Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

450 results about "Bruit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bruit, also called vascular murmur, is the abnormal sound generated by turbulent flow of blood in an artery due to either an area of partial obstruction or a localized high rate of blood flow through an unobstructed artery.

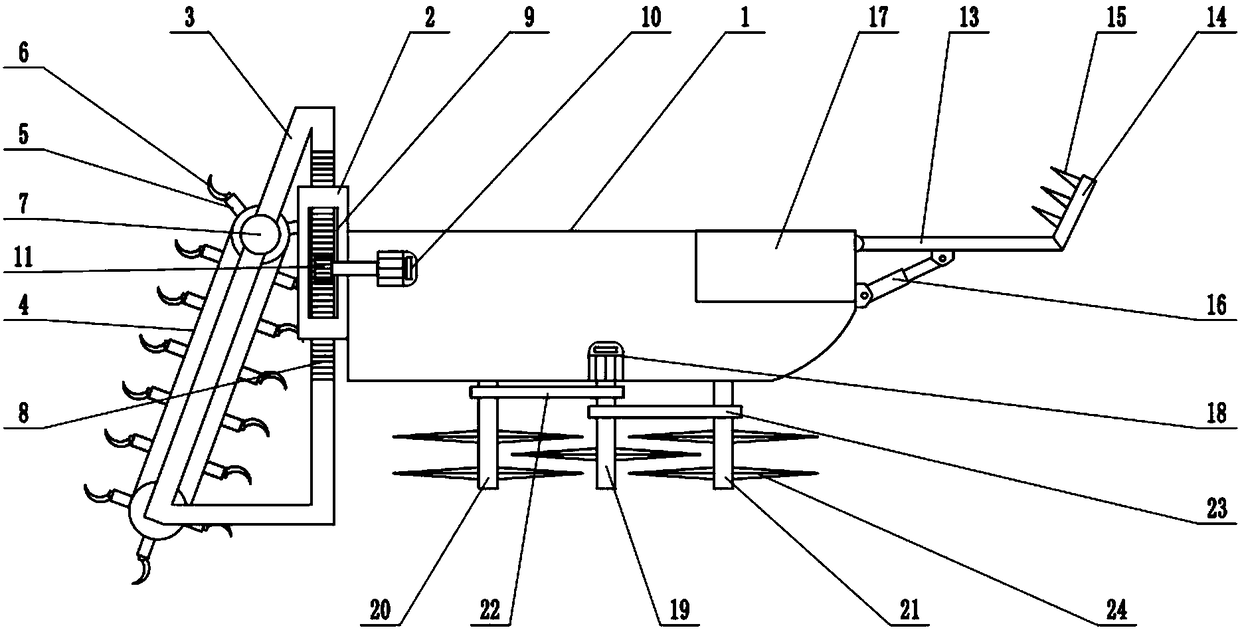

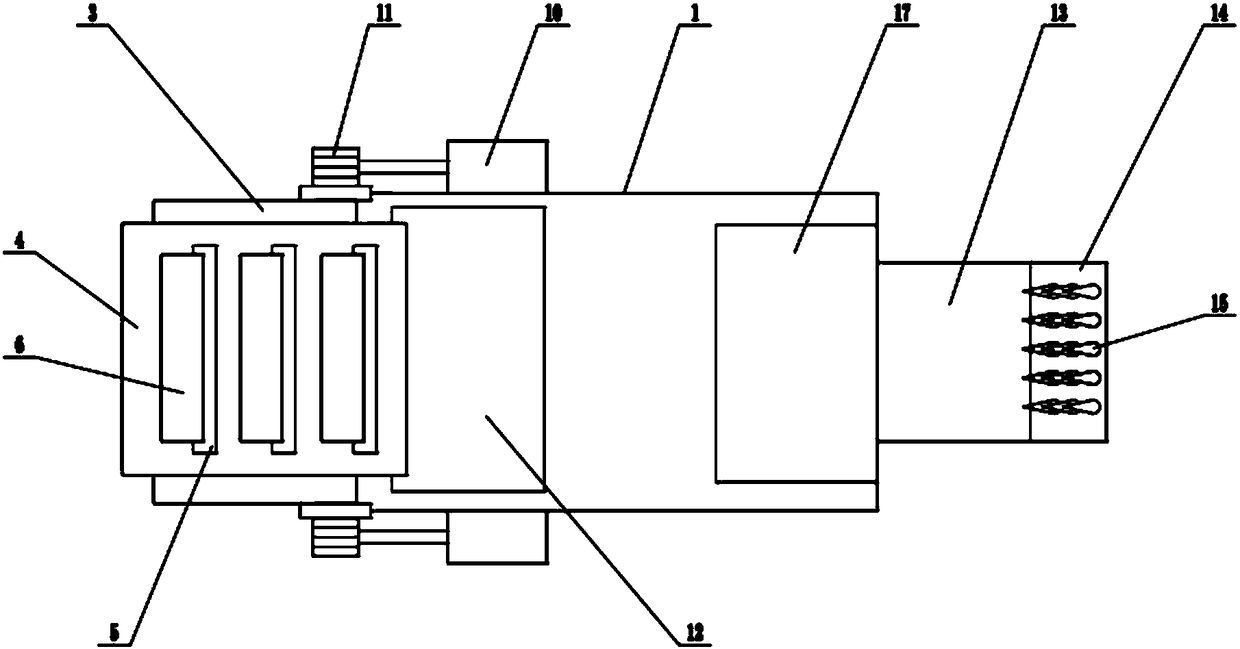

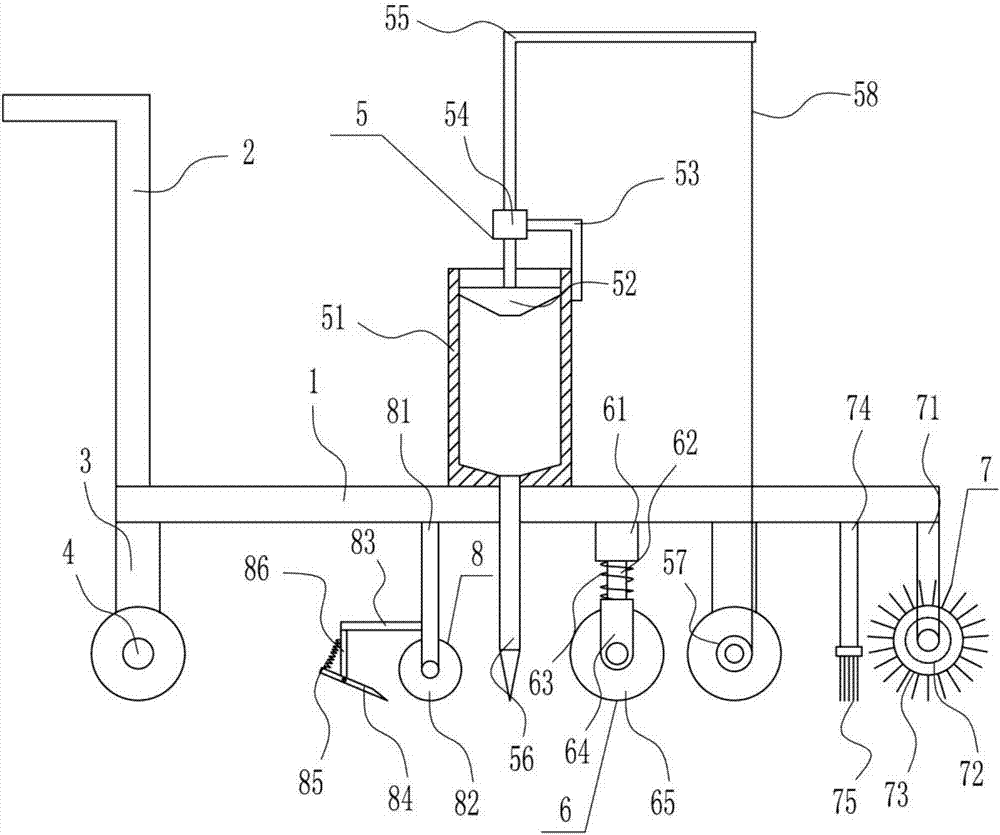

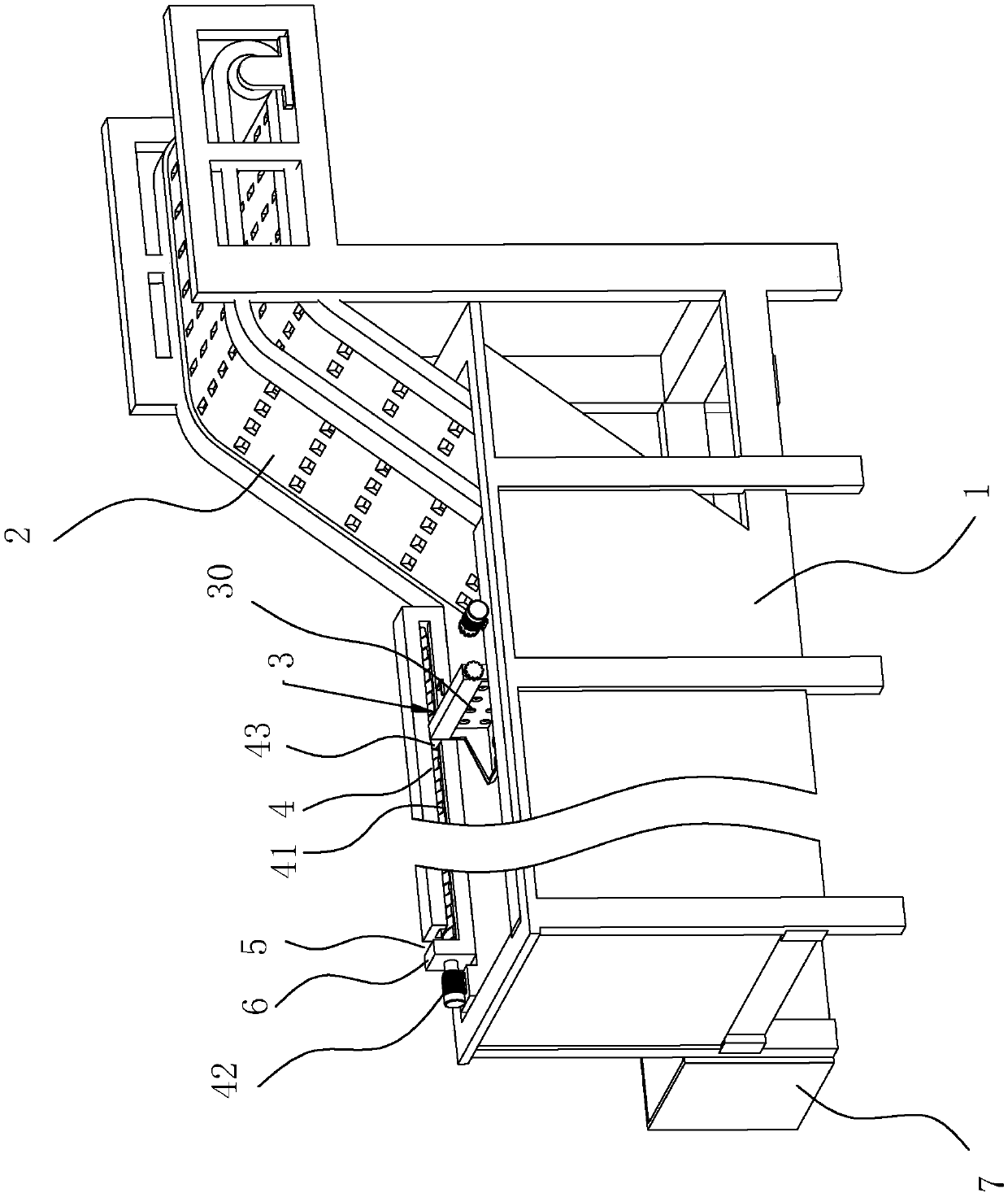

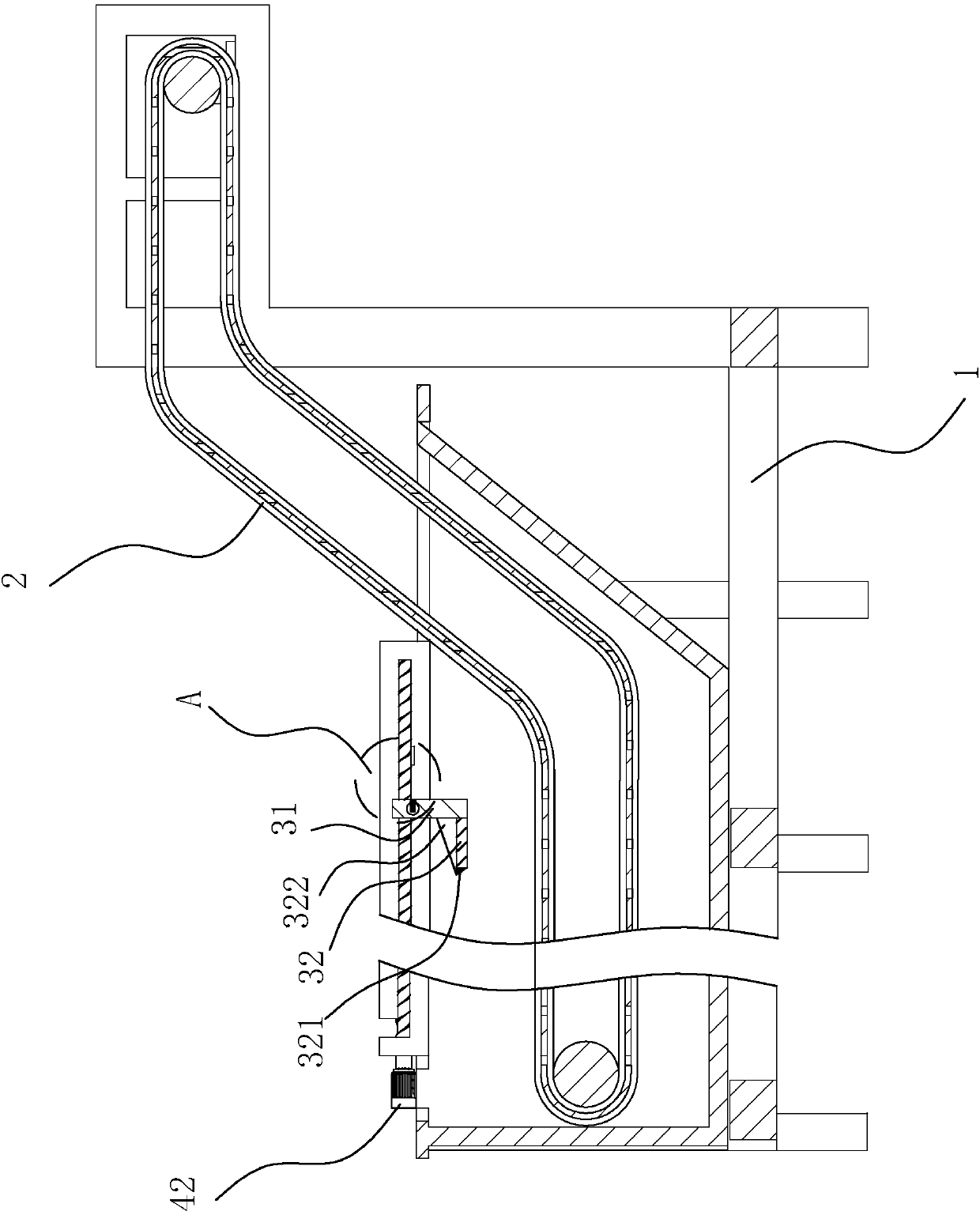

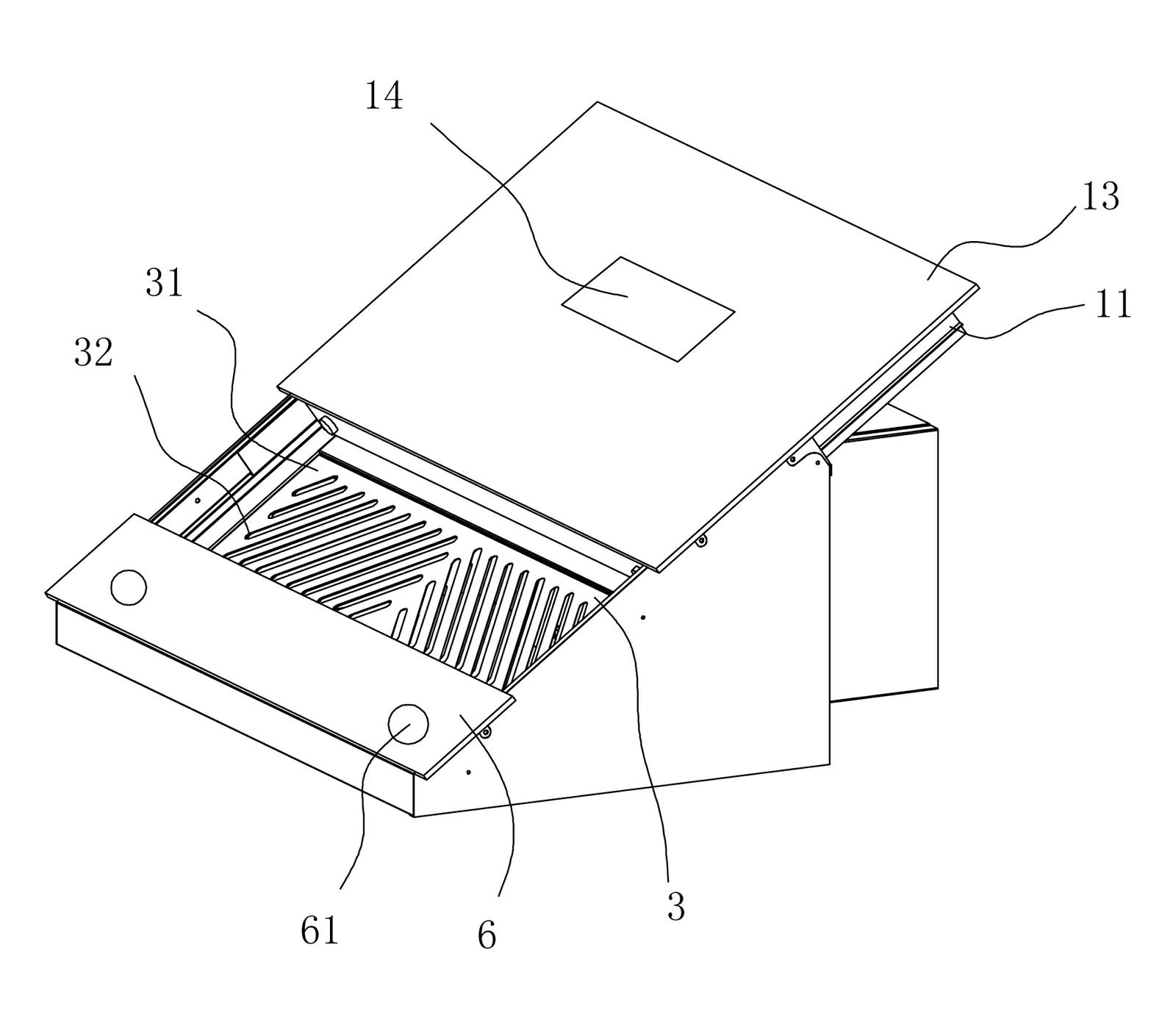

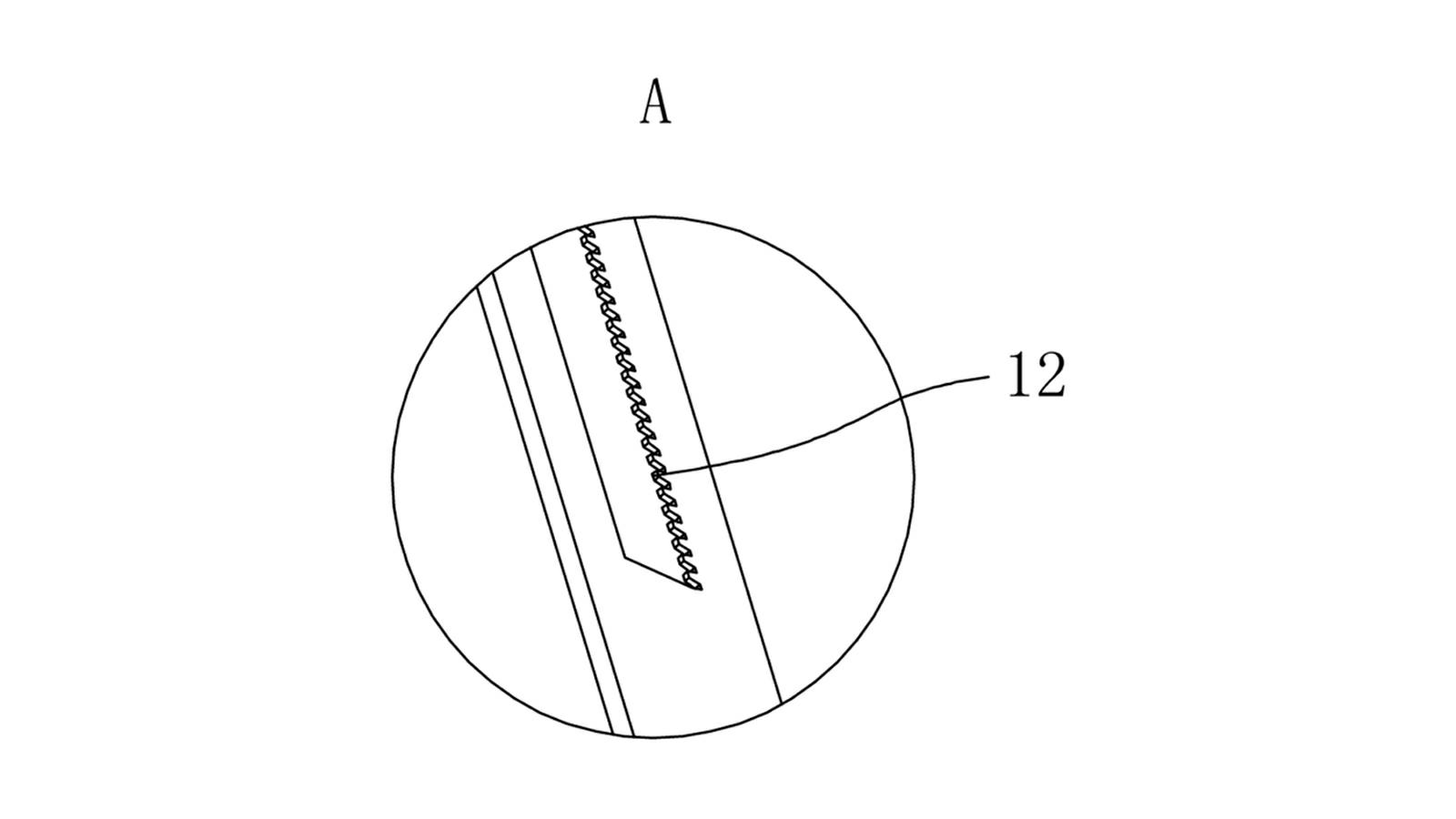

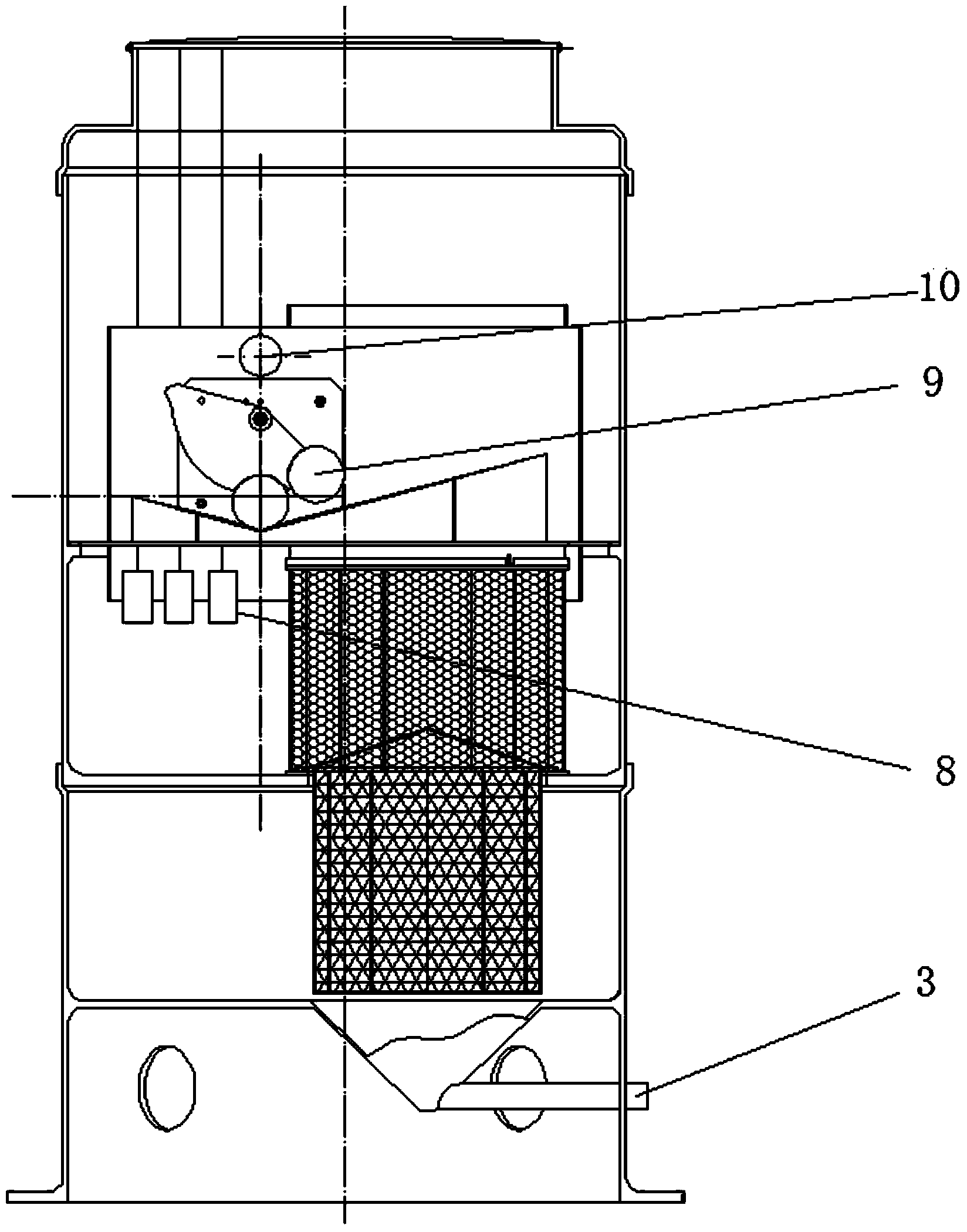

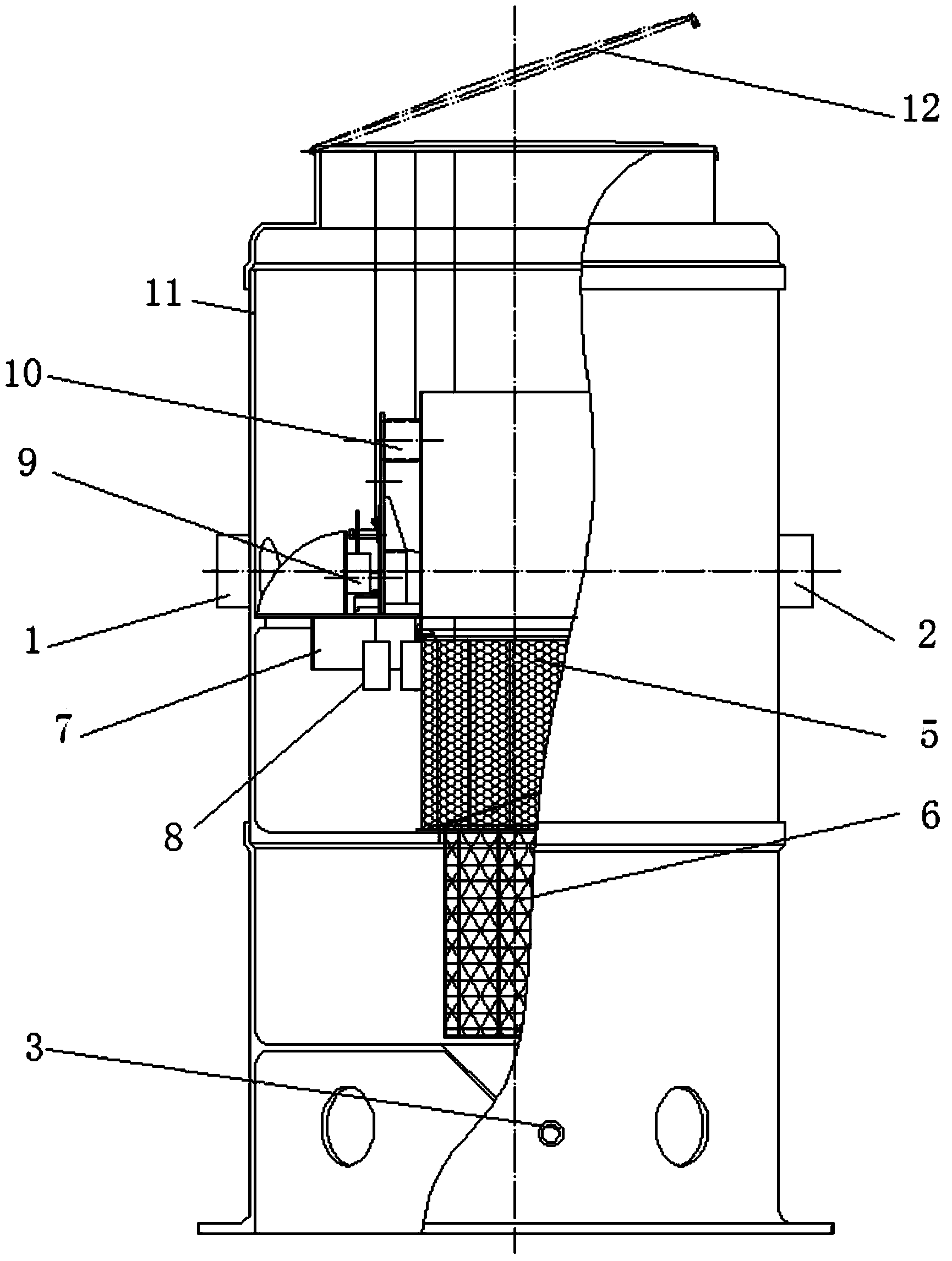

River dredger convenient for clearing weed

InactiveCN108082403AShorten the timeImprove dredging efficiencyWater cleaningWaterborne vesselsLitterEngineering

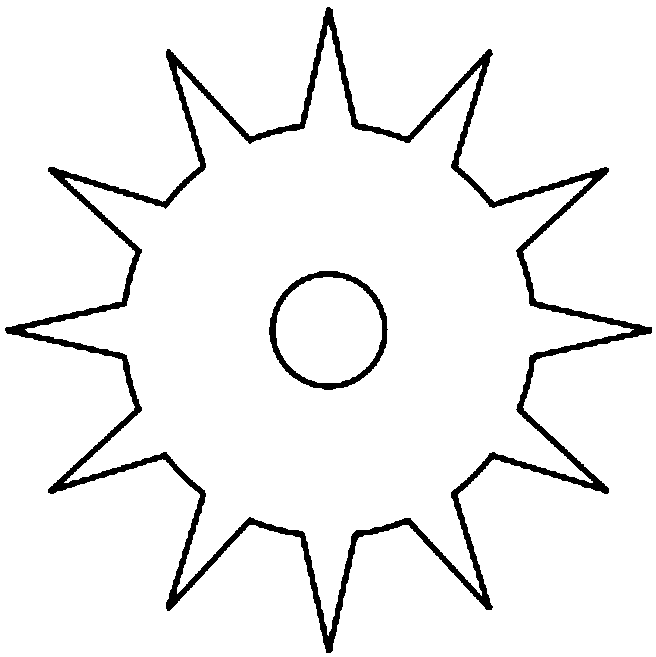

The invention discloses a river dredger convenient for clearing weed. The river dredger comprises a hull, sliding rails, a support frame, a silt groove, a collection groove and a cutter head, whereinthe sliding rails are fixedly connected to the rear part of the hull; the support frame is embedded between the sliding rails; a conveyor belt is mounted on the oblique side of the support frame; a plurality of fixing plates are distributed on the surface of the conveyor belt; curved plates are fixedly connected to the fixing plates; positive inversion motors are fixedly connected to the two sidesof the hull; gears are fixedly connected to the shaft-extension ends of the positive inversion motors; a guide plate is hinged to the bow section of the hull; a dredging plate is fixedly connected tothe right end of the guide plate; and a weeding motor is fixedly connected to the bottom of the hull. The curved plates are used for scraping silt from the bottom of a river and convey the silt to the silt groove for storage. The underwater depth of the left end of the conveyor belt can be adjusted