Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

840results about How to "Reduce the failure rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of clean high carbon chromic bearing steel

A method for manufacturing high-cleaning and high carbon complex bearing steel includes: 1) choosing charging mixture 2) first steel making molten steel by is greater than or equal to 30ton electric furnace a. smelting furnace burden b. running out foaming slag and adding lime c. alloying when steel tapping with 92% tap and >90% level 3) refining molten steel by steel ladle furnace a. cleaning steel ladle and furnace cleaning b. through bottom blowing argon mixing with 60 min, earlier stage argon blowing intensity 0.4Mpa and later stage 0.3Mpa, material adding amount is less than or equal to 8Kg / ton steel c. precipitating and deoxidizing by two-stage aluminum feeding method, adding crystallized silicon powder, fluorite(content of calcium is greater than or equal to 98%) into slag face, and dispersing deoxidizing 4) vacuum furnace treating a. bottom blowing argon 0.3Mpa, 25min, vacuum content is less than or equal to 140Pa b. bottom blowing argon mixing 15min, 0.1Mpa without materials after treating 5) molten steel mould casting under inactive gas a. ingot moulding temperature 70deg.C, runner brick coating b. pouring speed 5.1ton steel / min of ingot body and mouth. It achieves high yield.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

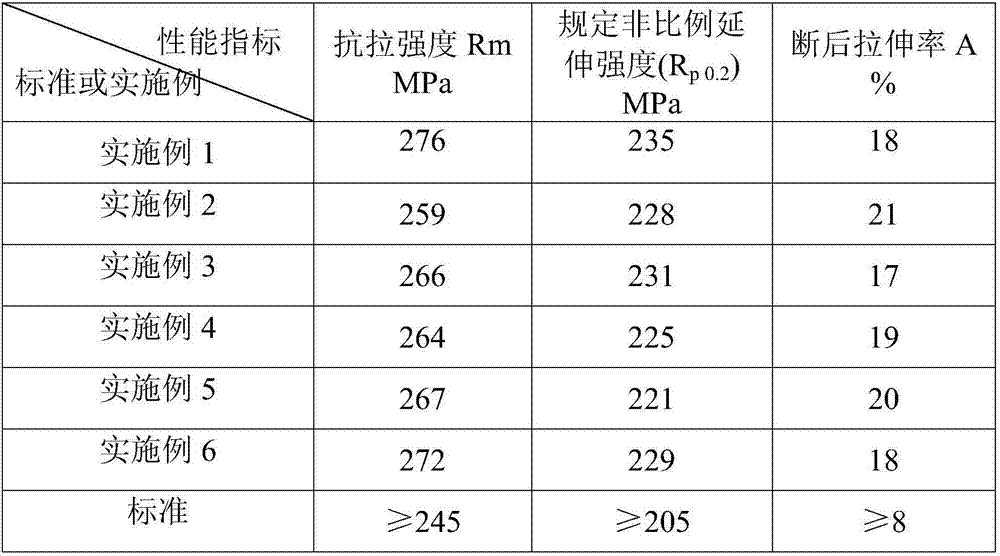

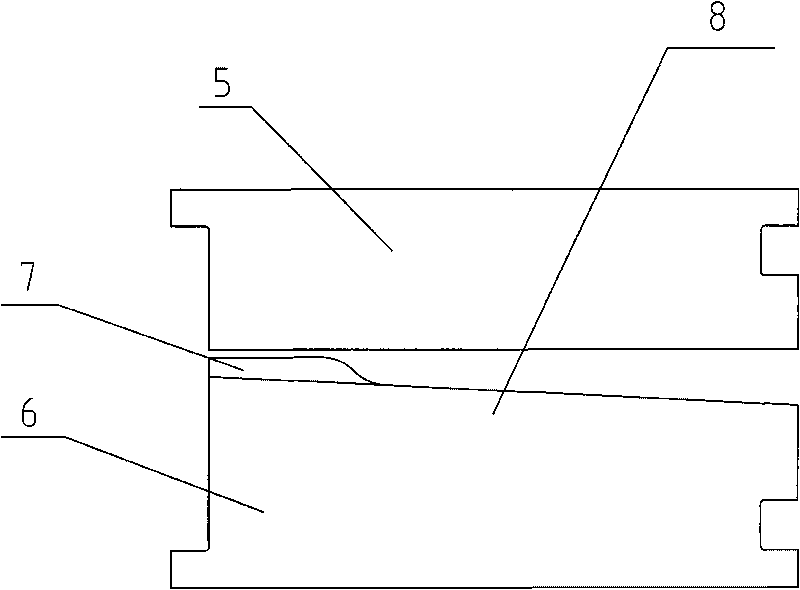

Aluminum alloy section for rail traffic car body skirtboard and manufacturing method of aluminum alloy section

InactiveCN107326227AGood mechanical propertiesReduce the failure rateExtrusion control devicesQuenchingRail transportation

An aluminum alloy profile for a rail transit car body skirt and a manufacturing method thereof, relating to the technical field of preparation of aluminum alloy profiles, the manufacturing method of the aluminum alloy profile for a rail transit car body skirt includes the following steps: alloy smelting, refining treatment, Casting into rods, sawing of cast rods, homogenization annealing, surface peeling of cast rods, heating of cast rods, extrusion, online quenching, stretching straightening, sawing, surface shaping, artificial aging, the manufacturing method strictly controls the process steps Each parameter can be mass-produced with qualified wall dimensions and good mechanical properties, meeting the strength requirements of aluminum alloy materials for rail transit car body skirts; the prepared aluminum alloy profiles for rail transit car body skirts can be specially used The production of rail transit car body skirts can reduce the occurrence of unqualified rates, improve production efficiency, and reduce manufacturing costs.

Owner:SHANDONG NANSHAN ALUMINUM +1

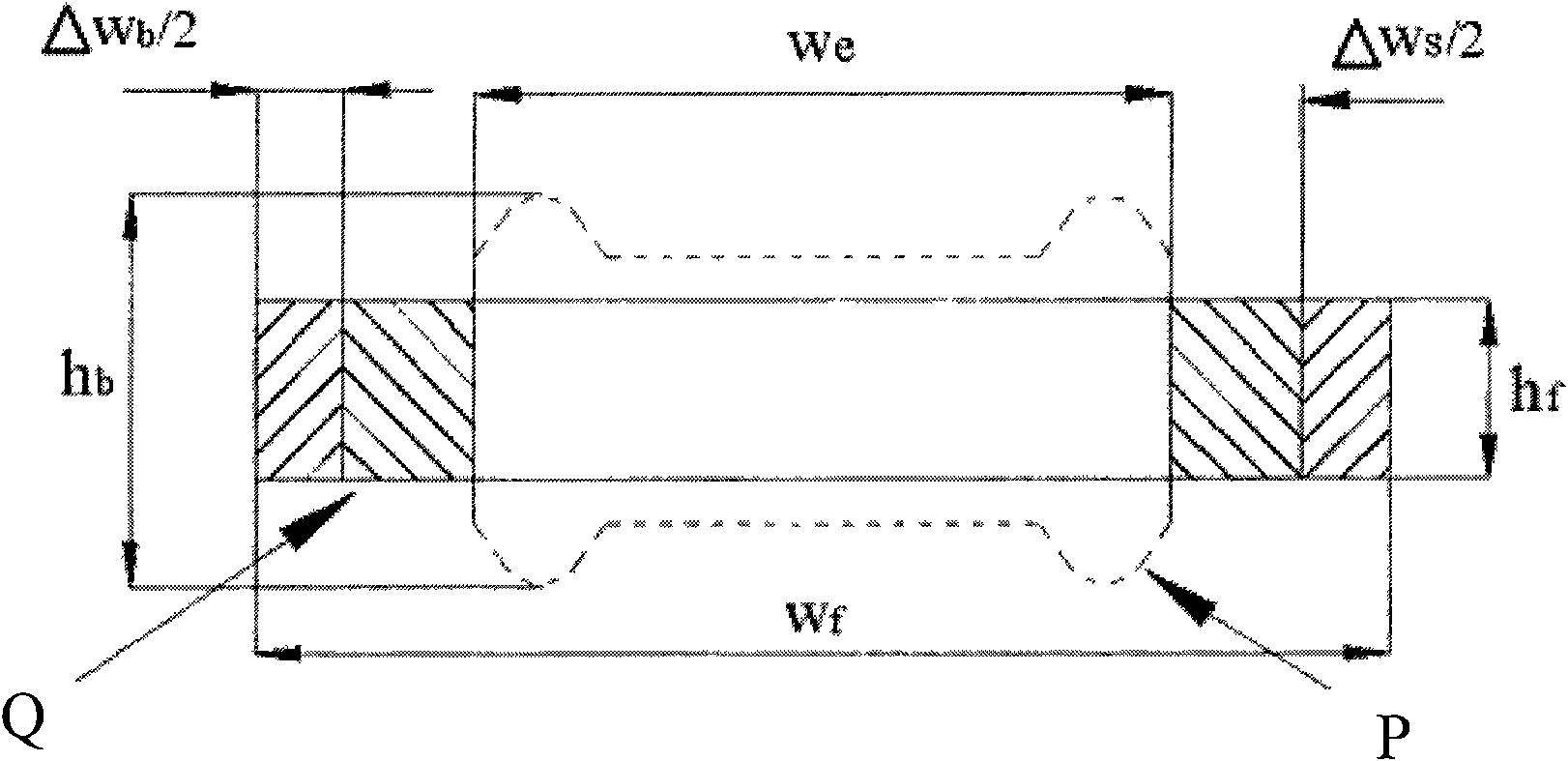

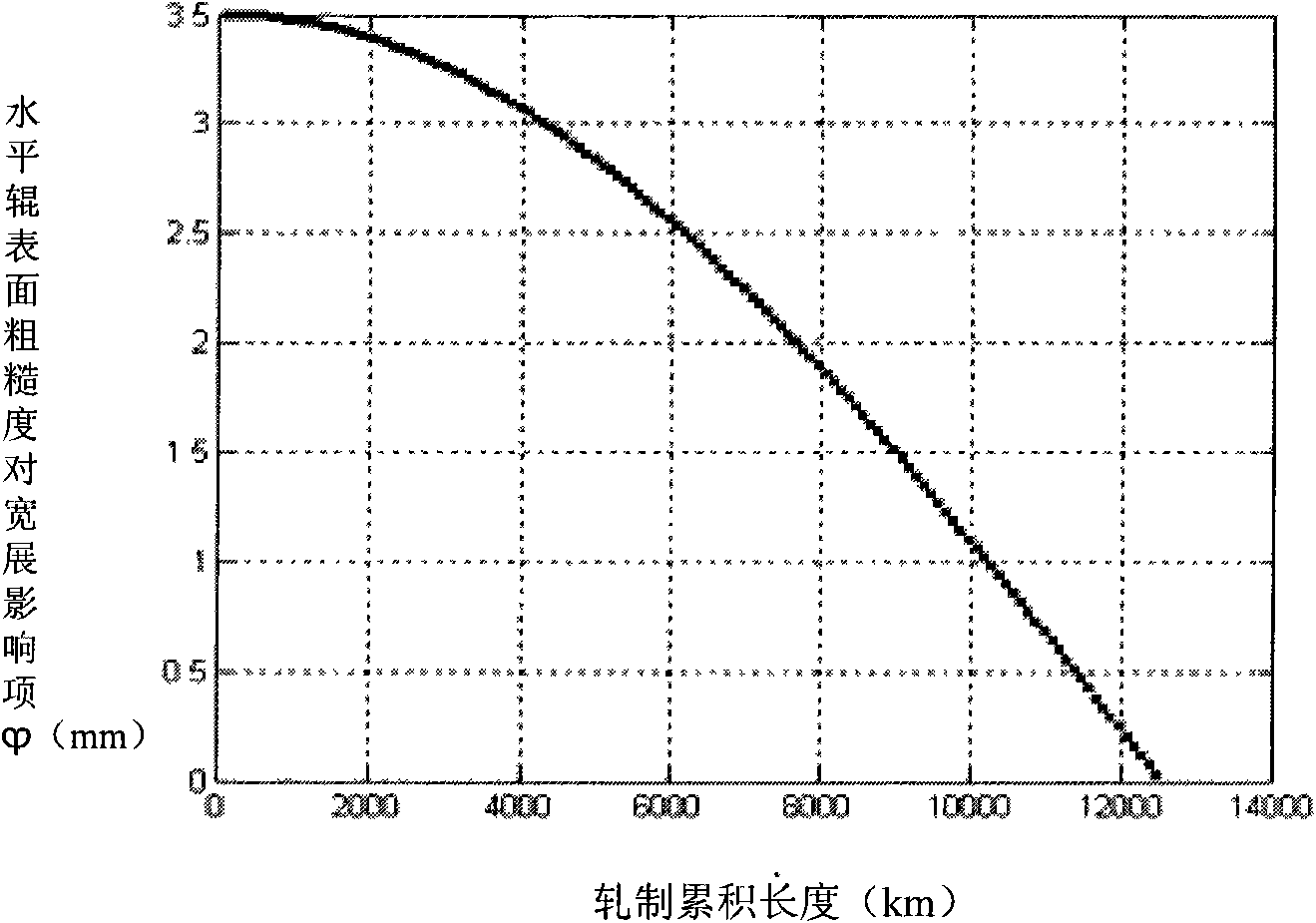

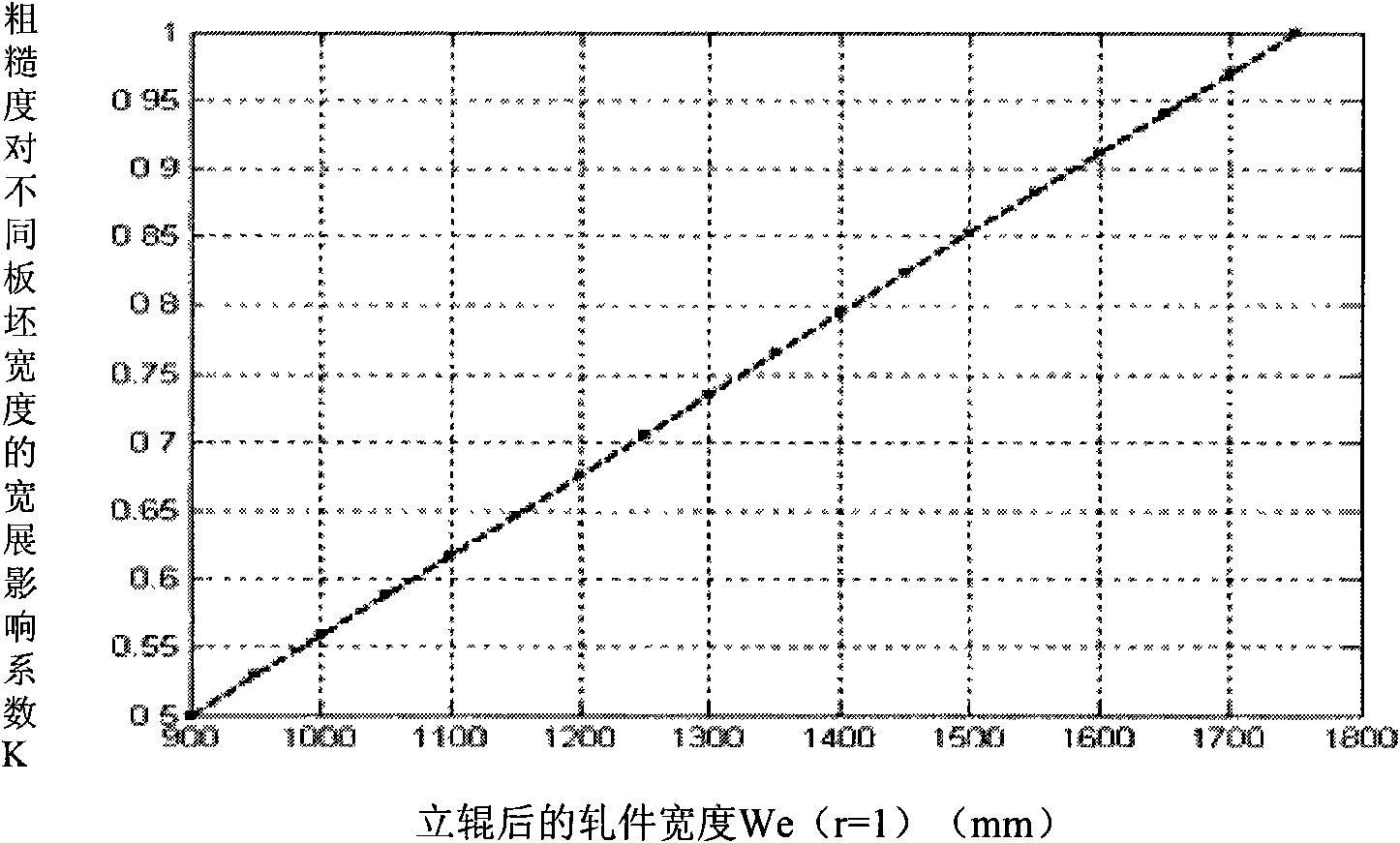

Method for improving control accuracy of hot rolling width

ActiveCN101653786AReduce interventionReduce the failure rateRoll mill control devicesMetal rolling arrangementsTotal thicknessControl models

The invention discloses a method for improving the control accuracy of hot rolling width, which is a width control method for combined rolling of hot rolling rough rolling vertical roll-horizontal roll in a rough rolling area in a hot rolling device. The method comprises the following steps: establishing the control model relation among the width control quantity, accumulated rolling length and the width of a rolling material by introducing the roll surface roughness into rough rolling width control, then determining the thickness reduction of each pass of each roll housing according to the total thickness reduction of a rolled piece, and then predicting the spread of each pass according to the control model and determining the width of a target outlet of each pass according to a width reduction distribution principle so as to determine the roll gap of a vertical roll of each pass; and realizing the width control on the outlet of each pass by controlling the roll gap of the vertical roll, and finally realizing the control on the target width of the rolled piece in the rough rolling area in the hot rolling device. The method solves the problem of width fluctuation when a rough rolling horizontal working roll is replaced every time in the prior art, reduces the intervention of operators, and can reduce the failure rate of rolling width and production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

