Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Uniform and stable flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

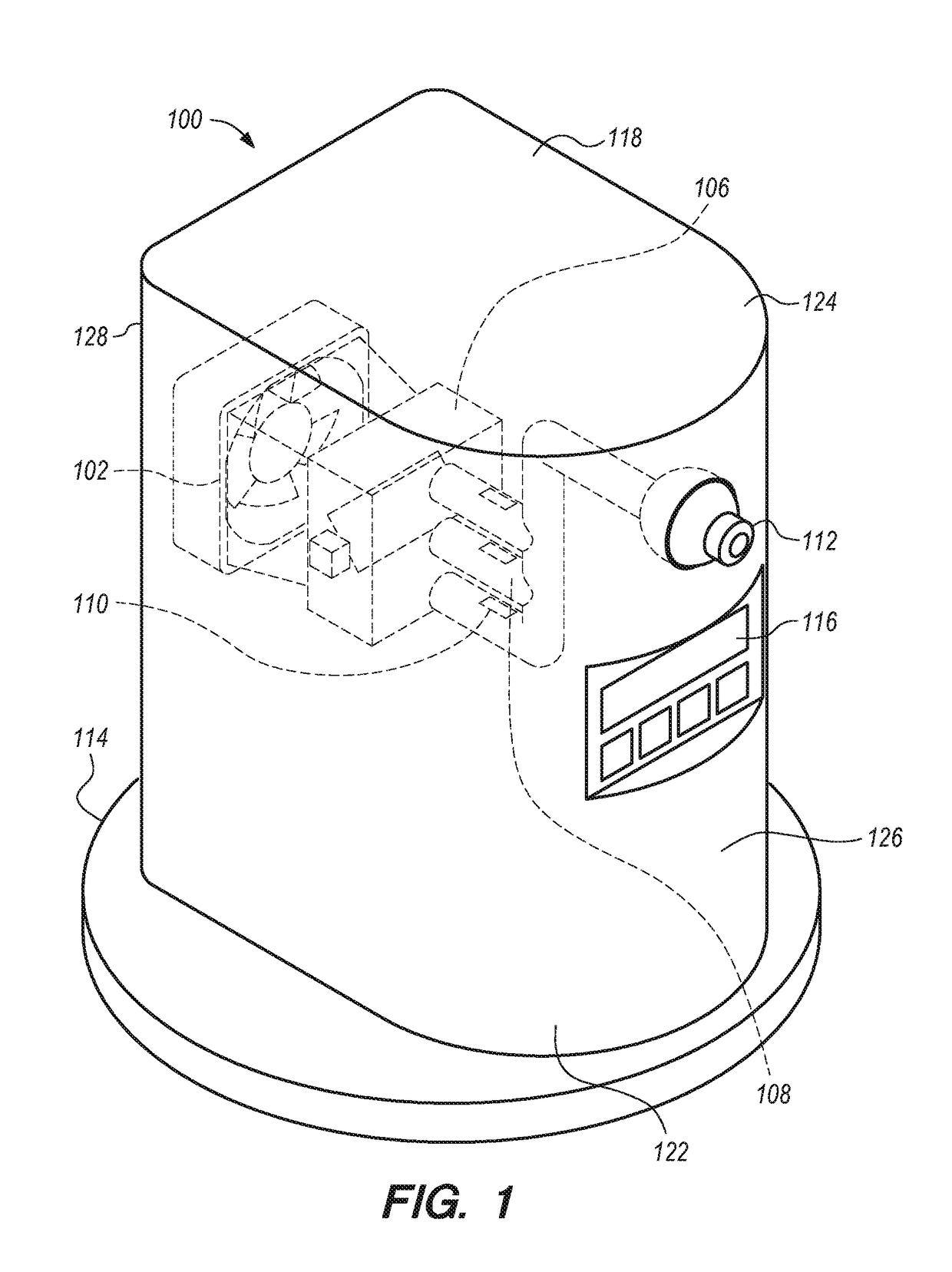

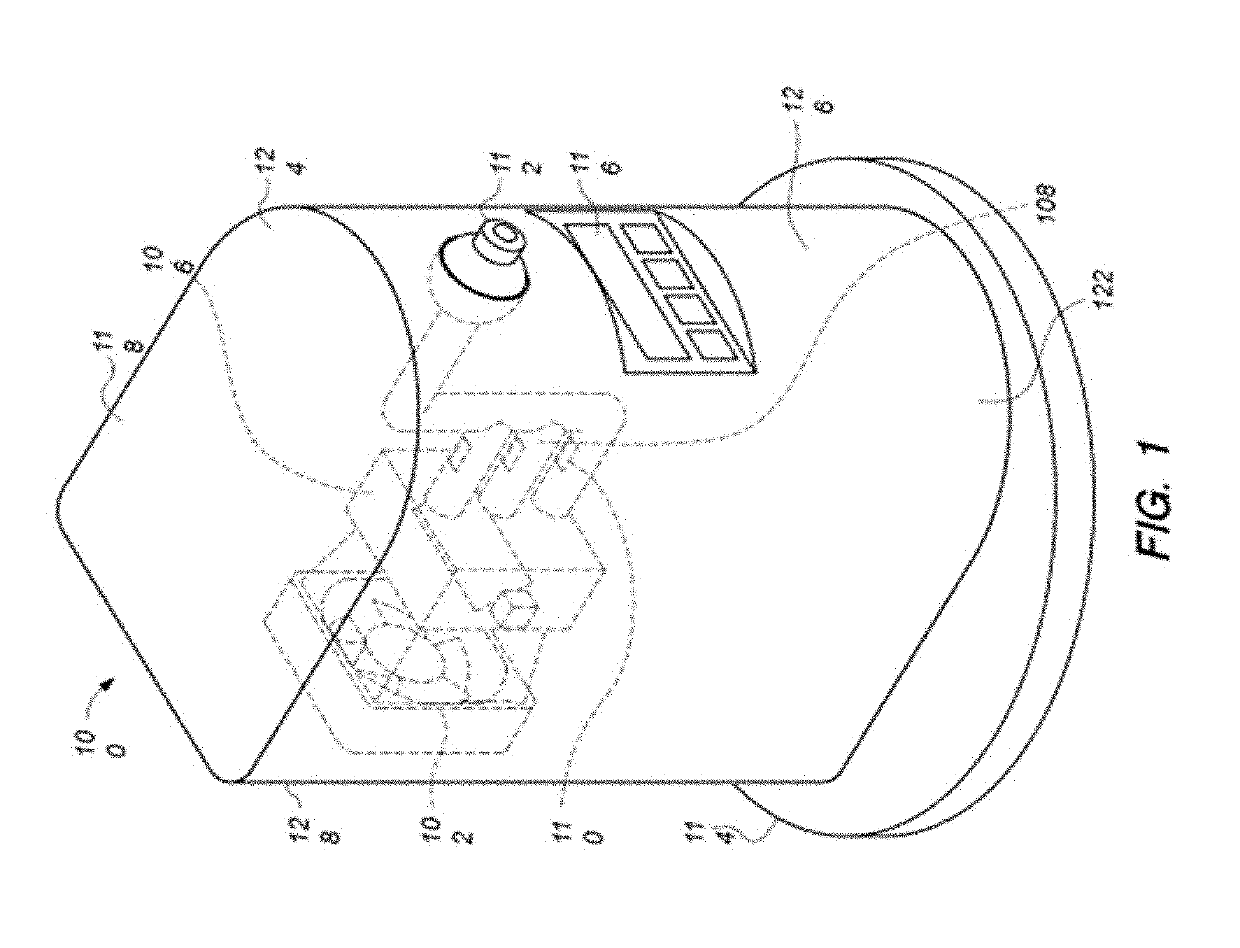

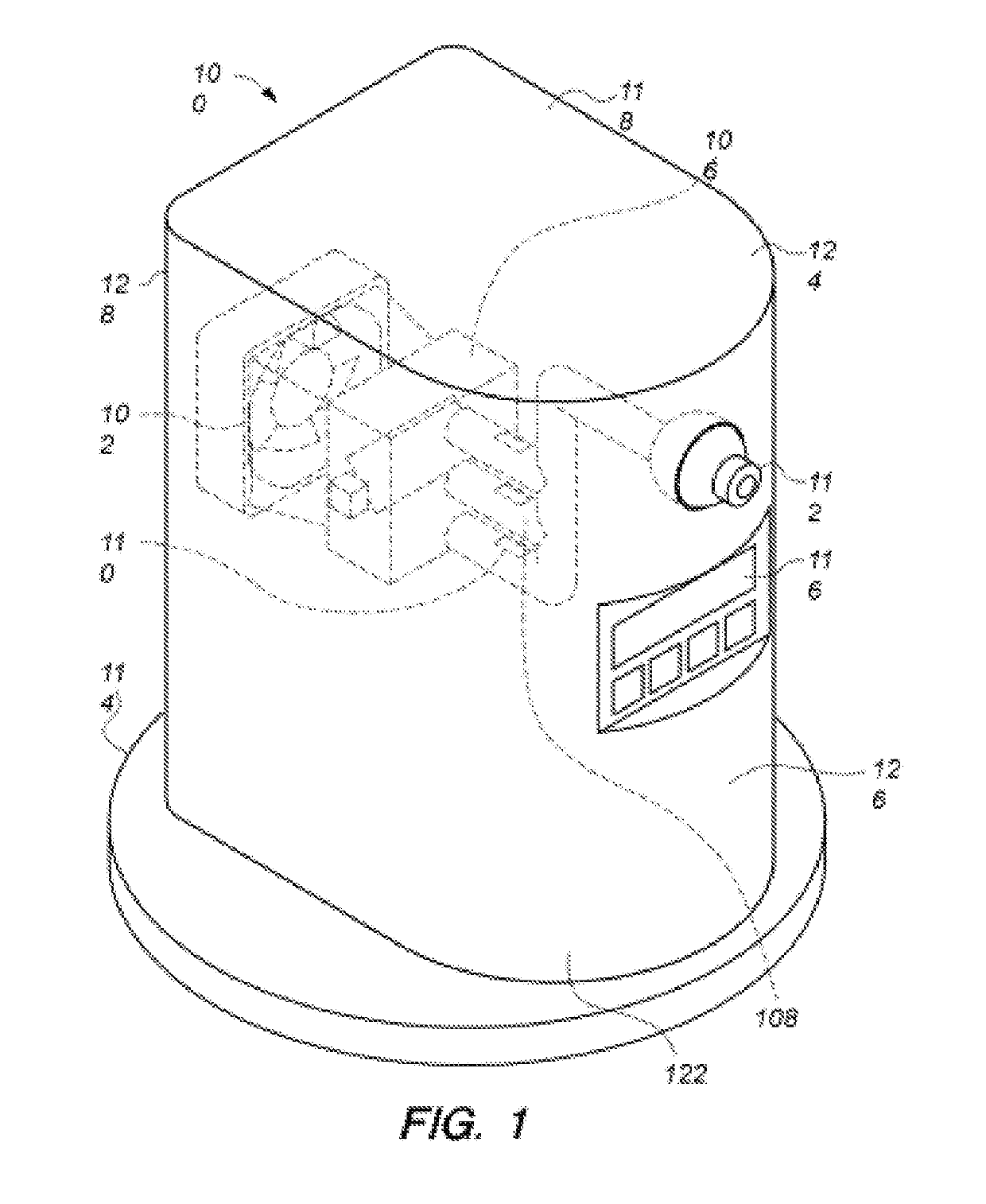

System and Method for Processing an Audio and Video Input in a Point of View Program for Haptic Delivery

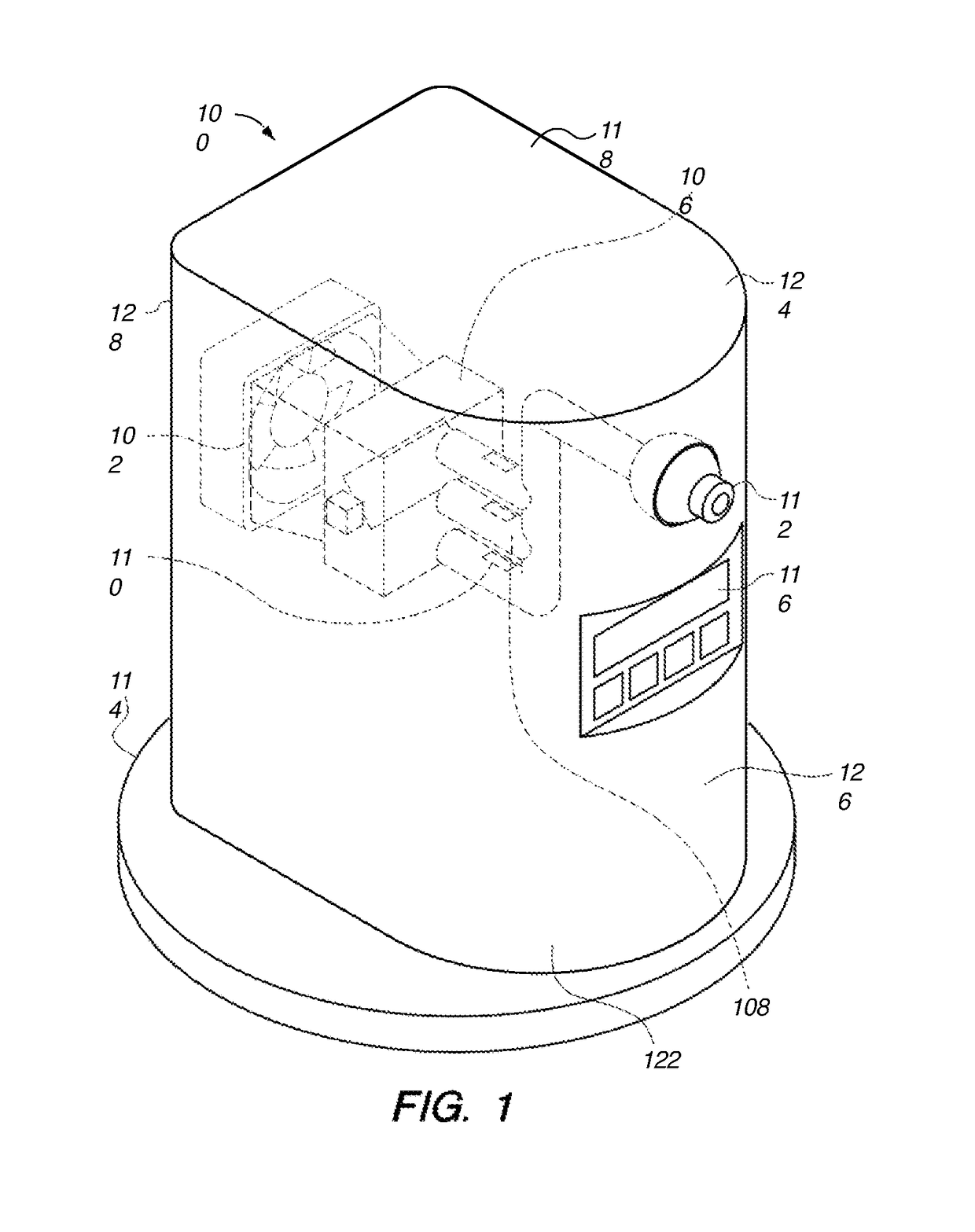

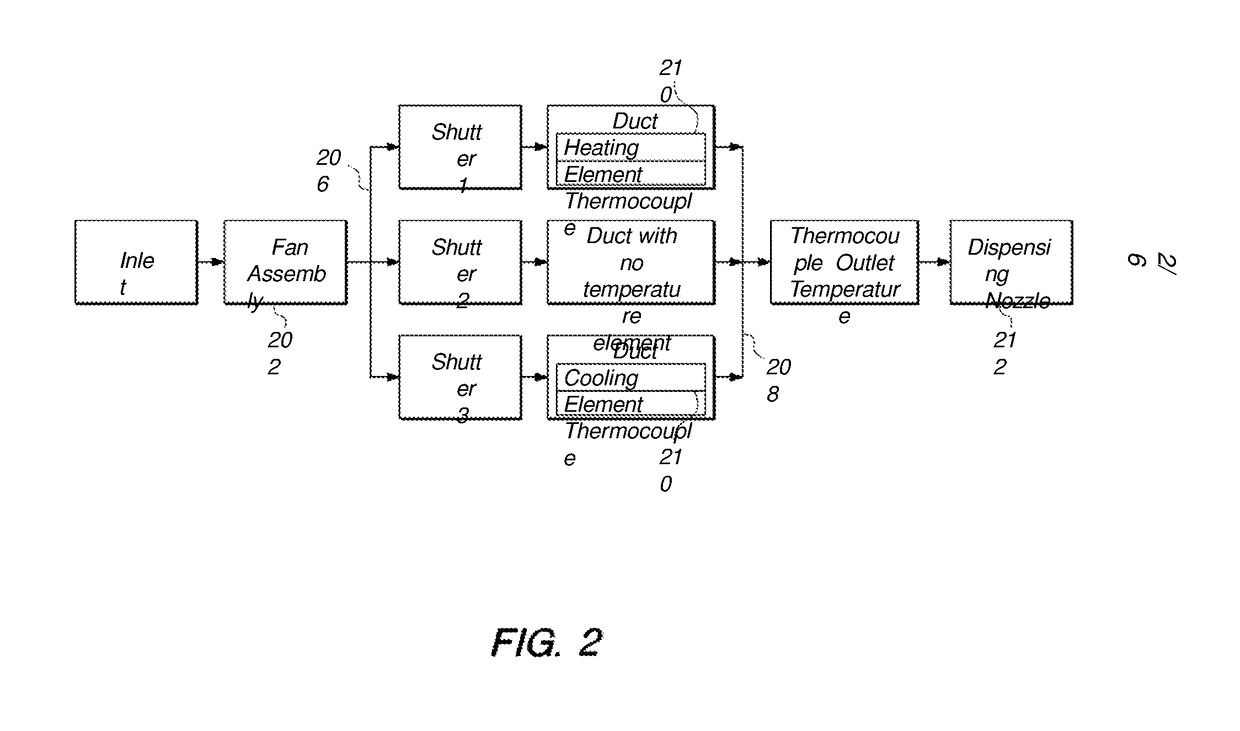

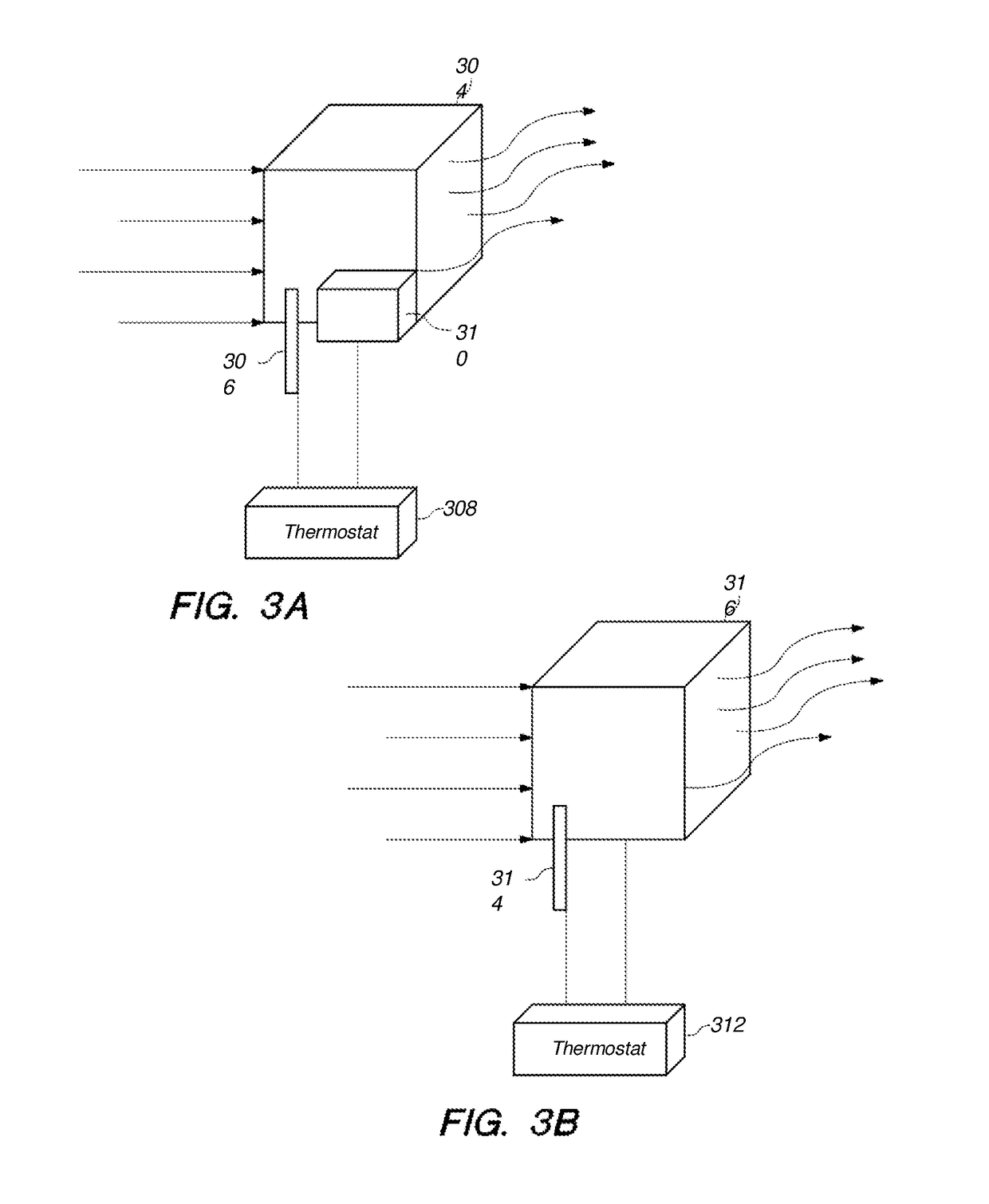

ActiveUS20170177085A1Lower latencyLighten the loadInput/output for user-computer interactionTactile signalling systemsModularityTower

The present embodiments disclose apparatus, systems and methods for allowing users to receive targeted delivery of haptic effects—air flow of variable intensity and temperature—from a single tower or surround tower configuration. The haptic tower may have an enclosed, modular assembly that manipulates air flow, fluid flow, scent, or any other haptic or sensation, for an immersed user. Moreover, the system has an application of sensor technology to capture data regarding a user's body positioning and orientation in the real environment. This data and, or data from a program coupled to the system, and, or audio-video data corresponding to a user in a virtual environment, is relayed to a haptic engine; recognized; scored along a plurality of parameters; and converted into a haptic output command for haptic output expression corresponding to the user in the virtual environment.

Owner:WHIRLWIND VR INC

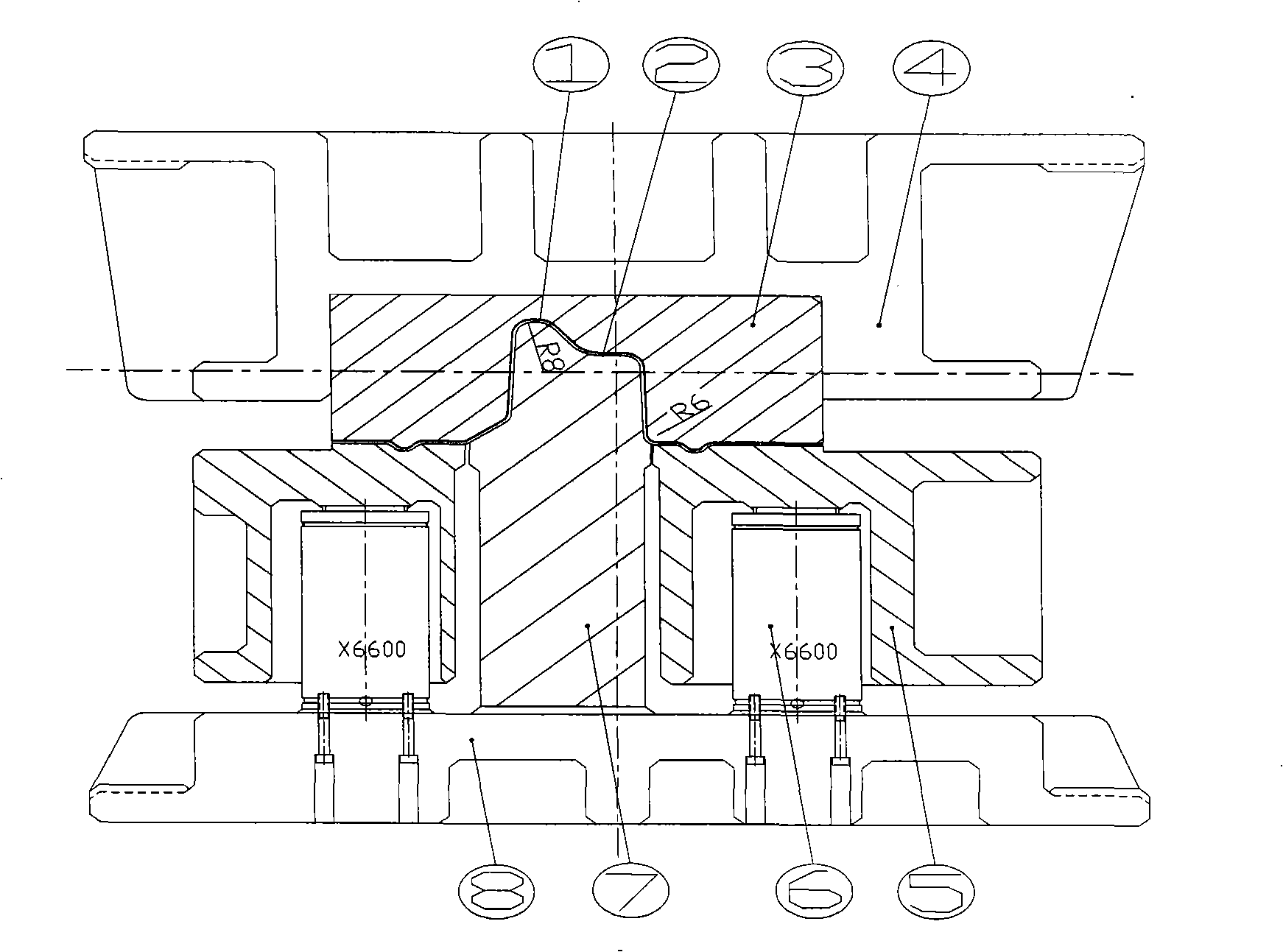

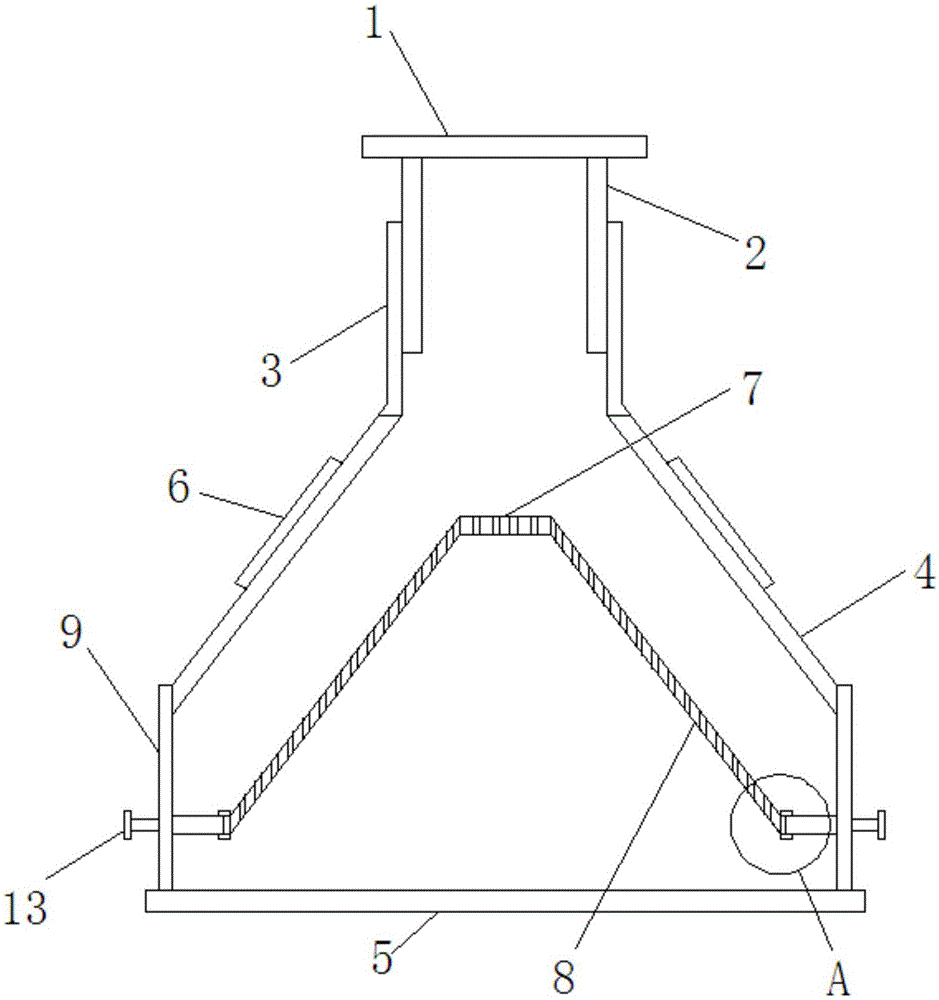

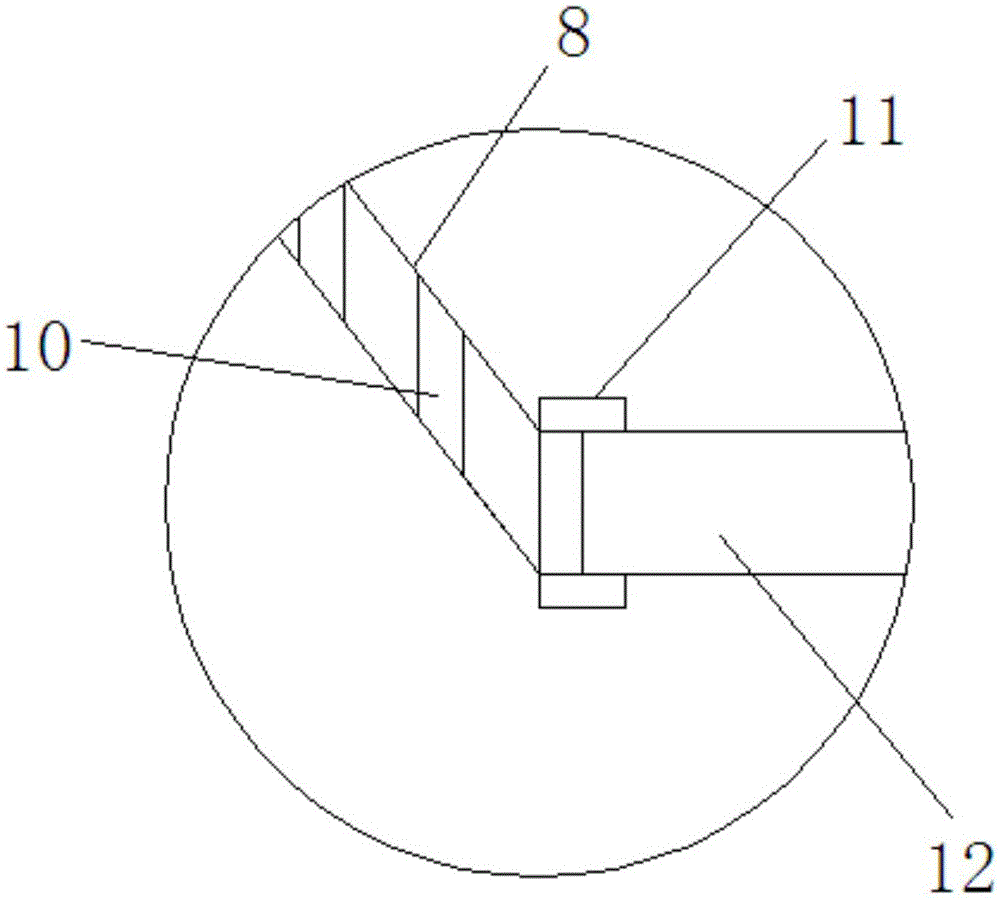

Sedan B-post high-strength plate cold stretching-forming die and technique

The invention relates to a die and a process for cold stretch forming of a B-column high-strength plate of a sedan, belongs to forming processing technology of metallic materials, and aims to effectively solve the technical problem of resilience of the high-strength steel plate during precision forming manufacturing. The die mainly comprises a concave die (3), a convex die (7) and a blank holder (5), wherein the concave die (3) and the convex die (7) are fixed on an upper die holder (4) and a lower die holder (8) respectively; a TD coating is fused on the concave die (3); and the bottom of the blank holder (5) is supported by a nitrogen spring (6) which is arranged on the lower die holder (8) and slidably matched with the convex die (7). The process comprises the following steps: a) blanking of technical chips; b) pre-forming of a product; c) realization of R-angle forming through reverse stretching of a workpiece in the pre-forming state; d) edging and punching of the workpiece after reverse stretching; and e) R-angle and surface reshaping of the workpiece after edging and punching.

