Method for producing composite pellet for extrusion molding, and composite pellet for extrusion molding produced by the method

A composite granule and extrusion molding technology, which is applied in the field of the manufacture of composite granules for extrusion molding and the field of composite granules for extrusion molding produced by the method, and can solve problems such as inability to extrude molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

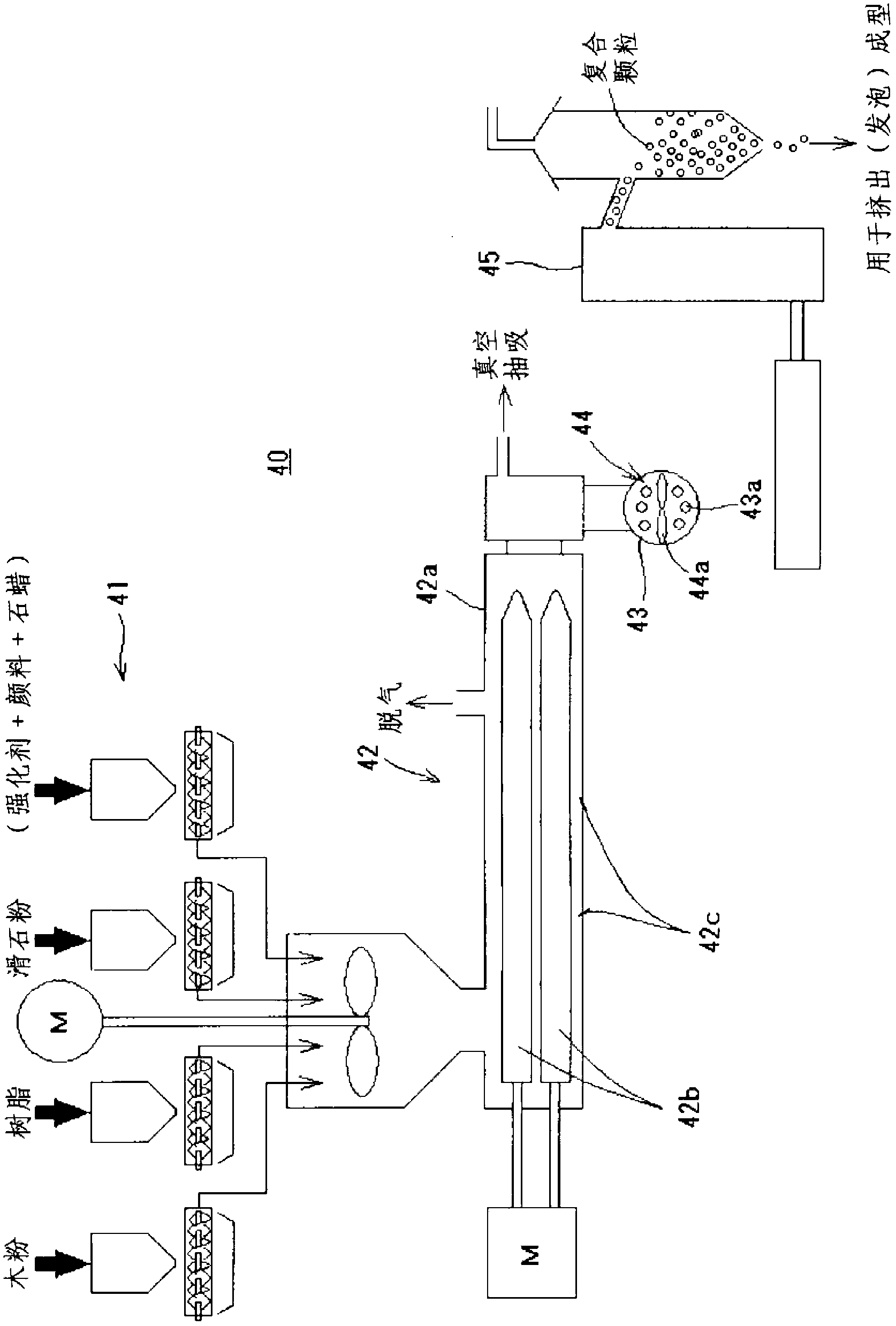

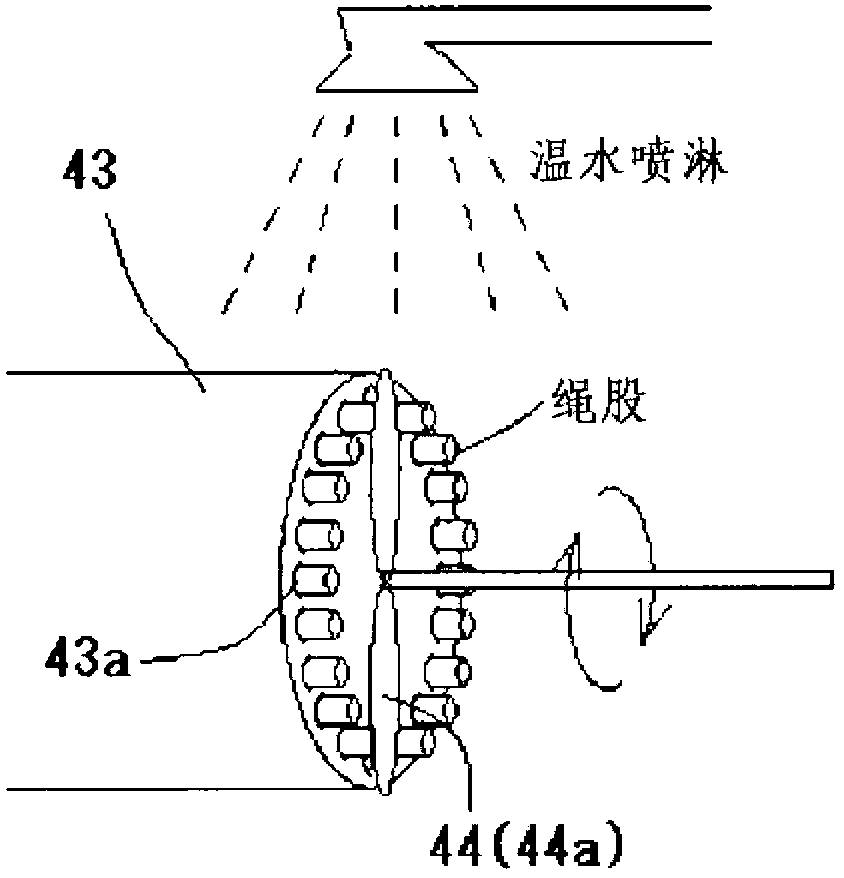

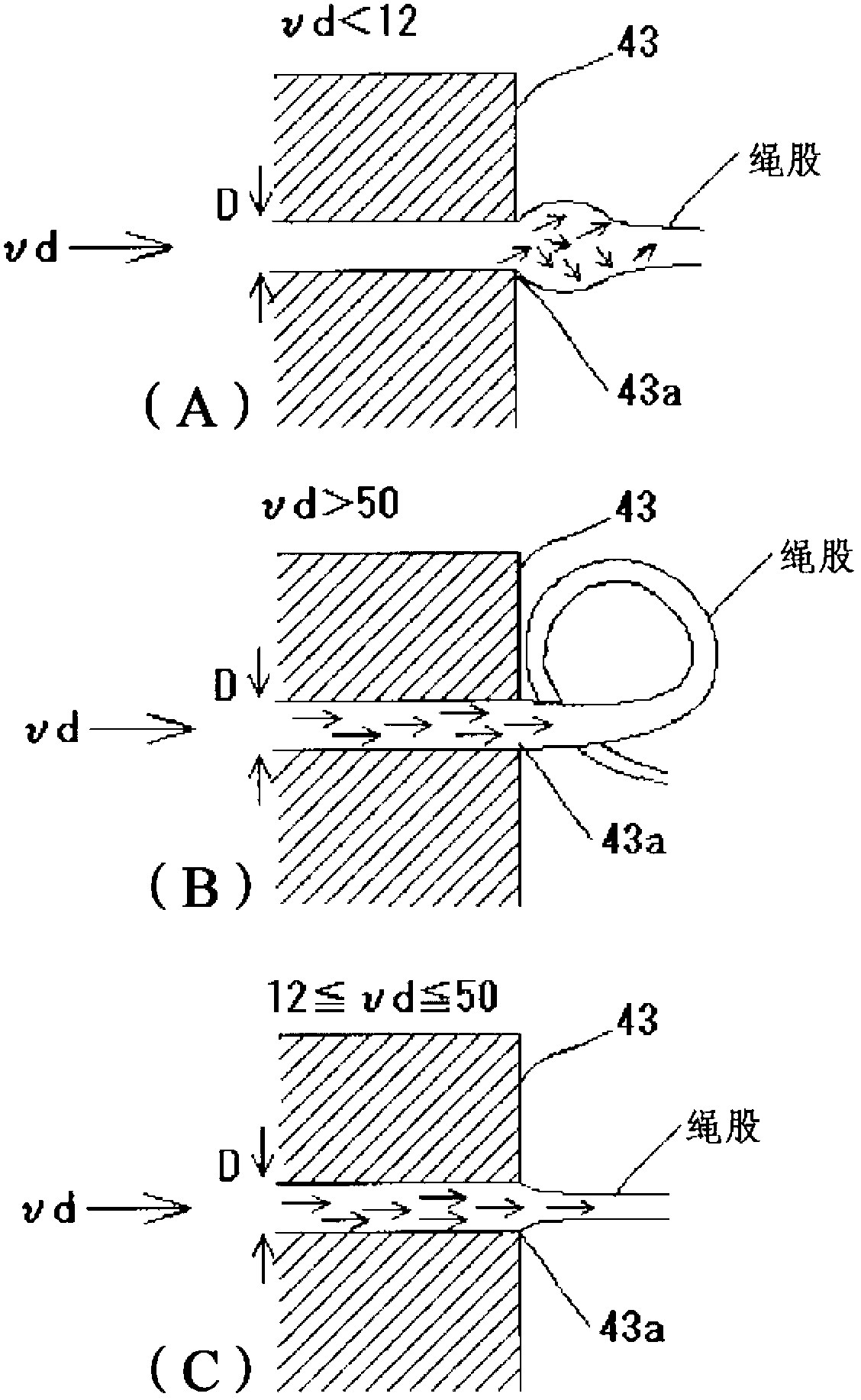

[0263] The production test examples of composite pellets produced by the production method of the present invention and the production