Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Inclusion control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

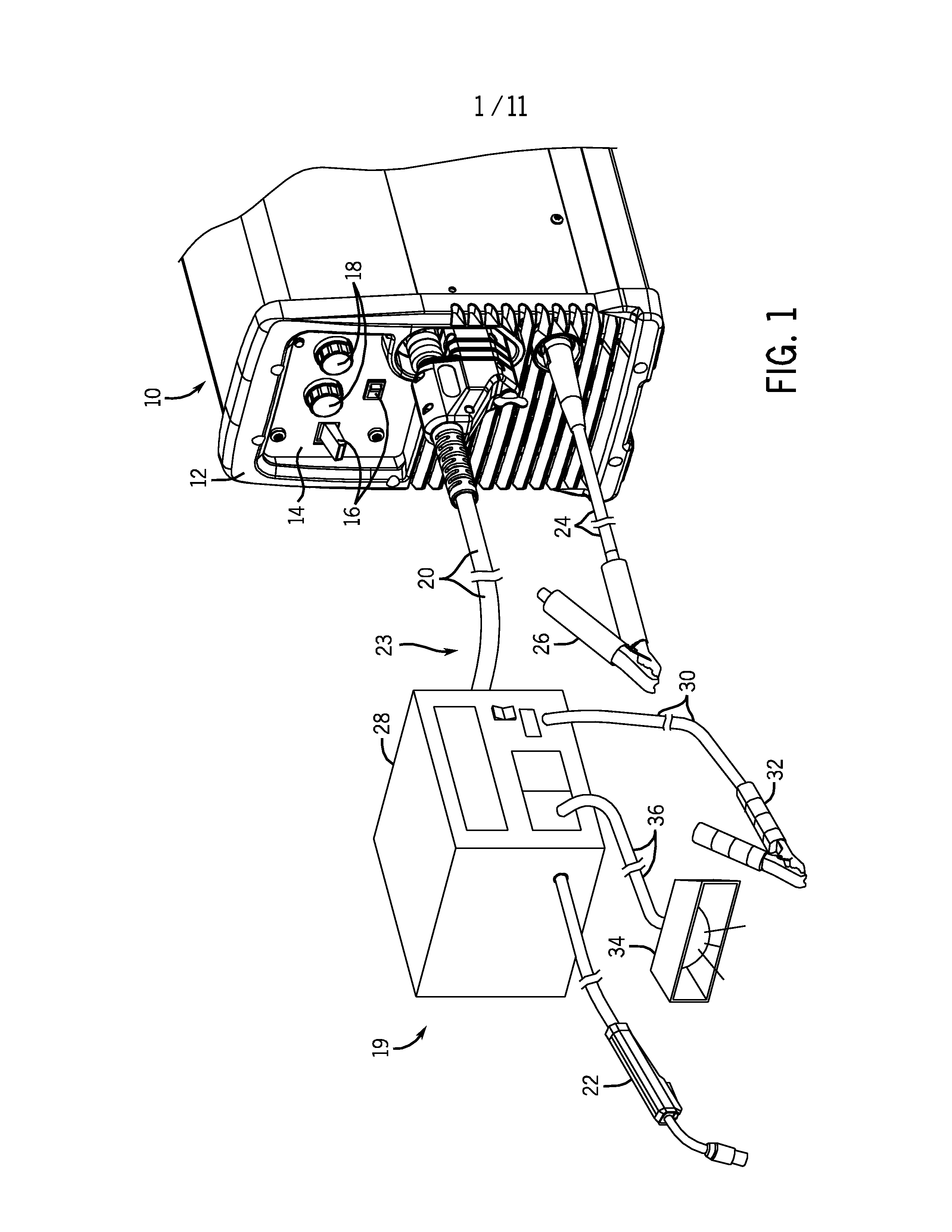

Electric ARC welder and controller to design the waveform therefor

InactiveUS6700097B1Simplified operator manipulationSimplify manipulationArc welding apparatusTelecommunications linkDisplay device

