Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Prevent from compromising accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

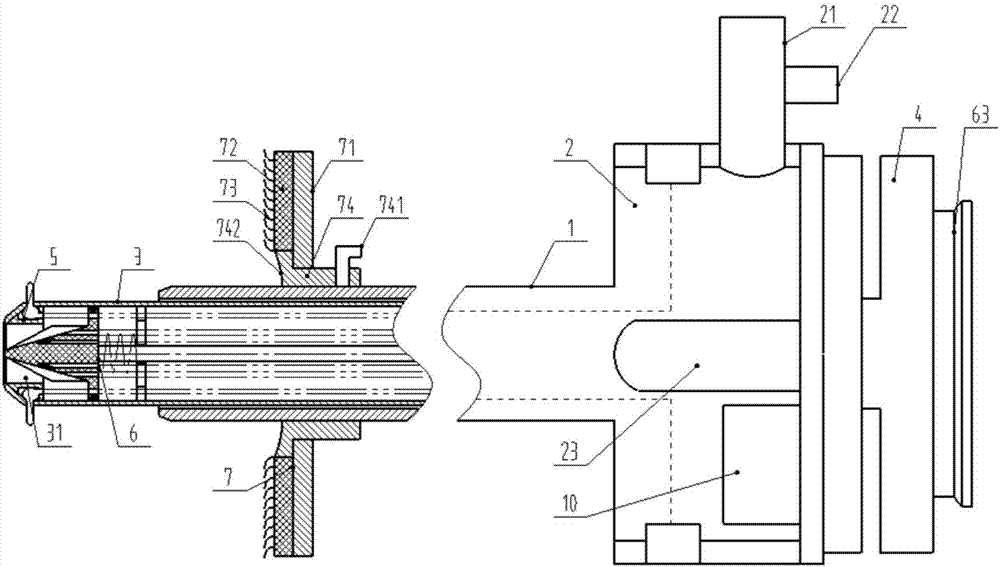

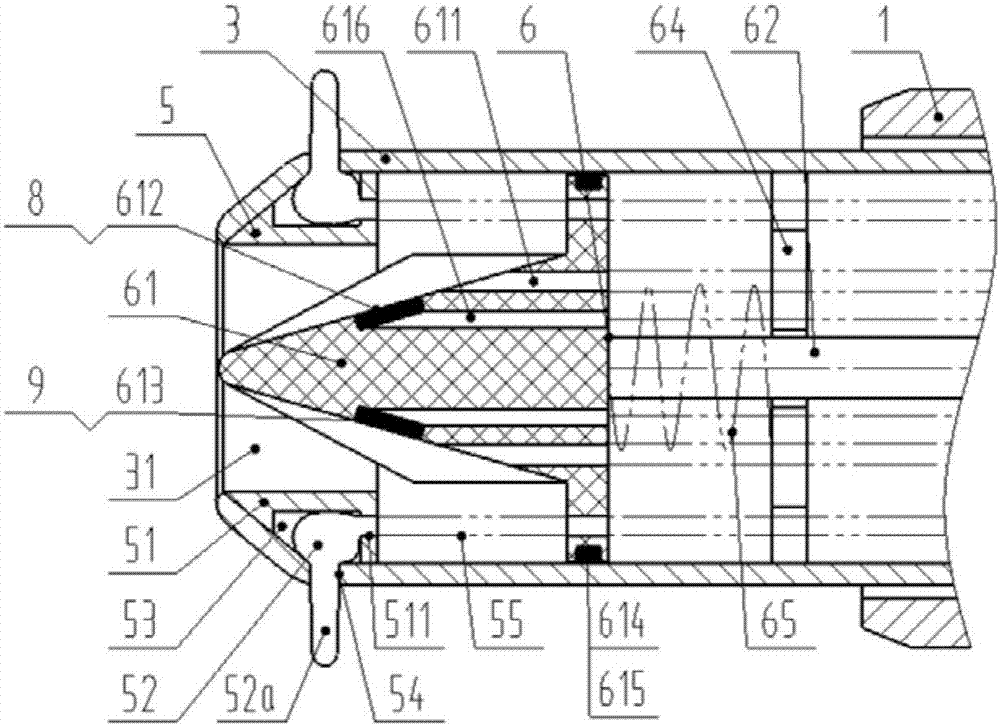

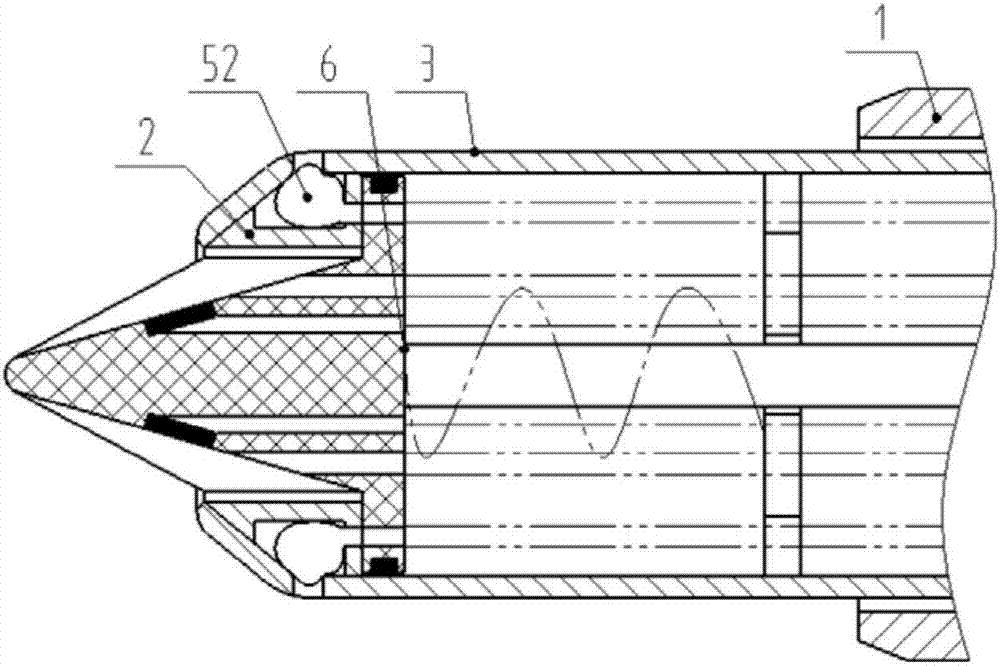

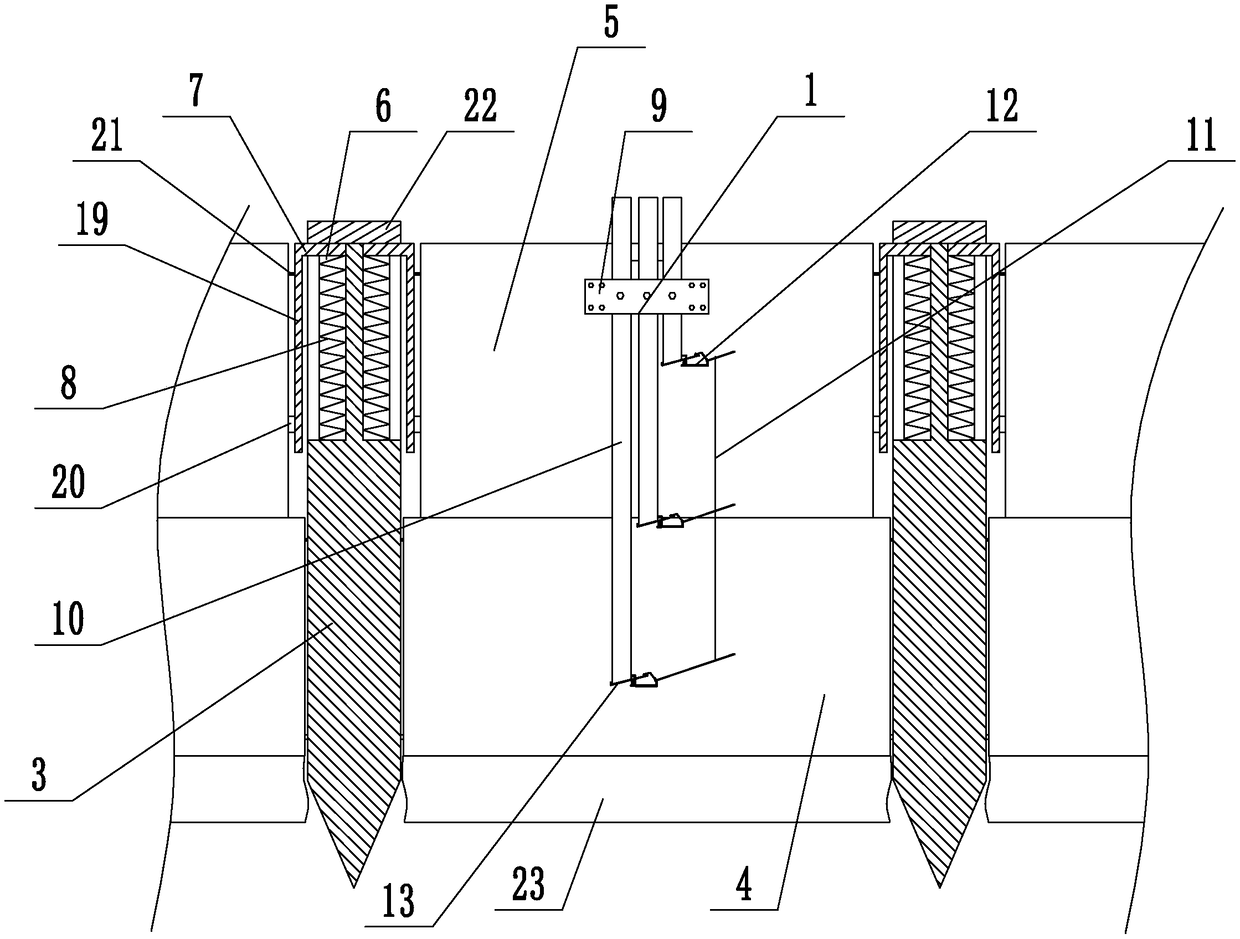

Laparoscopic varicocele ligation puncture device

InactiveCN107468292AInhibit sheddingMeet the needs of safe use functionsSurgical needlesDiagnostic recording/measuringVeress needlePERITONEOSCOPE

The invention discloses a laparoscopic varicocele ligation puncture device. Such structure design that a fixing mechanism and an anti-disengagement mechanism is adopted, the expansion stretch-out and draw-back principle of an elastic air bag and the adsorption principle of a carbon nano tube array are made use of, a conical head can be effectively prevented from being disengaged from a puncture part, a main sheath tube thus does not move in the human body or outside the human body in the operation process, the operability is largely improved, meanwhile an air guide hole is formed in the conical head, the air inflation effect of a veress needle can be achieved, and the safe use function requirements of puncture and pneumoperitoneum are met.

Owner:重庆爱德华医院有限公司

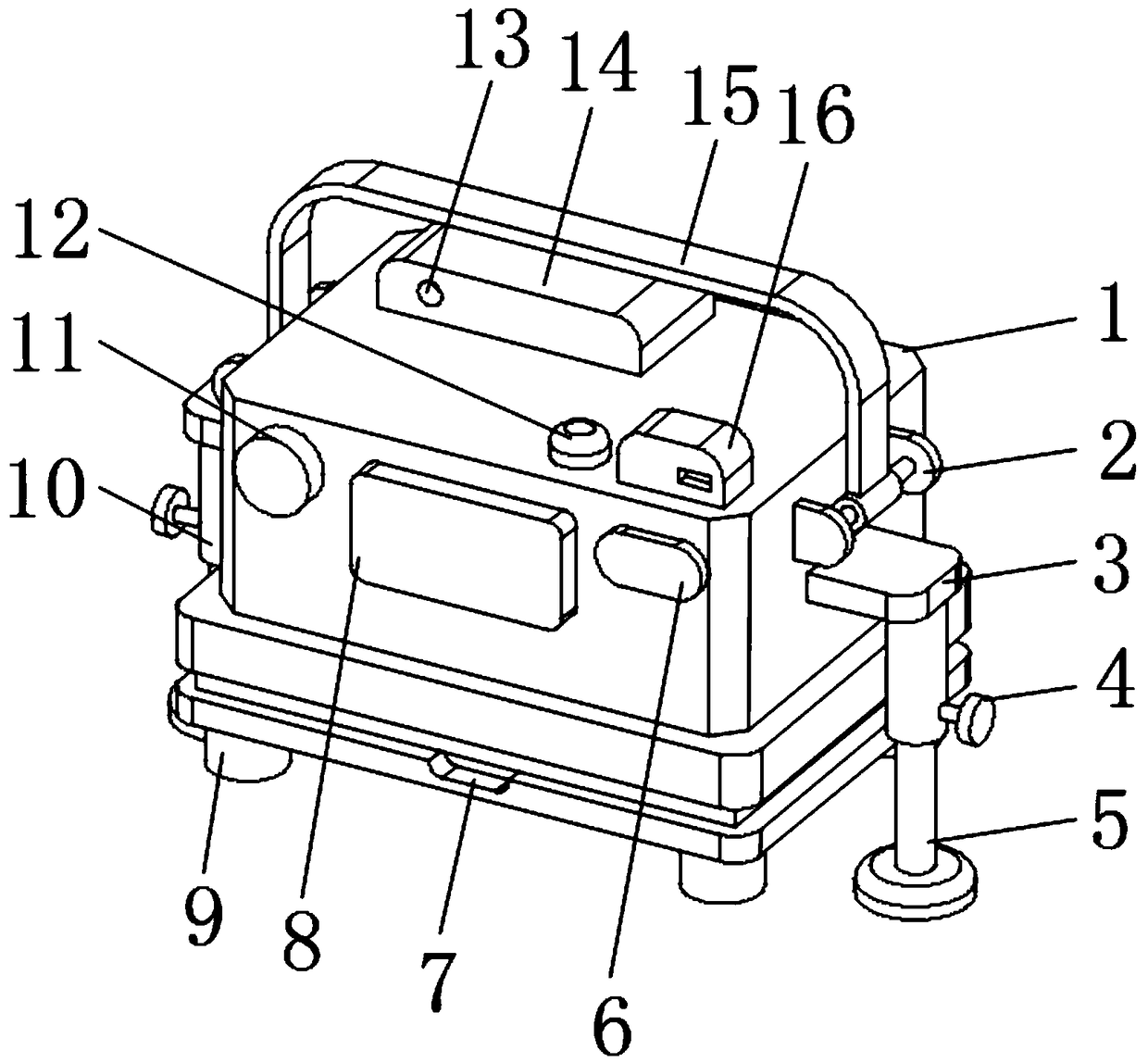

A fetus-voice meter for clinical use in obstetrics and gynecology

InactiveCN109199444AImprove protectionEasy to carryHeart/pulse rate measurement devicesInfrasonic diagnosticsWireless transceiverObstetric history

The invention discloses a fetus-voice meter for gynecology and obstetrics, including a fetus-voice meter body. A PLC control is arranged at that middle position of the front side of the main body of the fetus-voice meter. A wireless transceiver is arranged at a position close to the left side of the front side of the fetus-voice meter main body. A work indicator lamp is arranged at a position close to the right side of the front side of the fetus-voice meter main body. A loudspeaker and a memory are respectively arranged at positions close to that front side surface of the upper surface of thefetus-voice meter main body, the front side of the memory is provided with a USB socket. An accumulator is arranged at that position of the upper surface of the main body of the fetus-voice meter near the rear side surface. A Doppler probe is conveniently protected through the arrangement of a placement groove and a cover plate in the fetus-voice meter, so that the Doppler probe is prevented frombeing damaged, the accuracy of the detection is affected. The fixing bolt, the telescopic rod and the fixing barrel are convenient to support the main body of the fetus-voice meter, and the fixing bracket and the fixing shaft are convenient to carry the fetus-voice meter for the gynecology and obstetrics clinic, and the device is convenient to use.