Owner:长春三友汽车部件制造有限公司

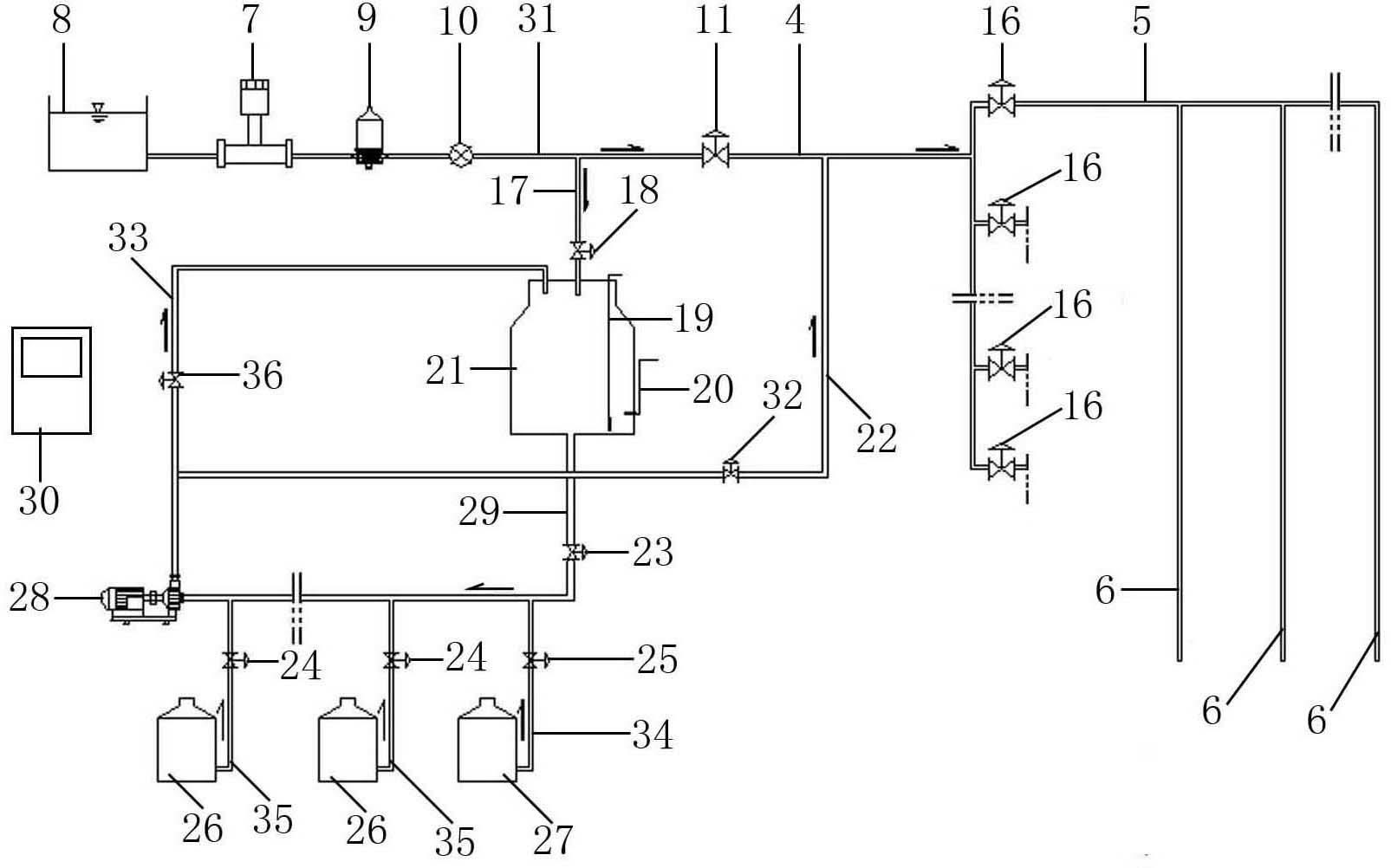

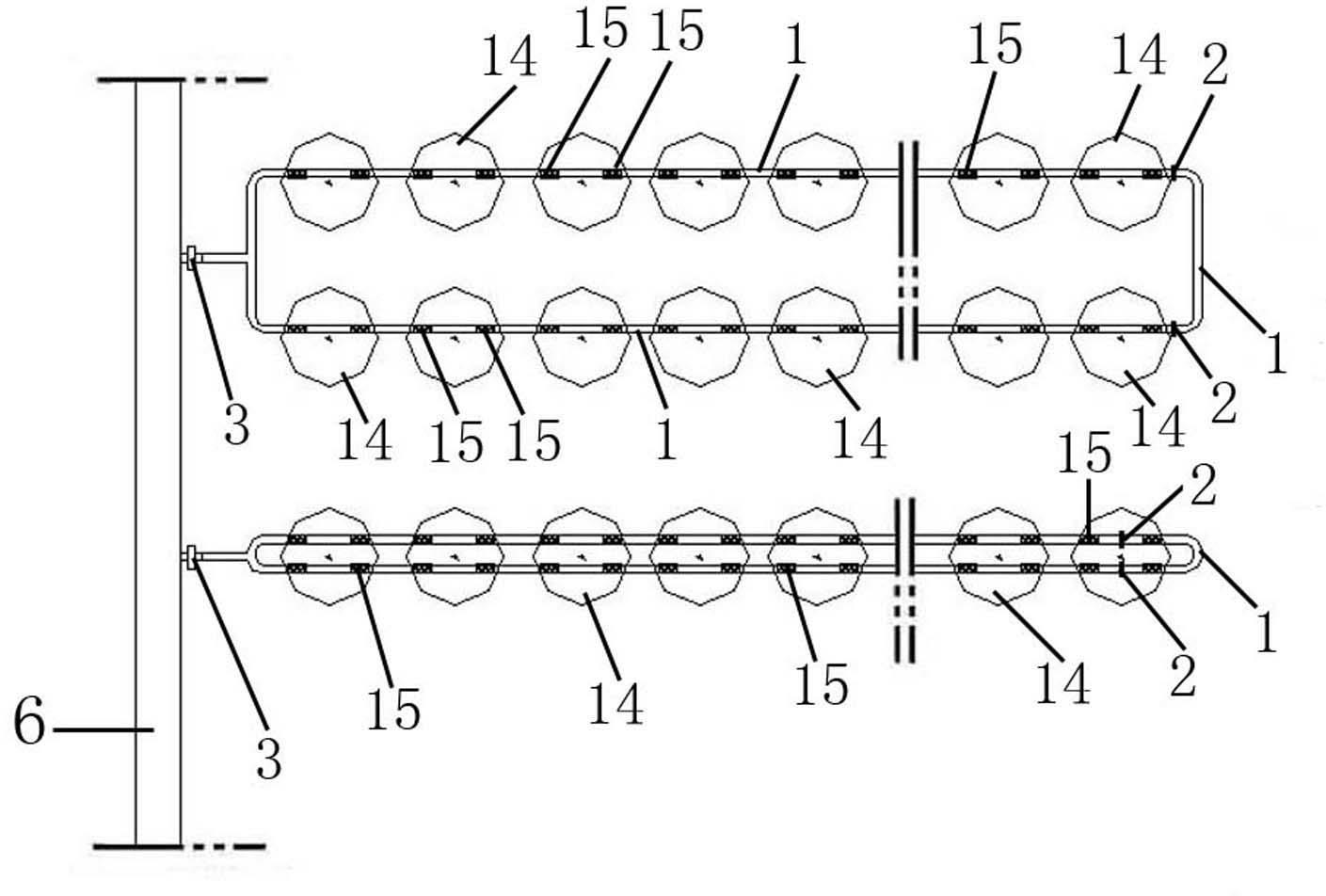

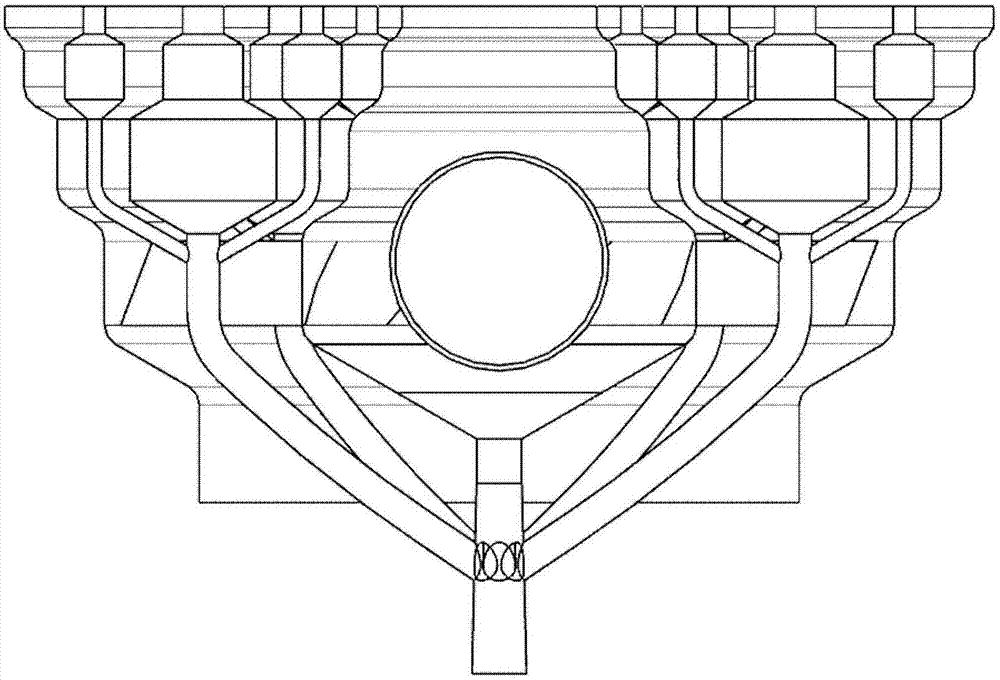

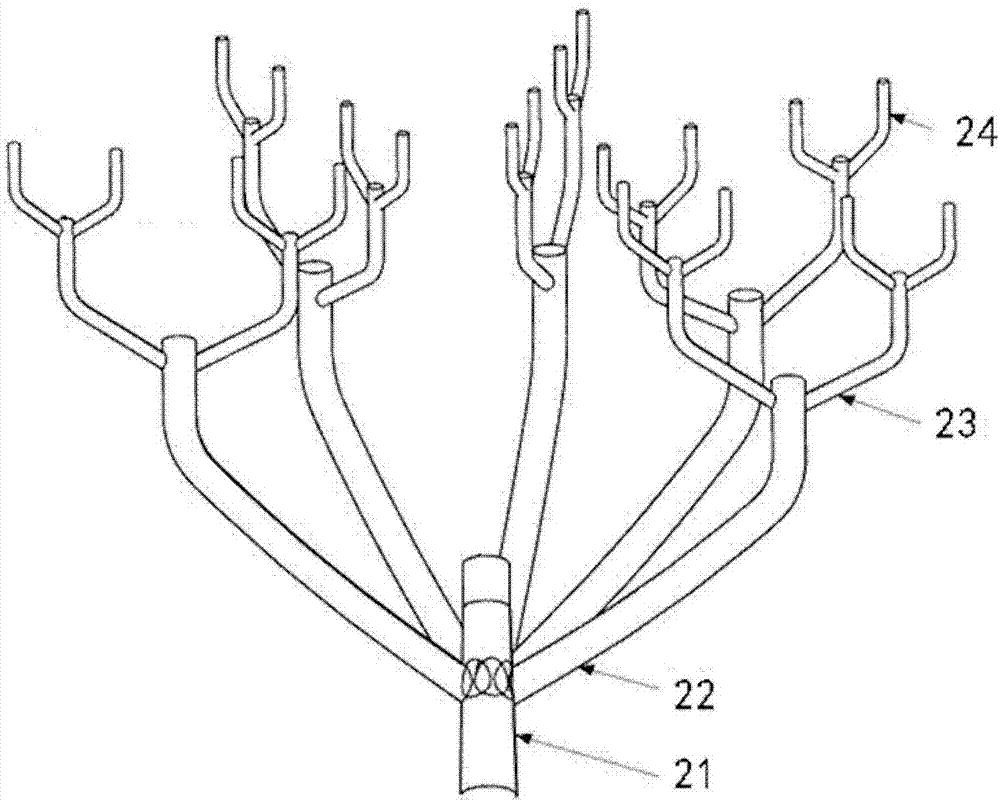

Closed-loop group flow drop irrigation, preparation and fertilization system as well as irrigation method, nutrient liquid preparation method and fertilization method

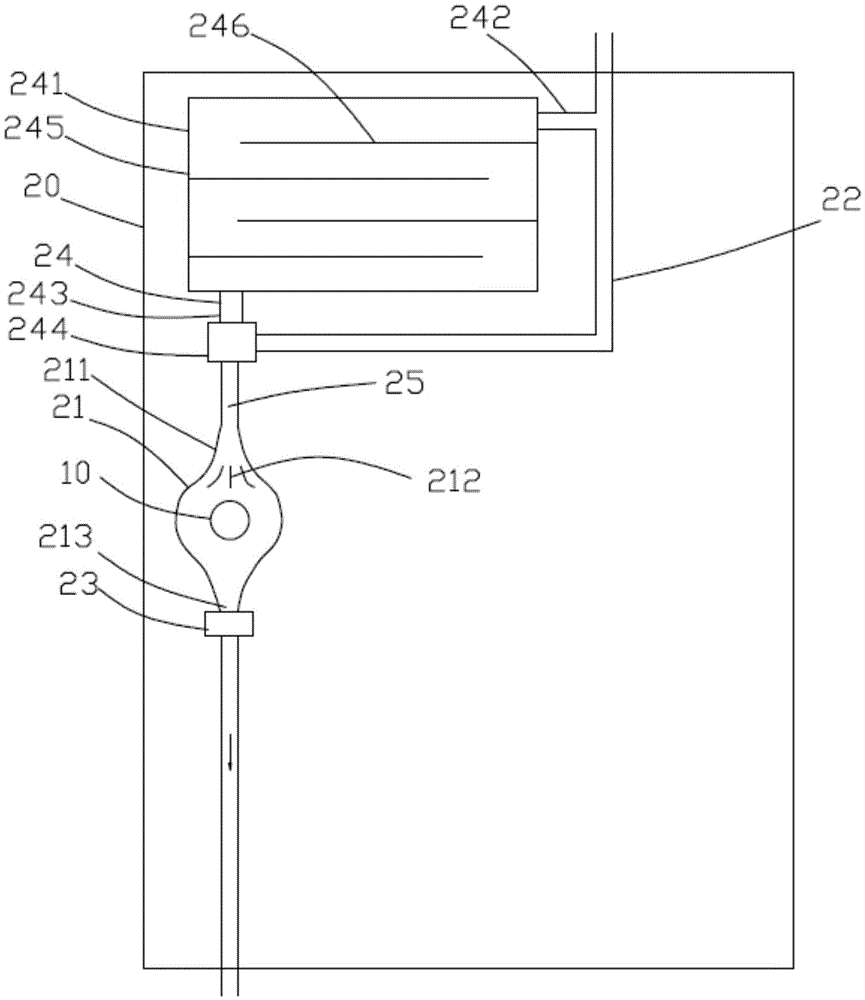

InactiveCN102318467AStrong flowUniform and stable flowFertilising methodsPressurised distribution of liquid fertiliserWater sourceLiquid storage tank

The invention relates to an irrigation method of a closed-loop group flow drop irrigation, preparation and fertilization system, a nutrient liquid preparation method and a fertilization method. The system is divided into an irrigation subsystem, a nutrition liquid preparation subsystem and a control subsystem and is composed of an impounding reservoir, a water division pump, a water source transportation pipeline, a water injection pipeline, a stored nutrient liquid output pipeline, a nutrient liquid storage tank, a nutrient liquid transportation pipeline, a nutrient liquid mother solution storage tank, an acid / base solution storage tank, a self-priming pump, a main controller, a main transportation pipeline, a branch pipe pipeline, a capillary pipeline, a supporting and positioning fixture, a flow stabilizer, a closed-loop group flow drop irrigation pipeline and water droppers, wherein the water source transportation pipeline is connected with the water injection pipeline and the main transportation pipeline; the main transportation pipeline is provided with the branch pipe pipeline; the branch pipe pipeline is provided with the capillary pipeline; the capillary pipeline is provided with the closed-loop group flow drop irrigation pipeline; and the closed-loop group flow drop irrigation pipeline is provided with the water droppers, and one water dropper is arranged on each drop irrigation point. The system disclosed by the invention is scientific in design, reasonable in structure and easy and simple to operate, and has the characteristics of remarkable property, strong function, low price and obvious benefits.

Owner:TIANJIN WATER RESOURCES RES INST

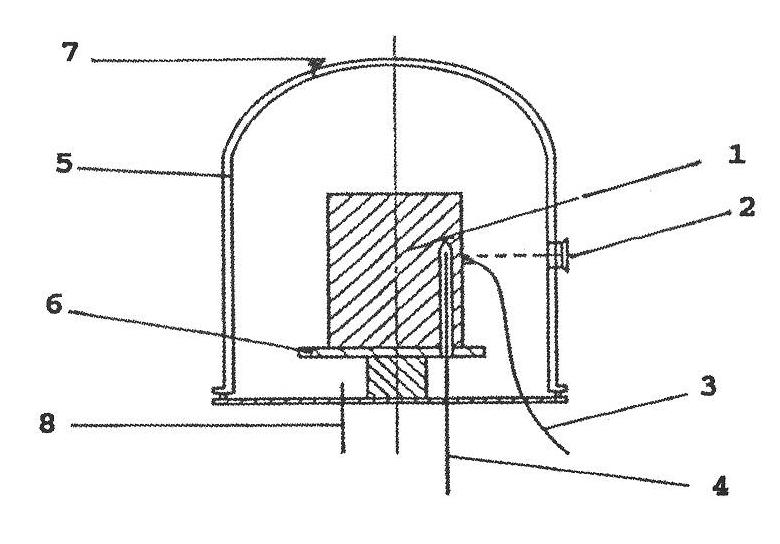

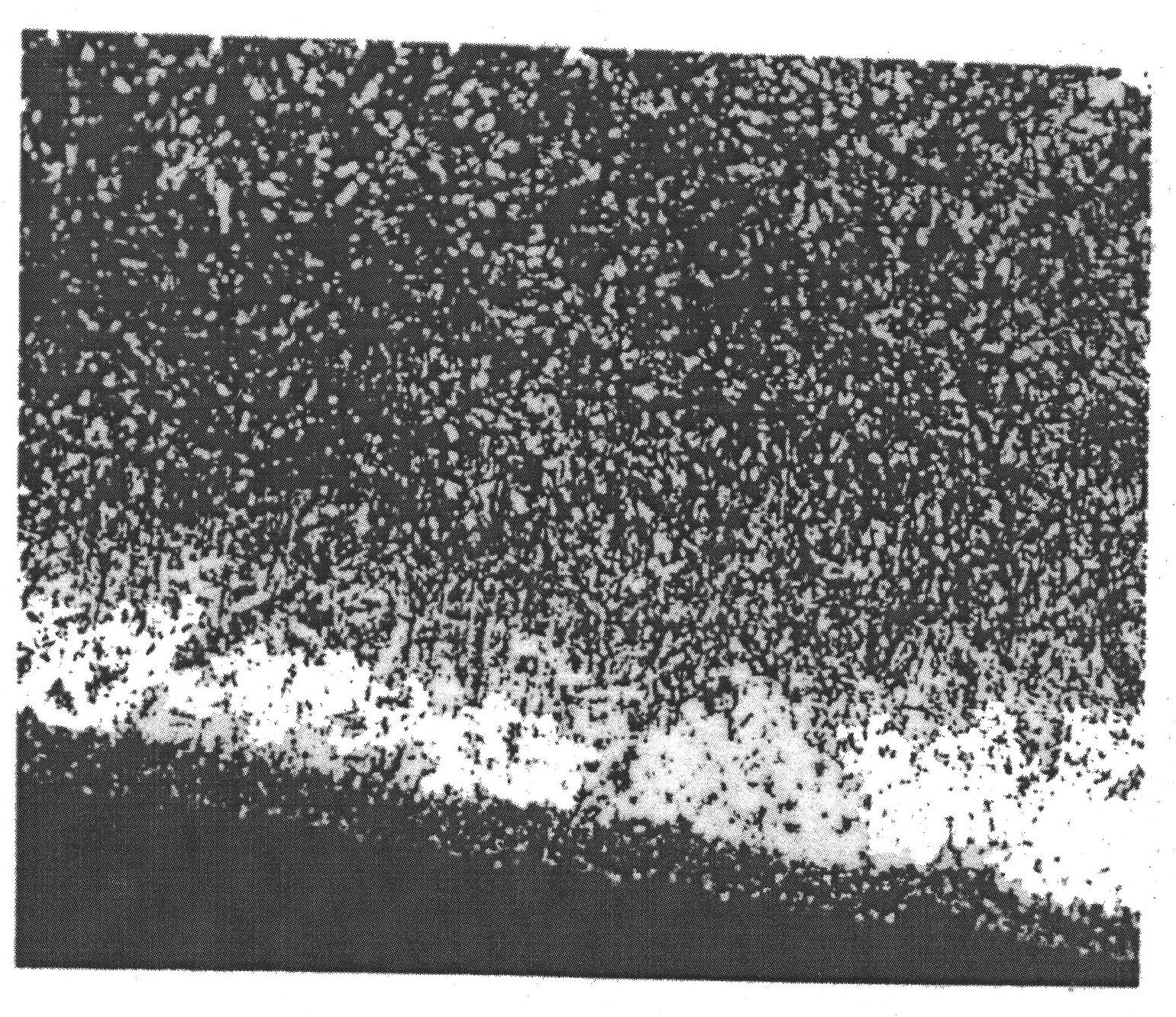

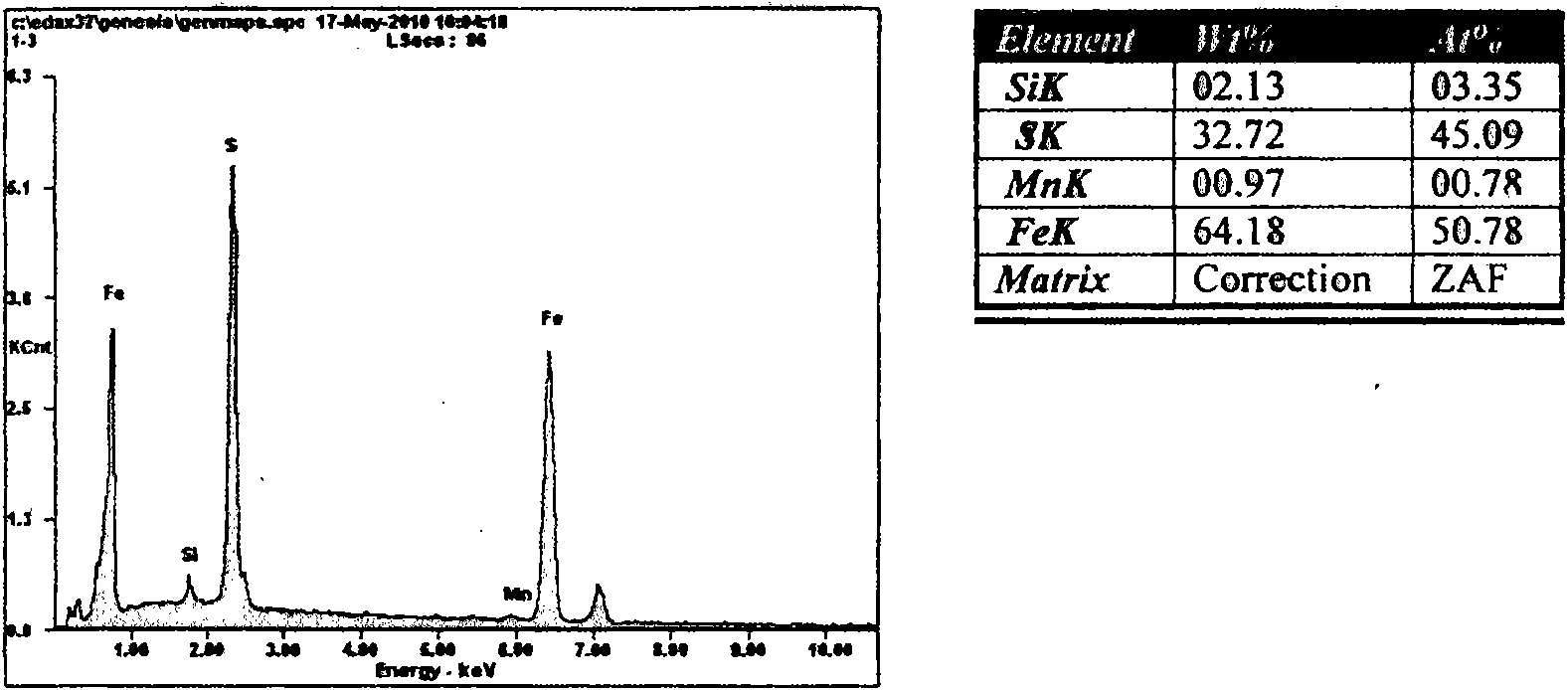

Gas plasma sulfurizing process

InactiveCN101956155AMeet technical quality requirementsEvenly distributedSolid state diffusion coatingWind drivenElectrolysis

The invention discloses a gas plasma sulfurizing process, which belongs to the technical field of surface heat treatment. In the process, a steel workpiece is placed in a sealed sulfurizing furnace with direct-current high voltage and high vacuum, then an appropriate amount of carrier gasses such as hydrogen gas, argon gas, ammonia gas and the like, and hydrogen sulfide are introduced into the furnace to form a sulfurizing atmosphere. Those gases are split into plasma states of nitrogen, hydrogen, argon and sulfur after entering the sulfurizing furnace and dash against the surface of the steel workpiece positioned on a negative plate to ensure that the temperature of the workpiece is raised, wherein sulfur ions infiltrate into the surface of a component to form ferrous sulfide which covers the whole surface of the component to fulfill the aim of sulfurizing. The process has the advantages of no pollution, low cost and high sulfurizing quality, overcomes the defects of serious pollution and high cost of the conventional electrolytic sulfurizing, and also overcomes the defect of low quality of plasma sulfurizing performed by using solid sulfur on the market at present. Through sulfurizing treatment, the mechanical life of a mechanical workpiece can be improved by 2 to 3 times, and the process has obvious economical and social benefits and extensive development prospect when applied to an automobiles, a train, a wind-driven generators, a petroleum machinery and a rolling machine.