according to the water depth so that the curved plates can be always in contact with the silt on the bottom of the water, so as to improve the dredging efficiency. The dredging plate and salvaging nails are used for hooking litter from the water surface and putting the litter in the collection groove. The cutter head is used for cutting off the weed in the water.

Owner:宁波市江北义盈工贸有限公司

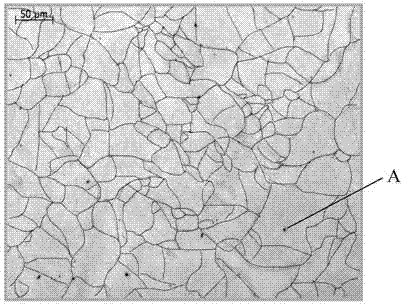

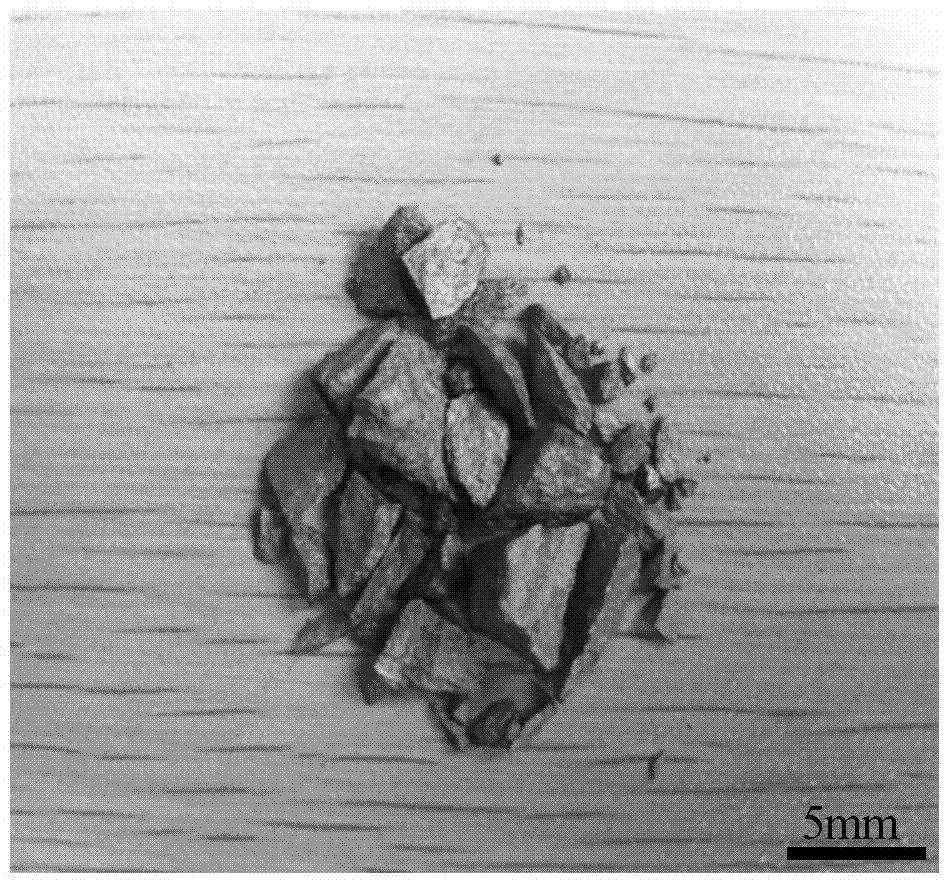

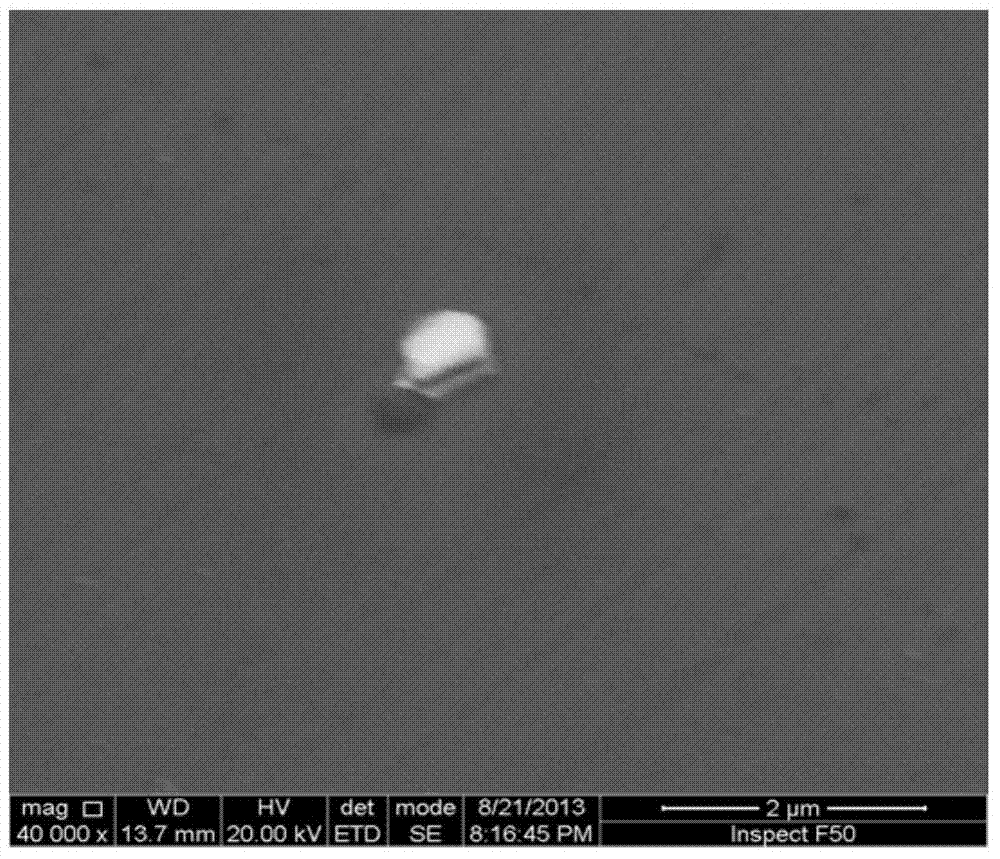

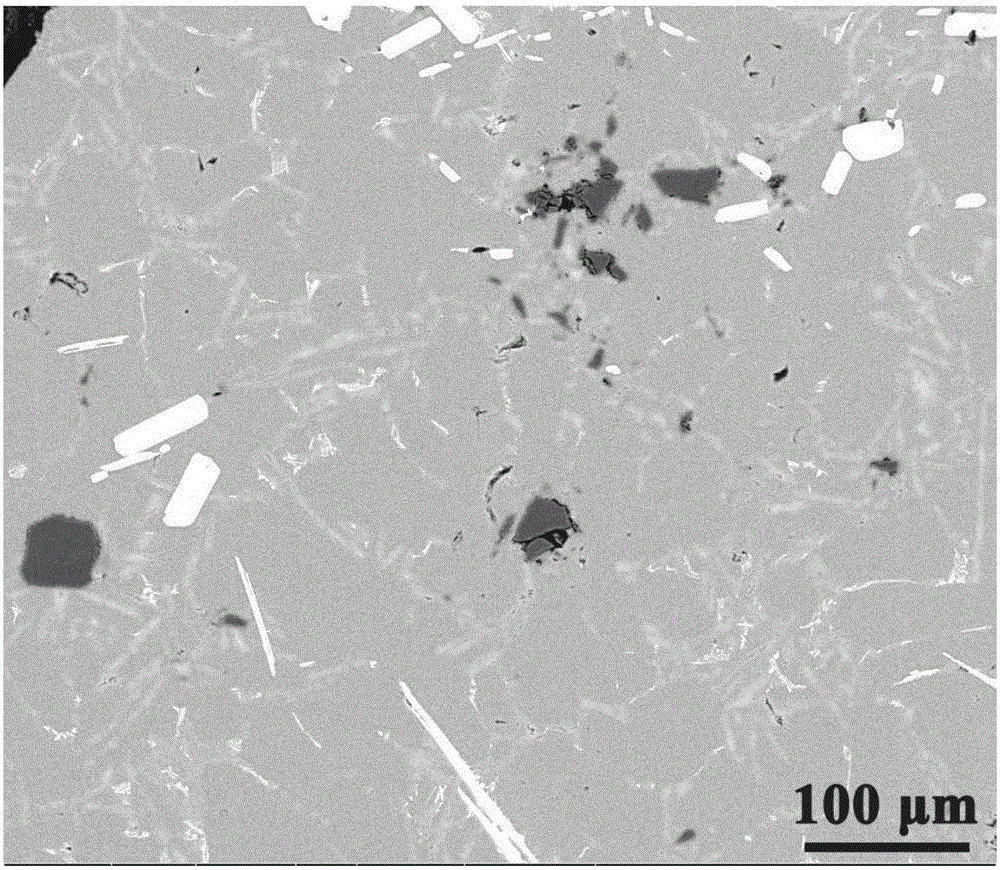

Smelting method of ultra-low oxygen pure steel

The invention relates to the field of smelting and specifically relates to a smelting method of ultra-low oxygen pure steel. A vacuum electric furnace or a vacuum induction furnace is adopted for smelting and vacuum pouring, and the vacuum degree is required to be 0.05-100Pa; after a metal charge is molten, a vacuum state is kept, molten metal is boiled for 5-30min, the oxygen content is reduced by vacuum carbon-oxygen reaction, and no deoxidizer or deoxidization alloy is added. The standing is performed for 20-30min after alloying, and the molten metal is boiled for 5-30min in the vacuum state. When the oxygen content is below 10ppm, 0.5-3kg / t of Si-Ca-Al-Mg-RE composite deoxidizer is added, the standing is performed for 1-10min after adding, then vacuum pouring is performed, and then the pure steel with the total oxygen content of below 4ppm can be obtained. The invention aims at solving the problems that existing steel ingots and cast blanks have more internal inclusions with relatively large sizes, the purity is not high and the channel segregation is serious. Simultaneously, by adopting a rare earth composite additive to perform modification treatment on the inclusions in the steel, the sizes of the inclusions are reduced, and the number of the inclusions in the steel is reduced, thus a new effective way is provided for pure smelting of molten steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