Owner:王敏

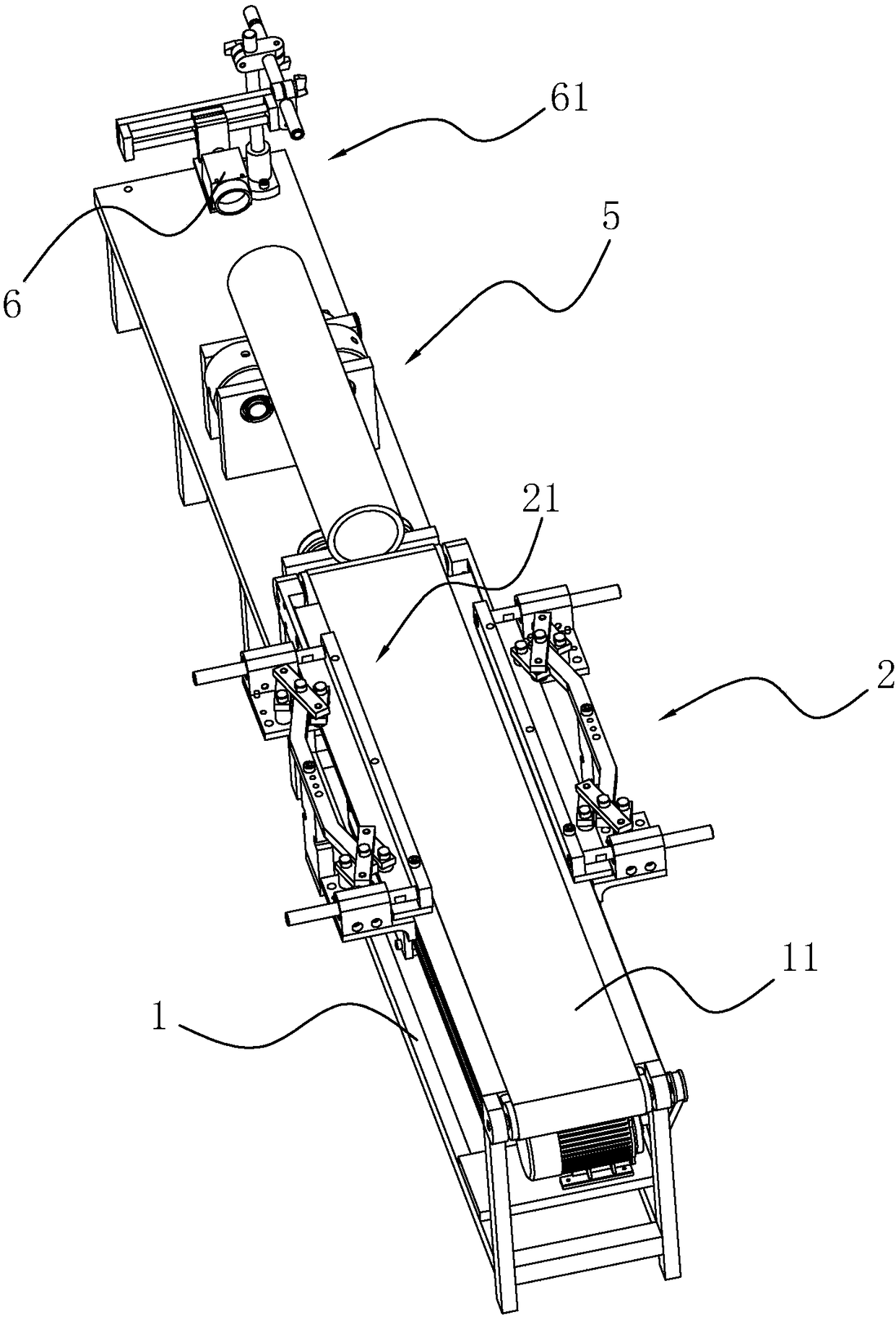

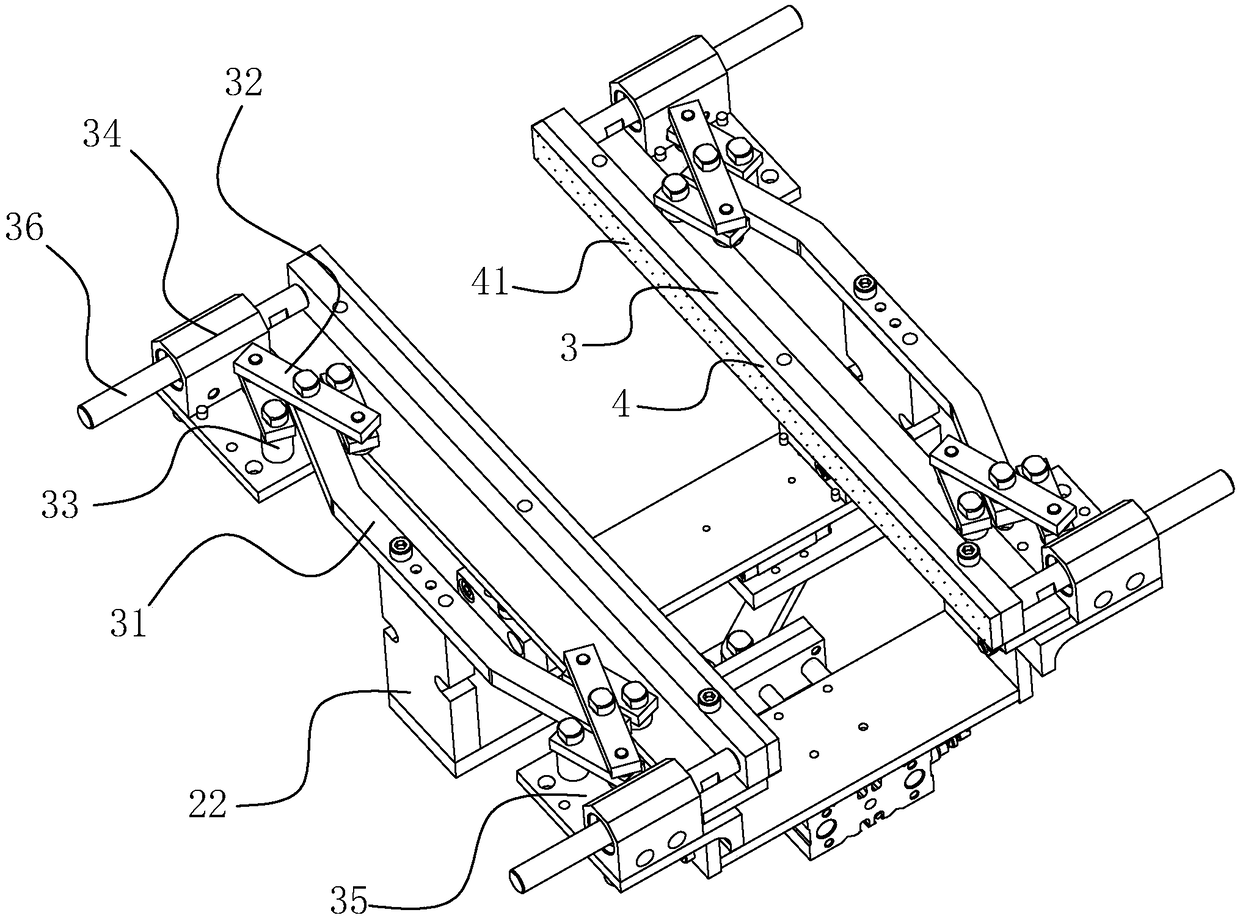

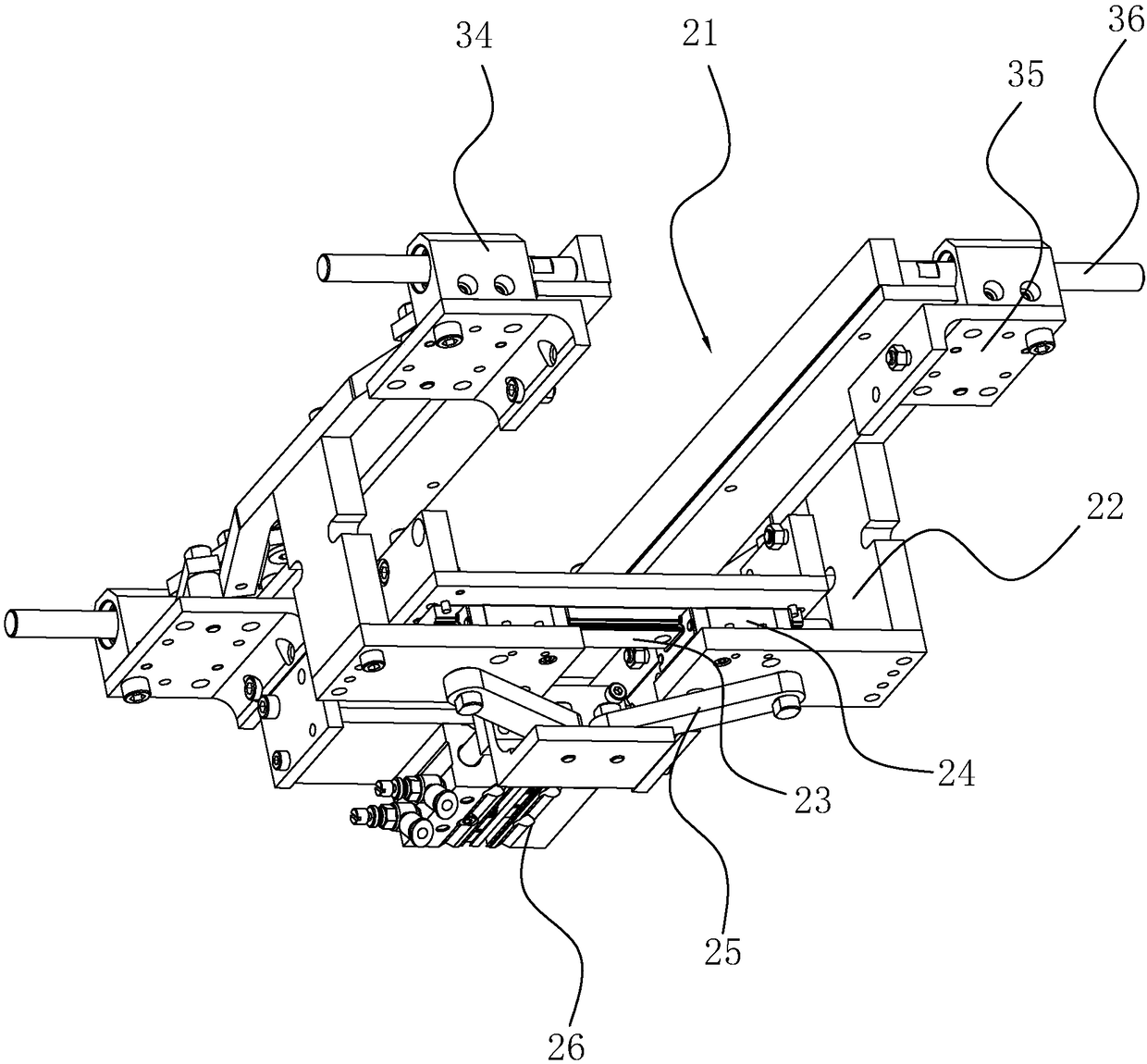

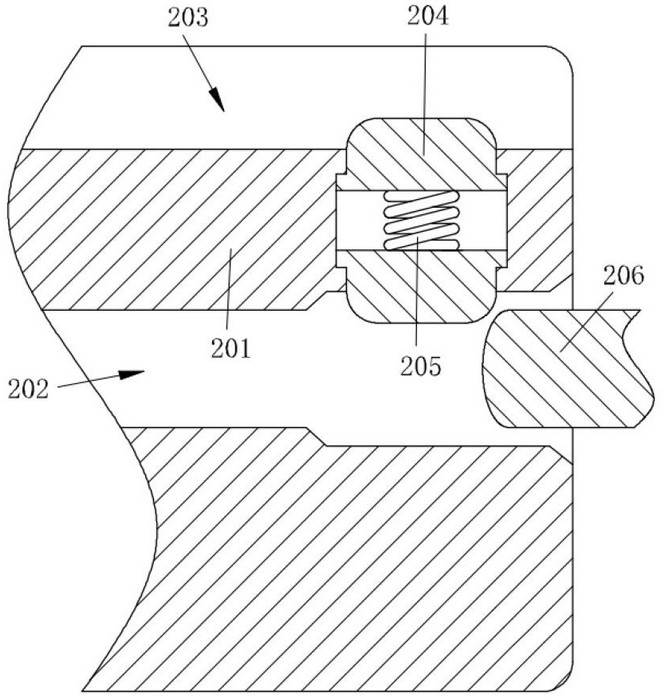

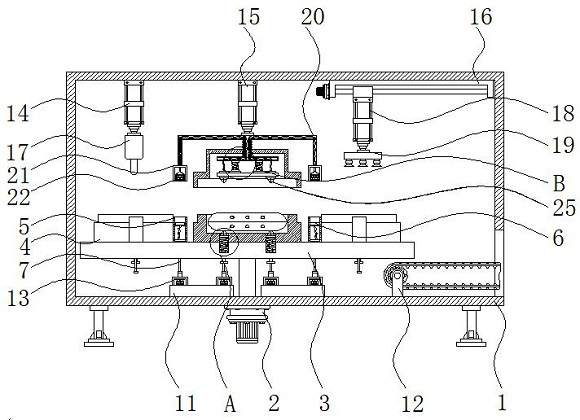

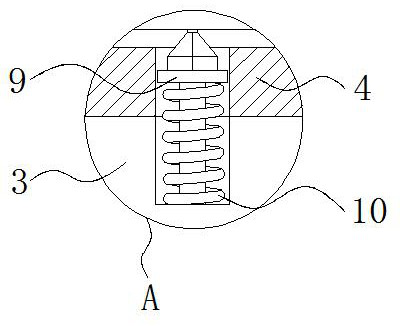

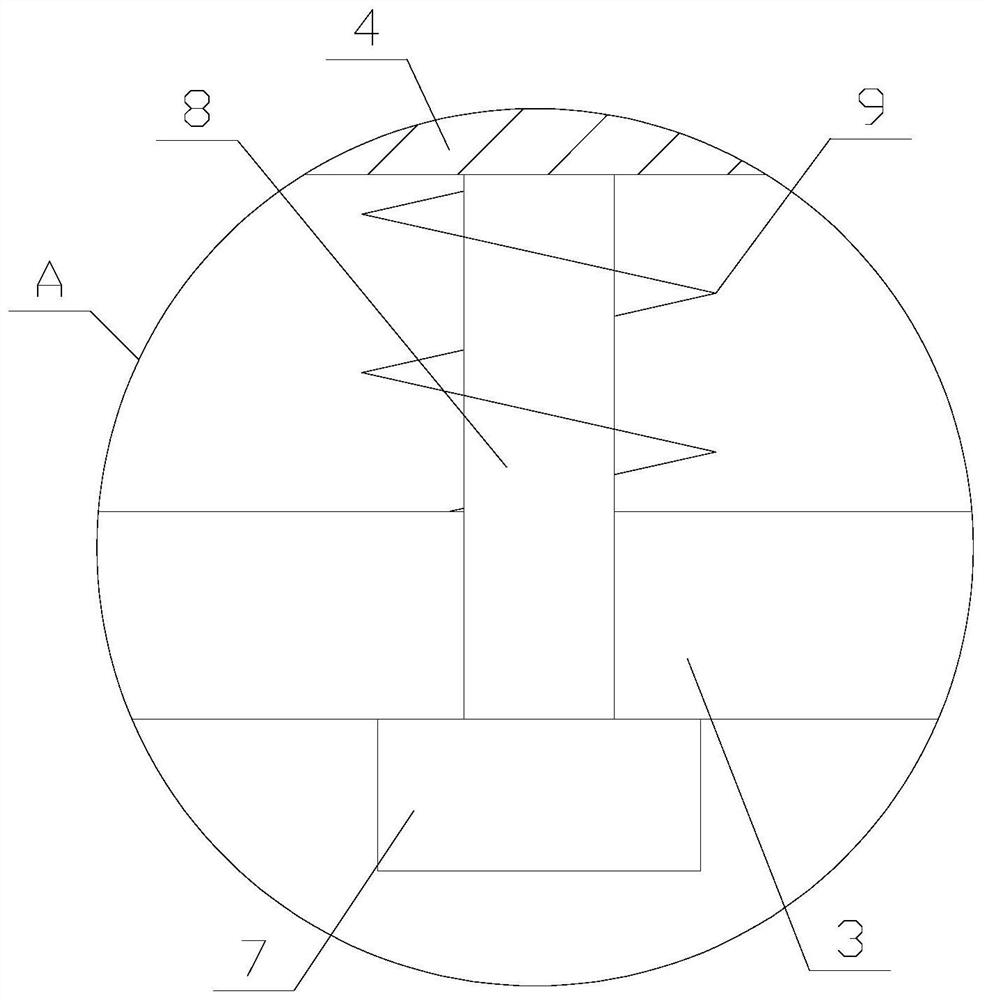

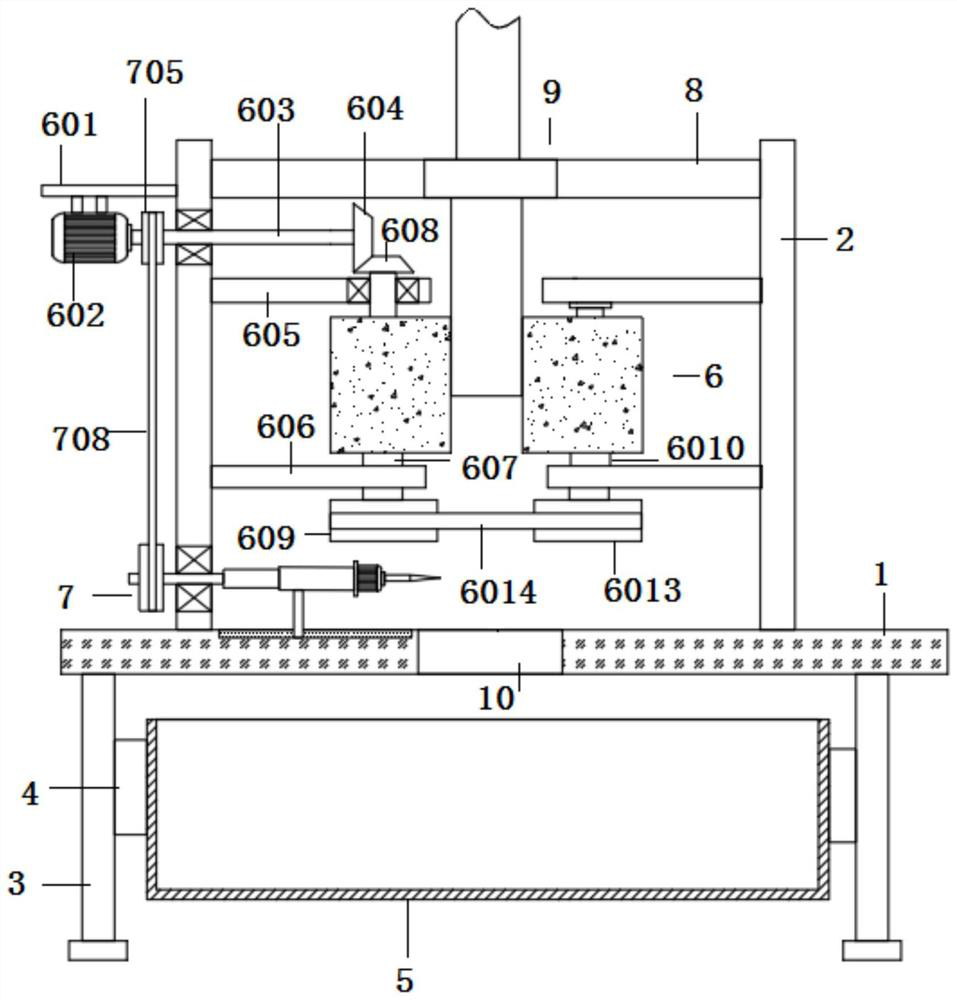

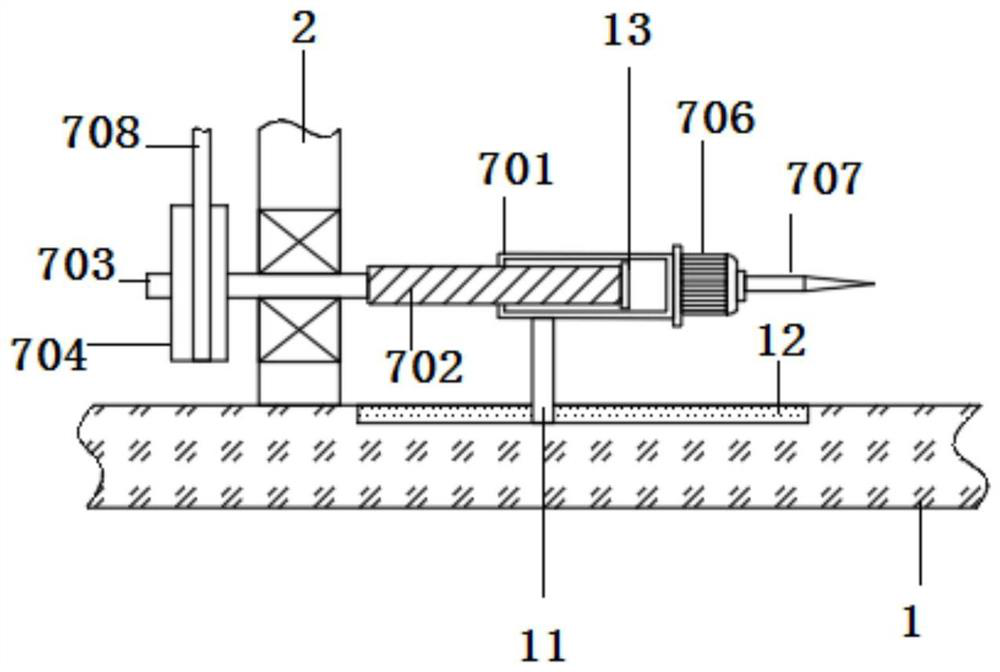

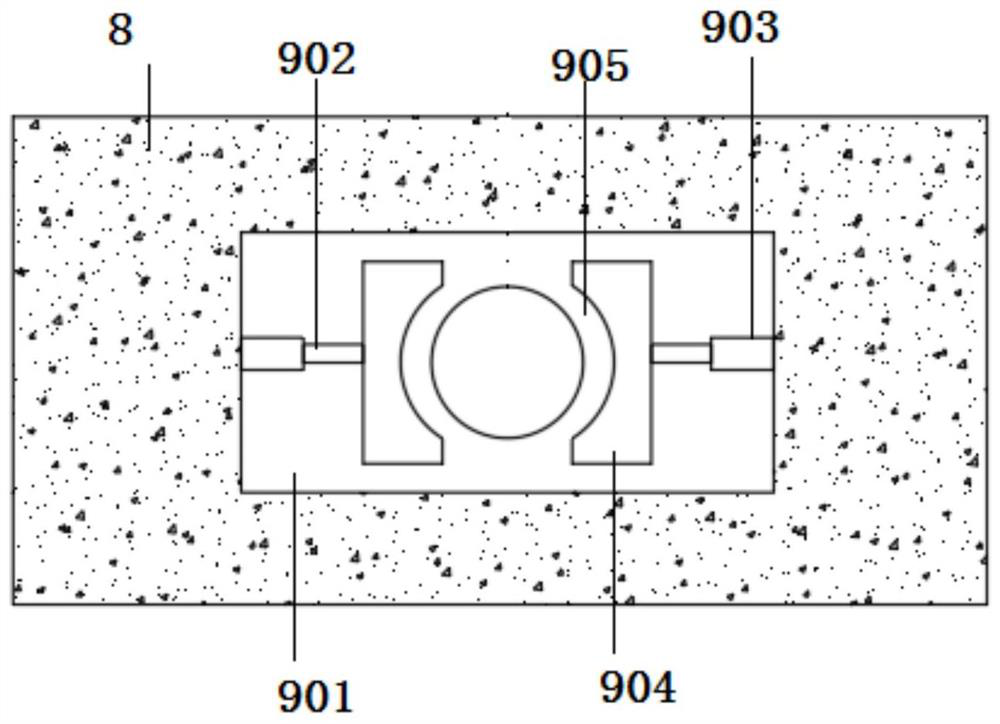

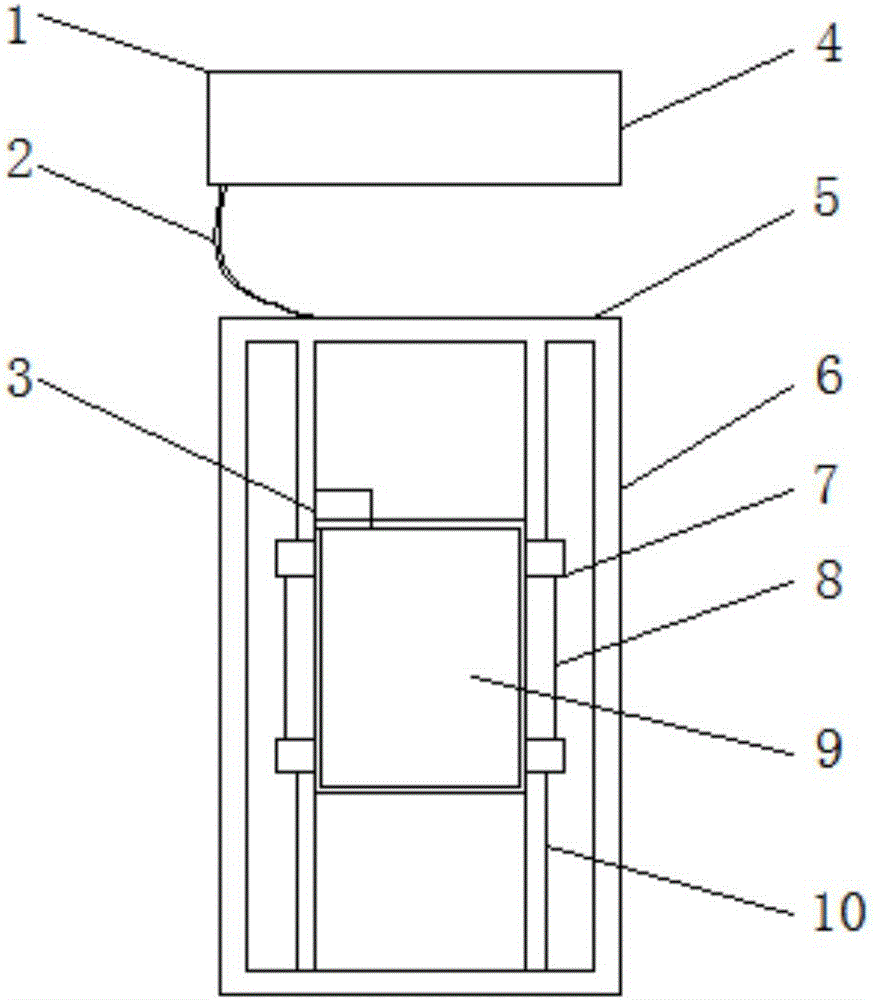

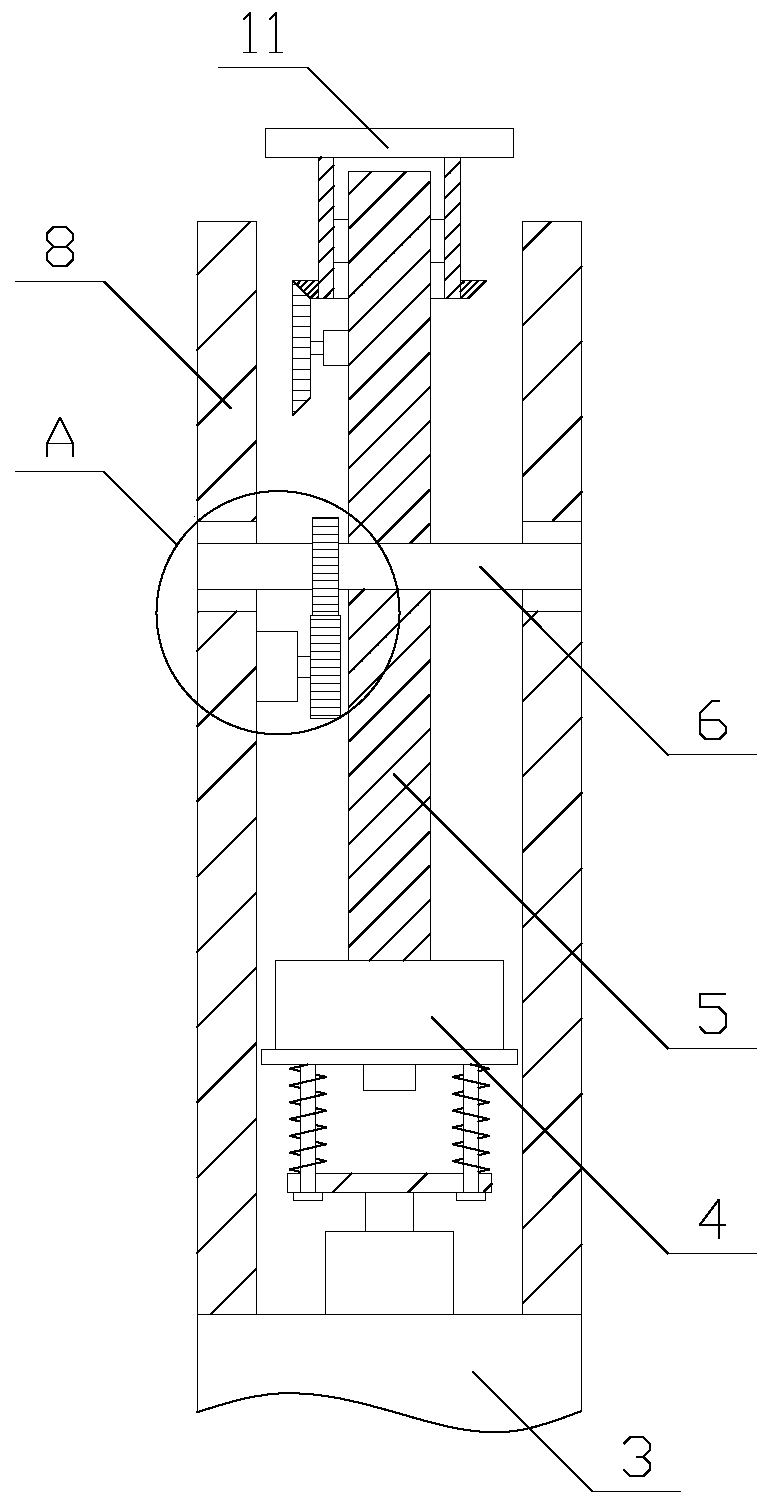

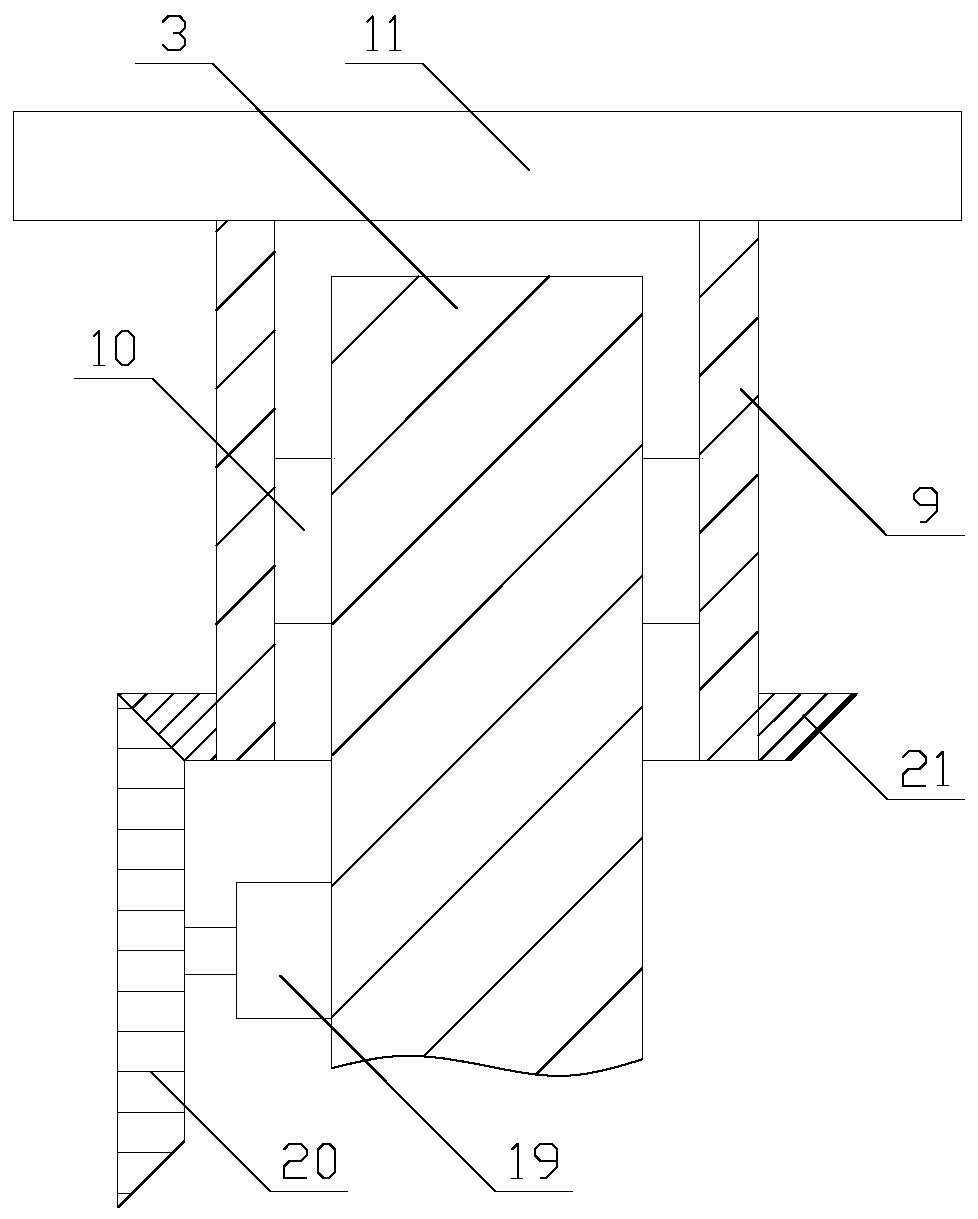

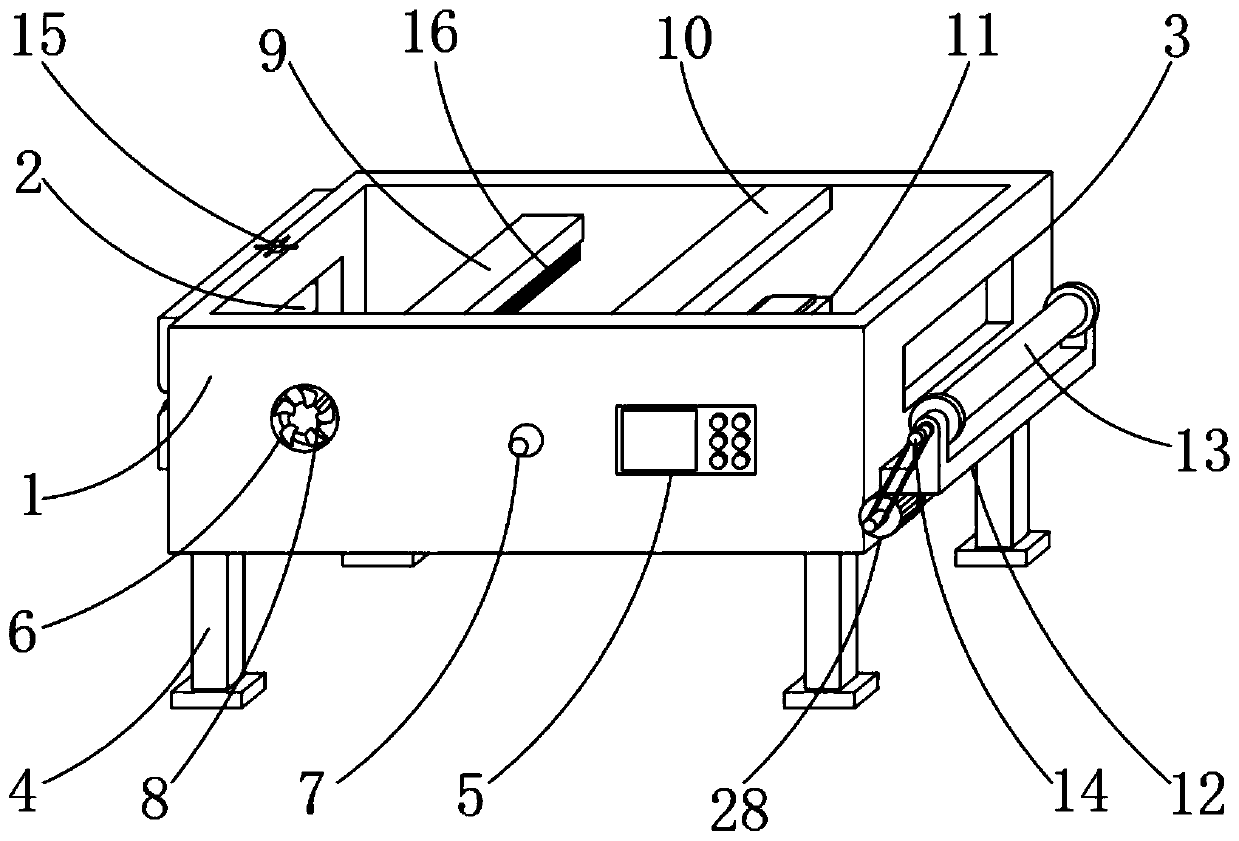

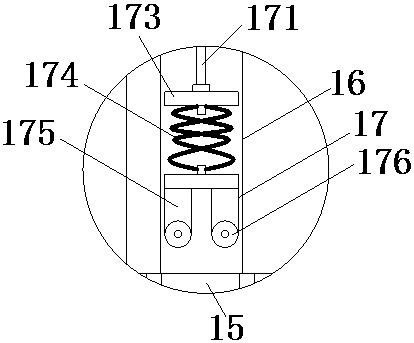

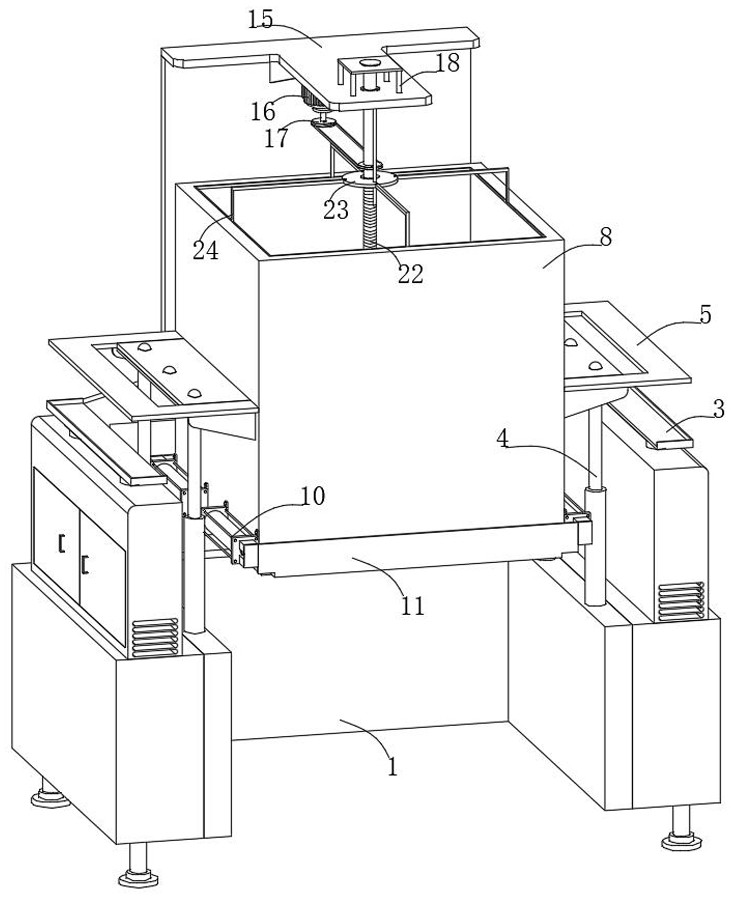

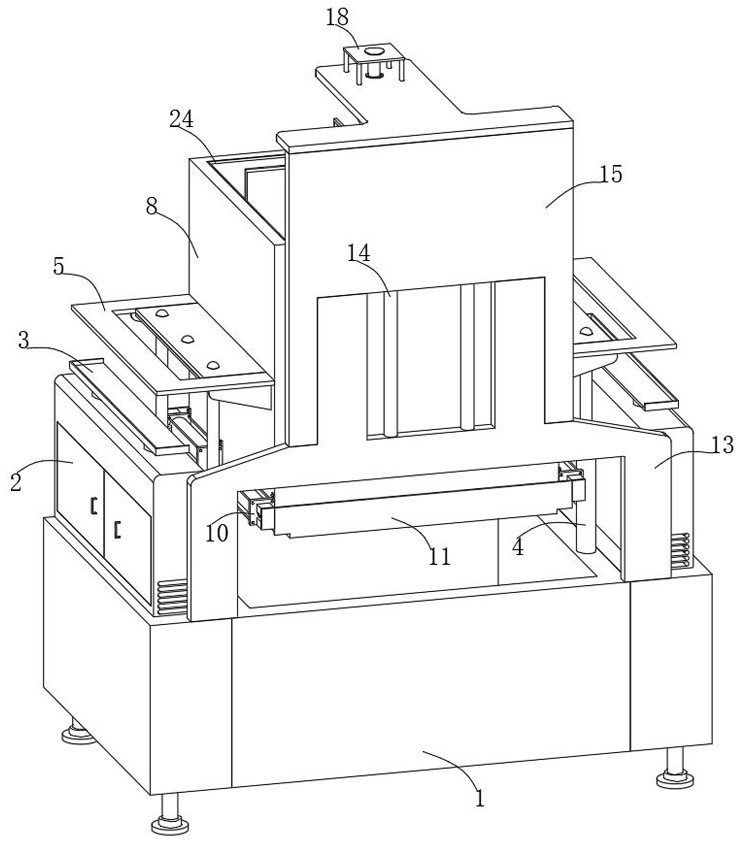

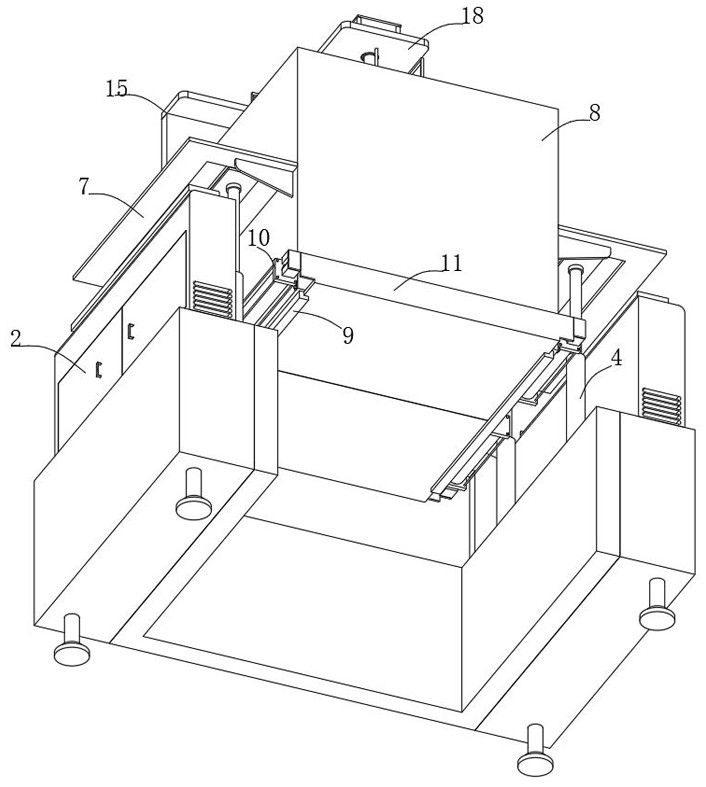

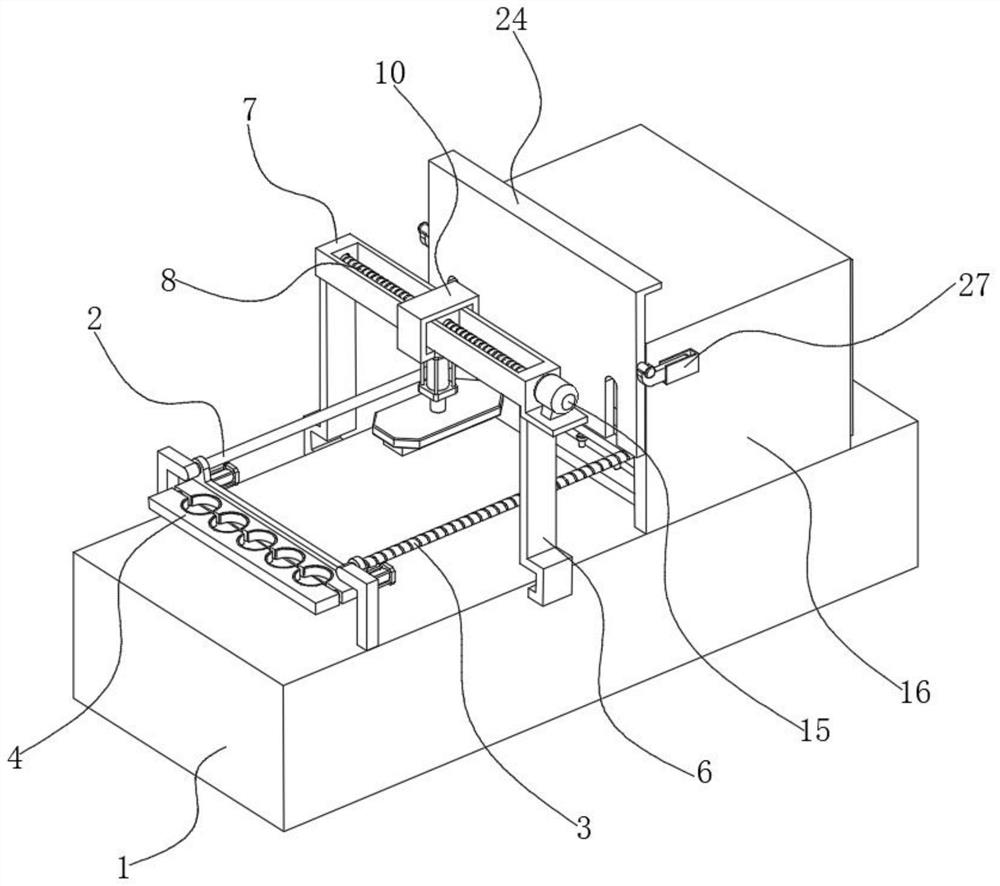

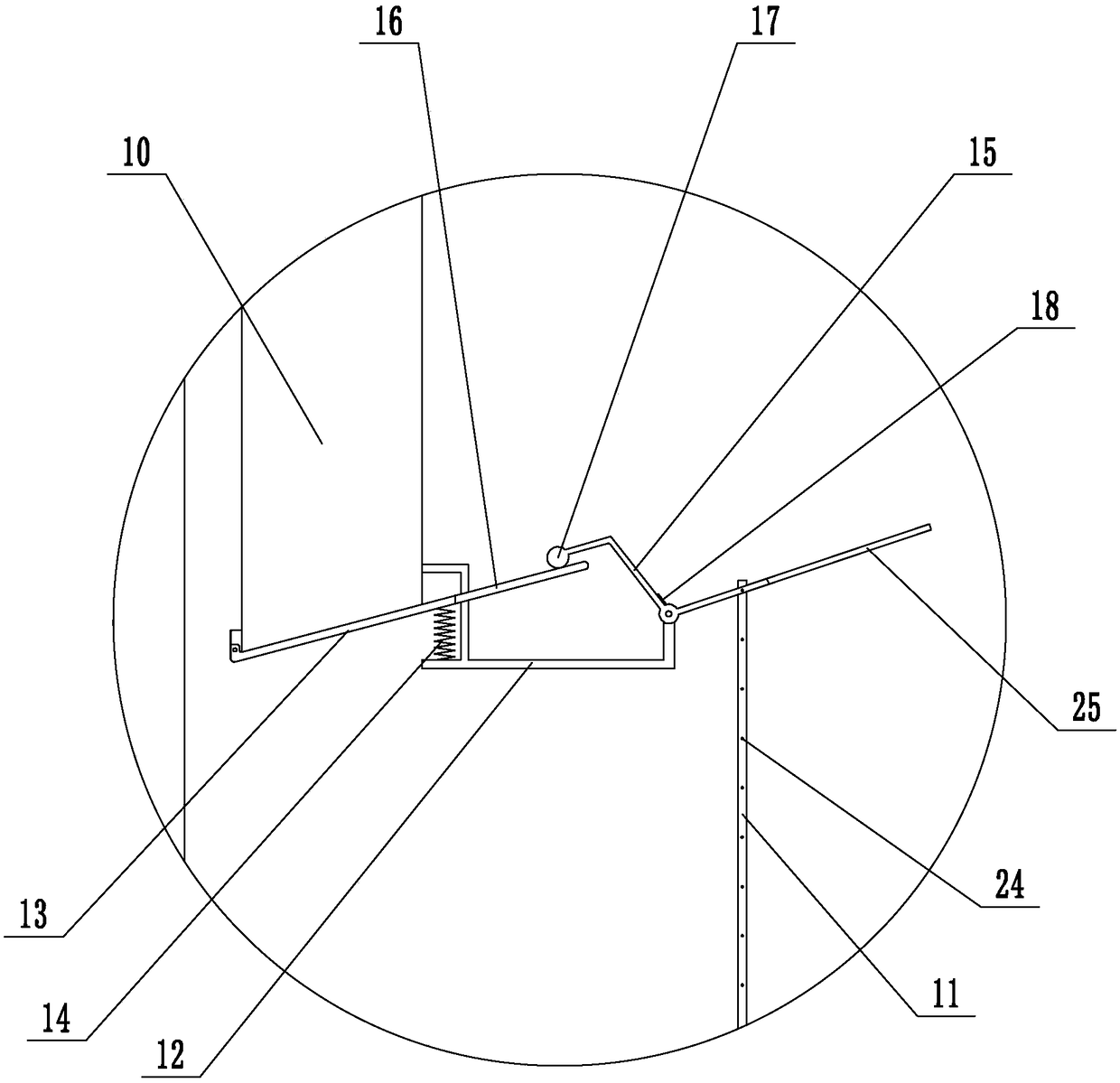

Automatic positioning-detecting system based on tube-boring perforating lathe

The invention discloses an automatic positioning-detecting system based on a tube-boring perforating lathe, and relates to the technical field of tube-boring automatic production lathes, and aims to solve the problem of offset of a boring tube to be machined due to inaccurate positioning. The automatic positioning-detecting system is technically characterized by comprising a rack, wherein the rackis provided with a belt wheel for conveying a boring tube; a positioning mechanism is arranged at a tail end of the belt wheel; the positioning mechanism comprises side top pieces which are arrangedsymmetrically and are positioned at the tail ends of the belt wheel; the two side top pieces are connected to one driving transmission mechanism; the driving transmission mechanism comprises connection blocks, a slide rail, a slide block, two connection rods and a cylinder; two connection blocks are arranged on outer sides of the two side top pieces respectively; the connection blocks are of L-shaped structures, the other sides of the connection blocks are fixed to the slide block; the slide block is in slide connection with the slide rail which is vertically arranged with the side top pieces;certain sides, close to the slide block, of the connection blocks are fixed to the connection rods; the other ends of the two connection rods are arranged on an output shaft of the cylinder. By adopting the automatic positioning-detecting system, the boring accuracy is increased in order to ensure machining quality.

Owner:NANTONG HONGYUAN GEOLOGICAL ENG MATERIAL

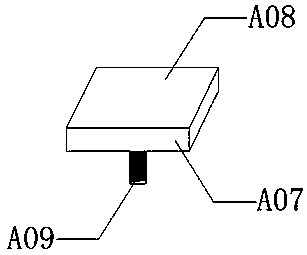

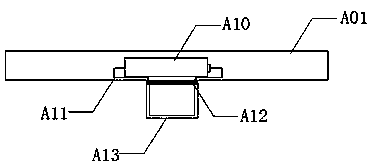

Stamping device for bicycle pipe fitting machining

InactiveCN111036751AAvoid manual rotationEasy to fixShaping toolsMetal-working feeding devicesPipe fittingElectric machinery