Owner:BEIJING TIANMA BEARING CO LTD

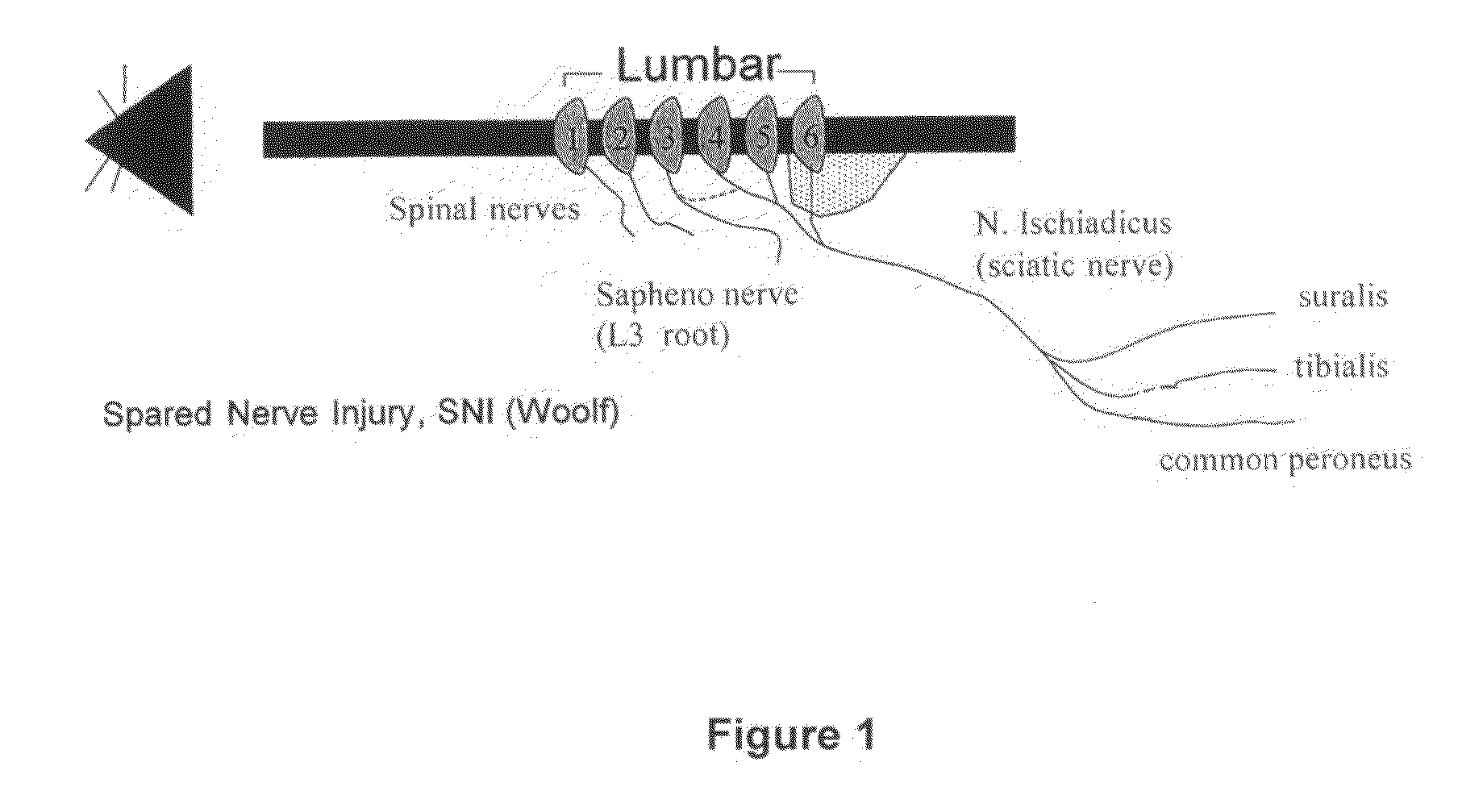

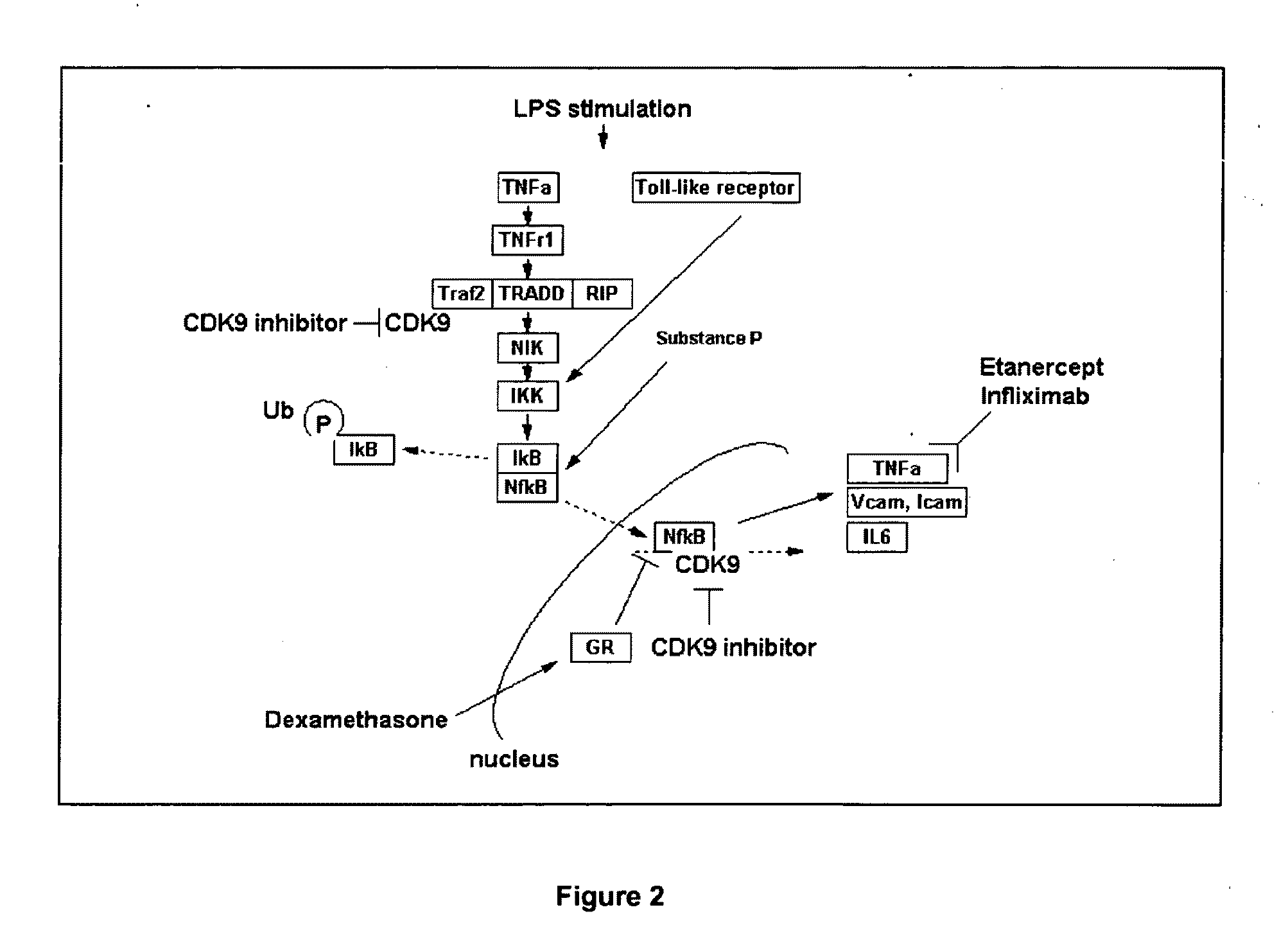

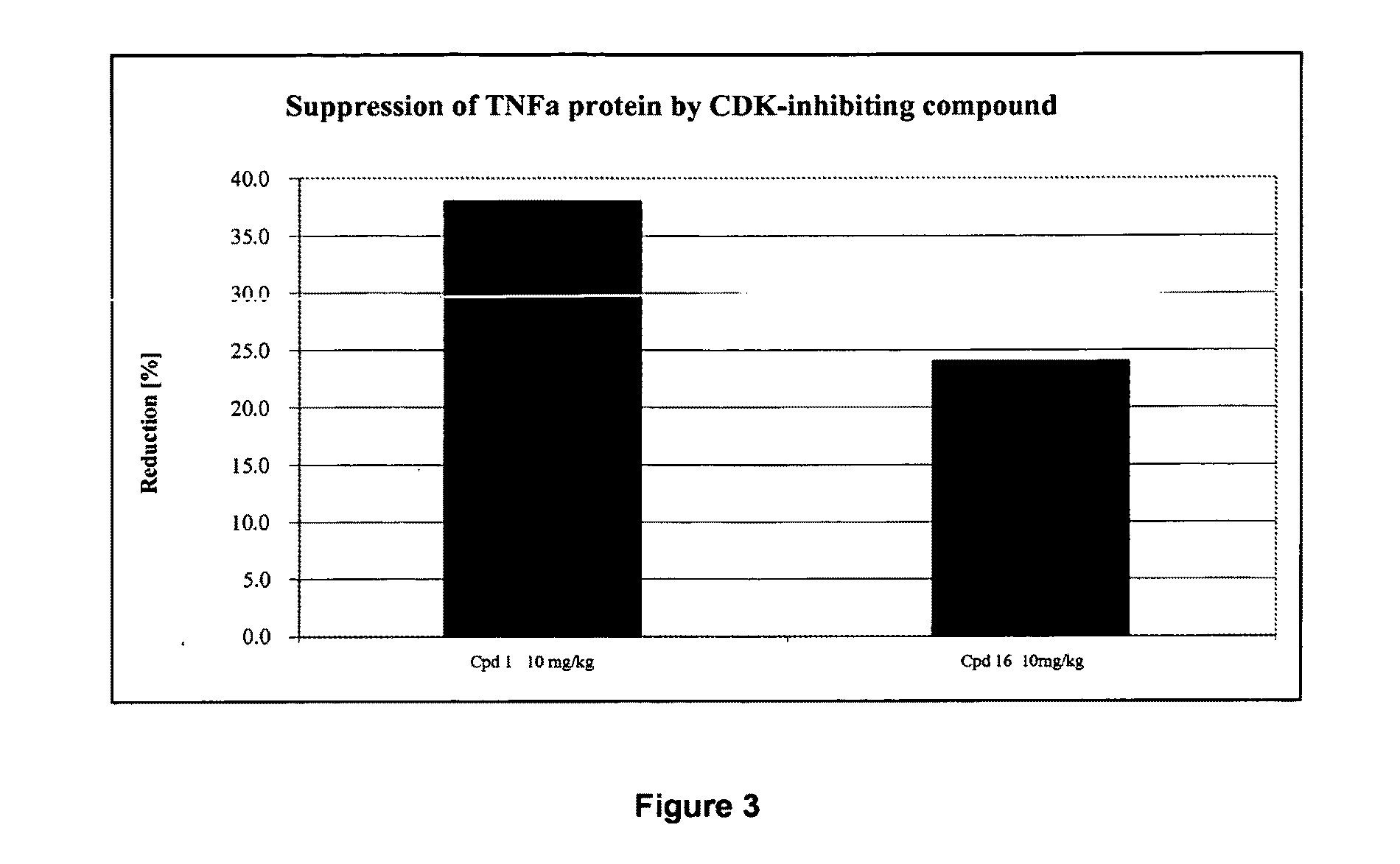

Inhibitors of Protein Kinases

InactiveUS20100249149A1Improve flow characteristicsUniform and stable flowOrganic active ingredientsBiocideCyclinBiochemistry

Owner:ASTRAZENECA AB

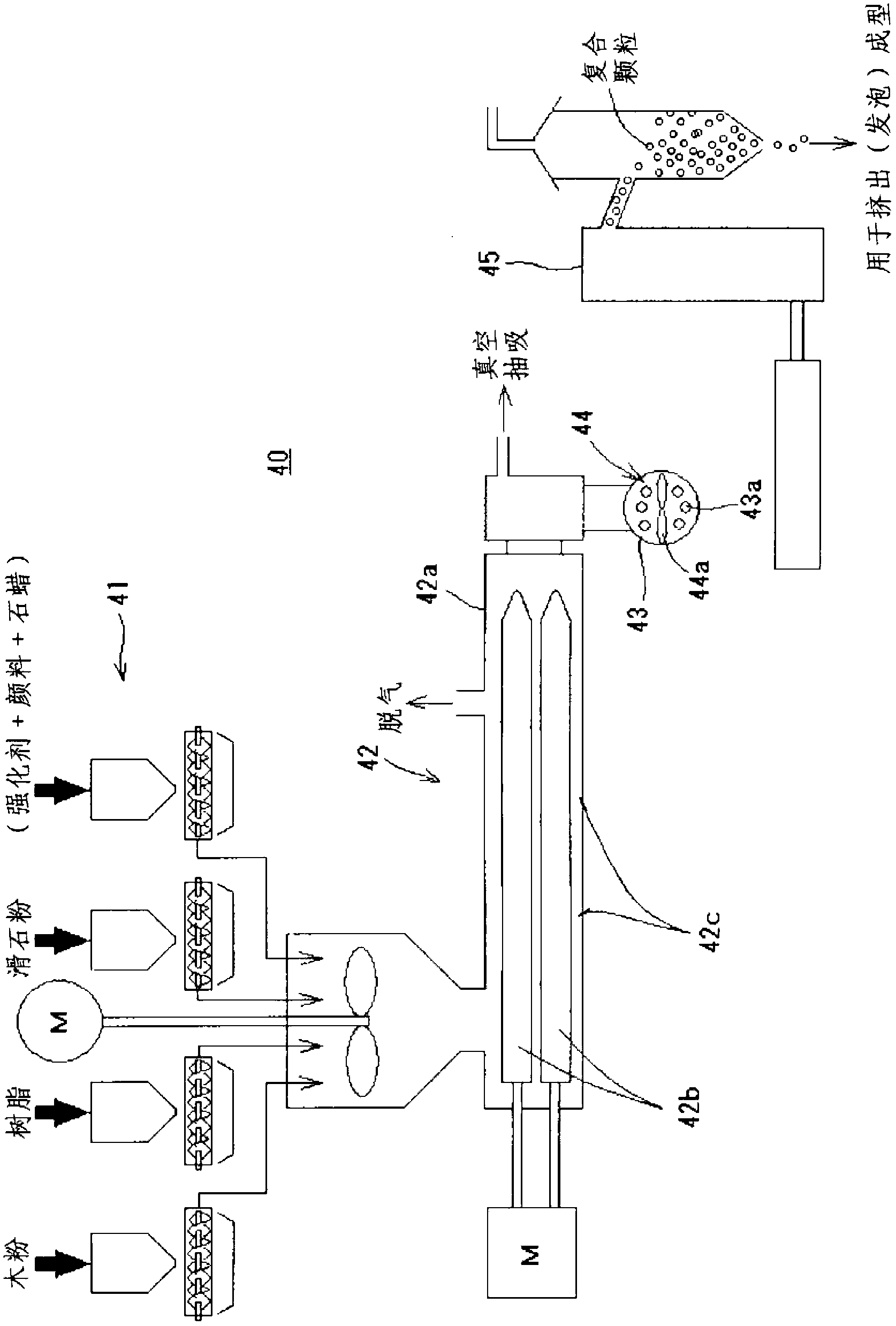

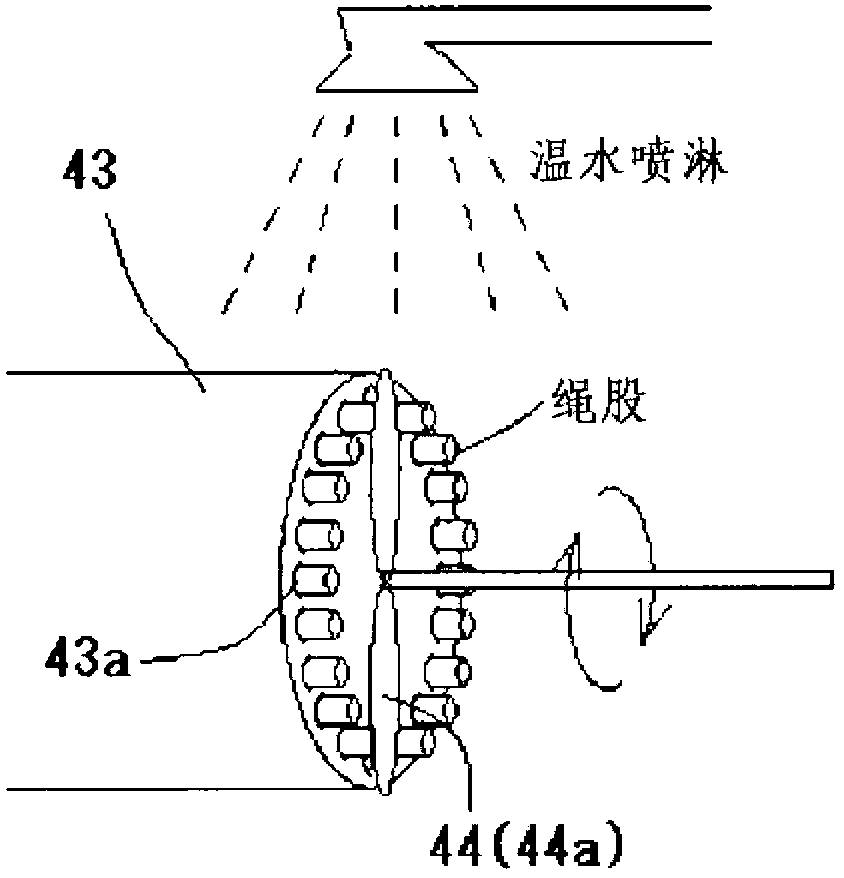

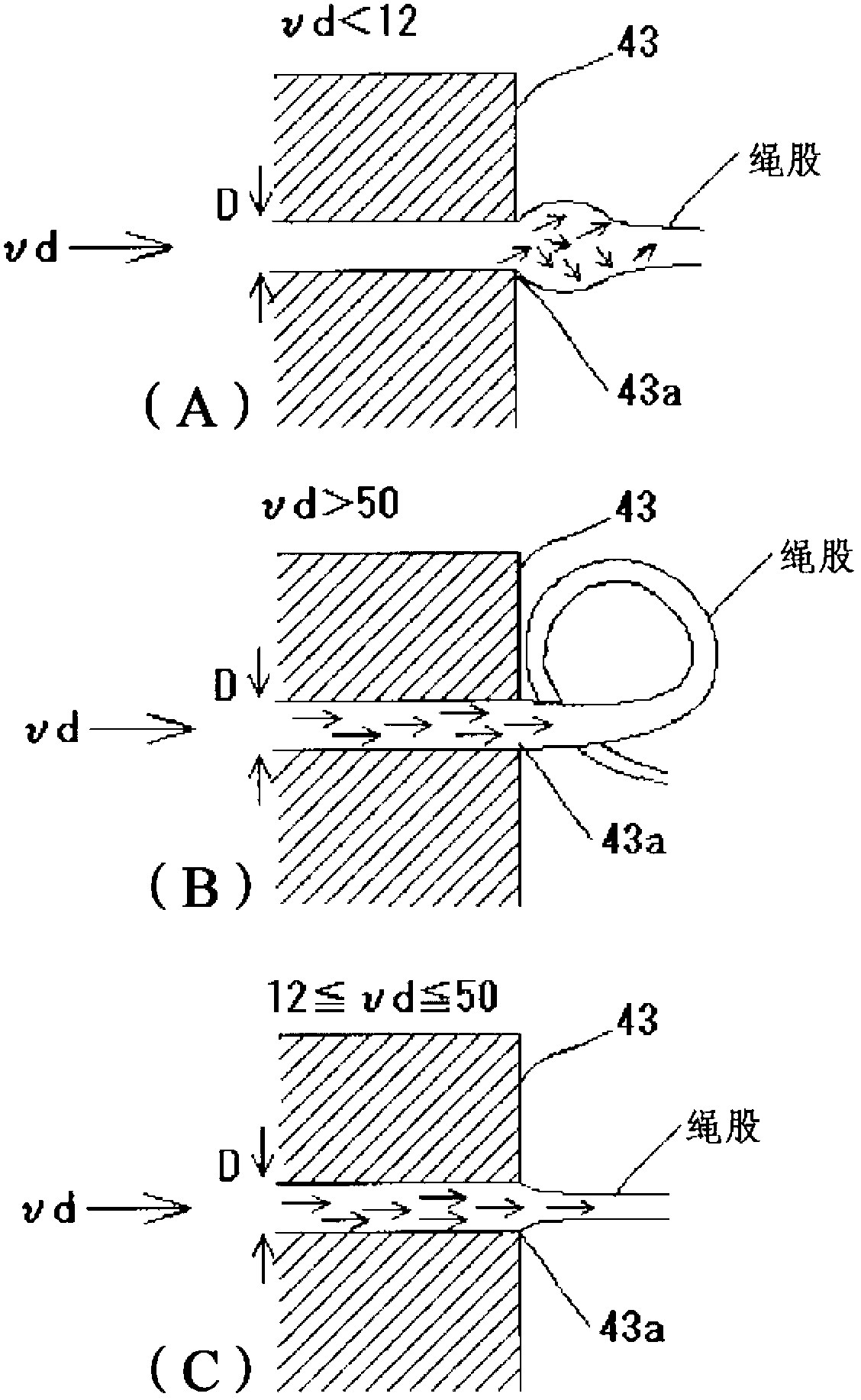

Method for producing composite pellet for extrusion molding, and composite pellet for extrusion molding produced by the method

InactiveCN102869484AInhibit swellingAvoid contactFlat articlesDomestic articlesHydroxystearic AcidVolumetric Mass Density

Disclosed are composite pellets for extrusion molding wherein fusion does not occur between the pellets, and there is no variation in size and density. A molten material obtained by an extruder for a raw material containing a thermoplastic resin and wood powder is extruded into a strand shape through a die nozzle of the extruder, and cut into a predetermined length to form a pellet. At this time, the extrusion amount, the diameter of each nozzle hole, and the number of nozzle holes are adjusted so that the linear velocity (vd) of the molten material in each nozzle hole of the die nozzle is in the range of 12 to 50 cm / sec. Further, regardless of the variations in particle diameter, etc., a stable amount of the composite pellets are supplied to the extruder, and smoothly introduced to a screw of the extruder. The composite pellets and 12-hydroxystearic acid containing a metal of Ca, Mg, or Zn are agitated together, and 0.03 to 0.4 mass% of the 12-hydroxystearic acid is attached to the periphery of 100 mass% of the composite pellet, and the pellets are used for extrusion molding.

Owner:WPC CORP

Honeycomb heater with infrared radiation function used on gas burner

ActiveCN101050875AUniform and stable flowFast decayDomestic stoves or rangesLighting and heating apparatusFiberCombustor

A cellular heating body being set with infrared radiation function and being used on fuel gas burner is prepared for forming surface cellular heating layer by high-temperature resisting and anticorrosion metal material and utilizing formed surface cellular heating layer as top layer of said cellular heating body, forming mesh body by high-temperature resisting and anticorrosion flexible metal material and utilizing formed mesh body as bottom layer of said cellular heating body.