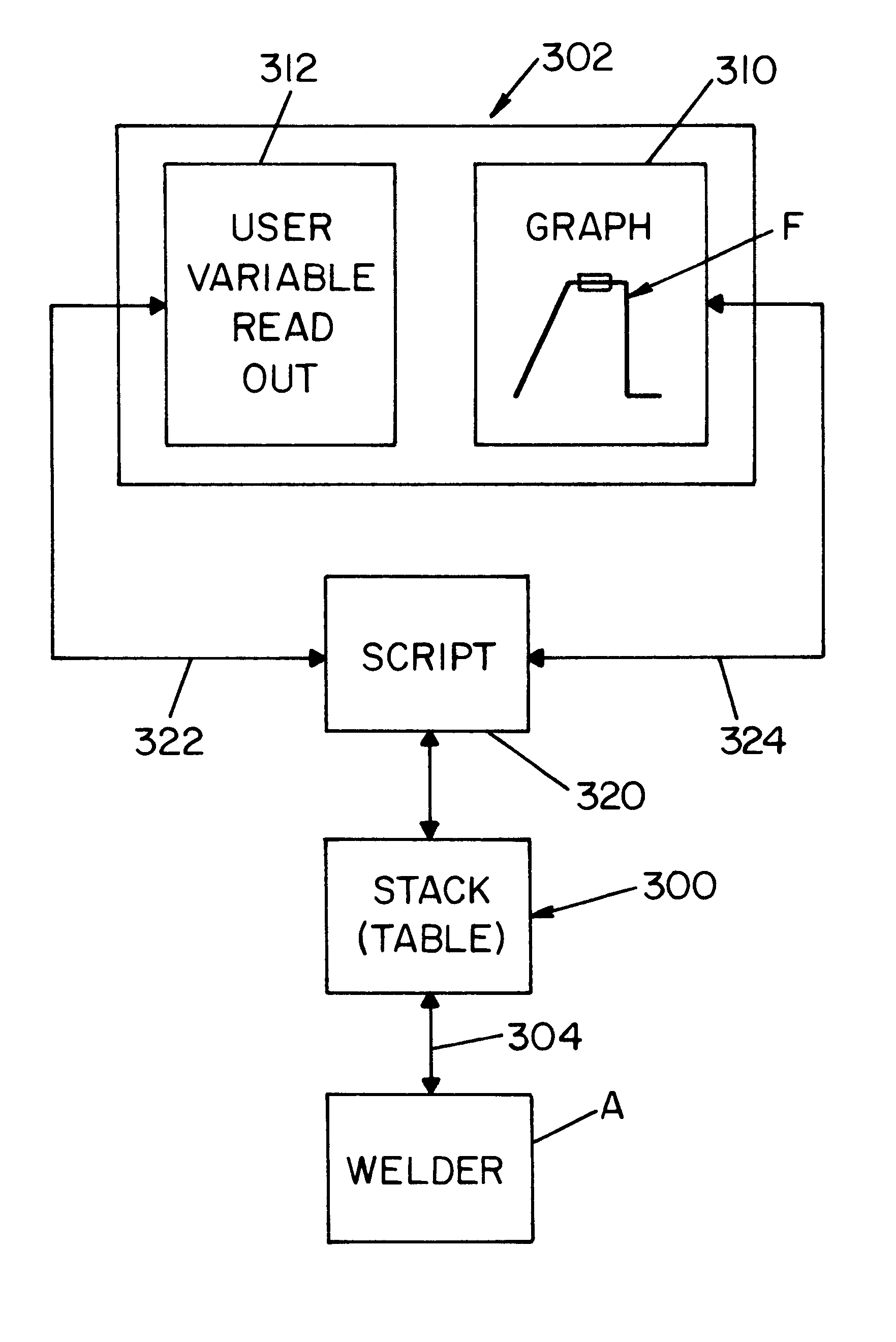

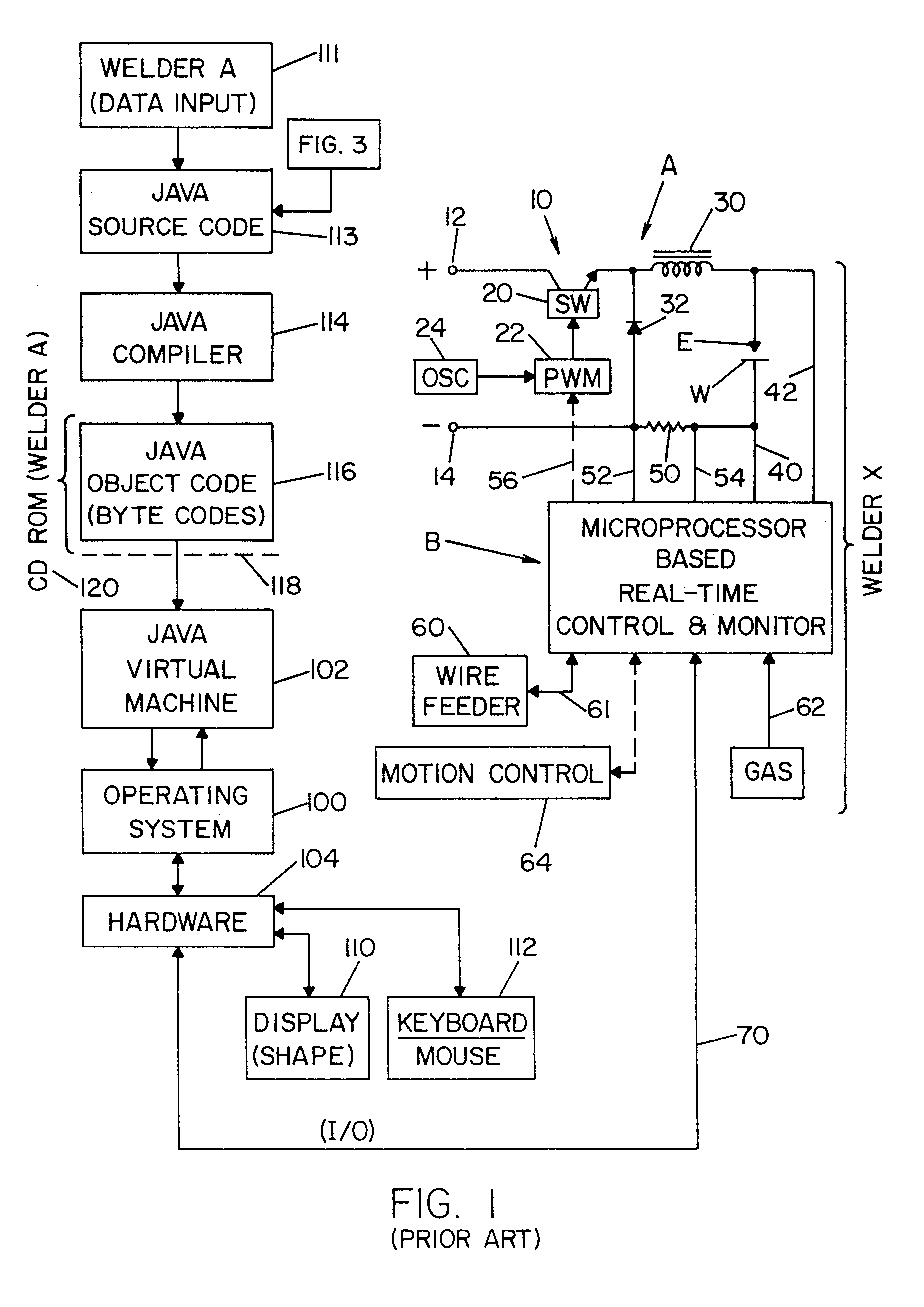

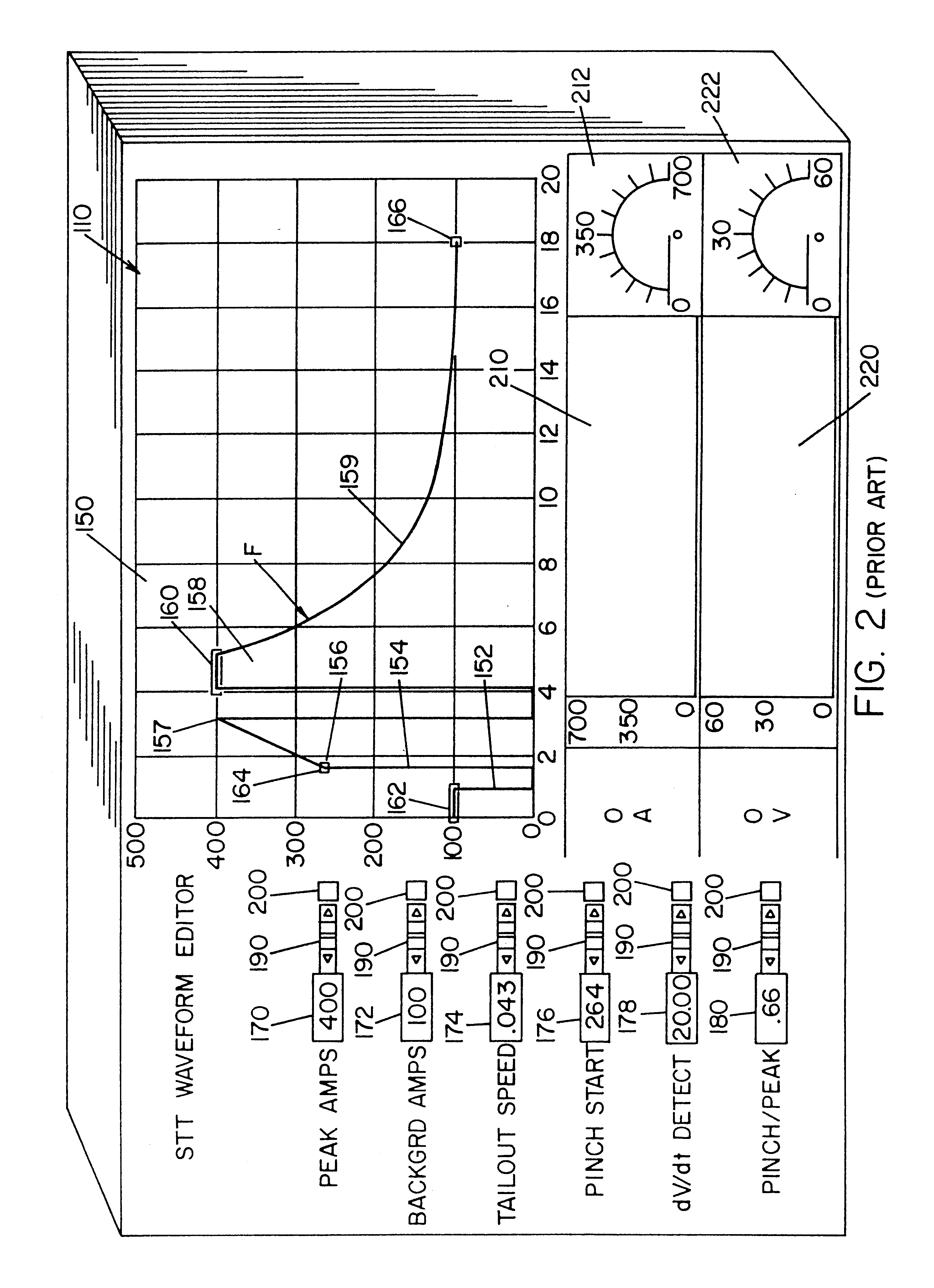

An electric arc welder for creating a welding cycle with a real time current waveform constituting several control parameters by a microprocessor that controls a power supply by a signal so the output of the power supply traces a desired waveform and dynamic reaction behavior to arc conditions defined by the control parameters. The welder has a controller for creating the signal and reading the parameters, a graphic user interface program controlled by input from a graphic user interface computer, a system with a first interface for an interactive display for displaying the desired waveform and dynamic behavior and at least one manipulative control parameter, a second interface for a manual data entry device to change the waveform and / or the parameters and a digital communication link from the graphic user interface to the welder microprocessor controller for causing the welder to perform the desired waveform by controlling the signal. A number of script language files each defining a given type of waveform logic and containing a user manipulative variable table of control parameters and graphical descriptive language to display a waveform to be implemented by the welder is used with an input stage for processing a selected one of the script files into graphic user interface components (readouts, charts, and / or panels) for operating the welder.