The invention relates to the technical field of bicycle pipe fitting machining and particularly relates to a stamping device for bicycle pipe fitting machining. The device comprises a base; supportingseats are symmetrically arranged at a bottom of the base; a fixed plate is arranged in the middle of a right supporting seat; a driving motor is mounted on the fixed plate; a screw is arranged at anoutput end of the driving motor; the screw penetrates an upper portion of the right supporting base and is rotationally connected with a left supporting base; the screw is symmetrically sleeved with nuts; and L-shaped rods are symmetrically arranged at tops of the nuts. The invention provides a stamping device for bicycle pipe fitting machining. Under the action of a first clamping block and a second clamping block, the effect of clamping a pipe fitting body is achieved; the fixing effect is good, the punching precision is improved, the effect of adjusting the punching position of the pipe fitting body is achieved under the action of a first driving air cylinder and a second driving air cylinder, an effect of adjusting a punching position of the pipe fitting body is achieved, different positions of a pipe fitting can be punched, meanwhile, punching is completed in the left direction and the right direction of the pipe fitting body, and the working efficiency is improved.

Owner:湖州屹鼎自动化科技有限公司

Servo motor for woodworking machine tool

ActiveCN114844289AEasy to installFirmly connectedMulti-purpose machinesGear lubrication/coolingOil canGear wheel

The invention relates to the technical field of servo motors, in particular to a servo motor for a woodworking machine tool, which comprises a motor body, a transmission mechanism is mounted on the motor body, a fastening mechanism is connected to the transmission mechanism, a lubricating mechanism is mounted on the motor body, and a dust removal mechanism is mounted on the motor body. The dust removal mechanism is provided with a connecting mechanism, and the motor body is provided with a wire clamping mechanism. Through cooperation of the transmission mechanism and the fastening mechanism, an external gear can be conveniently, stably and firmly installed, the situation that the precision of equipment is affected by loosening of the gear is prevented, through driving of the transmission mechanism to the lubricating mechanism and the dust removal mechanism, lubricating oil can be conveniently conducted on the installed gear, dust can be blown away, and dust is prevented from being attached to and stuck to the gear and a rack; the dust removal mechanism and the motor body are convenient to disassemble, assemble and maintain through the connecting mechanism, a data line and a power line on the motor body can be wound and clamped through the line clamping mechanism, and disordered abrasion cannot be caused.