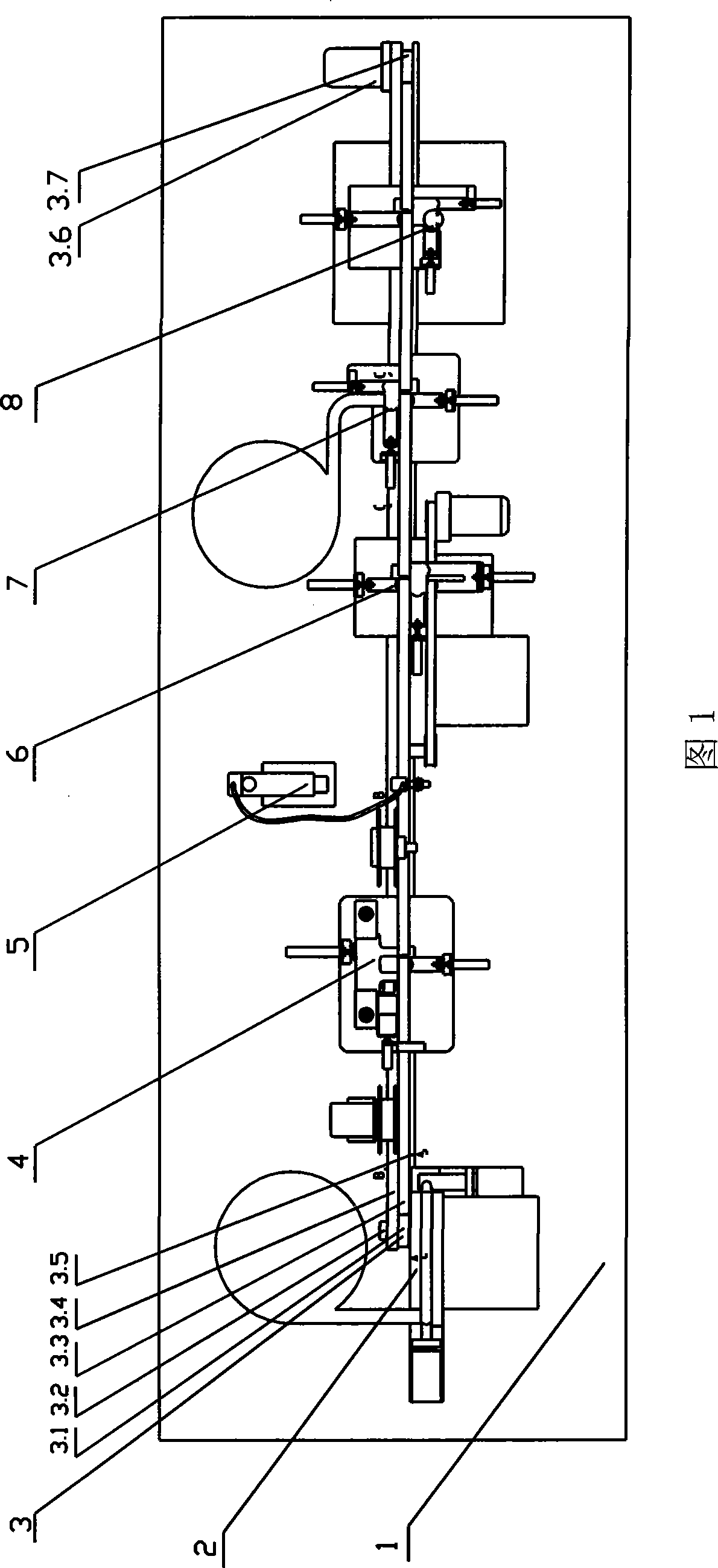

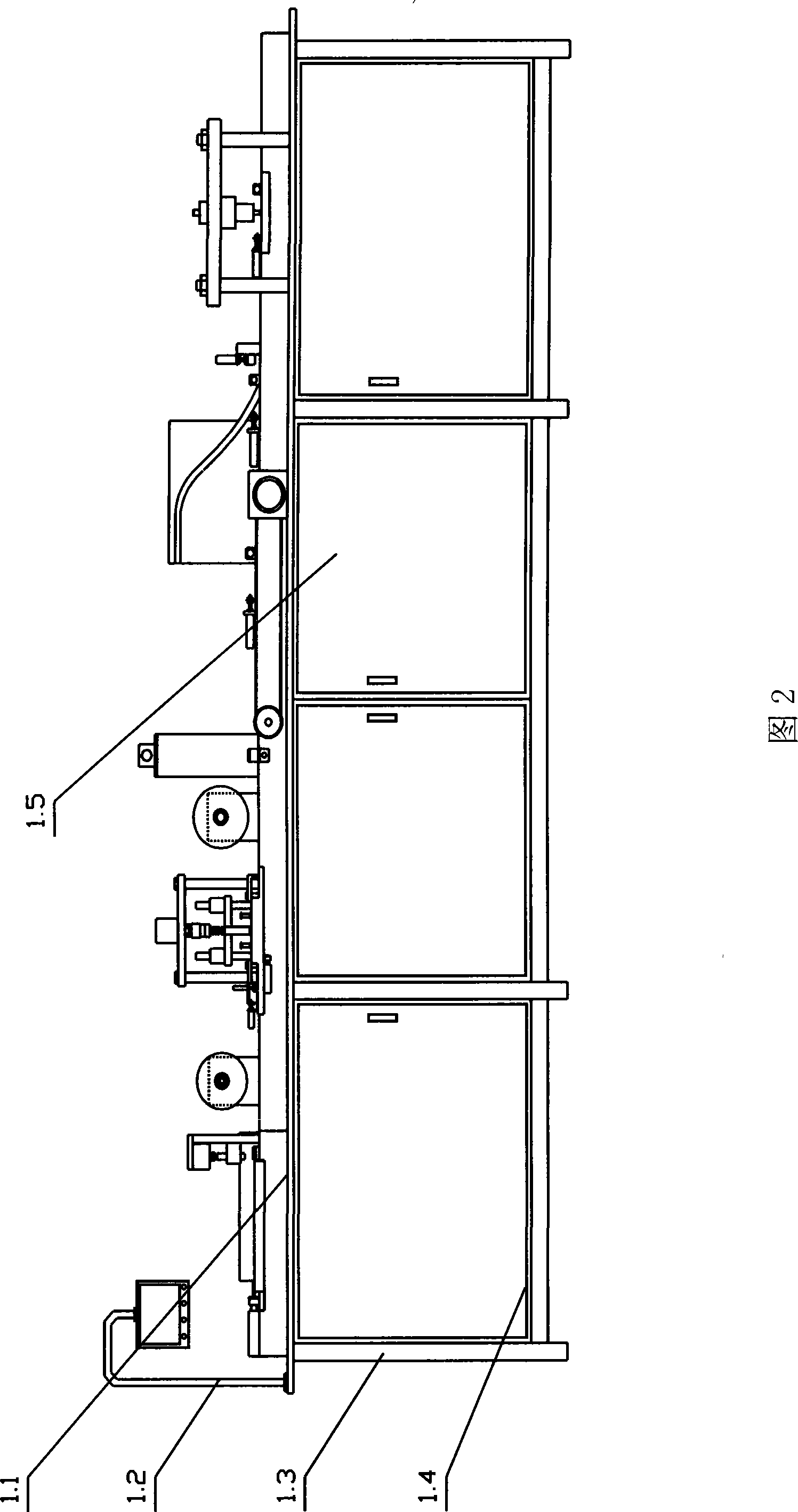

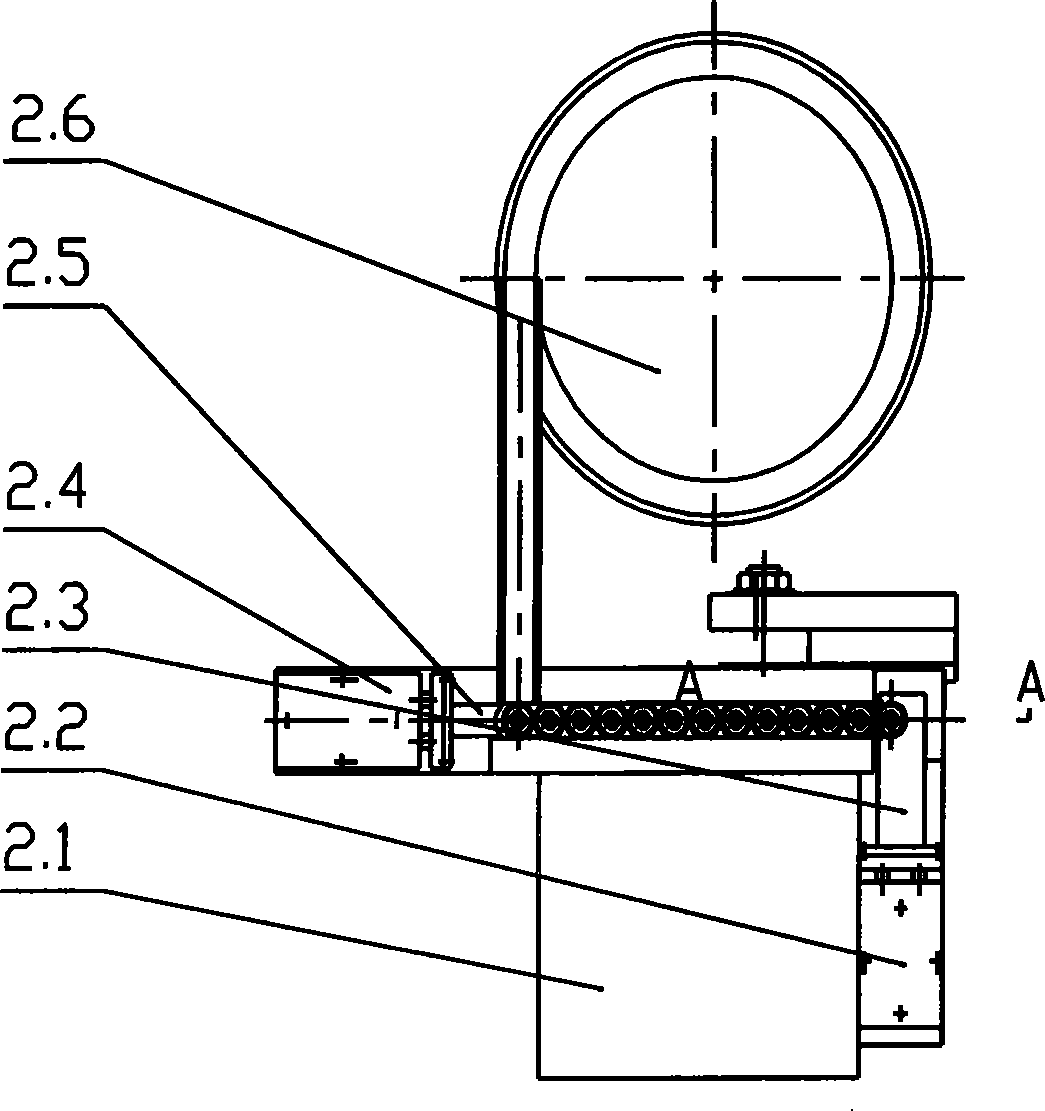

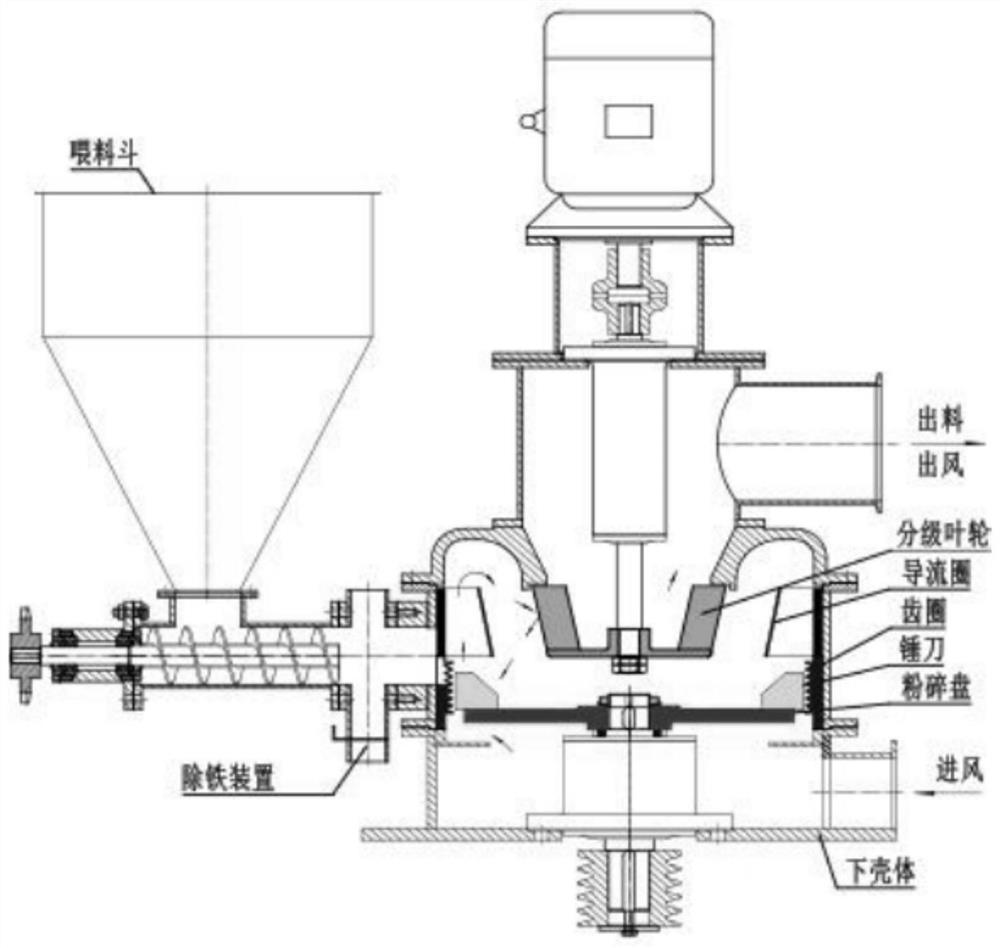

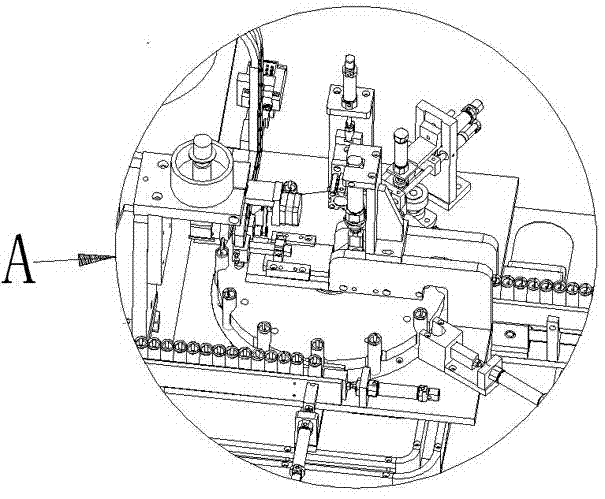

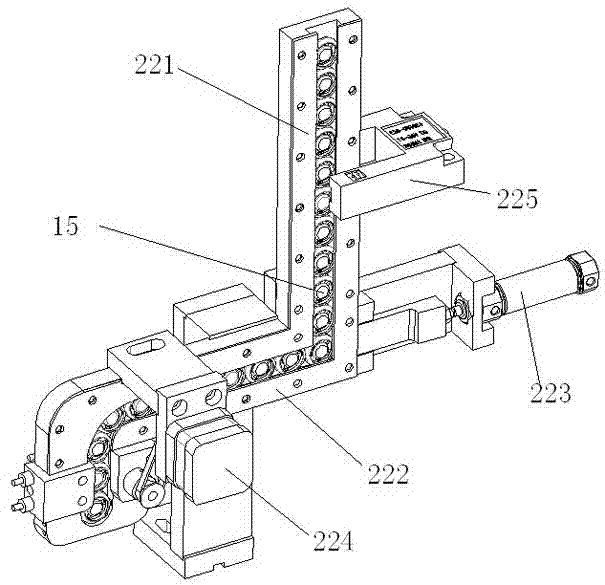

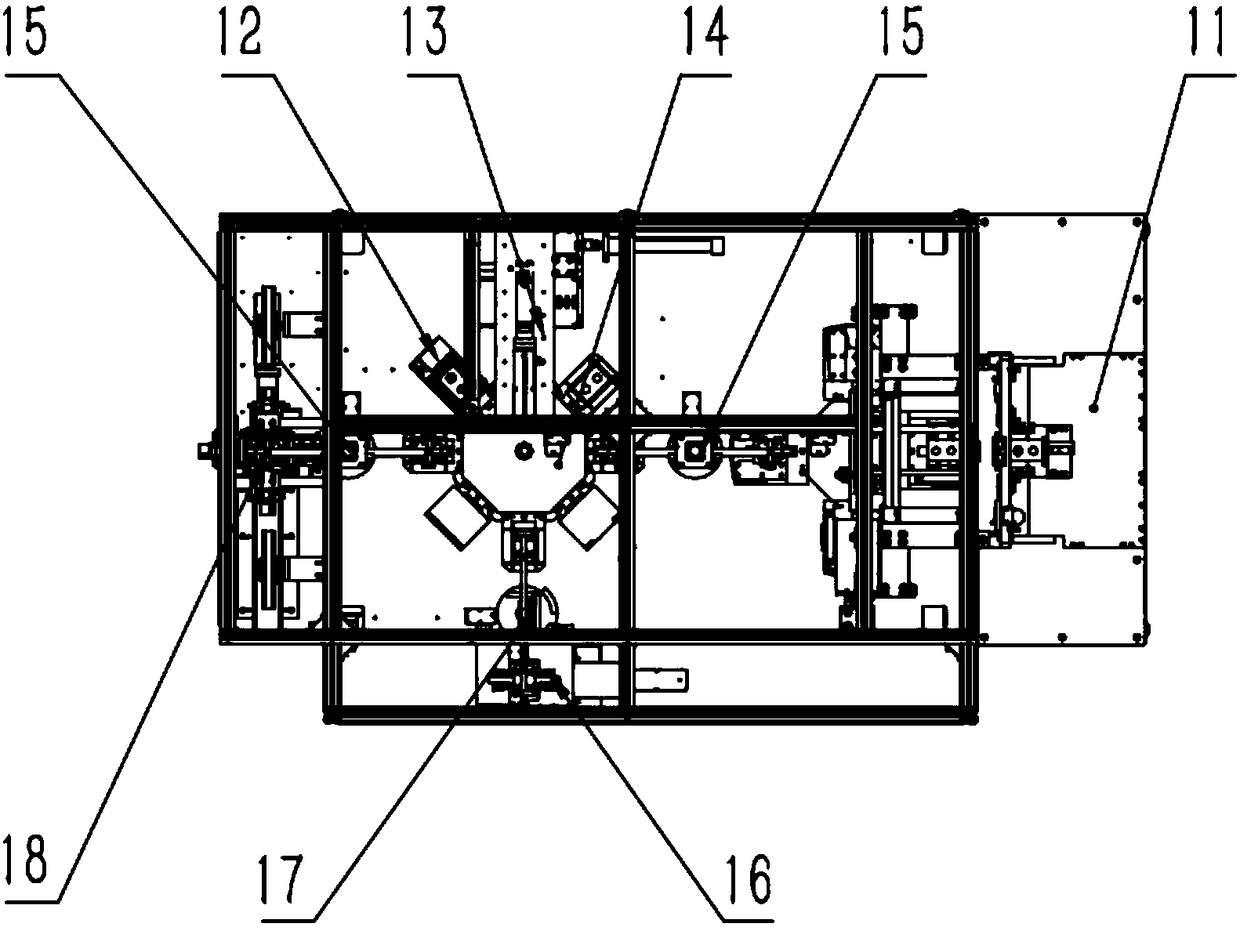

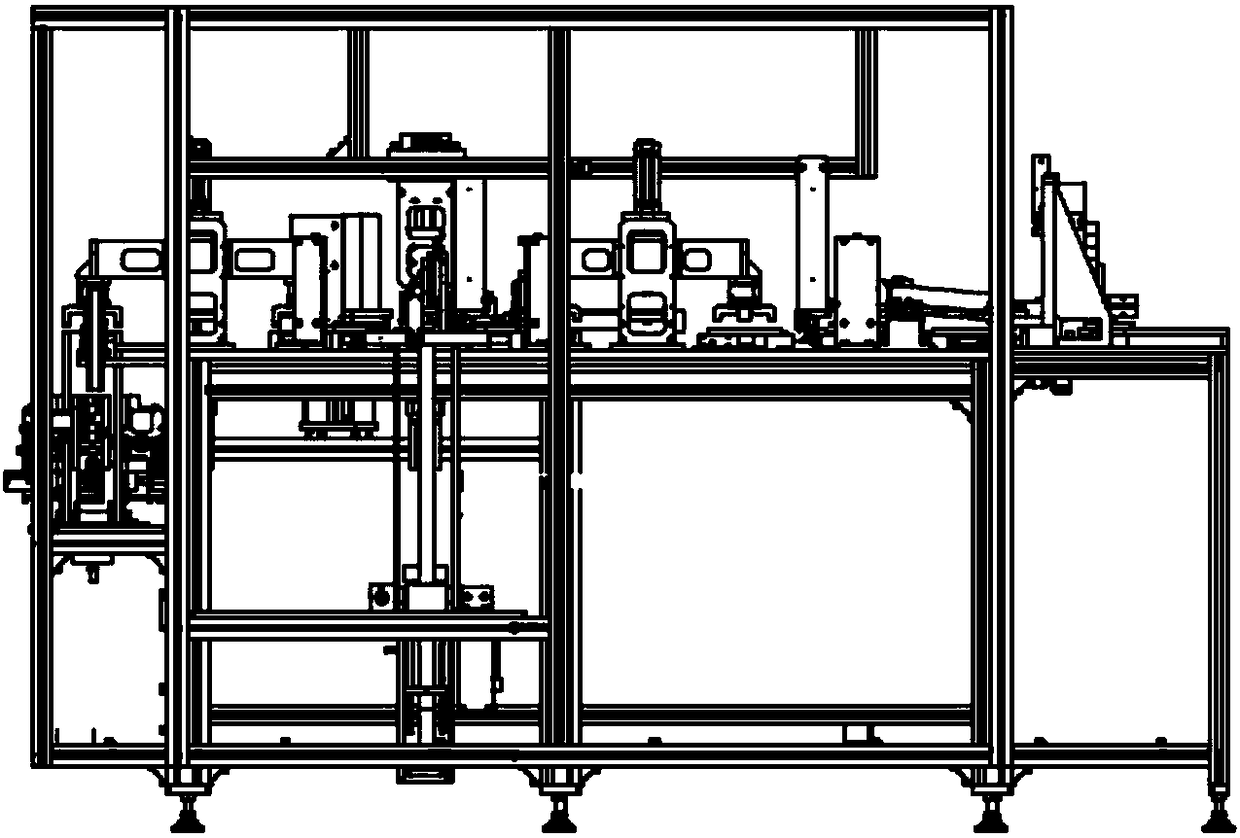

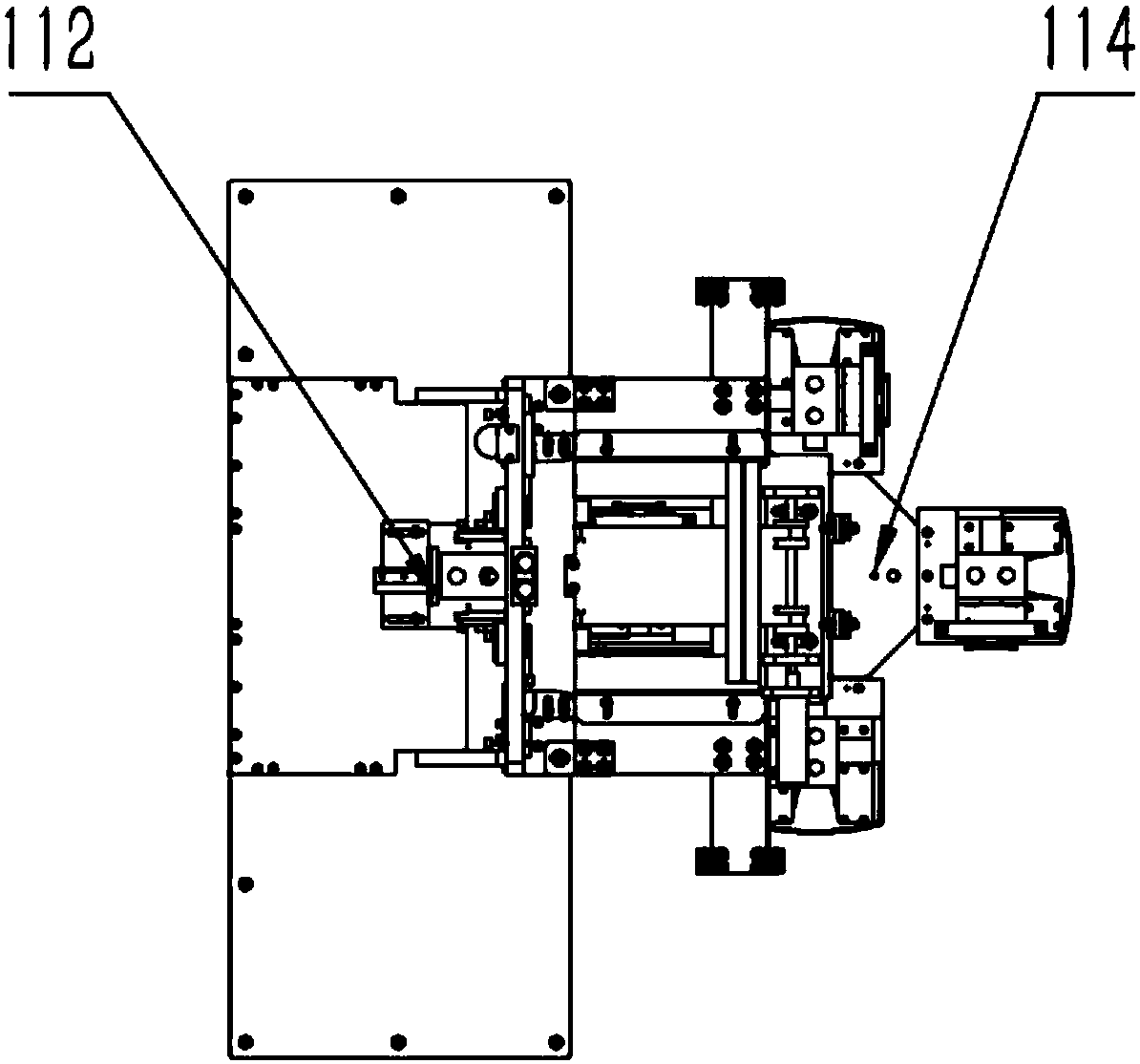

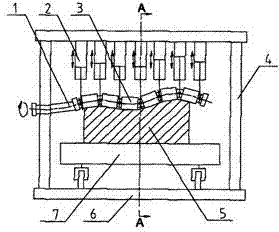

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

High-yield milk cow feed mixture

ActiveCN101878863AReduce the failure rateHigh in fatAnimal feeding stuffAdditive ingredientPeanut meal

The invention relates to a high-yield milk cow feed mixture, which consists of the following ingredients in percentage by weight: 3 to 8 percent of bean dregs, 2 to 15 percent of cotton dregs, 1 to 3 percent of vegetable dregs, 2 to 5 percent of peanut meal, 0 to 20 percent of corn DDGS, 1 to 2 percent of stone dust, 0 to 15 percent of wheat bran, 0 to 3 percent of soybean oil, 0.2 to 1.5 percent of common salt, 1 to 2.5 percent of calcium hydrophosphate, 20 to 60 percent of corn, 0.2 to 1 percent of mineral substances and vitamin, 0.5 to 2 percent of phagostimulant and 5 to 30 percent of rumen health care agents. When the high-yield milk cow feed mixture of the invention is fed in the milk cow high-yield period, compared with the method of feeding ordinary milk cow feed sold in the market, the invention has the advantages that the daily milk yield of each mil cow can be increased by 2 to 5kg, in addition, the protein content, the fat content, the dry substance content and the like in the produced milk are all correspondingly increased, and the milk production quality can be improved.

Owner:河南省乐丰饲料有限公司

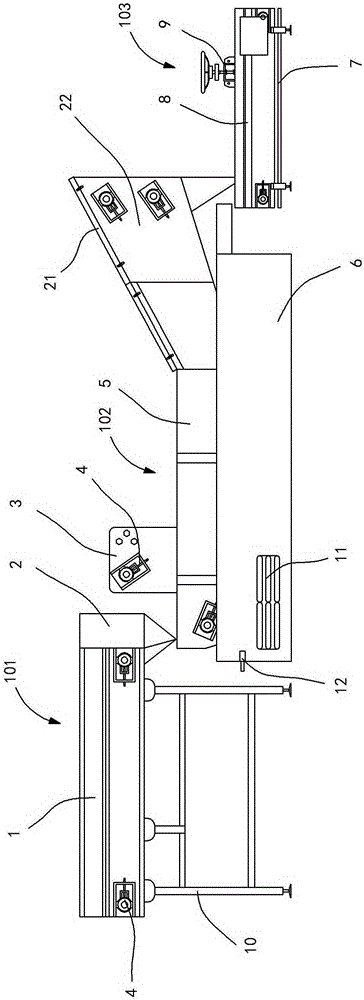

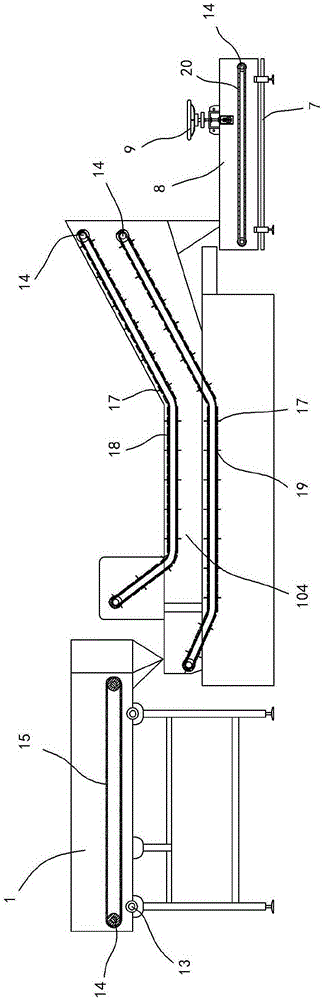

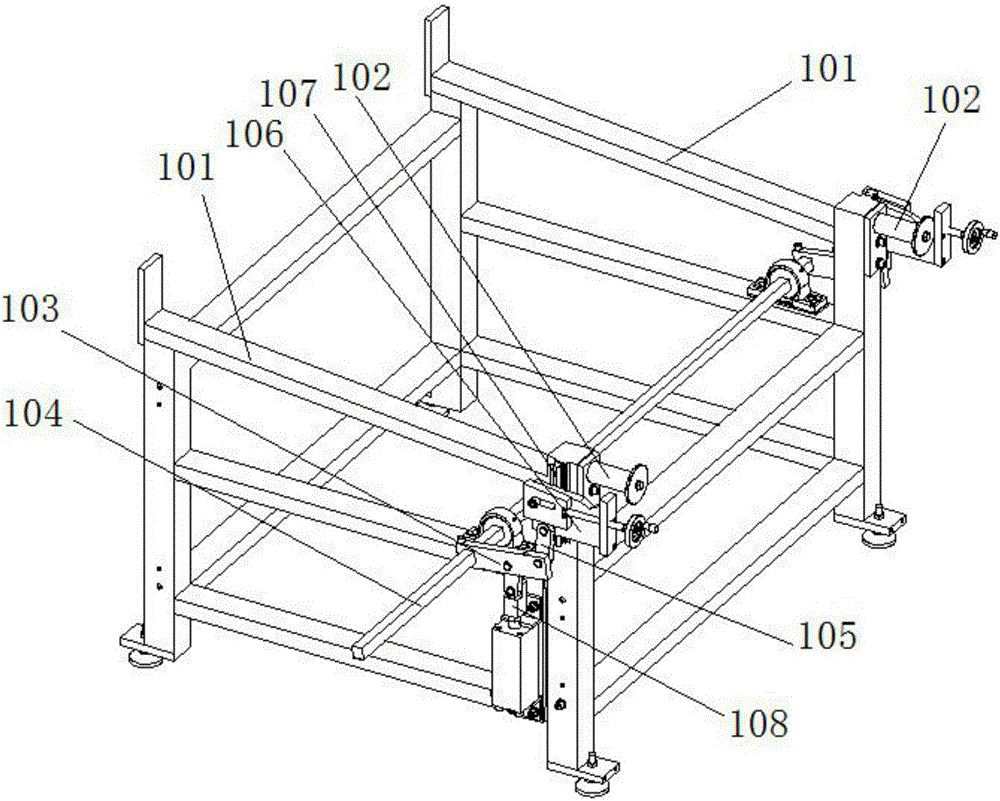

Fiber after-treatment equipment

ActiveCN105113160AIncrease productivityImprove qualityLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberAfter treatment

The invention discloses fiber after-treatment equipment which comprises a fiber input mechanism (101), a fiber soaking mechanism (102) and a fiber output mechanism (103). An outlet of the fiber input mechanism (101) is formed in an inlet of the fiber soaking mechanism (102). An outlet of the fiber soaking mechanism (102) is formed in an inlet of the fiber output mechanism (103). The fiber after-treatment equipment improves the production efficiency, greatly improves the quality of products, and reduces the product reject ratio in the production process.

Owner:JIANGSU XILUN NANO BIOTECH CO LTD

A reworking method on degraded products after the printing of crystal silicon solar battery

ActiveCN101217169AImprove pass rateImprove yieldFinal product manufactureSemiconductor devicesFailure rateSilver paste

The invention discloses a rework method of defective products of crystalline silicon solar cells after printing. The method includes the following three steps: an aluminum paste at the back surface of a cell is removed by using an HCl cleaning liquid; silver pastes at the positive and negative surfaces of the cell is removed by using isopropanol; the cell, the pastes of which is basically removed is treated with deep cleaning by using the deep cleaning liquid so as to thoroughly clean tiny impurities. The conversion efficiency of the cell can achieve the level of a normal cell by using the method for processing, and the appearance is not different from the normal cell, thus the invention achieves the purpose of rework cleaning. The failure rate of the silk screen printing of the cells is reduced to about 0.2 percent from original about 2 percent, thereby increasing the qualified rate and the yield of the silicon solar cells.

Owner:ZHEJIANG FORTUNE ENERGY

Chemical plating material and preparation method thereof

InactiveCN101654775ADense and firm attachmentReduce the failure rateLiquid/solution decomposition chemical coatingChemical platingAqueous solution