Owner:LINCOLN GLOBAL INC

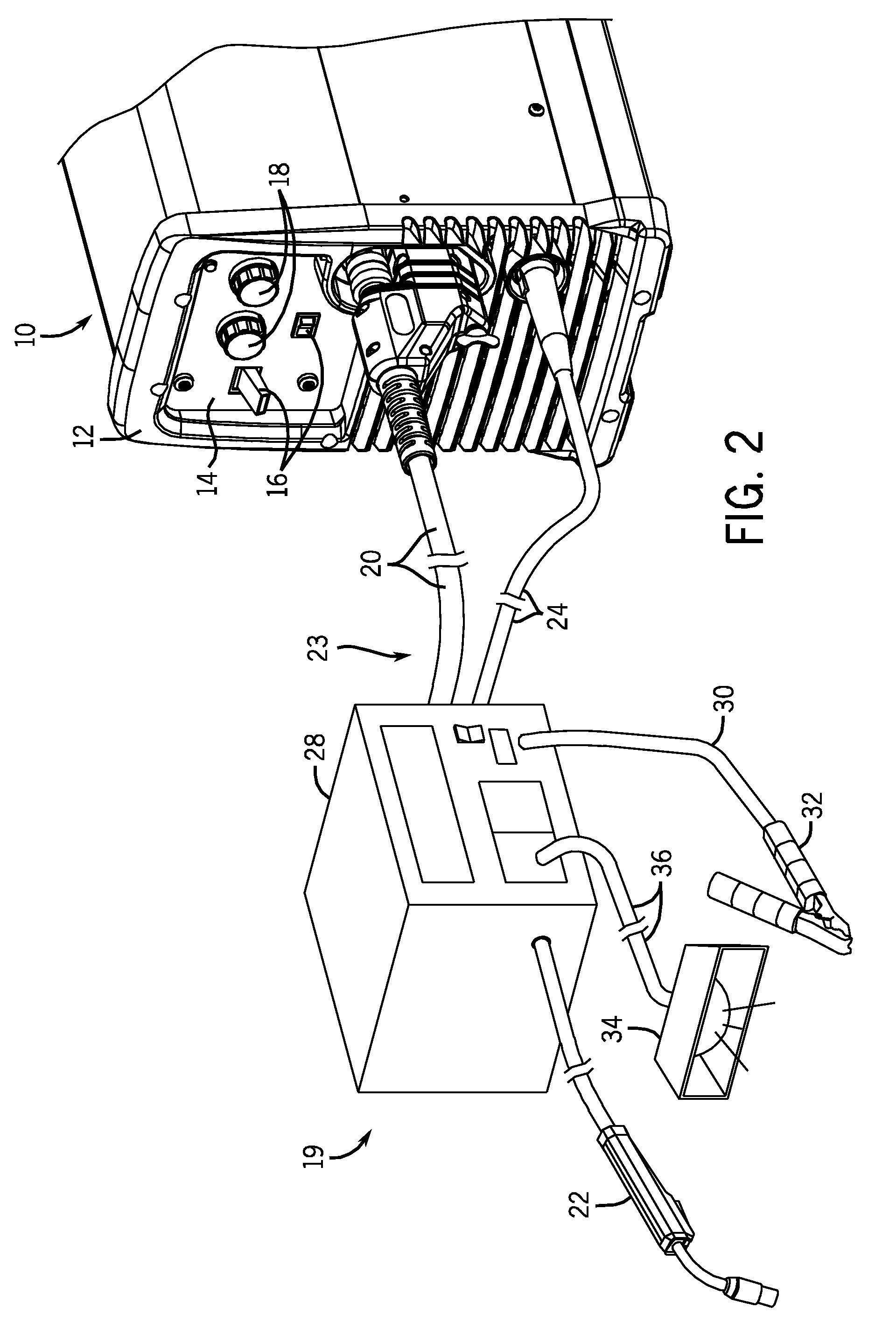

Welding power to auxiliary power conversion system and method

ActiveUS20100320183A1Facilitate easy replacement and transferSufficiently portableArc welding apparatusWelding power supplyAC power