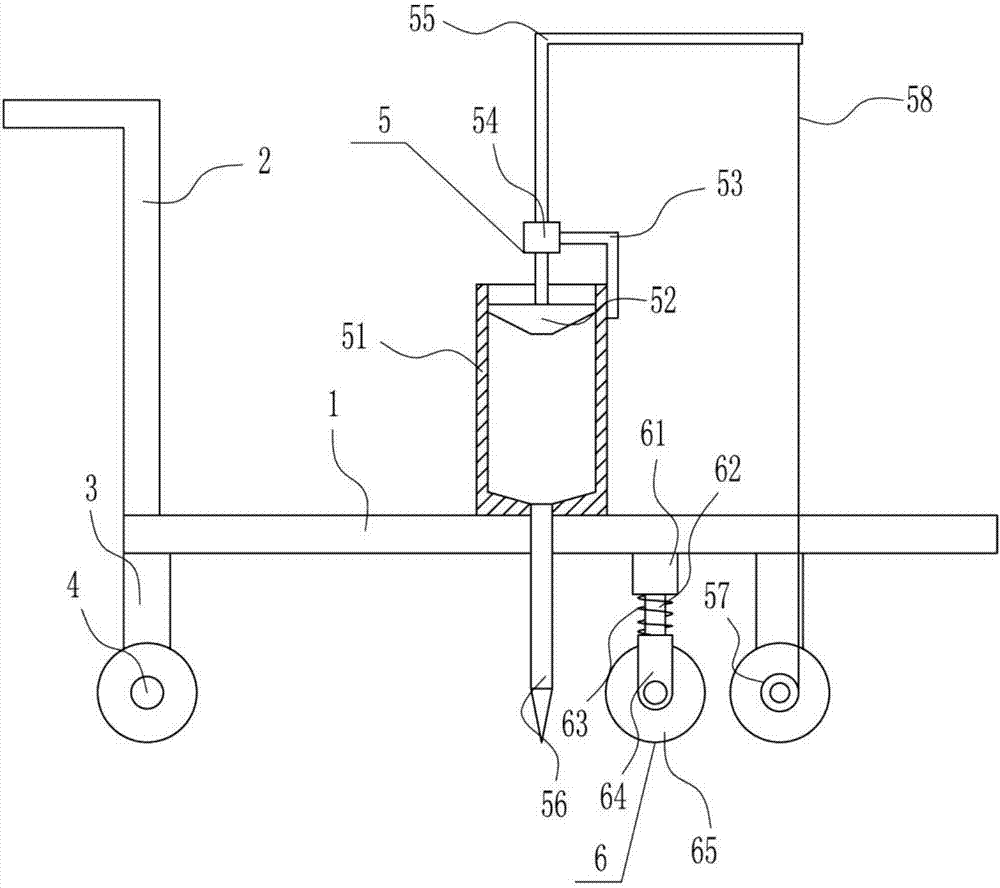

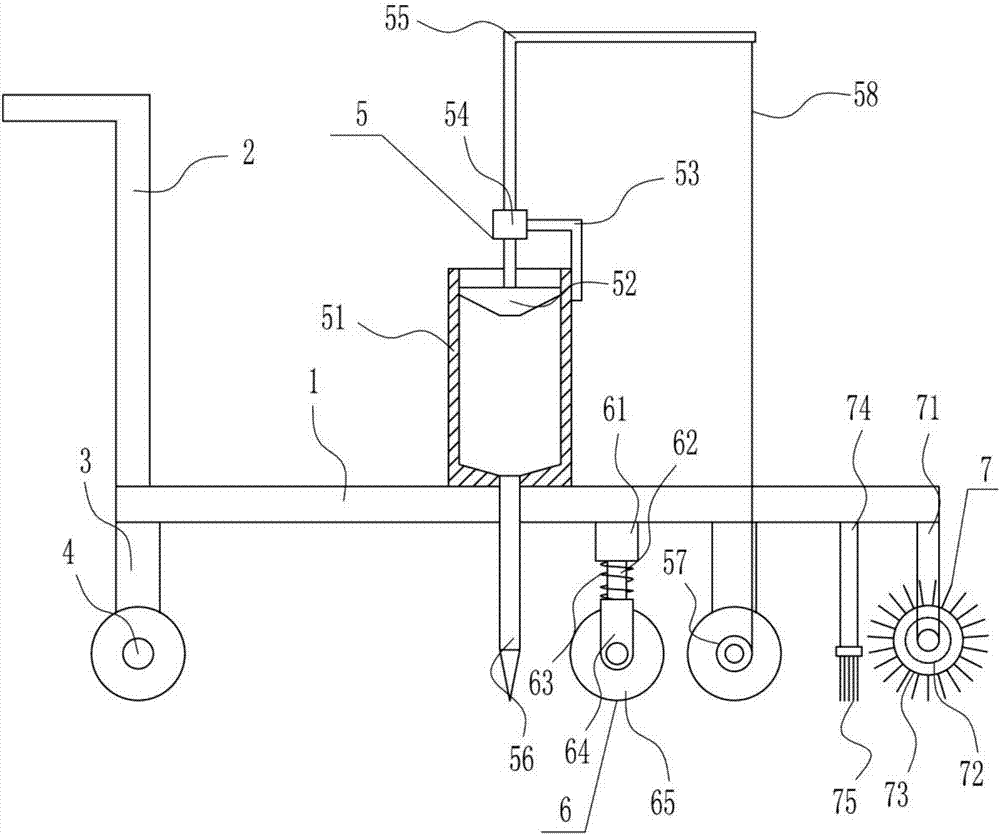

Tile base plate caulking device for house decoration

The invention relates to a caulking device, in particular to a tile base plate caulking device for house decoration. Against the technical problems to be solved, the invention provides the tile base plate caulking device for house decoration, which saves time and labor, can remove impurities in gaps, can also remove overflowing caulking adhesive without affecting attractiveness of tiles and can also make the caulking adhesive dried more quickly. In order to solve the technical problem, the invention provides the tile base plate caulking device for house decoration, which includes a base plateand the like. Vertical rods are mounted on the left side and the right side of the top of the base plate, wheels are rotatably mounted at the bottom ends of the vertical rods, a pushing hand is mounted on the left side of the top of the base plate, the right side of the bottom of the base plate is provided with a guide device, the guide device is located on the left side of the vertical rod on theright side, and the middle of the top of the base plate is provided with an adhesive-spraying device. According to the tile base plate caulking device for house decoration, through a leveling device,not only can the caulking adhesive be leveled, but also the overflowing caulking adhesive be removed. A drying device can dry the caulking adhesive to achieve effects of time saving and labor saving.

Owner:戚展鹏

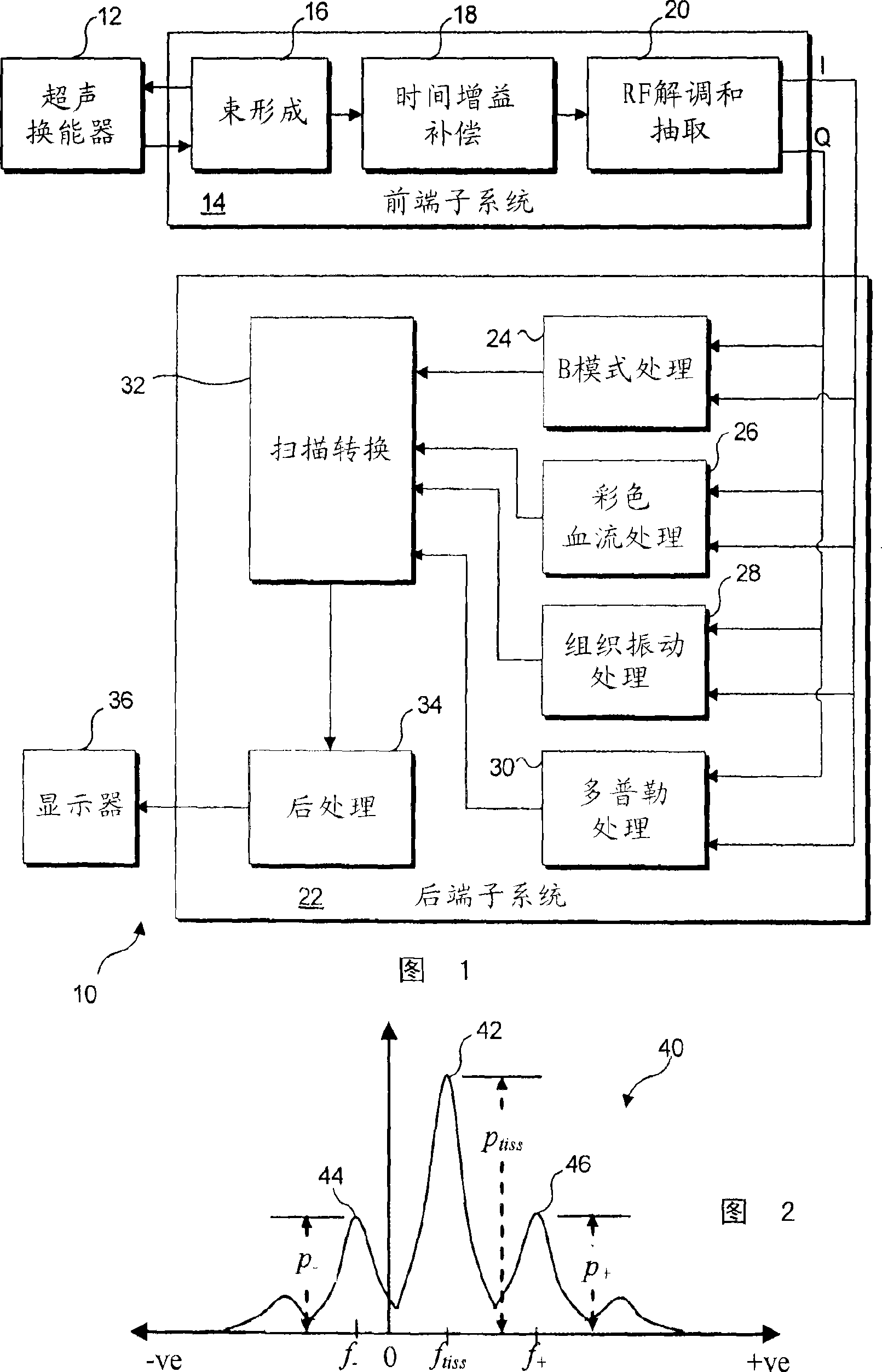

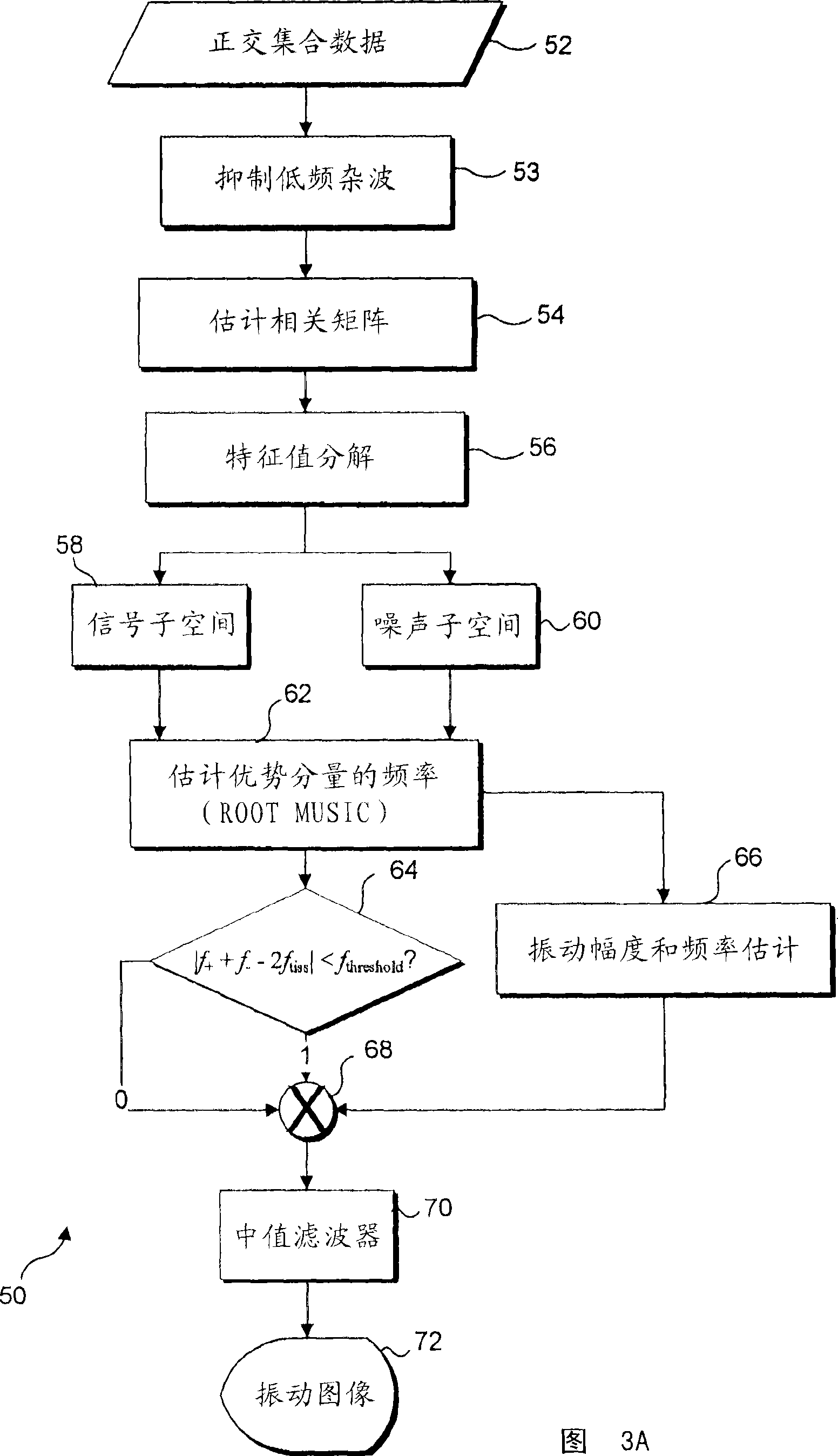

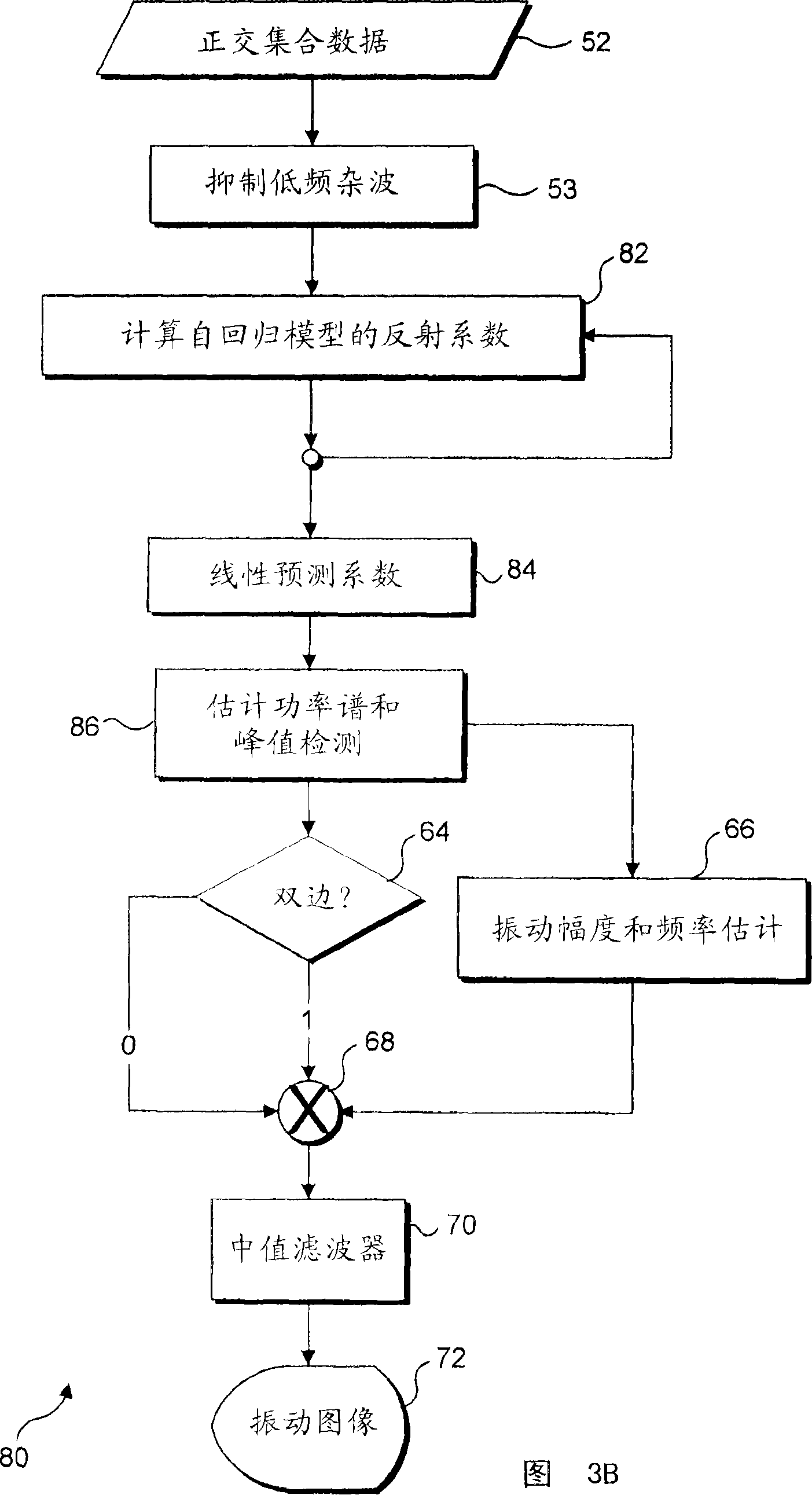

Ultrasonic technique for assessing wall vibrations in stenosed blood vessels

InactiveCN101022765AOrgan movement/changes detectionHeart/pulse rate measurement devicesSonificationFrequency spectrum

A real-time signal processing technique for ultrasonic imaging of tissue vibrations for localizing the source of a bruit in a 2D image with respect to the anatomy and / or for obtaining simultaneous information about vibrations and the underlying blood flow. The bruit can be quantitatively assessed using an ensemble of ultrasound echoes. Signal processing enables estimation of wall displacement and the display of time-resolved vibration spectrum. Vibrations are detected and color-coded according to their amplitude and frequency and overlaid on the B-mode and / or color-flow image in real time. Proposed vibration imaging algorithms use data acquired during conventional ultrasonic color-flow imaging and the clutter signal, normally suppressed in color-flow imaging, to detect and characterize tissue vibrations. Three vibration imaging algorithms based on parametric modeling of vibrations and other criteria distinguish between clutter, blood flow, and vibrations. The techniques are usable to detect, locate, image, and quantitatively grade stenoses in blood vessels.

Owner:WASHINGTON STATE UNIVERSITY

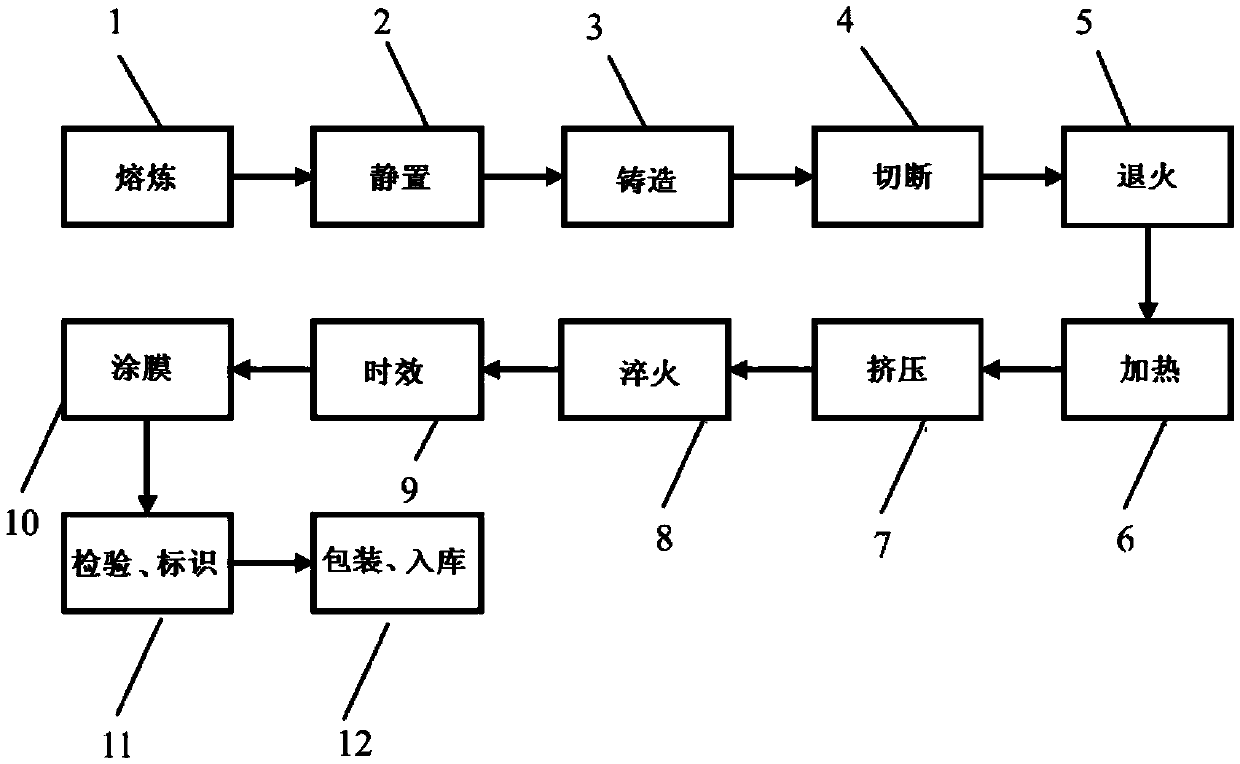

Manufacture method of aluminum alloy sectional material for building formwork

ActiveCN105506407AMeet the comprehensive performance requirementsImprove performanceForming/stuttering elementsManufacturing technologyUltimate tensile strength

The invention discloses a manufacture method of an aluminum alloy sectional material for a building formwork and belongs to the technical field of aluminum alloy sectional material manufacture. The objective of the invention is to solve the problems that the aluminum alloy sectional material for the building formwork, produced by the existing technology, is low in tensile strength, low in specified non-proportional extension strength, low in percentage elongation after fracture and low in corrosion performance. The method comprises the following steps of smelting, standing, casting, cutting, annealing, heating, extruding, quenching, aging and coating. Parameters in the technical step process are strictly controlled, and the aluminum alloy sectional material is enabled to have bigger cross section and better comprehensive performance, so that the use requirements on the building formwork are met, and the manufacture cost is reduced. Besides, through optimizing alloy components, and after extrusion, adopting an optimized aging technology and brushing a formwork protecting agent, the requirements of users on the comprehensive performance of the aluminum alloy sectional material are met, and the prepared aluminum alloy sectional material has the advantages of being high in strength, low in inclusion content, high in surface quality and outstanding in comprehensive mechanical property. The manufacture method is used for preparing the aluminum alloy sectional material for the building formwork.

