Cell-machine based dynamic scheduling method for large part flexible job shop

A technology of large-scale parts and flexible operation, applied in control/adjustment systems, instruments, adaptive control, etc., can solve the problems of low operation efficiency and poor stability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

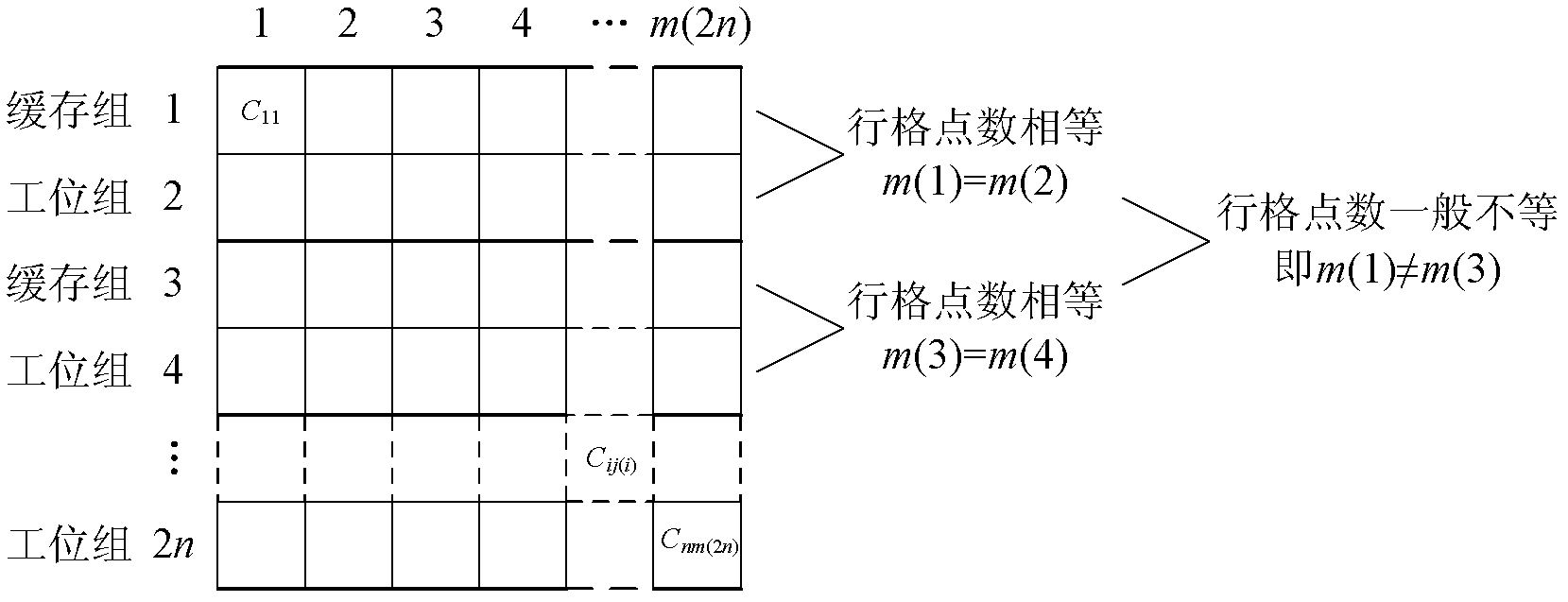

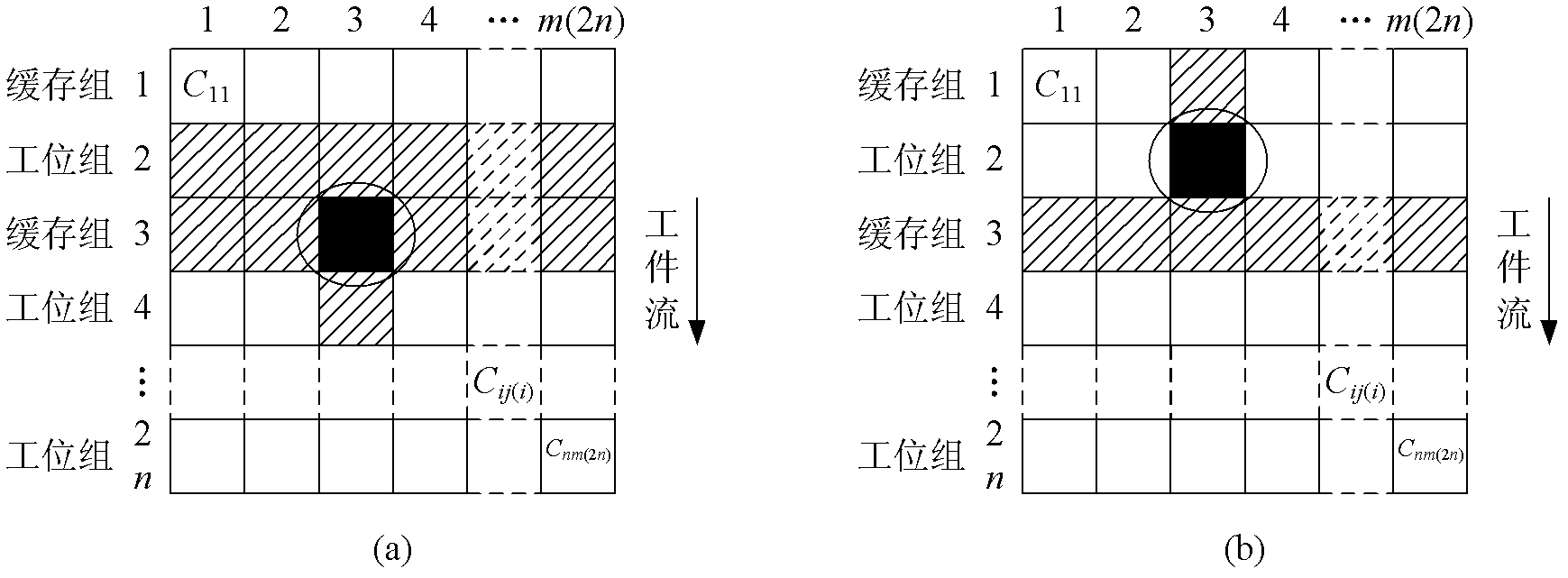

Method used

Image

Examples

example 1

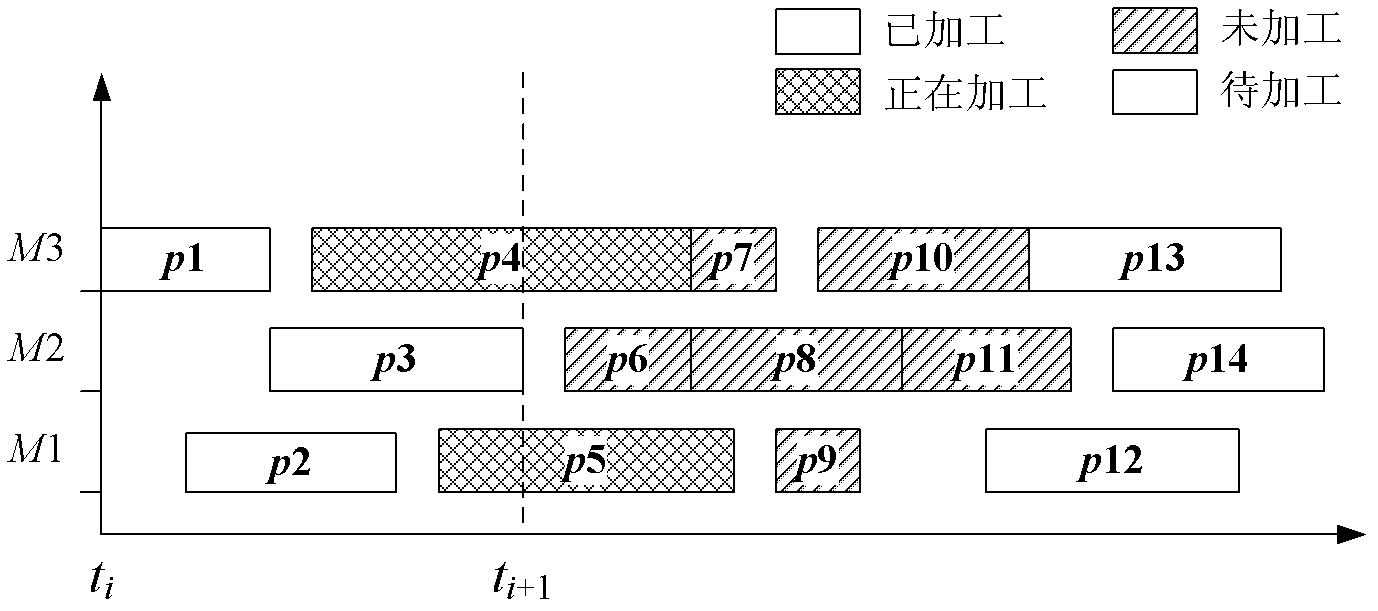

[0144] p in instance 1 1 Arrive first, to be in the next process group C 2 The processing of the first process is completed in , and the set of optional station cells is {C 21 , C 22 , C 23 , C 24 , C 25}, corresponding to s of the station set s The attributes are {0, 0, 0, 0, 0}. According to the rule R p→c , give priority to the station with a large pe, the set of pe attributes is {0.5, 1, 1, 1.5, 2}, the maximum is 2, and the station C is selected 25 . due to C 25 Corresponding buffer position C 15 The queue length is 0, when p 1 enter C 15 At the moment of , the value of qn becomes 1, and the task trigger rule R is activated ta , so p 1 The state of the t 0 of the moment updated to t 1 of the moment Can be regarded as directly entering the station cell C 25 . Correspondingly, C 25 status by update to The state of other cells and particles remains unchanged.

[0145] Artifact Sorting Subroutine: Artifact Sorting Rules R c→pMainly combine the FCF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com