Owner:深圳市盛泰奇科技有限公司

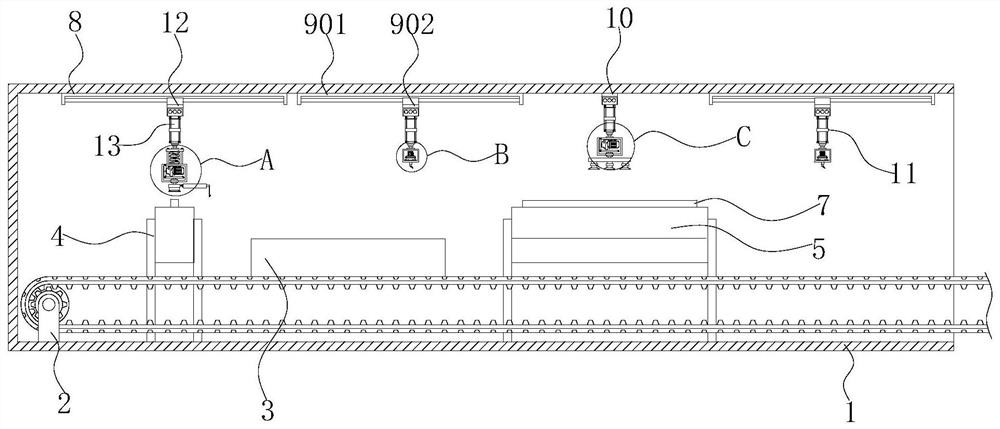

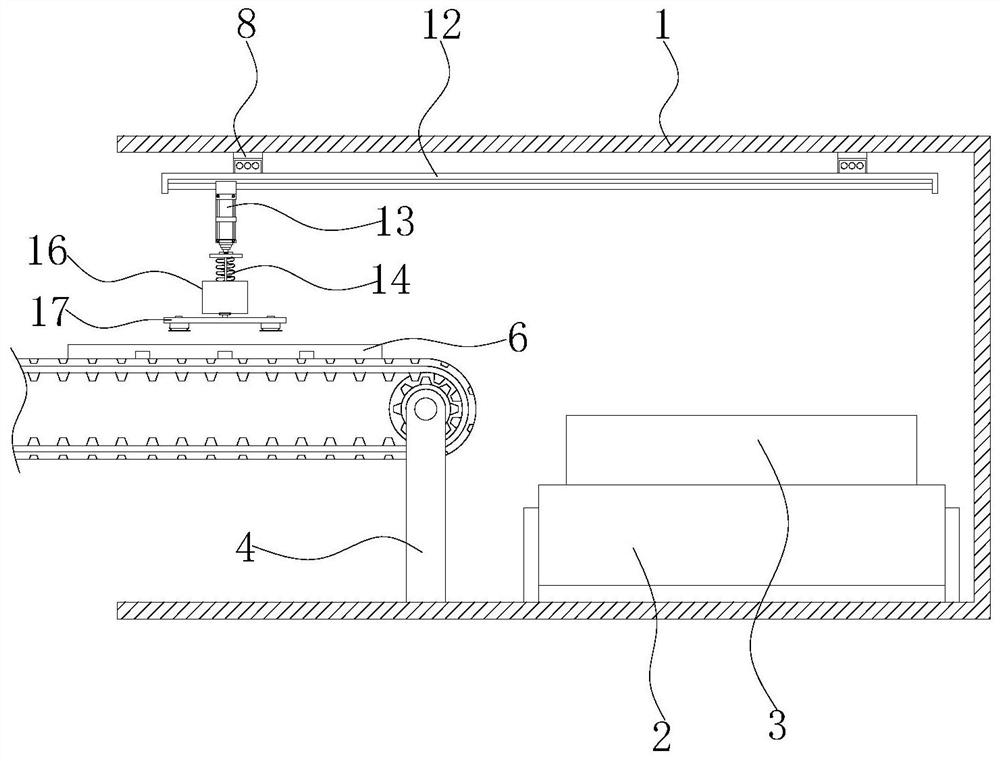

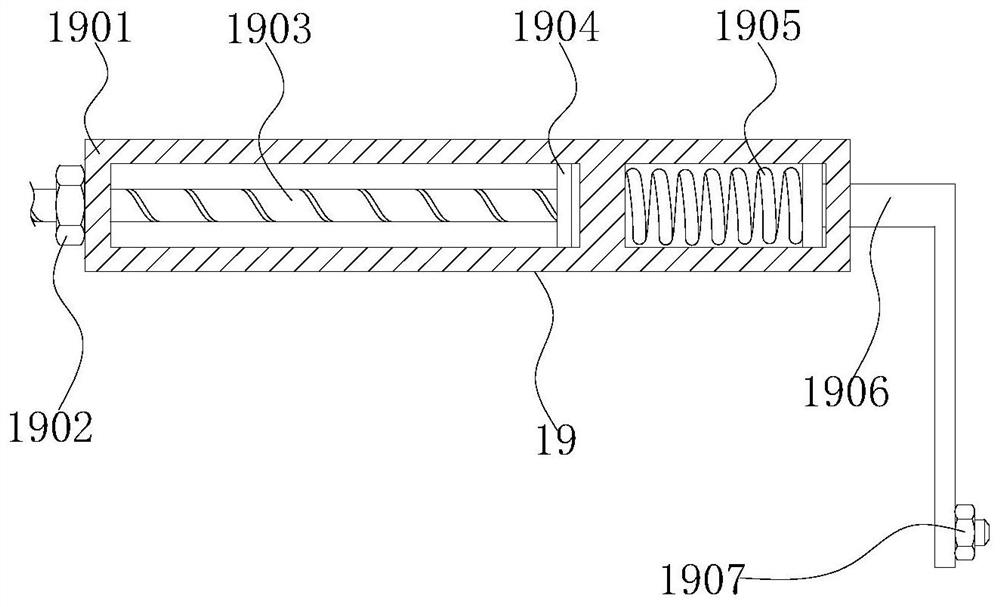

Automatic machining production line for elevator car production

InactiveCN112792492AFor precise pressingAvoid damageConveyorsWelding/cutting auxillary devicesAutomotive engineeringLeather belt

The invention relates to an automatic machining production line for elevator car production. The automatic machining production line for elevator car production comprises an equipment shell and an electromagnet, a first belt conveyor is arranged at the front end of the lower wall in the equipment shell, a second belt conveyor and a third belt conveyor are sequentially arranged at the rear end of the lower wall in the equipment shell from left to right, a sealing plate is placed at the upper end of the third belt conveyor, a first electric sliding rail, a first welding mechanism, a fourth electric sliding rail and a second welding mechanism are sequentially arranged on the upper wall of the interior of the equipment shell from left to right, a fifth electric sliding rail is installed at the lower end of the first electric sliding rail, a second multi-section hydraulic cylinder is installed at the lower end of the fifth electric sliding rail, and a first spring and a guide rod are sequentially arranged at the lower end of the second multi-section hydraulic cylinder from the middle to the left side and the right side. The installation position of reinforcing keels can be positioned through a contact sensor, grooves in an upper layer keel and a lower layer keel can be accurately in butt joint, and therefore the reinforcing keels can be accurately installed through equipment.

Owner:郭文辉

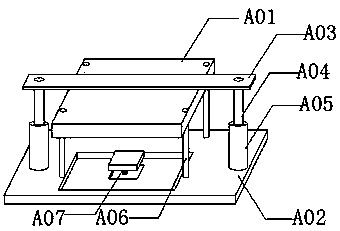

Die assembly used for light sheet machining and using method thereof

InactiveCN108145007AEasy to fixEasy to take outMetal-working feeding devicesPositioning devicesElectricitySheet steel

The invention discloses a die assembly used for light sheet machining and a using method thereof. The die assembly comprises a die plate, a clamping plate, a transmission plate, a hydraulic rod, a hydraulic box, a guide rod, a supporting device, a supporting plate, a spring support, an electricity box, a guide line, a first electromagnet, a die, a fixing groove, a clamping groove and a second electromagnet. The die assembly has the beneficial effects that by arranging the spring support and the first electromagnet at the bottom of the supporting device, the first electromagnet is energized toadsorb steel sheets, the spring support is compressed by the steel sheets to be clamped in the fixing groove and fixed, after die pressing is completed, the first electromagnet is powered off, the steel sheets are pushed by the spring support to return to the original position, thus, the steel sheets can be fixed and taken out conveniently, and the die pressing efficiency is improved. By arrangingthe second electromagnet in the die, after the die completes die pressing operation after making contact with the steel sheets, the second electromagnet is energized and thus can adsorb models pressed from the steel sheets, and the models can be taken out conveniently. The die assembly has the characteristics of being high in die pressing efficiency, simple and convenient to use.

Owner:丁年生

Insulativity detection device with safety structure for electronic part machining

InactiveCN112240970AWith elastic cushioning functionClose contactTesting dielectric strengthMeasurement instrument housingHydraulic cylinderElectric machine

The invention relates to an insulativity detection device with a safety structure for electronic part machining, which comprises an equipment shell and a third multi-section hydraulic cylinder, a motor is mounted at the lower end of the equipment shell, and a machining disc is connected to the middle of the lower wall of the interior of the equipment shell; a rubber insulating base and a lower protective cover are sequentially arranged on the periphery of the upper end of the machining disc from the middle to the two sides, the lower end of a metal power connector is connected with a magnet power connector, an electronic part shell is placed in the rubber insulating base, and a first spring is connected to the outer part of a first contact head. An electrified electric meter and a belt conveyor are sequentially arranged on the outer side of the lower wall of the interior of the equipment shell anticlockwise; the insulativity detection device with the safety structure for electronic part machining has the beneficial effects that the insulativity detection device with the safety structure for electronic part machining is in contact with the electronic part shell through the electrostatic neutralizer, therefore, the static electricity neutralizer neutralizes the static electricity on the shell of the electronic part, and the static electricity on the shell of the electronic part is prevented from interfering with the detection of equipment.

Owner:深圳市辉迪机电科技有限公司

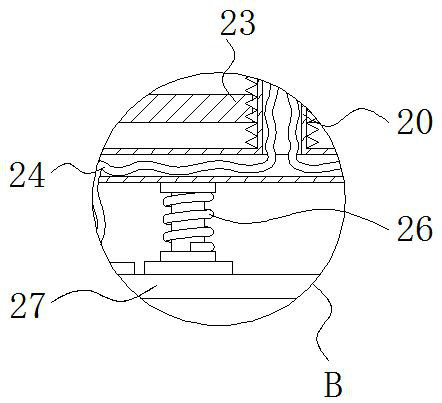

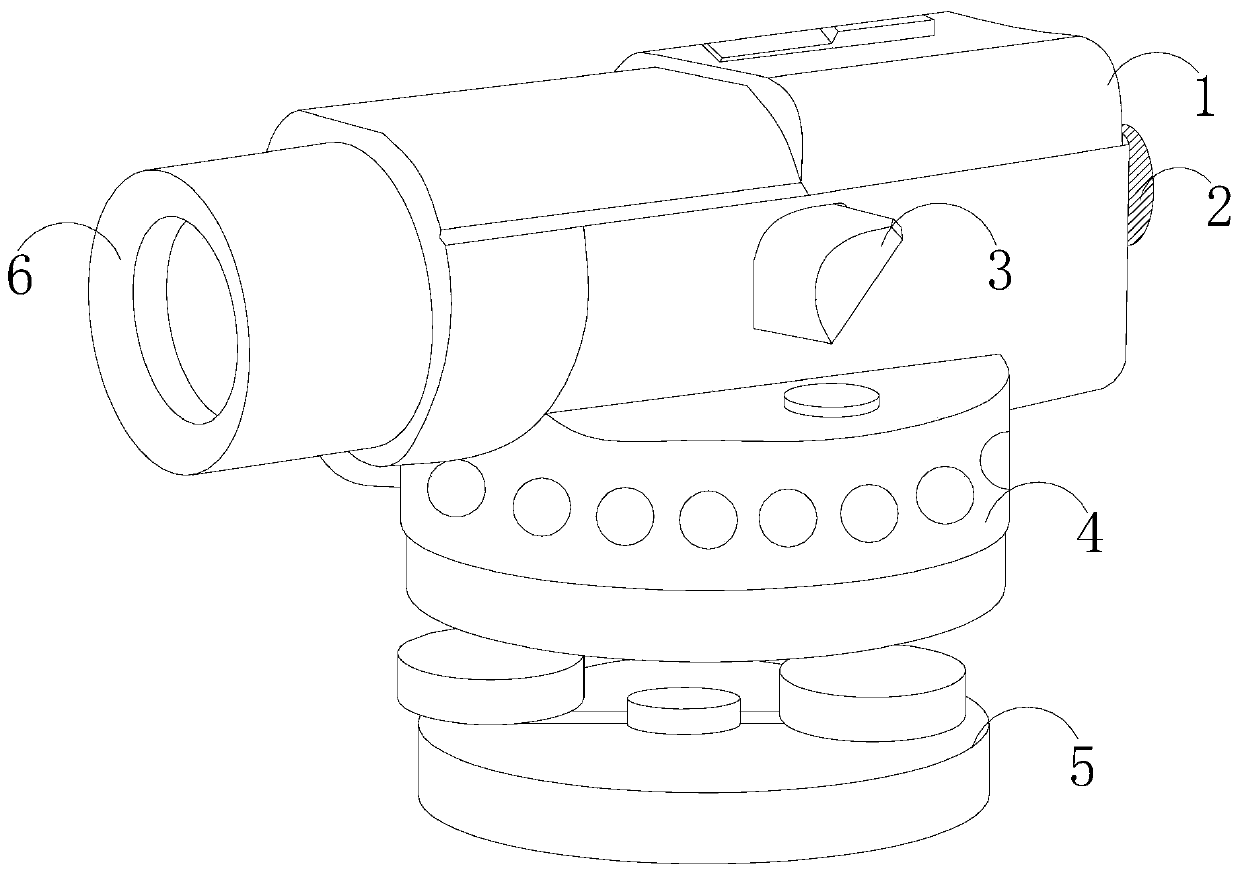

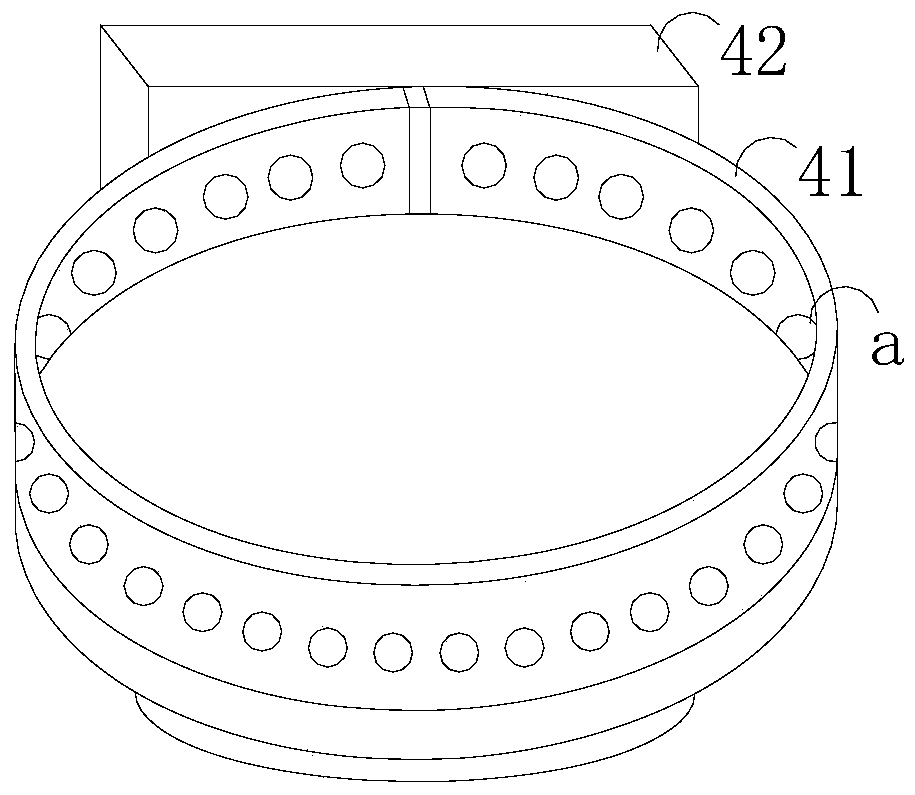

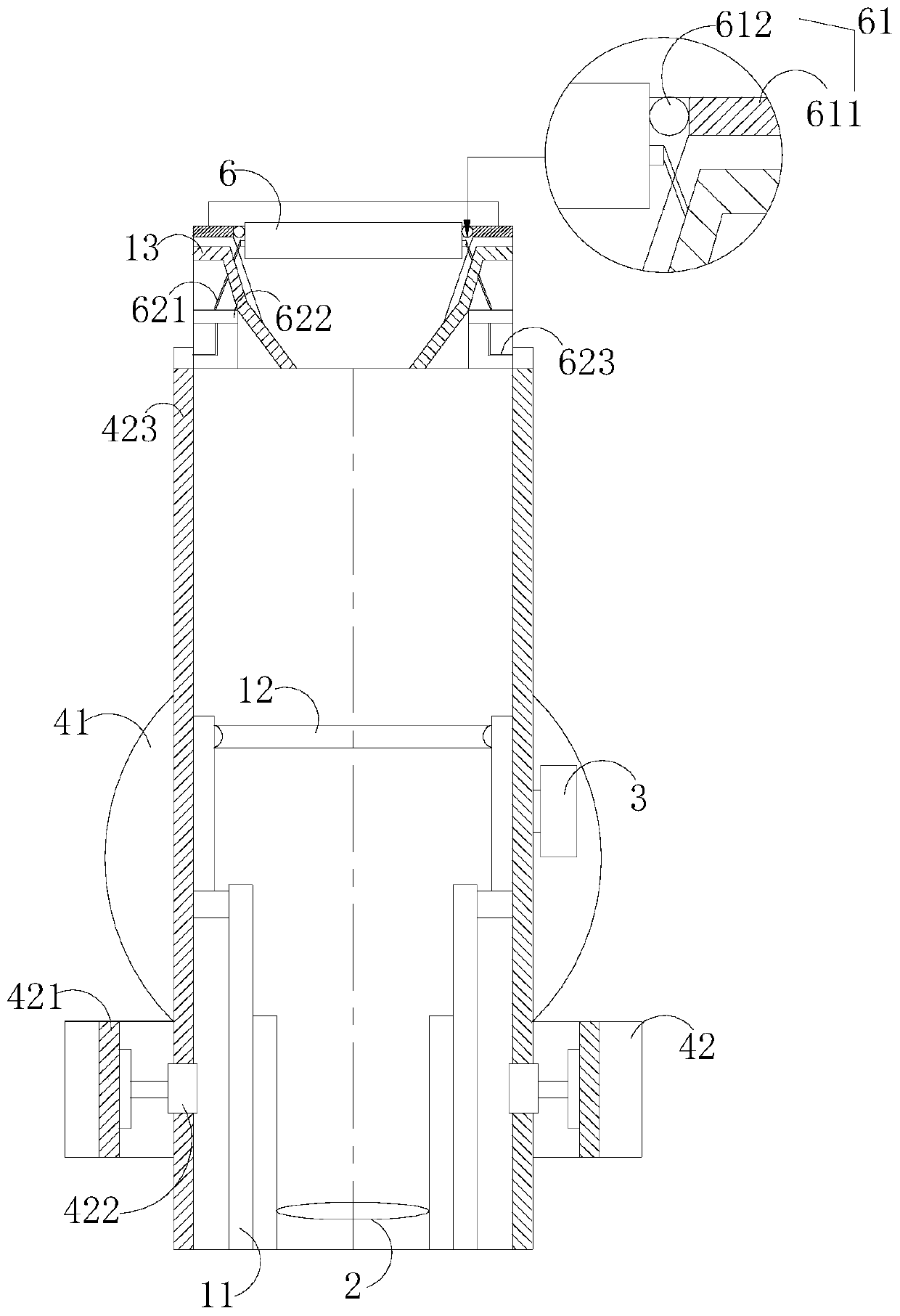

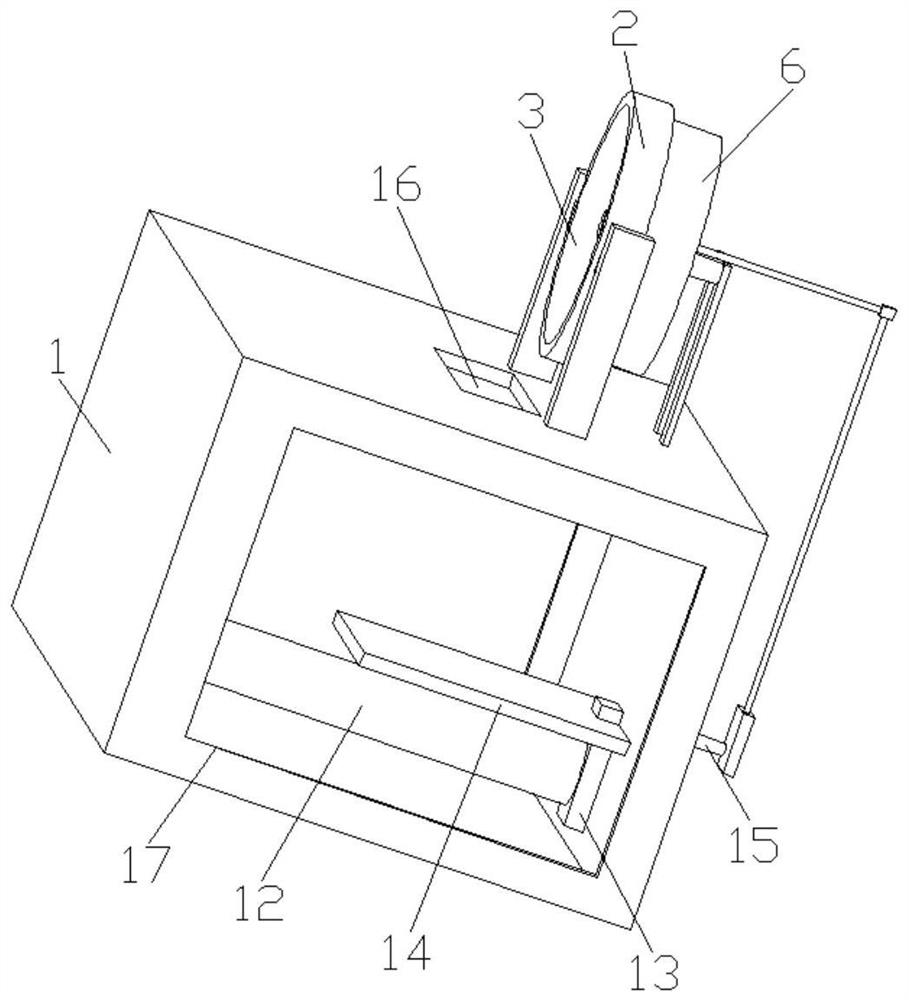

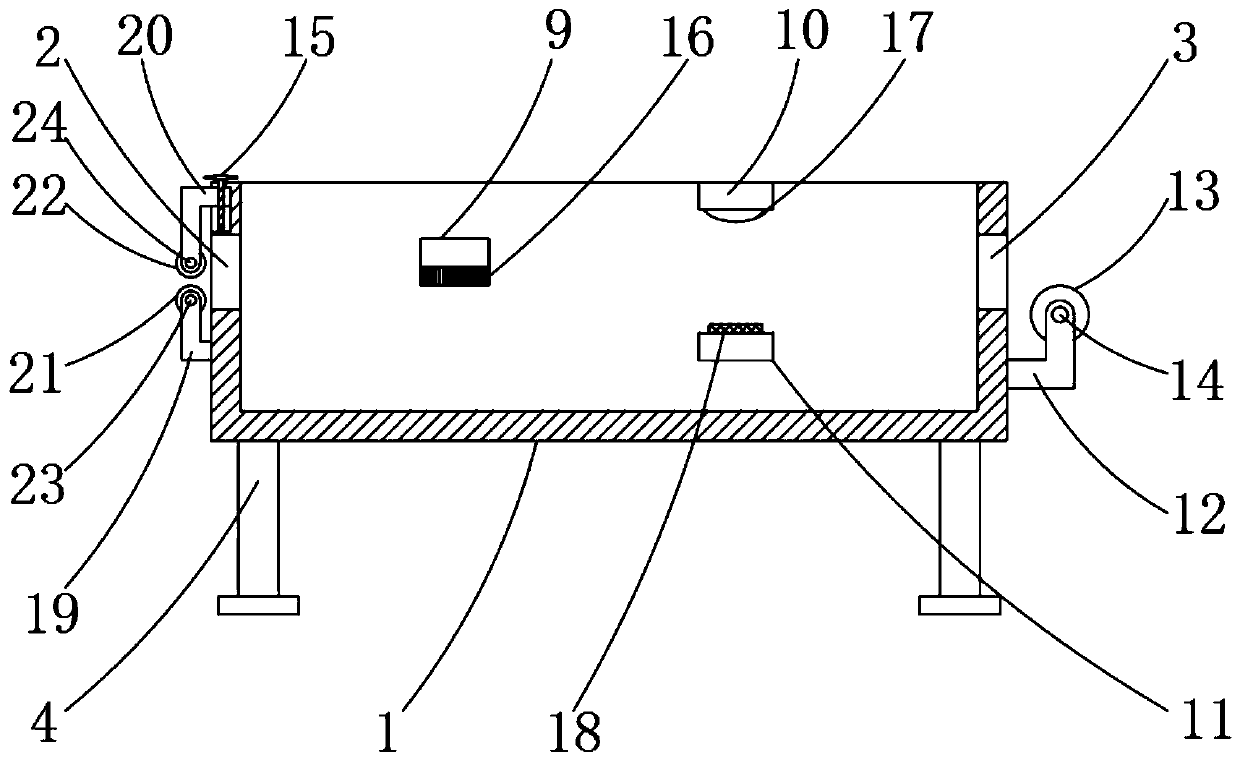

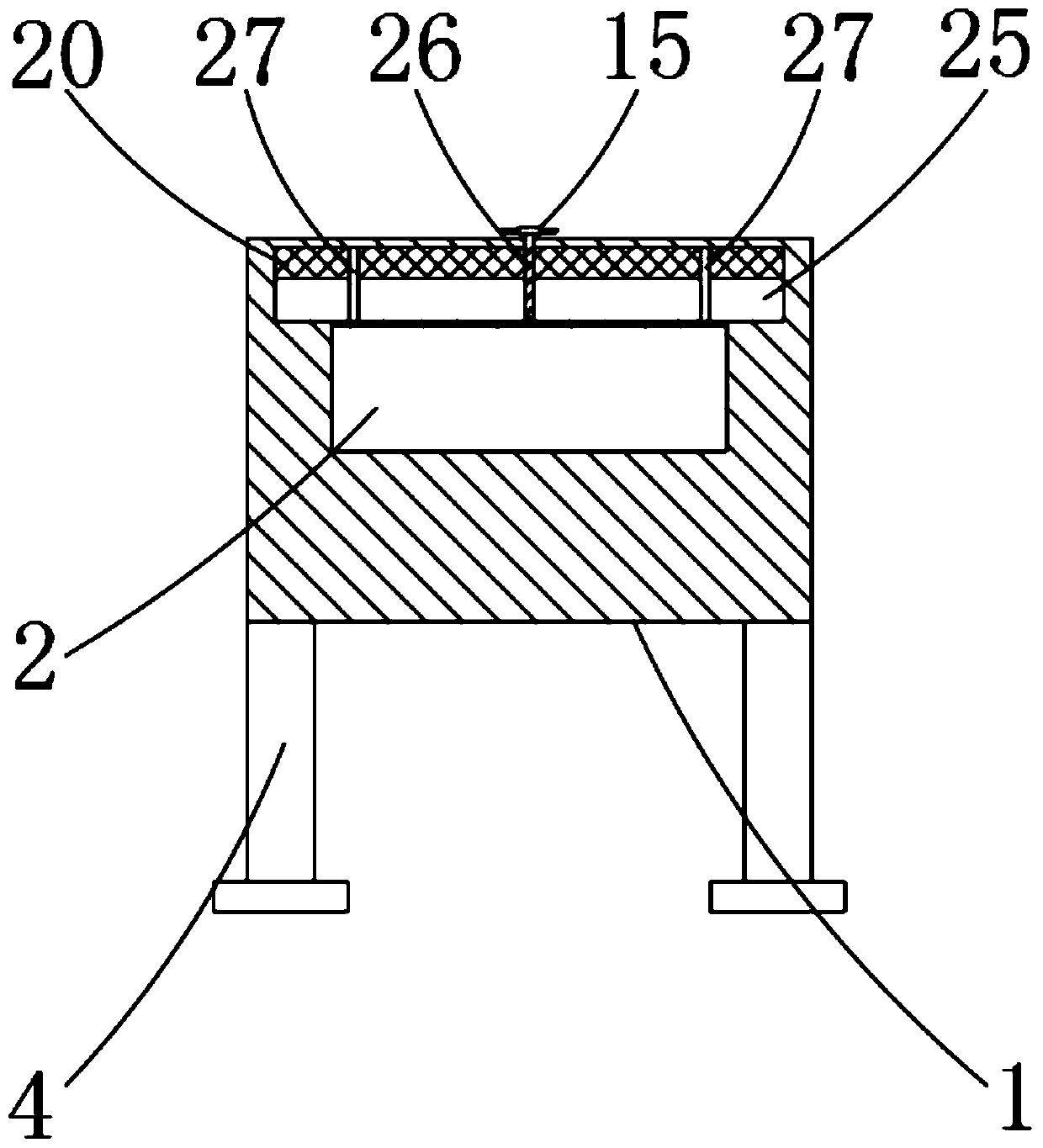

Height measurement level gage for building surveying and mapping

InactiveCN110715642ASolve the large measurement errorPrevent from compromising accuracyHeight/levelling measurementElectric machineryMicroscope objective

The invention discloses a height measurement level gage for building surveying and mapping. The height measurement level gage for building surveying and mapping comprises a machine frame, an eyepiece,a focusing screw, a rotary table, a base and an objective lens. The focusing screw which controls the eyepiece is arranged on the machine frame, the rotary table is installed on the base, the machineframe is fixed to the rotary table, the eyepiece, the objective lens and the focusing screw are arranged on the machine frame, an outer retaining ring and a connecting base are arranged on the outersurface of the rotary table, more than two wind holes are evenly formed in the circumference surface of the retaining ring, and a rotary handle, a connecting rotary shaft and a screw are arranged in the connecting base. Through combined action of the wind holes in combination with a detecting opening, a motor, an output transmission end, a transmission track, a belt pulley, the screw and the connecting rotary shaft, the rotary table capable of detecting wind magnitude in real time can turn off the surveying and mapping work of the leveling gage in time when the wind is strong to avoid excessive measurement errors.