Owner:CHINA ZHONGWANG

Abrupt slope spray-seeding greening method

InactiveCN104303749AAvoid churnGreen realizationExcavationsVegetative propogationFiberDrip irrigation

The invention provides an abrupt slope spray-seeding greening method. The method comprises the following steps of clearing away loose stones and impurities on the surface of a slope; embedding grouting anchors in the abrupt slope, grouting for anchoring, inserting common anchors, and fixing by using reinforced belts; laying a geogrid, namely horizontally and longitudinally laying porous water pipes on the geogrid in a staggered way and laying an inverted filter on the geogrid and the porous water pipe until the inverted filter covers the porous water pipe; spraying a matrix and a seed mixture onto the inverted filter, or planting seedlings of plants in a matrix; laying a plant fiber net on the matrix and fixing by using a rattan net; laying a nonwoven geotextile on the rattan net; performing maintenance on plants, watering in an initial stage, performing drip irrigation in a later period, and removing the geotextile after the plants survive. According to the method, water and soil loss of the slope can be effectively prevented, the water-holding capacity of the laid green belt is high, the green belt is subjected to drip irrigation to save water resource, the slope can be greened in a short time, and the restored slope has a good greening effect and is stable in structure.

Owner:WUHAN GAN SHI DAI ENVIRONMENT RESOURCE TECHCO

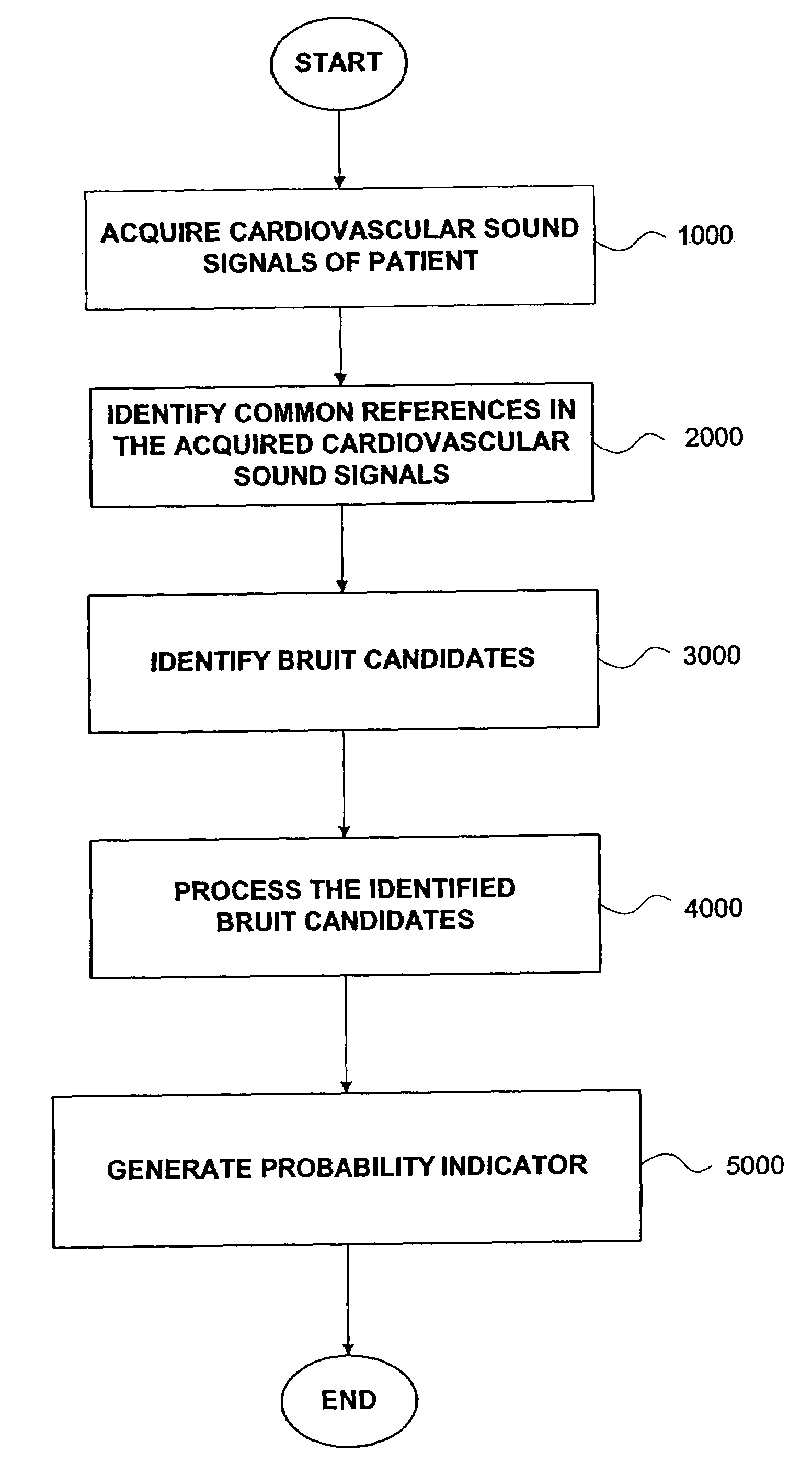

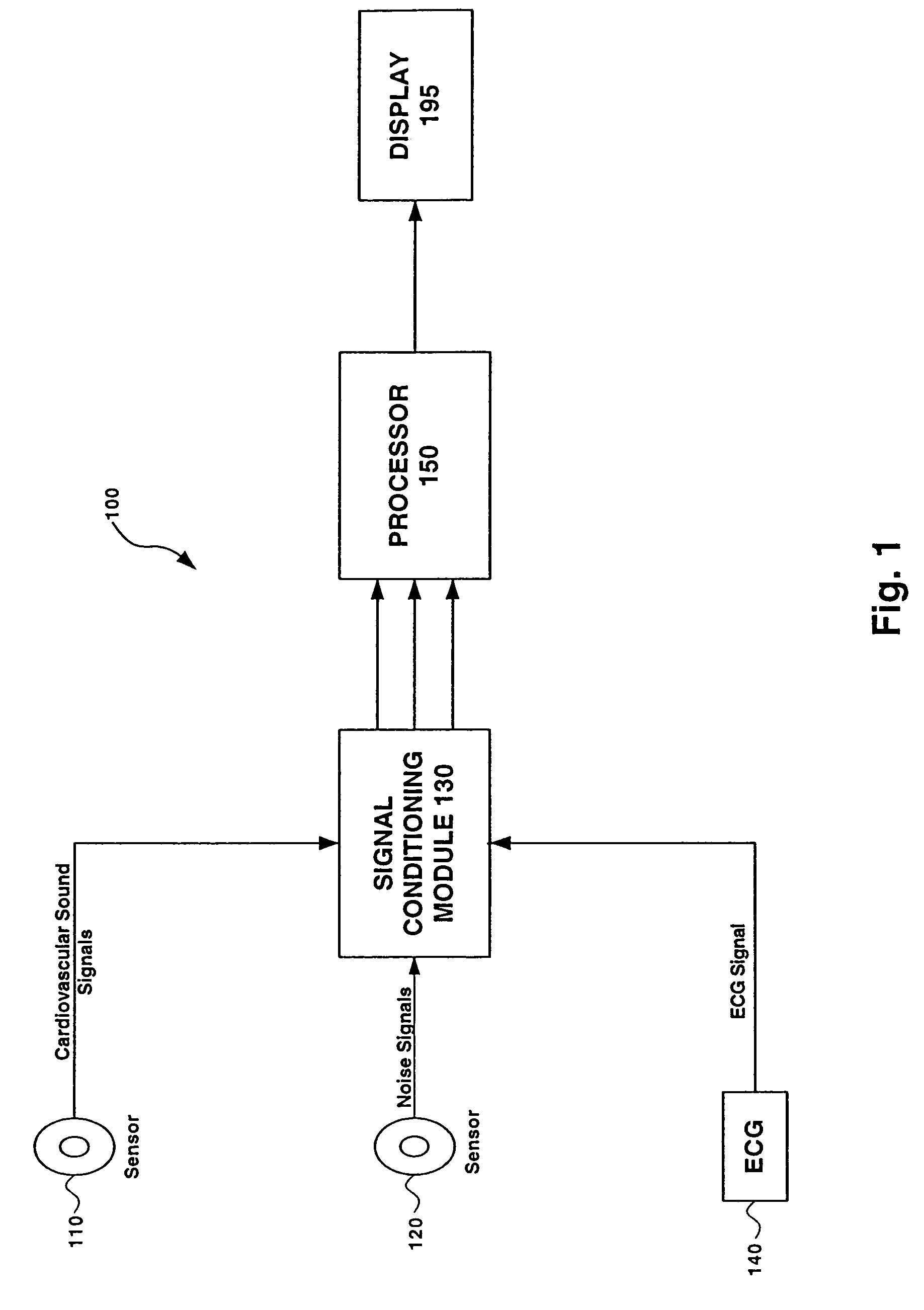

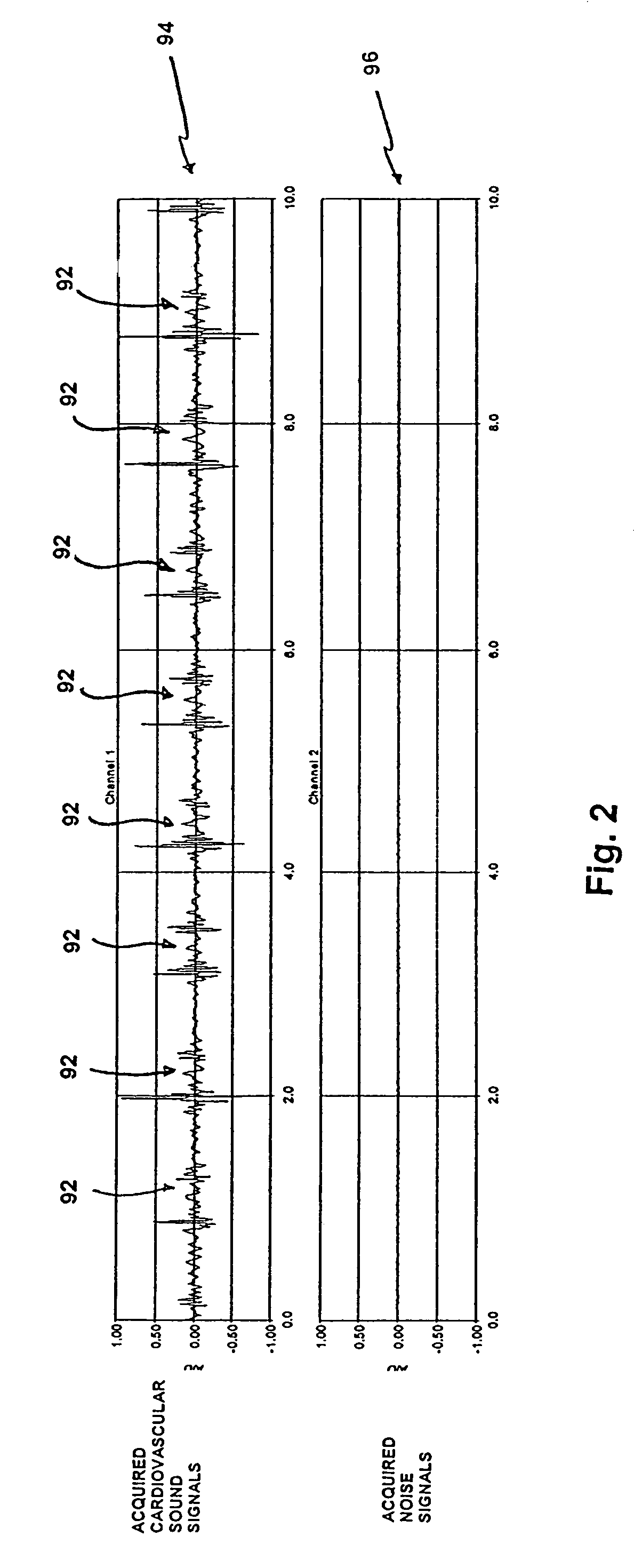

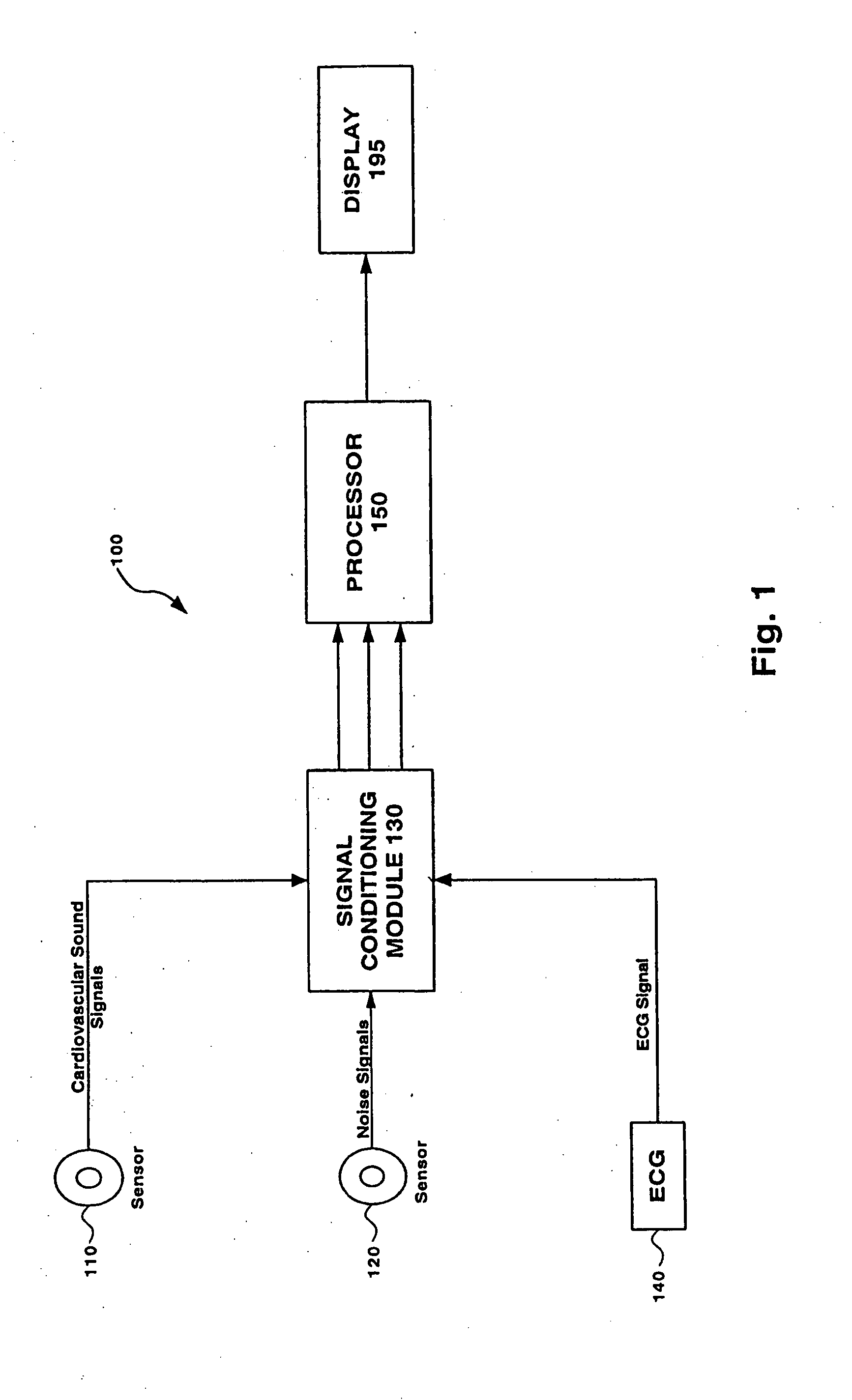

Method and system for generating a likelihood of cardiovascular disease, analyzing cardiovascular sound signals remotely from the location of cardiovascular sound signal acquisition, and determining time and phase information from cardiovascular sound signals

A system, method, and computer executable code for generating a likelihood of cardiovascular disease from acquired cardiovascular sound signals is diesclosed, where the generated likelihood of cardiovascular disease is based at least on an overlapping in time of bruit candidates in one heart cycle or in different heart cycles. Also disclosed is a system, method, and computer executable code for collecting, forwarding, and analyzing cardiovascular sound signals, where the collecting and analyzing may occur at locations that are remote from each other. Further disclosed is a system, method, and computer executable code for determining the time and phase information contained in cardiovascular sound signals, for use in analyzing those cardiovascular sound signals.

Owner:AUSCULSCI INC

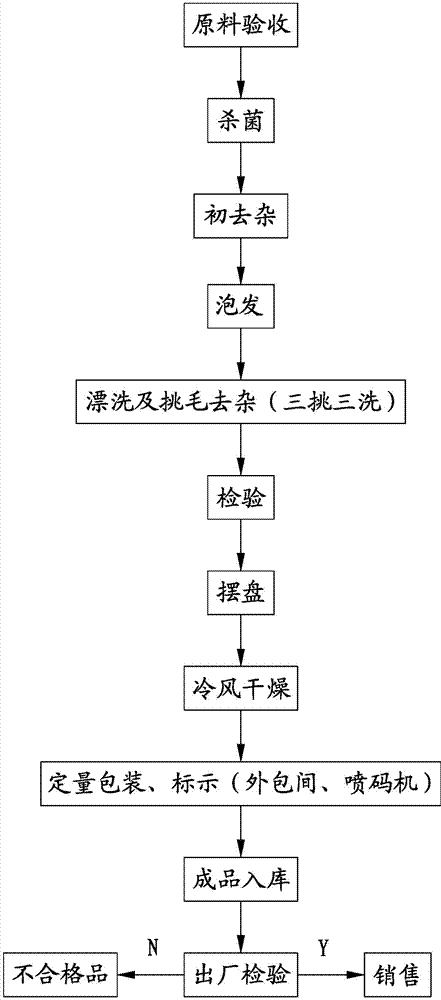

Production method of pure cubilose

The invention discloses a production method of pure cubilose. The production method comprises the following steps of: firstly, checking and accepting raw materials, namely, selecting light hair or medium hair crude cubilose raw materials; secondly, sterilizing, namely, disinfecting and sterilizing the raw materials by using ultraviolet rays; thirdly, primarily removing impurities, namely scrubbing black dots on the raw materials, removing the impurities on the raw materials; fourthly, soaking for swelling; fifthly, rinsing and picking hairs and removing the impurities, wherein the picking and washing are carried out for three times; sixthly, checking. According to the production method, the raw materials are finely checked and accepted, the sterilization and primary impurity-removing procedures are added, the soaking for swelling and the three-time picking and washing are carried out so that the cubilose is high in purity, the effect of the cubilose is ensured, and the cubilose is pure without foreign tastes, and is relatively good in mouth feel.

Owner:XIAMEN YANANJU FOOD

Method and system for generating a likelihood of cardiovascular disease, analyzing cardiovascular sound signals remotely from the location of cardiovascular sound signal acquisition, and determining time and phase information from cardiovascular sound signals

A system, method and computer executable code for generating a likelihood of cardiovascular disease from acquired cardiovascular sound signals is disclosed, where the generated likelihood of cardiovascular disease is based at least on an overlapping in time of bruit candidates in one heart cycle or in different heart cycles. Also disclosed is a system, method, and computer executable code for collecting, forwarding, and analyzing cardiovascular sound signals, where the collecting and analyzing may occur at locations that are remote from each other. Further disclosed is a system, method, and computer executable code for determining the time and phase information contained in cardiovascular sound signals, for use in analyzing those cardiovascular sound signals.