Owner:罗添翼

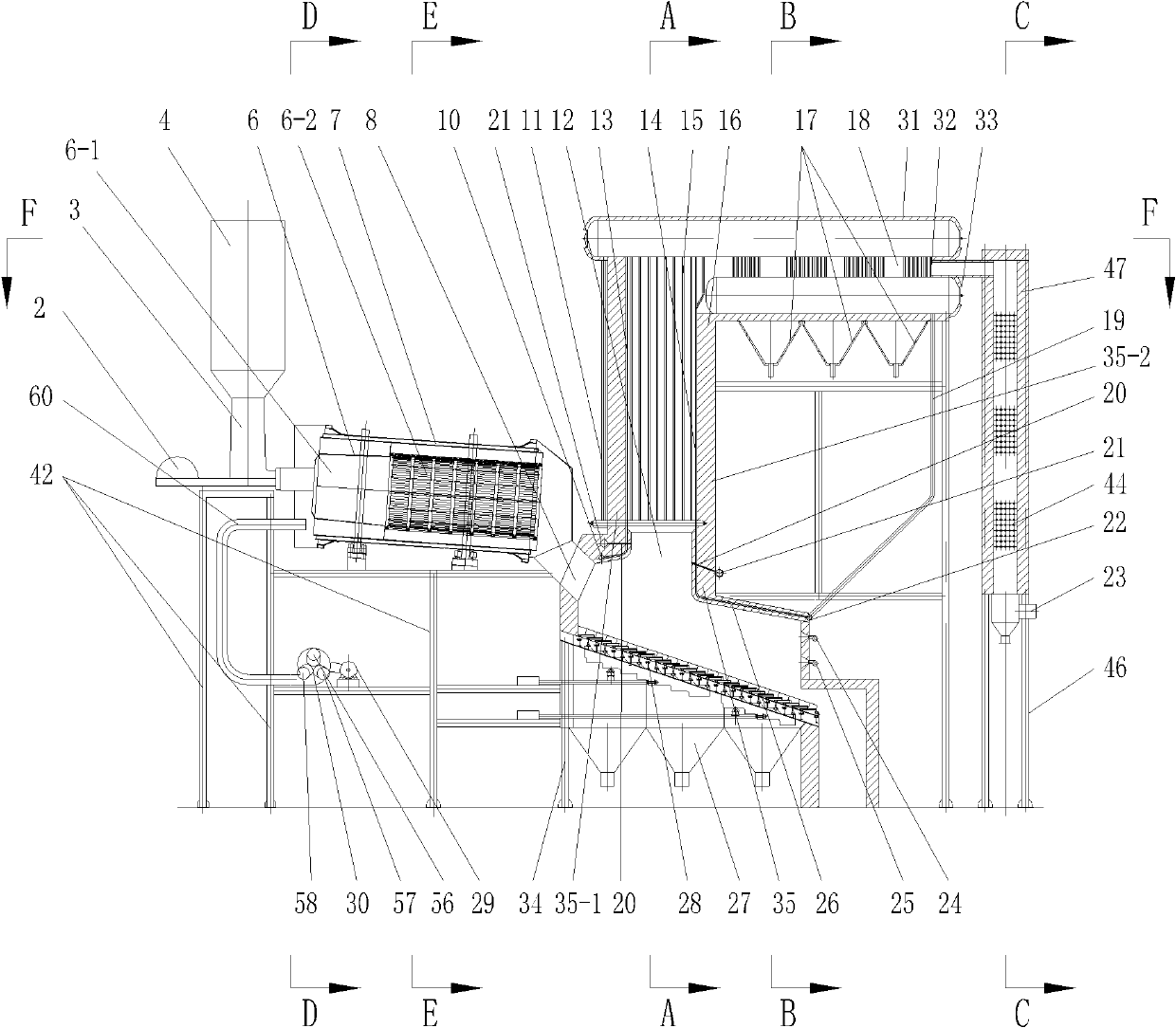

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

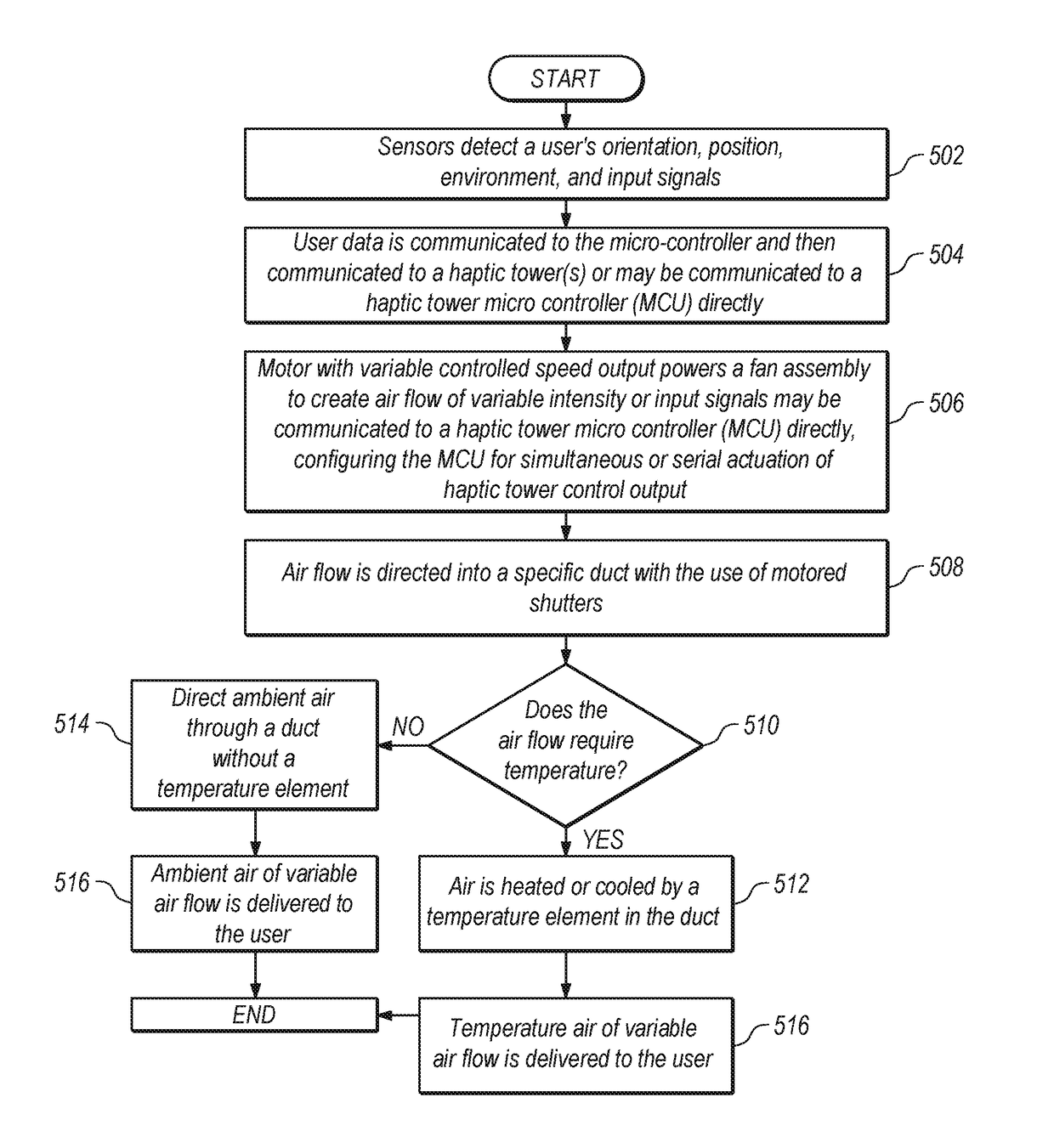

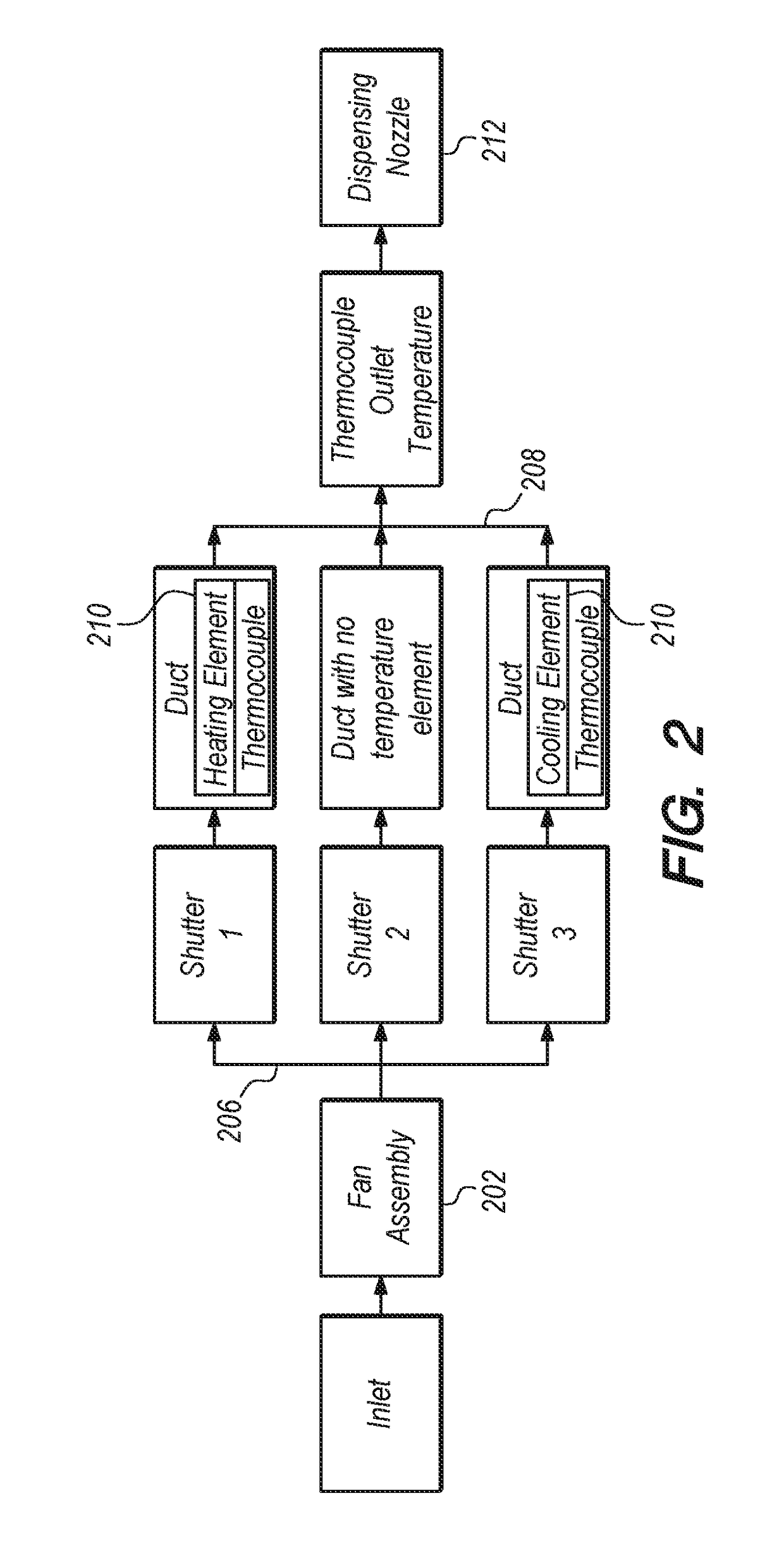

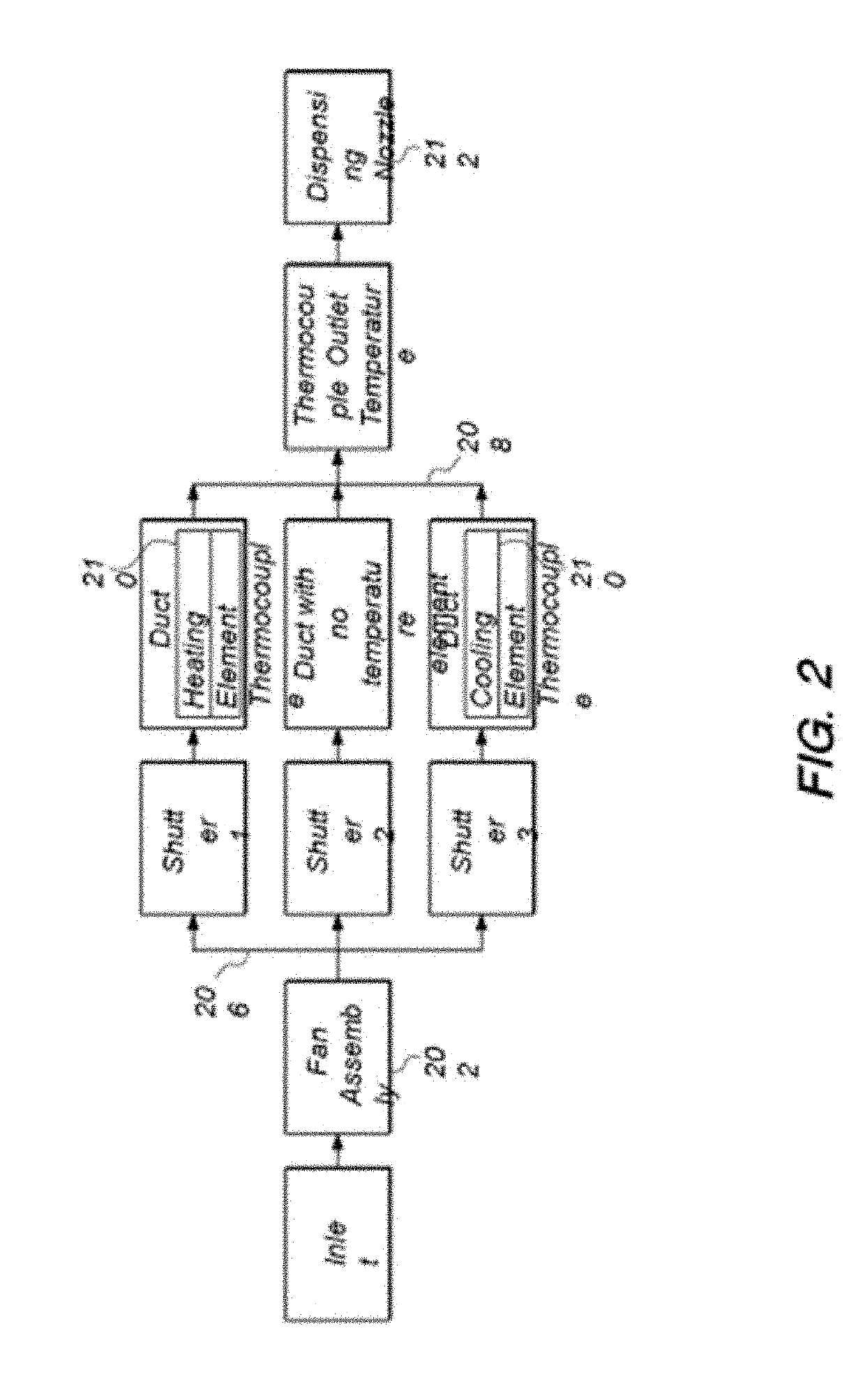

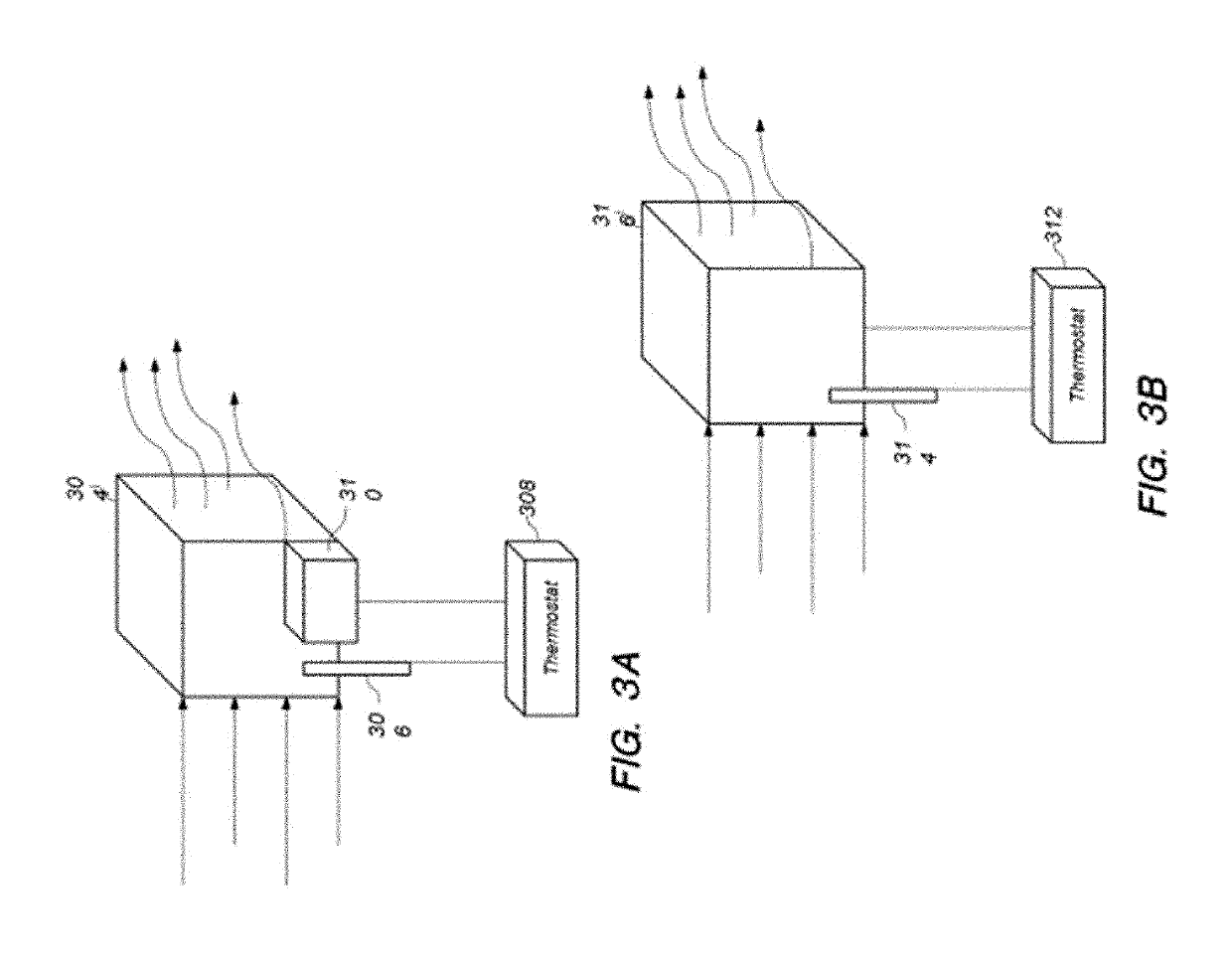

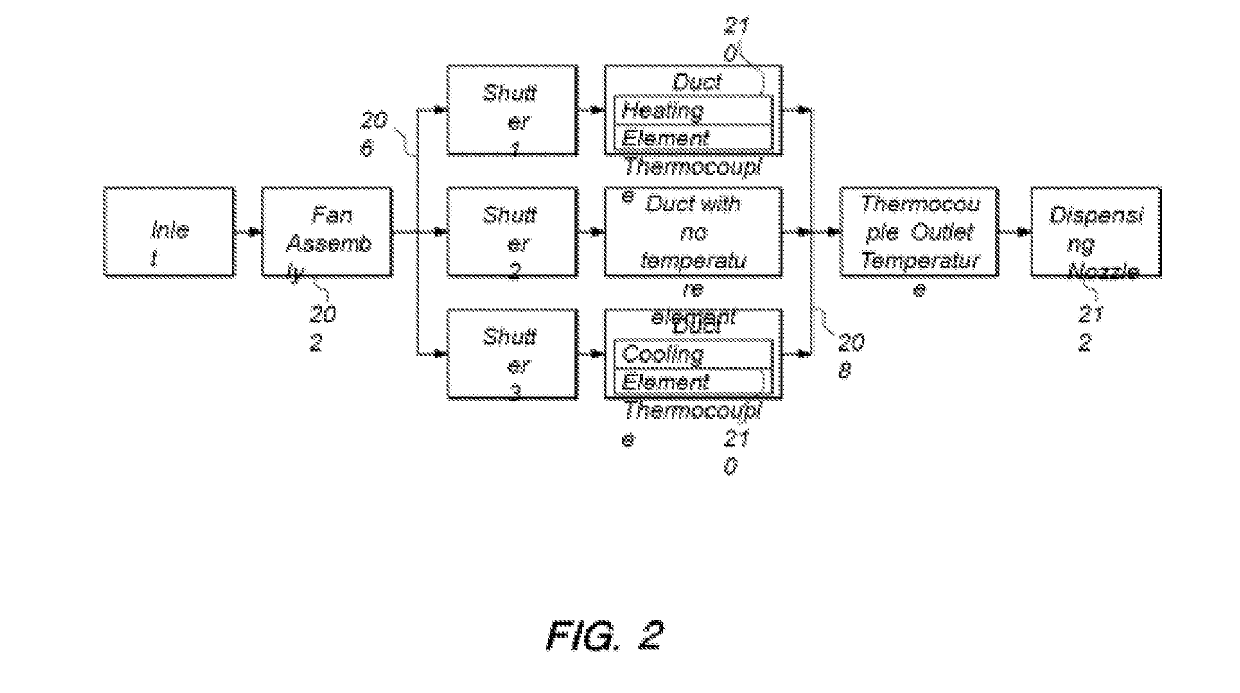

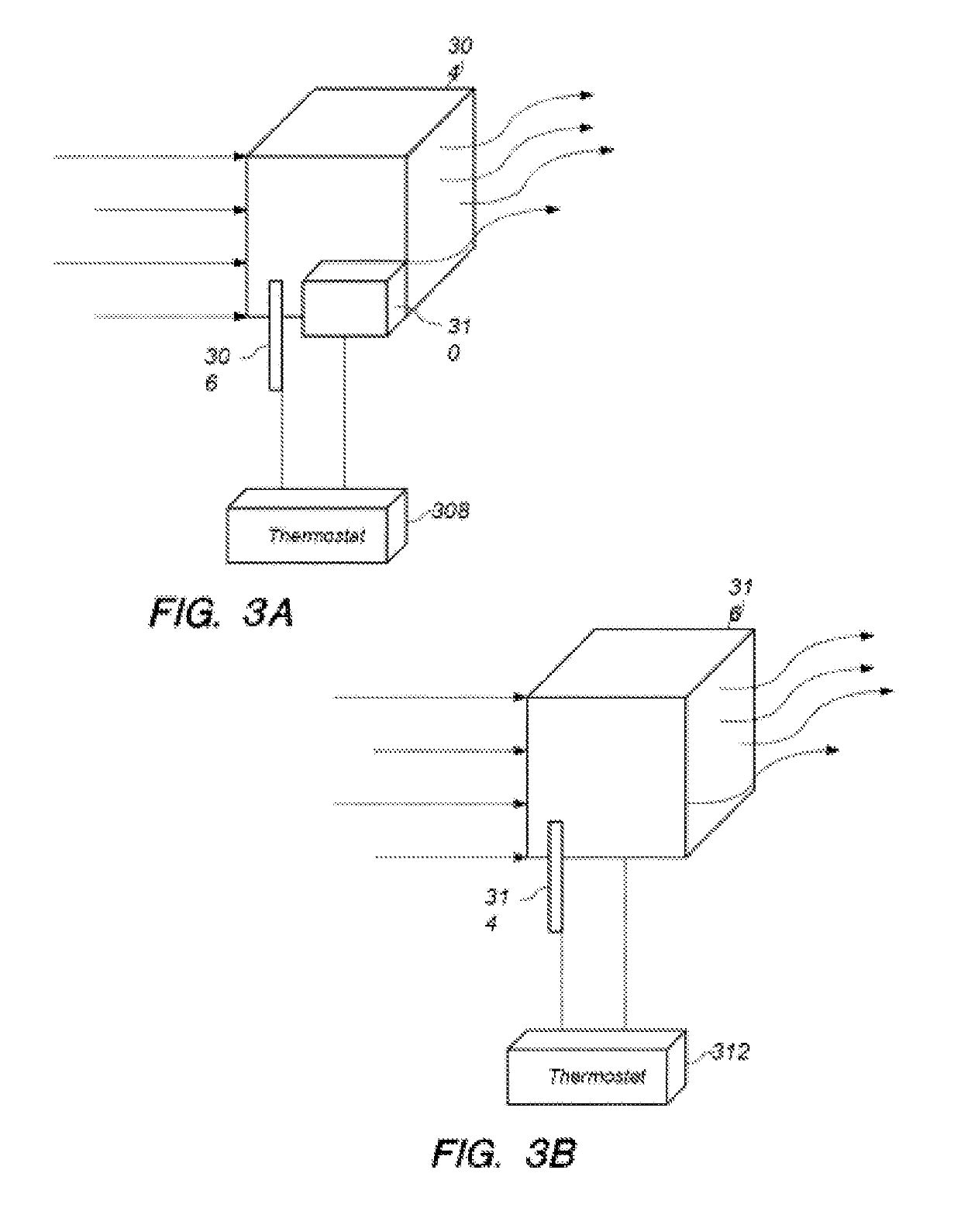

System and Method for Delivery of Variable Flow Haptics in an Immersive Environment with Latency Control

InactiveUS20190079480A1Non-uniform flow of airUniform and stable flowProgramme controlComputer controlDashboardMobile apps

The present embodiments disclose apparatus, systems and methods for allowing users to receive targeted delivery of haptic effects with latency control. The haptic tower may have an enclosed, modular assembly that manipulates air flow, fluid flow, scent, or any other haptic or sensation, for an immersed user, or may be a stationary installation for more industrial-scale or group use. Moreover, the system has an application of sensor technology to capture data regarding a users' body positioning and orientation in the real environment. This data, along with the data from a program coupled to the system, is relayed to the micro-controller with instructions coded thereon to direct air flow, variable intensity of air flow, variable temperature of air flow, and targeted dispensing of haptic effect with latency control. These features expand the sense of realism and immersion of a user in a virtual space. Other back-end functionalities may be taken advantage of by a user through an interactive mobile app or from the high-resolution, easy-to-use user-interface display. Aside from the sophisticated components and electronics delivering precision haptics, the intelligent and contextually-aware system also easily integrates with any home automated system via Wi-Fi, ZigBee, or Bluetooth 4.0. The system also easily connects to a cloud-based server allowing it to interface with the mobile app, enabling the user to choose from a variety of informative dashboard alerts and features. Moreover, a peer-sharing tool allows for users to share aspects of their immersive experience.

Owner:WHIRLWIND VR INC

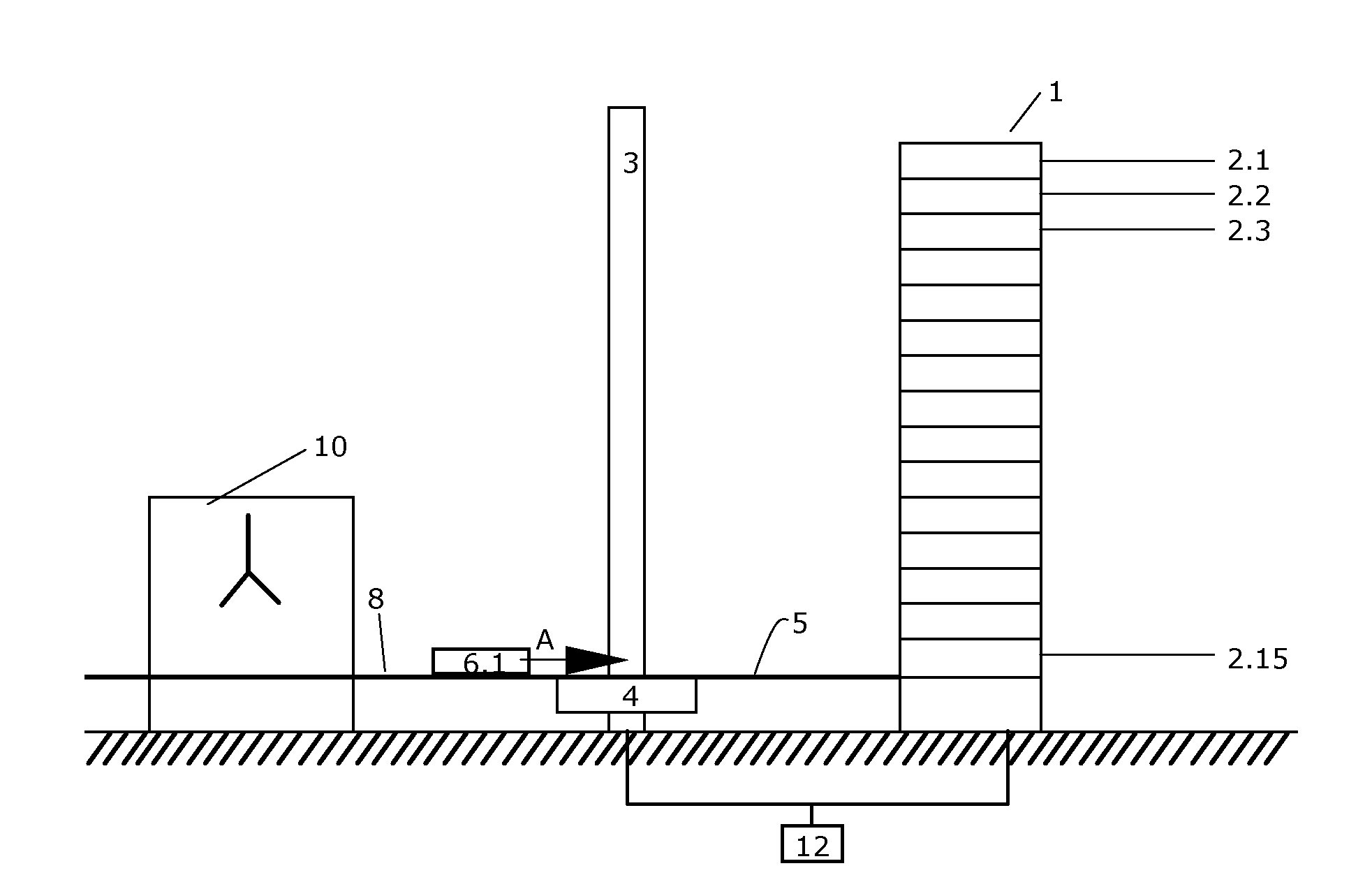

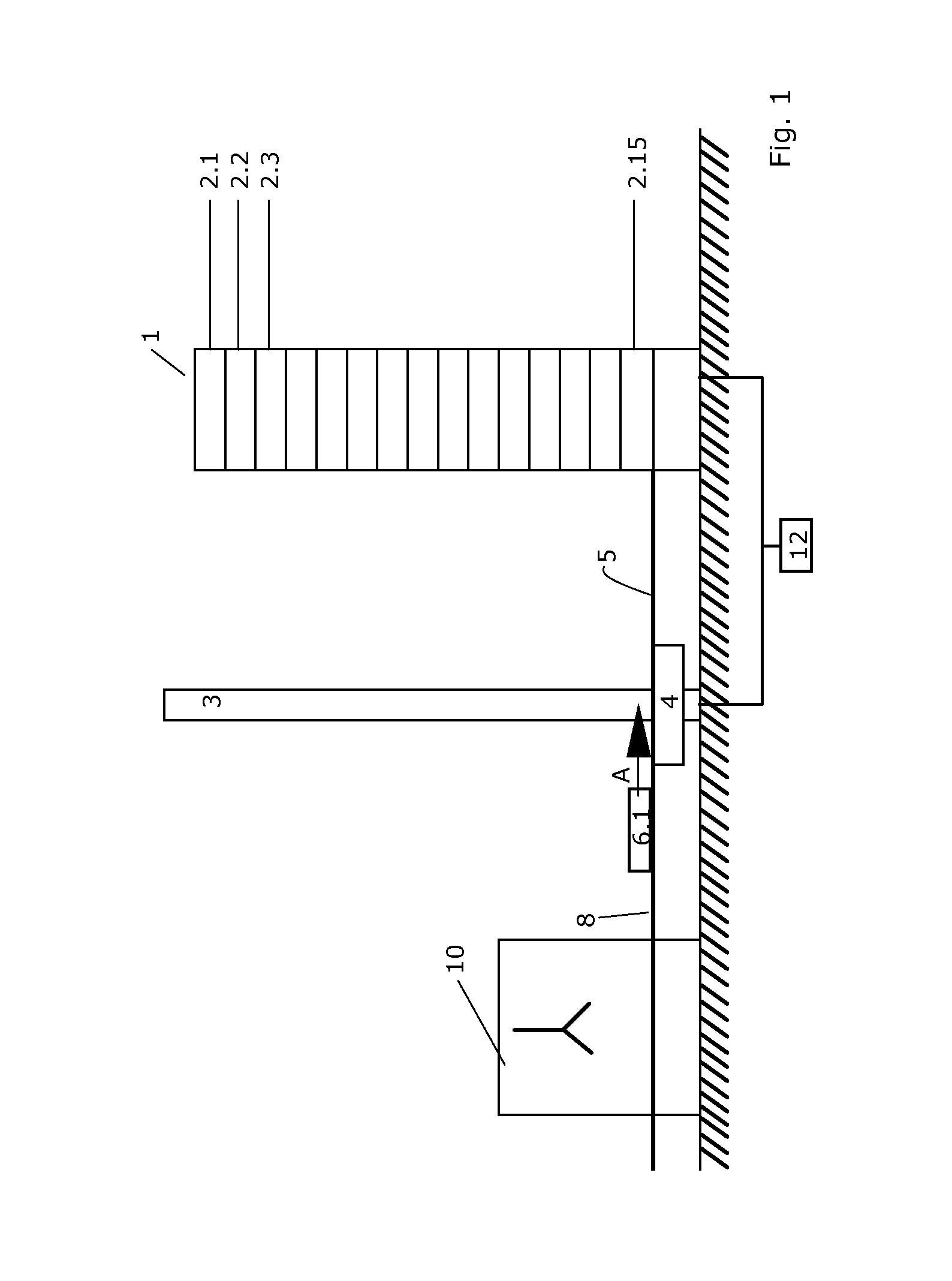

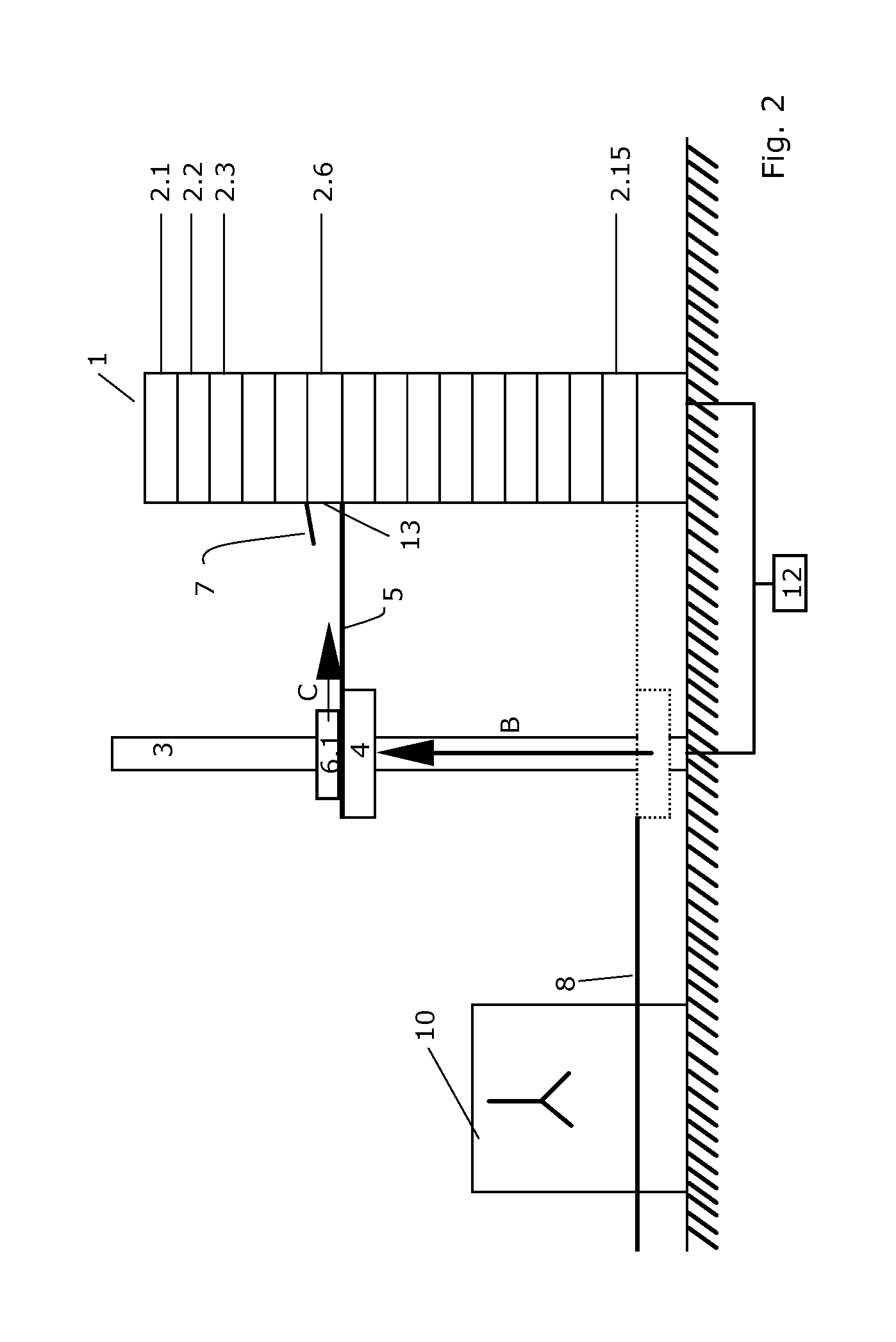

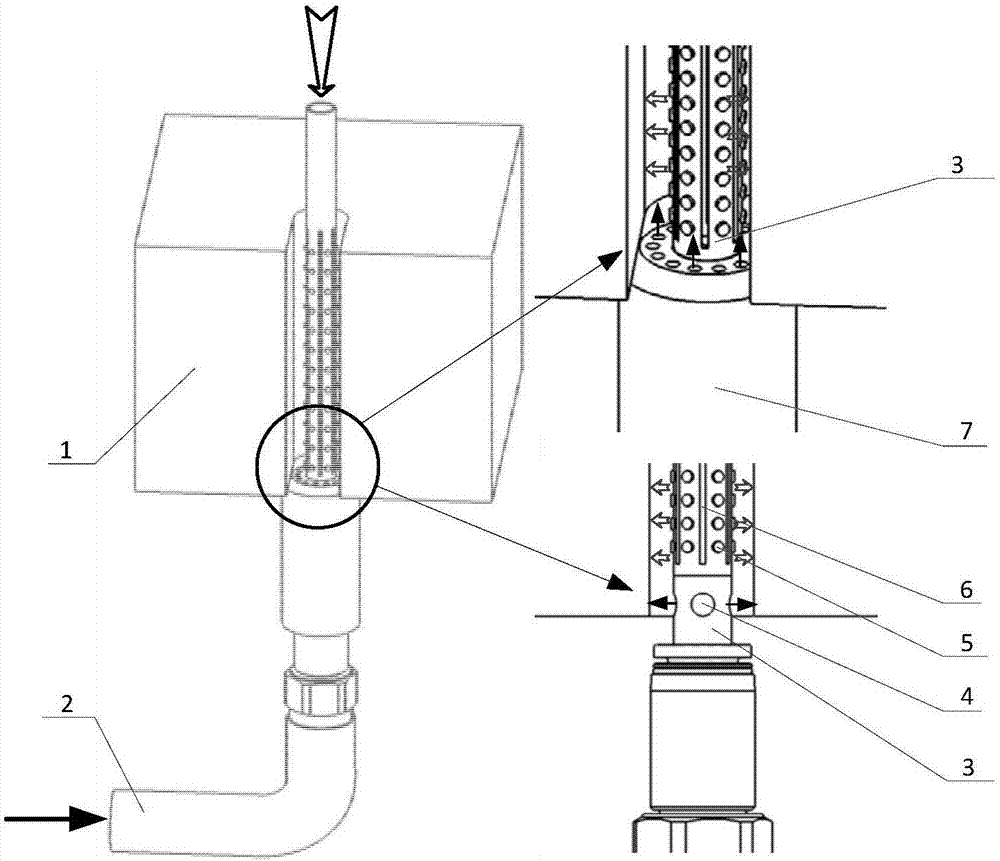

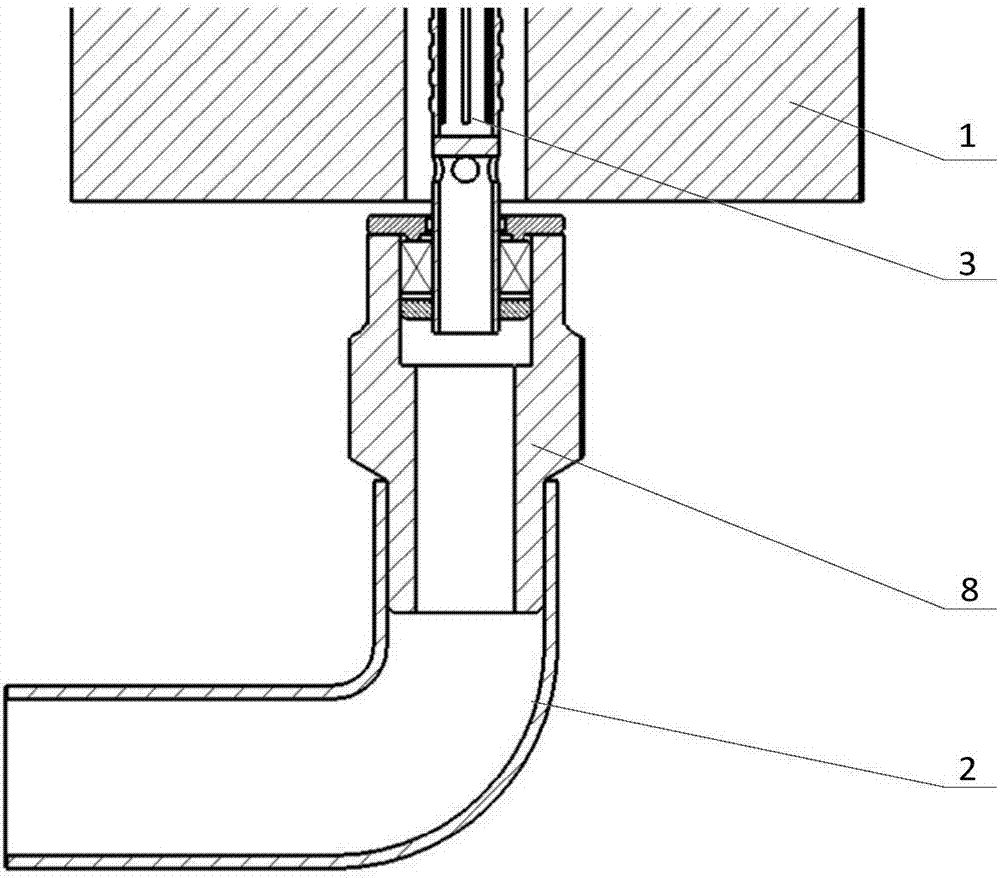

Method and apparatus for drying workpieces

InactiveUS20140173928A1Uniform and stable flowImprove surface qualityDrying solid materials without heatDrying chambers/containersEngineering

The present invention relates to a method and a device for drying, in particular for drying painted workpieces (6), which has at least two drying units (2), wherein the individual drying unit is set up to receive a number of painted workpieces, and heating means, which are set up to generate a constant temperature in the drying device (1) and in each of the drying units (2).