The invention discloses a chemical plating material, which comprises a plastic substrate and a chemical plating layer, wherein the chemical plating layer comprises a simple substance copper particle layer and a metal plating layer; the simple substance copper particle layer is positioned between the plastic substrate and the metal plating layer; the particle diameter of simple substance copper particles is between 15 and 100 nanometers; and the bonding force between the chemical plating layer and the plastic substrate is between 100 and 400MPa. The invention also discloses a preparation methodfor the chemical plating material, which comprises that: the plastic substrate is contacted with aqueous solution of a reducing agent and cupric brine solution, so that the surface of the plastic substrate is adhered with the simple substance copper particle layer; and the metal plating layer is formed through metal deposit, and the simple substance copper particle layer and the metal plating layer form the chemical plating layer, wherein the contact condition ensures that the reducing agent reduces cupric salt into simple substance copper particles of which the diameter is between 15 and 100nanometers, and the bonding force between the chemical plating layer and the plastic substrate is between 100 and 400MPa. The method has high production efficiency and low cost; and the chemical plating layer can be firmly bonded with the substrate.

Owner:安徽新合富力科技有限公司

Multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and construction method

PendingCN112163688AIncrease productivityReduce operating costsForecastingResourcesInformation interoperabilitySmart factory

The invention provides a multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and a construction method. The invention breaks through a multi-dosage-form Chinese and western medicine product manufacturing process and a digital equipment technology. Advanced intelligent equipment such as intelligent equipment facilities, intelligent sensors, intelligent instruments and meters, industrial robots and the like are applied to implementation, and an advanced industrial control system, industrial control software and the like are integrated through technologies such as the Internet of Things technology, the big data technology, cloud computing, artificial intelligence, information security and the like. The information intercommunication between people and equipment, the information intercommunication between equipment and equipment, the information intercommunication between equipment and systems and the information intercommunication between systems are achieved. The full-life-cycle information integration of products from research and development design, planned purchasing, production and manufacturing, quality inspection, sales delivery,product tracing, after-sales service and the like is achieved.

Owner:CHONGQING PHARSCIN PHARM CO LTD

Method of forming car steering knuckle forging die cavity

InactiveCN101716642AReduce the failure rateExtend your lifeForging/hammering/pressing machinesForgeMaterials science

The invention relates to a method of forming car steering knuckle forging die cavity. The method comprises the following steps: (1) blanking; (2) splitting material: placing the blank which is heated to over 1100 DEG C on a splitting table for beating to ensure that one end of the blank is pressed to form two branches and the other end is flattened; (3) preforging forming: placing the blank in a preforging mould after splitting material to ensure that the end with branches of the blank covers the two-branch part of the preforging cavity, performing preforging forming to the forge piece; (4) finish forging forming: after the preforging forming, placing the blank on a finish forging mould to perform finish forging forming; and (5) trimming and correcting the blank after the finish forging forming, wherein in the preforging mould and the finish forging mould, the two branches of the cavity both face to the end of the forging die for operation of workers; the other end of the cavity is provided with a lock catch for balancing the displacement force of the forge piece, and the lock catch is a half-surrounded type boss. The method has the following beneficial effects: the forming difficulty of the forge piece is low and the displacement force of the forge piece is reduced, etc; and the method can be widely applied in the forging process field.