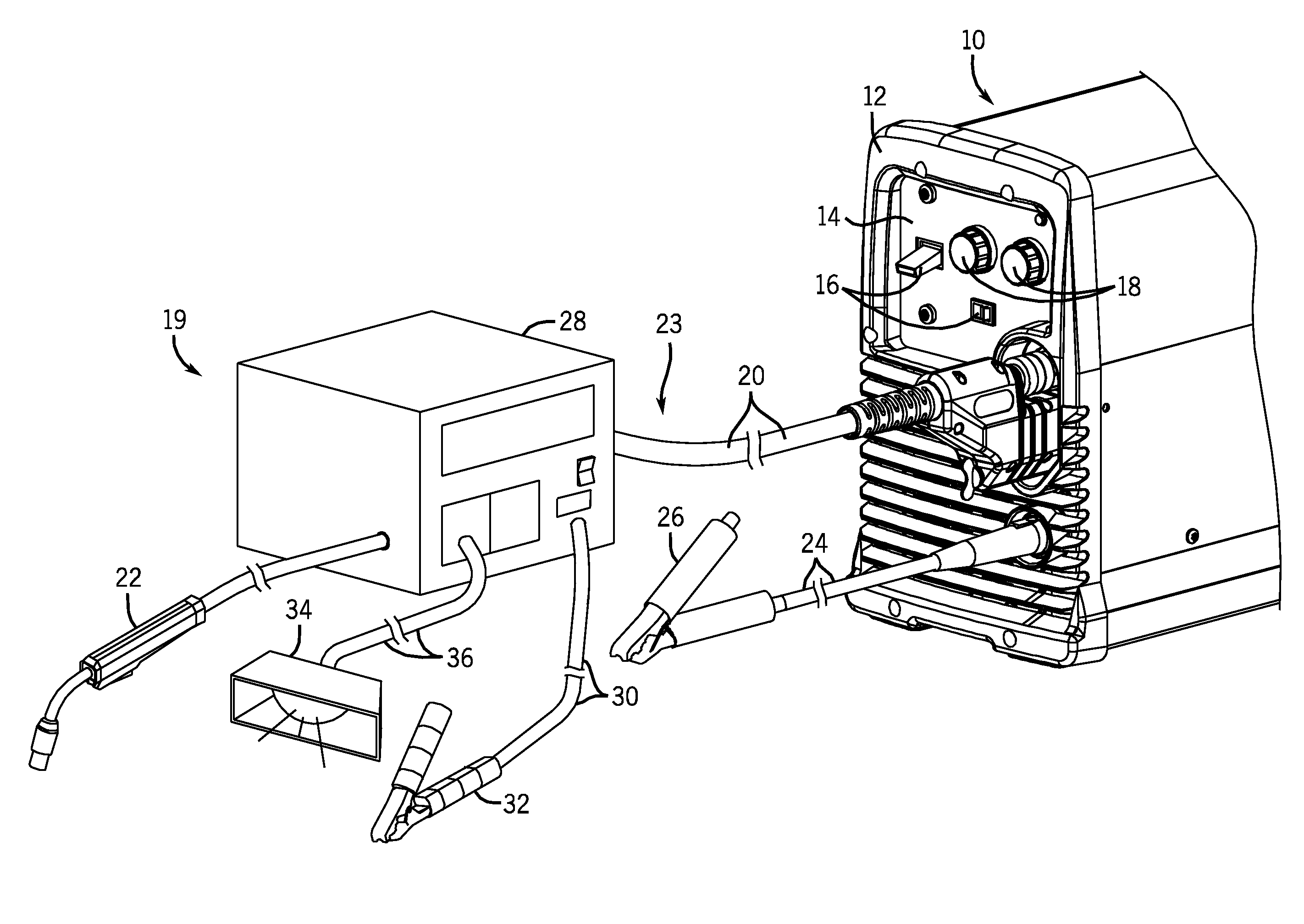

Methods and systems for manufacturing and using the auxiliary power conversion unit, which is capable of being remotely located from a welding power supply unit during a welding operation, are provided. In some embodiments, the auxiliary power conversion is capable of outputting DC as well as AC power, capable of outputting multiple voltages consistent with the demands of typical auxiliary tools, such as a hand grinder or a light. In certain embodiments, the power conversion unit may be a stand-alone system or may be incorporated into a device, such as a wire feeder, which is configured to derive power from the arc potential. The power conversion unit may contain control and processing electronics that may include a controller, a processor, memory, and so forth.

Owner:ILLINOIS TOOL WORKS INC

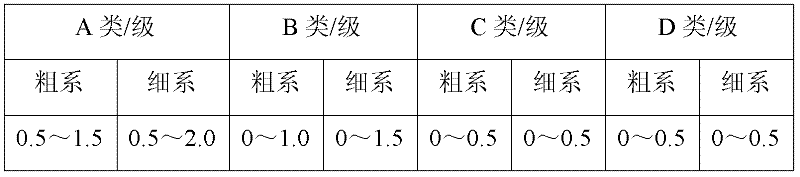

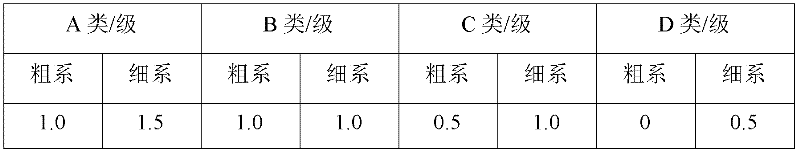

Control method of inclusions in steel

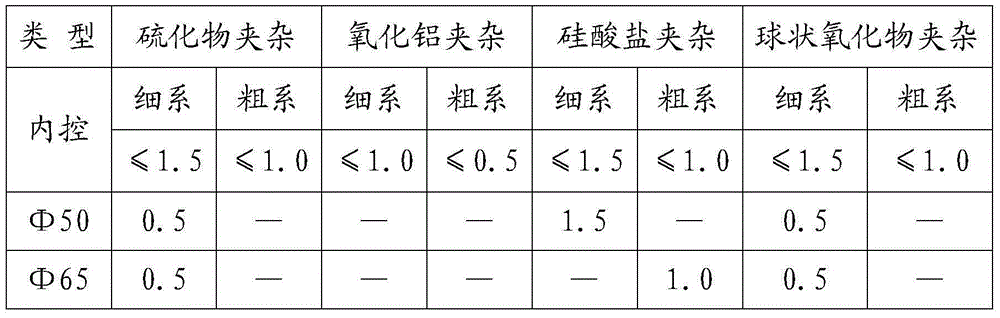

The invention specifically relates to a control method for inclusions in steel, which belongs to the technical field of iron and steel metallurgy. The invention provides the control method for inclusions in steel to reduce the content of inclusions. The control method comprises the following process flow: A, steel making in a converter; B, slag washing for tapoffs; C, LF refining; D, RH vacuum treatment; E, continuous casting. The key step affecting the control of inclusions is to control components of ladle slag, and the step enables effective control and reduction of the content of inclusions; T[O] of steel can be guaranteed to be no more than 20 ppm with simultaneous cooperation of sectional type calcium treatment. Inclusion grades of steel obtained by the inclusion control method provided in the invention are all low and accord with corresponding standard.

