Flexible job shop scheduling system based on Petri network and improved genetic algorithm

An improved genetic algorithm and workshop scheduling technology, applied in the field of flexible job workshop scheduling, can solve the problems of less research on production plan scheduling optimization, lack of selection of process execution time, increased indirect energy consumption and time cost, etc., to improve industry competitiveness , optimize formulation and execution, and maximize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

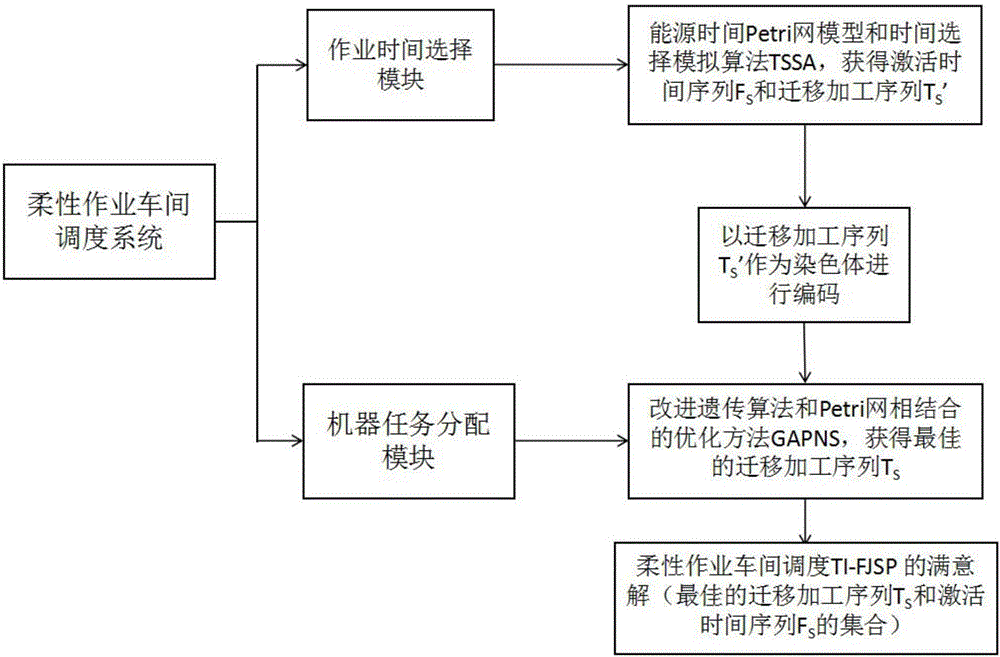

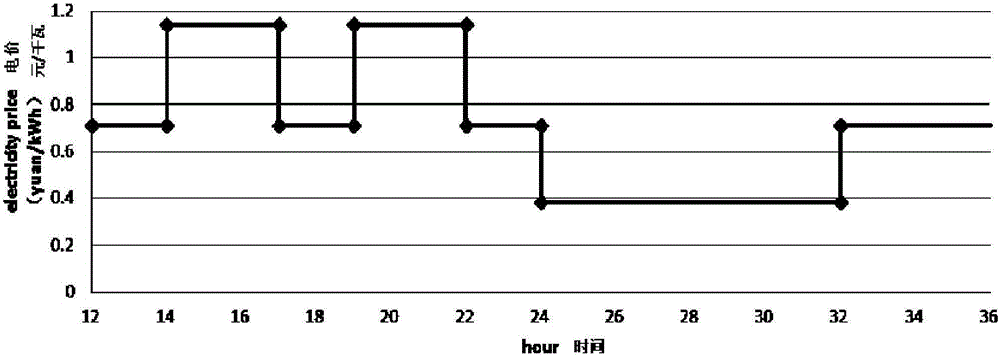

[0054] A flexible job shop scheduling system based on Petri net and improved genetic algorithm, said flexible job shop scheduling system is a system that minimizes completion time and electricity cost by considering peak and valley electricity prices and indirect energy consumption, including a job time selection module and machine task assignment module;

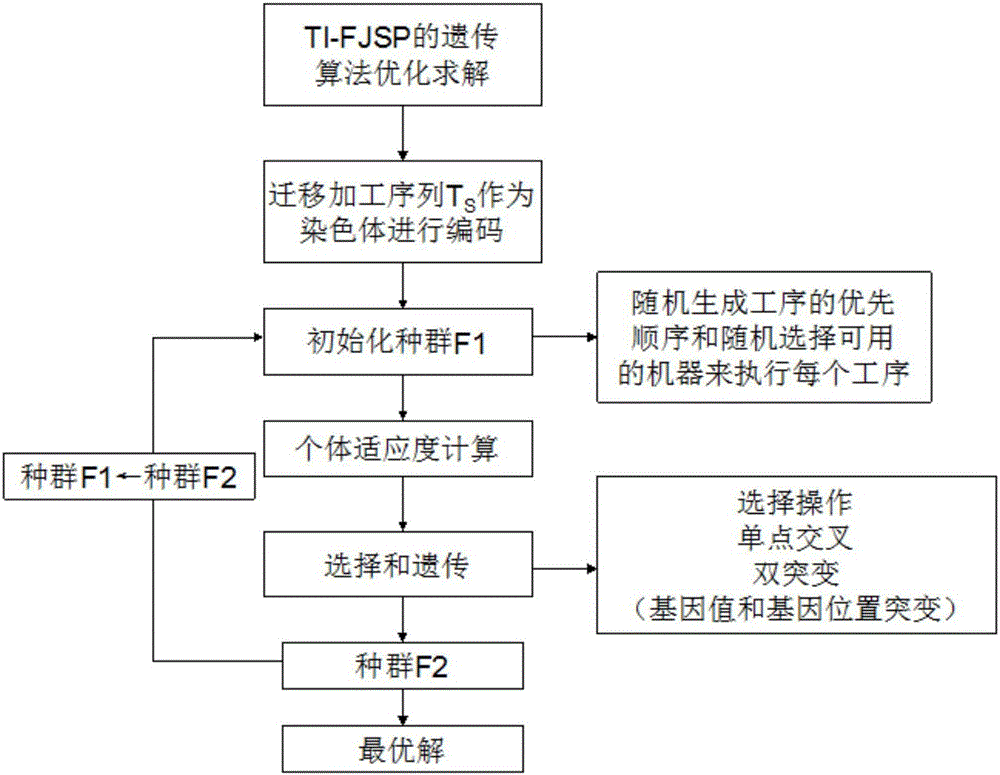

[0055] The operation time selection module obtains the migration activation time series F by establishing the energy time Petri net model and the time selection simulation algorithm TSSA S and migration processing sequence T S ’, on this basis, the machine task allocation module is to simulate GAPNS through the combination of improved genetic algorithm and Petri net to find out the best migration processing sequence T S , that is, finally obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com