Owner:DONGFENG MOTOR CO LTD

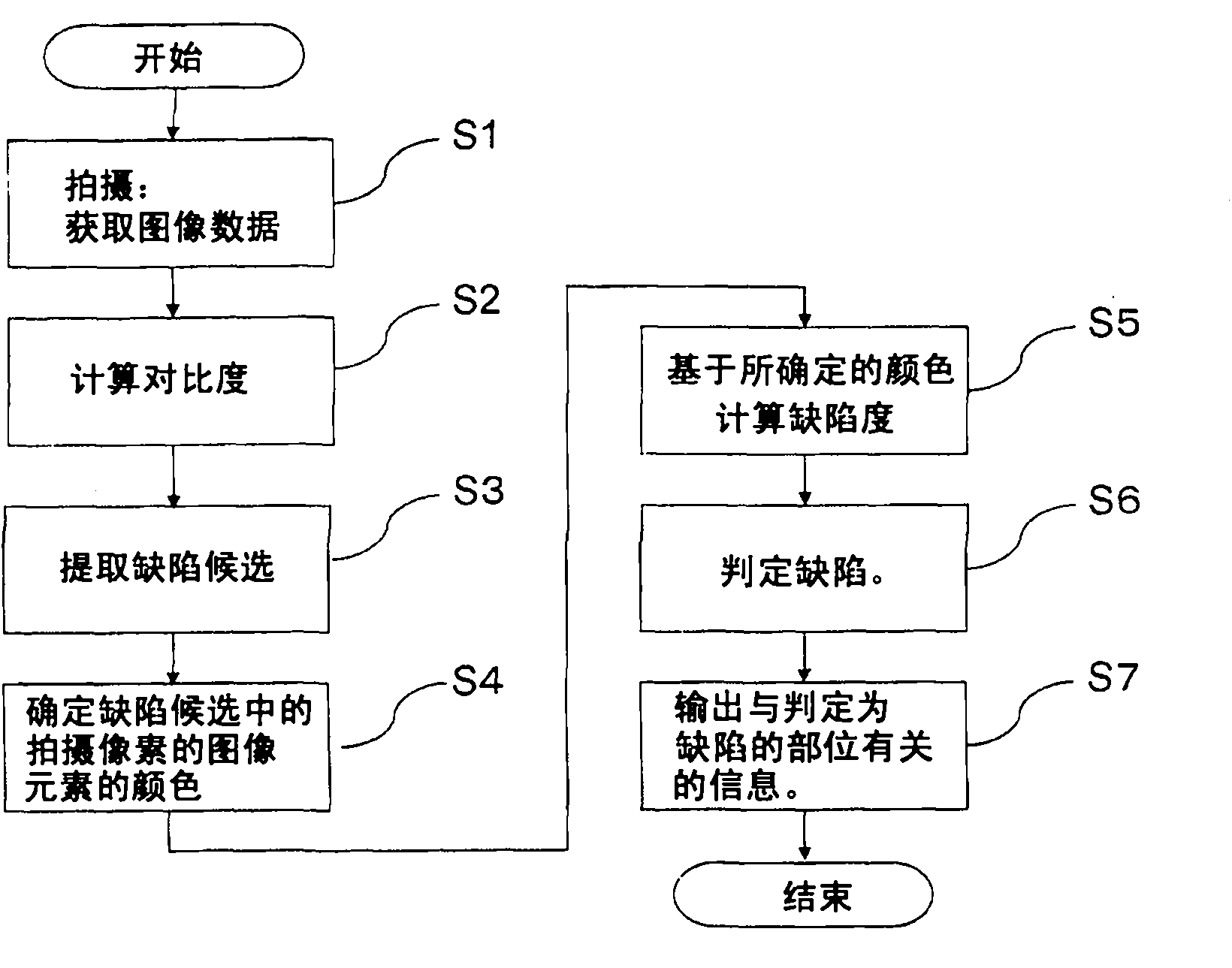

Defect detection device, defect repair device, defect detection method

InactiveCN102279189APrevent false detectionDefect correctOptically investigating flaws/contaminationNon-linear opticsColor imageDefect repair

The invention discloses a defect detecting device, a defect restoring device and a defect detecting method. The invention provides a defect detecting device which is capable of judging defects in a proper standard according to the color proportion even when the defects contain multiple-color image elements. The defect detecting device comprises a shooting part for shooting a display panel and obtaining image data; a defective part detecting part for selecting defective part candidates from the image data; a color determining part for determining the image element color of the defective part candidates; and a judging part for calculating the defective rate by multiplying a contrast degree with a correction coefficient varying with different colors, and then judging the defects by comparing the defective rate with a judging value. The judging part concludes after the contrast degree and a corresponding correction coefficient of each color are multiplied to calculate the defective rates when a defective part candidate comprises multi-color image elements.

Owner:SHARP KK

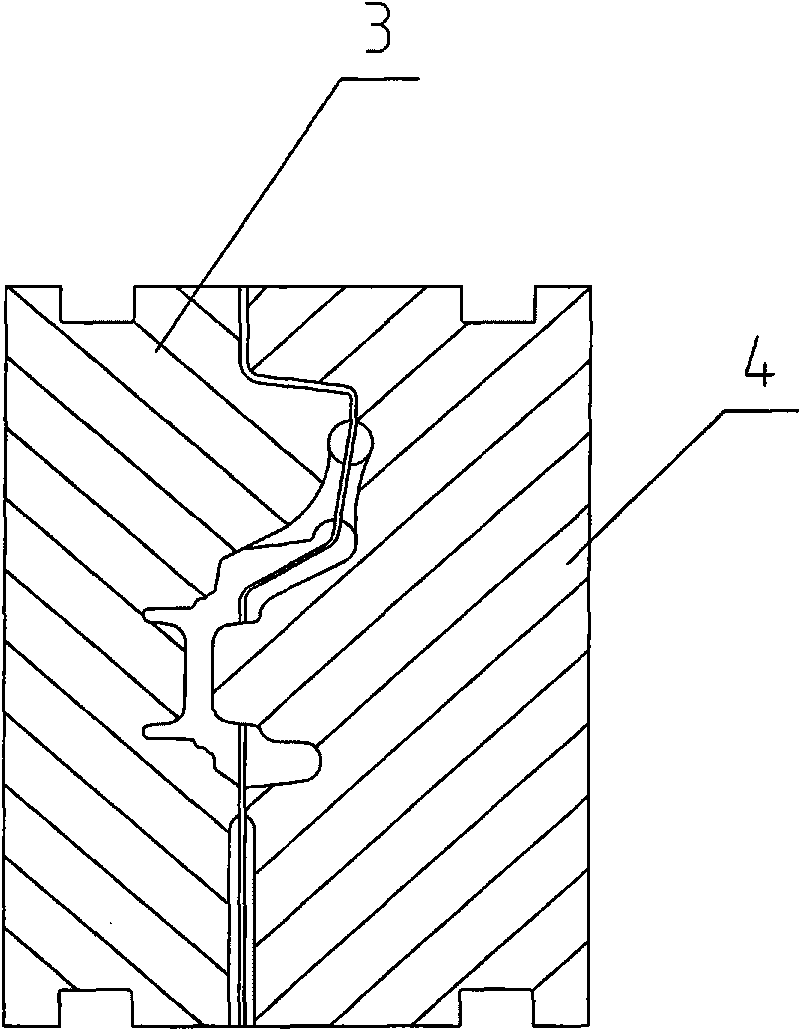

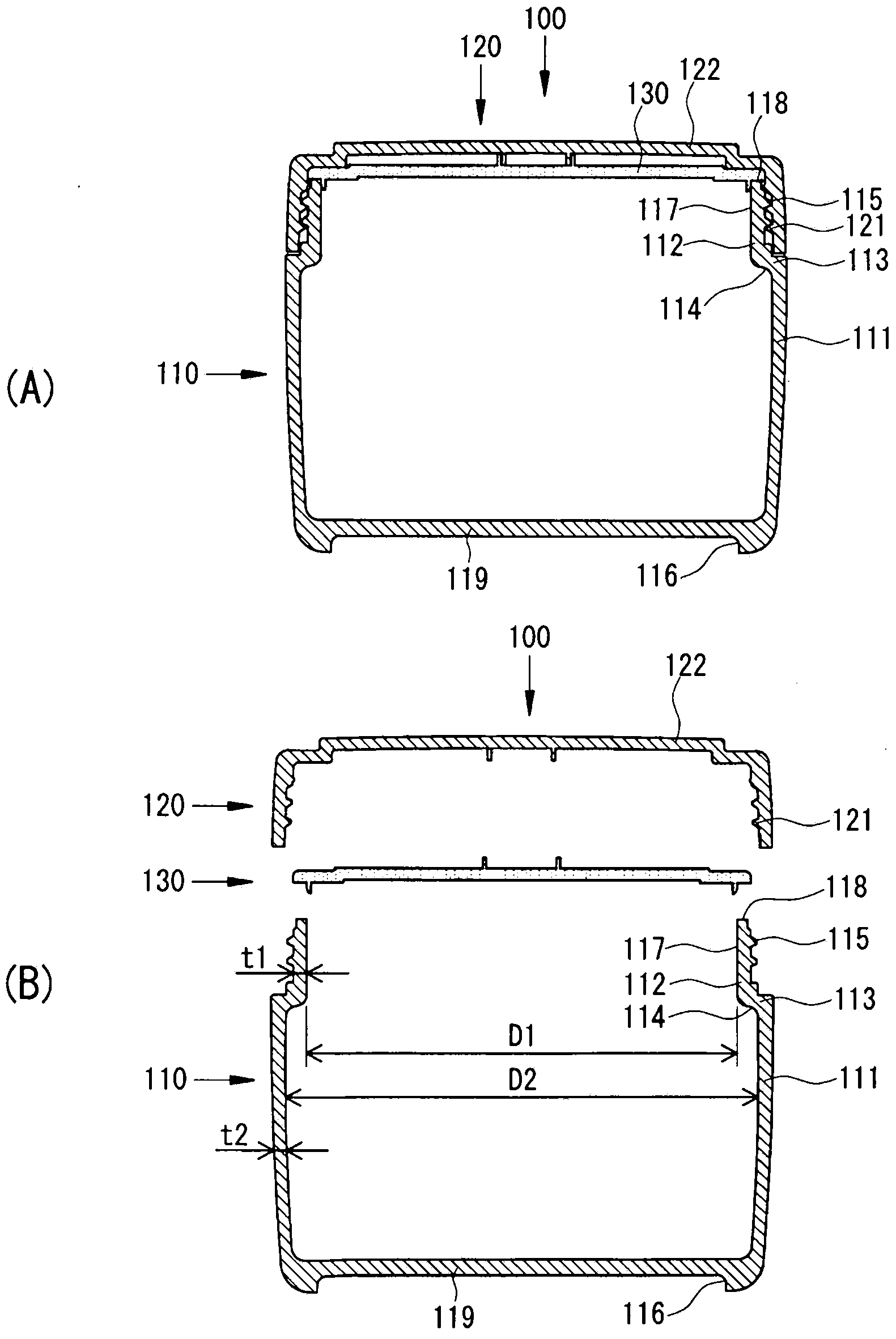

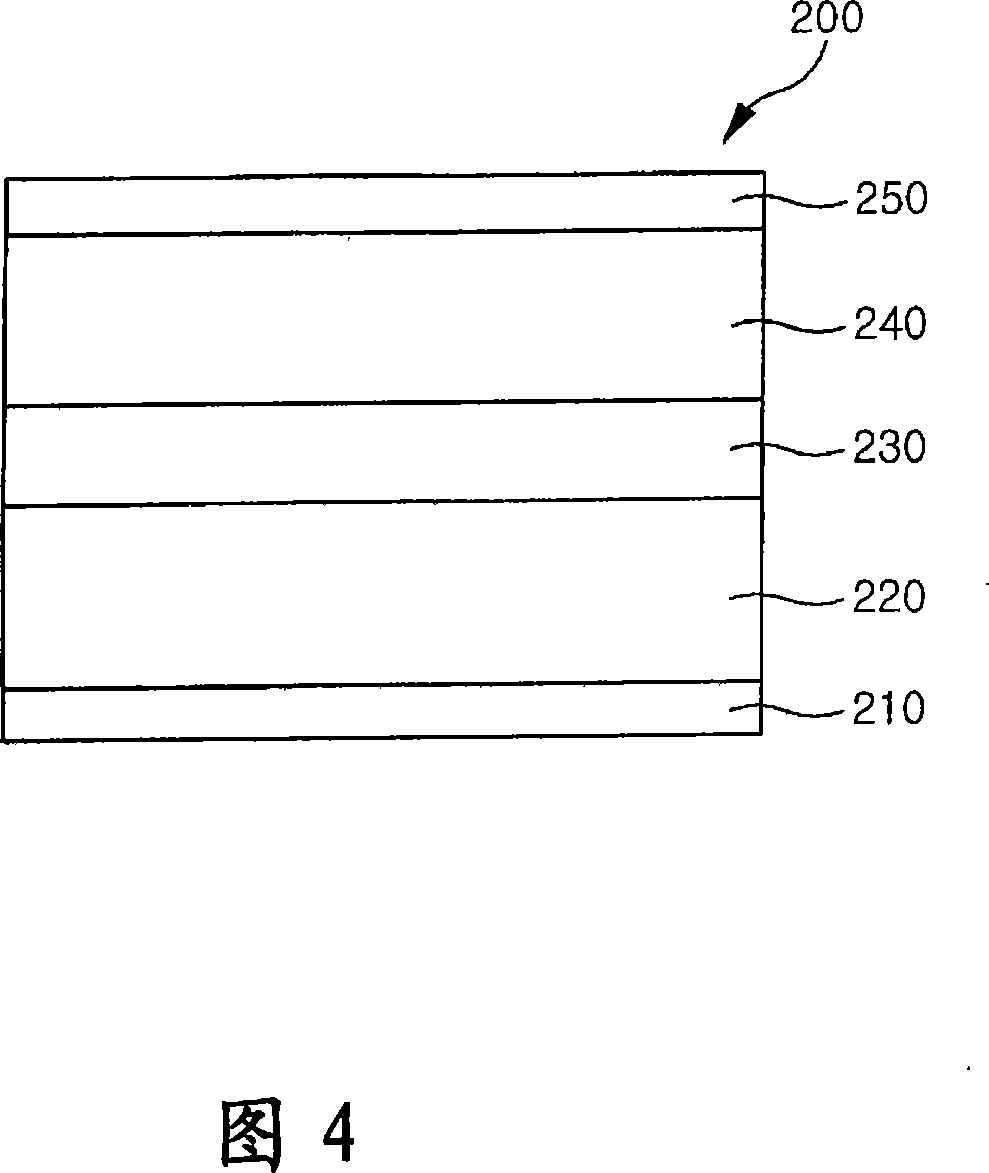

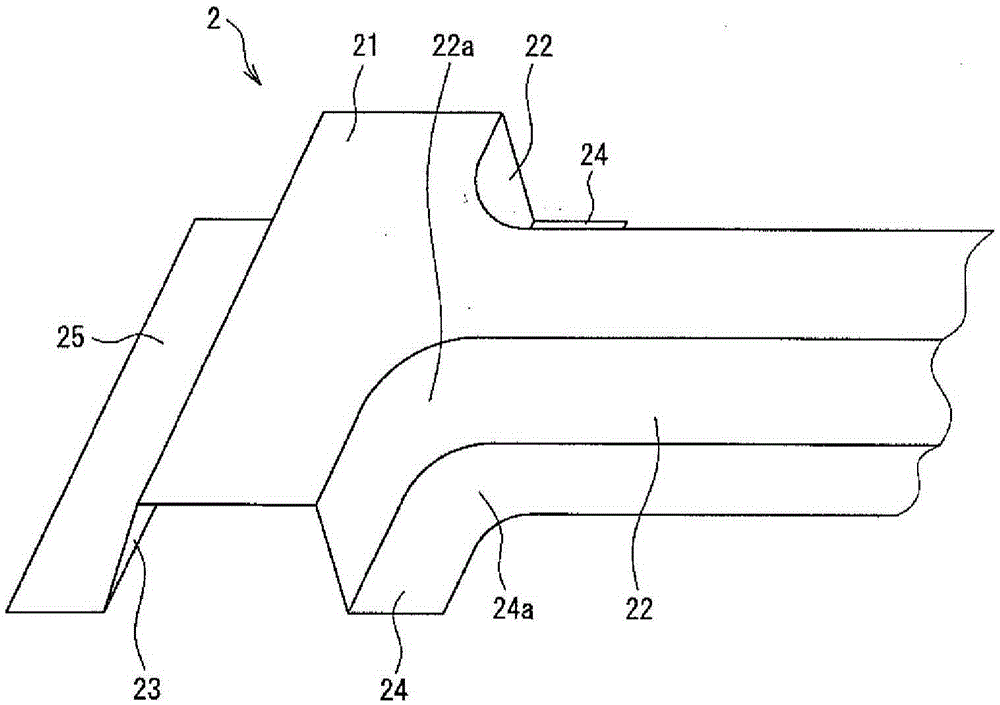

Container, injection molding method of container, and mold for injection molding of container

InactiveCN104070638AImprove air tightnessUniform contact pressureCans/barrels/drumsDomestic articlesNeck partsInjection molding machine

The invention discloses a container, an injection molding method of container, and a mold for injection molding of a container. The container, which is provided with a wide opening, and is disposed on the inner side of the container body in an inverted manner, can be used to improve the airtight performance of the container, and can be used to produce the container at low costs. The mold (200) is provided with a neck inside side mold (90),which is provided with a first molding surface capable of continuously molding from inner periphery of the neck part (112) of the container body (110) to the end part (118) of the opening part (117); a first sliding core (50) and a second sliding core (60), which penetrates the neck inside side mold (90), and can be used to form the continuous peripheral inverted buckles (114) facing to the inner periphery of the cylinder part (111) of the container body (110) and the inner periphery of the neck part (112); and a core block (70), which penetrates the neck inside side mold (90), and is configured to be in the area enclosed by the first sliding core (50) and the second sliding core (60).