Owner:PANZHIHUA IRON AND STEEL +2

Self-Cleaning Well Control Fluid

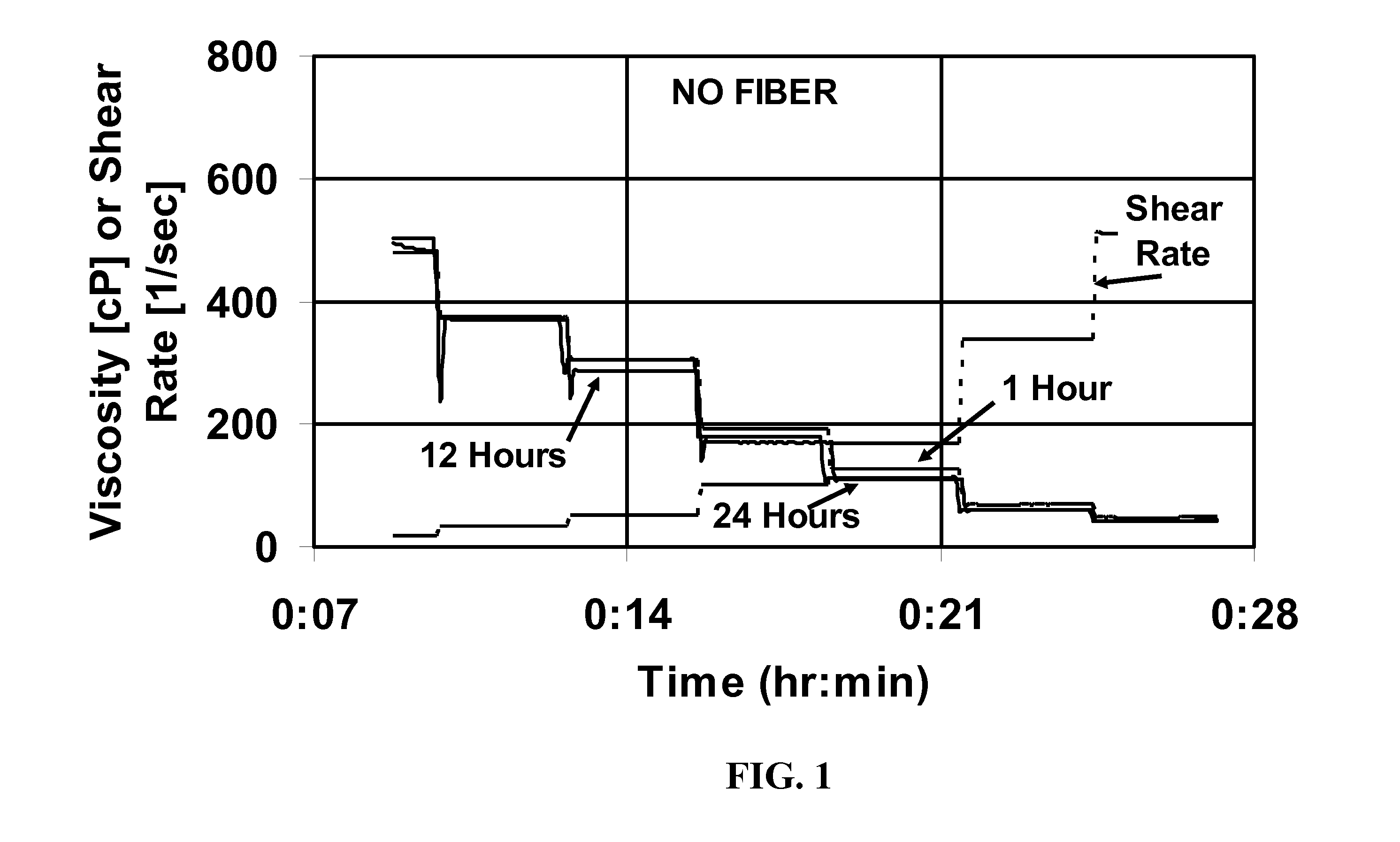

A composition and method is given for a well control fluid that is injected into a well during completion or remediation and prevents fluid flow from a formation into the well during operations (such as shut-in, or placement or adjustment of tools / hardware) when no fluid flow is desired. The composition includes a viscoelastic surfactant fluid system (VES) and a decomposable first solid material, preferably in fiber form, that forms a pack or plug in the well at the location where fluid would otherwise leak off, and then decomposes without intervention to release a product that is a breaker for the surfactant or the micelles of the VES. The composition optionally also contains a pH control agent and a second solid (that may also be a fluid loss agent) that affect the decomposition of the first solid.

Owner:SCHLUMBERGER TECH CORP

Method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb

InactiveCN105200349AImprove corrosion resistanceReduce hardnessManufacturing convertersProcess efficiency improvementChemical compositionSmelting process

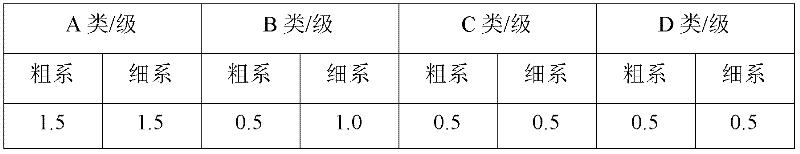

The invention discloses a method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb, wherein the method comprises the following steps: 1) reasonably determining the chemical composition and the inclusion control level of round steel 09CrCuSb; 2) determining the revolving furnace smelting process and N, H and O gas contents; 3) formulating an appropriate continuous casting secondary cooling schedule to make a casting blank keep away from a cracking temperature in a straightening zone, reasonably adopting crystallizer cooling water parameters and vibration negative slip parameters, and controlling casting blank surface cracks; and 4) determining a reasonable heating schedule and a rolling process, choosing low temperature for fast sintering, and reasonably distributing materials, so as to reduce enrichment of Cu elements on the steel surface and avoid the round steel from generating star-shaped cracks; and by controlling the rhythm of steel rolling, avoiding scratches of the round steel surface. By adding alloy elements such as Cr, Cu and Sb, a passivation film is formed on the steel surface; by formulating reasonable smelting, continuous casting and steel rolling processes, the round steel composition is effectively ensured, corrosion resistance can conform to relevant standards and requirements; and through the process, generation of the cracks of the copper-containing steel is avoided.

Owner:TIANJIN IRON & STEEL GRP

Inclusion control method of Si-Mn-killed non-oriented silicon steel

ActiveCN108660294AOxygen Potential StabilizationReduce oxidationProcess efficiency improvementMetallic aluminumNon-metallic inclusions

The invention provides an inclusion control method of an Si-Mn-killed non-oriented silicon steel, and belongs to the technical field of steel smelting. The non-oriented silicon steel comprises the following chemical components: not greater than 0.005% of C, 0.4-1.0% of Si, 0.20-0.80% of Mn, not greater than 0.04% of P, not greater than 0.005% of S, not greater than 0.005% of Als, and the balance Fe and inevitable impurities. The method comprises the processes of smelting through a converter, refining under RH and vacuum, and continuously casting; the slag amount of the steel from the converteris strictly controlled; lime, synthetic slag and calcium carbide are added to adjust the slag; the refining under HR and vacuum is that a deep decarbonization mode is carried out; after decarbonization, metallic aluminum is added to realize preliminary dexidation, and SiC is added to the ladle slag surface at the same time in order to deoxidize and modify the slag; the operation is circulated for1-3min; then low-carbon low-titanium ferrosilicon is added to realize Low carbon, low titanium ferrosilicon; the operation is circulated for 3-6min, then manganese metal, ferrophosphorus and the likeare added to alloy, and the net circulating time is beyond 8min after alloying. With the adoption of the method, the composition of nonmetal inclusions in the steel can be improved, so that the performances of the non-oriented silicon steel can be improved, and the foundation is supplied to develop high-performance non-oriented silicon steels.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