Owner:AUSCULSCI INC

Method for preparing foamed glass by using waste fiberglass products

InactiveCN101955319AEfficient use ofImprove structural strengthAntimony trioxideSodium hexafluoroaluminate

The invention relates to a method for preparing foamed glass by using waste fiberglass products, which comprises the following steps of: firstly, airing collected waste fiberglass mats and fiberglass meshes, manually sorting out the impurities of metal, organic matter and the like, cutting into fragments smaller than 20 mm*20 mm, and ball-milling to 200 meshes to form glass powder; loading the glass powder, silicon carbide, diantimony trioxide, sodium sulfate, sodium fluoaluminate, sodium nitrate and cobalt oxide into a ball mill, and ball-milling to form a batch; loading the batch into a heat-resisting mold, and firing into foam glass. In the invention, the waste fiberglass products are used as a main raw material to produce foam glass, and the prepared foam glass has low density, high strength, small heat conductivity and low water absorption rate. The preparation method has simple operation process, low founding temperature and low cost, not only changes wastes into valuables, but also protects the environment, and is applicable to industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Phi 500-650mm Cr6 type forged-electroslag-steel cold-rolled work roll blank forging and deforming technology

ActiveCN106734805AReduce generationReduce crackingMetal-working apparatusWork rollNon-metallic inclusions

The invention discloses a Phi 500-650mm Cr6 type forged-electroslag-steel cold-rolled work roll blank forging and deforming technology. The technology includes the steps of converter producing plus LF refining plus VD vacuuming, continuous casting of round blank, hot annealing of electronic blank, clearing, electroslag remelting, annealing of electroslag ingot, forging and annealing after forging, wherein four-fire mode production is adopted in forging, upsetting and drawing out deformation methods are adopted in the first fire time, forging under great pressure is adopted in the second fire time, and forging to forming in the third and fourth fire time. Temperature and heat preservation time in high-temperature diffusion are key to control in forging, furnace return temperature and time in each fire time of forging and deformation and final forging temperature of each fire time are controlled. The spheroidized structure of the produced Cr6 type forged-electroslag-steel cold-rolled work roll blank is 2-3 in grade, carbide mesh is less than or equal to 2.0 in grade, carbide strap and liquation are below 1.0 in grade, total non-metallic inclusions is less than or equal to 2.0 in grade, flaw detection eligibility rate is increased from original 75% to 95%, carbide distribution is small and diffused, and long service life is achieved.

Owner:建龙北满特殊钢有限责任公司

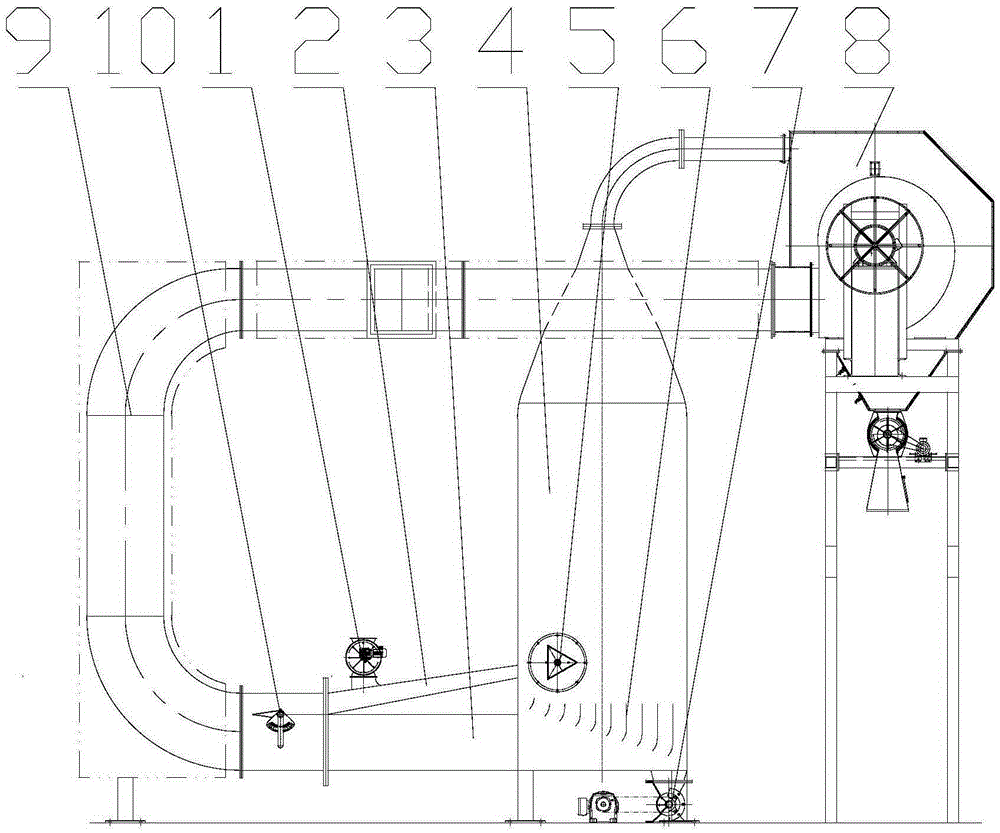

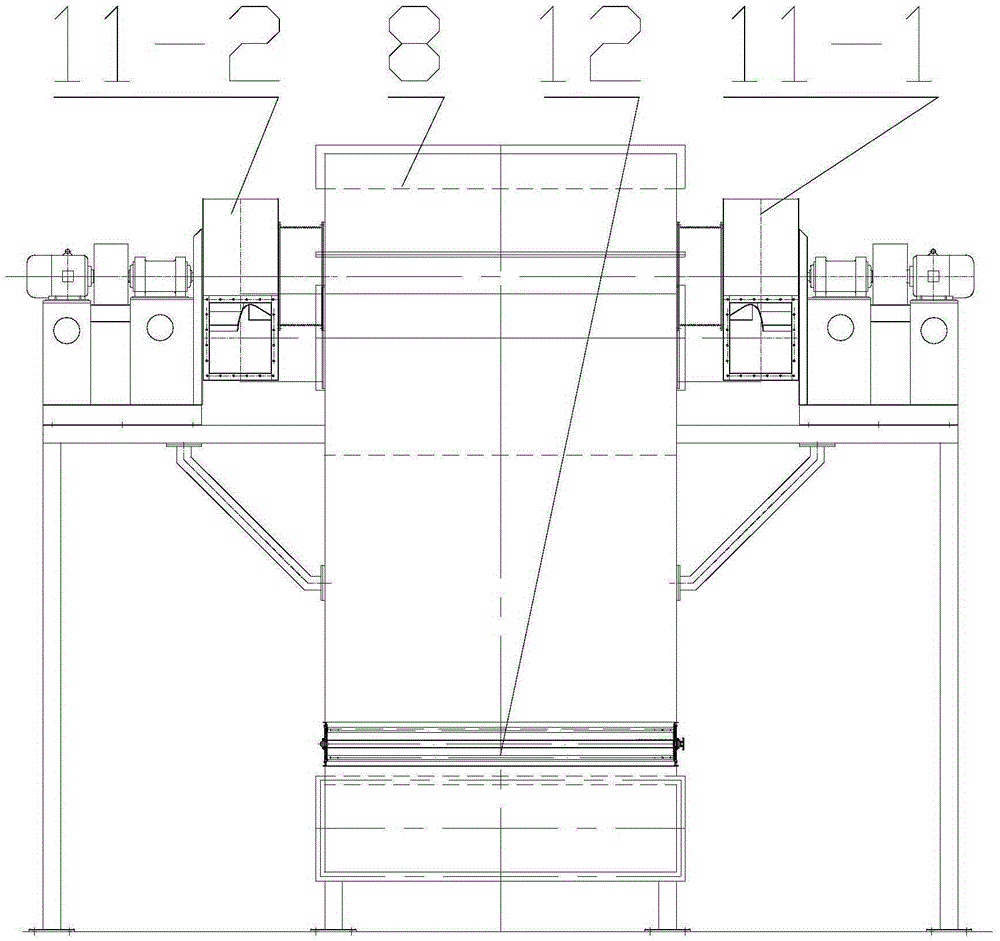

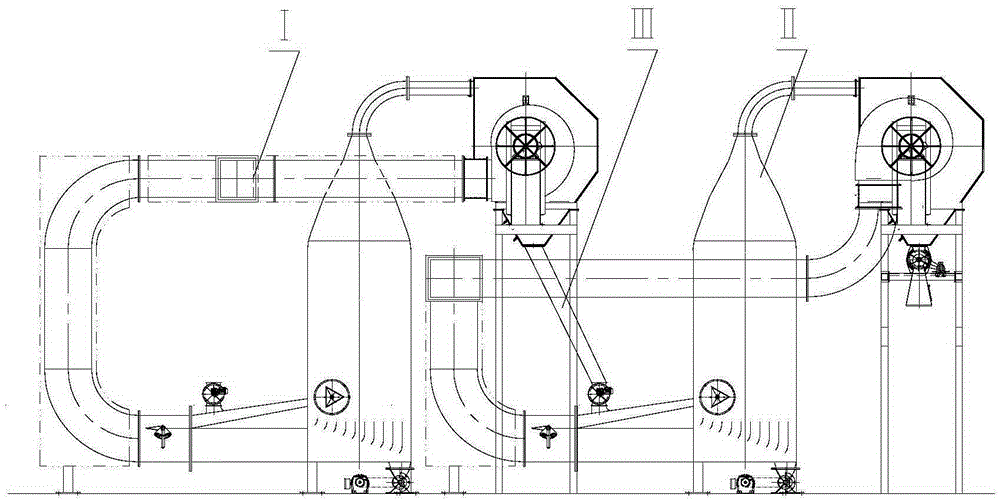

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

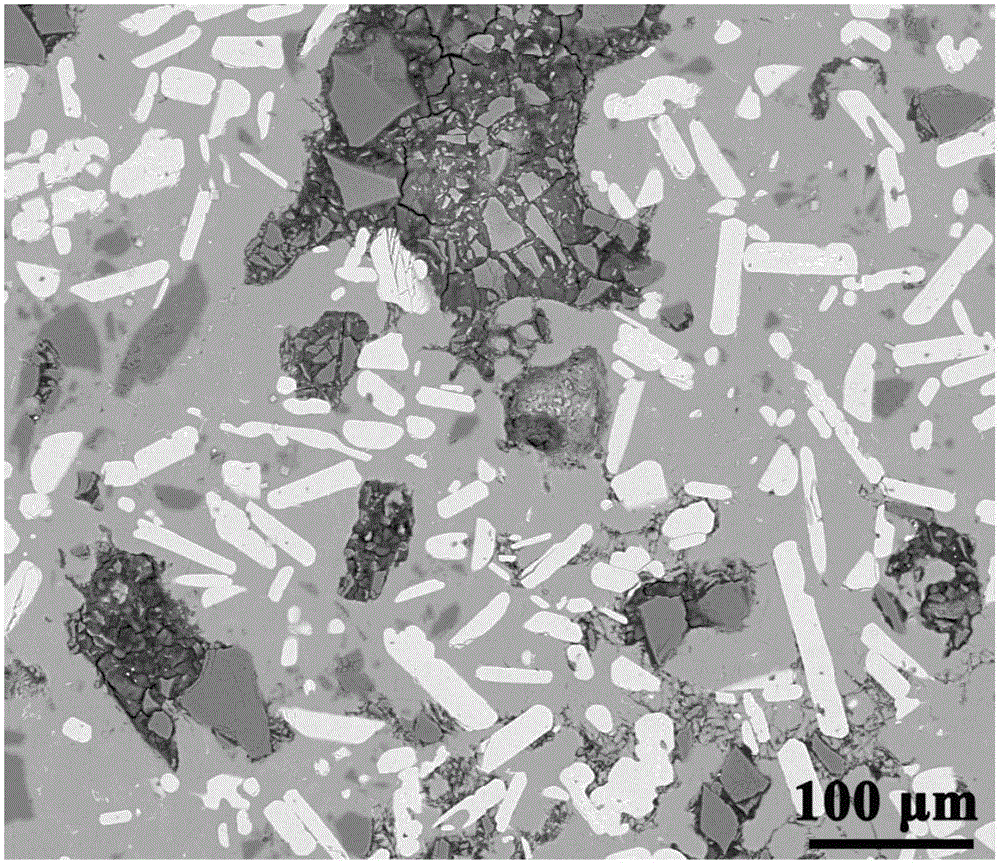

Control method for plasticization of tire cord steel inclusion

The invention discloses a control method for plasticization of a tire cord steel inclusion, and belongs to the technical field of steel and iron smelting. The method comprises the following process steps of: performing a catch carbon process at an end point of a converter, wherein the mass fraction of end point carbon is 0.1-0.4 percent; performing deoxidization alloying on Si-Fe and Mn-Fe alloy during tapping of the converter, wherein 1.0-3.0 kg of Si-Fe alloy is added per ton of steel, and 3.0-6.0 kg of Mn-Fe alloy is added per ton of steel; adding ferrosilicon powder into the top of slag during LF ladle furnace refining, wherein the 0.5-1.5 kg of ferrosilicon powder is added per ton of steel; feeding 0.1-0.5 kg of magnesium wire per ton of steel into a ladle; and blowing argon to the ladle in two stages. The method has the advantages that: the special magnesium or zirconium ladle is not required any longer during production of tire cord steel; meanwhile, the inclusion control levelwhich meets the production requirement is achieved; and thus, the production cost per ton of steel is reduced, and the economic benefit is increased.

Owner:SHOUGANG CORPORATION

Process for recycling of kitchen waste and garden waste

InactiveCN104591816AImprove energy efficiency ratioNo lossBio-organic fraction processingClimate change adaptationEngineeringMoisture

The invention aims at providing an energy-saving and environmentally-friendly efficient process for recycling of kitchen waste and garden waste by using low-grade energy. The process comprises the following steps: firstly preprocessing the waste; uniformly classifying the collected kitchen waste and smashing the kitchen waste; smashing the collected large-size garden waste by a large pulverizer, and putting the large-size garden waste and the other small-size garden waste into a small pulverizer to further smash; proportionally putting the preprocessed kitchen waste and the garden waste into a high-temperature aerobic fermentation reactor, wherein the feeding method is a sequencing batch feeding method, and the moisture content of the reacted product is less than or equal to 30%; sieving the processed initial product to filter out the non-treatable large-particle-size impurities, after mixing, processing the product into a planting soil raw material, a soil conditioner or an organic fertilizer according to different uses.

Owner:上海申迪园林投资建设有限公司 +1

Extra-thick steel plate production process of plastic dies steel

The invention relates to an extra-thick steel plate production process of plastic die steel. The maximum thickness of the die steel can achieve 250mm. The production process comprises the following steps: adopting a proper composition design to produce the die steel belonging to middle-carbon high-alloy steel, performing steelmaking in a converter, continuously casting to form the material through a phi1000mm round billet, and obtaining a pre-hardened plastic die thick steel plate with excellent internal quality and good processing performance through a reasonable heating mode, a rolling technology and a heat-treating system. The steel plate is uniform in tissue, uniform in performance, and capable of achieving JB / 4730.3-2005 standard I level, low in occluded foreign substance, and good in steel plate processing performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