Owner:ハタ

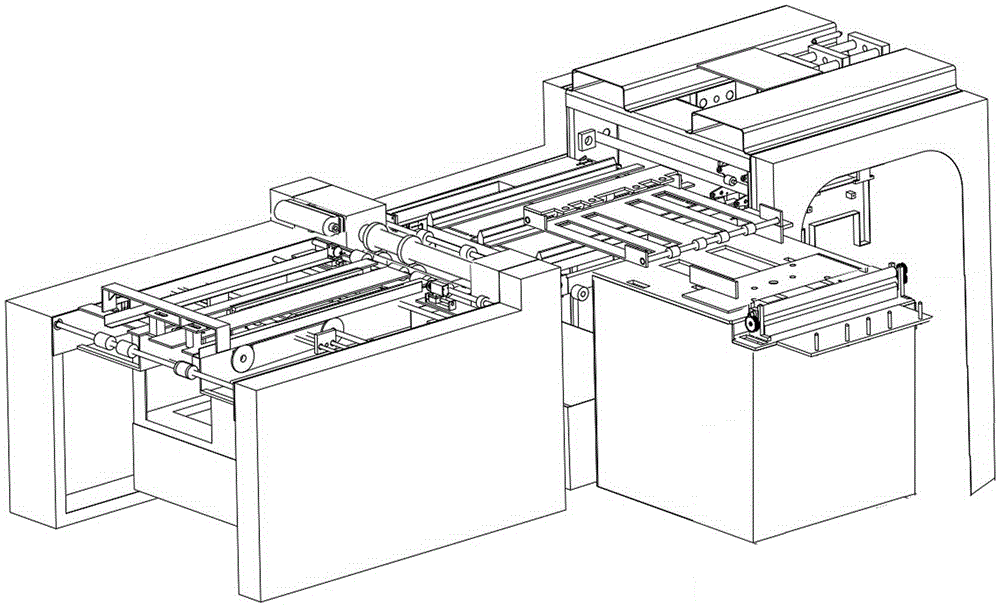

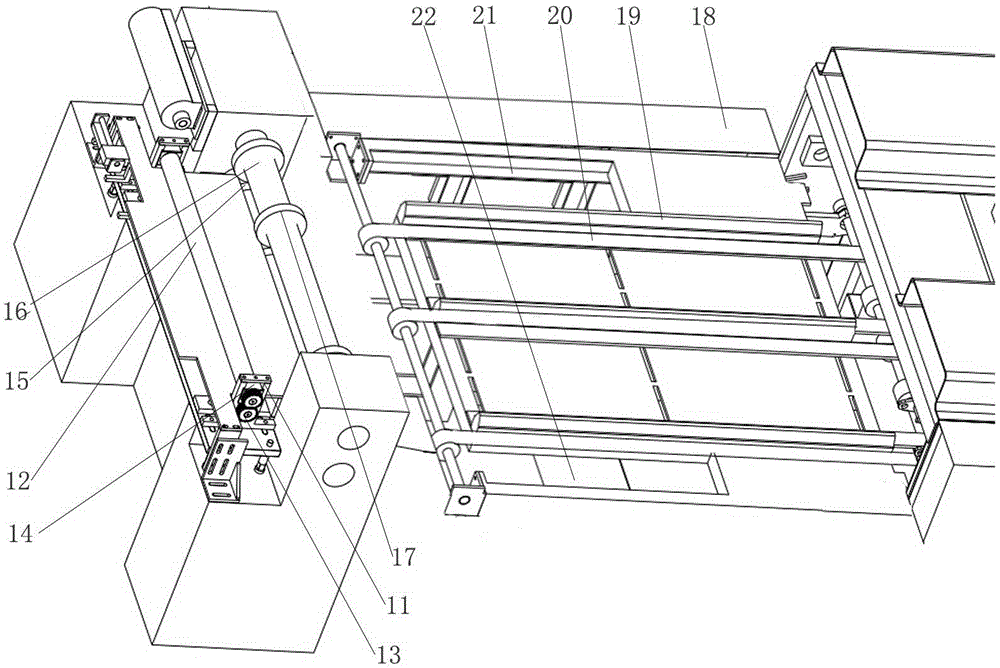

Metal sheet automatic cutting production line

ActiveCN105397170AReduce material wasteReduce manufacturing costShearing machinesShearing machine accessoriesEngineeringElectrical and Electronics engineering

The invention discloses a metal sheet automatic cutting production line. The metal sheet automatic cutting production line comprises a conveyor having a calibration device, a pressing cutter, an automatic detector and an absorption blanker arranged in sequence, wherein a conveying table is arranged at the downstream of the pressing cutter; and the tail end of the conveying table is connected with the absorption blanker. The metal sheet automatic cutting production line, disclosed by the invention, integrates conveying, calibration, pressing, cutting, online detection, electromagnetic absorption and vertical blanking as a whole, detects online to give an alarm through an alarm when discovering unqualified products, prompts to timely adjust the calibration device of the conveyor, guarantees metal sheets to be linearly conveyed and not deflected in the cutting and conveying process, and improves the product pass percent.

Owner:ZHENGZHOU JINTAI CANNER

Full-automatic circular sawing machine

InactiveCN105689793AHigh degree of automationReduce labor costsMetal sawing devicesCircular sawEngineering

The invention discloses a full-automatic circular sawing machine which comprises a material feeding mechanism, a material conveying mechanism and a circular sawing machine body, wherein the circular sawing machine body is mounted on a sliding rail on a base; the material conveying mechanism is mounted on one side of the circular sawing machine body and matched with the circular sawing machine body to complete material conveying and cutting actions; the material conveying mechanism consists of front and rear two clamping mechanisms which are connected with each other through a guide column; clamping assemblies are arranged on the front and rear clamping mechanisms; the front clamping mechanism is fixed, and the rear clamping mechanism can move back and forth along the guide column; the material feeding mechanism comprises a material conveying frame and a material storage rack arranged on one side of the material conveying frame; a workpiece on the material storage rack is transferred to the material conveying frame through a jacking mechanism; the material conveying mechanism is arranged at the end part of the material storage rack of the material feeding mechanism; the workpiece on the material storage rack is aligned to a clamping part of the rear clamping mechanism. The full-automatic circular sawing machine is high in automation degree; the labor cost can be greatly saved, and the production efficiency is improved. Meanwhile, the cutting length can be precisely controlled, and the disqualification rate of a product is reduced.

Owner:浙江百金机床制造有限公司

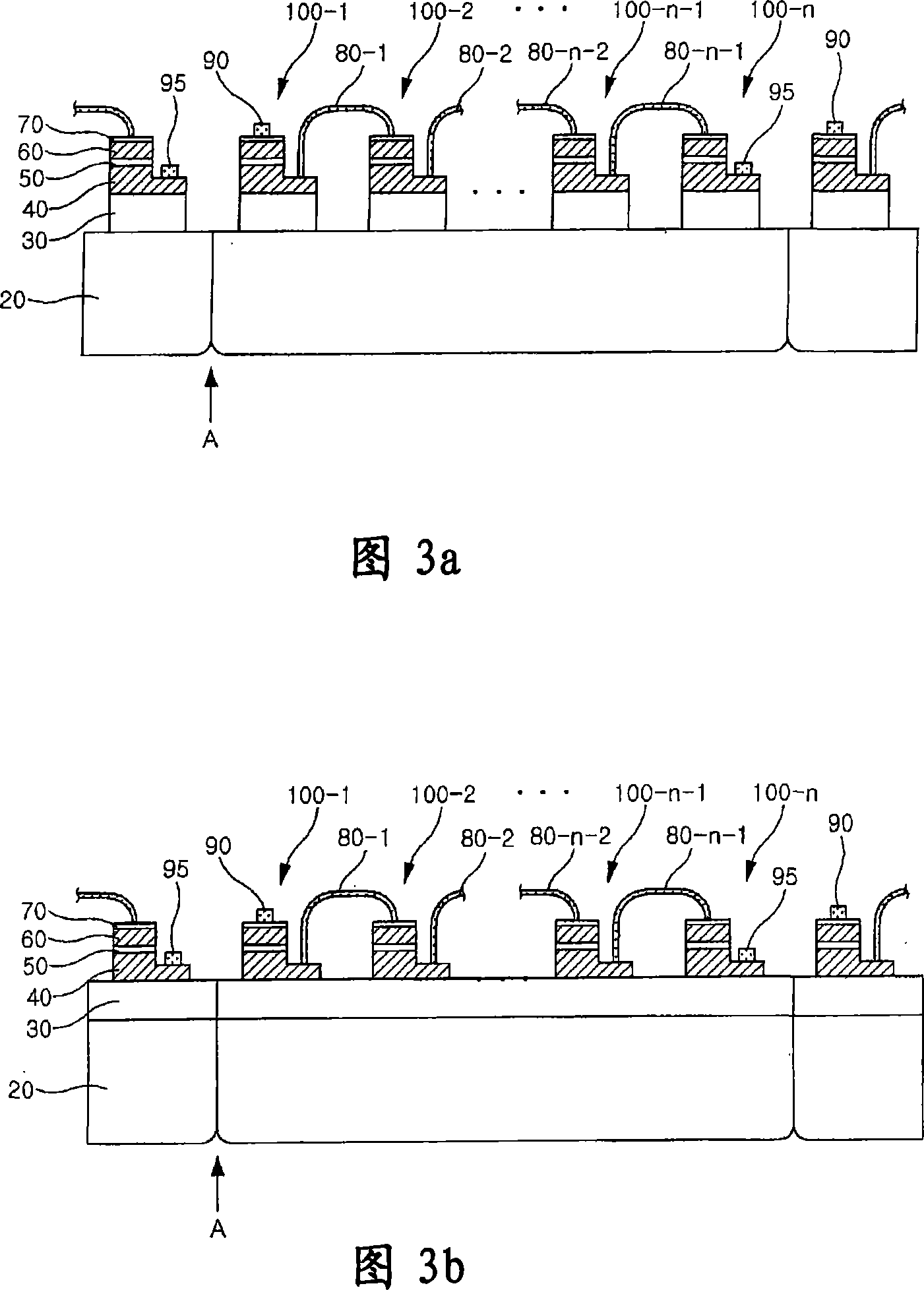

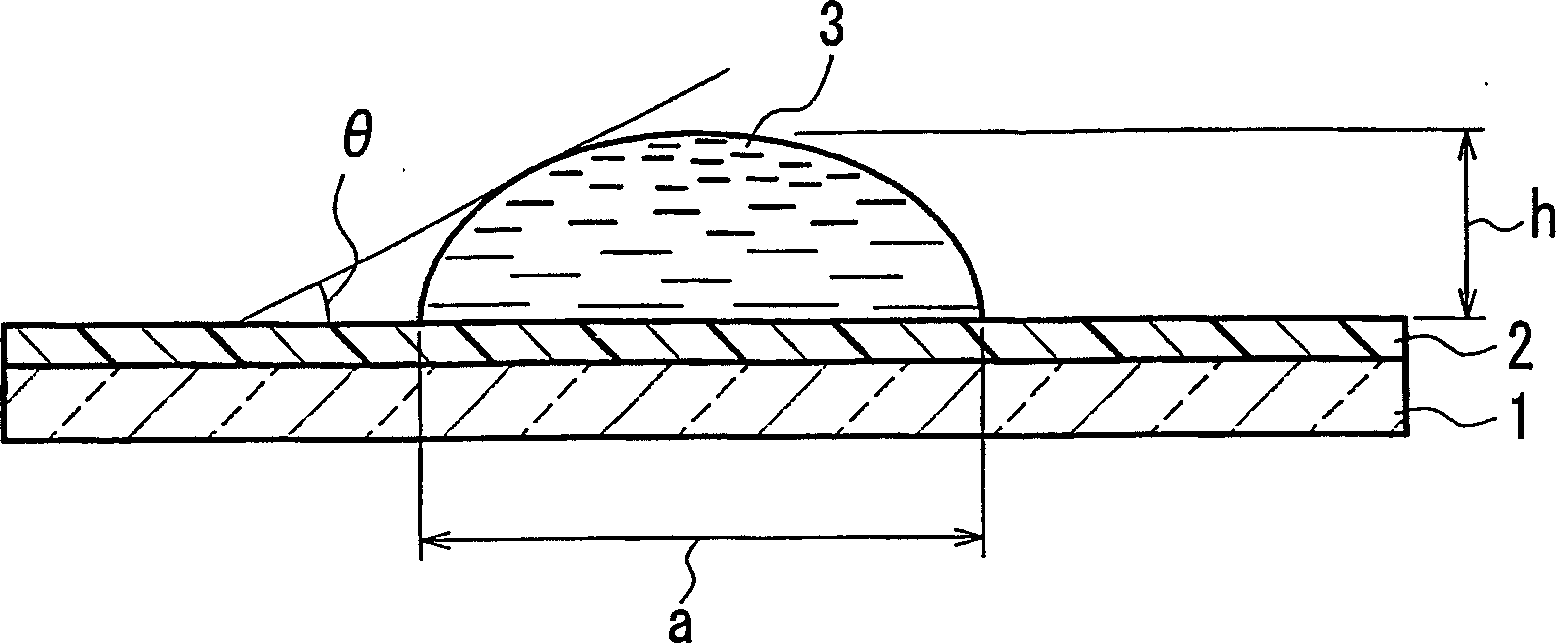

Light emitting element with a plurality of cells bonded, method of manufacturing the same, and light emitting device using the same

ActiveCN101015069ASimple manufacturing processReduce the failure rateSolid-state devicesSemiconductor lamp usageHigh volume manufacturingAC power

The present invention relates to a light emitting element with arrayed cells, a method of manufacturing the same, and a light emitting device using the same. The present invention provides a light emitting element including a light emitting cell block with a plurality of light emitting cells connected in series or parallel on a single substrate, and a method of manufacturing the same, wherein each of the plurality of light emitting cells includes an N-type semiconductor layer and a P-type semiconductor layer, and the N-type semiconductor layer of one light emitting cell is electrically connected to the P-type semiconductor layer of another adjacent light emitting cell. Further, the present invention provides a light emitting device including a light emitting element with a plurality of light emitting cells connected in series. Accordingly, it is possible to simplify a manufacturing process of a light emitting device for illumination capable of being used with a household AC power source, to decrease a fraction defective occurring in manufacturing a light emitting device for illumination, and to mass-produce the light emitting device for illumination. Further, there is an advantage in that DC driving efficiency can be enhanced in an AC operation by installing a predetermined rectifying circuit outside the light emitting element.

Owner:SEOUL VIOSYS CO LTD

Crystalline silica solar energy cell PECVD rainbow film reworking method

ActiveCN102306687AImprove pass rateImprove yieldFinal product manufactureCleaning using liquidsRainbowMolecular physics

The invention relates to solar energy cell sheet processing. Concretely the invention is a crystalline silica solar energy cell sheet plasma enhanced chemical vapor deposition (PECVD) method rainbow film reworking method which is a cleaning process method of a cell sheet having a rainbow film on a surface, and the rainbow film is caused by abnormal discharge in a process of preparing a crystalline silica solar energy cell sheet by utilizing a plasma enhanced chemical vapor deposition method. The cell sheet which is processed by the reworking method is subjected to film plating, printing, and sintering anew, conversion efficiency of the cell sheet can reach a normal level of a cell sheet, appearance of the cell sheet is the same as a normal cell sheet, and a purpose of reworking cleaning is achieved.

Owner:湖南红太阳新能源科技有限公司

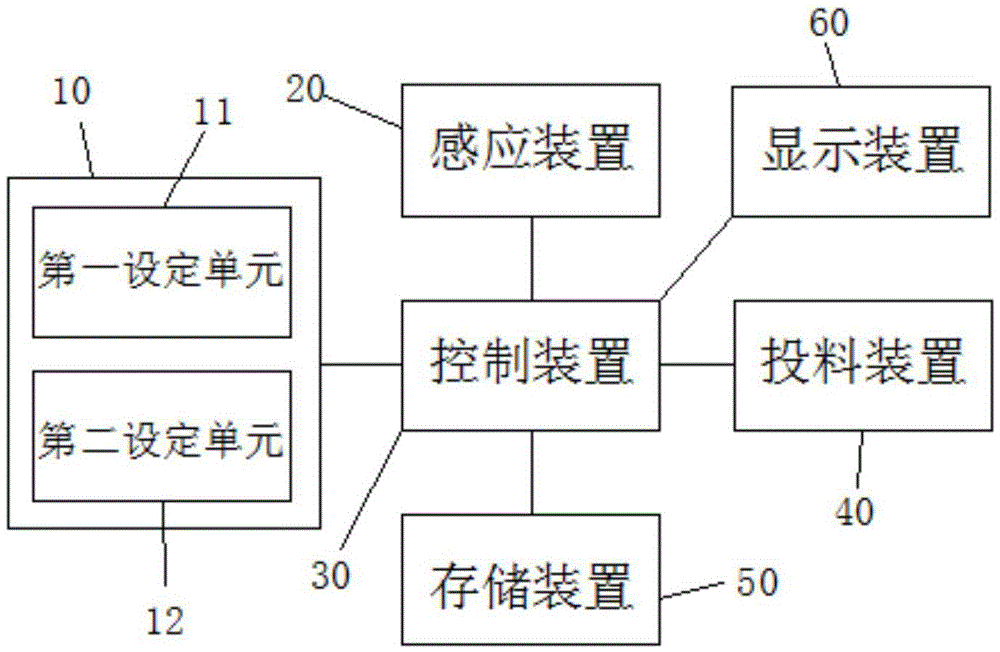

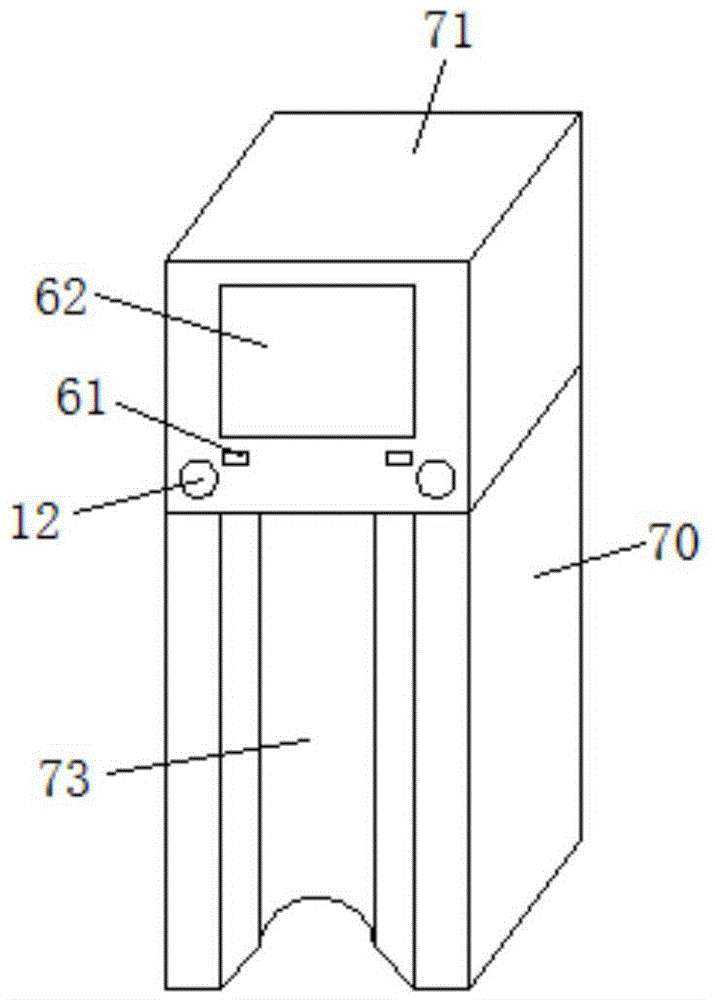

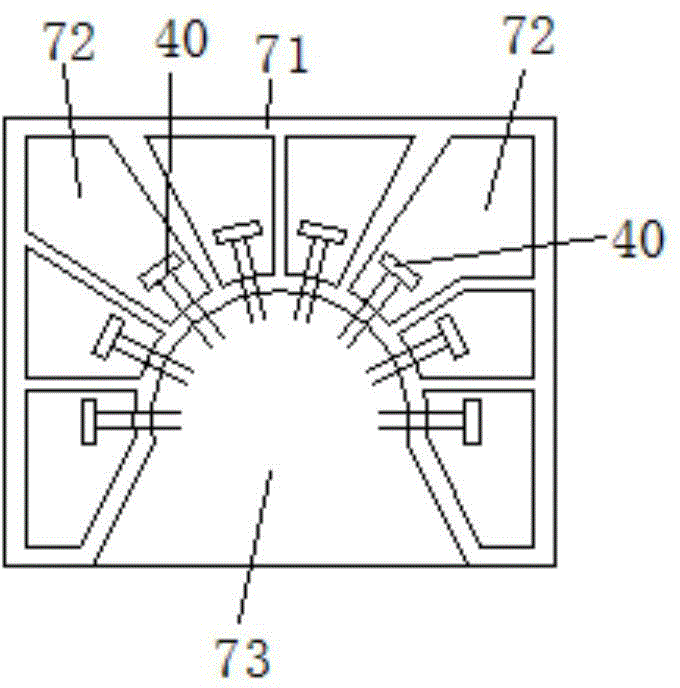

Seasoning adding control system and seasoning adding device

InactiveCN104688097AAvoid standardizationAvoid procedural workKitchen equipmentFlavorAutomatic control

The invention relates to a seasoning adding control system. A setting device sets a current processed dish and a required flavor and sends information to a control device, the control device acquires a seasoning ratio matched with the dish and the flavor by means of program calculation, a sensing device sends signals to the control device after sensing a cooking spoon put by a cook, the control device sends control instructions to the seasoning adding device, the seasoning adding device adds seasonings according to the seasoning ratio, and seasoning adding time, types and quantities can be controlled automatically. The invention further provides the seasoning adding device with the control system. The seasoning adding control system and the seasoning adding device have the advantages that dish processing efficiency can be improved evidently, time cost is reduced for catering enterprises, and competitiveness is promoted.