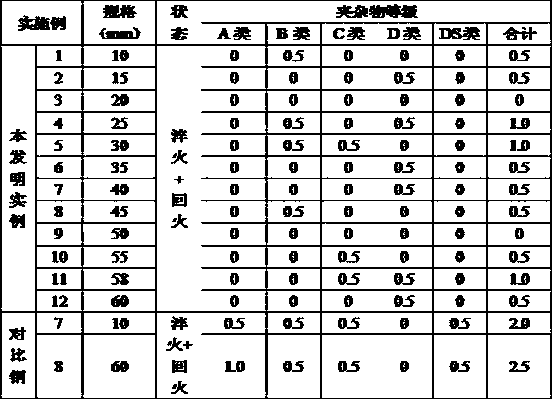

Inclusion control method for rod and wire alloy steel

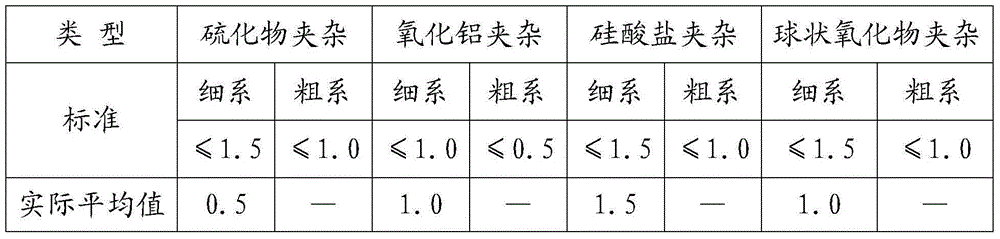

The invention relates to the technical field of metallurgy, in particular to an inclusion control method for rod and wire alloy steel, which solves the problem of inclusion standard exceeding of the rod and wire material alloy steel, improves the molten steel cleanness and improving the molten steel casting performance. The method has the technical scheme that a production process of converter smelting, laser fusion (LF) refining, relative humidity (RH) refining and square blank continuous casting is adopted, the molten steel is subject to the calcium treatment after the LF refining completion during the production, and the RH treatment is then carried out after the soft blowing. The concrete steps are as follows: (1) the molten steel smelted by the converter is deoxidized by aluminum; (2) calcium wires are fed into the molten steel after the LF refining completion; (3) argon soft flowing is carried out on the molten steel after the wire feeding completion; (4) the molten steel is subject to RH vacuum treatment; (5) argon soft flowing is carried out on the molten steel after the RH vacuum treatment completion; and (6) tundish covering agents are added, and the continuous cast steel long nozzle argon blowing protection casting is adopted. The inclusion control method has the advantages that the production cost is greatly saved, and in addition, the inclusion grade is obviously reduced through being compared with that of the original process.

Owner:NORTHEASTERN UNIV +1

Control method for plasticization of tire cord steel inclusion

The invention discloses a control method for plasticization of a tire cord steel inclusion, and belongs to the technical field of steel and iron smelting. The method comprises the following process steps of: performing a catch carbon process at an end point of a converter, wherein the mass fraction of end point carbon is 0.1-0.4 percent; performing deoxidization alloying on Si-Fe and Mn-Fe alloy during tapping of the converter, wherein 1.0-3.0 kg of Si-Fe alloy is added per ton of steel, and 3.0-6.0 kg of Mn-Fe alloy is added per ton of steel; adding ferrosilicon powder into the top of slag during LF ladle furnace refining, wherein the 0.5-1.5 kg of ferrosilicon powder is added per ton of steel; feeding 0.1-0.5 kg of magnesium wire per ton of steel into a ladle; and blowing argon to the ladle in two stages. The method has the advantages that: the special magnesium or zirconium ladle is not required any longer during production of tire cord steel; meanwhile, the inclusion control levelwhich meets the production requirement is achieved; and thus, the production cost per ton of steel is reduced, and the economic benefit is increased.