Owner:周美花

Fingerprint identification device with cleaning function for attendance management system

InactiveCN110782541AReduce gapImprove transfer efficiencyRegistering/indicating time of eventsAcquiring/reconising fingerprints/palmprintsIdentification deviceSurgery

The invention relates to a fingerprint identification device with a cleaning function for an attendance management system. The device comprises a main body and a connection ring, wherein the main bodyis a cuboid; an identification system is arranged in the main body; a detection hole is arranged at one side of the main body; the connection ring is in the main body; an axis of the connection ringis vertical to the top of the main body; a cleaning mechanism and an auxiliary mechanism are arranged in the main body; and both the cleaning mechanism and the auxiliary mechanism are at the side, farfrom the top of the main body, of the connection ring and at the side, far from the detection hole, of the connection ring. The fingerprint identification device with the cleaning function for the attendance management system realizes a function of removing impurities on a glass disk through the cleaning mechanism so as to prevent impurities form affecting detection accuracy, and realizes a finger heating function through the auxiliary mechanism so as to make the finger sweat to prevent the finger from being too dry to affect collection of finger information.

Owner:深圳市壹闻科技有限公司

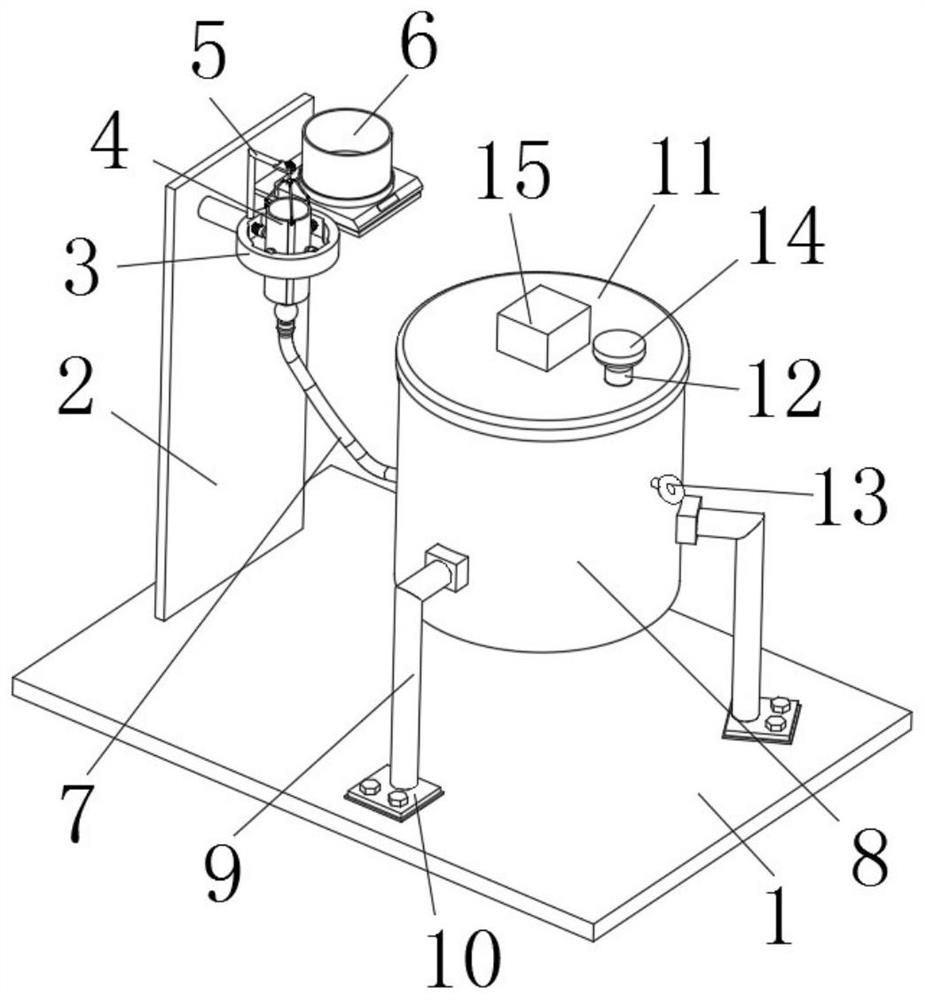

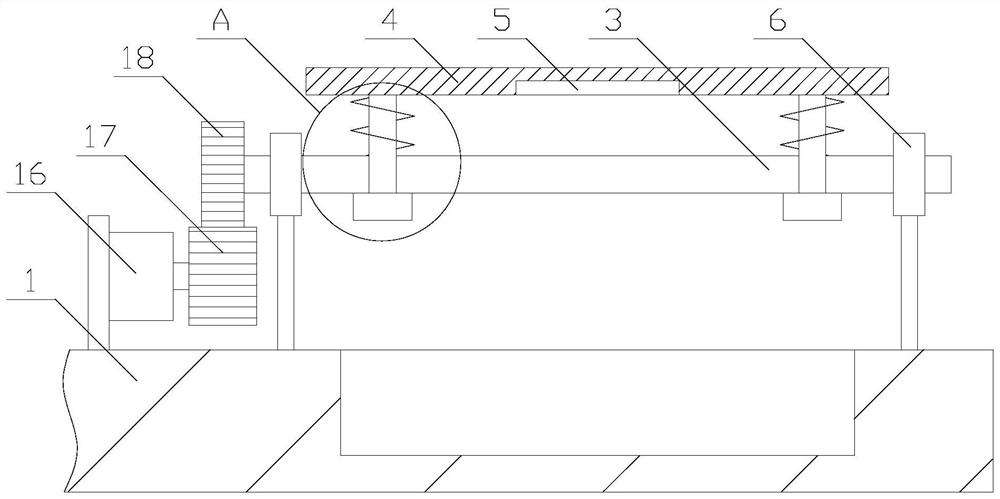

Binder preparation device for producing hollow glass of textile machinery

InactiveCN112975776AAffected readingsFast manufacturingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a binder preparation device for producing hollow glass of textile machinery, and relates to the technical field of binder preparation devices. The binder preparation device comprises a bottom plate, a side plate is fixedly connected to the top of the bottom plate, a fixing frame is fixedly connected to the side wall of one side of the side plate, and a measuring cylinder clamping part is installed on the fixing frame. A measuring cylinder balancing part is installed on the fixing frame, a measuring cylinder is installed on the measuring cylinder balancing part, the measuring cylinder and the measuring cylinder clamping part are arranged in a matched mode, and a scale plate is fixedly connected to the side wall of the measuring cylinder. A placing plate is fixedly connected to the side wall of one side of the side plate, an electronic metering scale is installed at the top of the placing plate, and a placing box is arranged at the top of the electronic metering scale. The binder preparation device for producing the hollow glass of the textile machinery is reasonable in structure, measurement, smashing, grinding and stirring are integrated, the integration effect is good, the preparation speed of a binder is increased, and the binder is prepared uniformly.

Owner:杭州柔谷防护用品有限公司

Drilling equipment for mold production

InactiveCN112846309AGood removal of impuritiesAvoid scratchesBoring/drilling componentsMaintainance and safety accessoriesPhysicsDrill hole

The invention relates to drilling equipment for mold production. The drilling equipment comprises a workbench, a supporting rod and an execution device, wherein the workbench is horizontally arranged, the supporting rod is vertically fixed to the workbench, and the execution device is located above the workbench; the workbench is provided with an auxiliary mechanism, and the auxiliary mechanism is located between the workbench and the execution device; the supporting rod is provided with a cleaning mechanism, and the cleaning mechanism is located between the auxiliary mechanism and the execution device; and the auxiliary mechanism comprises a rotating shaft, a supporting plate, an electromagnet, a power assembly and two connecting assemblies, and the connecting assemblies comprise first bearings, limiting blocks, guide rods, reset springs and guide holes. According to the drilling equipment for mold production, the function of cleaning impurities on a workpiece is achieved through the cleaning mechanism, the impurities are prevented from influencing the drilling accuracy, and in addition, the function of removing chippings in a blind hole is achieved through the auxiliary mechanism.

Owner:南京群博新能源技术开发有限公司

High-density polyethylene product processing cutting device

InactiveCN113664890APrevent affecting accuracyEasy to disassemble and installGrinding carriagesRevolution surface grinding machinesHigh densityElectric machinery

The invention relates to the field of polyethylene production and processing, in particular to a high-density polyethylene product processing cutting device. The device comprises a cutting processing table, the cutting machining tables are symmetrically fixed to the two sides of the top of the cutting processing table, supporting stand columns are symmetrically fixed to the two sides of the bottom of the cutting processing table, a polyethylene recycling box is connected between the two supporting stand columns through a detachable mechanism, a grinding mechanism and a cutting mechanism are arranged between the two sets of cutting machining tables from top to bottom, a mounting top plate is fixed to the position, between the grinding mechanism and the cutting mechanism, of the two sets of cutting machining tables, and the mounting top plate is provided with a limiting fastening mechanism. The device prevents a polyethylene pipe from moving during the grinding and cutting of the outer wall of the polyethylene pipe, the polishing or cutting precision is influenced, grinding pieces on the two sides are driven to rotate, the outer wall of the polyethylene pipe is rotationally ground, a cutting sleeve rod is driven to horizontally move, and a cutting motor is started to drive a cutting tool to cut the polyethylene pipe.

Owner:连云港有道新材料科技有限公司

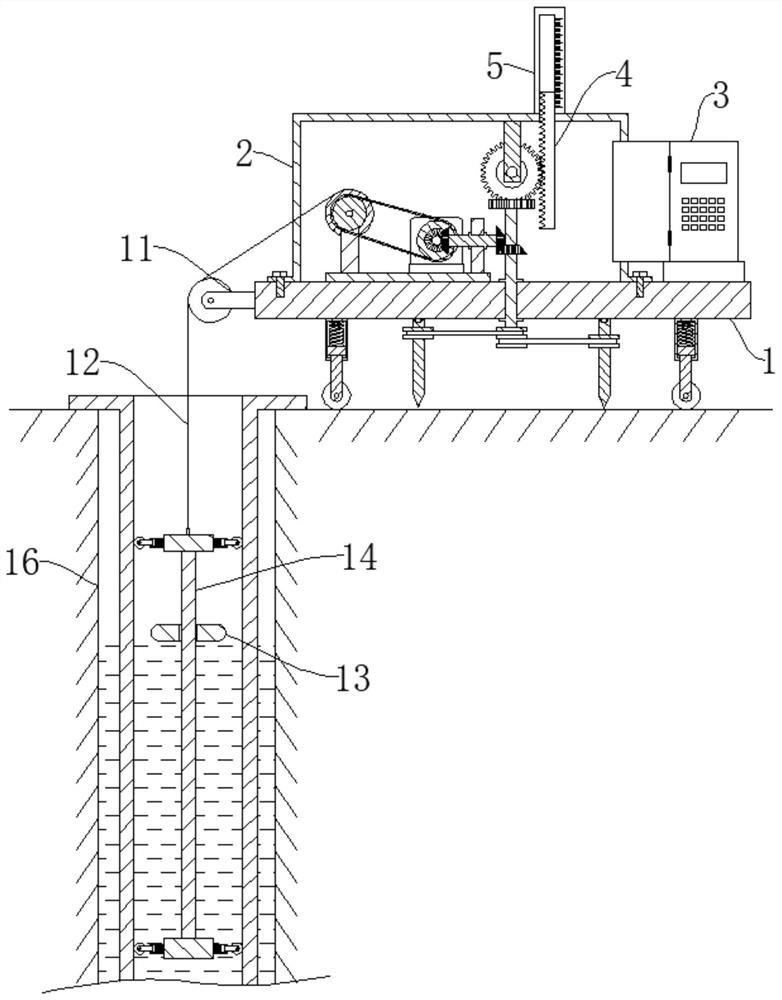

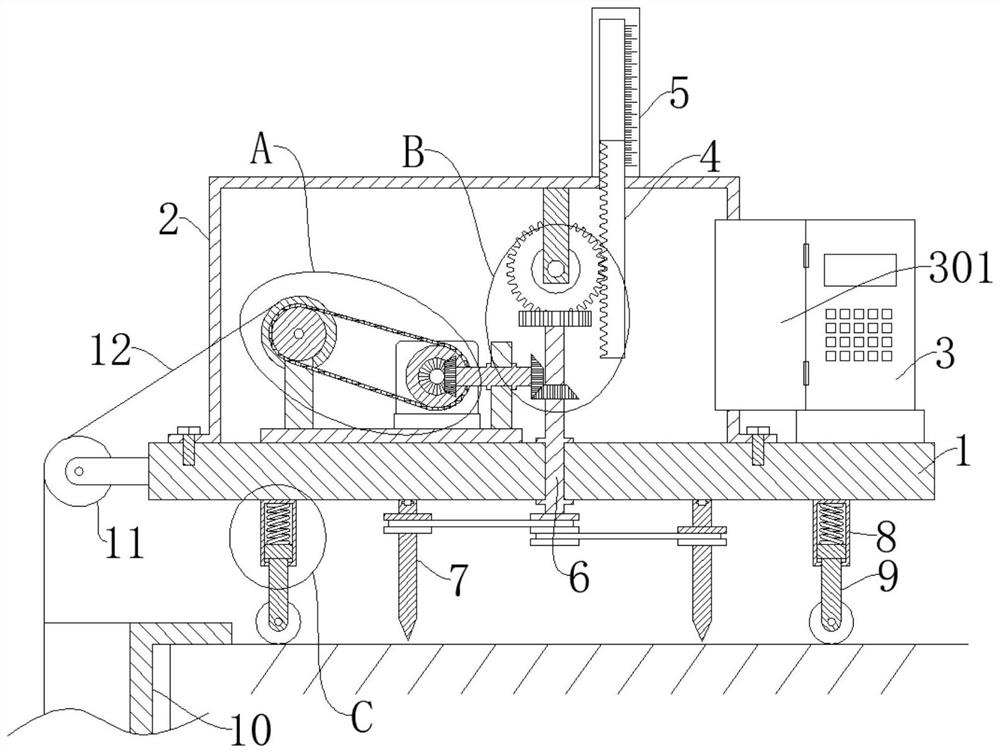

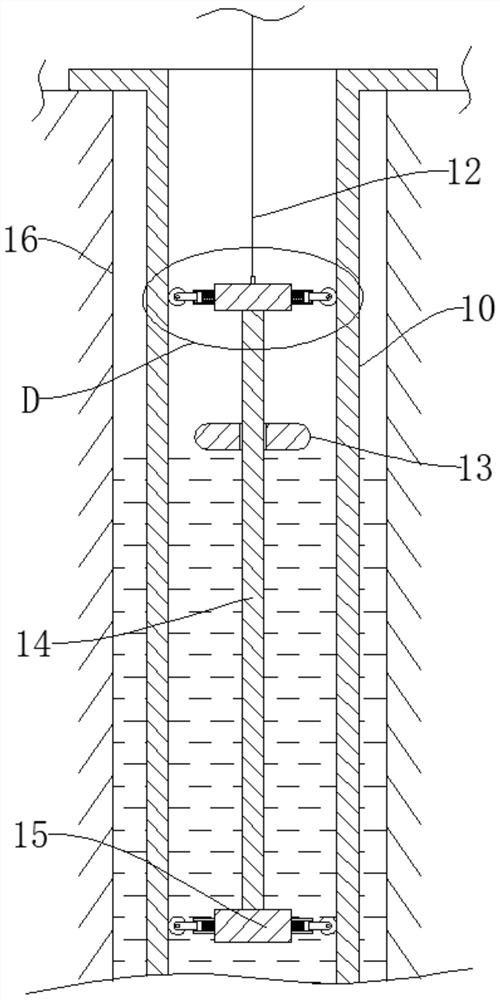

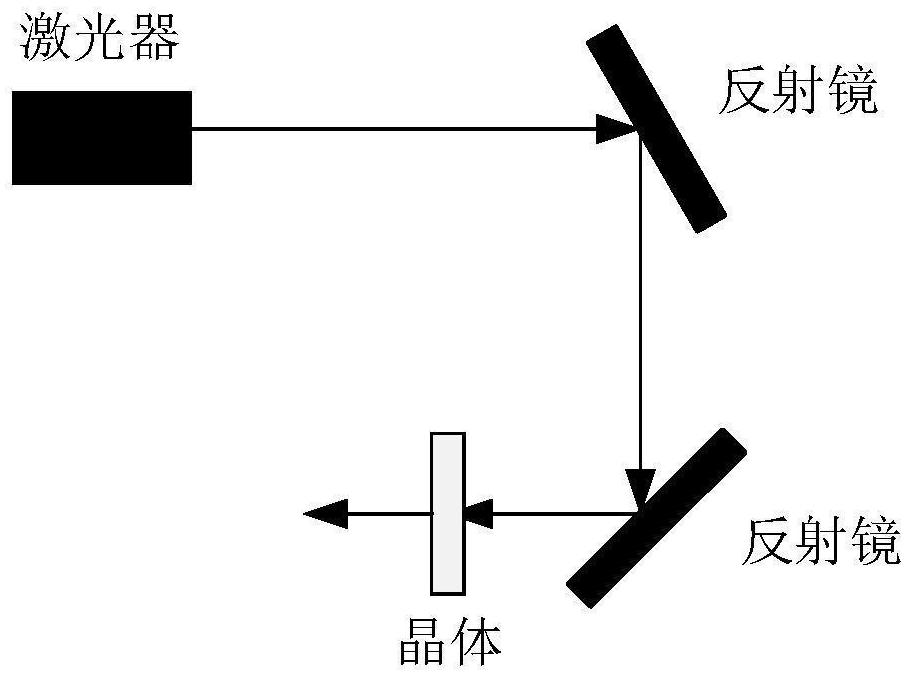

Following type magnetostrictive water level gauge for hydraulic engineering piezometric tube

InactiveCN113049065APlay a fixed roleAvoid shakingMachines/enginesLubrication indication devicesEngineeringHydraulic engineering

The invention discloses a following type magnetostrictive water level gauge for a hydraulic engineering piezometric tube, and belongs to the technical field of measuring devices. The following type magnetostrictive water level gauge for the hydraulic engineering piezometric tube comprises a piezometric tube body and a water level gauge body, the water level gauge body comprises a waveguide rod, a magnetic floating body and a balancing weight, and the magnetic floating body is slidably connected with the waveguide rod; the balancing weight is fixedly connected with the lower end of the waveguide rod, and the upper end of the waveguide rod is connected with a fixing block. According to the following type magnetostrictive water level gauge, through the arrangement of a limiting mechanism, the water level gauge body can be fixed, the situations that the water level gauge body shakes due to water surface fluctuation, and the measurement accuracy is affected, are prevented, and the stability of the water level gauge body in the measurement process is effectively improved; by arranging a driving mechanism and a wire harness winding mechanism, a user can conveniently adjust the position of the water level gauge body, so that the magnetic floating body (13) is flush with the water surface, and the detection accuracy is improved.

Owner:刘土仙

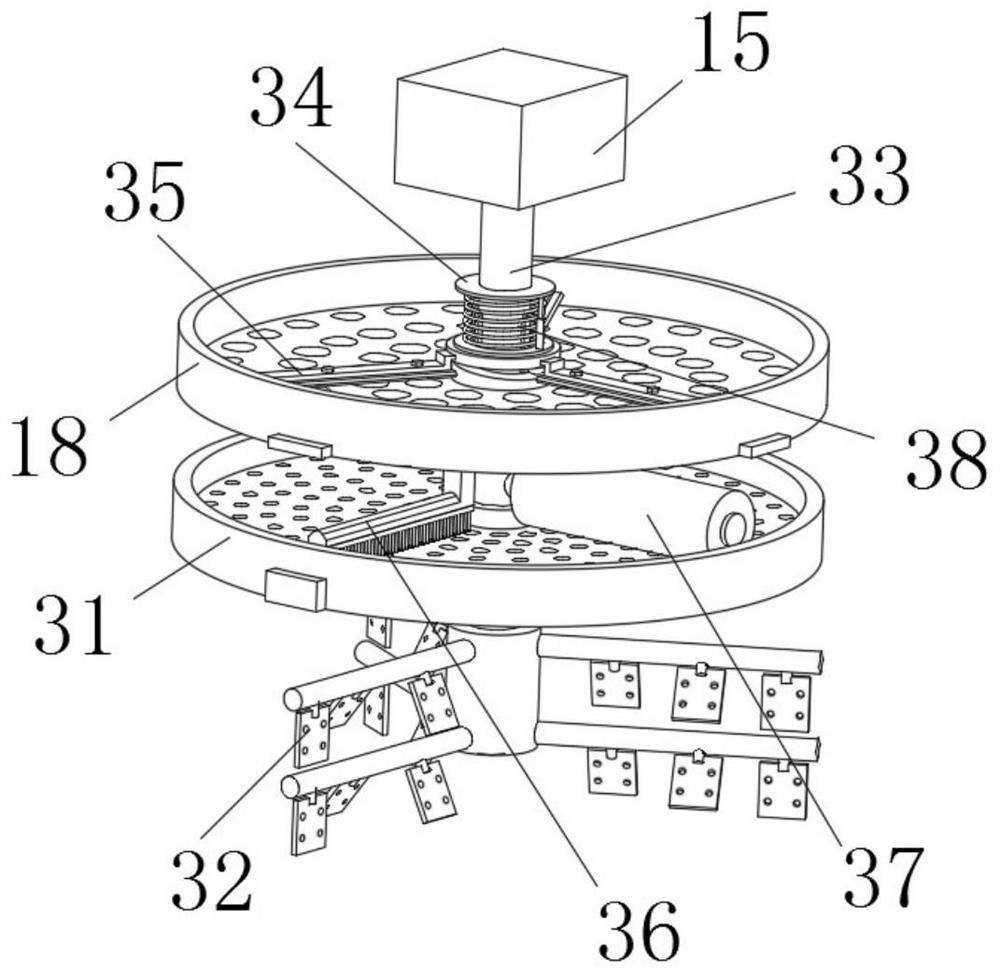

Device for visually detecting rubber ring of valve core sleeve

PendingCN114485323APrevent affecting accuracyRealize the function of visual inspectionMechanical diameter measurementsUsing optical meansRubber ringStructural engineering

The invention relates to a valve core sleeve rubber ring visual inspection device which comprises a bottom box, a detection disc is arranged above the bottom box, the detection disc is fixedly connected with the bottom box, the axis of the detection disc is horizontally arranged, a cylindrical groove is formed in one side of the detection disc, the groove and the detection disc are coaxially arranged, and the detection disc is fixedly connected with the bottom box. According to the device for visually detecting the rubber ring of the valve core sleeve, the visual detection function is achieved, the detection convenience and the detection efficiency are improved, impurities in the groove can be removed, the impurities are prevented from influencing the visual detection accuracy, the automatic sorting function can be achieved, the labor intensity of workers is reduced, and the working efficiency of the workers is improved. And the convenience and the working efficiency are further improved.