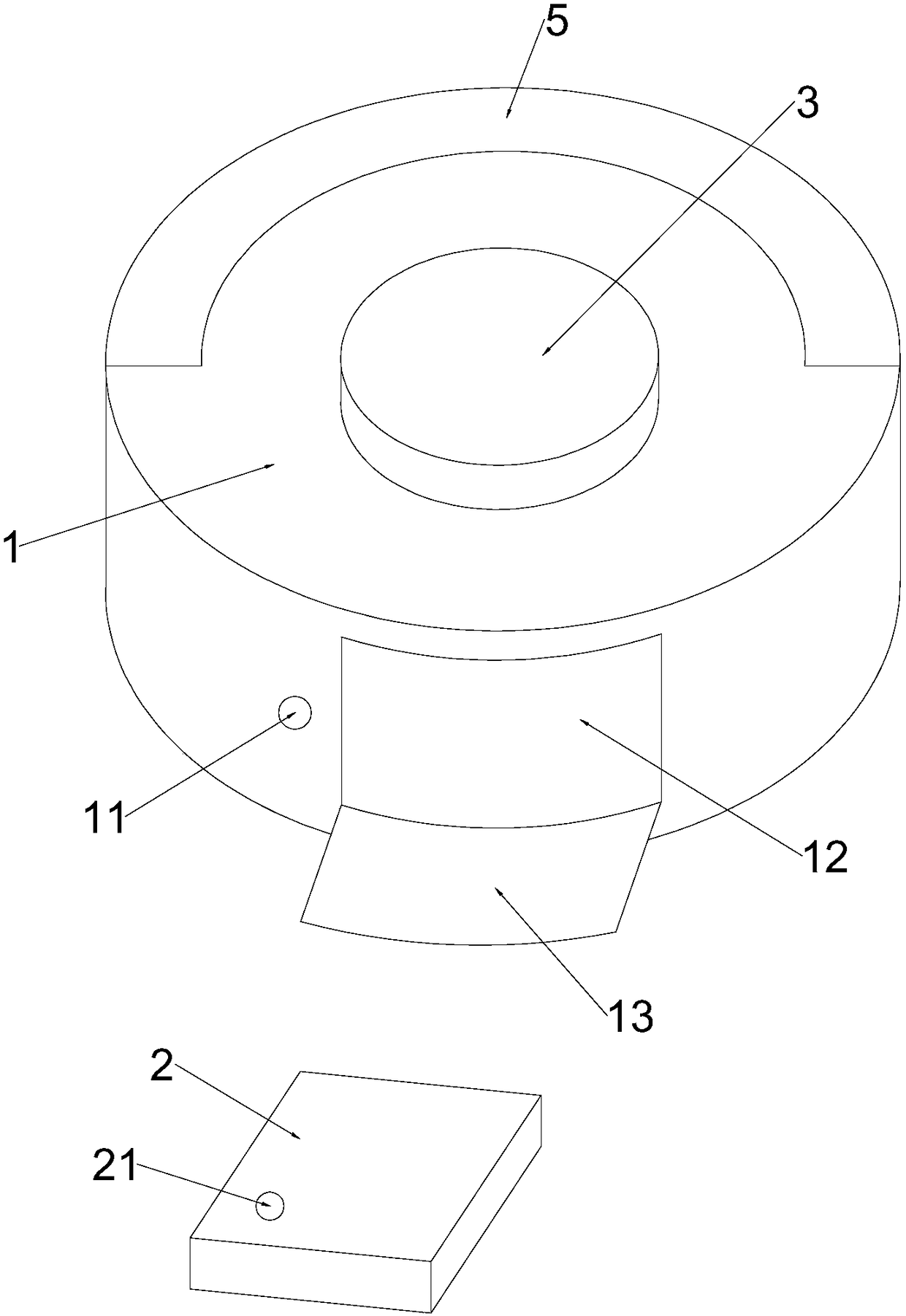

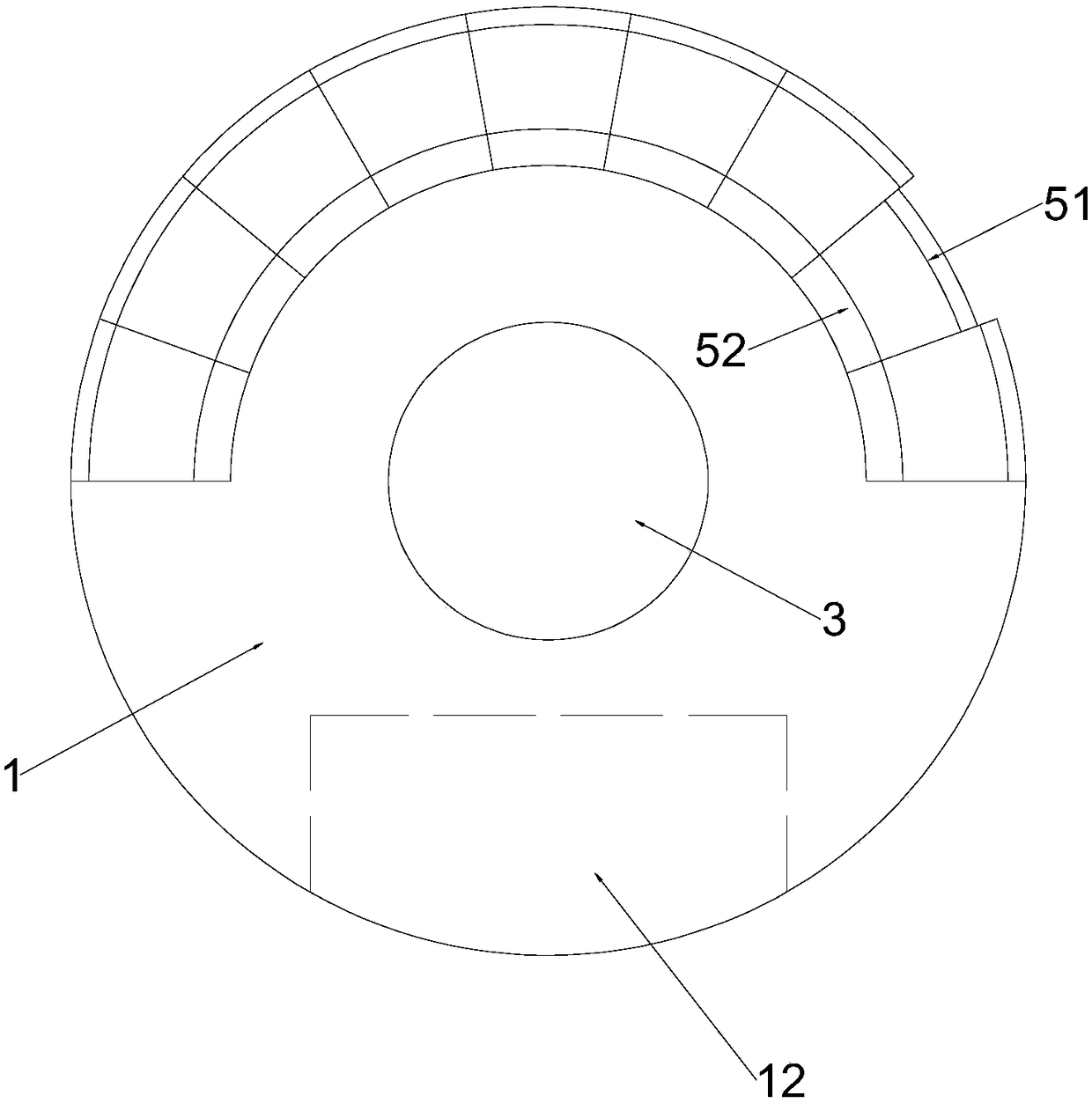

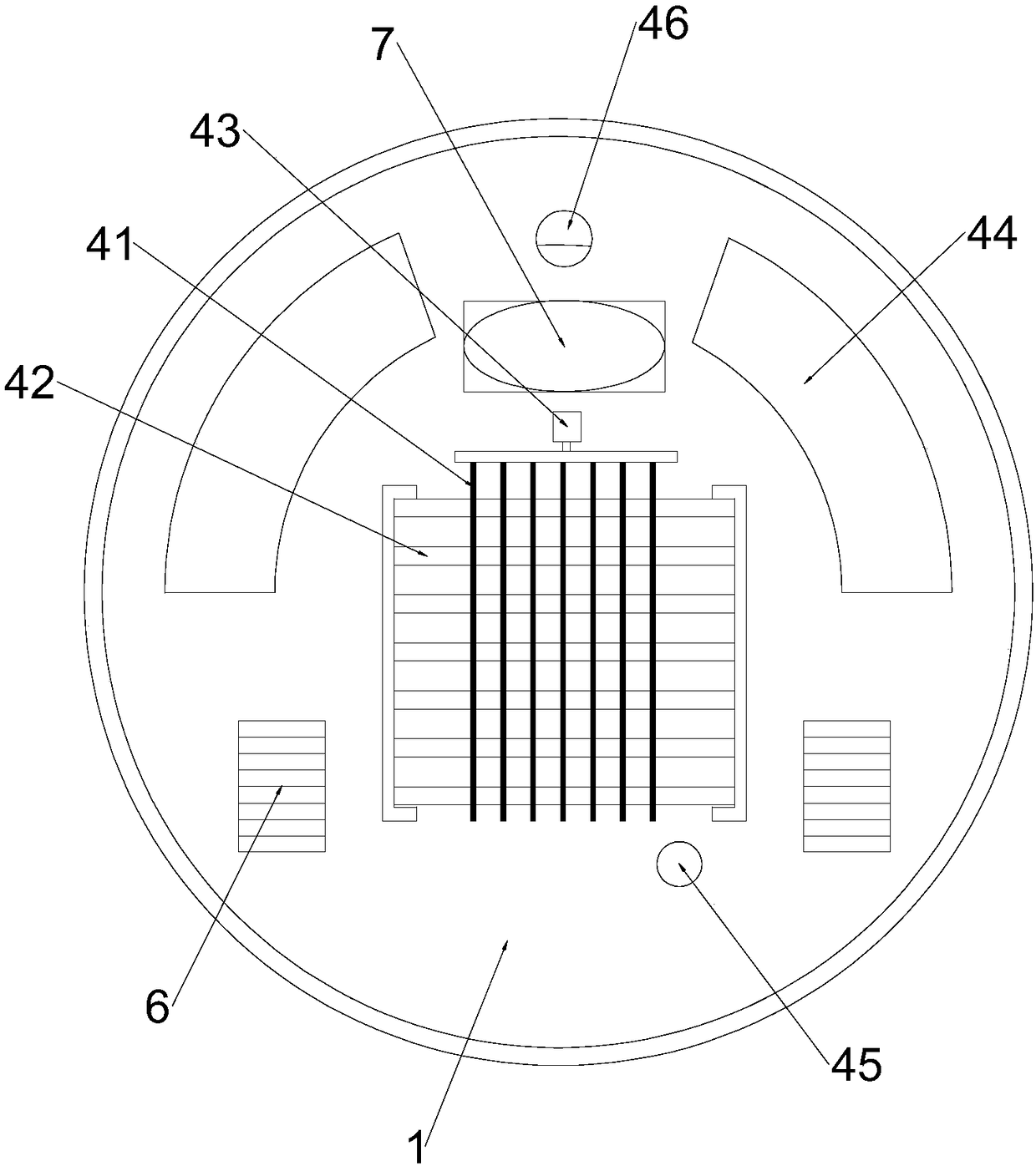

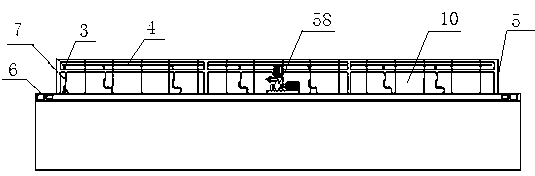

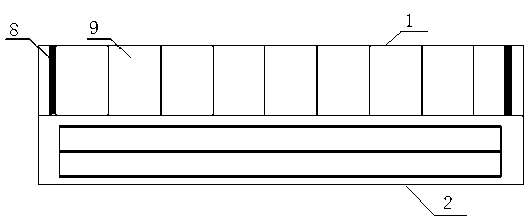

Intelligent sweeping robot

PendingCN108158512AAll-round cleaningAdd mopping functionAutomatic obstacle detectionTravelling automatic controlOmnidirectional antennaObstacle avoidance

The invention relates to an intelligent sweeping robot. The intelligent sweeping robot comprises a main cleaning machine for removing and storing garbage, a sub-cleaning machine for moving the garbageand an obstacle avoidance device. The sub-cleaning machine is detachably mounted on the main cleaning machine, the size of the sub-cleaning machine is smaller than that of the main cleaning machine,the main cleaning machine is in a disc shape, and the sub-cleaning machine is in a square shape. The top end of the main cleaning machine is further provided with a regulating water tank, a cleaning mechanism is arranged at the bottom end of the main cleaning machine and includes first cleaning components, second cleaning components and a cleaning motor, and when the first cleaning components rotate, static electricity is generated through friction between the first cleaning components and the second cleaning components to adsorb debris. Arc-shaped base plates are arranged, at the front end ofthe cleaning mechanism, on the bottom surface of the main cleaning machine, and mopping cloths are bonded to the bottom surfaces of the arc-shaped base plates through hook and loop fasteners. Omnidirectional cleaning can be performed through the sub-cleaning machine. Through arrangement of the adjusting water tank and the mopping cloths, a mopping function is added. The intelligent sweeping robothas a higher adsorption capacity for small and slender debris. By reading signals of each collision detecting unit, a collision orientation can be accurately and specifically identified.

Owner:东莞市铭煜电子科技有限公司

Cyclic acid pickling device and method of trough type pickling tank

The purpose of the invention is to provide a cyclic acid pickling device of a trough type pickling tank and a cyclic acid pickling method of a trough type pickling tank. Rusts and other impurities adhering to the inner and outer surfaces of a pipeline can be efficiently removed through the device and the method provided by the invention; the production cost is reduced and the discharge of waste acids is reduced because the acid pickling solution is cyclically filtered and used repeatedly; and therefore, actual use effects of energy conservation and emission reduction are achieved. According to the invention, the processes of soaking acid pickling, side spray forced cyclic acid pickling, cyclic acid pickling by injecting an acid into a pipeline and acid pickling by spraying outside the pipeline are adopted to performing multi-directional acid pickling on the pipeline, and the acid pickling effect on the pipelines which are deep in rusting degree, large in pollutant adsorption quantity, and multiply bent are especially obvious; simultaneously, a method of cyclically filtering and recycling the acid pickling solution and complete covering with soft plastics is adopted, so that the purposes of energy conservation and emission reduction are achieved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

20Cr2Ni4 gear steel and production technology thereof

InactiveCN106967931AReduce gas contentImprove hardenabilityElectric furnaceProcess efficiency improvementElectric arc furnaceSmelting process

The invention discloses 20Cr2Ni4 gear steel and a production technology thereof. The 20Cr2Ni4 gear steel is made of 20Cr2Ni4, and the mass percentage of Mo in the 20Cr2Ni4 is 0.15-0.30%. The production technology comprises the steps of burdening, smelting in an electric arc furnace and smelting in a refining furnace, wherein in the smelting process in the electric arc furnace, steel is molten, the temperature reaches 1570-1590 DEG C, and sampling is carried out for detection analysis so as to enable the mass percentage of the Mo to reach 0.15-0.30%; and in the smelting process in the refining furnace, the temperature reaches 1570-1590 DEG C, and sampling is carried out for detection analysis so as to enable the mass percentage of the Mo to reach 0.15-0.30%. According to the 20Cr2Ni4 gear steel and the production technology thereof, impurities in the steel are reduced, the content of H, O and N gas in the steel is reduced, the harmful elements such as P, S, As and Sn in the steel are reduced, a proper amount of the Mo is added, and therefore the steel can be used for parts such as a large gear and a shaft, and the comprehensive performance such as the hardenability, the heat resistance, the grain refinement performance and the steel strength improvement performance can be improved.

Owner:CHONGQING JINKAI SPECIAL STEEL PROD

Ship propeller protection net

InactiveCN102267553AEnsure driving safetyBlock the impactPropulsive elementsForeign matterSafety net

The invention discloses a marine propeller protection net, which comprises a net cover arranged on the periphery of the propeller and connected with the bottom of the hull; The protective net at the bottom of the propeller, the protective net at the bottom of the propeller and the rear protective net of the propeller are connected to each other and are respectively connected to the bottom of the hull; the present invention arranges a net cover around the propeller of the ship, which does not affect the effect of the water flow and the propeller, and can block the impact of foreign objects The propeller, and debris such as weeds or fishing nets are not easy to touch the propeller, and it is not easy to wrap around the propeller, which ensures the life of the propeller and the safety of the ship.

Owner:金海

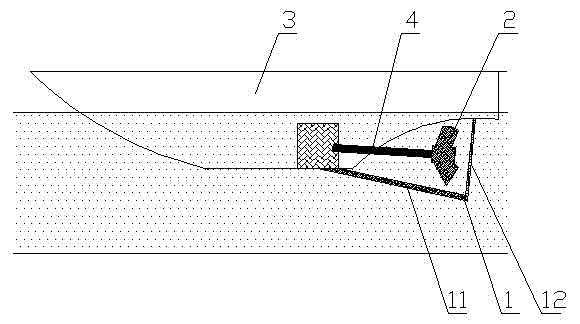

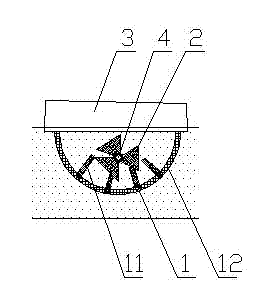

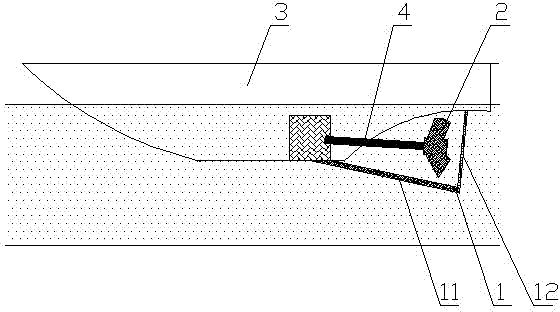

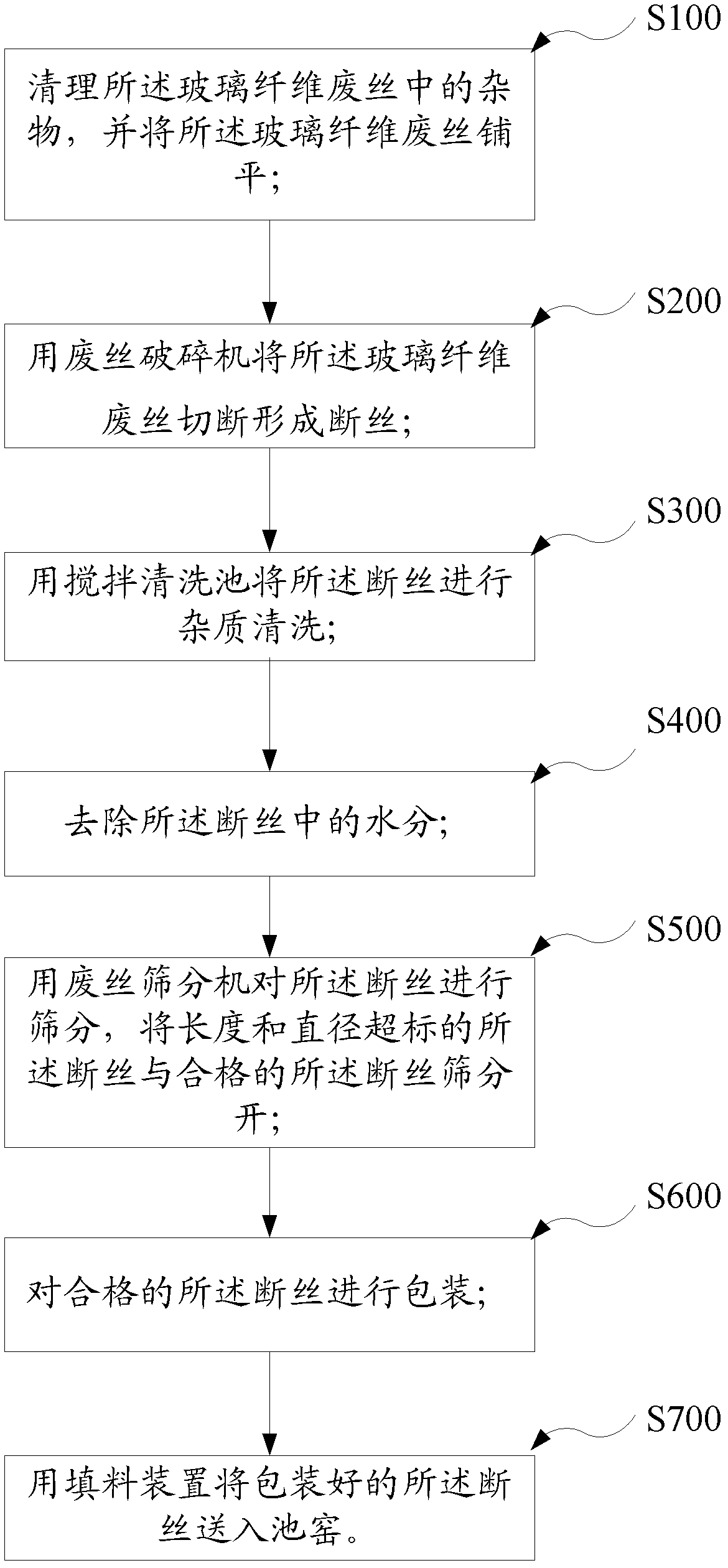

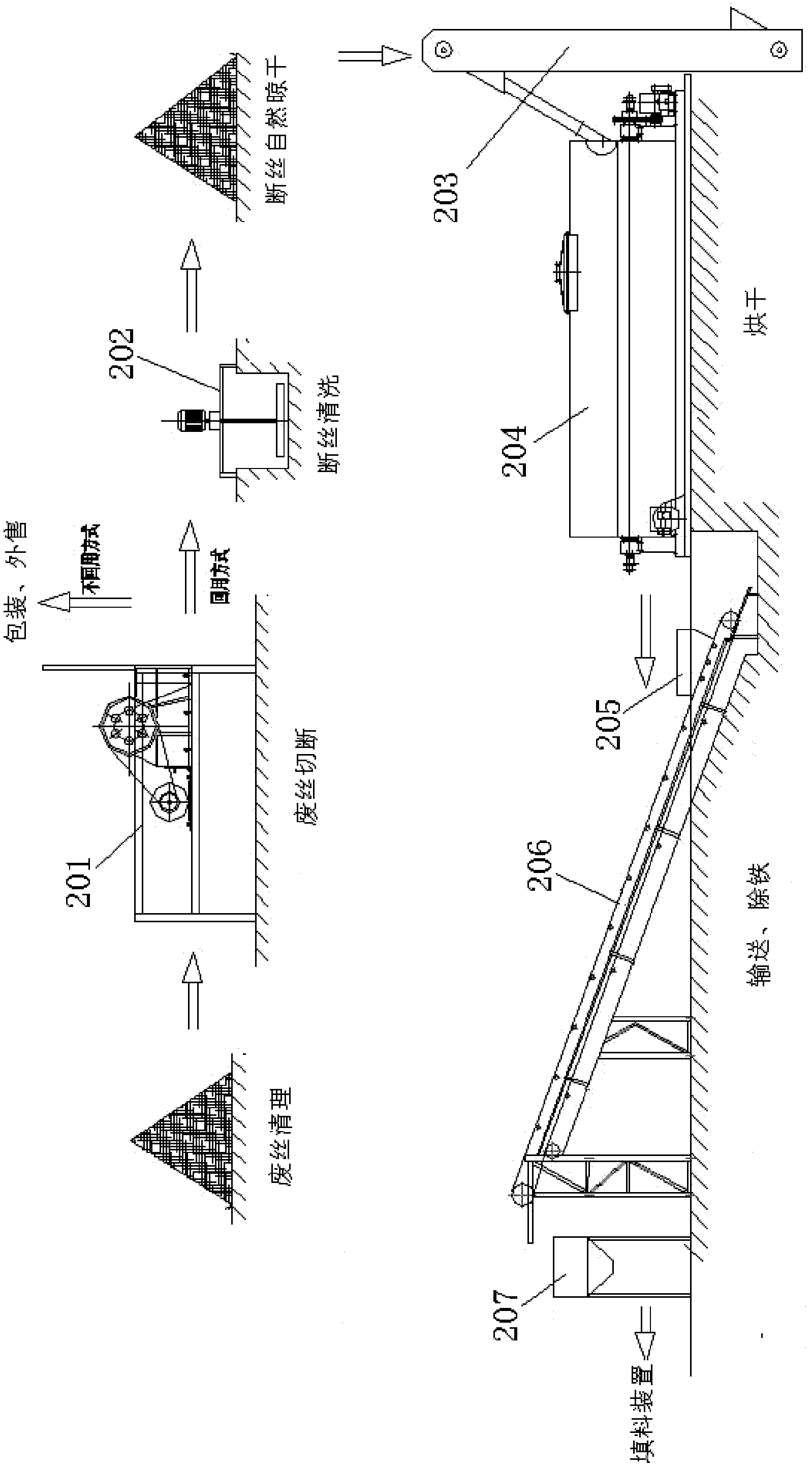

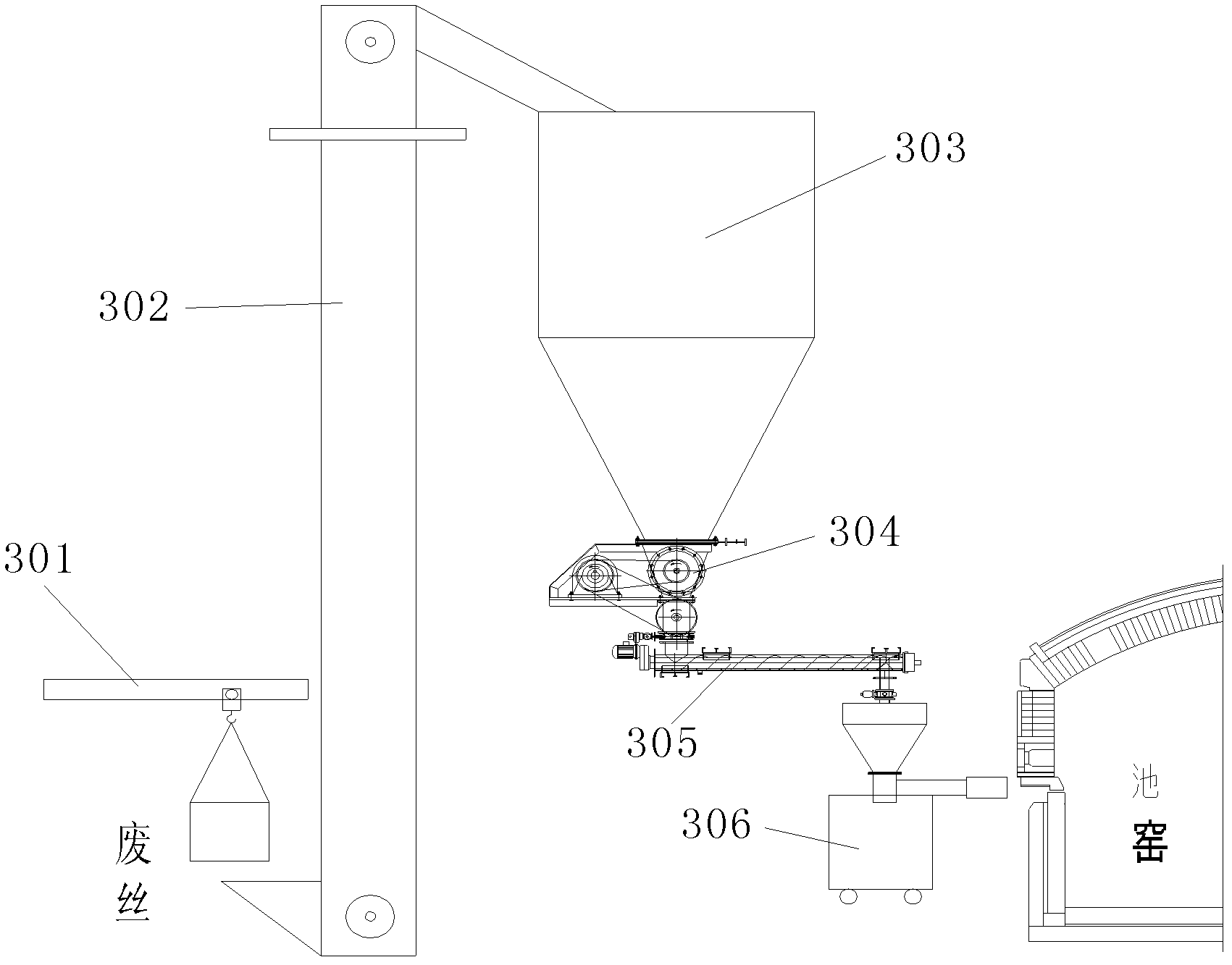

Recovery method for glass fiber waste silks

InactiveCN102489492AEfficient use ofSave raw materialsSolid waste disposalGlass fiberRecovery method

The invention discloses a recovery method for glass fiber waste silks. The recovery method for the glass fiber waste silks comprises the following steps of: 1) cleaning sundries in the glass fiber waste silks and paving the glass fiber waste silks; 2) cutting off the glass fiber waste silks by using a waste silk crushing machine so as to form broken filaments; 3) cleaning impurities of the broken filaments by using a stirring cleaning pool; 4) removing moisture in the broken filaments; 5) sieving the broken filaments by using a waste silk sieving machine, and separating the broken filaments with exceeding lengths and diameters from the qualified broken filaments; 6) packaging the qualified broken filaments; and 7) transmitting the packaged broken filaments into a tank furnace by using a filling device, wherein the method further comprises a step 41) of removing metal impurities in the broken filaments by an electromagnetic iron remover (205) between the step 4) and the step 5), wherein the broken filaments in the step 2) can be broken filaments with the lengths of not more than 30 mm. According to the recovery method provided by the invention, the production cost of the glass fiber can be reduced.

