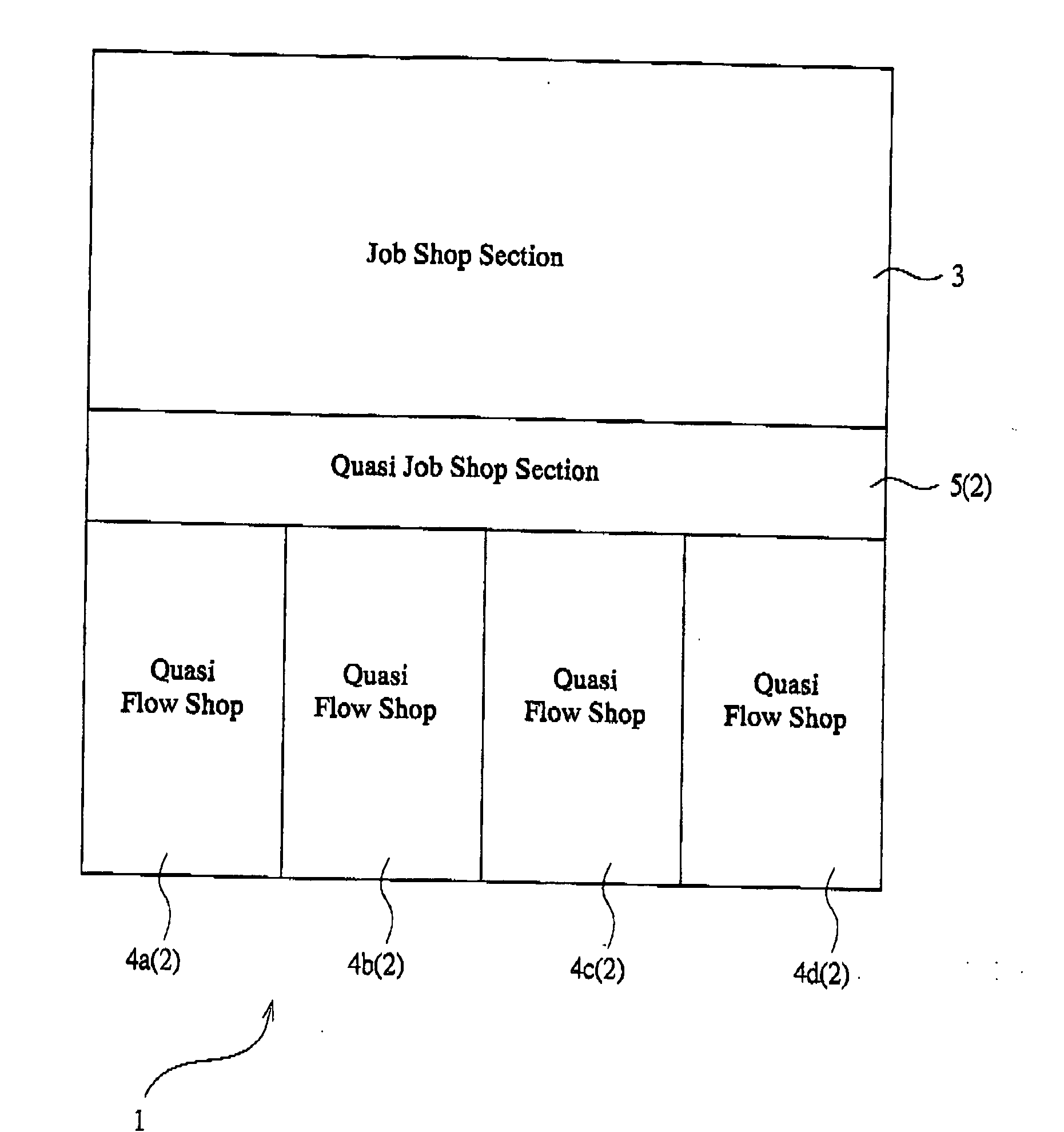

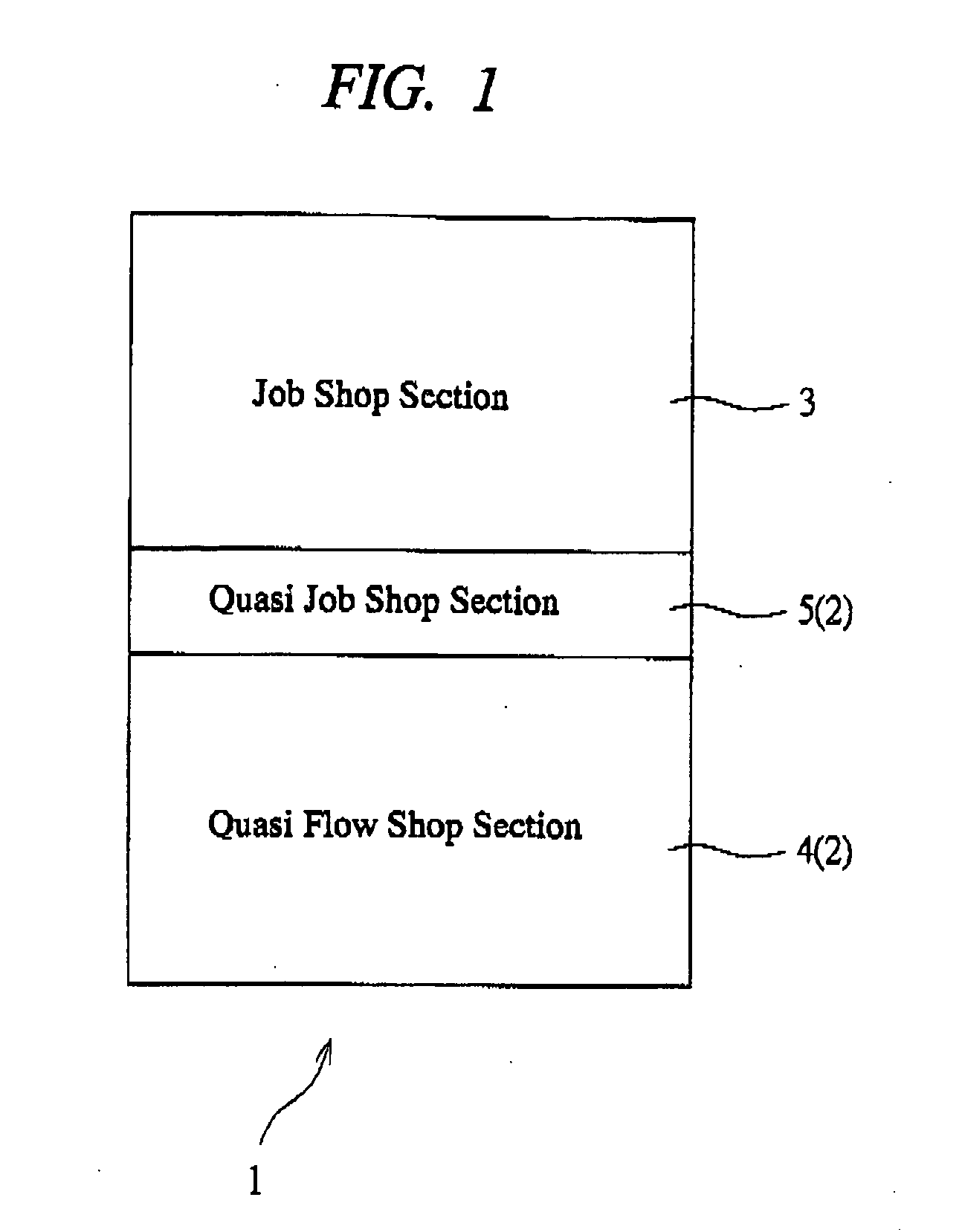

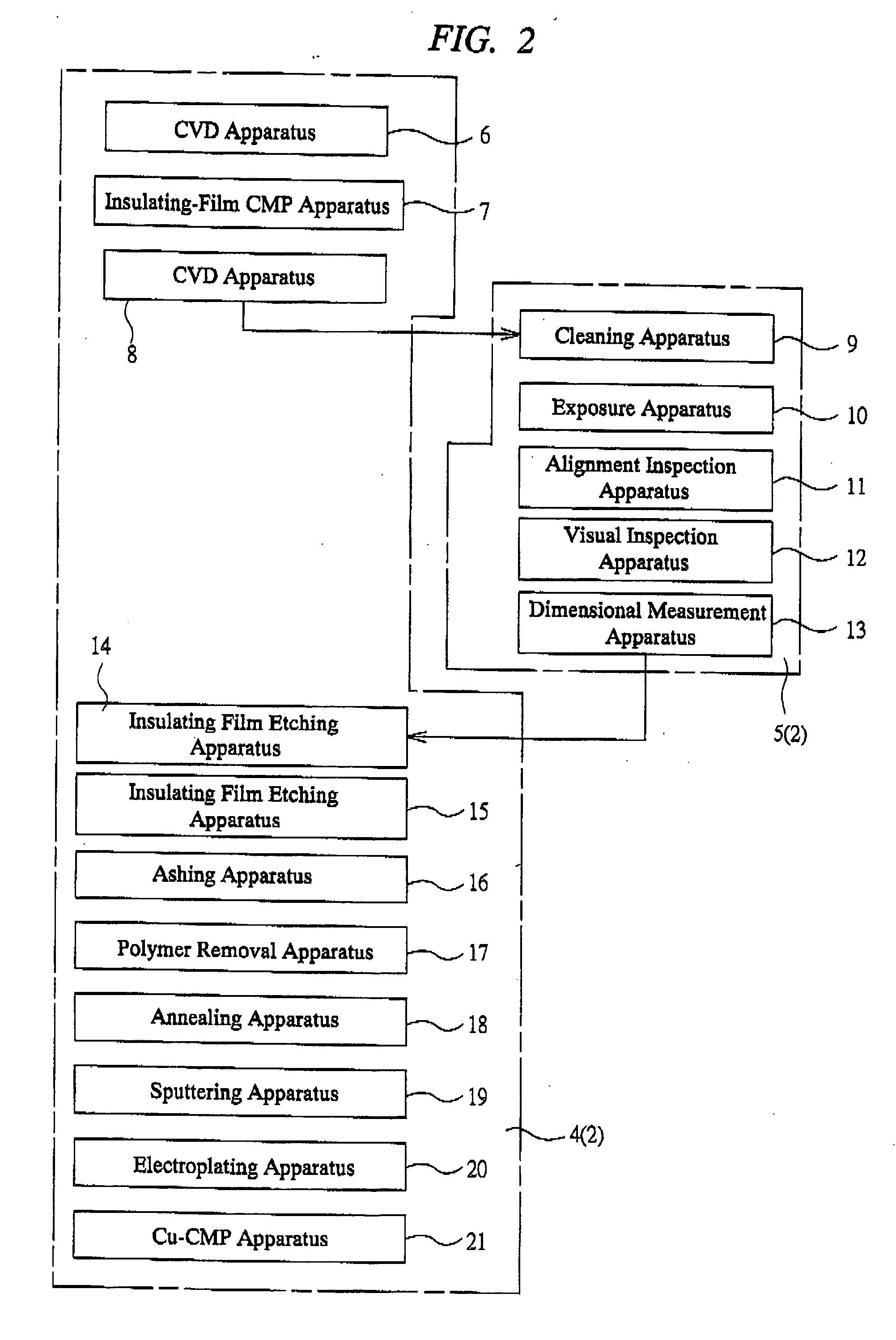

Semiconductor manufacturing system, work manufacturing system, and conveyance system

InactiveUS20050149217A1Increase profitEfficient preparationSemiconductor/solid-state device manufacturingResourcesProduction rateJob shop

A semiconductor manufacturing system in a clean room is composed of a combination of a flow shop section and a job shop section. The flow shop section is composed of a quasi flow shop section and a quasi job shop section. In the quasi flow shop section, manufacturing apparatuses are arranged respectively so that a difference between processing ability of the manufacturing apparatuses is taken into consideration and a balance in productivity is achieved. In the quasi job shop section, manufacturing apparatuses are arranged respectively so that the balance in productivity is not achieved due to low or high processing ability of the manufacturing apparatuses, and are provided so as to be shared by the quasi flow shop section. Accordingly, a difference between the processing ability of the manufacturing apparatuses can be reduced and the cycle time can be significantly reduced.