Owner:江阴市创新气门嘴有限公司

Mobile phone screen pressure test device

PendingCN112964543AFully automatedAchieve precisionMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a mobile phone screen pressure test device which comprises a test device body. The test device body comprises a base, a test platform and an air cylinder. The test platform is arranged above the base. First sliding rails are arranged on the two sides of the base. First movable supports are arranged on the two sides of the first sliding rails. Second sliding rails are arranged on the opposite faces of the first movable supports arranged on the two sides. A second movable support is mounted in the second sliding rails. A third sliding rail is arranged on one side of the second movable support. The air cylinder is mounted in the third sliding rail. A fixed support is arranged on the upper surface of the test platform. The fixed support comprises a fixed base and more than one fixed buckle which is oppositely mounted. The more than one fixed buckle which is oppositely mounted is mounted above the fixed base. According to the invention, the pressure test standard value of a mobile phone screen is set in a PCB motherboard, if the mobile phone screen fails under the test of the pressure test standard value, the mobile phone is a faulty mobile phone, and automatic and precise screen pressure test is realized.

Owner:深圳市环测威检测技术有限公司

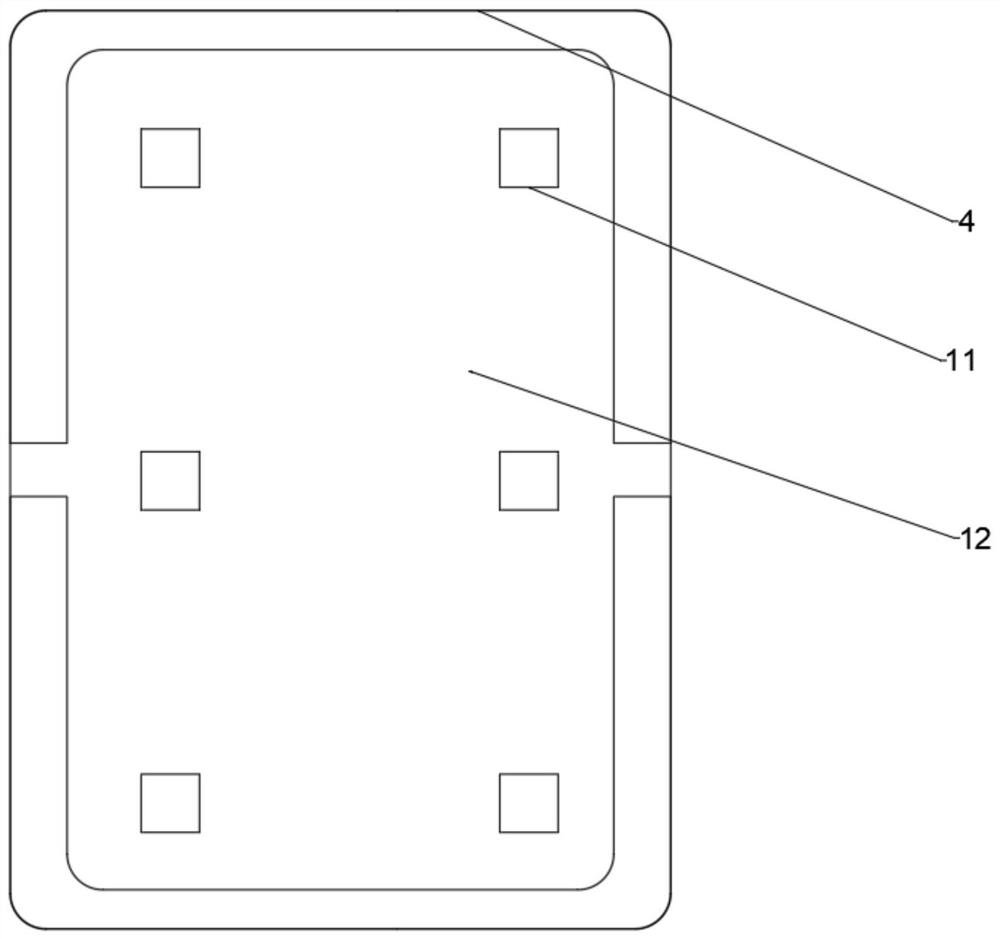

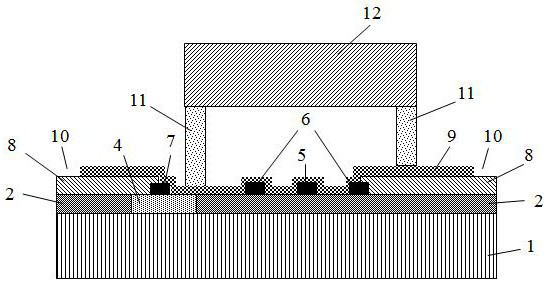

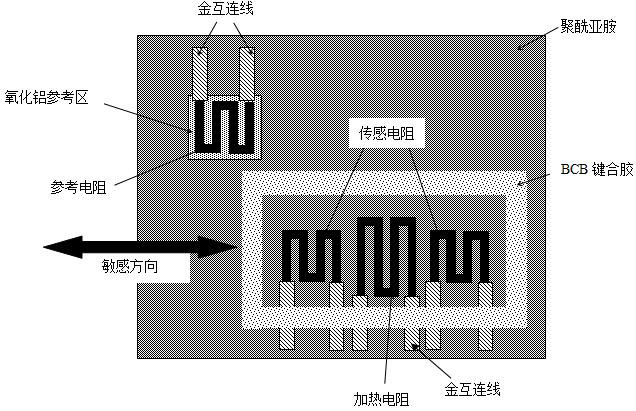

A MEMS Acceleration Sensor Based on Heat Convection Principle

ActiveCN107192849BStable structureAvoid getting lostAcceleration measurement using interia forcesGlass coverAccelerometer

The invention relates to the design and manufacturing method of a micro-mechanical acceleration sensor based on the heat convection principle. The thermal convection micro-mechanical acceleration sensor involved in the present invention does not open a hole on the silicon chip to form a cavity structure, but forms a closed cavity by bonding the glass cover plate and the silicon chip through BCB bonding glue, and in the first A layer of polyimide film is made on the substrate to prevent heat loss, to ensure that the hot air mass plays a better role and reduce power consumption. In addition, the polyimide film can also prevent the leakage of platinum electrodes. This design makes the process easier. The method is simple and the fabricated sensor has a more stable structure, high reliability and better performance.

Owner:HANGZHOU DIANZI UNIV

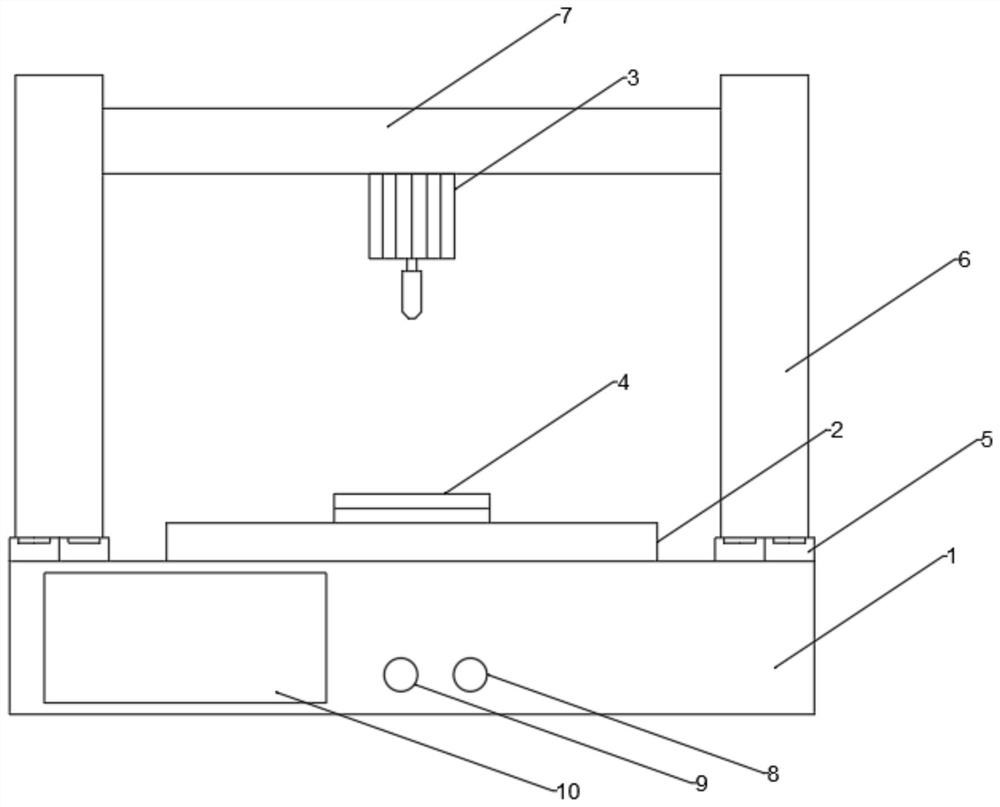

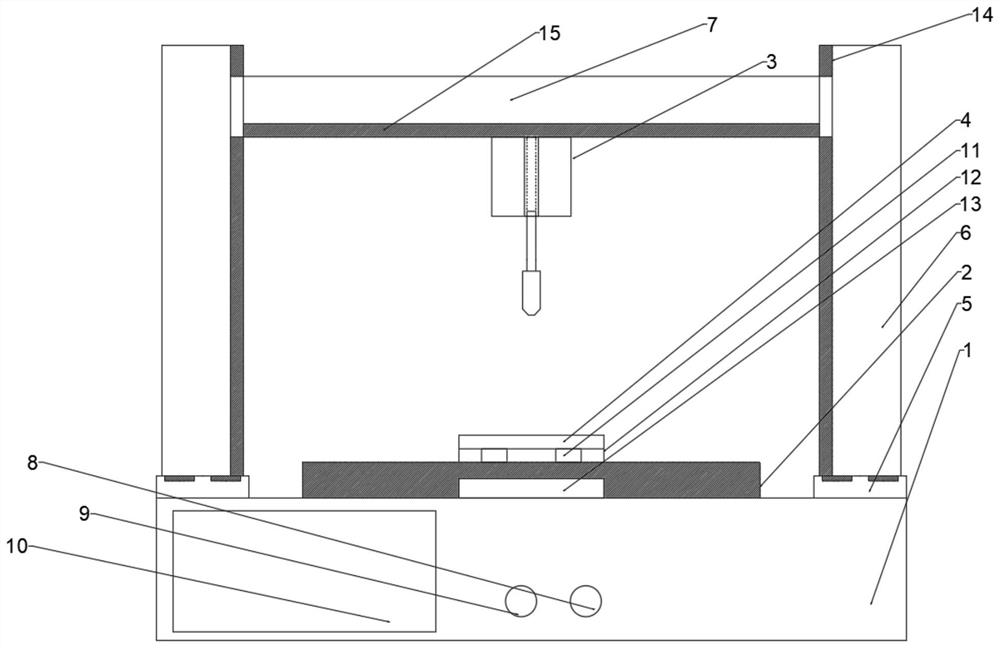

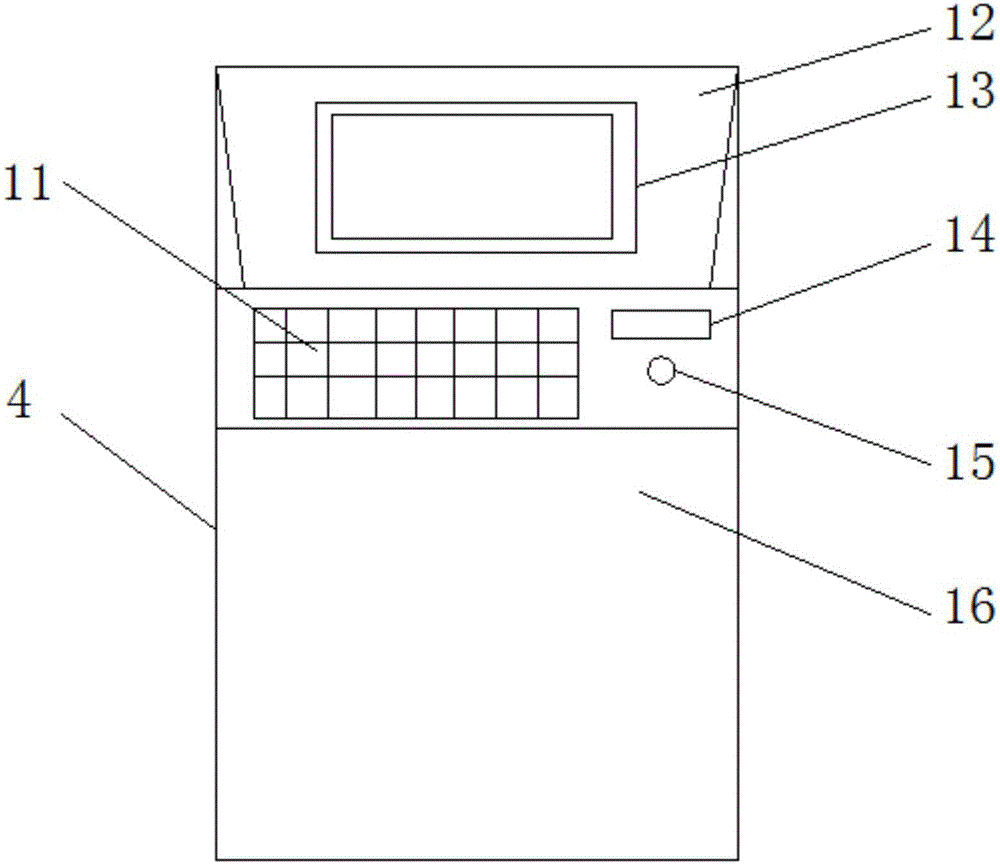

Electronically controlled precision displacement platform

InactiveCN106371464AImprove accuracyInfluence angleControl using feedbackWork benchesEngineeringDisplay device

The present invention discloses an electronically controlled precision displacement platform. The platform comprises a device body, an operation board, a control table a containing table, a side board and a control panel. The operation board is arranged at one end of the device body; an outer frame is arranged at the upper side of the operation board; the containing table is arranged at the upper side of the operation table; drivers are installed at two sides of the containing table; a movement track is arranged at the upper side of the operation board; a driver is embedded at the upper side of the movement track; the side board is arranged at the upper side of the operation board; legs are installed at the bottom end of the operation board; the operation board is connected with the control table through wires; and the control panel is arranged at the upper side of the control panel; a display is arranged at the upper side of the control panel; control buttons are installed at the upper side of the control panel; and a distribution box is installed at the bottom end of the control table. The electronically controlled precision displacement platform is provided with displacement measurement instruments installed around the containing table to monitor the movement distance at each angle after the containing table is moved so as to enhance the accuracy of the device body.

Owner:无锡信欧光电科技有限公司

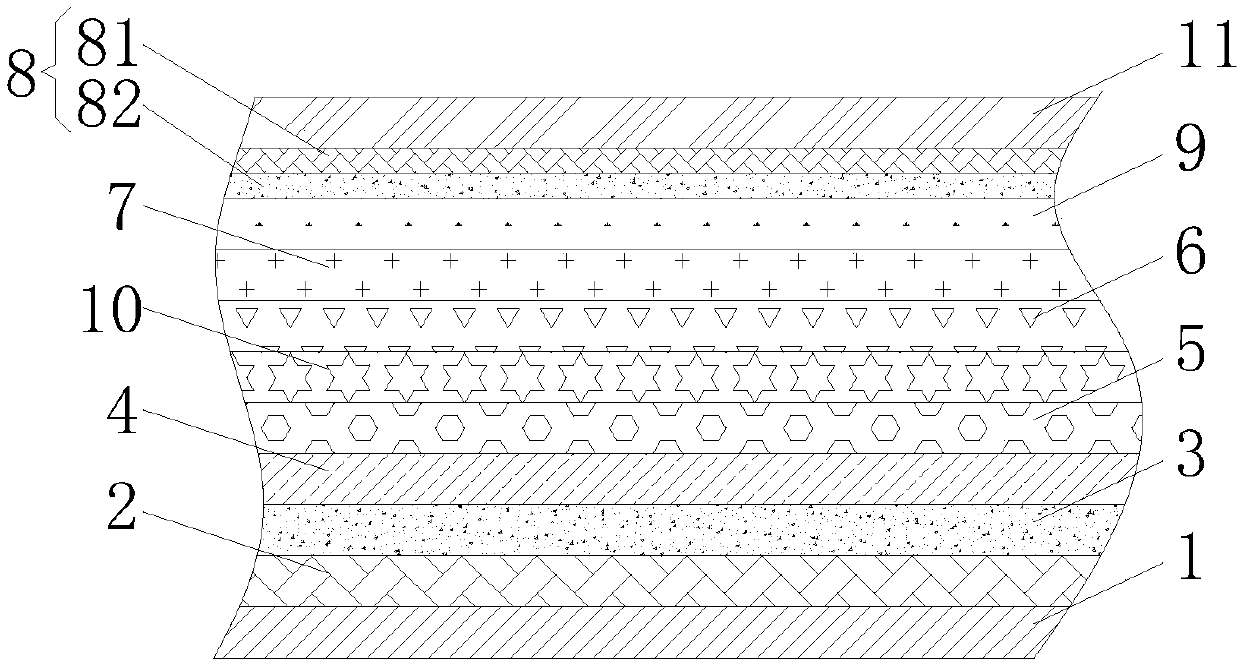

Electronic tag

InactiveCN107729979AImprove adhesionExtended service lifeRecord carriers used with machinesScreen printingAdhesive

The present invention discloses an electronic tag. The electronic tag comprises a special screen printing antenna; an electronic tag chip is attached on the surface of the special screen printing antenna; adhesive is arranged on the side of the electronic tag chip away from the special screen printing antenna; a protective film is arranged on the side of the adhesive away from the electronic labeltag; and the protective film is provided with an anti-corrosion layer on the side away from the adhesive. According to the electronic tag disclosed by the present invention, by setting the adhesive,the adhesiveness between the electronic tag chip and the protective film is increased, so that the electronic tag chip and the protective film are more closely attached, and the positional change of the electronic tag chip is prevented from affecting the accuracy of the scanning; by setting the protective film, protection can be carried out on the special screen printing antenna, the electronic tag chip, and the adhesive; and by setting the anti-corrosive layer, the anti-corrosion property of the electronic tag is improved, the service life of the electronic tag is increased, and the inventiveperformance of the electronic tag is increased.

Owner:惠州伊尚生活科技有限公司

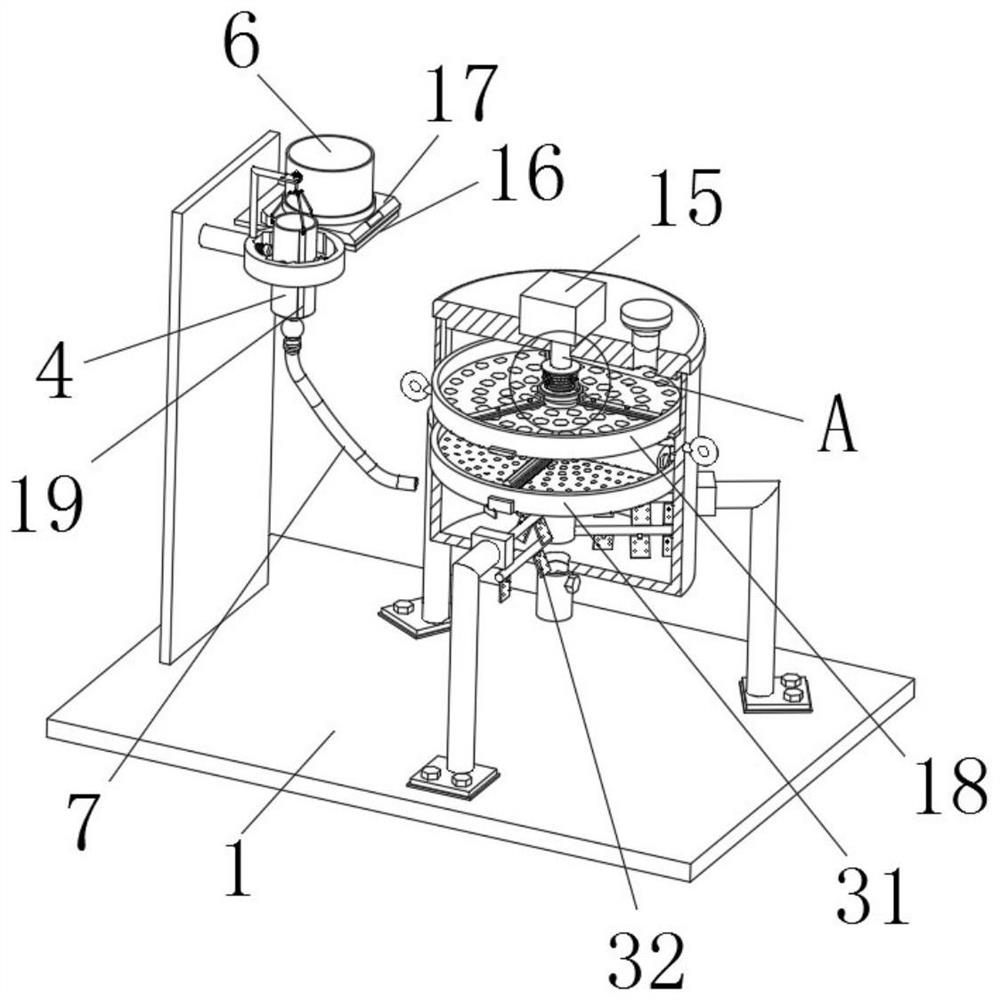

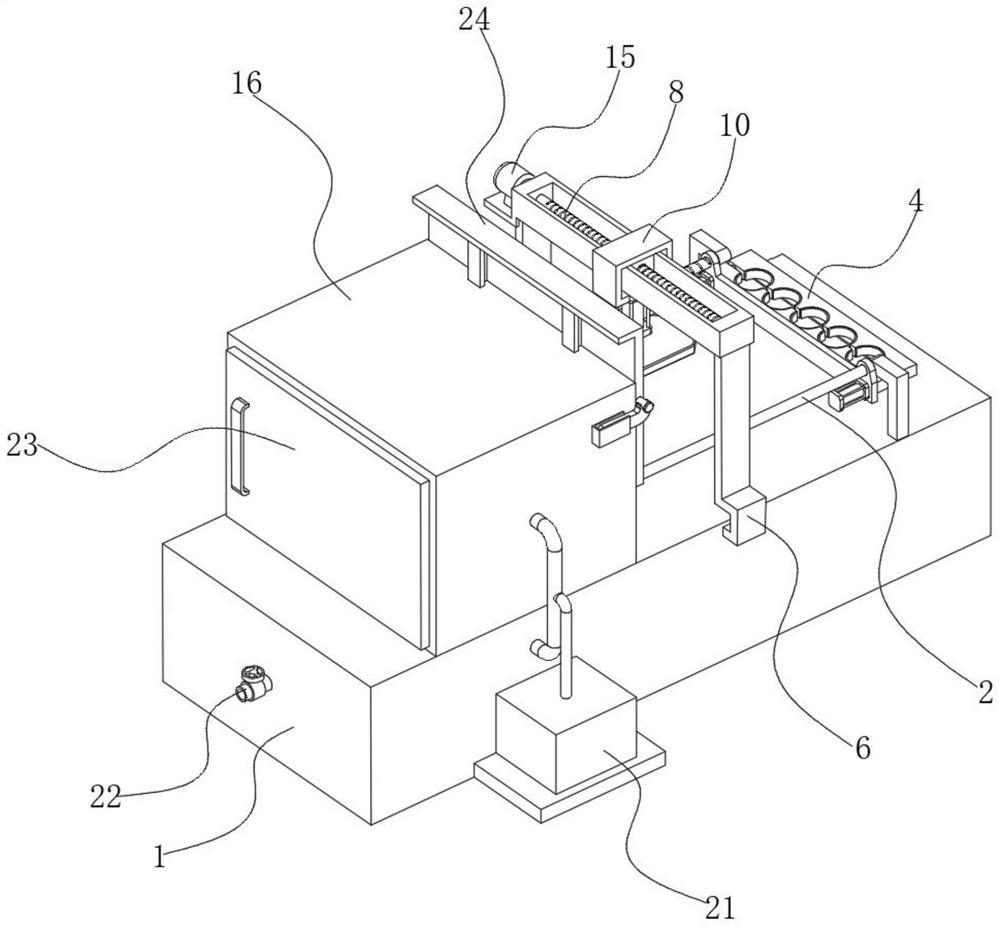

Automatic glass sorting and processing equipment and glass sorting and processing method

InactiveCN109351683BEasy to fixSorting is accurateCleaning using toolsCleaning using liquidsEngineeringBruit

The invention relates to an automatic glass sorting and processing equipment and a glass sorting and processing method, which includes a bottom plate, a water removal device, a screening device, and a cleaning device. The number of the water removal devices is two, and the water removal device is symmetrically installed on the bottom plate. The screening device is installed on the upper end face of the middle part of the base plate, and the cleaning device is installed on the upper end face of the right side of the base plate. The invention can solve the problem that the existing glass sorting equipment is not accurate enough in sorting glass, cannot fix broken glass well during sorting, the glass after sorting is not dewatered in time, and the glass on the glass is not removed before sorting. There are problems such as interlayer phenomenon in debris cleaning and sorting glass; it can realize the function of automatically sorting and recycling glass and removing water from the sorted glass.