test examples of wooden molded articles (boards) using the composite pellets obtained by the production test examples are shown below.

[0264] 1. Manufacture test of composite particles

Embodiment approach 2

[0367] The production examples of the composite pellets of the present invention are described below, and the results of confirmation tests for confirming the feeding performance of the extruder and the performance of the screw entering the extruder are shown using the composite pellets obtained in the production test examples.

manufacture example

[0369] Composition of raw materials

[0370] Composite particles to which 12HOS-M is attached were produced using raw materials having compositions shown in Table 6 below.

[0371] [Table 6]

[0372] Composition of composite particles (before attaching 12HOS-M)

[0373] Element

Manufacturer and specifications, etc.

Mixing ratio (mass%)

PP

(Co., Ltd.) Prime Polymer "P102" homopolymer MI=1

19.92

PP

Sun Aroma Co., Ltd. "EM500A" homopolymer MI=3

9.96

Bottle Cap Recycling Granules

Dafeng Chemical Industry (PP / PE=7 / 3)

9.96

wood powder

Average particle size 150μm

44.92

Talc powder

Fuji Tarku Co., Ltd. average particle size 50μm

10.17

Strengthening agent (maleic acid modified PP)

Sanyo Chemical "ユ一メツス1010"

0.42

paint

Nikhiro Bitsukusu "PO-ET2782C"

2.54

Paraffin

Mitsui Hiwatsukusu "HW200P"

2.12

total

100.0

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com