Owner:CHONGQING POLYCOMP INT

Method for sorting titanium middling from iron-separating tailings

The invention relates to the technical field of ilmenite beneficiation and specifically discloses a method for sorting titanium middling from iron-separating tailings. The method comprises the following steps of: removing impurities of the iron-separating tailings to concentrate, discarding the tailings through strong magnetic separation, grinding ores, and enabling ilmenite to further subject tomonomer separation; sorting iron ore concentrate through weak magnetic separation, performing strong magnetic roughing on rest of ore pulp, performing chute reselection on rough concentrate, grindingreselected concentrate, and performing further monomer separation on ilmenite; sorting secondary iron concentrate through weak magnetic separation, performing strong magnetic concentration on rest ofore pulp, enabling concentrated concentrate to further enter a chute to further subject to concentration, and performing solid-liquid separation on concentrate ore pulp, thereby obtaining titanium middling with grade higher than 38%. The method is simple in process flow, is reasonable in sorting way, and is high in metal recovery rate, and a titanium middling product is high in quality and is stable in grade, so that economic benefits are good.

Owner:HEBEI IRON AND STEEL

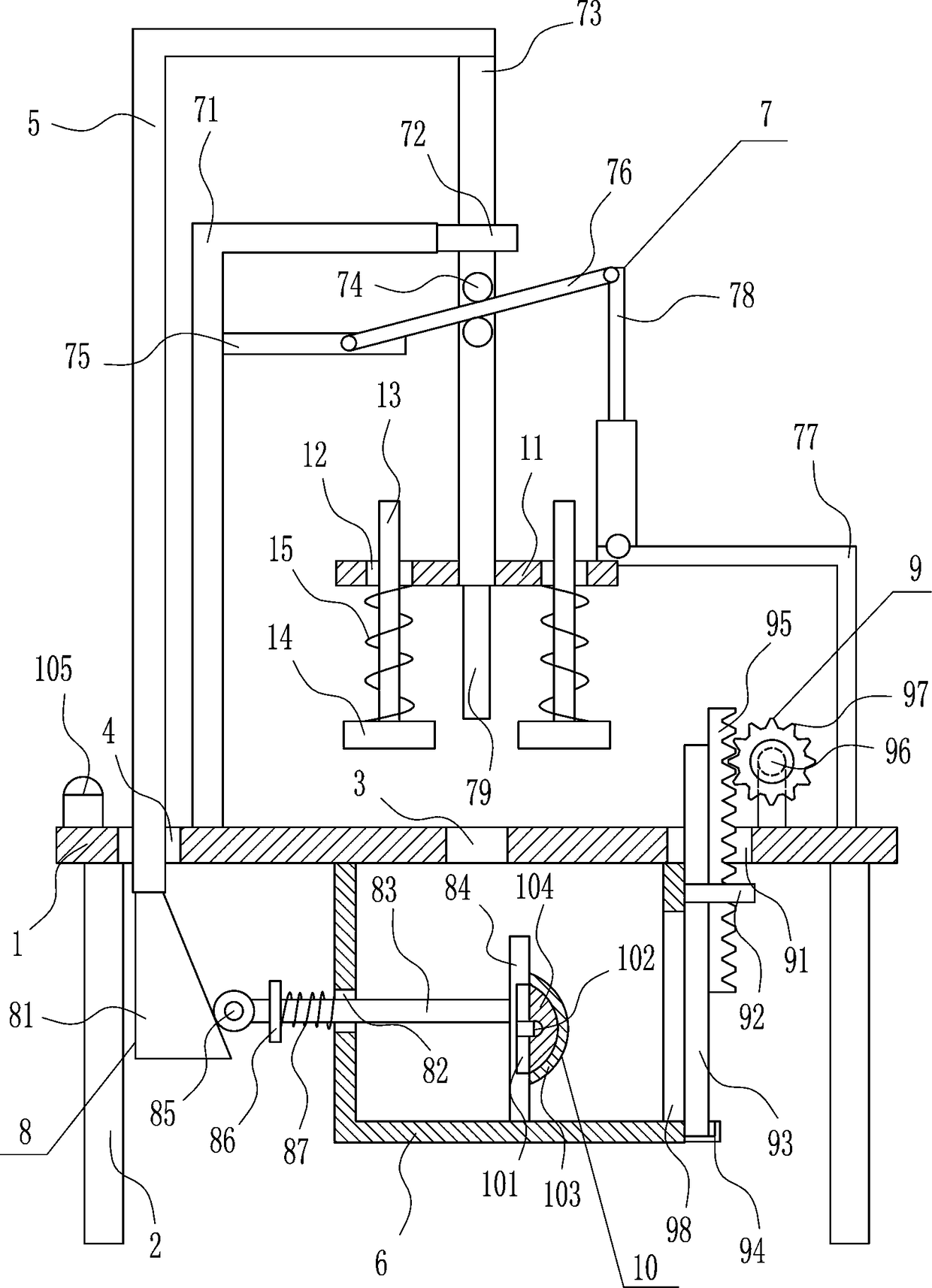

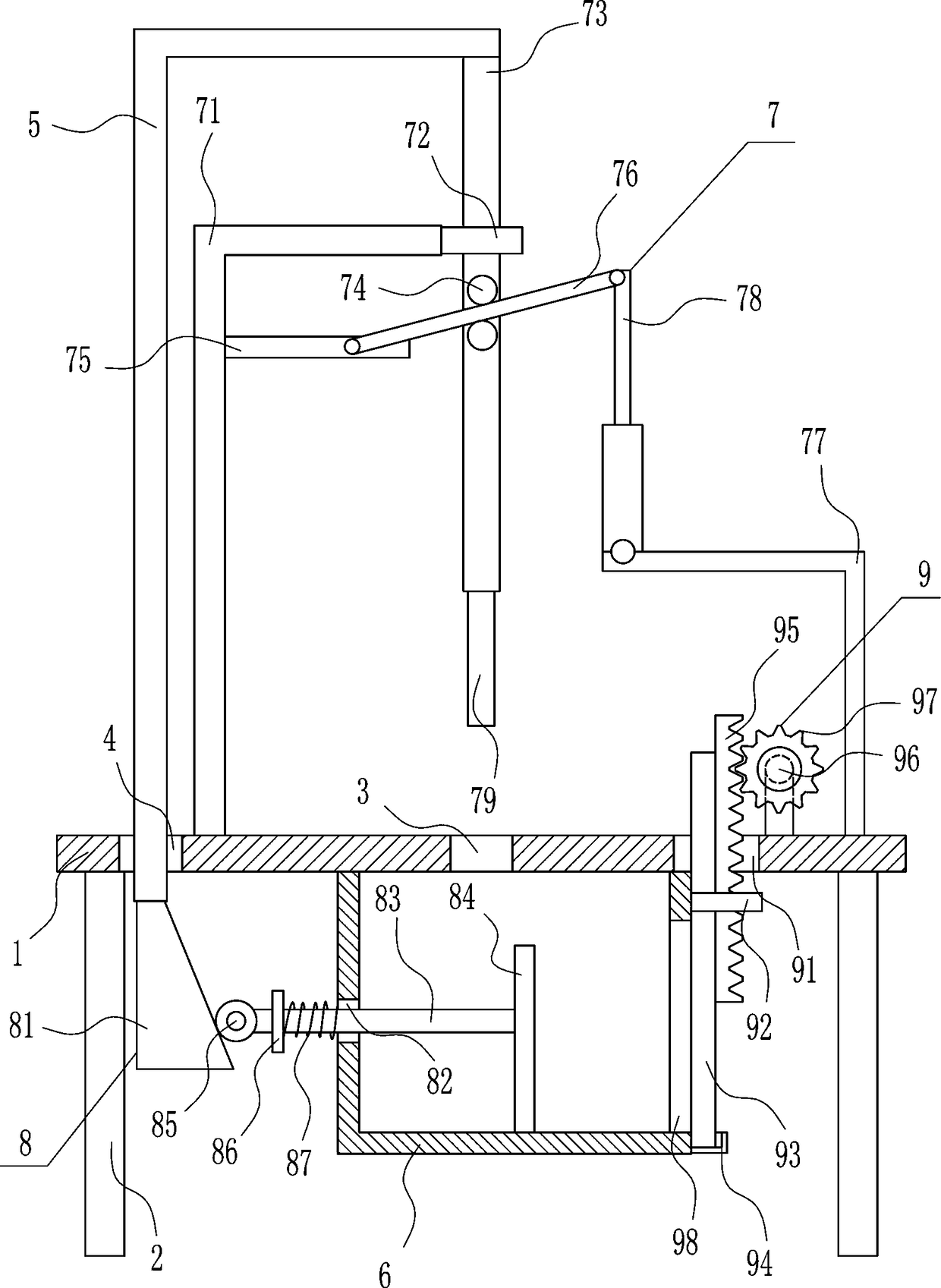

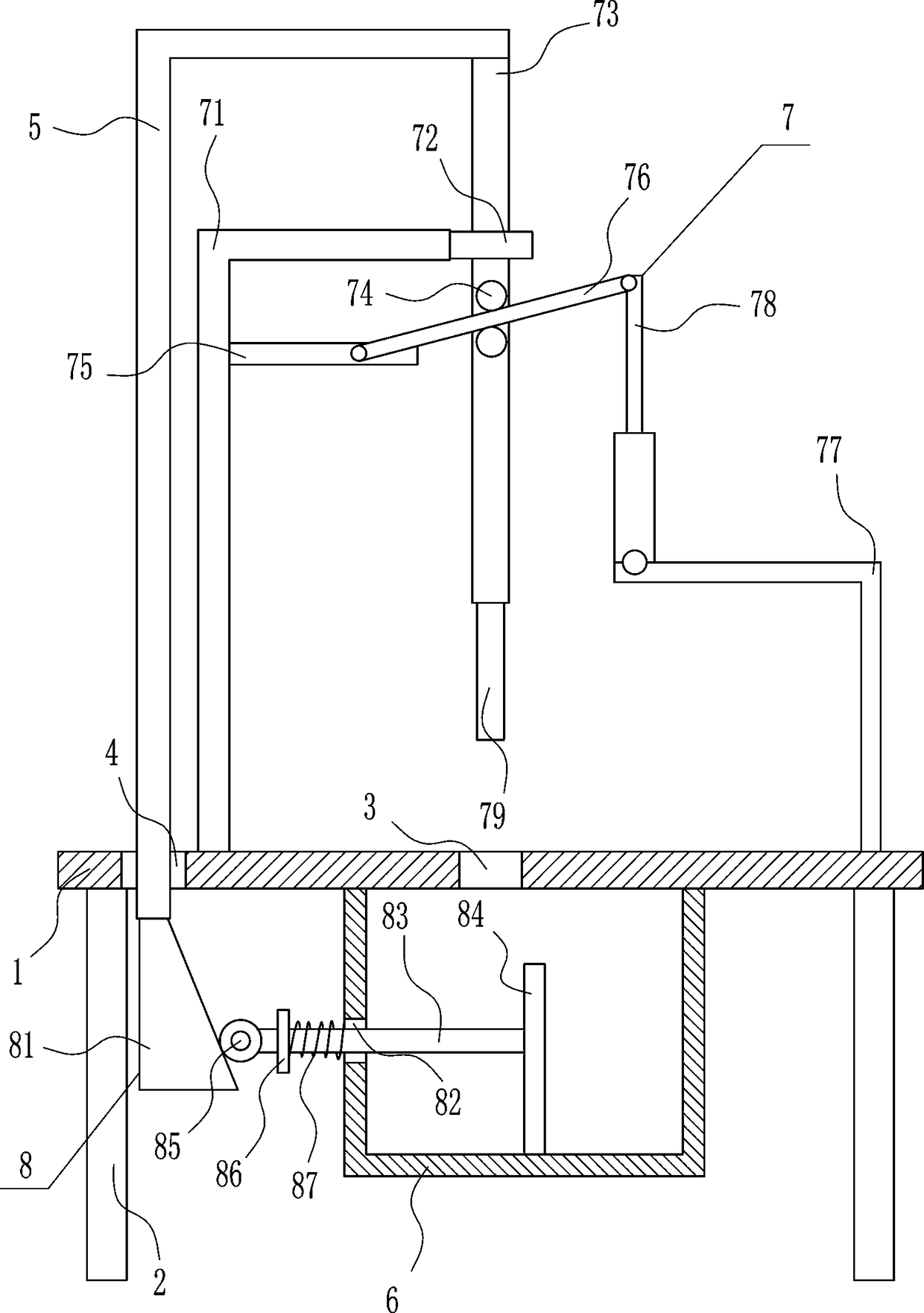

Corrugated board perforating machine for printing factory

InactiveCN108214655AEasy to take outMove up and down steadilyMetal working apparatusPressesCompression deviceEngineering

The invention relates to a perforating machine, in particular to a corrugated board perforating machine for a printing factory. The corrugated board perforating machine for the printing factory has the advantages of being time-saving and labor-saving, high in perforating speed and capable of compressing sundries left after perforation without influencing the surrounding environment. The corrugatedboard perforating machine for the printing factory comprises a containing plate and the like, wherein supporting legs are symmetrically mounted on the left side and the right side of the bottom of the containing plate, a first through hole is formed in the middle of the containing plate, and a second through hole is formed in the left part of the containing plate; and a first 7-shaped plate is arranged in the second through hole, a perforating device is arranged on the right side of the top of the containing plate, and a perforating part of the perforating device is located right above the first through hole. According to the corrugated board perforating machine for the printing factory, through a compression device, the sundries falling during perforating can be compressed, so that people can conveniently process the sundries, and the advantages of being time-saving and labor-saving and high in perforating speed are realized.

Owner:郑文平

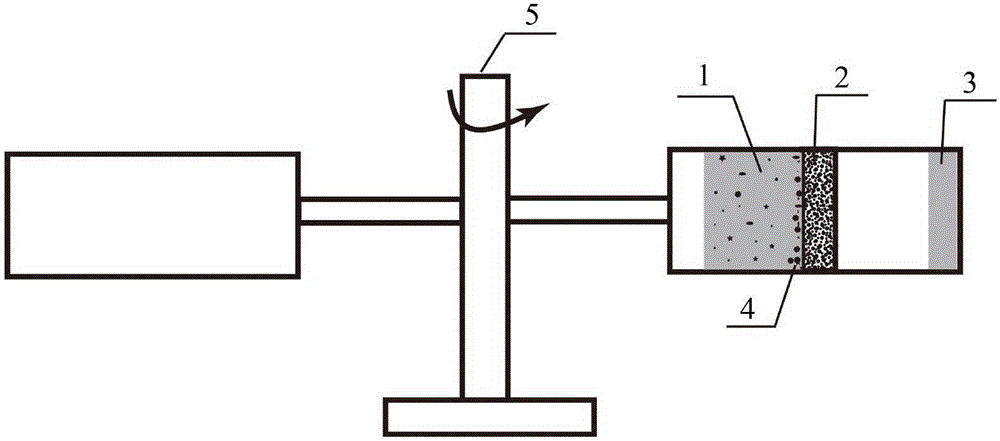

Method for purifying aluminum and aluminum alloy melt through supergravity filtering and recombination

InactiveCN105886789AEfficient separationSimple processProcess efficiency improvementPhysical fieldNon-metallic inclusions

The invention provides a method for removing inclusions in aluminum and aluminum alloy melt through supergravity filtering and recombination. The method belongs to a novel technology for purifying metal melt through a physical field. A supergravity field is produced by utilizing the rotation of a centrifuge, and supergravity filtering treatment is carried out on aluminum melt by adopting a filter. After supergravity filtering, oxide inclusions and impurity elements in the aluminum melt can be thoroughly separated from an aluminum matrix. By utilizing a supergravity filtering and recombination purifying method, non-metallic inclusions and impurity elements in the aluminum and aluminum alloy melt are rapidly removed, and the cleanliness of the aluminum melt is obviously improved. Compared with common filtering in actual production, the method can adopt the filter with a smaller hole diameter in the supergravity field, so that smaller inclusions can be removed without affecting the filtering rate of the melt.

Owner:UNIV OF SCI & TECH BEIJING

Cleaning machine of vegetables

InactiveCN107594577AAffect cleaning effectFood treatmentMoving filtering element filtersEngineeringConveyor belt

The invention relates to a cleaning machine of vegetables. According to the cleaning machine, the effect of cleaning vegetables can be improved. The cleaning machine mainly comprises a cleaning box, wherein a conveyor belt is arranged in the cleaning box; the conveyor belt is hollow; an output end of the conveyor belt is higher than the cleaning box; a sieve plate is arranged in the cleaning box;the sieve plate is arranged in the width direction of the cleaning box; and the sieve plate partially extends into liquid in the cleaning box. According to the technical scheme disclosed by the invention, the sieve plate is arranged at the end adjacent to the output end of the conveyor belt, in the cleaning box; and the sieve plate is partially located under the liquid surface and partially protrudes from the liquid surface, so that when the conveyor belt drives vegetables to extend out from the liquid, impurities floating on the liquid surface are trapped on the side deviating away from the output end of the conveyor belt, of the sieve plate, so that the condition that the foreign substances are stuck to the vegetables when the vegetables extend out from the water to influence the effectof cleaning the vegetables, can be avoided.

Owner:青岛禹璇食品有限公司

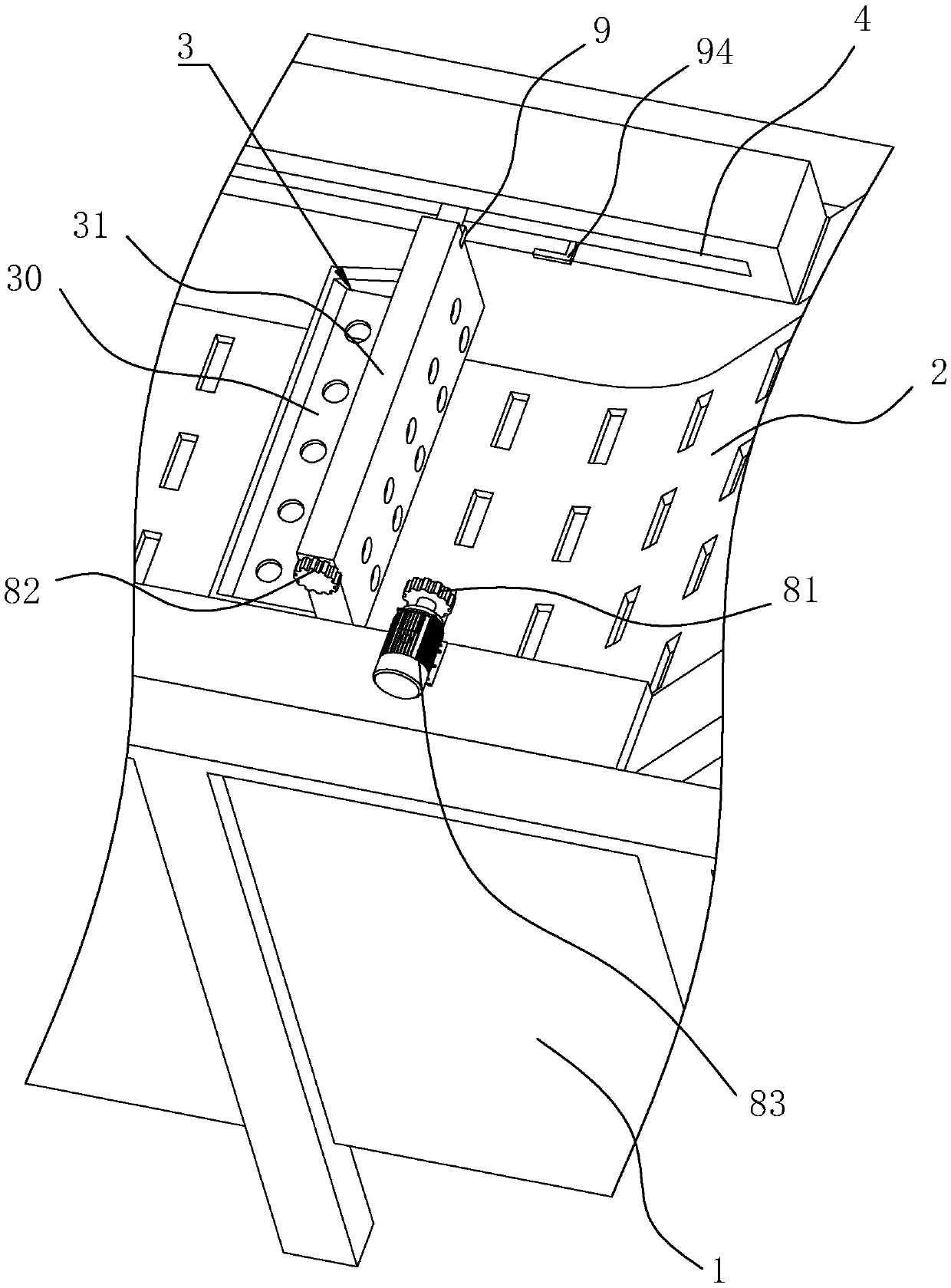

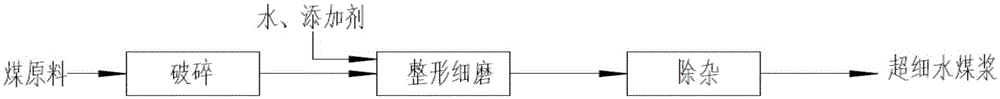

Ultrafine coal water slurry preparation method

InactiveCN105154154AAchieve ultra-fine grindingLarge adjustment range of solid contentLiquid carbonaceous fuelsCoal waterMass ratio

The present invention relates to an ultrafine coal water slurry preparation method, which comprises: (1) crushing a coal raw material to achieve a particle size of less than or equal to 13 mm to obtain a first slurry; (2) mixing the first slurry and water according to a mass ratio of 5-85:15-95 to obtain a second slurry; (3) carrying out wet shaping fine grinding on the second slurry to obtain a third slurry, wherein the particle size of the third slurry is less than 1 mm, and the material having the particle size of less than 45 [mu]m accounts for more than or equal to 80% of the total material; and (4) carrying out screen mesh impurity removing on the third slurry to remove impurities so as to obtain the ultrafine coal water slurry. According to the present invention, with the ultrafine coal water slurry preparation method, the process for preparing the ultrafine coal water slurry by using the material having the single characteristic or a variety of different characteristics as the slurry preparing raw material can be achieved; the solid content in the prepared ultrafine coal water slurry has the large adjusting amplitude and can be adjusted between 30-70 wt%; and the preparation method is the wet ore grinding, and has characteristics of safety, stability and long-period operation.