Owner:TRECENTI TECHNOLOGIES INC

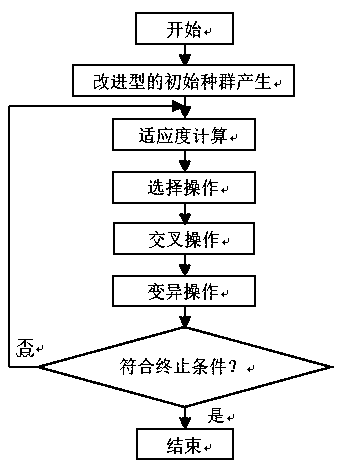

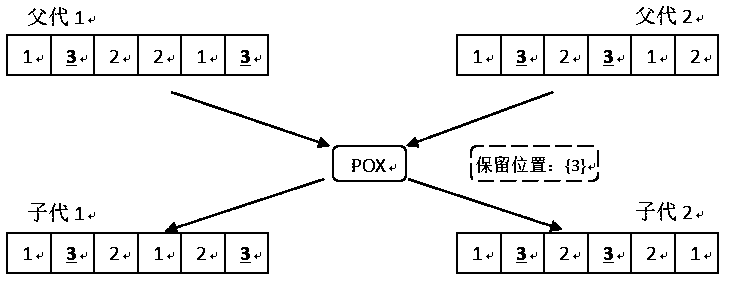

Job-shop scheduling method based on an improved genetic algorithm

InactiveCN108805403ADiversity guaranteedQuality improvementArtificial lifeResourcesCompletion timeAlgorithm

The invention discloses a job-shop scheduling method based on an improved genetic algorithm. The method comprises the operation steps of (1) determining operation parameters, including a population scale, a crossover probability, a variation probability and the number of iterations; (2) generating an improved initial population, and combining individuals generated by adopting an active method withindividuals generated randomly in a certain proportion to form an initial population; (3) performing fitness calculation, and taking a reciprocal of the total completion time of a scheduling scheme corresponding to the individuals as a fitness value; (4) performing selection operation by adopting a roulette selection operator; (5) performing crossover operation by selecting and using a POX crossover operator; (6) selecting and using an inverse variation operator as a variation operator; and (7) performing stop judgment, judging whether a stop condition is met or not, and if yes, stopping theprocess and outputting an optimal scheduling scheme, otherwise, going to the step (3). According to the method, the convergence speed of solving can be increased; the solving performance is good; andfor the production scheduling problem of job-shop, the method has high application values.