Owner:欧阳亮

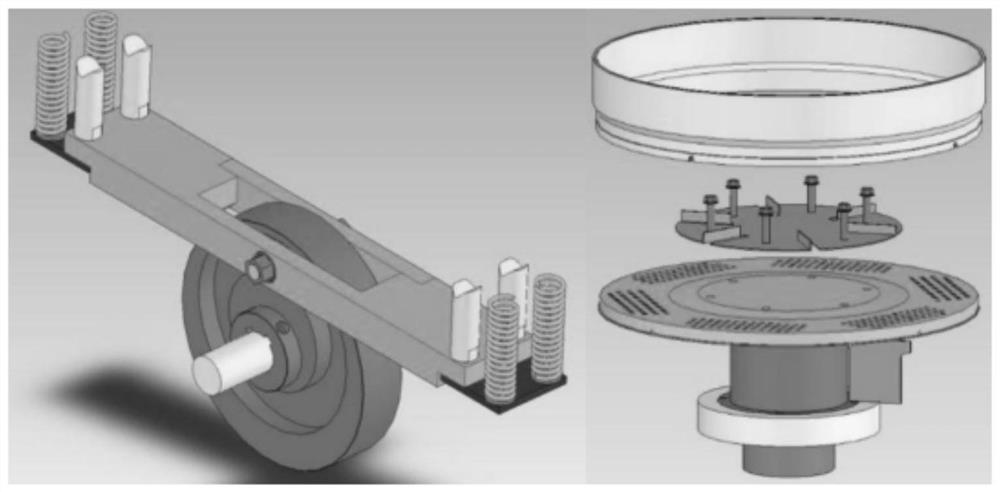

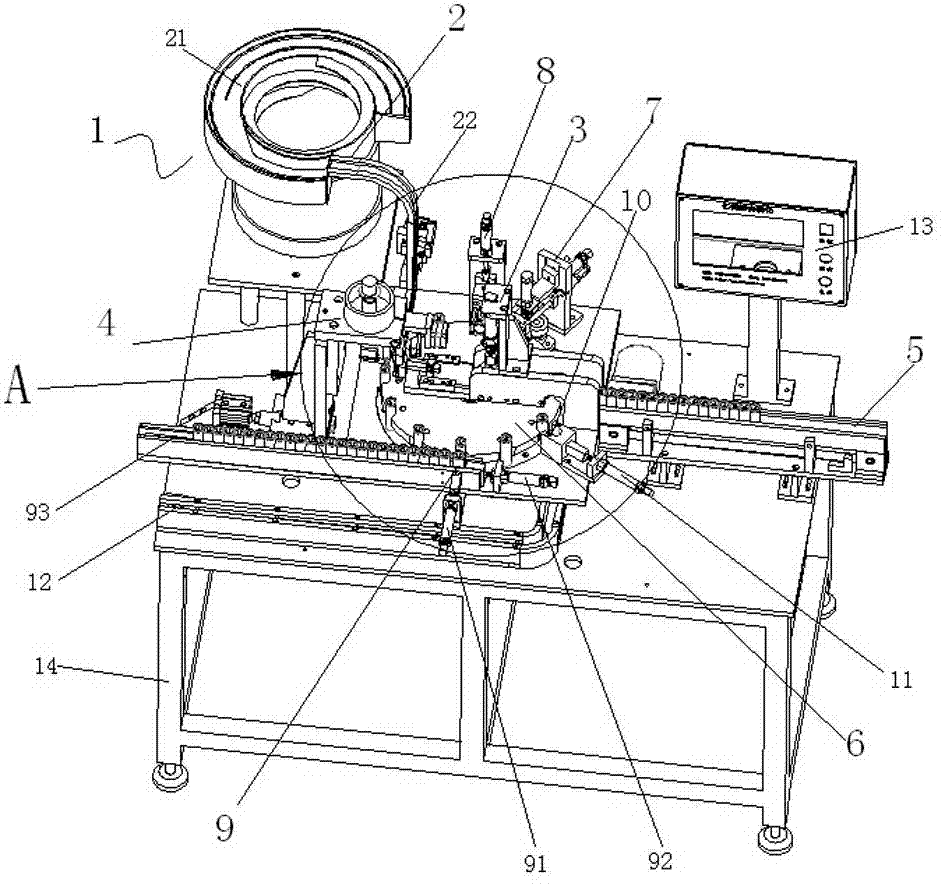

Automatic cylindrical battery cap welding machine

ActiveCN104505486AImprove work efficiencyReduce the failure rateCell component detailsNozzleUltrasound control

The invention provides an automatic cylindrical battery cap welding machine. The automatic cylindrical battery cap welding machine comprises a rack and a cap welding device arranged on the rack, wherein the cap welding device comprises a cap discharging unit, a cap pushing unit and an ultrasonic welding unit; the cap discharging unit comprises a vibrating disk, a cap discharging groove and a cap anti-explosion point locating unit; the cap pushing unit comprises a vacuum suction nozzle for sucking caps from the cap discharging groove and a cap pushing air cylinder connected with the vacuum suction nozzle; and the ultrasonic welding unit comprises an ultrasonic controller and a battery pushing-up air cylinder, and an anode tab and the cap are welded by an ultrasonic welding head connected with the ultrasonic controller. According to the automatic cylindrical battery cap welding machine, the battery production process is full-automatic, the working efficiency is greatly improved, the unqualified rate of products can be reduced through accurate cooperation of precise parts, time and labor are saved, and the qualified rate of the products is increased.

Owner:惠州亿恒特自动化科技有限公司

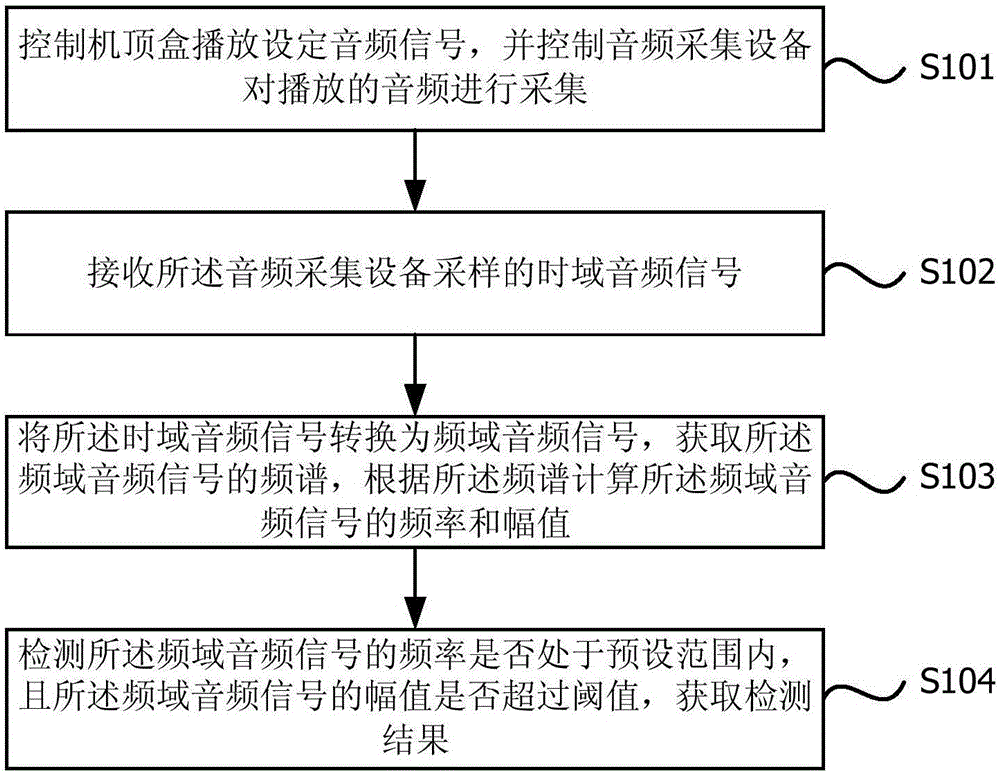

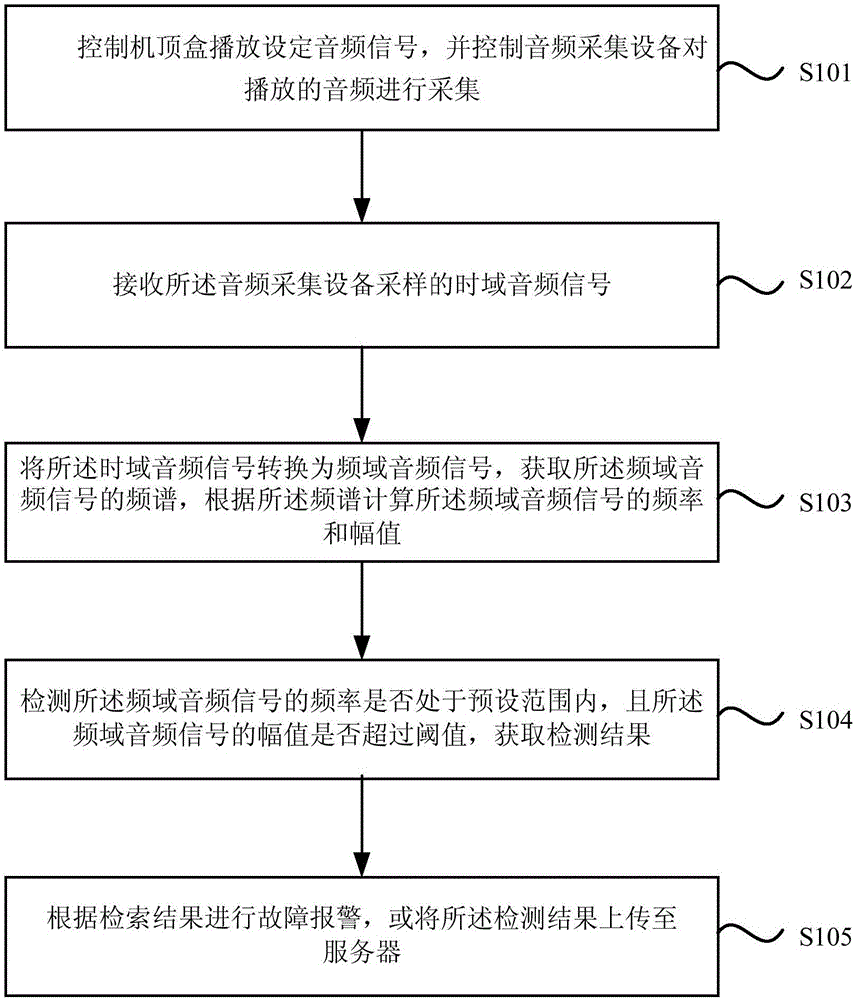

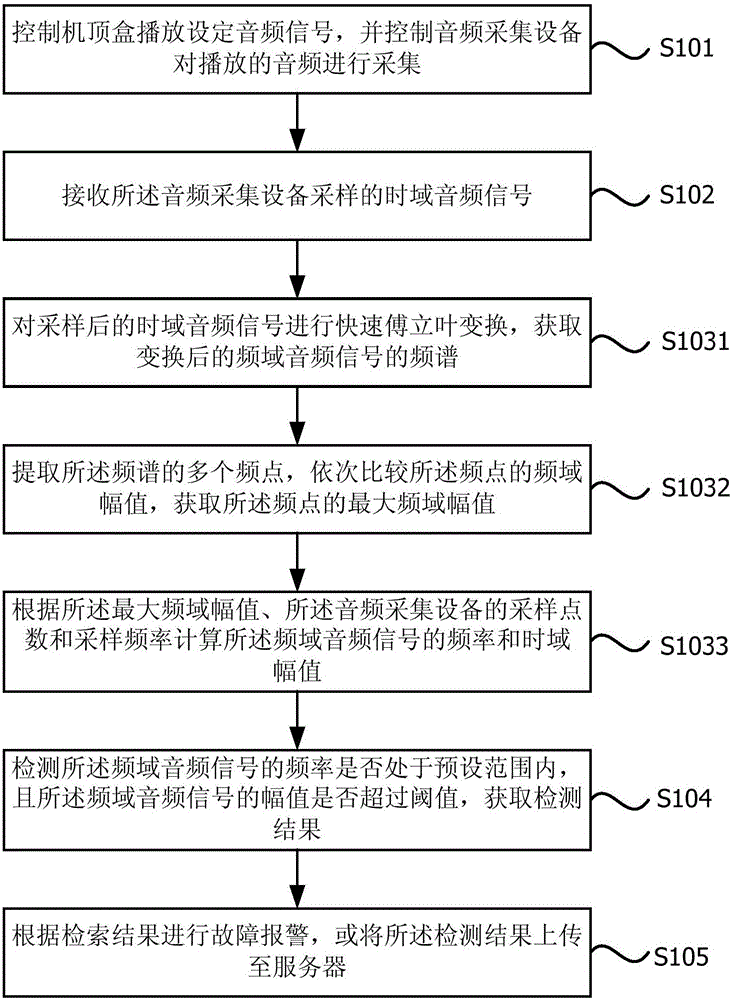

Audio automatic testing method and terminal

InactiveCN106791825AAvoid errorsAvoid misjudgmentTelevision systemsSelective content distributionTime domainFrequency spectrum

The embodiment of the invention discloses an audio automatic testing method and terminal. The method comprises the steps of: controlling a set top box to play a set audio signal, and controlling audio acquisition equipment to acquire a played audio; receiving a time domain audio signal sampled by the audio acquisition equipment; converting the time domain audio signal into a frequency domain audio signal, acquiring a frequency spectrum of the frequency domain audio signal, and according to the frequency spectrum, calculating a frequency and an amplitude of the frequency domain audio signal; and detecting whether the frequency of the frequency domain audio signal is in a preset range and whether the amplitude of the frequency domain audio signal exceeds a threshold, and acquiring a detection result. By the technical scheme of the invention, an error and misjudgment which are caused by manual operation can be effectively prevented, detection accuracy is high, detection efficiency is effectively improved, and production cost is saved.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

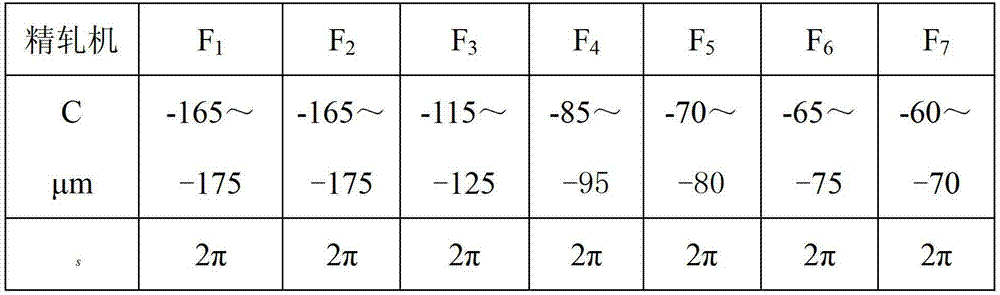

Plate shape control method of hot rolled high-strength thin strip steel

InactiveCN103203369AQuality improvementReduce the failure rateProfile control deviceProcess systemsWork roll

The invention provides a plate shape control method of hot rolled high-strength thin strip steel. A work roll shifting mill is used as a finishing mill group; the adopted roll shape of a work roll is a cosine roll type curve; a varying contact supporting roll shape technology is adopted by the roll shape of a supporting roll; a high-frequency large-stroke roll shifting strategy is performed; the proportion convexity of the strip steel reaches a set target proportion convexity through front four finishing mills; a rear mill keeps a constant proportion convexity; the plate shape straightness target value is 0-5 IU; an edge masking technology is adopted by laminar cooling; and the strip steel rolling rhythm is controlled to be 135-145 s / roll. Through integral design of a plate shape control system of type configuration, roll shape design, process system, model control and the like, the problems of large fluctuation of the plate shape of the high-strength thin strip steel and uncontrolled composite wave shape in a rolling process are solved, and the straightness of the hot rolled high-strength thin strip steel can be controlled at a high standard level within 20 IU, so that the plate shape quality of the high-strength thin strip steel is greatly improved and the disqualification rate is reduced.

Owner:ANGANG STEEL CO LTD

Method for preventing shell expansion of thick and large surface of precision-casting stainless steel casting

InactiveCN102189220AReduce the failure rateReduce laborFoundry mouldsFoundry coresProduction rateRefractory

The invention relates to a method for preventing shell expansion of a thick and large surface of a precision-casting stainless steel casting. The method comprises the following steps of: 1, manufacturing all layers according to a traditional process till the layer of shell where a thick and large surface of a precision-casting stainless steel casting shell is bundled with iron wires, wherein the layer of shell bundled with iron wires can be any layer between the fourth layer and the antepenult layer and one thick and large surface is bundled with two rounds of iron wires between which the distance is not larger than 70mm; 2, completely covering the bundled iron wires with a pasty fireproof coating, completely filling gaps between the iron wires and previous layer of shell with the fireproof coating, and spreading fireproof sand on the pasty fireproof coating; 3, drying the pasty fireproof coating and the fireproof sand on the iron wires, and then fabricating next layer of shell till subsequent shell fabrication is completed according to process requirements; 4, dewaxing; 5, roasting; and 6, casting the shell. By the method disclosed by the invention, the percent defective of castings, caused by shell expansion, can be reduced to below 1.5% from the original more than 25%, labor load of subsequent process steps can be reduced greatly, and productivity is improved.