Owner:VENJAKOB MASCHBAUU

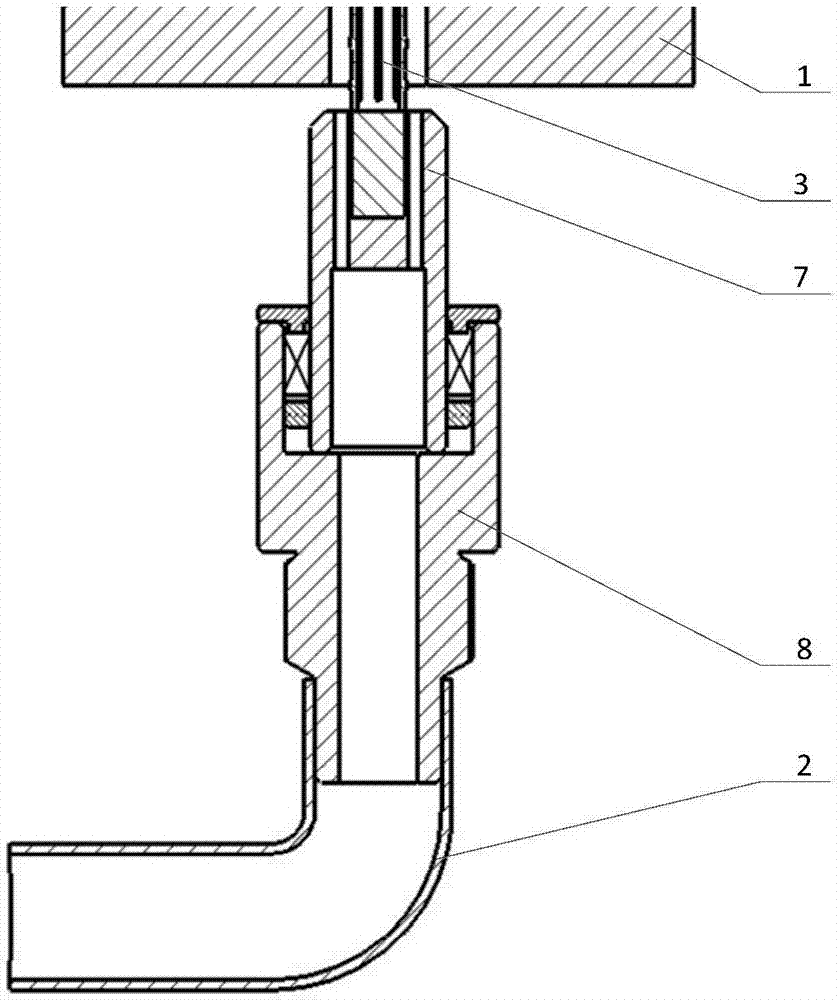

Tubular electrode abrasive particle assisting multi-bath electrolytic cutting machining device and method

ActiveCN107999905AEfficient electrolytic cutting processUniform and stable flowElectrochemical machining apparatusElectrolysisPersonal computer

The invention relates to a tubular electrode abrasive particle assisting multi-bath electrolytic cutting machining device and a tubular electrode abrasive particle assisting multi-bath electrolytic cutting machining method and belongs to the field of electrolytic machining. The device and the method are characterized in that the surface of a tubular electrode is additionally provided with abrasiveparticles; an anode metal which is not removed by electrolysis in time due to lack of liquid and a passivation layer formed on the surface of titanium alloy in an electrolytic machining process can be removed by a grinding force generated by the abrasive particles in high-speed rotation of the tubular electrode, so high-efficiency proceeding of electrolytic machining is promoted; in the machiningprocess, the tubular electrode rotates at a high speed; a plurality of narrow gaps are uniformly distributed on the sidewall of the tubular electrode in order to spray liquid at a high speed so thatproducts generated in an electrolytic machining region can be discharged rapidly; the bottom of the tubular electrode is provided with a radial or axial air blowing opening; the air blowing opening can keep a certain air pressure (backpressure) at an electrolyte outlet and can promote an electrolyte flow field of the machining region to be more stable, and improvement of the surface quality of a work piece in the machining region is facilitated. The machining device comprises the following components: a rotary connecting pipe, an air charging pipeline, a sidewall multi-bath tubular electrode,an industrial personal computer, an electrolytic machining machine tool, a large-power direct-current power supply and an electrolyte circulating system. The machining device provided by the inventionhas important significances for increasing the flowing speed of an electrolyte, rapidly discharging products and guaranteeing one-time electrolytic cutting of a large-thickness work piece.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

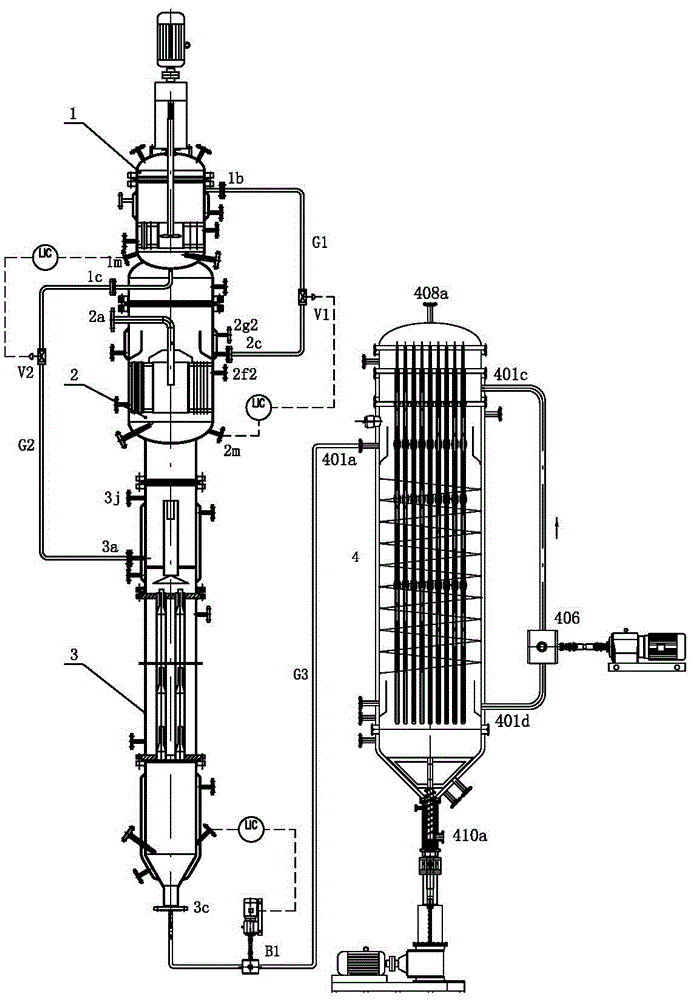

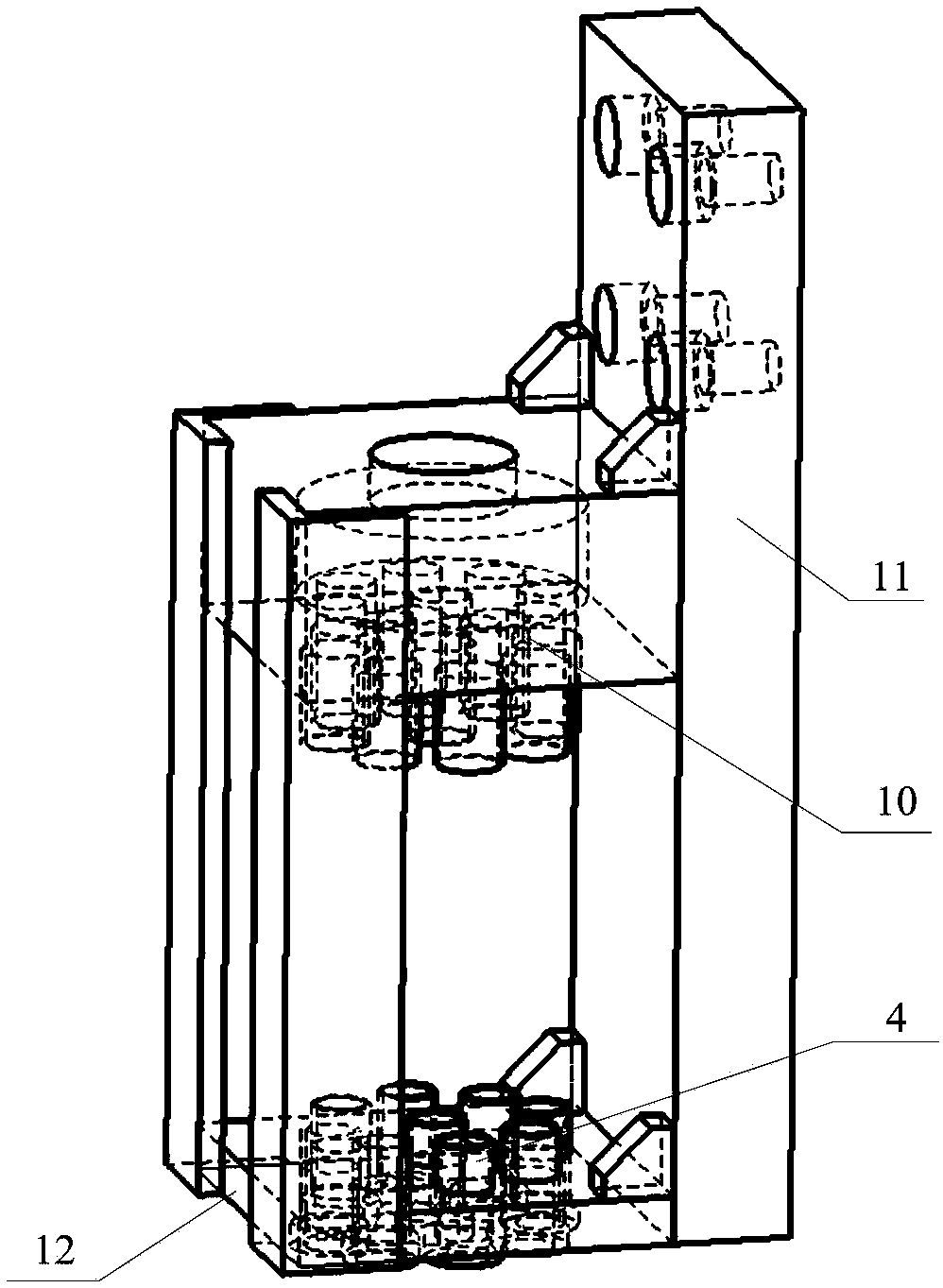

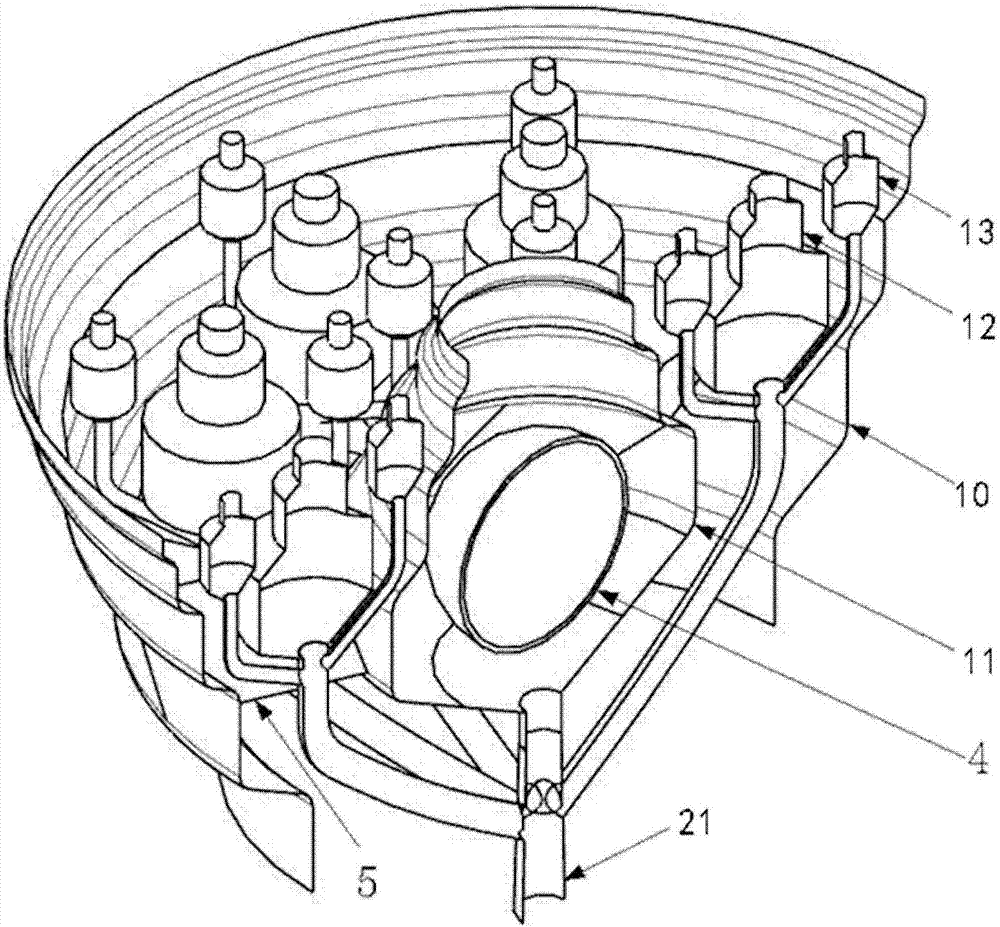

Esterification and polymerization double-kettle apparatus

ActiveCN105771868ACompact structureSmall footprintChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsPolymer scienceSmall footprint

The invention relates to an esterification and polymerization double-kettle apparatus. The apparatus comprises an esterification pre-condensation reaction tower and a stirring-free polymerization reactor, wherein a pre-condensation discharging hole of the esterification pre-condensation reaction tower is communicated with a feeding hole of the polymerization reactor through a pre-condensation melt conveying pump; a liquid distribution plate is arranged at the upper part of an inner cavity of the polymerization reactor; a falling-film tube is arranged in the liquid distribution hole; a hot medium heating tube is inserted in an inner cavity of the falling-film tube; the feeding hole of the polymerization reactor and a vacuumizing hole are formed in the outer wall of the upper part of a cylinder body; a discharging spiral and a polymer discharging hole are formed in the bottom of the polymerization reactor; an annular liquid distribution groove is formed in a part, corresponding to the feeding hole of the polymerization reactor, of the inner wall of the cylinder body; a uniform annular gap is reserved in the lower end of the liquid distribution groove; a liquid collection groove is formed in the inner wall of the lower part of the cylinder body; a middle melt outlet communicated with the liquid collection groove is formed in the outer wall of the cylinder body and is communicated with a middle melt inlet through a middle melt conveying pump; the middle melt inlet is formed in the upper part of the liquid distribution plate. The apparatus is compact in structure, small in occupied area and high in production efficiency.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

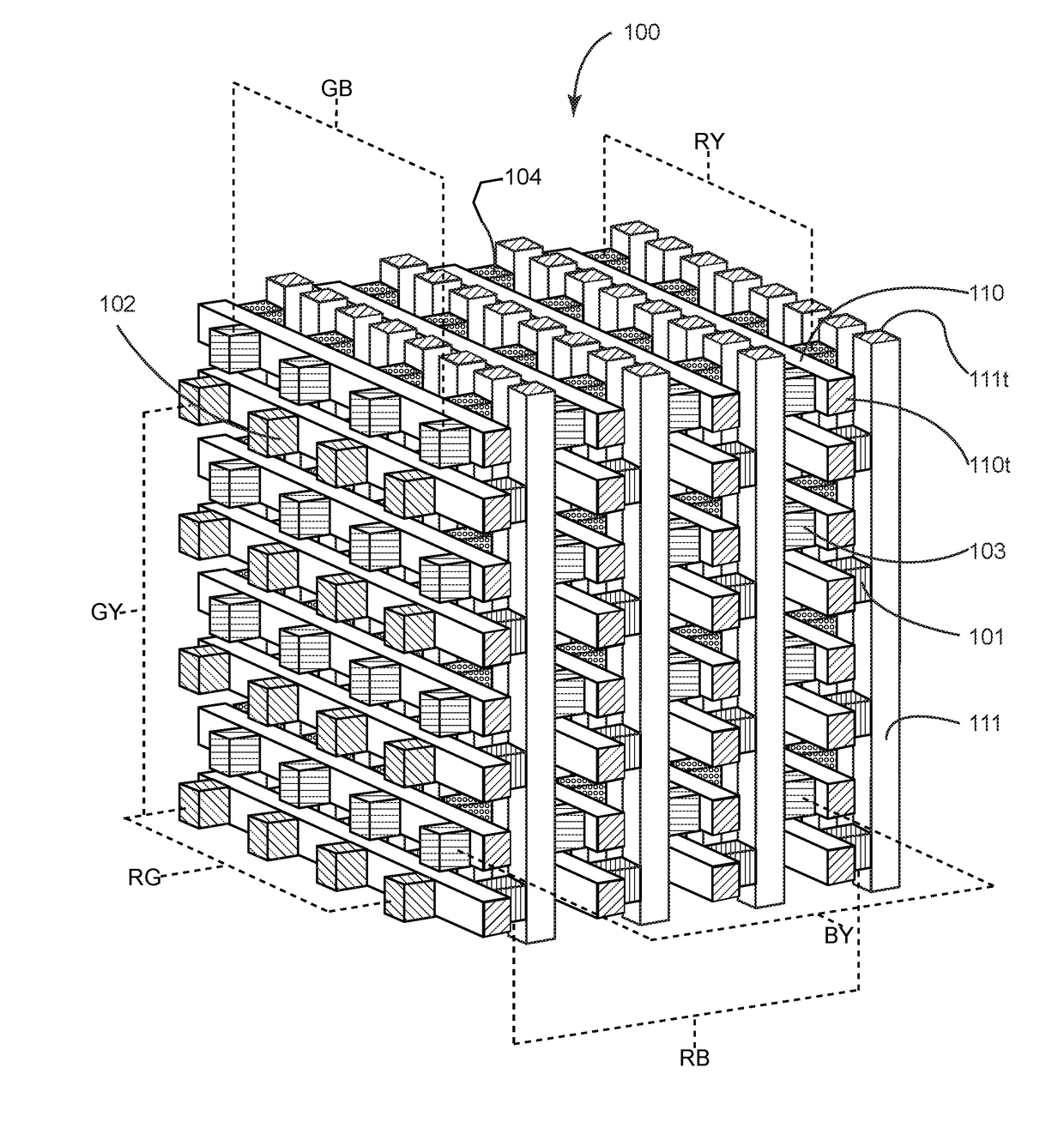

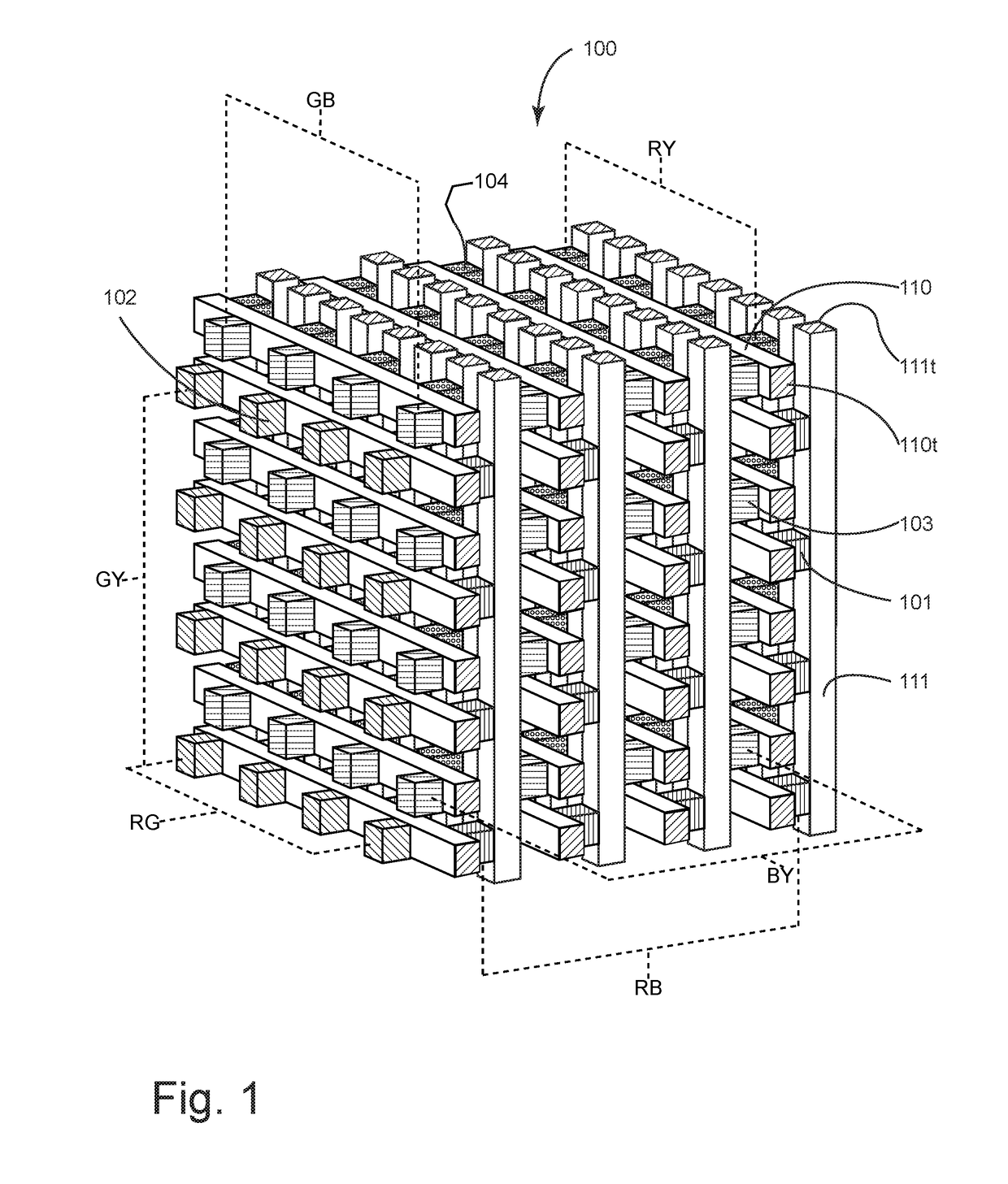

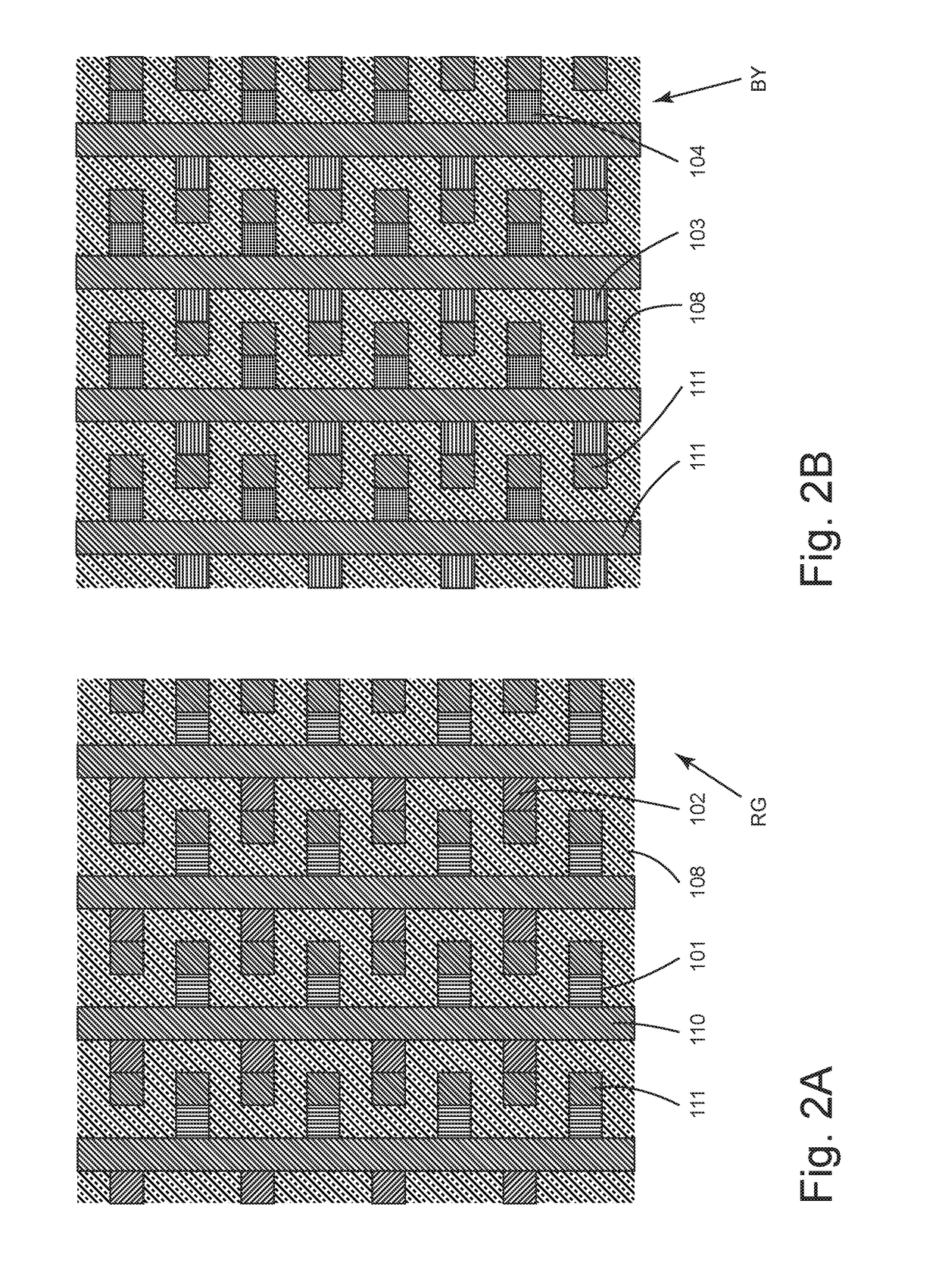

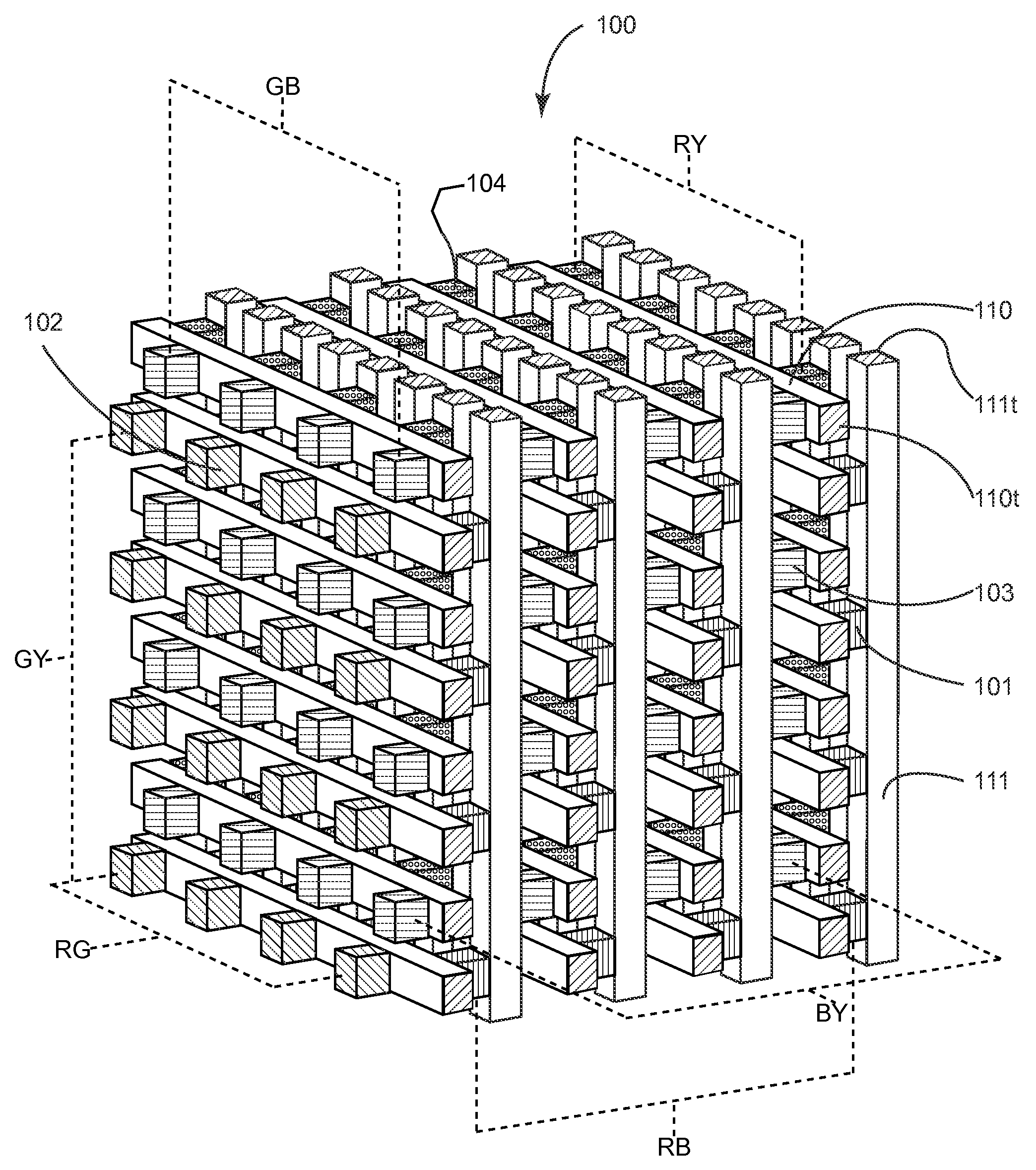

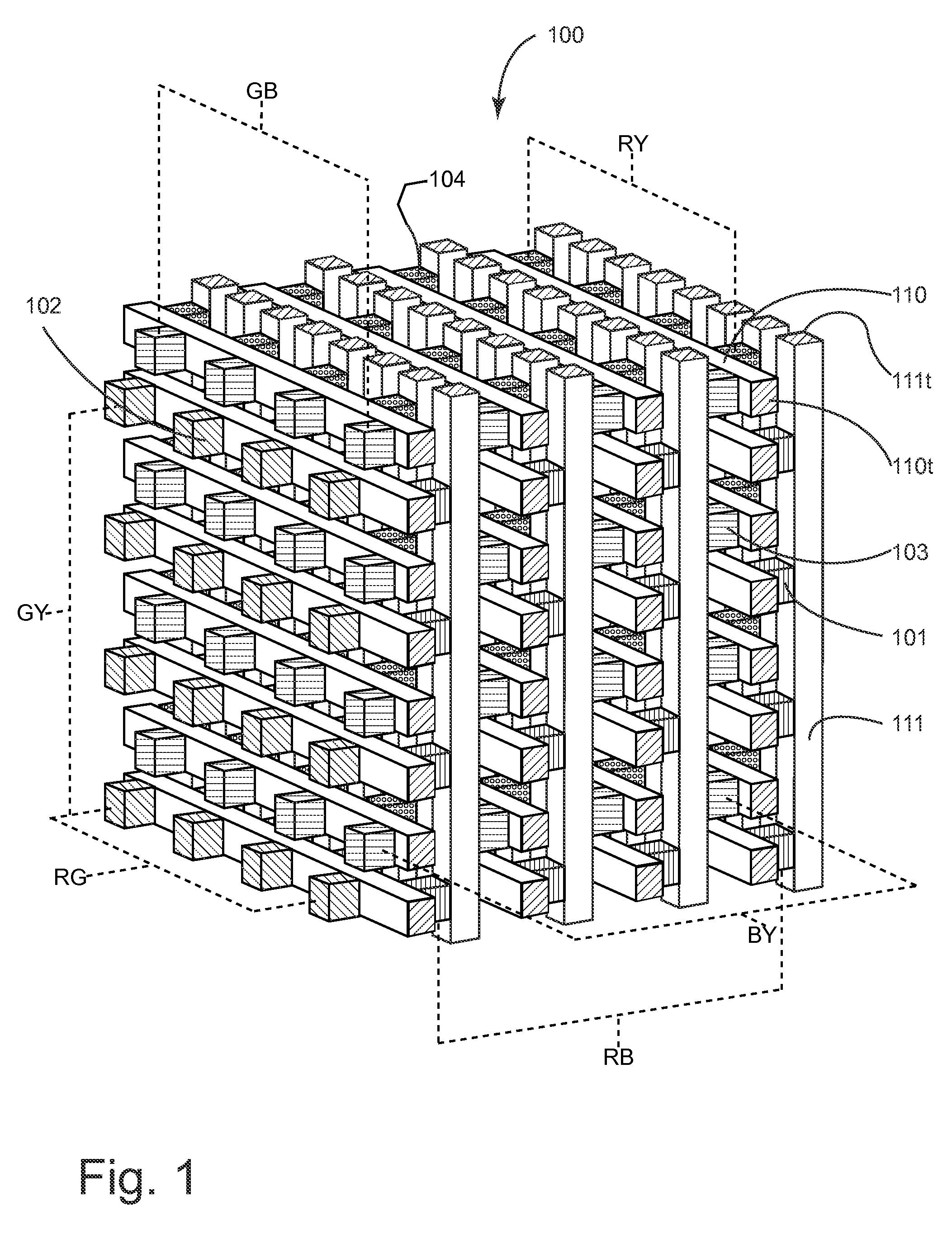

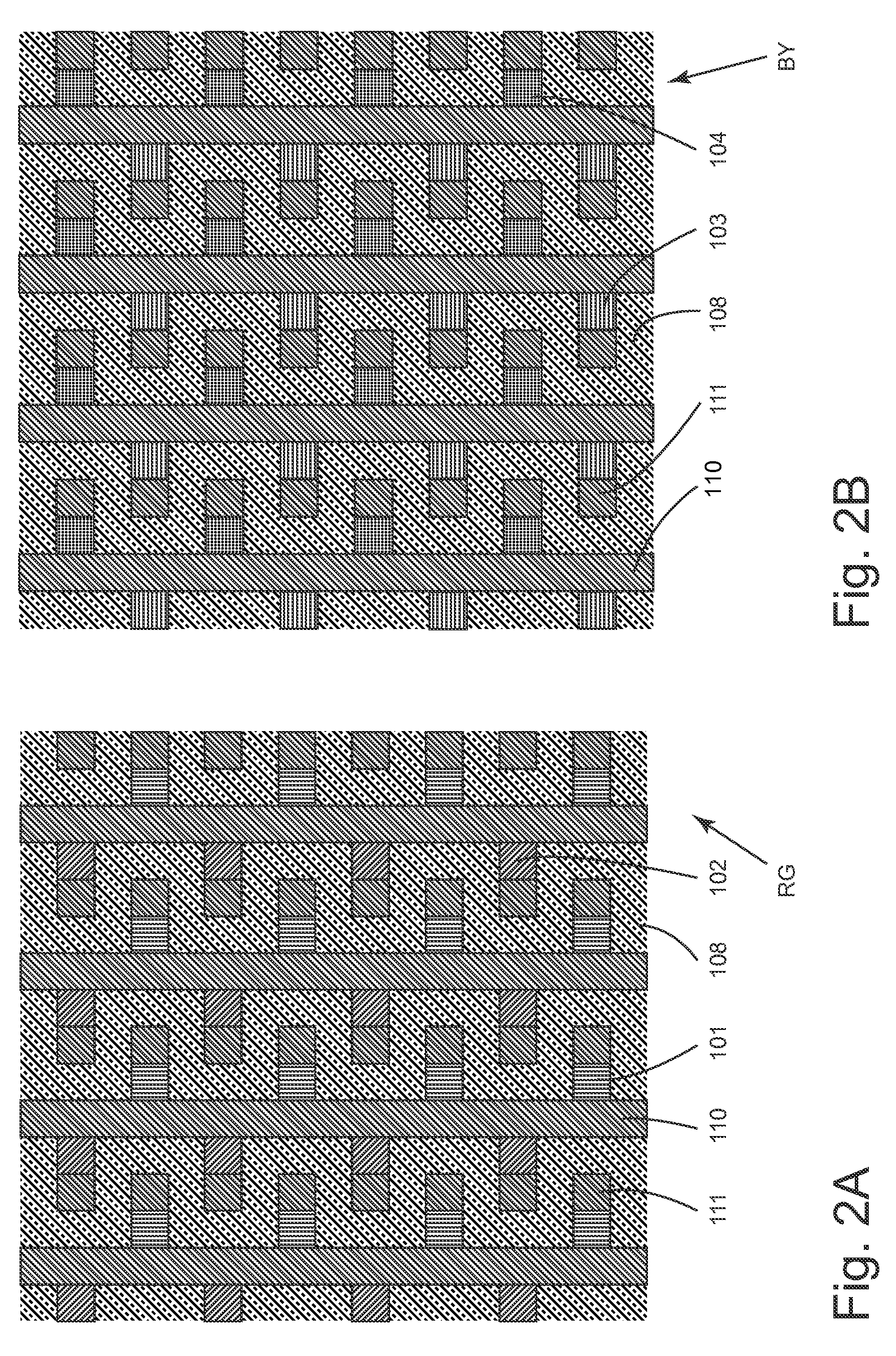

Volumetric three-dimensional display

InactiveUS20170090209A1Improve performanceUniform and stable flowReconstruction from projectionStatic indicating devicesVoxelElectrical conductor

Novel arrangements of elements (e.g., individual emitters or stacks thereof) produce three-dimensional full-color light-emitting displays. In an embodiment, planar arrays of regularly-spaced elements and electrical conductors can be configured together by staggering the layers' respective lateral positioning and controlling the pitch between layers. Various advantages may include smooth flow of voxels and boundaries and / or enhanced three-dimensional appearance versus conventional direct stacks.