Owner:SHANGHAI UNIV

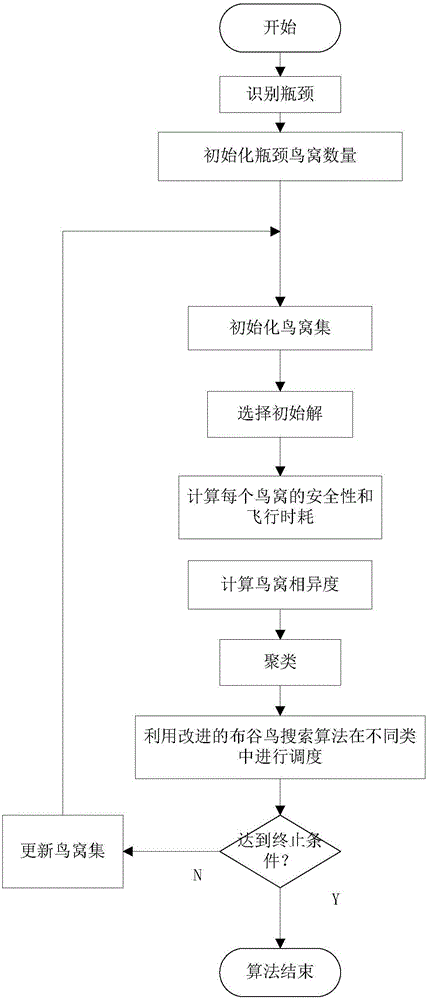

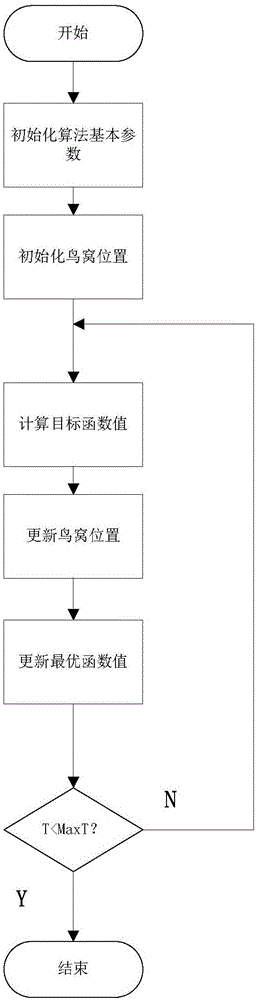

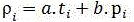

Method for solving job shop process bottleneck problem based on cuckoo search algorithm

InactiveCN106611382AOptimize job schedulingFast executionData processing applicationsArtificial lifeGeographic siteGeolocation

The invention provides a method for solving a job shop process bottleneck problem based on a cuckoo search algorithm. Bottleneck resources are judged by using the TOC principle, and the processing scheduling of shop bottleneck process is optimized by using an improved cuckoo search algorithm. According to the method provided by the invention, the work scheduling of the bottleneck process is optimized targetedly, thereby avoiding a lot of unnecessary optimization processes, accelerating the execution speed of the algorithm and meanwhile improving the solution accuracy of the algorithm; bird nest groups are classified by using an improved K_means algorithm, and then optimized scheduling is carried out the clusters by using the improved cuckoo search algorithm, thereby reducing the calculation amount of the algorithm on one hand, and effectively improving the solution accuracy of the algorithm on the other hand; and the difference of bird nests is expressed by safety and flight time consumption, the safety is expressed by random number, and the flight time consumption is expressed by geographic positions, thereby being simple and effective, applicable to the actual conditions and easy to understand.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