Owner:CCTEG CLEAN ENERGY CO LTD

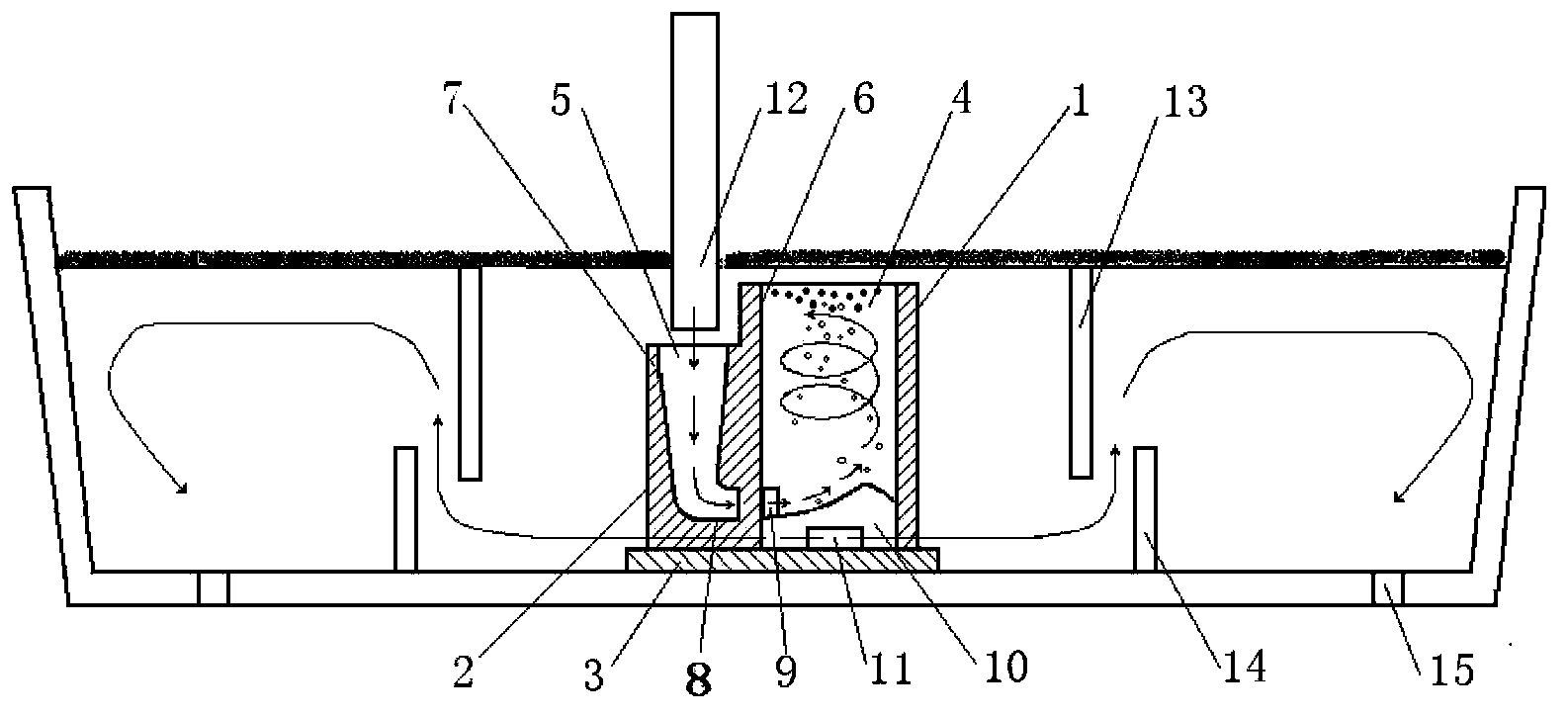

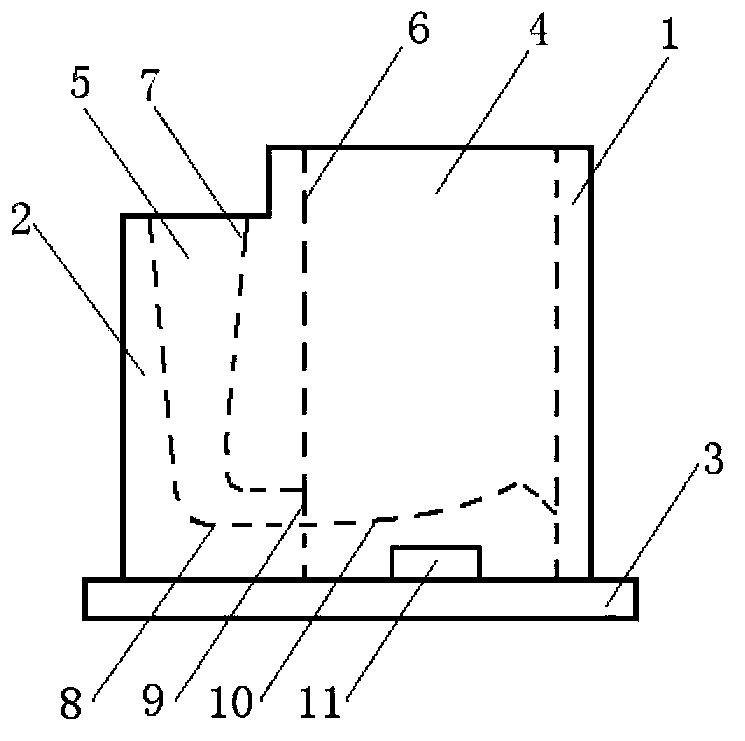

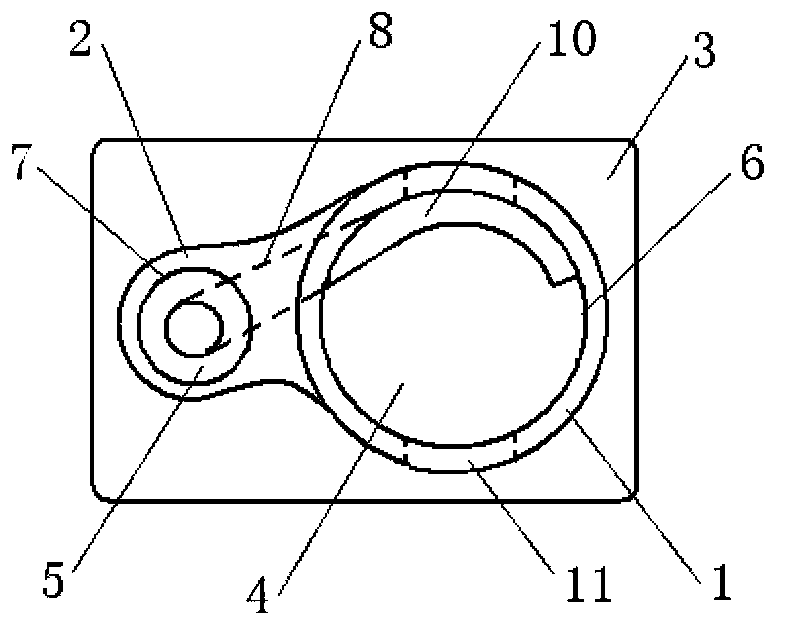

Device and method for purifying molten steel in tundishes

The invention discloses a device for purifying molten steel in tundishes. The device comprises a base, a cyclone portion and a flow guide portion. The cyclone portion and the flow guide portion are fixed to the upper side of the base; the cyclone portion and the flow guide portion are integrally formed, the cyclone portion is provided with an opening hollow inner cavity which is a cyclone cavity; the cyclone cavity is provided with side walls, two symmetric through flow guide ports are formed in the bottom of the cyclone cavity, two symmetric through tangential nozzles are arranged at the bottom of the cyclone cavity, and a slide jump plate is arranged on the lower portion of the cyclone cavity; the flow guide portion is provided with an opening hollow inner cavity which is a flow guide cavity; the flow guide cavity with a thick upper portion and a narrow lower portion is provided with side walls and tangential side walls and is communicated with the cyclone cavity via the tangential nozzles. The device has the advantages that steel slag which flows into the tundishes can quickly float up under the effect of the device, accordingly, slag entrapment can be prevented, large nonmetallic inclusion can be removed, effects of purifying the molten steel in the tundishes can be improved, and the problem of deficiency of devices for efficiently removing inclusion in molten steel and purifying the molten steel in tundishes at present can be solved.

Owner:ANGANG STEEL CO LTD

Mechanical processing method for dry cylinder liners

InactiveCN103769821AReduce weightReduce processing stepsCylinder headsCylindersEngineeringWater jacket

The invention discloses a mechanical processing method for dry cylinder liners. The method comprises the steps: shot blasting before a rough boring process to remove a coating layer and sundries from an external surface, so as to enable the external surface of a cylinder liner blank to be smooth and clean; during rough boring, locating by using a belt of a cylinder liner and the excircle blank surface of a water jacket part, so as to enable a three-point self-centering clamp to locate and clamp the blank excircle of the cylinder liner, and difference in the inner hole wall of the cylinder liner to be controlled within 0.5 mm. The method is adopted to process the dry cylinder liner, the blank weight of the cylinder liner can be reduced by more than 15%, three machining processes are eliminated on the basis of the original process, quality of the shoulder, the excircle and the inner hole of the cylinder liner can be effectively controlled, the passing rate of finished products of cylinder liners is improved to more than 90% from less than 85%, and the manufacturing cost of dry cylinder liners is reduced.

Owner:江苏爱吉斯海珠机械有限公司

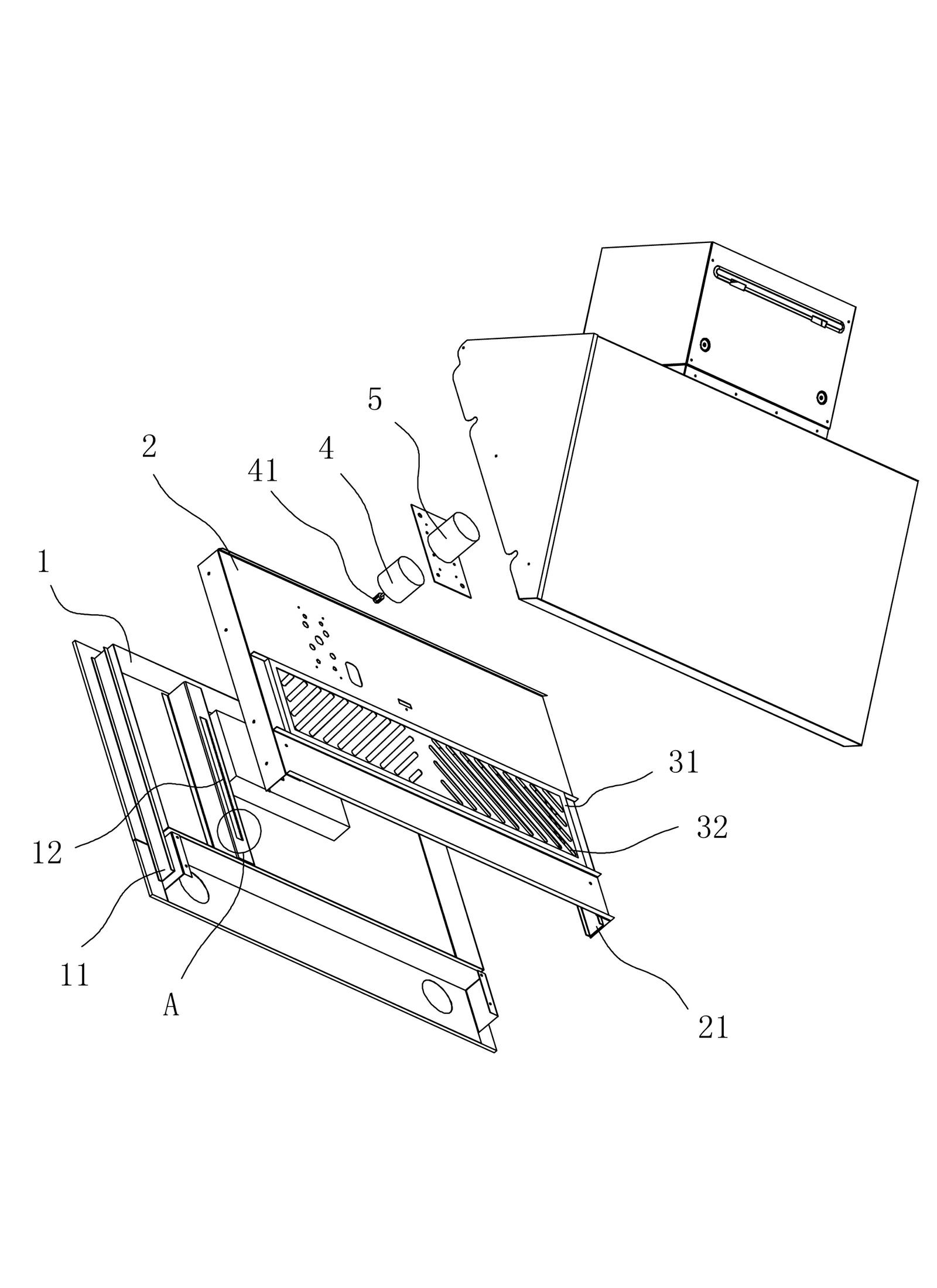

Range hood capable of automatically closing down

InactiveCN102116500AWill not affect work efficiencyAvoid enteringDomestic stoves or rangesLighting and heating apparatusMotor driveForeign substance

Owner:梁雪华

Rain-dirt separation device and rain-dirt separation method

InactiveCN103816715AWon't clogReduce pollution loadMultistage water/sewage treatmentFiltration circuitsParticulatesSeparation technology

The invention relates to the field of a solid-liquid separation technology, specifically to a rain-dirt separation device and its rain-dirt separation method. The method comprises the following steps: a, interflowing sewage enters a cylindrical swirling barrel, flows along the swirling channel and flows along the curved surface of the barrel under tangential acceleration out of an outlet at the bottom; b, the interflowing sewage which undergoes the swirling rotates violently such that heavier foreign materials and particles are aggregated to the center of the eddy flow and are sunken to the bottom of a fine filter cylinder and a clear liquid part flows out of fine filter screen holes at the side wall of the fine filter cylinder; and c, heavier foreign materials and particles enter a coarse filter basket so as to intercept large pieces of foreign materials. According to the invention, dirty rainwater is directly divided into two streams and a pile of foreign materials, namely about 90% of clear rainwater, about 10% of silt-containing sewage and large pieces of foreign materials. And then, separated rainwater enters a river. Thus, pollution load is mitigated greatly, and treatment cost of a sewage plant is low.

Owner:上海纳珂科技有限公司

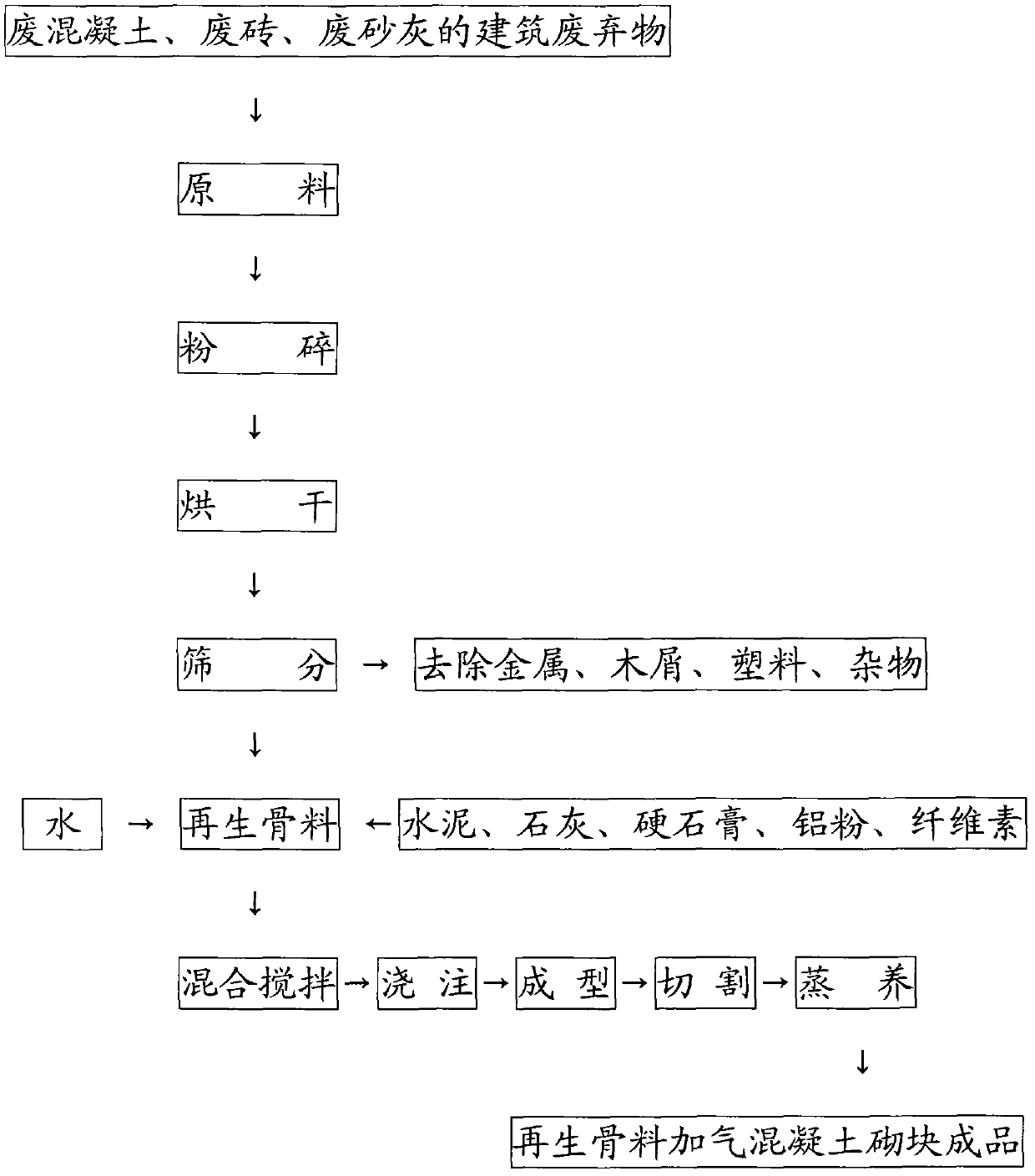

Preparation method of recycled aggregate aerated concrete block

InactiveCN102701779AEffective protectionEffective consumptionSolid waste managementCeramicwareCelluloseBrick

The invention discloses a preparation method of a recycled aggregate aerated concrete block, relating to the technical field of building raw materials.. The method adopts the key technology of'waste utilization', takes the building waste including waste concrete smaller than 690mm, waste bricks and waste lime-sand mortar as raw materials, and comprises the following steps of: fixing the quantity of the raw materials according to the needs; grinding the raw materials and drying until the moisture content is less than or equal to 0.5%; screening to remove metal, wood dust, plastics and impurities to obtain recycled aggregate with the particle size of 0.3-2.36mm; adding cement, lime, anhydrite, aluminum powder, cellulose and water, and mixing; and performing pouring, molding, cutting and steaming to obtain a finished product of the recycled aggregate aerated concrete block which is used as a building raw material. The method disclosed by the invention protects natural resources, saves labor, time and effort, turns waste into wealth, conforms to the requirements of low-carbon production and low-carbon life, and makes contribution to the sustainable development.

Owner:SHENZHEN WEILUN BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com