Owner:BRINDISI THOMAS J

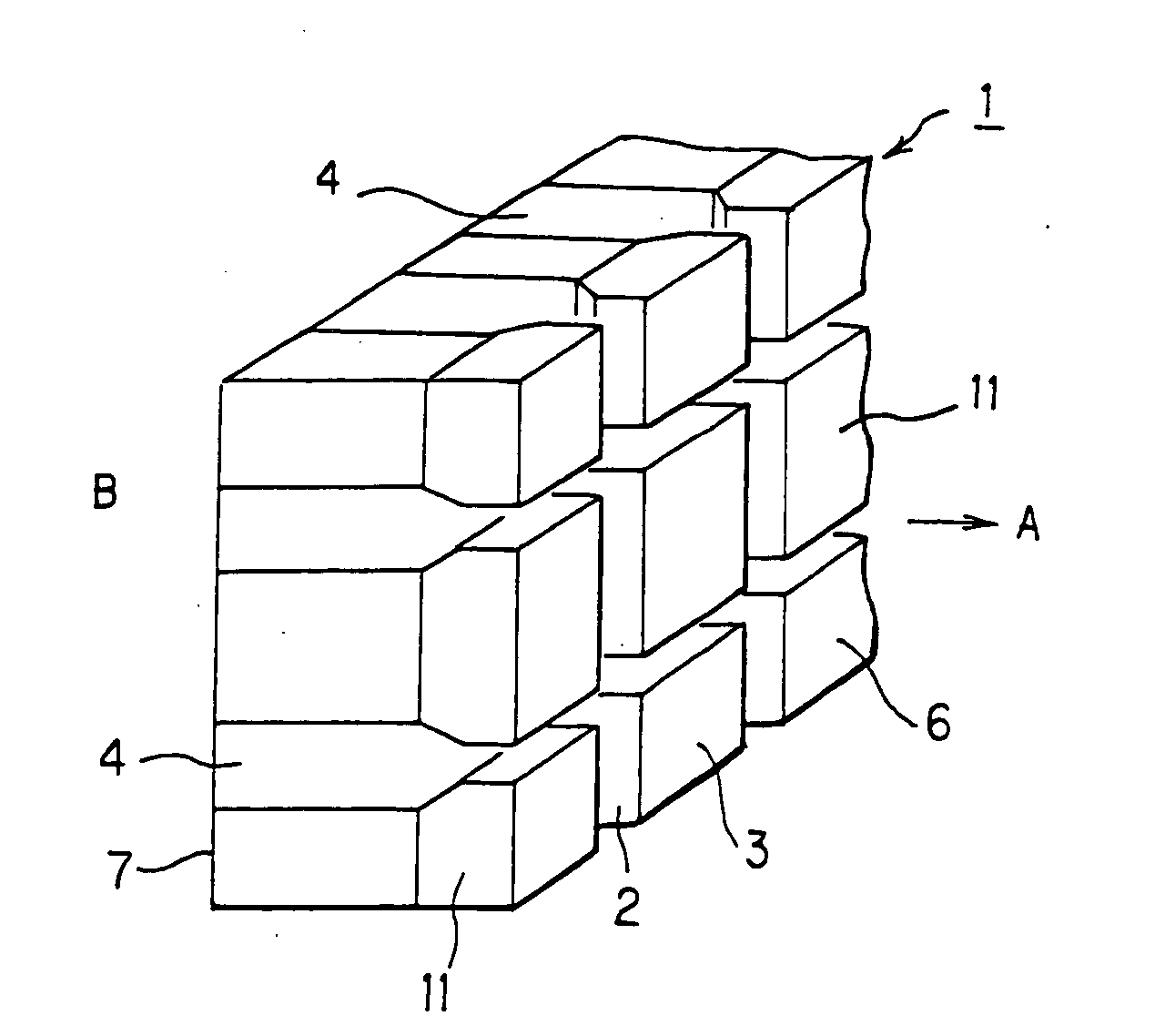

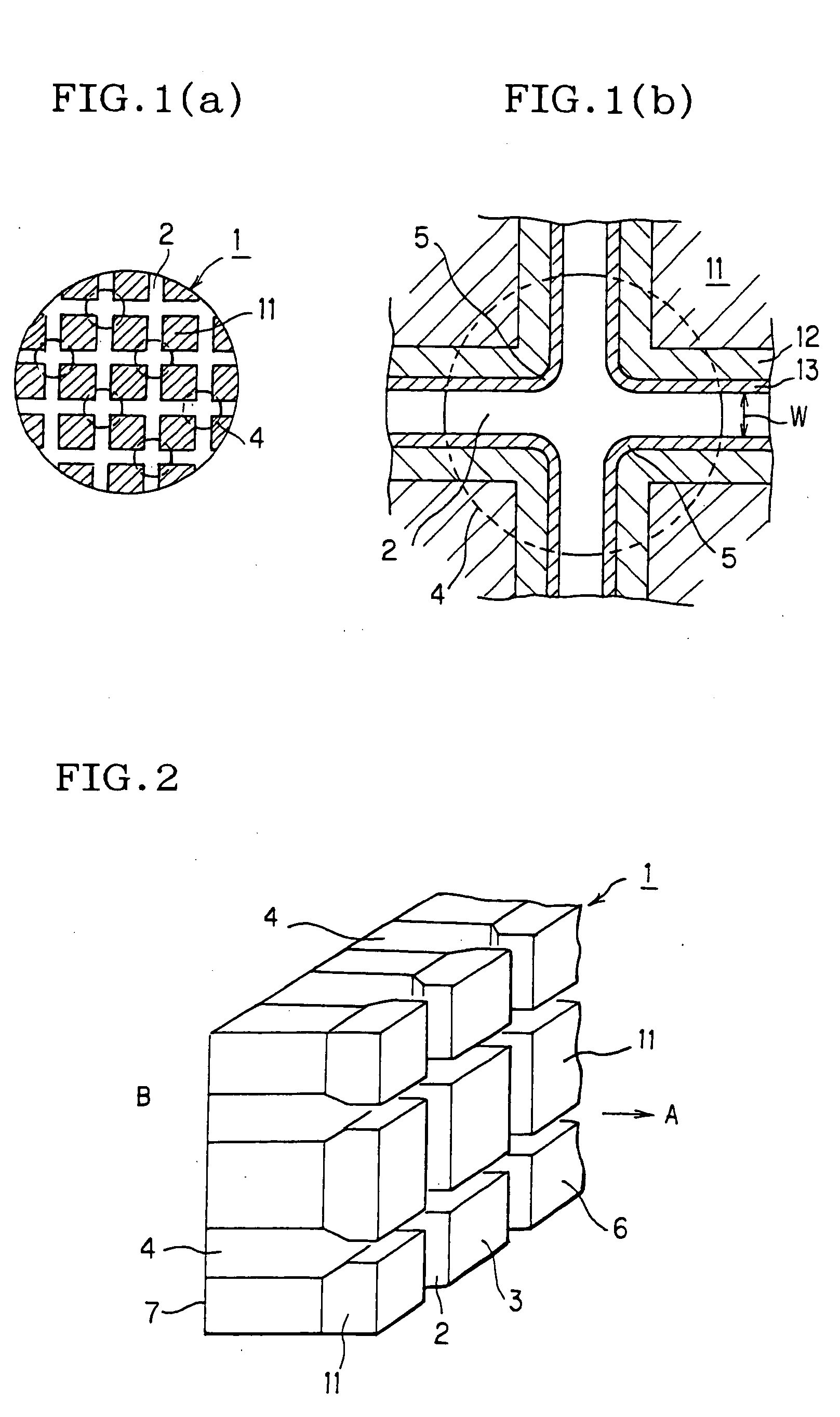

Honeycomb structural body forming ferrule and method of manufacturing the ferrule

ActiveUS20050031727A1Improve accuracyAvoiding poor formingPhysical/chemical process catalystsConfectioneryProduction rateSurface layer

A die for extrusion-forming a honeycomb structure which includes: a die base provided with ceramic puddle introducing holes and slits in communication with the ceramic puddle introducing holes; and a substrate layer, which roughly defines the final width of the slits, and a surface layer, which precisely defines the final width of the slits, formed on the die base in this order so that the final width of the slits becomes 15 to 200 μm, wherein the surface layer is made up of tungsten carbide particles which are 5 μm or less in average particle diameter and contain W3C as a main ingredient. According to this invention, there is provided a die for extrusion-forming a honeycomb structure which can restrain fluctuation in extrusion-forming speed among its parts and resistance to pushing force, both caused at the time of extrusion-forming, to be very small and is superior in productivity and durability.

Owner:NGK INSULATORS LTD

System and Method for Modulating a Light-Emitting Peripheral Device Based on an Unscripted Feed Using Computer Vision

ActiveUS20190243454A1Non-uniform flow of airUniform and stable flowInput/output for user-computer interactionImage enhancementVisual perceptionComputer science

Owner:WHIRLWIND VR INC

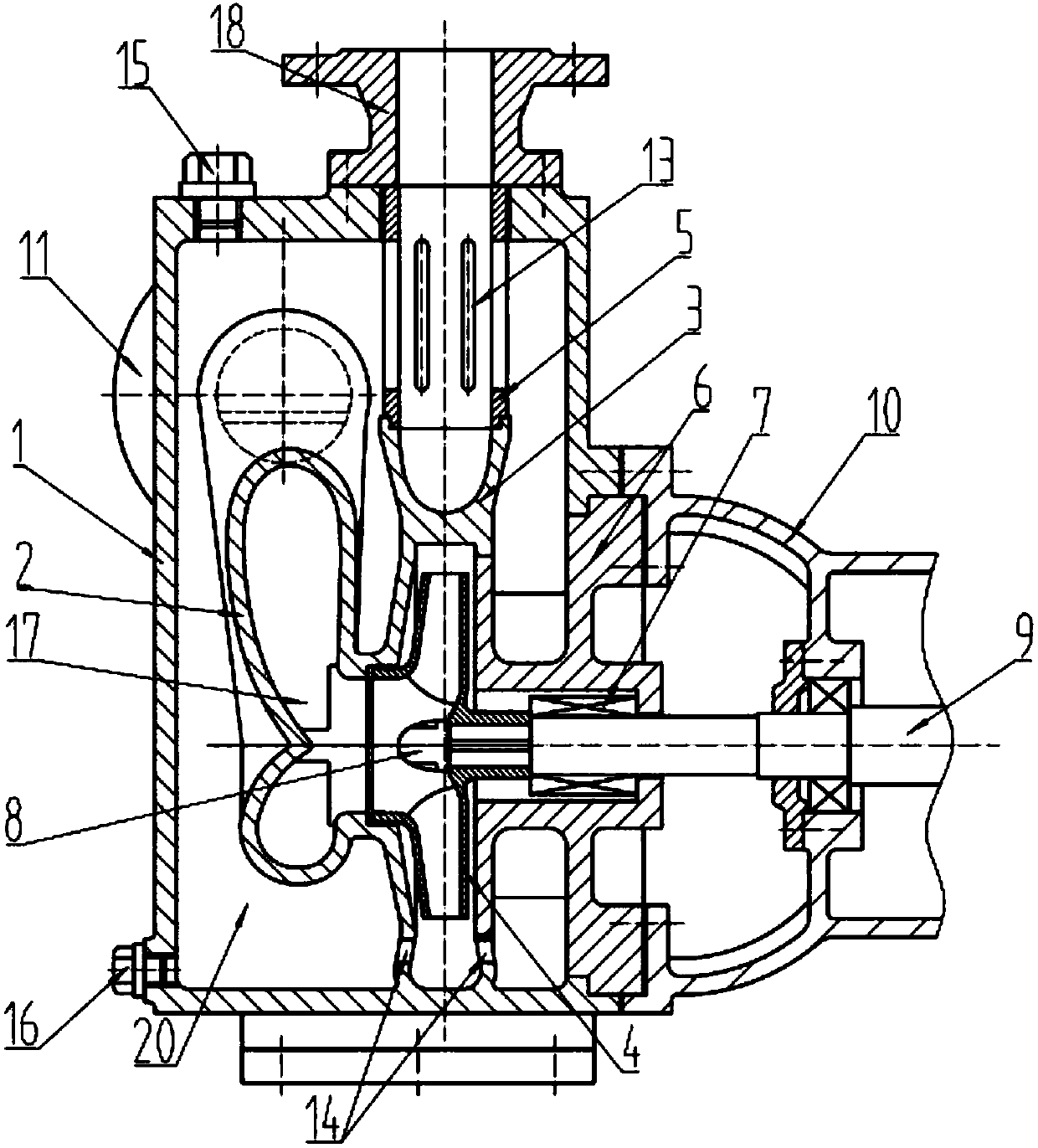

Double-outlet multipurpose external mixing type self-priming pump with quasi-spiral suction chamber

PendingCN107588008AImprove self-priming performanceImprove hydraulic performancePump componentsPriming pumpAgricultural irrigationPetrochemical

The invention provides a double-outlet multipurpose external mixing type self-priming pump with a quasi-spiral suction chamber. The double-outlet multipurpose external mixing type self-priming pump mainly comprises an inlet flange, a pump body, an impeller, an air-liquid separating pipe, a rear cover, a suspension body part, an outlet flange and a flange cover, wherein the pump body is formed by the quasi-spiral suction chamber, a spiral compression chamber and a liquid storage chamber through integral casting and is provided with double outlets and the like. The hydraulic performance of the pump is effectively improved while the self-priming performance of the self-priming pump is improved, the flow losses of fluid media in a suction chamber and a water compressing chamber are remarkablyreduced, and the double-outlet multipurpose external mixing type self-priming pump has the advantages of being high in efficiency and reliability, compact in structure, convenient to install and maintain and multipurpose, serving as a pipeline self-priming pump accessed horizontally only by slightly adjusting an installing mode and the like, is suitable for the fields of agricultural irrigation and drainage, river and pond breeding, municipal drainage, petrochemical metallurgy and the like and can be installed on a movable pump truck for fire-fighting operation and the like.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

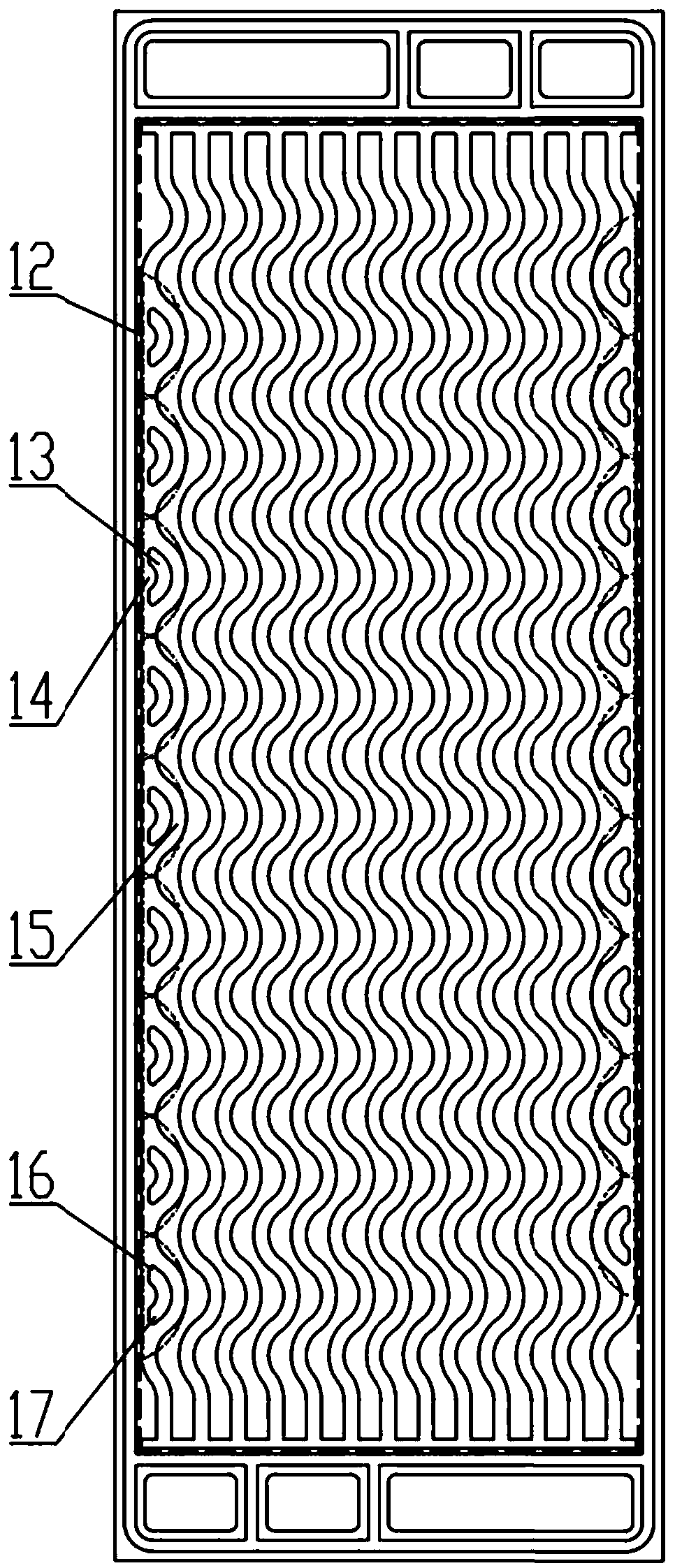

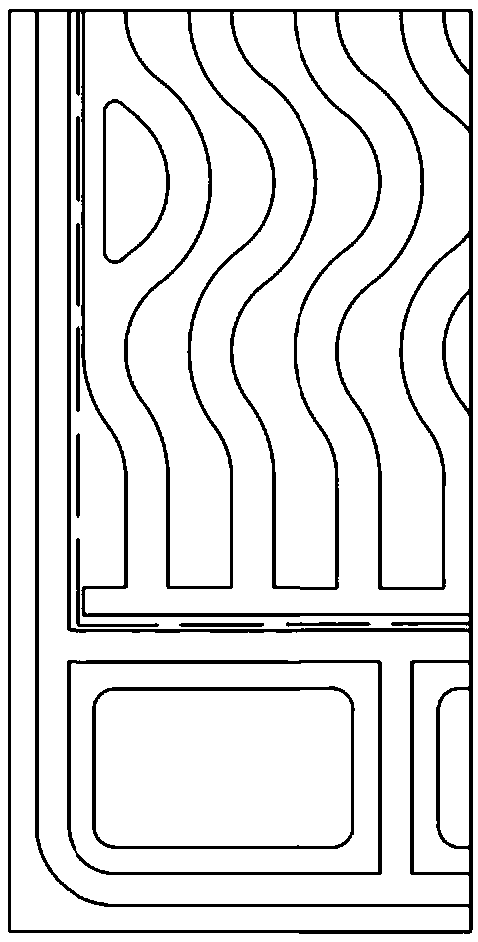

Flow field structure for improving effective area of bipolar plate waveform flow channel flow filed of fuel cell

ActiveCN109509896AUniform and stable flowReduce power generation capacityFuel cellsElectrochemical responseFuel cells

The invention relates to a flow field structure for improving an effective area of a bipolar plate waveform flow channel flow filed of a fuel cell. A half-moon-like lug boss similar to the shape of awaveform flow channel and flow channels around the half-moon-like lug boss are arranged on electrochemical reaction weakening regions distributed at two sides of the waveform flow channel flow filed,so that each electrochemical reaction weakening region is provided with an electrochemical reaction with the same degree as a fuel cell main body flow field. The effective area of the bipolar plate waveform flow channel flow filed can be improved through the flow field structure, and the effective electrochemical reaction area is improved through reducing the electrochemical reaction weakening regions of each fuel cell. Although the ratio of the electrochemical reaction weakening regions in the flow field of the fuel cell is relatively low, since the fuel cell galvanic pile is formed by stacking dozens even hundreds of fuel cells, for one fuel cell galvanic pile, the increase in the effective area of electrochemical reaction of the fuel cell is considerable.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

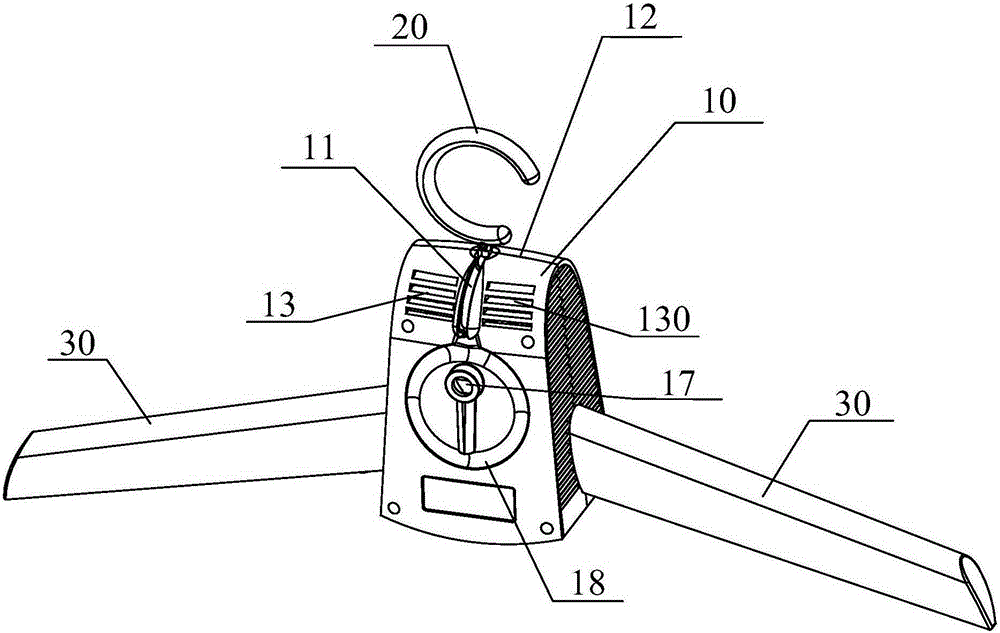

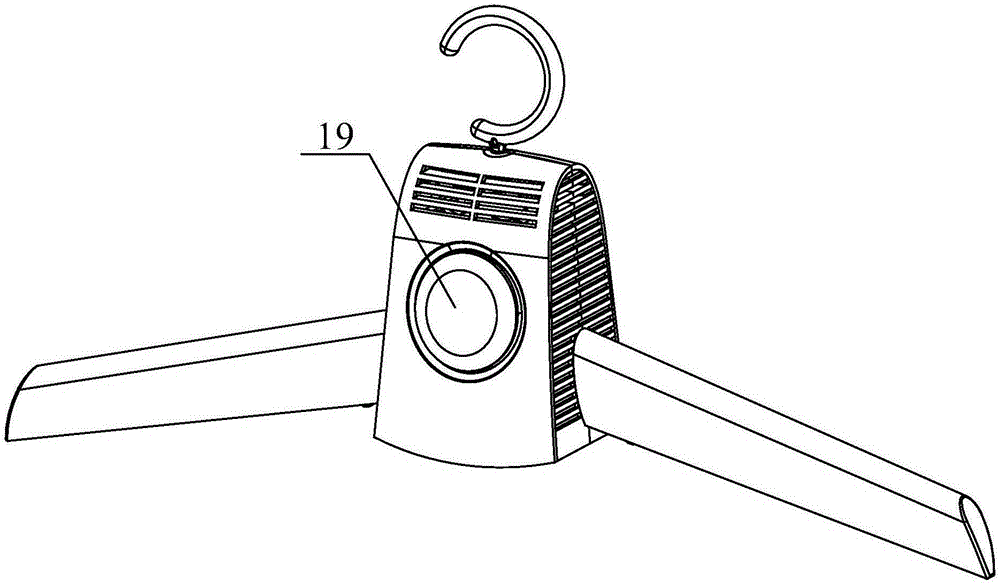

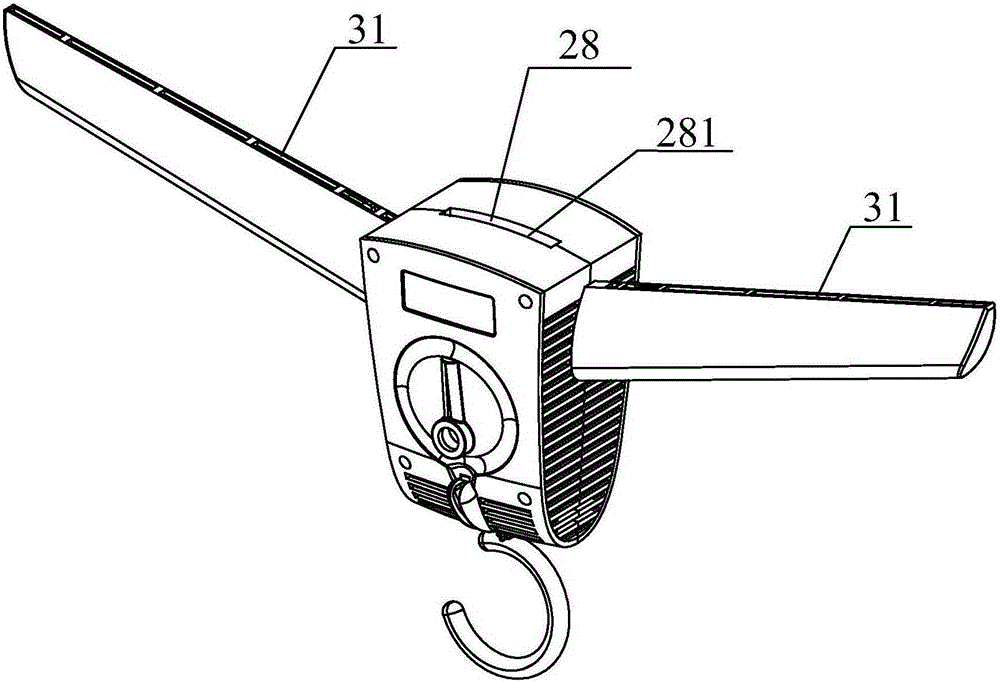

Clothes hanger

InactiveCN105177952AHigh densityBig impactOther drying apparatusTextiles and paperEvaporationEngineering

The invention discloses a clothes hanger which comprises a clothes hanger body. An air outlet is formed in the clothes hanger body. A heating body is also arranged in the clothes hanger body. An air outlet channel is arranged between the heating body and the air outlet. The cross sectional area of the air outlet channel is gradually reduced when the air outlet channel is gradually close to the air outlet. By the adoption of the structure, after the airflow passing through the heating body reaches the air outlet channel, the airflow is squeezed due to the fact that the cross sectional area of the air outlet channel is gradually reduced, and the airflow speed is gradually increased; due to the closing-in arrangement of the air outlet channel, the airflow is larger in density and impact force; when the airflow rushes out of the air outlet, larger flushing force is produced to clothes hung on the clothes hanger, the airflow flowing speed is increased, and therefore water drops on the clothes can be flushed away more easily; or evaporation of water in the clothes is accelerated, and therefore the clothes are dried more rapidly.