Owner:SHANDONG TAISHAN STEEL GROUP

Method for preparing high-purity low-chlorine electroplating-grade cupric oxide

InactiveCN103101957AAvoid bringing inGuaranteed purityEnergy inputCopper oxides/halidesDecompositionCarbonization

The invention discloses a method for preparing high-purity low-chlorine electroplating-grade cupric oxide. According to the method, copper, liquid ammonia and high-purity carbon dioxide are taken as raw materials, stronger ammonia water is prepared firstly, carbonated ammonia water is obtained through introducing the high-purity carbon dioxide into the stronger ammonia water and controlling carbonization degree, the carbonated ammonia water reacts with the copper under certain air pressure so as to prepare copper-ammonia complexation liquid, the copper-ammonia complexation liquid is then subjected to heating, ammonia distilling, separating, washing, drying and sieving so as to prepare high-purity heavy basic copper carbonate, and the heavy basic copper carbonate is then subjected to heating calcination and decomposition, thereby preparing the high-purity low-chlorine electroplating-grade cupric oxide. According to the method, the carbon dioxide is directly used as a raw material, so that the problems of the traditional method that impurities, such as heavy metal ions and chloride ions, are introduced by raw materials used in the production of basic copper carbonate are solved, the rate of reaction is increased, the production cycle is shortened, the production efficiency is greatly increased, and products are low in impurity content, high in purity, high in activity and wider in application; and meanwhile, the method is high in yield, low in energy consumption, and low in cost and hardly causes pollution.

Owner:TAIXING SMELTING PLANT

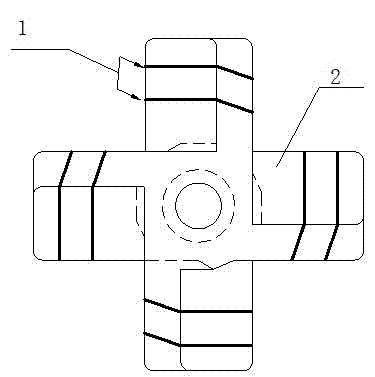

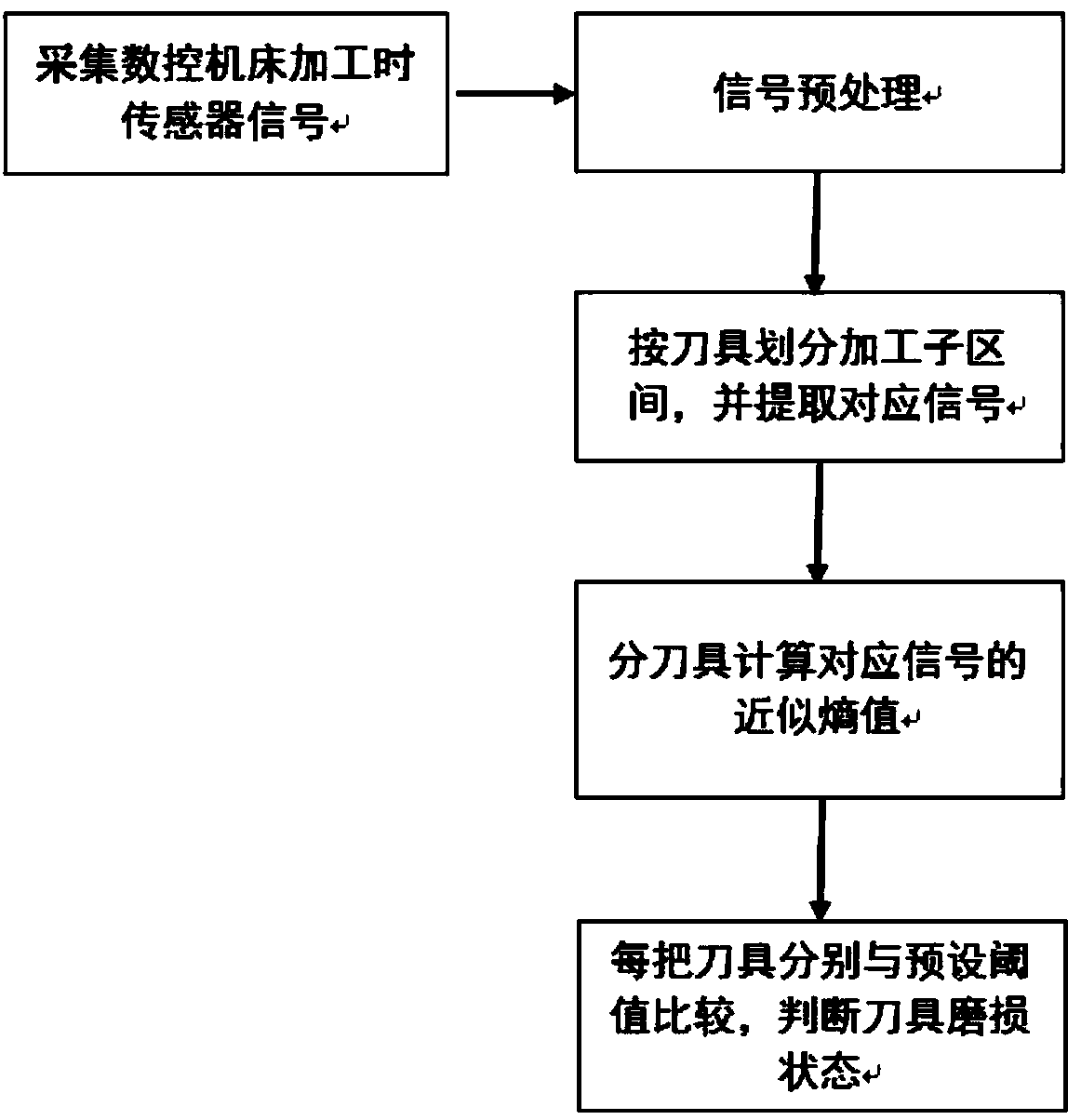

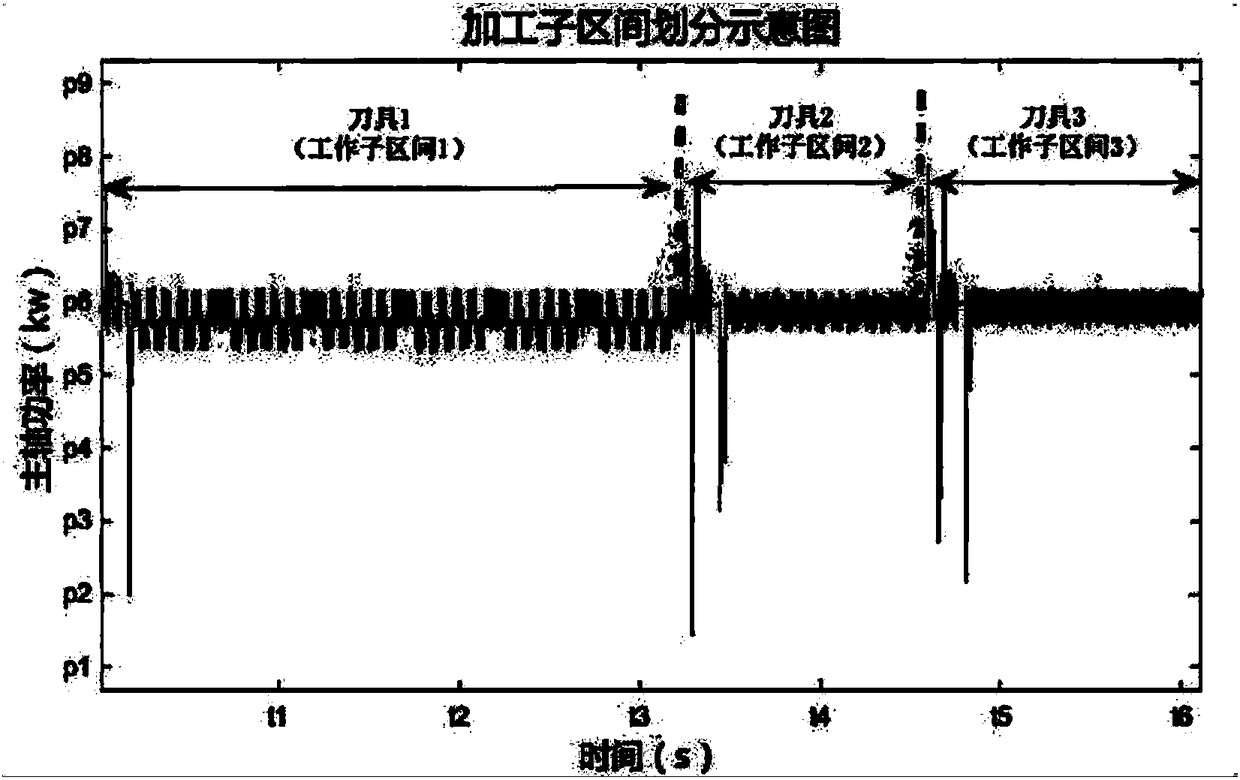

Numerical control machine tool cutting tool wear state real-time monitoring method

ActiveCN108490880ANo change in structureDoes not affect dynamic characteristicsProgramme controlComputer controlNumerical controlMeasurement device

The invention discloses a numerical control machine tool cutting tool wear state real-time monitoring method, which comprises the following steps: collecting sensor signals during machining of a numerical control machine tool in real time, and carrying out signal preprocessing; dividing the machining process into a plurality of working subintervals according to different machining tools, and extracting signal data during machining of each tool of the numerical control machine tool; calculating approximate entropy of the signal obtained during machining of each tool of the numerical control machine tool; and comparing the calculated approximate entropy of each tool and a preset threshold, and judging the tool wear state. The method has the advantages of needing no measuring equipment and needing no construction of an experiment platform, and is fast in prediction speed and high in accuracy; and meanwhile, the tool does not need to be assembled or disassembled, normal machining of the numerical control machine tool is not affected, and real-time monitoring of the wear state of the numerical control machine tool cutting tool can be realized.

Owner:谷城万利铸造有限公司

High-purity copper or high-purity copper alloy sputtering target, process for manufacturing the sputtering target, and high-purity copper or high-purity copper alloy sputtered film

ActiveCN102165093AReduce the failure rateInhibitionVacuum evaporation coatingSputtering coatingNon-metallic inclusionsRejection rate

A high-purity copper or high-purity copper alloy sputtering target which has a purity of 6N or higher and in which the contents of P, S, O, and C are each 1ppm or lower, characterized in that the content of non-metallic inclusions having particle diameters of 0.5 to 20[mu]m is 30,000 pieces / g or lower. The rejection rate of wirings of semiconductor devices, said wirings being formed by sputtering a high-purity copper target, is lowered with high reproducibility by using, as the raw material, high-purity copper and / or a high-purity copper alloy which have a reduced content of harmful P, S, C and O type inclusions, and thus controlling the form of existence of non-metallic inclusions.

Owner:JX NIPPON MINING & METALS CORP

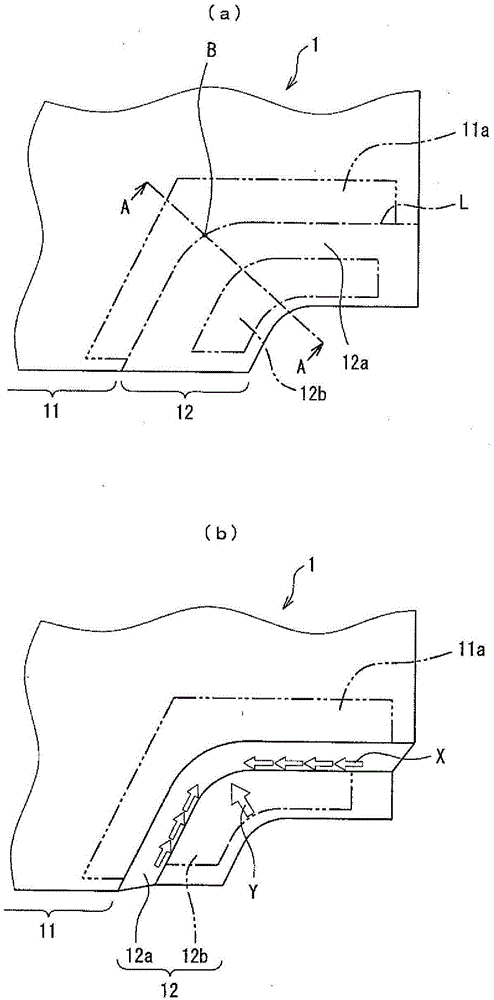

Press molding method

ActiveCN105392575ARestrains deformation of elongated flangesAvoid crackingVehicle componentsShearing deformationEngineering

The present invention provides a method for manufacturing a bent channel component having a bend in a vertical wall thereof by press molding, the method mitigating stretch flange deformation, which occurs in the vertical wall portion and a flange portion. This method for manufacturing a bent channel component has a shearing deformation step as a step for forming the vertical wall portion. In the shearing deformation step, a boundary portion (11a) between a base (11) and a deformed portion (12) of a blank (1), and an external portion (12b) of the deformed portion (12) are separately restrained, a portion (12a) to be a vertical wall of the deformed portion (12) is shear-deformed along the plate surface thereof, and a material is caused to flow from a portion separated from the bend to the bend (movement of material in the blank) in an outer edge of the portion (12a) to be the vertical wall.