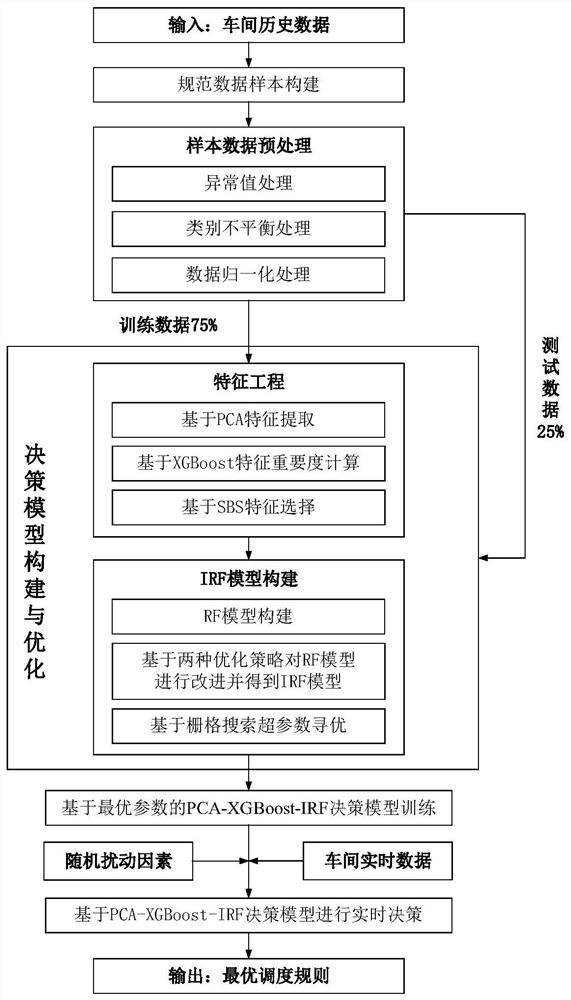

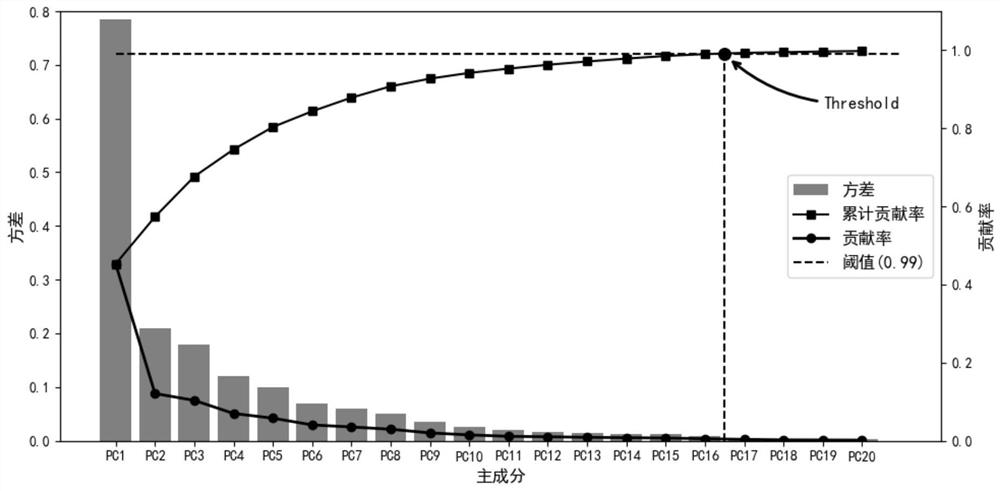

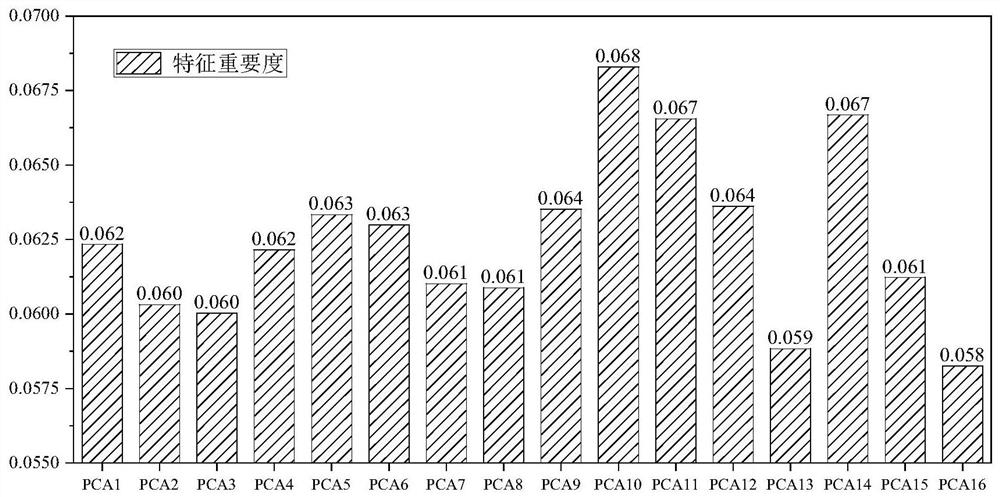

Job shop real-time scheduling method based on PCA-XGBoost-IRF

ActiveCN113256066AReduce time complexityRapid responseCharacter and pattern recognitionMachine learningData setDecision model

The invention discloses a job shop real-time scheduling method based on PCA-XGBoost-IRF. The method comprises the steps of 1, constructing a standard data sample; 2, pre-processing the sample data, performing abnormal value processing, class imbalance processing and normalization processing on the sample data, and segmenting a data set to meet the input requirements for decision model construction; 3, carrying out feature engineering processing on a training set, wherein the feature engineering processing comprises feature extraction, feature importance calculation and feature selection; 4, carrying out decision model construction based on an improved random forest, including random forest model construction, improvement of an RF model to obtain an IRF model, and optimization of hyper-parameters of the IRF model based on grid search; 5, performing PCA-XGBoost-IRF decision model training based on the optimal parameters; and 6, realizing the real-time selection and decision-making of a dynamic job shop scheduling rule by using a decision-making model based on PCA-XGBoost-IRF. According to the present invention, the real-time scheduling method which is more reliable and higher in robustness and generalization is provided for the intelligent scheduling research based on data driving.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com