Owner:尚平

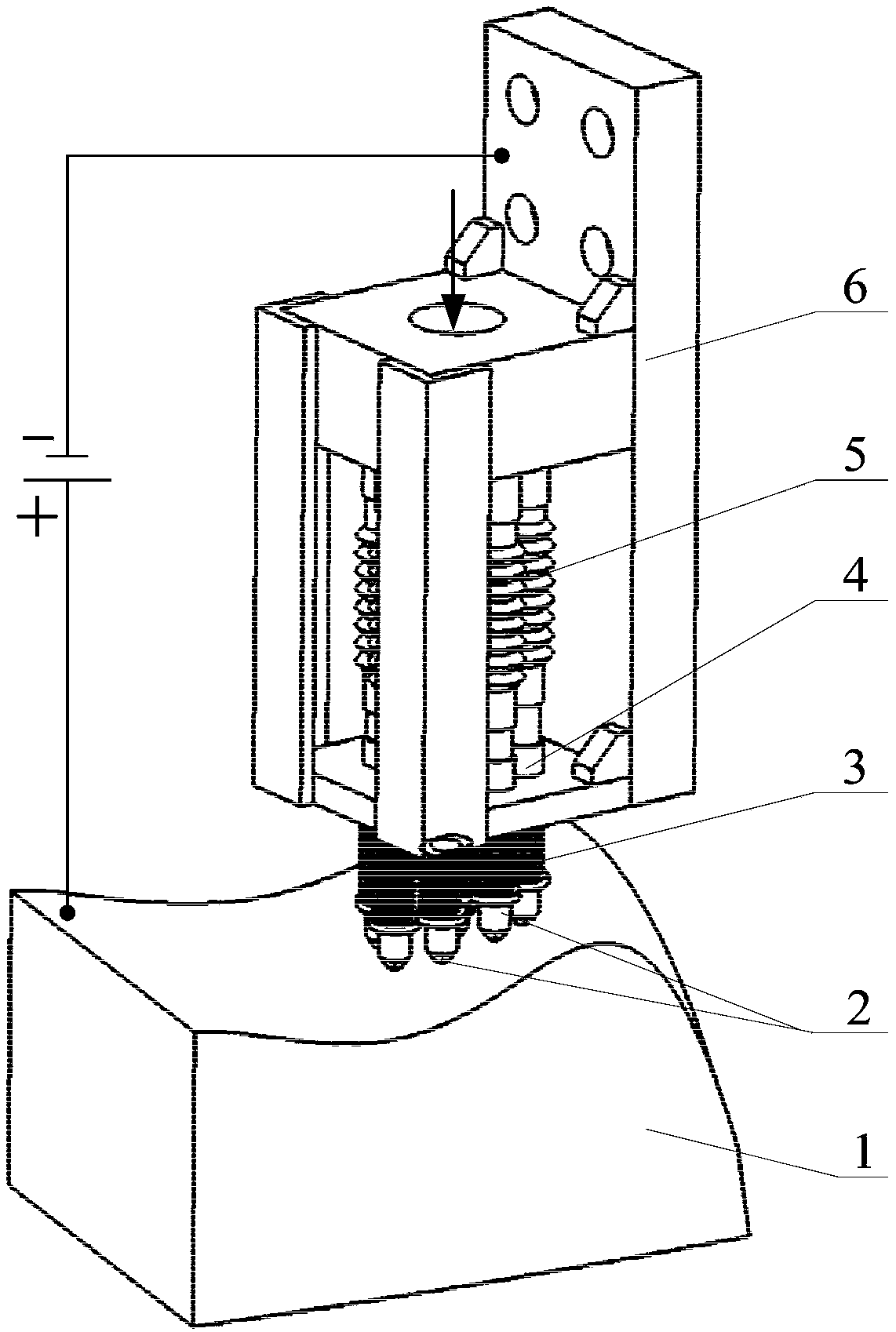

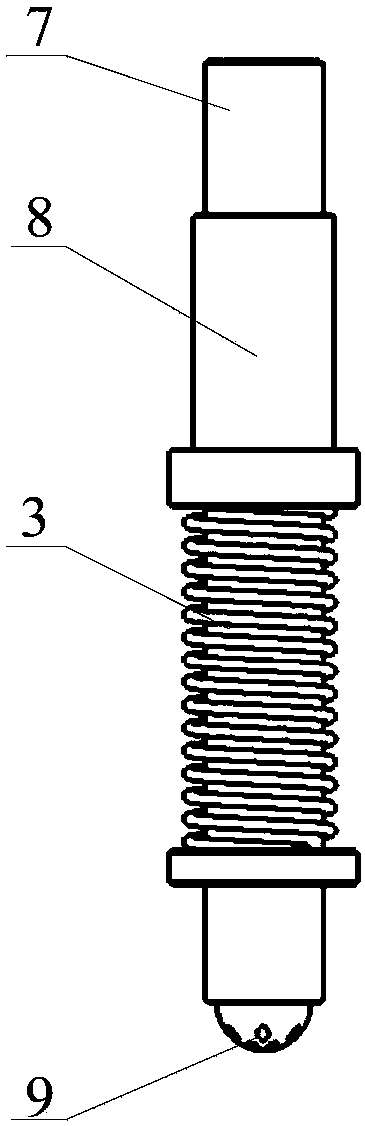

Multi-pipe floating complex curved surface self-finding track electrolytic processing device and method

ActiveCN108213623AUniform and stable flowLow skill level requiredMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a multi-pipe floating complex curved surface self-finding track electrolytic processing device and method, and belongs to the field of electrolytic processing. The method is characterized in that an inner liquid spraying tube electrode group can be floated up and down on the surface of a curved surface part according to a specified processing track under the action of springs and a guide device, and the method can be used for electrolytic processing of workpieces with complex outer surfaces; and in addition, due to the fact that the multi-pipe liquid spraying processing is adopted, the flow field of a processing area is more stable compared with a single-pipe liquid spraying process. The processing device comprises the following components of group tube electrodes,the springs, elastic soft infusion tubes, a clamp body, a guide tube and the like. The method and the device has important significance in improving the electrolytic processing efficiency and stability and reducing the difficulty of programming and operation of numerical control machining the curved surface part.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

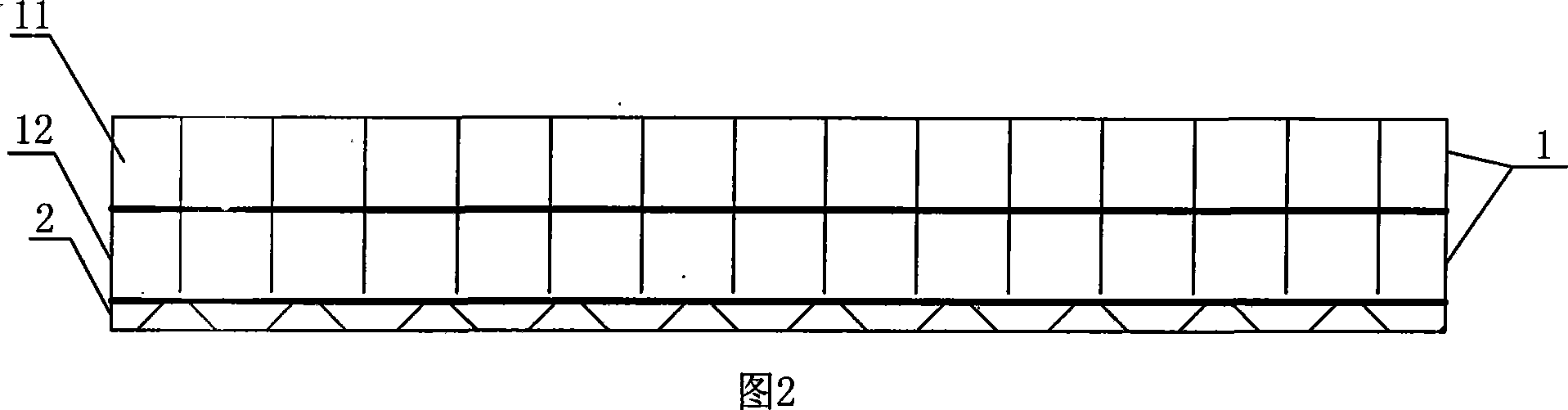

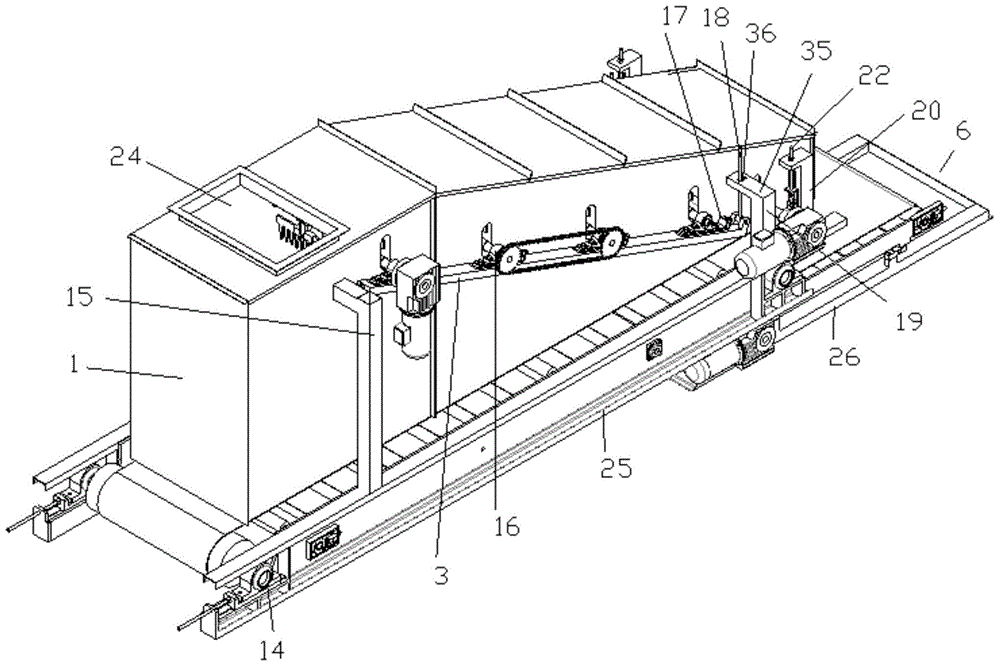

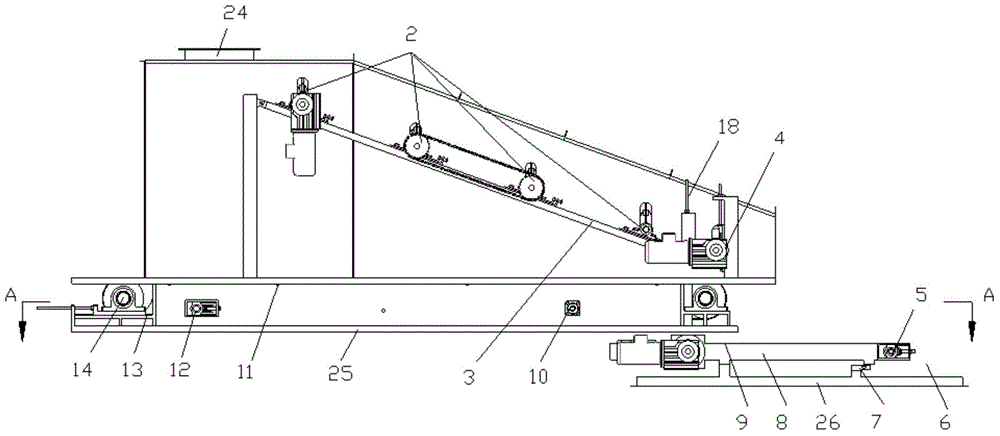

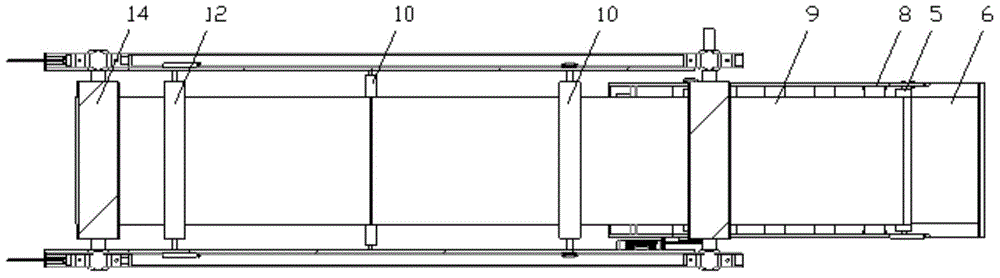

Wood shaving conveying metering device and method for conveying wood shaving thereof

InactiveCN105858263AIncrease the areaGood spread effectConveyorsWood working apparatusWood shavingsEngineering

The invention discloses a wood shaving conveying metering device, comprising a base, a stock bin, a conveying device which has a first conveyer belt and a second conveyer belt, a blanking roller device, and a self-balancing metering device. The blanking roller device is provided with a brush blanking roller. The gap between the brush blanking roller and the first conveyer belt can be adjusted. The self-balancing metering device is installed under the second conveyer belt, and is provided with a scale body structure used to realize self-balance. The brush blanking roller is used to absorb and sow wood shavings, so as to uniformly sow the wood shavings conveyed by the first conveyer belt on the second conveyer belt. The scale body structure comprises a scale rack and balance weight connected with one end of the scale rack. The scale rack and the balance weight are in a balance state. The device is simple in structure, and conveyed wood shavings are uniform in thickness, and wood shaving sowing effect is good. The device provides convenience for calculating conveying flow of the wood shavings. The device solves problems of poor sizing quality caused by errors of the wood shaving conveying flow in a subsequent sizing procedure. In addition, the invention also discloses a method for conveying wood shavings by using the above device.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Adsorption device and adsorption method

ActiveCN104722398AImprove adsorption capacityImprove filter qualityMagnetic separationCleaning using liquidsIron removalCleaning station

The invention discloses an adsorption device and an adsorption method. The adsorption device comprises an adsorption chamber, at least two adsorbers, a cleaning station and a switching device, wherein liquid is fed into the adsorption chamber from a first liquid inlet, when the liquid flows through the adsorbers, impurities in the liquid are attached to the adsorbers, and then the liquid subjected to adsorption and filtering flows out of a first liquid outlet; and after one adsorber adsorbs impurities, the switching device is adopted for switching the adsorber from the adsorption chamber to the cleaning station, and after the other adsorber is switched to the adsorption chamber, a cleaning device is adopted for cleaning the adsorbers. The cleaning station and the adsorption chamber are independently arranged, and the cleaning process of the adsorber does not take up the impurity adsorption time, so that the iron removal efficiency is greatly improved; and the device is simple in structure, easy to control and convenient to maintain.

Owner:广州粤有研矿物资源科技有限公司

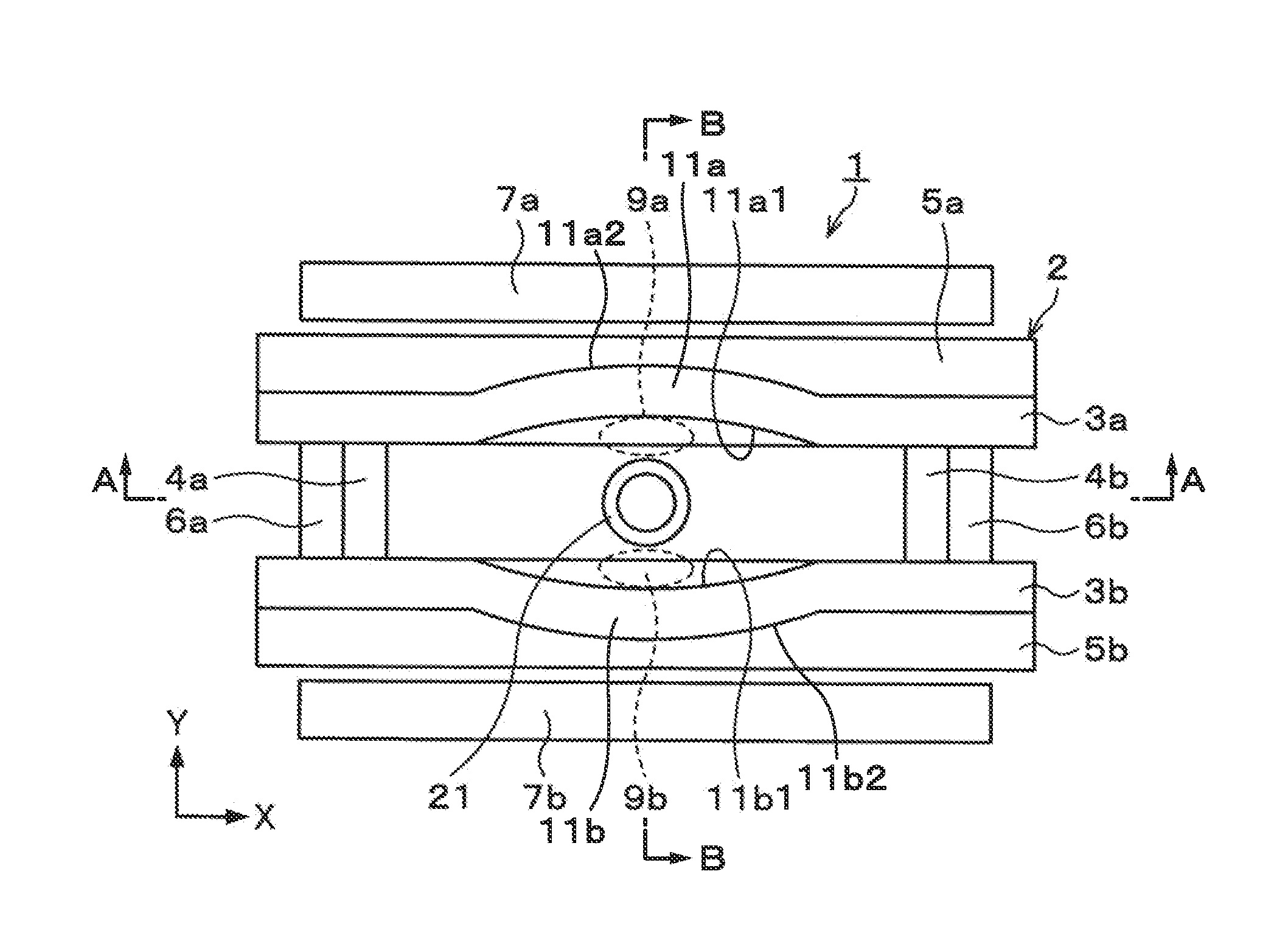

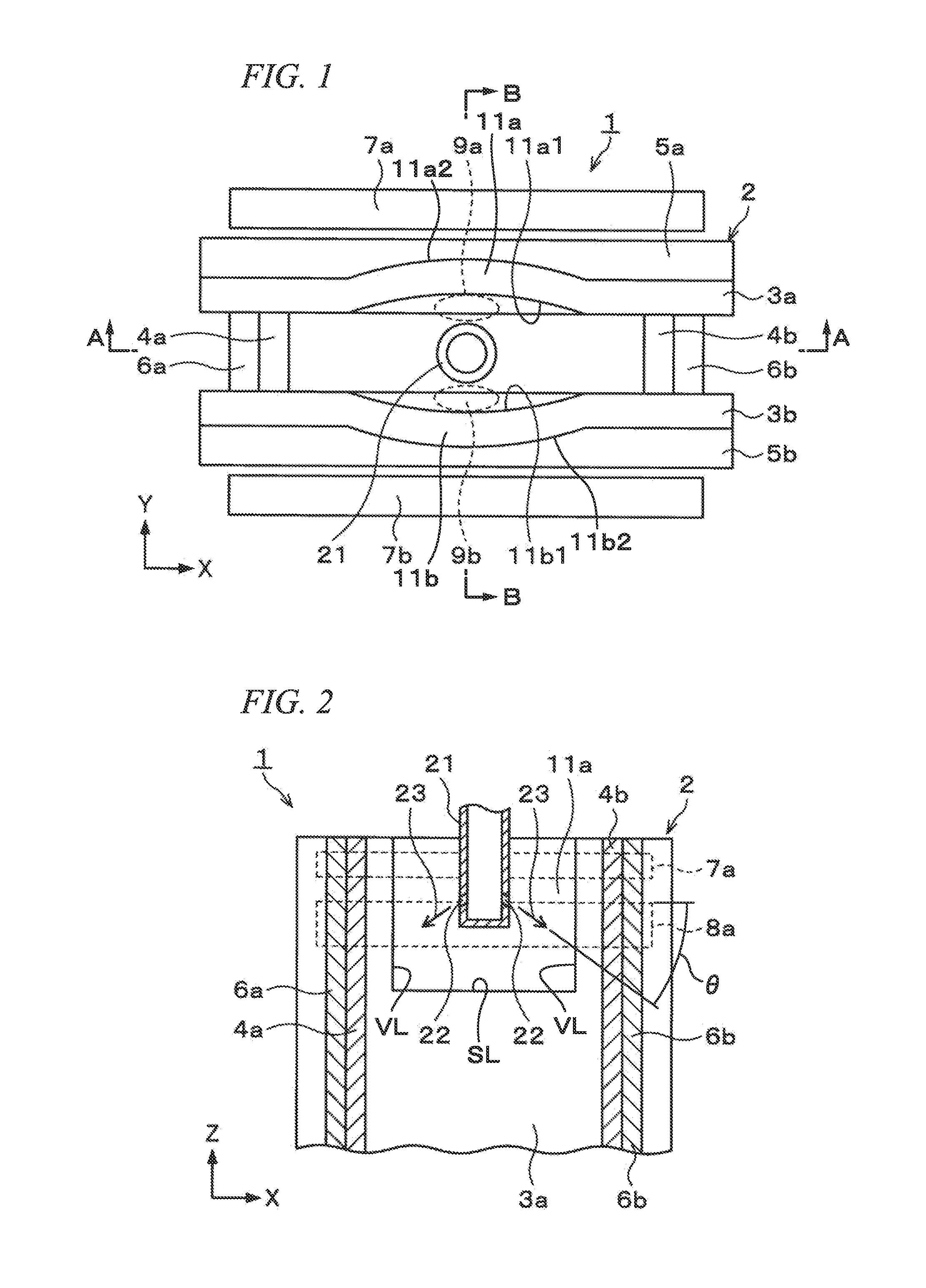

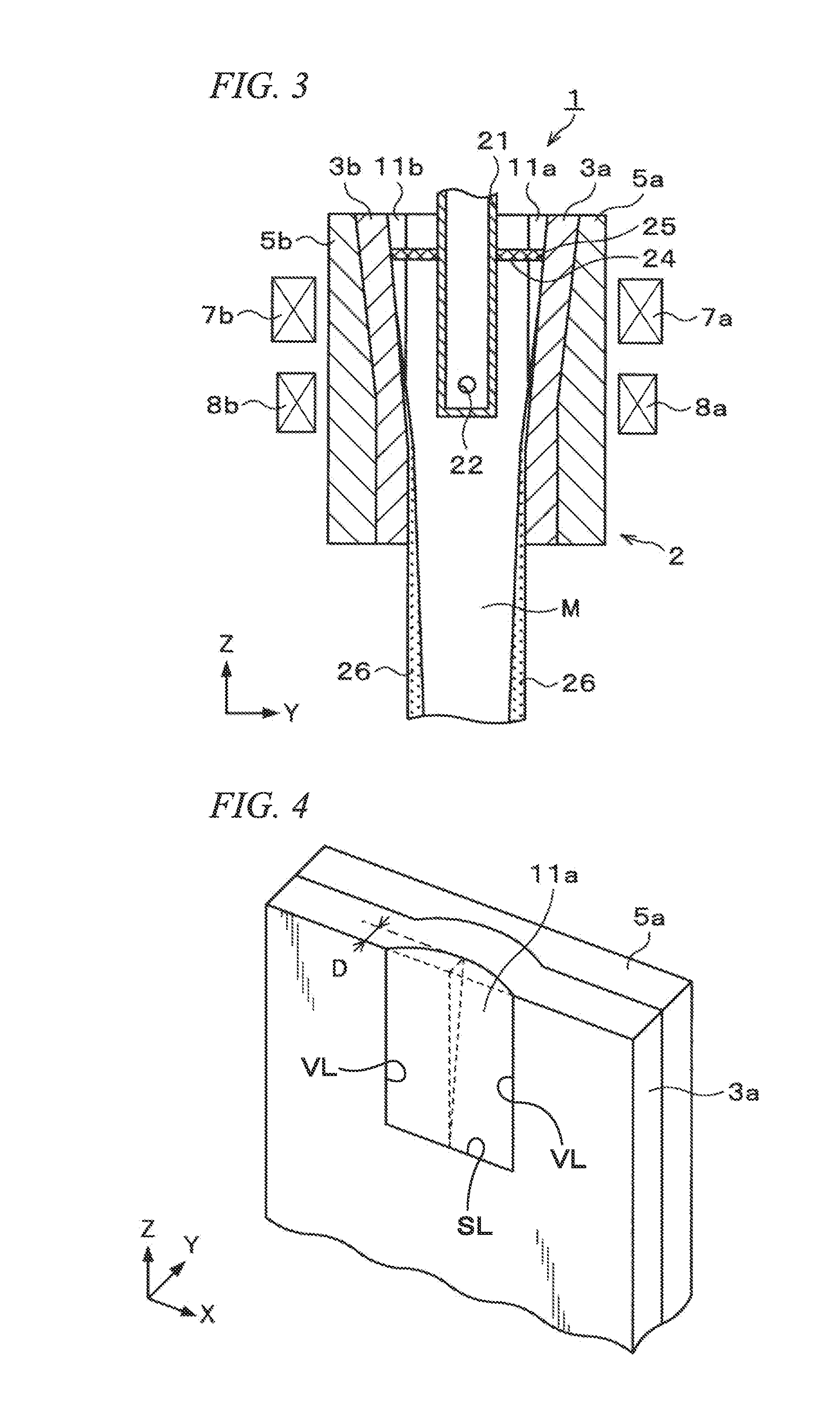

Continuous casting apparatus for steel

A continuous casting apparatus for steel includes: a casting mold for casting a molten steel with a pair of long side walls and a pair of short side walls; a submerged entry nozzle which discharges the molten steel into the casting mold; and an electromagnetic stirring device which is disposed along each external surface of each of the long side walls and stirs an upper portion of the molten steel within the casting mold. A curved portion which is convexly curved toward the electromagnetic stirring device in plan view is formed at least at a position where the curved portion faces the submerged entry nozzle on each of the long side walls, and each of the long side walls including the curved portion has a uniform thickness. The shortest horizontal distance between a top which is a most depressed position when an internal surface of the curved portion is seen in plan view and an outer peripheral surface of the submerged entry nozzle is 30 mm to 80 mm in a range from a lower end portion of the electromagnetic stirring device to a position higher than an upper end portion thereof by 50 mm when viewed along a vertical direction.

Owner:NIPPON STEEL CORP

High-speed hot extrusion die

ActiveCN104226709AUniform and stable flowReduce resistanceExtrusion diesEngineeringMechanical engineering

The invention discloses a high-speed hot extrusion die. The high-speed hot extrusion die comprises a die body, wherein a diversion hole, a draining hole, a molding hole and a discharging hole are successively formed in the die body and are in a through connection; the diversion hole outwards extends towards the direction of the front end surface of the die body; the front end of the draining hole outwards extends towards the direction of the diversion hole. The depths of the draining hole at each place are different, a high-low fluctuating surface formed at the bottom surface is a falling head of a work zone, and the molding hole is placed at the back end of the draining hole. The side wall of the molding hole is named as the work zone which plays roles of material molding and flow velocity adjustment, and the falling head of the work tape is arranged at the jointed position of the front end of the molding hole and the draining hole. Through the successive guiding of the diversion hole and the draining hole, the high-speed hot extrusion die enables metal to flow more uniformly and stably. The length of the work tape can be correspondingly shortened, and the falling head of the work tape can also be made smaller. When an extruding machine runs at a speed closer to the highest extrusion speed, the quality of products can still be ensured. When the extruding machine runs at a higher extrusion speed, the molding time of sectional materials can be shortened, and the production efficiency can be improved.

Owner:CHANGSHA XINZHENSHENG GRP

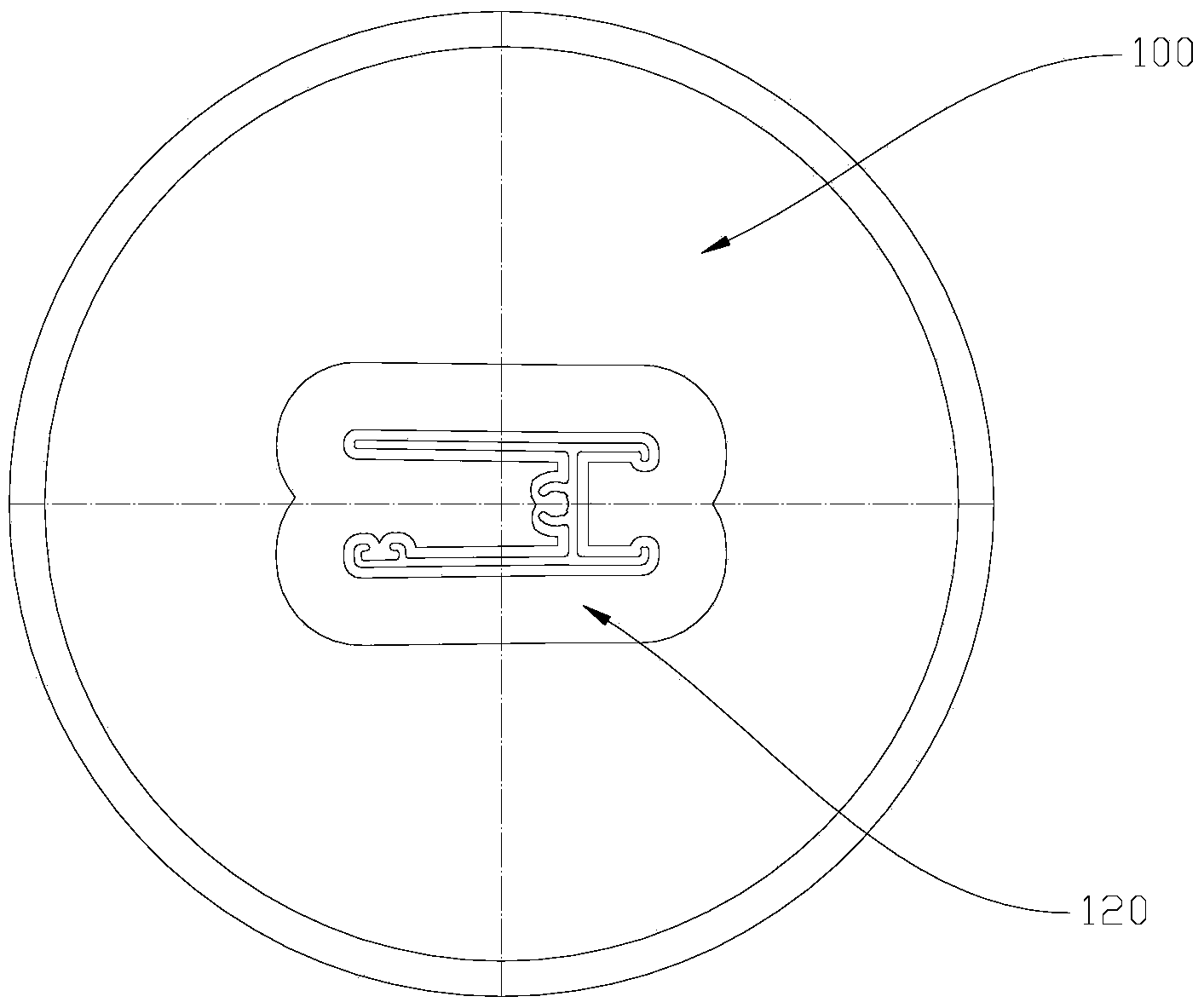

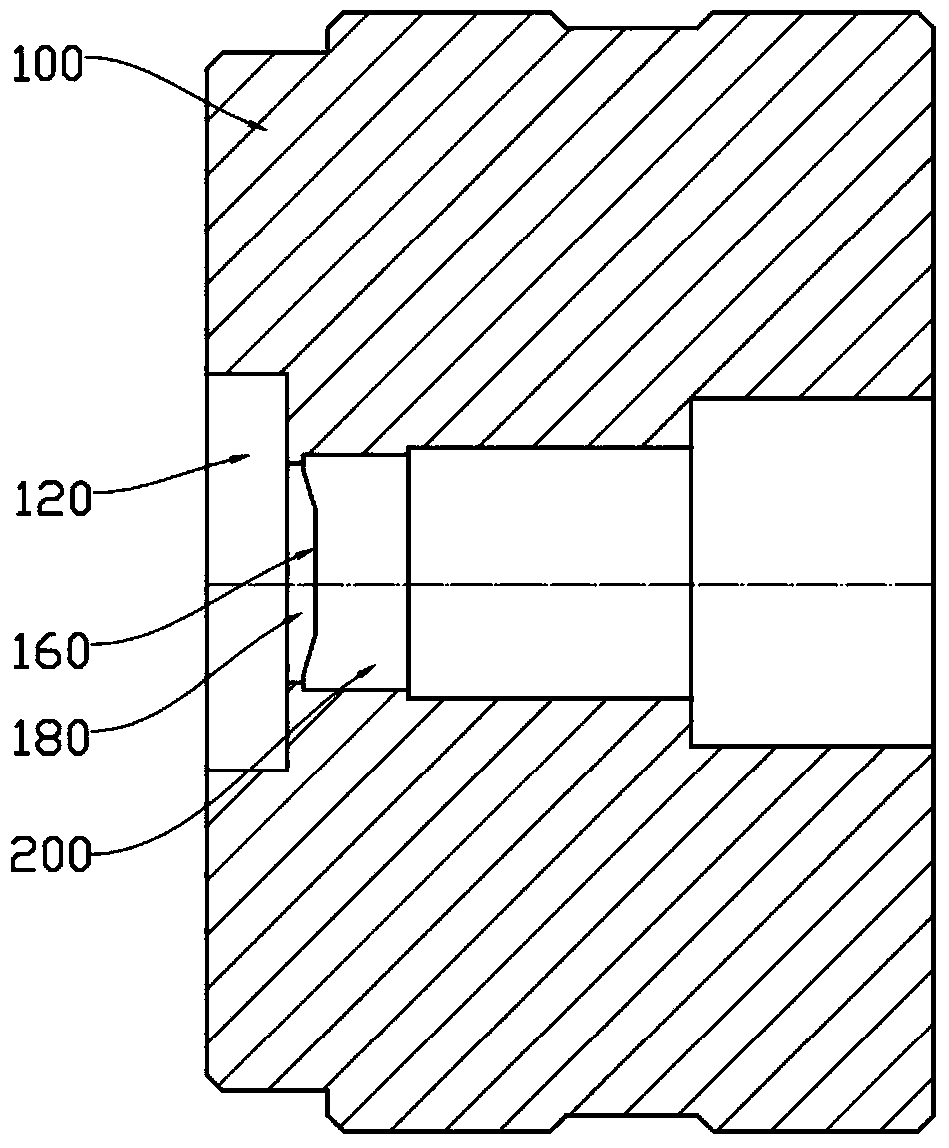

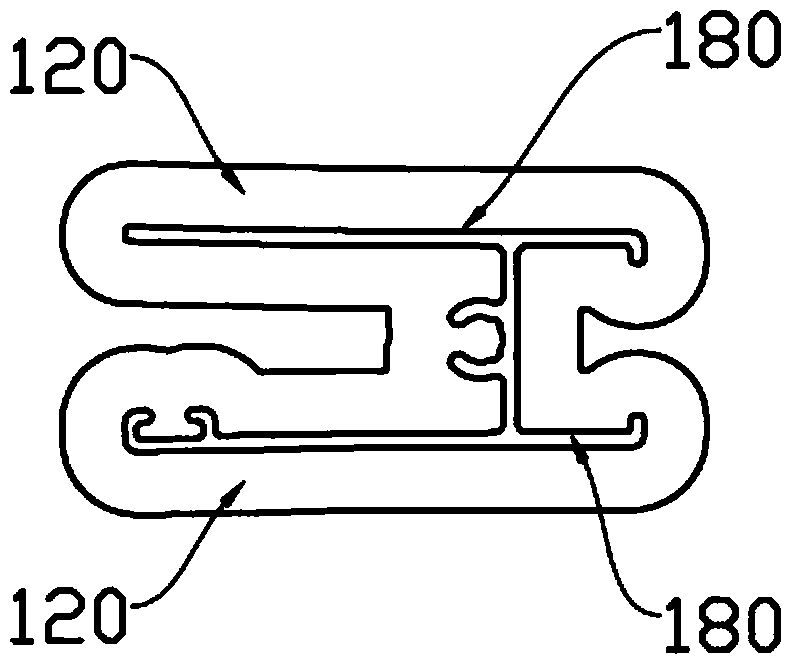

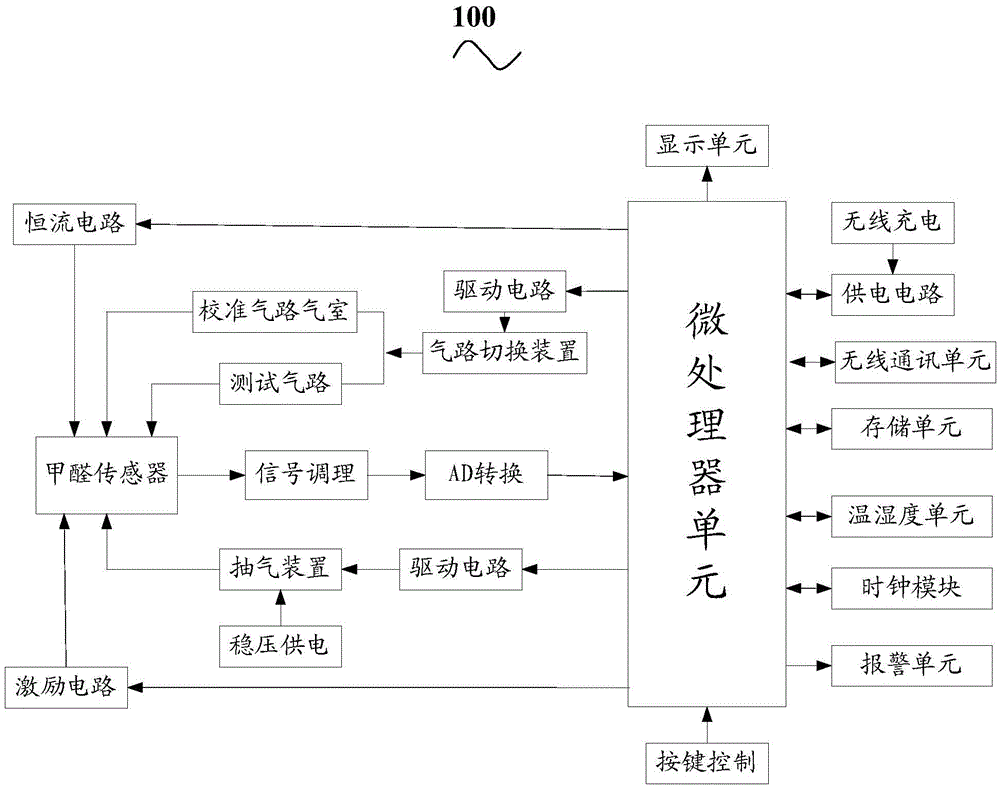

Formaldehyde tester

InactiveCN105606765APrevent from compromising accuracyReliable test resultsTransmission systemsMaterial analysisCalibration gasTester device

The invention provides a formaldehyde tester. The formaldehyde tester comprises a sensor, a gas channel and gas chamber unit, a signal acquisition and processing unit and a microprocessor unit, wherein the gas channel and gas chamber unit comprises a sensor cavity for accommodating the sensor, a test gas channel connected with one side of the sensor cavity, a calibration gas channel connected in parallel in the same side of the sensor cavity with the test gas channel as well as an exhaust device arranged on the other side of the sensor cavity, one end of the test gas channel is connected with outside to-be-tested gas, and the other end is connected with the sensor cavity; the signal acquisition and processing unit is electrically connected with the microprocessor unit and the sensor; the exhaust device is electrically connected with the microprocessor unit. The formaldehyde tester can calibrate calibration of the sensor and prevent the sensor from affecting test accuracy due to own drifting, so that a test result is accurate and reliable.

