Job-shop scheduling method based on an improved genetic algorithm

An improved genetic algorithm and workshop scheduling technology, applied in the field of single-piece workshop scheduling, can solve problems such as unsatisfactory evolutionary optimization and high complexity, and achieve the effects of shortening processing time, ensuring diversity, and accelerating convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

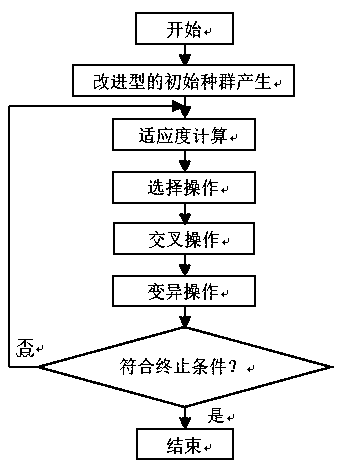

[0041] Embodiment one: see figure 1 , the single-piece shop-shop scheduling method based on the improved genetic algorithm, which is characterized by:

[0042] The operation steps are as follows:

[0043] Step 1: Determine the operating parameters.

[0044] Step 2: Improved initial population generation.

[0045] Step 3: Calculation of individual fitness.

[0046] Step 4: Select Actions.

[0047] Step 5: Crossover operation.

[0048] Step 6: Mutation operation.

[0049] Step 7: Terminate discrimination.

Embodiment 2

[0050] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0051] The operating parameters are the population size M, the crossover probability Pc, the mutation probability Pm and the number of iterations T.

[0052]The improved initial population generation is as follows: using the process code-based method to obtain process codes, generating individuals, and forming an improved initial population together with individuals obtained by using the minimum and earliest completion time method.

[0053] The calculation of the individual fitness is: according to the earliest completion time criterion, select machines for each workpiece process in the individual, and calculate the total completion time, and use the reciprocal of the total completion time as the fitness value; obviously, the shorter the completion time, the greater the fitness. The higher the value.

[0054] The selection operation adopts a roulette selectio...

Embodiment 3

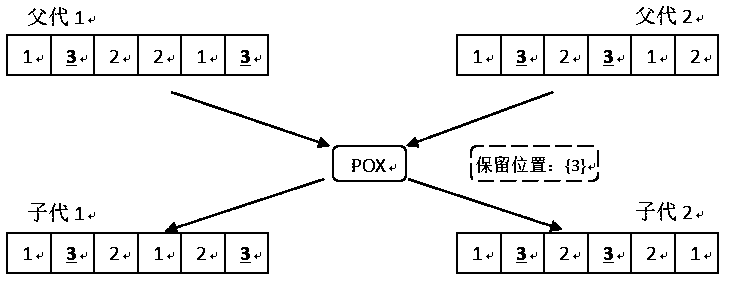

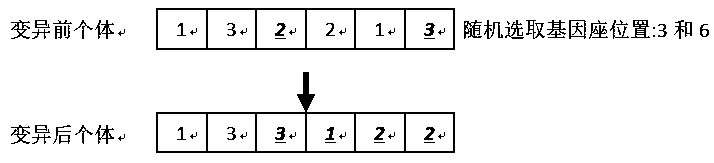

[0058] Embodiment three: see Figure 1~Figure 3 , the operation steps of this single-piece shop-shop scheduling method based on the improved genetic algorithm are detailed as follows:

[0059] Step 1. Determine the operating parameters

[0060] The operating parameters of the genetic algorithm: the population size M is generally 20~100, the crossover probability Pc is generally 0.4~0.99, the mutation probability Pm is generally 0.0001~0.1, and the number of iterations is generally 100~500.

[0061] Step 2. Improved initial population generation

[0062] The generation of the initial population relies on encoding to obtain the process code. The encoding method based on the process is: each workpiece is represented by the corresponding workpiece number, and the order in which the same workpiece number appears represents the process corresponding to the workpiece number. For the sorting problem of n workpieces and m procedures, the individual procedure code has n×m gene bits, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com