Owner:佛山市宇璟装饰材料科技有限公司

High-precision ultrasonic detection equipment for flaw detection of workpiece

InactiveCN111272880AIngenious structurePracticalAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric machineryEngineering

The invention relates to high-precision ultrasonic detection equipment for workpiece flaw detection. The high-precision ultrasonic detection equipment comprises a host, wires, a connecting rod and a probe; one end of the connecting rod is arranged on the main machine through a wire. The probe is arranged on the connecting rod; the probe is electrically connected with the host through a wire. A cleaning mechanism and an auxiliary mechanism are arranged at the end, away from the wire, of the connecting rod. The auxiliary mechanism comprises a power assembly, a rotating rod, a rotating shaft, a grinding assembly, two first bearings and two supporting rods. The grinding assembly comprises a rotating pipe, a second bearing, a grinding disc and a driving unit. The cleaning mechanism is positioned between the probe and the connecting rod; the cleaning mechanism comprises a first motor, a driving disc, a cleaning disc, an electromagnet and two transmission assemblies, the high-precision ultrasonic detection equipment for workpiece flaw detection achieves the function of removing impurities on a probe through the cleaning mechanism, and in addition, the function of polishing a workpiece isachieved through an auxiliary mechanism.

Owner:广州市沙唯士电子科技有限公司

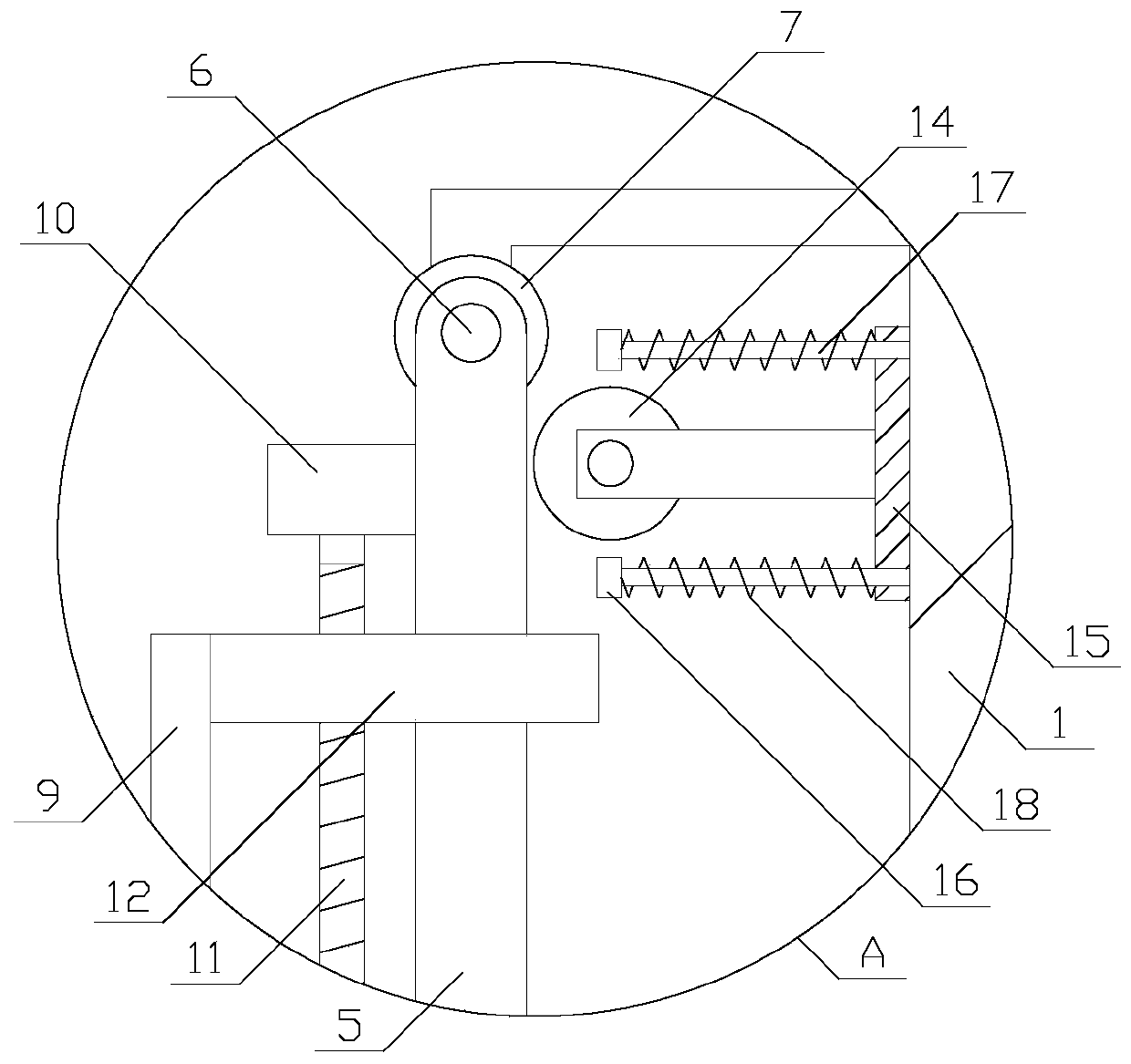

Inspection device for production of PTFE membrane material

InactiveCN110865079APrevent from compromising accuracyTo achieve the test effectOptically investigating flaws/contaminationElectric machineryStructural engineering

The invention discloses an inspection device for the production of a PTFE membrane material, and relates to the technical field of PTFE membrane material production. The device comprises a box body, afeeding hole is formed at one side of the box body, and a discharging hole is formed at the other side of the box body; a cleaning plate is fixedly installed at the side, close to the feeding hole, in the box body, and a first detection plate is fixedly installed at the other side in the box body. In the present invention, through the use of a motor, a first connecting part, a first connecting shaft, a first roller, the cleaning plate, a brush and a fan, the dust or impurities on the surface of the PTFE membrane material are removed, and dust or impurities are prevented from blocking holes inthe surface of the PTFE membrane material to influence the inspection accuracy; through the cooperative use of a hand wheel, a vertical shaft, a limiting shaft, a second connecting part, a second connecting shaft, a second roller, a third connecting part, a third connecting shaft and a third roller, the PTFE membrane material is limited, so that the PTFE membrane material smoothly enters the boxbody, and the PTFE membrane material is prevented from wrinkling to influence the inspection result.

