Multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and construction method

An intelligent manufacturing, full-process technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as insufficient intelligence in production lines, aging equipment, and limited production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] Example 1: Pretreatment and extraction workshop construction of traditional Chinese medicine / plant medicinal materials:

[0145] The production equipment of the pre-treatment and extraction and separation workshop of traditional Chinese medicine / plant medicinal materials integrates digital self-controlled medicinal material extraction system, concentration system, and CIP cleaning system. All production data are uploaded to the MES system through industrial Ethernet, and analyzed and processed by professional data processing software. Intelligent monitoring and real-time optimization control of production.

[0146] The selection of core equipment is as follows:

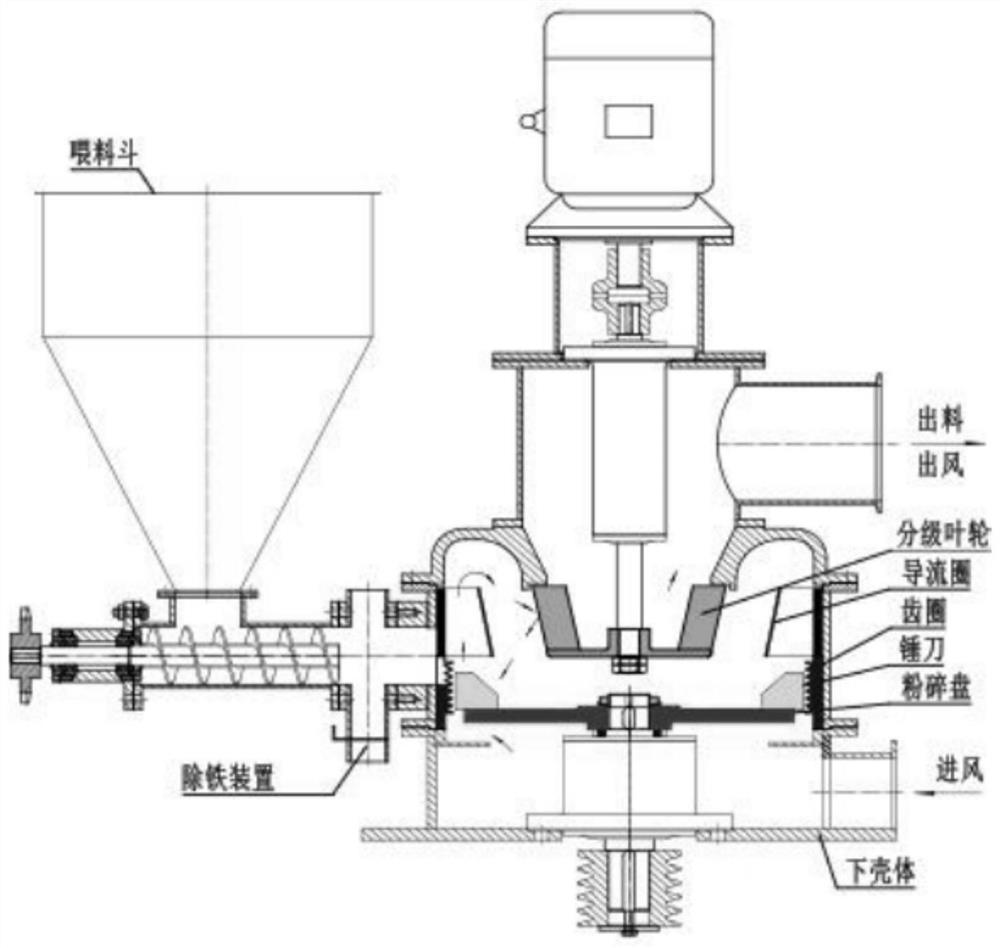

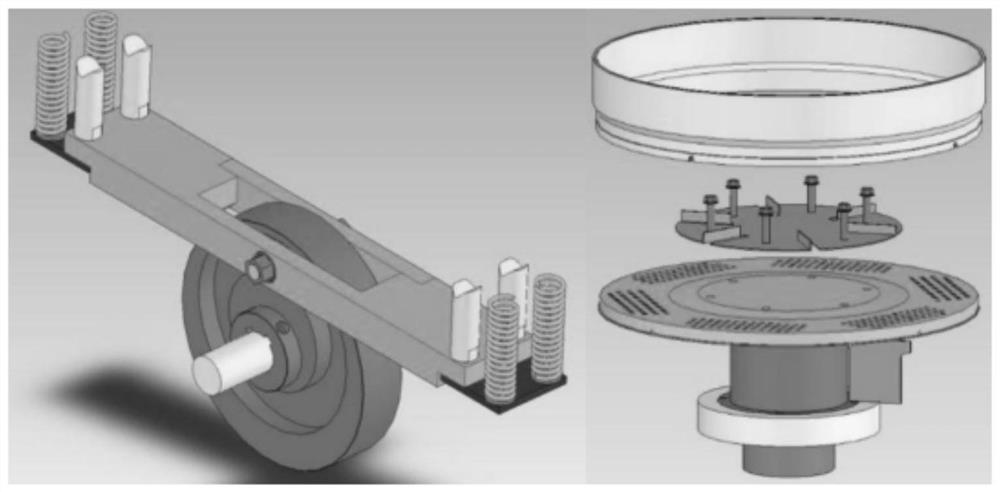

[0147] The pulverizing equipment is JYNU series pulverizer, which adopts the latest traditional Chinese medicine pulverization principle: vertical shaft, shear pulverization, which makes Jieyina ultrafine pulverizer dust-free, no tailings, second discharge, no screen design, pulverization disc and The grading ...

Embodiment 2

[0167] Example 2: Construction of oral solid preparation intelligent manufacturing workshop:

[0168] The core equipment of the oral solid preparation production workshop includes continuous production granulation, drying, mixing intelligent production lines, tablet presses, capsule filling machines, coating machines, blister packaging machines, hopper cleaning machines and post-packaging lines, etc.

[0169] The workshop is equipped with powder pretreatment and automatic batching system.

[0170] The automatic batching system determines the raw and auxiliary materials according to the process formula, identifies the raw materials entering the production site, and confirms whether they need to be crushed, sieved, and dried according to the physical characteristics of the raw materials. The main raw and auxiliary materials are directly put into the storage bin through the dust-free feeding station according to the variety and quantity required by the operation plan, and the sto...

Embodiment 3

[0237] Example 3: Construction of an intelligent manufacturing workshop for sterile preparations

[0238] The core equipment of the sterile preparation intelligent manufacturing workshop includes automatic liquid dosing and filtration system, bottle washing oven filling linkage production line, intelligent freeze-drying machine, AGV (automatic guided vehicle), automatic light inspection machine, automatic post-packaging production line, etc.

[0239] ·Automatic liquid dosing and filtration system

[0240] The batching system adopts an automatic liquid dosing and filtering system, and the rest of the process, such as the key operating area of the vacuum freeze dryer, adopts isolation system protection and digital control technology, which minimizes the probability of contact between personnel and materials, and can effectively reduce the risk of product contamination by particles and microorganisms , The whole system includes the equipment integration of batching, bottle wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com