Owner:SUZHOU NANOGRID TECH

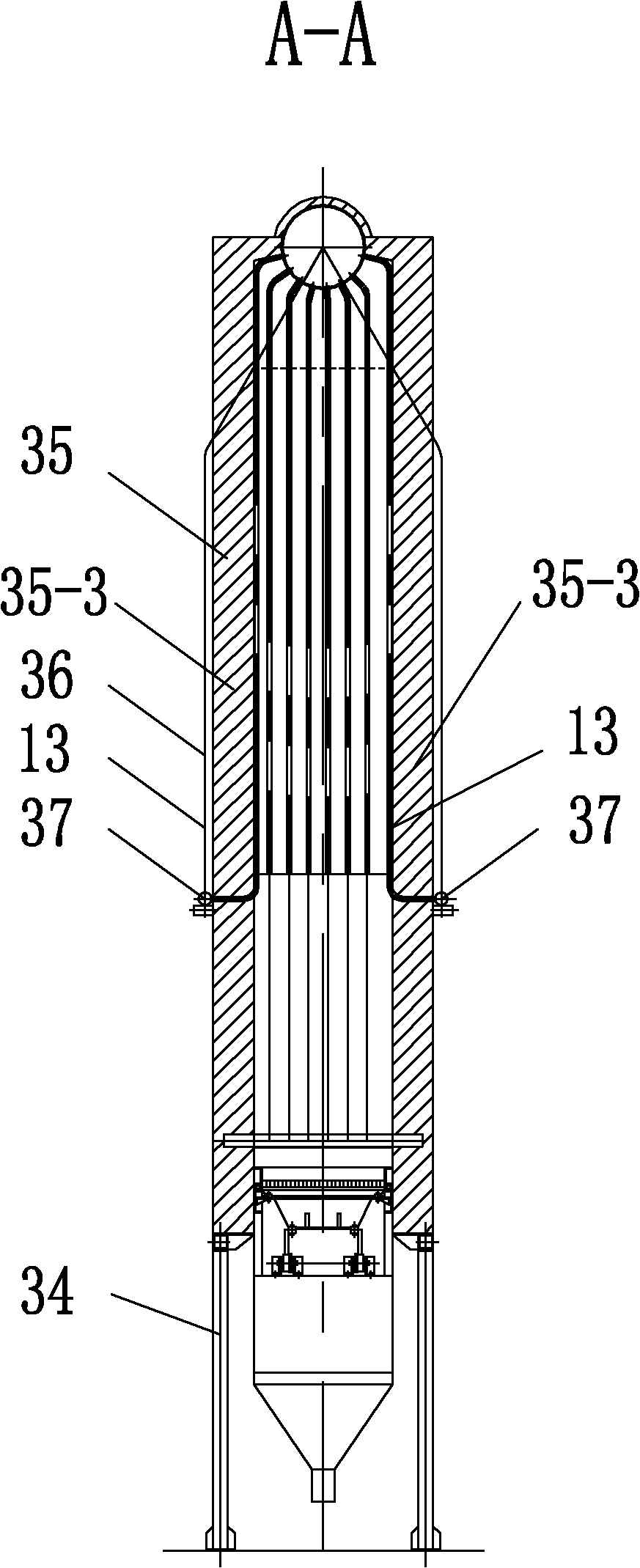

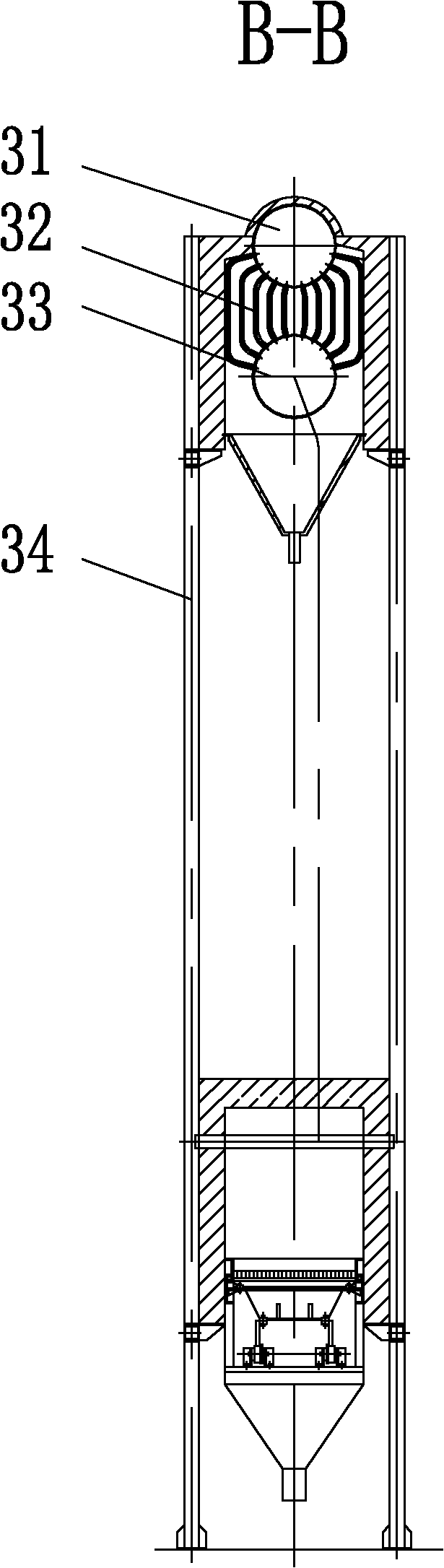

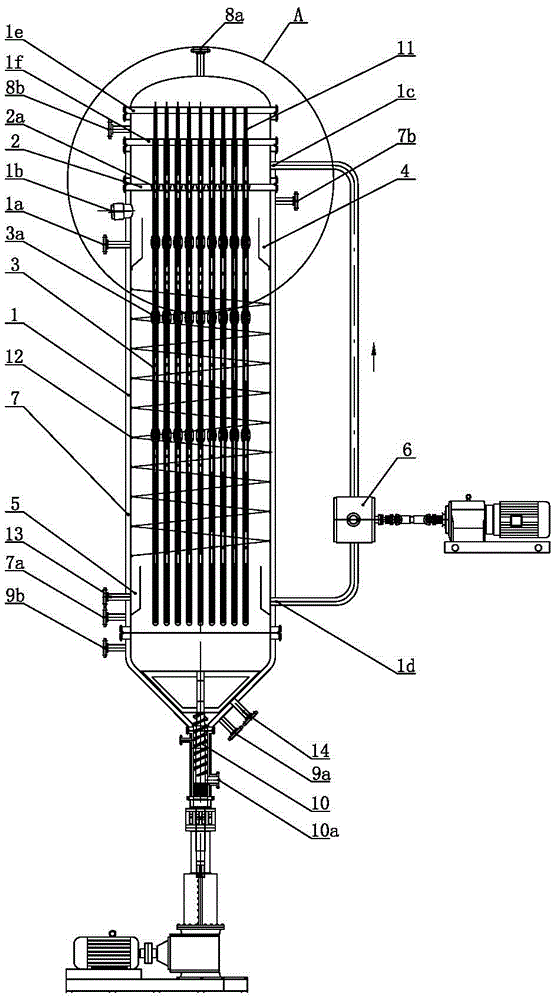

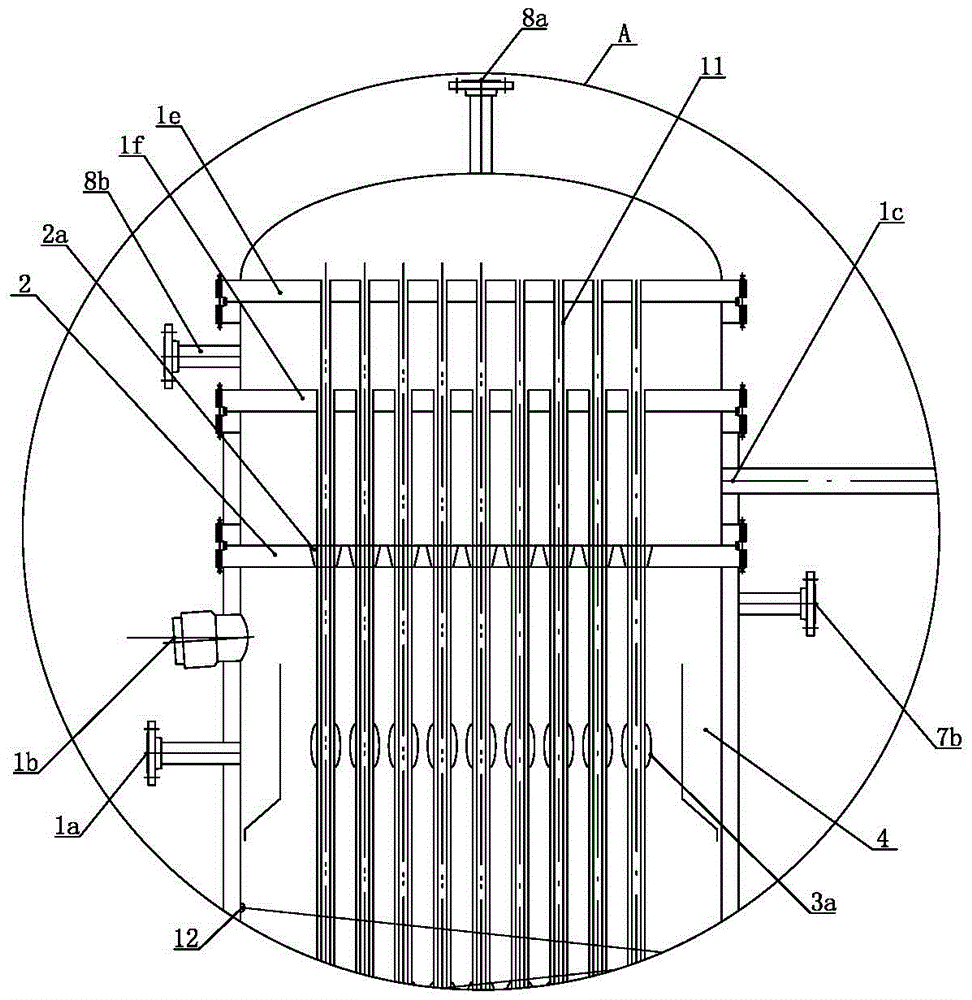

Vertical type stirred-free polymerization reactor

ActiveCN105536663AReduce power consumptionLow failure rateLiquid-liquid reaction processesEngineeringEnergy consumption

The invention relates to a vertical type stirred-free polymerization reactor. A liquid distribution disc is arranged at the upper part of the internal chamber of a tubular body, liquid distribution holes are formed in the liquid distribution disc, falling-film tubes are arranged in the liquid distribution holes, heat-medium heating tubes are inserted into internal cavities of the falling-film tubes, a charging opening and a vacuumizing opening are formed in the external wall of the upper part of the tubular body, a discharging spiral and a discharging opening are formed in the bottom of the tubular body, a tubular body jacket is arranged at the outer periphery of the tubular body, the charging opening is located below the liquid distribution disc, an annular liquid distribution groove is formed in the internal wall, corresponding to the charging opening, of the tubular body, and uniform annular slots are reserved between the lower end of the liquid distribution groove and the internal wall of the tubular body; an annular liquid collecting groove is formed in the internal wall of the lower part of the tubular body, the upper end of the liquid collecting groove is open, and the lower end of the liquid collecting groove is closed; an intermediate melt outlet communicating with the bottom of the liquid collecting groove is formed in the external wall of the tubular body and is connected with an inlet of a conveying pump, an outlet of the conveying pump is connected with an intermediate melt inlet, and the intermediate melt inlet is located in the external wall of the tubular body and is located above the liquid distribution disc. The reactor is high in production efficiency and low in energy consumption.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Spray nozzle with multiple scales of permanent flames and combustor

ActiveCN107023834ABlowout preventionFlexible adjustment of flow rateIncinerator apparatusGaseous fuel burnerCombustorSpray nozzle

The invention provides a spray nozzle with multiple scales of permanent flames and a combustor. The spray nozzle comprises an axial symmetry cylindrical outer wall, N levels of auxiliary spray nozzle structures and N levels of fuel pipe structures, wherein the N levels of auxiliary spray nozzle structures and the N levels of fuel pipe structures are arranged inside the outer wall. The N levels of auxiliary spray nozzle structures comprise from the Nth-level auxiliary spray nozzle, the (N-1)th-level auxiliary spray nozzle to the first-level auxiliary spray nozzle. The N levels of fuel pipe structures comprise from the Nth-level fuel pipe, the (N-1)th-level fuel pipe to the first-level fuel pipe. The ith-level fuel pipe corresponds to an inlet of the ith-level auxiliary spray nozzle in a one-to-one manner. The ith-level auxiliary spray nozzle is of a cylindrical structure, and i is a positive integer not larger than N.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

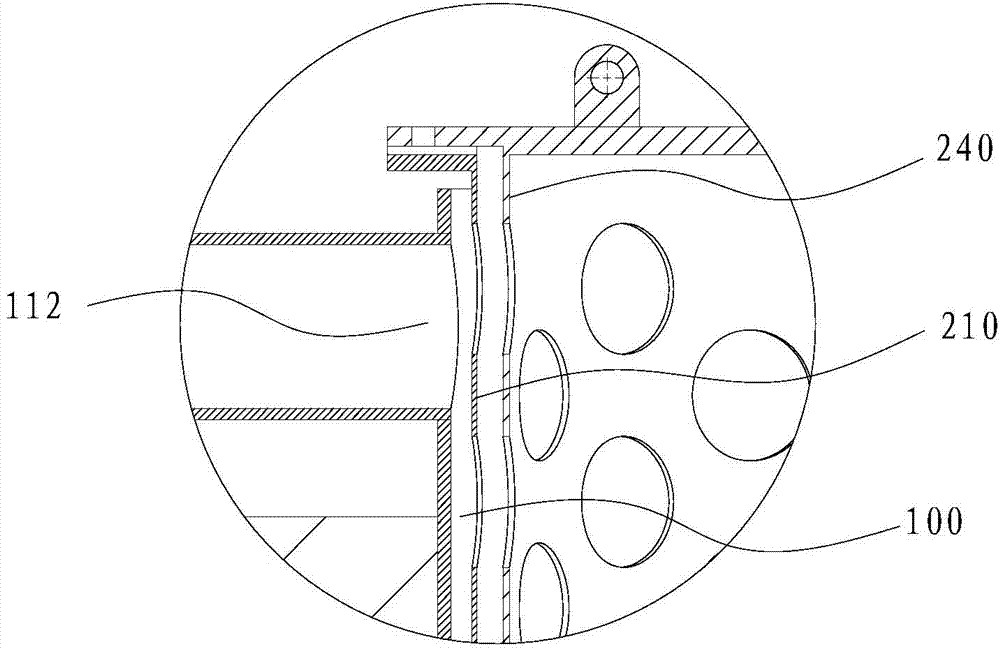

Draft tube for single crystal furnace

The invention relates to a draft tube for a single crystal furnace. The draft tube comprises a horn-shaped tube body, a feeding flange and a discharging flange, wherein the feeding flange and the discharging flange are connected to a narrow opening end and a wide opening end of the horn-shaped tube body respectively, a lengthening device is arranged between the narrow opening end of the horn-shaped tube body and the feeding flange, a baffle is arranged between the wide opening end of the horn-shaped tube body and the discharging flange, guide plates are arranged in the horn-shaped tube body, through holes are uniformly formed in the guide plates, filter plates are further arranged between the lower ends of the guide plates and the side wall of the horn-shaped tube body, an overhaul port is further formed in the side wall of the horn-shaped tube body, and the side wall, located on the outer side of the overhaul port, of the horn-shaped tube body is further movably connected with an observation window. By means of the design, the flowing area is increased through the guide plates, so that substances more uniformly and stably flow, and the utilization rate of the draft tube is increased.

Owner:JIANGSU HUASHENG TIANLONG PHOTOELECTRIC

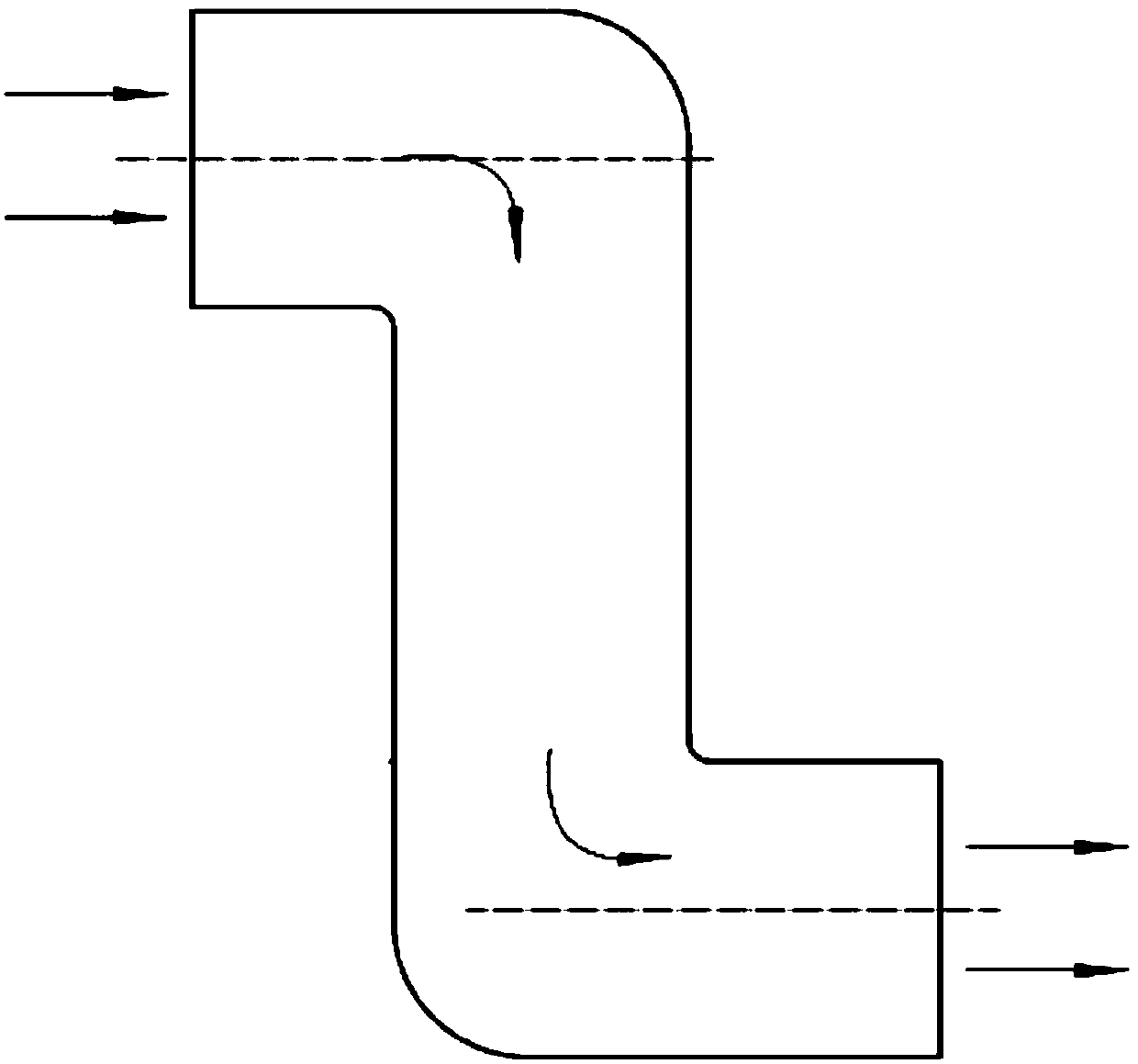

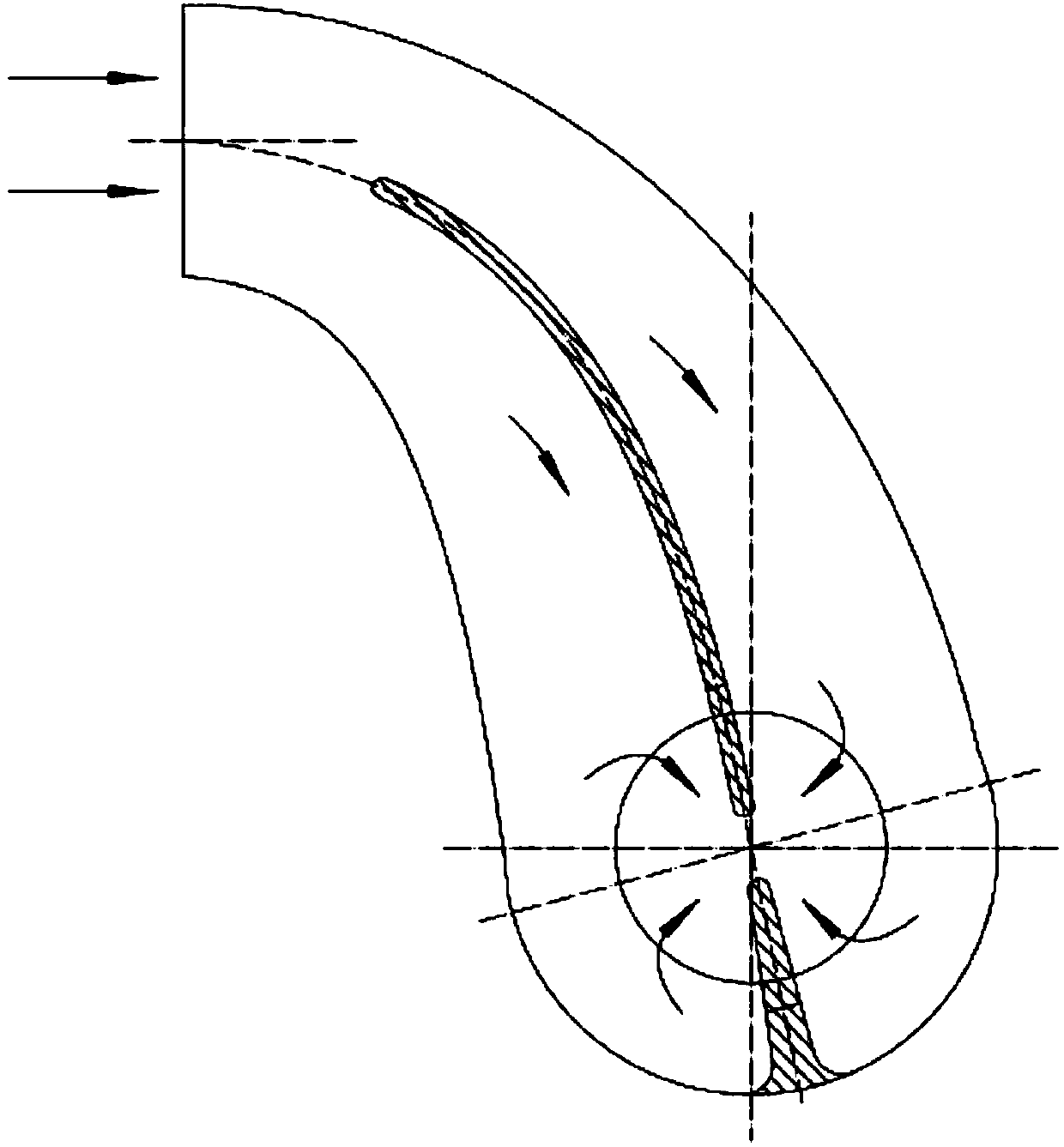

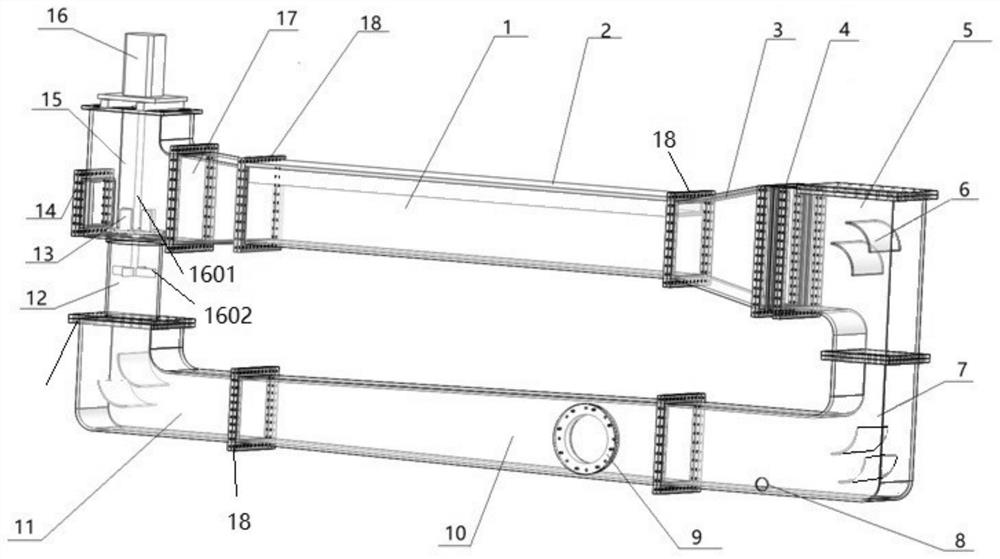

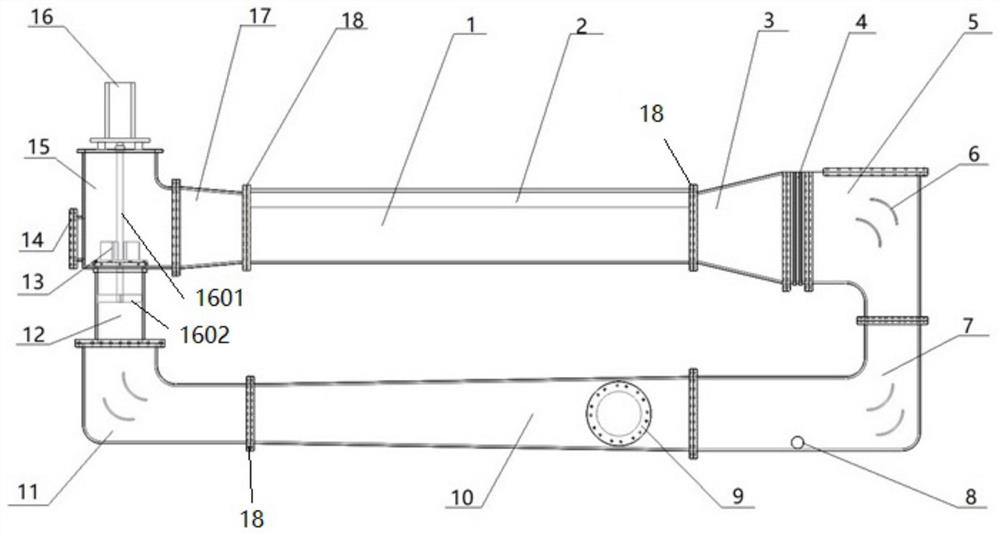

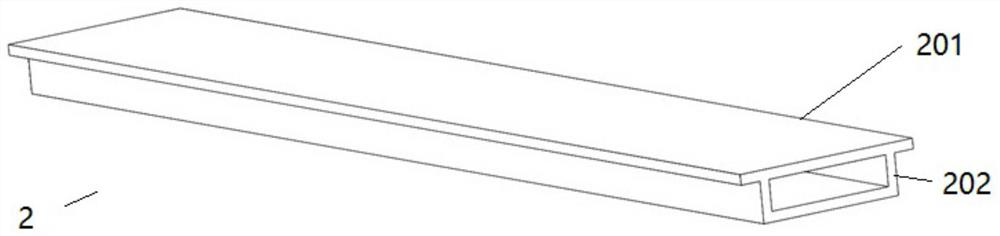

Small experimental circulating water tank

PendingCN112595488AMeet the experimental requirementsFlow field speed can be adjustedHydrodynamic testingHoneycombMechanical engineering

The invention relates to a small experimental circulating water tank which comprises a water tank body, and the water tank body comprises a test section (1), an upper expansion section (17), a power section (15), a connecting section (12), a third-stage guide section (11), a lower expansion section (10), a second-stage guide section (7), a first-stage guide section (5), a rectification section (4)and a contraction section (3) which are connected in sequence to form a loop, wherein the the test section (1) is horizontally arranged, the first-stage guide section (5), the second-stage guide section (7) and the third-stage guide section (11) are arranged at corners, a honeycomb rectifier (401) is arranged in the rectification section (4), and a plurality of flow deflectors (6) are arranged inthe first-stage guide section (5), the second-stage guide section (7) and the third-stage guide section (11). Compared with the prior art, the experimental requirements can be met, the flow field speed is adjustable, flowing is uniform and stable, the flow velocity distribution of the test section is uniform, and advection and turbulence can be controlled.

Owner:SHANGHAI INST OF TECH

System and Method for Modulating a Peripheral Device Based on an Unscripted Feed Using Computer Vision

ActiveUS20190163274A1Non-uniform flow of airUniform and stable flowInput/output for user-computer interactionImage enhancementVisual perceptionModulation effect

A system for processing at least one of an audio or video input for non-scripted modulation of at least one peripheral device, comprising: the at least one peripheral device in physical contact with at least one user or free from the at least one user and in communication with at least a first device playing at least one of an original programming feed or live feed unscripted with modulation triggers; a processor; a memory element coupled to the processor; a program executable by the processor to: recognize at least one of the audio or video input from the at least one of the original programming feed or live feed, and determine for at least one tagged event, at least one of a pixel color score, a pixel velocity score, an event proximity score or an audio score; and convert the at least one scored event into at least one of an output command that triggers or controls a modulation effect of the at least one peripheral device in physical contact or free from the user in communication with the at least the first device playing the at least one of the original programming feed or live feed, thereby enabling modulation of the at least one peripheral device based on any programming comprising at least one of an audio or video input and not requiring scripted modulation triggers.

Owner:WHIRLWIND VR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com