Owner:湖州博创氟材科技有限公司

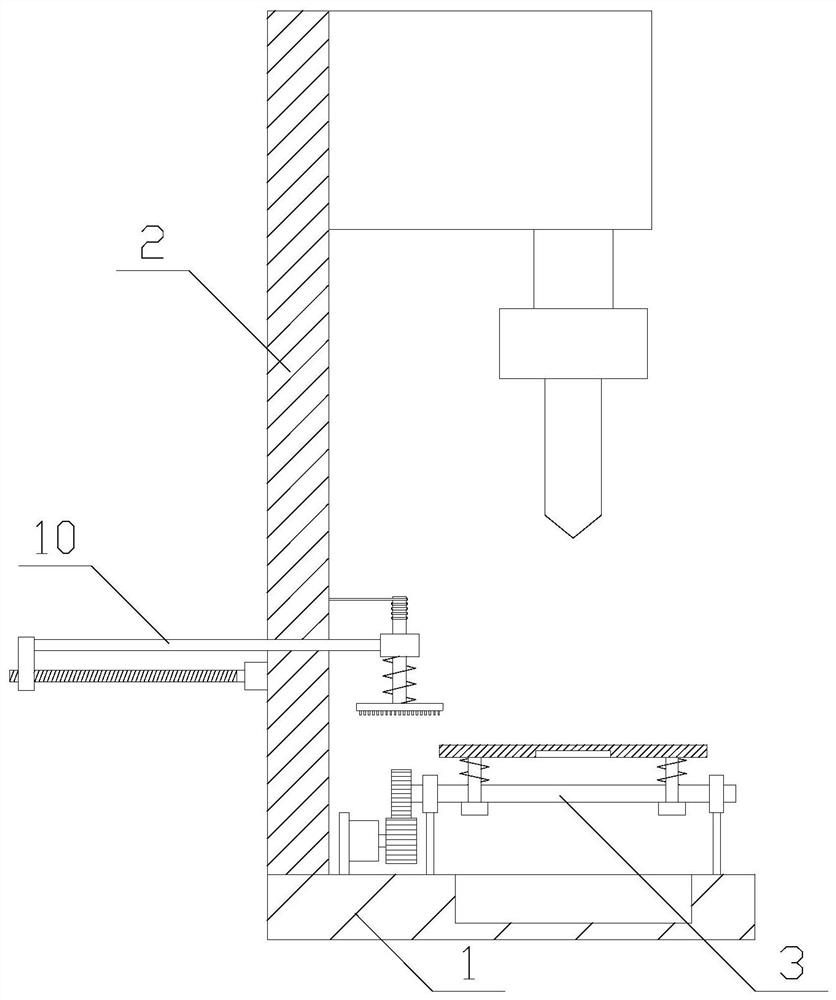

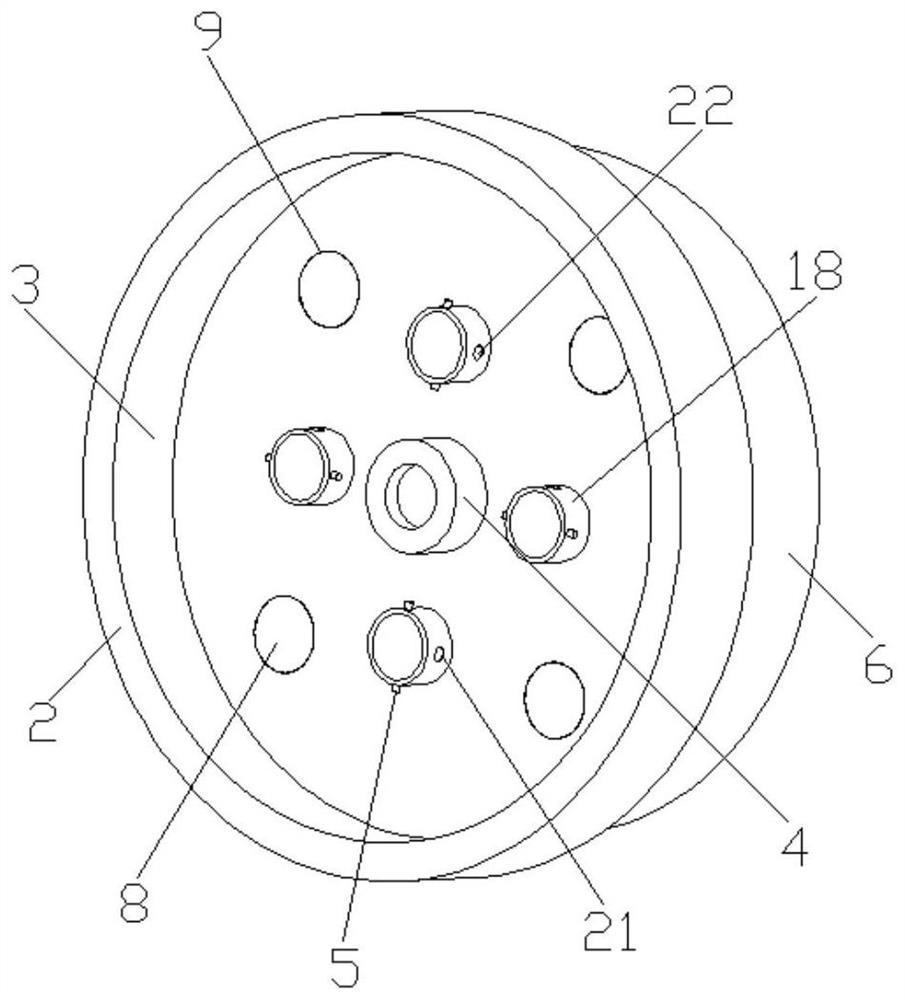

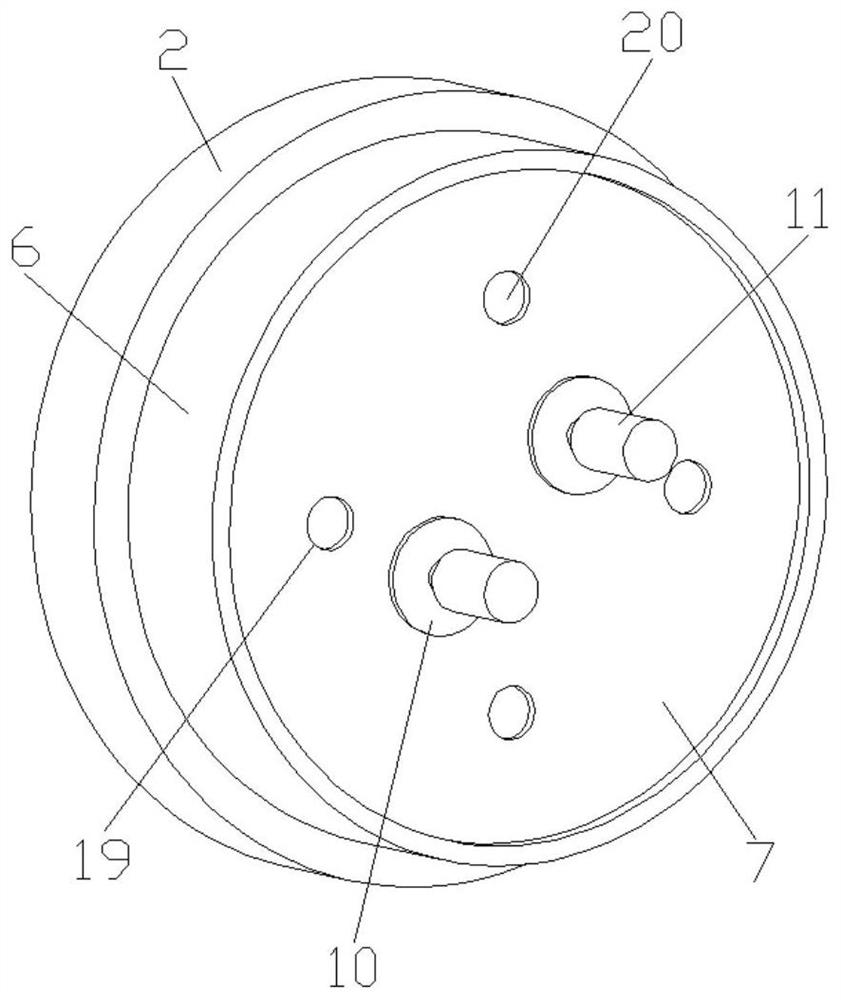

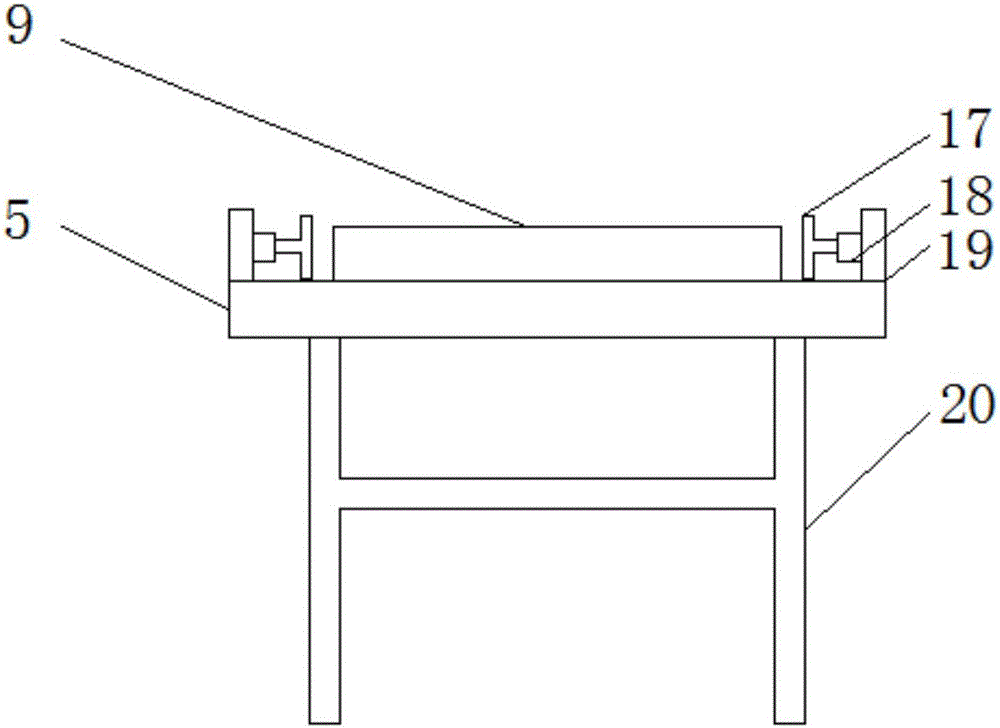

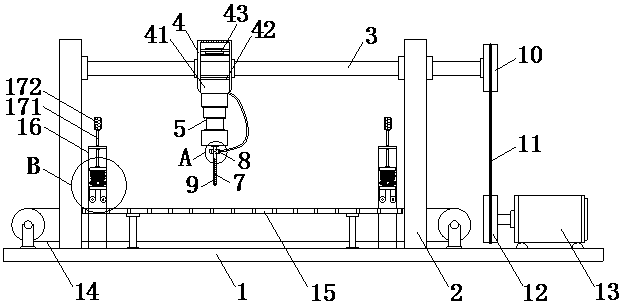

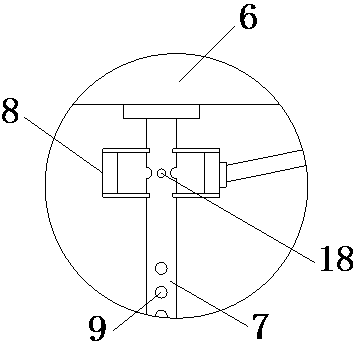

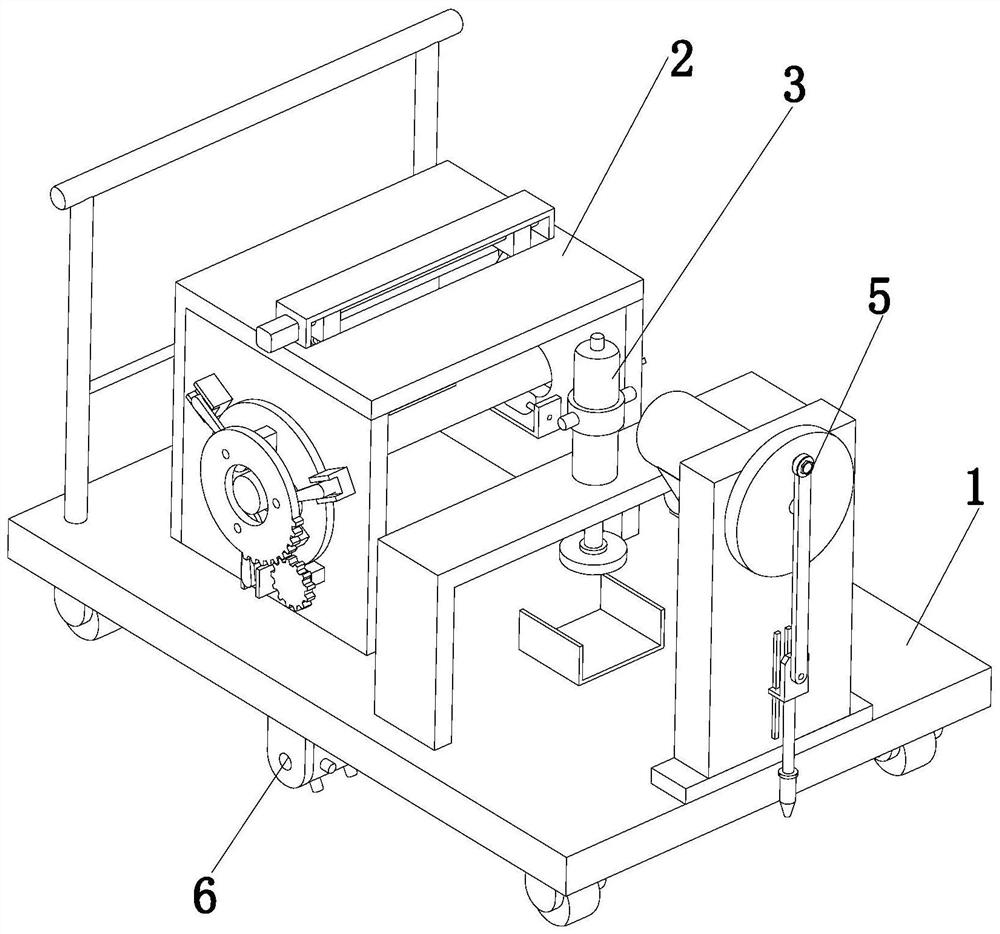

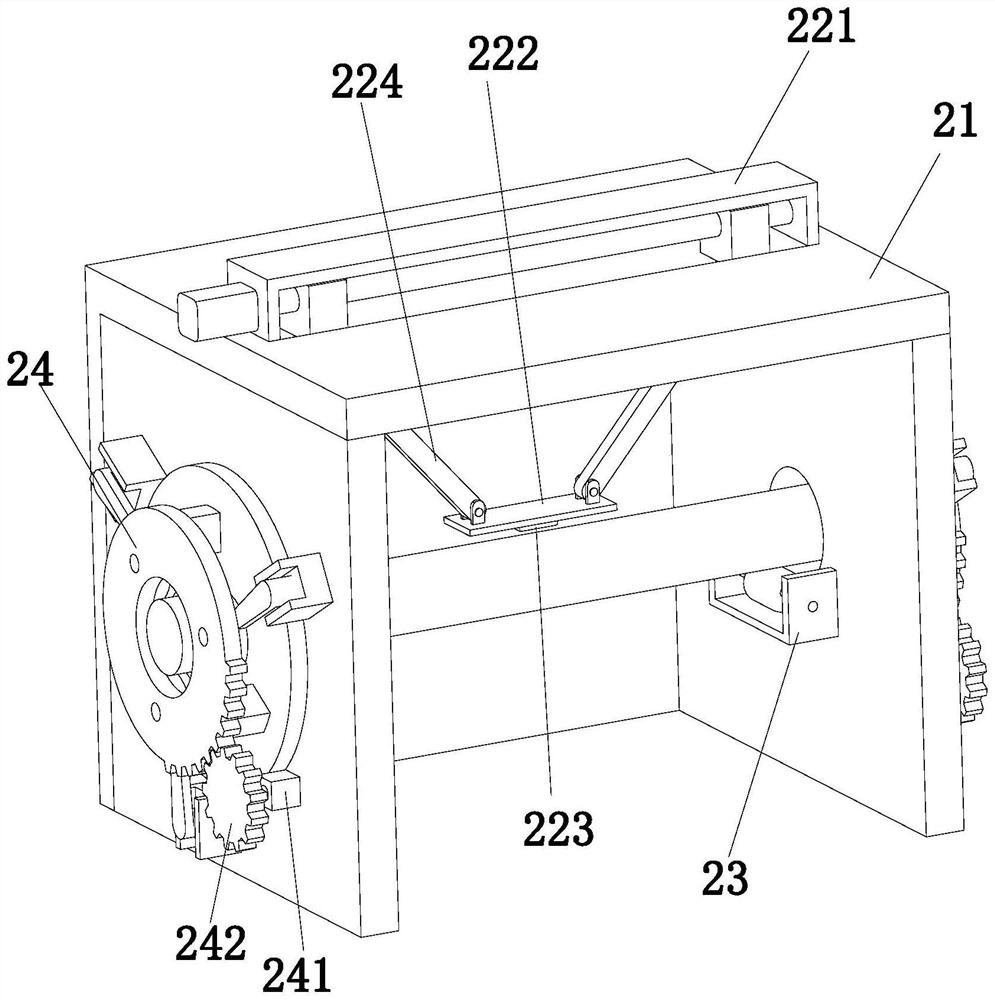

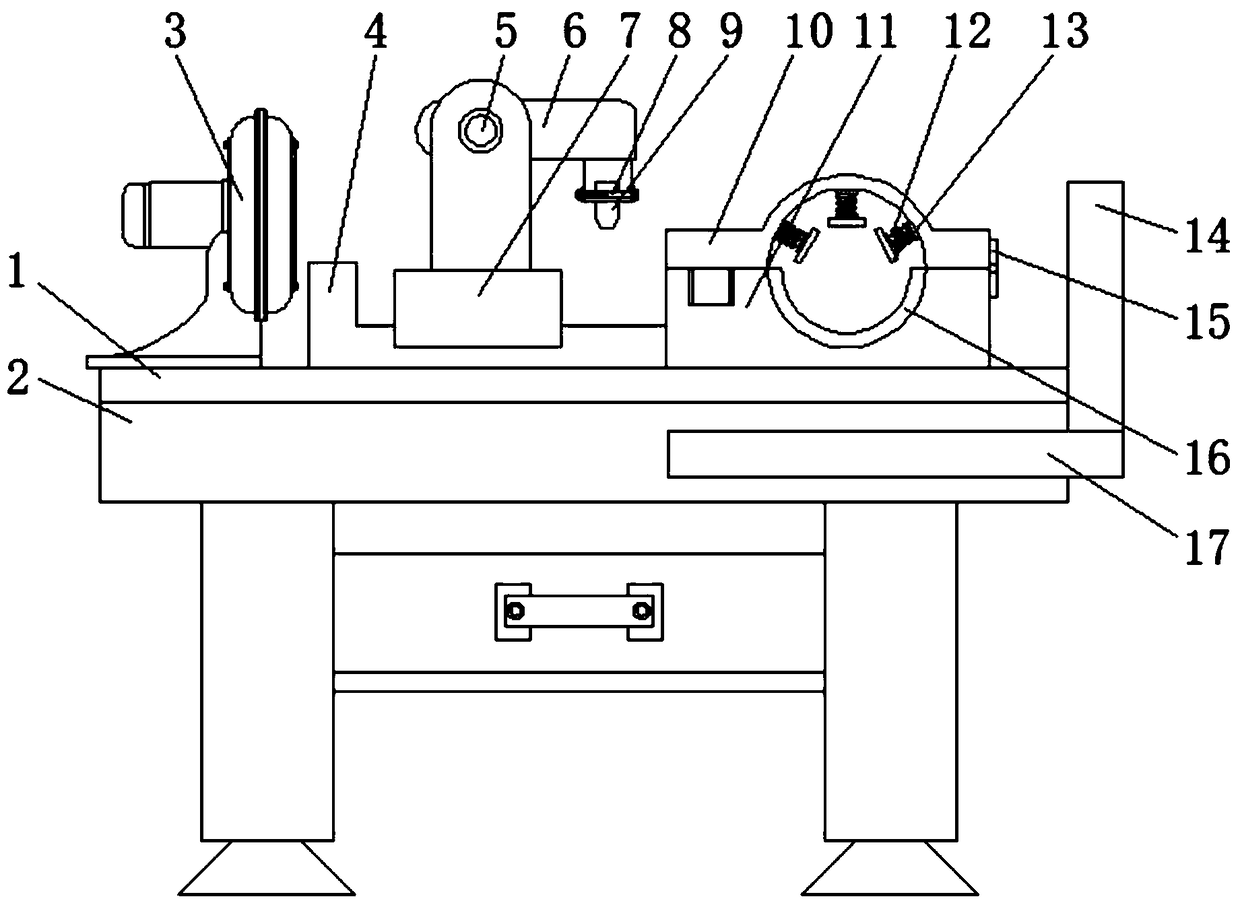

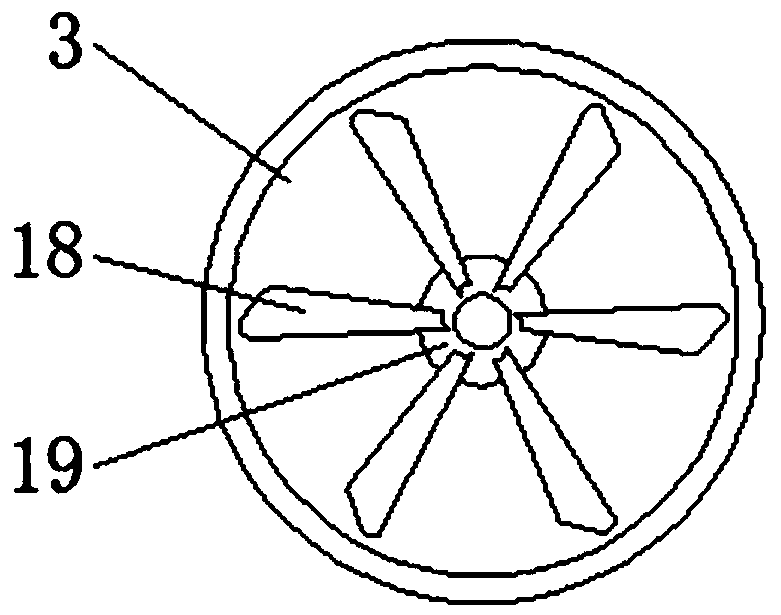

A steel pipe punching machine

ActiveCN106041166BAvoid affecting manufacturing processesPrevent from compromising accuracyFeeding apparatusPositioning apparatusPunchingEngineering

The invention discloses a steel pipe perforating machine which comprises a base. Supporting frames are fixedly mounted at the two ends of the upper surface of the base. A moving lead screw is mounted on the supporting frames in a sleeved manner. A scrap collection mechanism is mounted on the moving lead screw in a sleeving manner. The bottom end of the scrap collection mechanism is fixedly connected with an electric telescopic rod. The end, far away from the scrap collection mechanism, of the electric telescopic rod is fixedly connected with a perforating motor. A drill bit is fixedly mounted on an output shaft of the perforating motor. A scrap guide hole communicating with the scrap collection mechanism through a hose is formed in the top of the drill bit. A sealing piece is arranged on the outer portion of the scrap guide hole, wherein the drill bit is sleeved with the sealing piece. Scrap collection holes communicating with the scrap guide hole are formed in the bottom end of the drill bit at equal distance. One end of the moving lead screw penetrates and extends out of one supporting frame to be fixedly connected with the axis of a driven disc. According to the steel pipe perforating machine, the scrap collection holes are formed in the drill bit and cooperate with the scrap collection mechanism, negative pressure is generated through a draught fan, and therefore scraps generated by machining can be collected, and the situation that the scraps are accumulated, and consequently next machining is influenced is avoided.

Owner:无锡市汇鼎金属制管有限公司

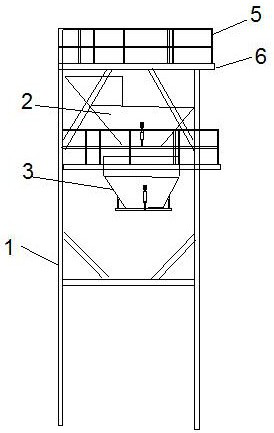

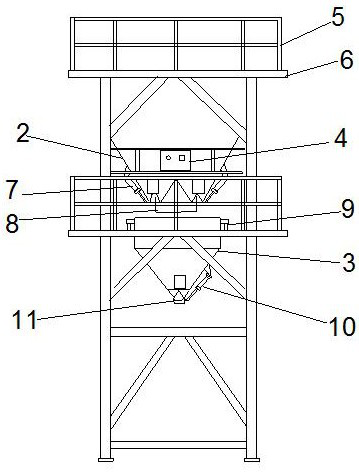

Weighing equipment for commercial concrete production

ActiveCN112763031AEfficient dischargePrevent from compromising accuracyHollow article cleaningCleaning using toolsArchitectural engineeringStructural engineering

The invention discloses weighing equipment for commercial concrete production; the equipment comprises a weighing mechanism, the weighing mechanism comprises a base, weighing bodies are fixedly connected to the positions, close to the edges of the two sides, of the top of the base, a tray is fixedly connected to the input end of each weighing body, and a group of first oil cylinders are fixedly connected to the two sides of the center of the top of the base; each set of first oil cylinders comprises two first oil cylinders, a supporting plate is fixedly connected between the top ends of the two first oil cylinders in each set, and a connecting plate is arranged on the top of each supporting plate. In use, the equipment can be stably placed at a designated use site through the base, a storage frame can be stably placed between the two scale bodies through cooperation of the tray and the connecting plate, then the scale bodies can effectively weigh and measure the mass of concrete in the storage frame, after measurement is finished, a second oil cylinder is started, and the second oil cylinder can move the sealing plate under the limitation of the position of the L-shaped sliding strip, so that concrete can be effectively discharged from the interior of the storage frame.

Owner:嘉峪关市共嘉实业有限责任公司

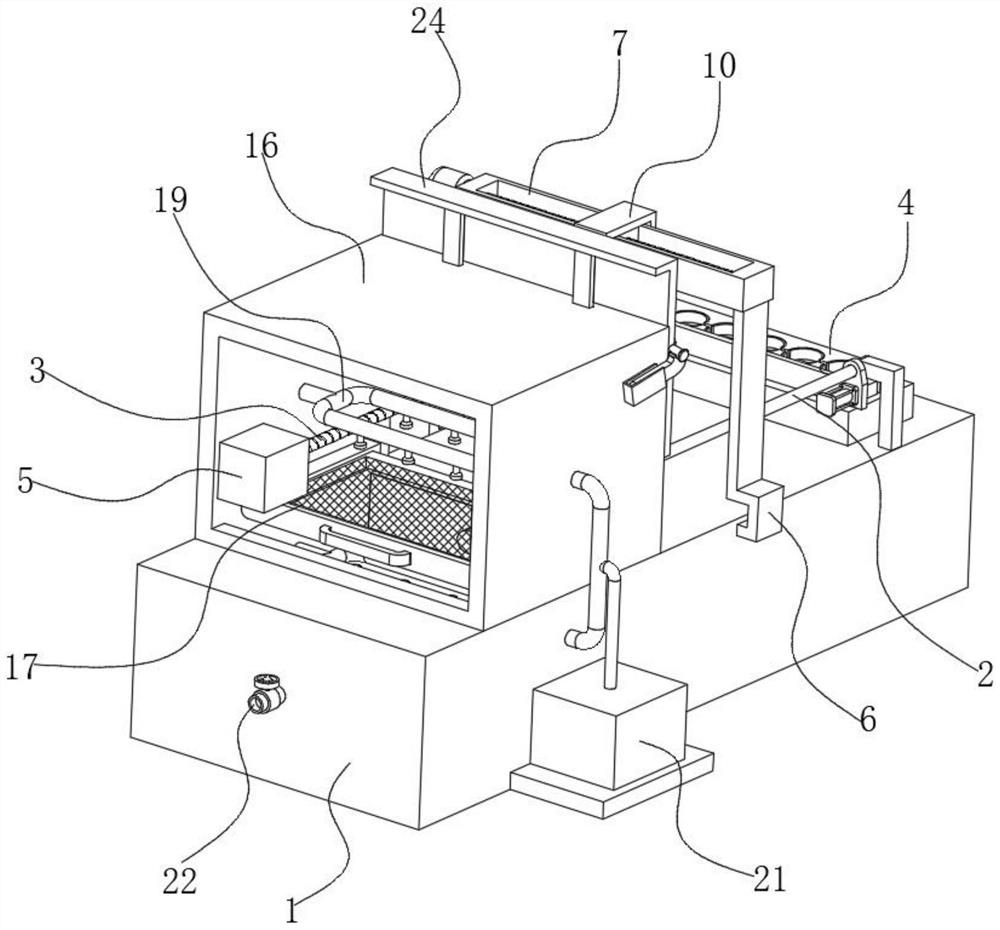

Medical endoscope testing device and testing method

PendingCN114018186AEasy to useImprove practicalityWeather/light/corrosion resistanceUsing subsonic/sonic/ultrasonic vibration meansElectric machineryEngineering

The invention discloses a medical endoscope testing device and method, and the device comprises a base, a first motor and a second motor, the exterior of a first lead screw is in threaded connection with a clamping mechanism, the bottom of a sliding frame is fixedly provided with a lifting cylinder, and one end of the bottom of a mounting plate is fixedly provided with a distance measuring sensor. An ultrasonic sensor is fixedly mounted at the end, away from the distance measuring sensor, of the bottom of the mounting plate, a placement net is slidably mounted in the shell, injection cylinders are fixedly mounted in the base and the shell, atomizing nozzles are fixedly mounted on the opposite sides of the two injection cylinders, and an atomizing mechanism is fixedly mounted at one end of the back face of the base. By arranging a distance measuring sensor, an ultrasonic sensor and an atomizing mechanism, the effect that the laparoscope lens can be subjected to multiple tests in one device is achieved, workers do not need to transfer the laparoscope lens for multiple times, use by the workers is facilitated, the practicability of the testing device is greatly improved, and the working efficiency is improved.

Owner:苏州科卓医疗科技有限公司

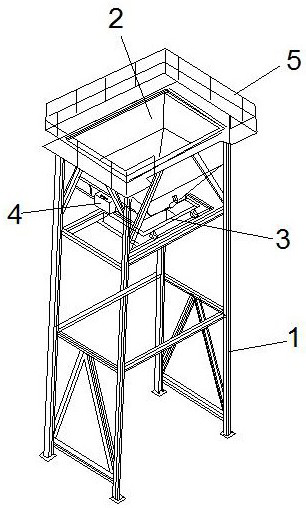

Metering system for water-stabilized mixing materials

PendingCN113899435AHigh precisionImprove accuracyWeighing auxillary devicesSpecial purpose weighing apparatusControl engineeringSignal amplification

The invention discloses a metering system for water-stabilized mixing materials. The metering system comprises a supporting frame and a raw material bin, wherein the raw material bin is arranged on the top layer of the supporting frame, a pedal is arranged on the periphery of the raw material bin, a guardrail is arranged on the periphery of the pedal, a metering bin is correspondingly arranged below the raw material bin, a plurality of weight sensors are arranged on the upper edge of the metering bin, and the plurality of weight sensors are uniformly distributed on the peripheral side of the measuring bin; the measuring bin is connected with the supporting frame through a weight sensor, pedals are arranged on the periphery of the measuring bin, and the pedals are provided with guardrails. The metering bin is arranged to meter a continuous working occasion, opening of the feeding door and the discharging door is controlled in a matched mode, the weight or the flow of materials is obtained through signal collection of the weight sensor, filtering, signal amplification and AD conversion, and the metering accuracy is improved.

Owner:濮阳光大路桥混凝土有限公司

Building material hardness detection device

InactiveCN112147015AAvoid compromising accuracyJudge hardnessInvestigating material hardnessMaterials testingStructural engineering

The invention discloses a building material hardness detection device, and belongs to the technical field of building material testing. The building material hardness detection device comprises a moving vehicle, a pipe hardness detection device, a blocky building material detection device, a ground hardness detection device and a ground cleaning device; the pipe hardness detection device is arranged on the moving vehicle, and the pipe hardness detection device comprises a mounting frame, a hardness detection assembly, a detection conveying assembly and two detection fixing assemblies, whereinthe two detection fixing assemblies are symmetrically arranged at the top of the moving vehicle, the hardness detection assembly is arranged at the top of the mounting frame, and the detection conveying assembly is arranged on one detection fixing assembly; the blocky building material detection device is arranged at the top of the moving vehicle; the ground hardness detection device is arranged at the rear end of the moving vehicle; and the ground cleaning device is arranged at the bottom of the moving vehicle. According to the building material hardness detection device, when fixing is conducted, pipes with different diameters can be fixed so that the building material hardness detection device can be applied to hardness detection operation of different types of pipes.

Owner:安徽黎搏装饰工程有限公司

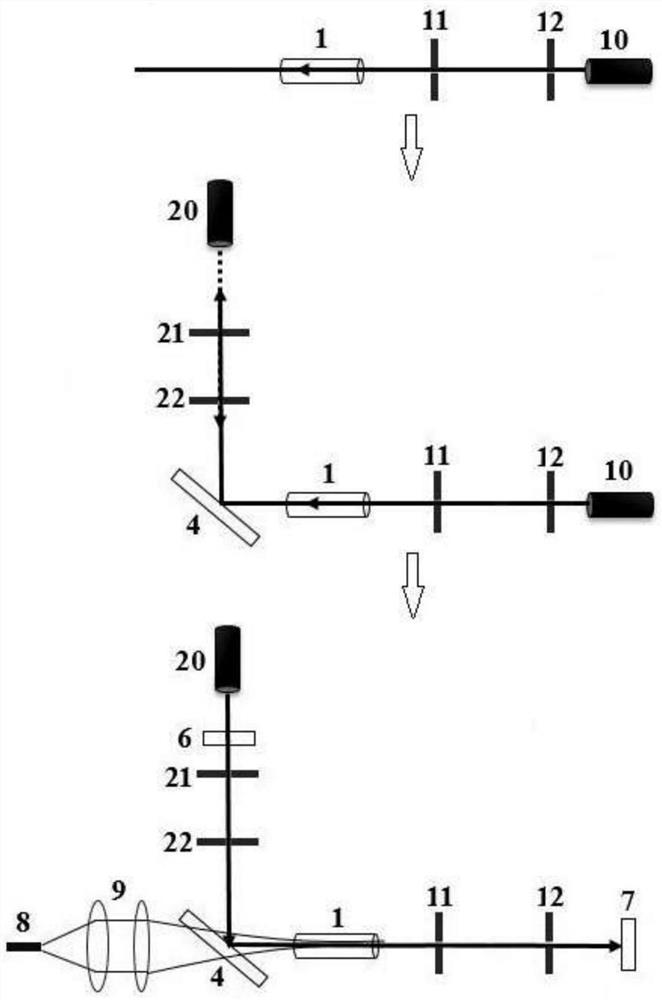

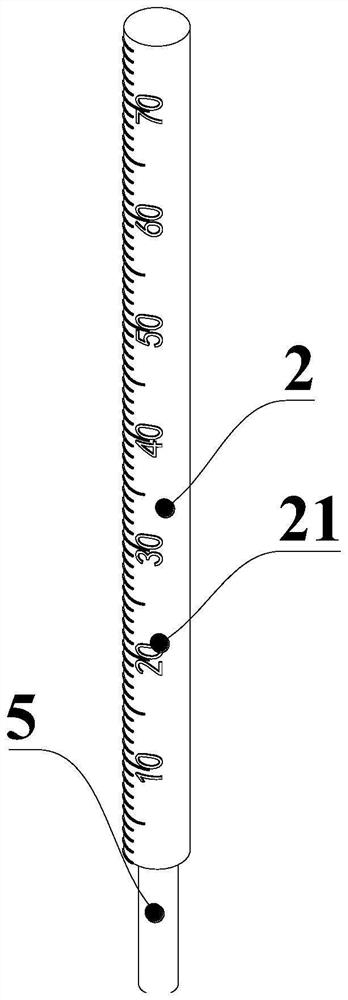

Light path calibration tool and method

PendingCN114442336AEasy to switchPrevent from compromising accuracyOptical elementsLight spotEngineering

The invention provides a light path calibration tool, which comprises a fixing rod and a calibration rod which are coaxially arranged, the diameter of the calibration rod is approximately the same as that of a light spot to be calibrated, and the fixing rod can be axially inserted and matched with a fixing hole in the surface of an optical platform, so that the calibration rod is positioned on a light path to be calibrated and is placed above the optical platform. The invention further provides an optical path calibration method, and the optical path calibration tool is sequentially used from front to back to adjust the optical devices so as to calibrate the optical path. The calibration tool has the advantages that the fixing rod can be directly inserted into the fixing hole, screw connection is not needed, the calibration tool can be quickly inserted and pulled out in the use process, and use is convenient; the calibration result is judged by judging whether the light spot is completely covered by the calibration rod, and the light path calibration precision is high; and the calibration rod can be directly irradiated by a light spot to check whether the size is proper or not before an experiment, so that the calibration precision is prevented from being influenced by processing errors. The device is suitable for quantum information related optical experiments such as quantum communication and quantum measurement.

Owner:QUANTUMCTEK

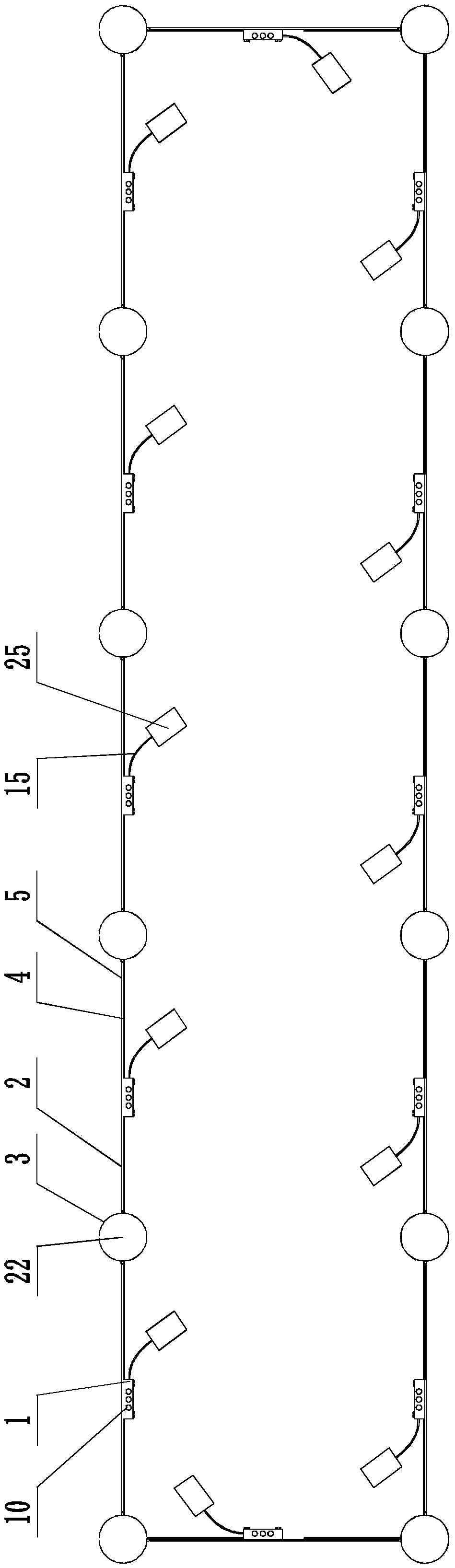

Method for monitoring concentration of suspended matters in construction sea area by utilizing multi-layer distribution sampling device

ActiveCN109060447AConcentration values are accurate and reliableEasy to spreadWithdrawing sample devicesTesting waterDiffusionEngineering

The invention discloses a method for monitoring the concentration of suspended matters in a construction sea area by utilizing a multi-layer distribution sampling device, and aims to solve the problemthat it is inconvenient to sample sea water of different depths in a construction sea area, and the monitored concentration value of suspended matters in the construction sea area is not accurate enough caused by the fact that the suspended matters diffuse to outwards easily due to that the construction sea area is open. A fence ring is arranged in the construction sea area, and a mechanical gripper is adopted for construction in a sea area defined by the fence ring, so that influence to the sampling accuracy caused by outward diffusion of the suspended matters is prevented; and openings in the lower end of a sampling pipe are formed in different water level positions, so that distribution sampling of a plurality of layers of water areas can be realized. In the construction process of themechanical gripper, a push rod is touched, and the push rod is driven to rotate anticlockwise, and the push rod abuts against a sealing cover and drives the sealing cover to rotate downwards, so thatthe openings in the lower end of the sampling pipe are opened, and the seawater in the opening positions at the lower end of the sampling pipe flows into the sampling pipe for sampling.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Split shaft tube splicing welding platform

InactiveCN108907595AAvoid damagePlay a fixed roleWelding/cutting auxillary devicesAuxillary welding devicesAir blowerWelding

The invention discloses a split shaft tube splicing welding platform. The split shaft tube splicing welding platform comprises a workbench, a welding head and a base, wherein an insulating plate is connected to the upper surface of the workbench; the workbench and the insulating plate are connected through pasting; an air blower is mounted on the insulating plate; a fixed block is arranged in theair blower; blades are connected in the fixed block; the fixed block and the blades are connected through bolts; a sliding chute is formed in the right side of the air blower; a movable bracket is connected to the inner surface of the sliding chute; a pin rod is mounted in the movable bracket; a supporting rod is arranged on the right side of the pin rod; a bolt is connected in the welding head; and the welding head is positioned under the supporting rod. Compared with a conventional ordinary split shaft tube splicing welding platform, the split shaft tube splicing welding platform has the advantages that welded materials can be cleared and collected, unnecessary waste is avoided, besides, a shaft tube can be fixed, and the shaft tube is prevented from shaking during welding.

Owner:十堰合强工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com