Owner:JFE STEEL CORP

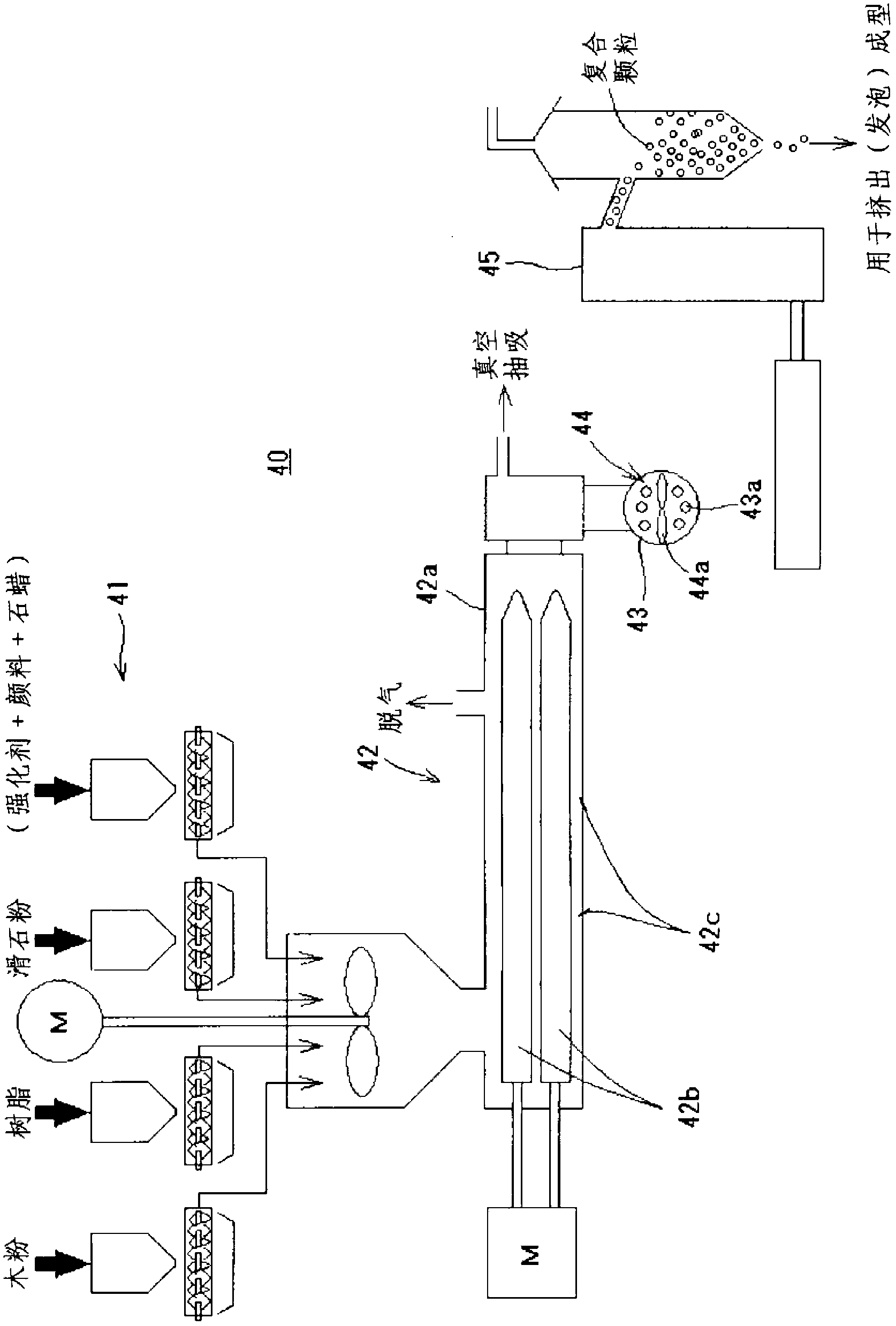

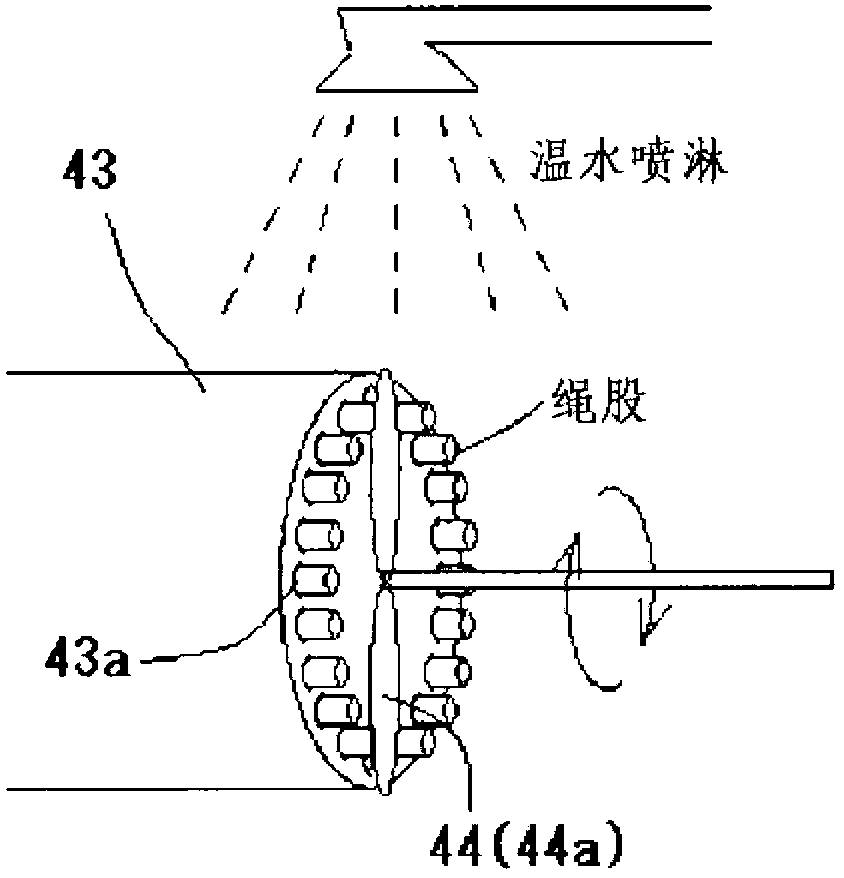

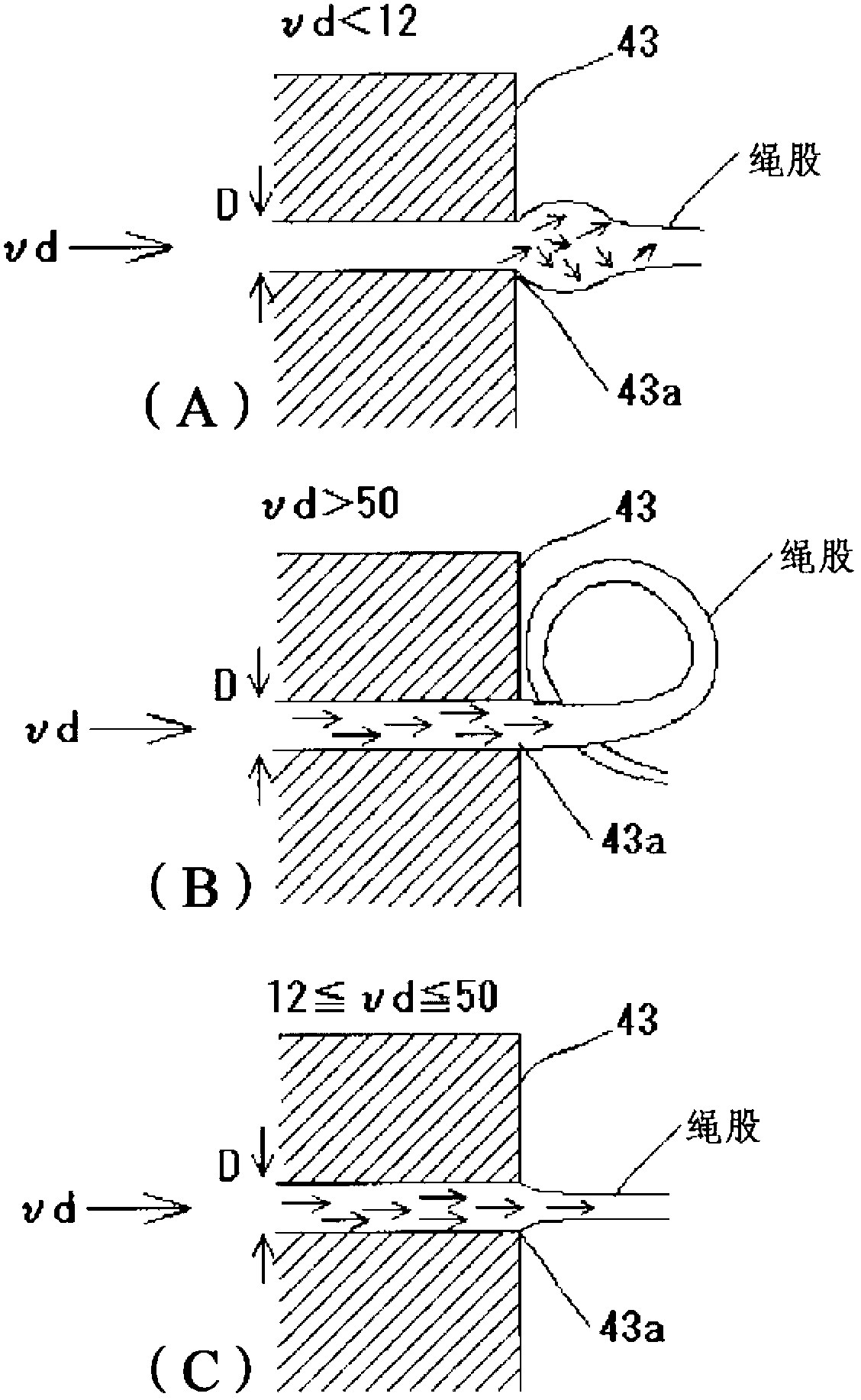

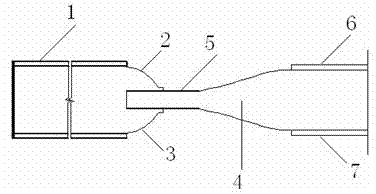

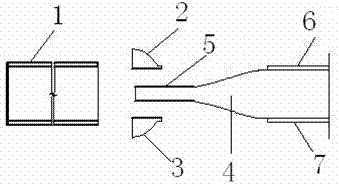

Method for producing composite pellet for extrusion molding, and composite pellet for extrusion molding produced by the method

InactiveCN102869484AInhibit swellingAvoid contactFlat articlesDomestic articlesHydroxystearic AcidVolumetric Mass Density

Disclosed are composite pellets for extrusion molding wherein fusion does not occur between the pellets, and there is no variation in size and density. A molten material obtained by an extruder for a raw material containing a thermoplastic resin and wood powder is extruded into a strand shape through a die nozzle of the extruder, and cut into a predetermined length to form a pellet. At this time, the extrusion amount, the diameter of each nozzle hole, and the number of nozzle holes are adjusted so that the linear velocity (vd) of the molten material in each nozzle hole of the die nozzle is in the range of 12 to 50 cm / sec. Further, regardless of the variations in particle diameter, etc., a stable amount of the composite pellets are supplied to the extruder, and smoothly introduced to a screw of the extruder. The composite pellets and 12-hydroxystearic acid containing a metal of Ca, Mg, or Zn are agitated together, and 0.03 to 0.4 mass% of the 12-hydroxystearic acid is attached to the periphery of 100 mass% of the composite pellet, and the pellets are used for extrusion molding.

Owner:WPC CORP

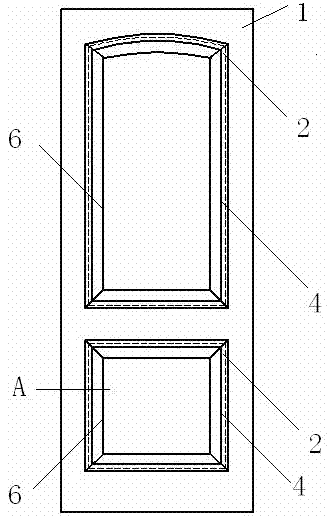

Wooden door processing technology for conveniently improving production efficiency

ActiveCN103029194AReduce size requirementsEfficient use ofWood working apparatusUltravioletEngineering

The invention discloses a wooden door processing technology for conveniently improving production efficiency, which comprises the following processing technologies of: (1) a processing technology for a door leaf of a wooden door; and (2) a processing technology for a doorframe 16 of the wooden door. Both the processing technologies comprise the following steps of: (1) a process of processing and forming each component in advance, wherein a door leaf frame and a flexible cord frame are formed in a splitting manner; (2) a process of painting each component, i.e. painting the parts with large painting areas and flat surfaces in a manner of adopting a machine to carry out roll coating and enabling each part which is painted in a manner of adopting the machine to carry out roll coating to be irradiated by ultraviolet (UV) and be subjected to drying treatment; and (3) an assembling process, i.e. assembling the parts which are completed in the painting process in the step (2) according to a special corresponding structure obtained in the step (1) of processing and forming in advance so as to respectively obtain the door leaf of the wooden door and the doorframe of the wooden door. According to the invention, labor cost can be reduced, controllability of product quality is improved and wooden door production efficiency is greatly improved.

Owner:重庆积艺智能家居有限公司

Paper box inner box forming equipment and forming method thereof

PendingCN108466449AReduce manufacturing costLow application costBox making operationsPaper-makingEngineeringMachining process

The invention discloses a paper box inner box forming equipment and a forming method thereof, and belongs to the technical field of packaging equipment. An enclosing strip mold forming mechanism, an inner box forming rotary plate mechanism, an inner box pressure maintaining rubberizing mechanism and other mechanisms are arranged for completing processing of all links in the inner box forming process correspondingly, the inner box forming process is conducted on a rotary plate, a plurality of inner box forming cavities are formed in the rotary plate and correspondingly provided with a lower cover charging mechanism, a lower cover gluing mechanism, an upper cover charging mechanism and the parts for completing charging and machining processes of all materials in the inner box forming processing, and thus inner box forming is completed. According to the paper box inner box forming equipment and the forming method thereof, through coordinate operation of the multiple mechanisms or devices,unintermittent inner box precise forming can be achieved, compared with traditional manual forming techniques, the precision in the inner box forming process is effectively ensured, the inner box forming efficiency is improved, the production cost of inner boxes even paper boxes is lowered, and the paper box inner box forming equipment and the forming method thereof have great application value.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

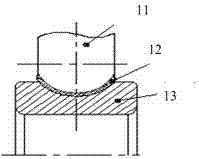

Novel plunge type inner/outer curved surface cutting/grinding/polishing process and system

InactiveCN102441830AInsufficient trimming accuracy defectsReduce the failure ratePolishing machinesLapping machinesPolishingMachine

Disclosed is plunge type inner / outer curved surface cutting / grinding / polishing process, which comprises a hard pressure head, a cutting layer and a workpiece. The appearance of the hard pressure head can be optionally selected according to needs, the shape of an end of the hard pressure head is processed and shaped according to technical process requirements on an inner / outer curved surface of the workpiece, and the hard pressure head can be made of metal and nonmetal materials while the rigidity, the abrasion resistance and the size of the pressure head are determined according to conditions of machines and equipment. The cutting layer is made of composite cutting materials, is high in strength, not easy to be broken and fine in coincidence property, is heat-resistant, and can realize cutting / grinding / polishing effects. The workpiece is a processed part. By the aid of plunge type cutting / grinding / polishing of the forming hard pressure head, deviation of shapes and positions of inner / outer curved surfaces caused by conventional grinding wheels and abrasive stones can be avoided, the shortcoming of poor precision caused in a previous production procedure can be overcome, and reject ratio of products can be greatly reduced. The plunge type cutting / grinding / polishing technology has the advantages that firstly, the shape of the same pressure head can keep basically consistent regardless of the amount of curved surfaces of workpieces processed by the aid of the hard pressure head, and secondly, inner / outer curved surfaces in any shapes can be processed only by means of changing the shape of the pressure head, and application range of the plunge type inner / outer curved surface cutting / grinding / polishing process is wide.

Owner:上海腾企机械技术配套有限公司

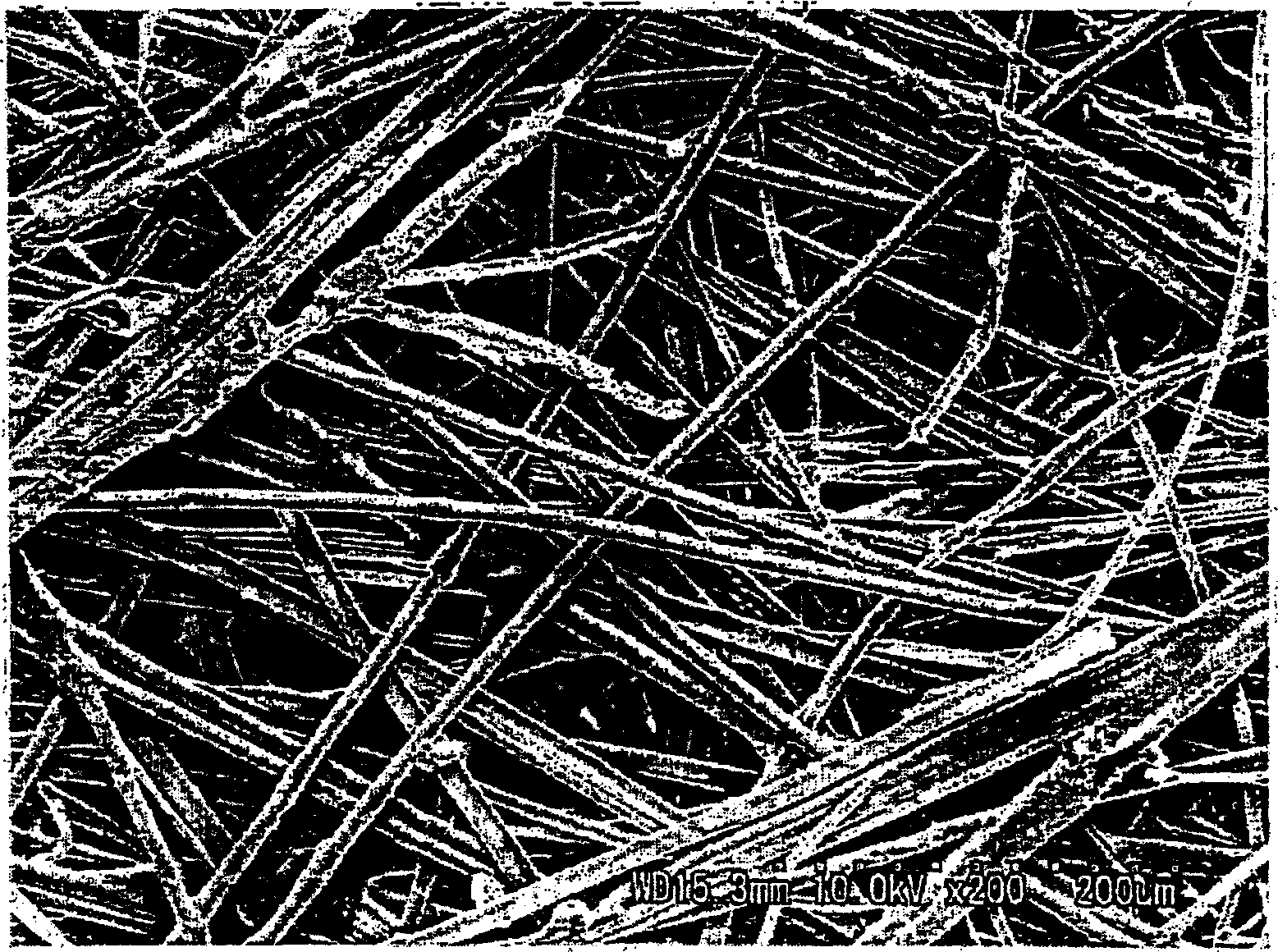

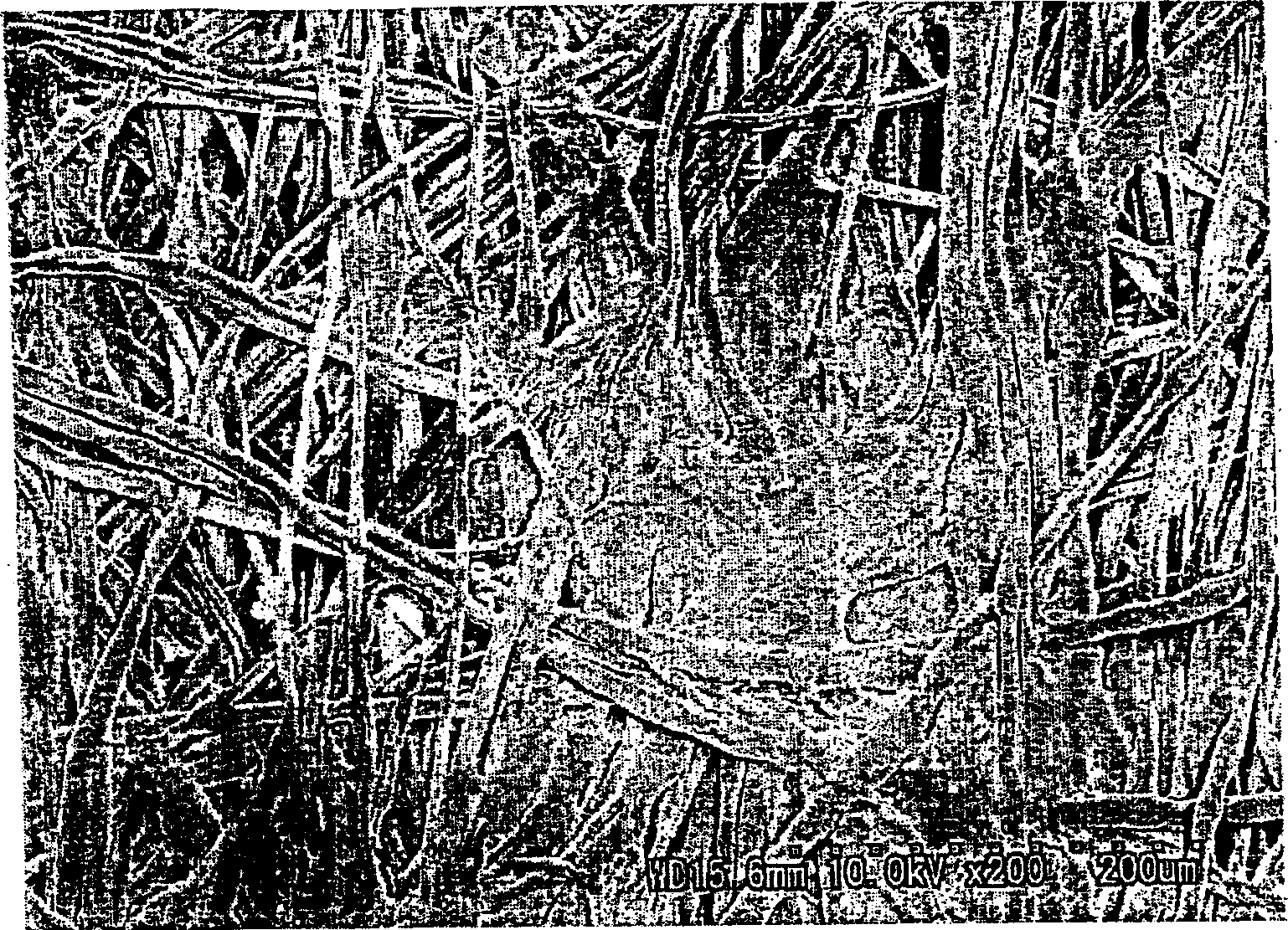

Separator for organic electrolyte battery, process for producing the same and organic electrolyte battery including the separator

InactiveCN1708865AImprove yieldImprove retentionCell seperators/membranes/diaphragms/spacersFinal product manufacturePore diameterNonwoven fabric

The separator for an organic electrolyte battery of the present invention is composed of a non-woven fabric containing a wet heat gelling resin capable of being gelled by heating in the presence of moisture and other fibers that are moist-heated from the wet heat gelling resin The gelled product is fixed, and the average pore diameter of the nonwoven fabric measured in accordance with ASTM F316 86 is in the range of 0.3 μm to 5 μm, and the maximum pore diameter is in the range of 3 μm to 20 μm. In this way, the other fibers constituting the nonwoven fabric can be fixed with the hydrothermal gelling resin, and the desired average pore size and maximum pore size can be obtained, thus providing an organic electrolyte battery with good safety, less short circuit, and excellent battery characteristics. .

Owner:DAIWA BOSEKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com