Owner:SHOUGANG CORPORATION

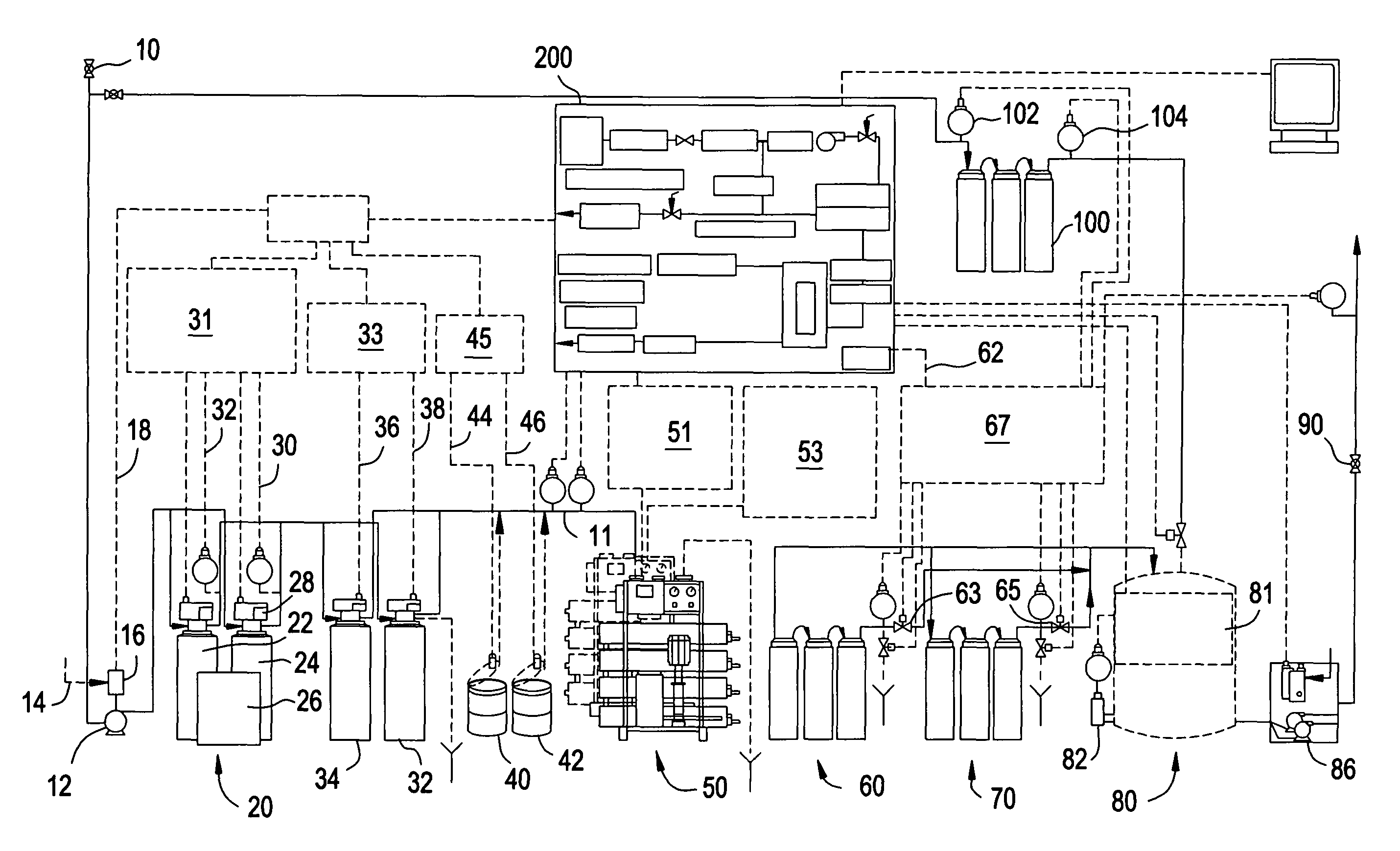

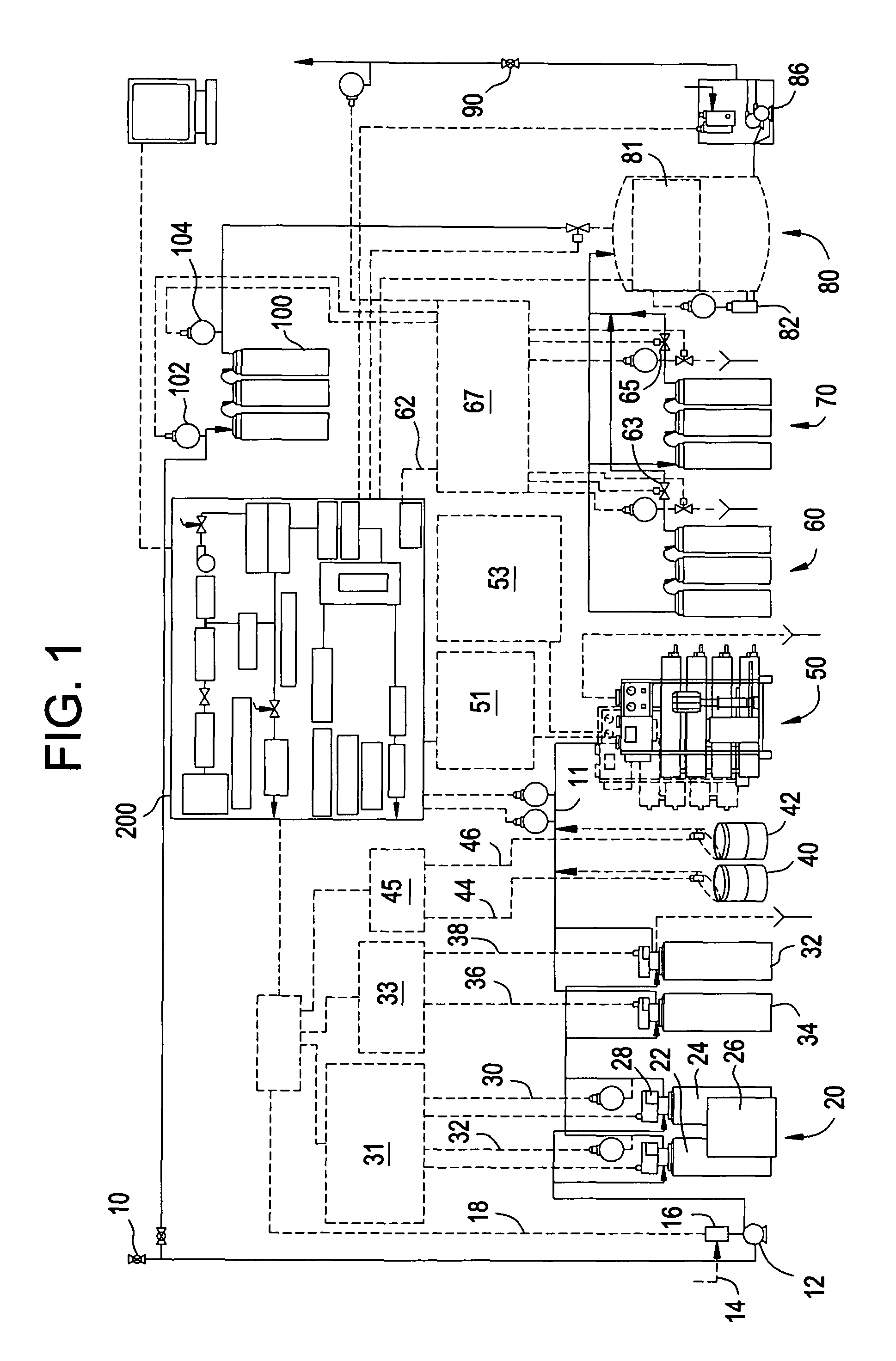

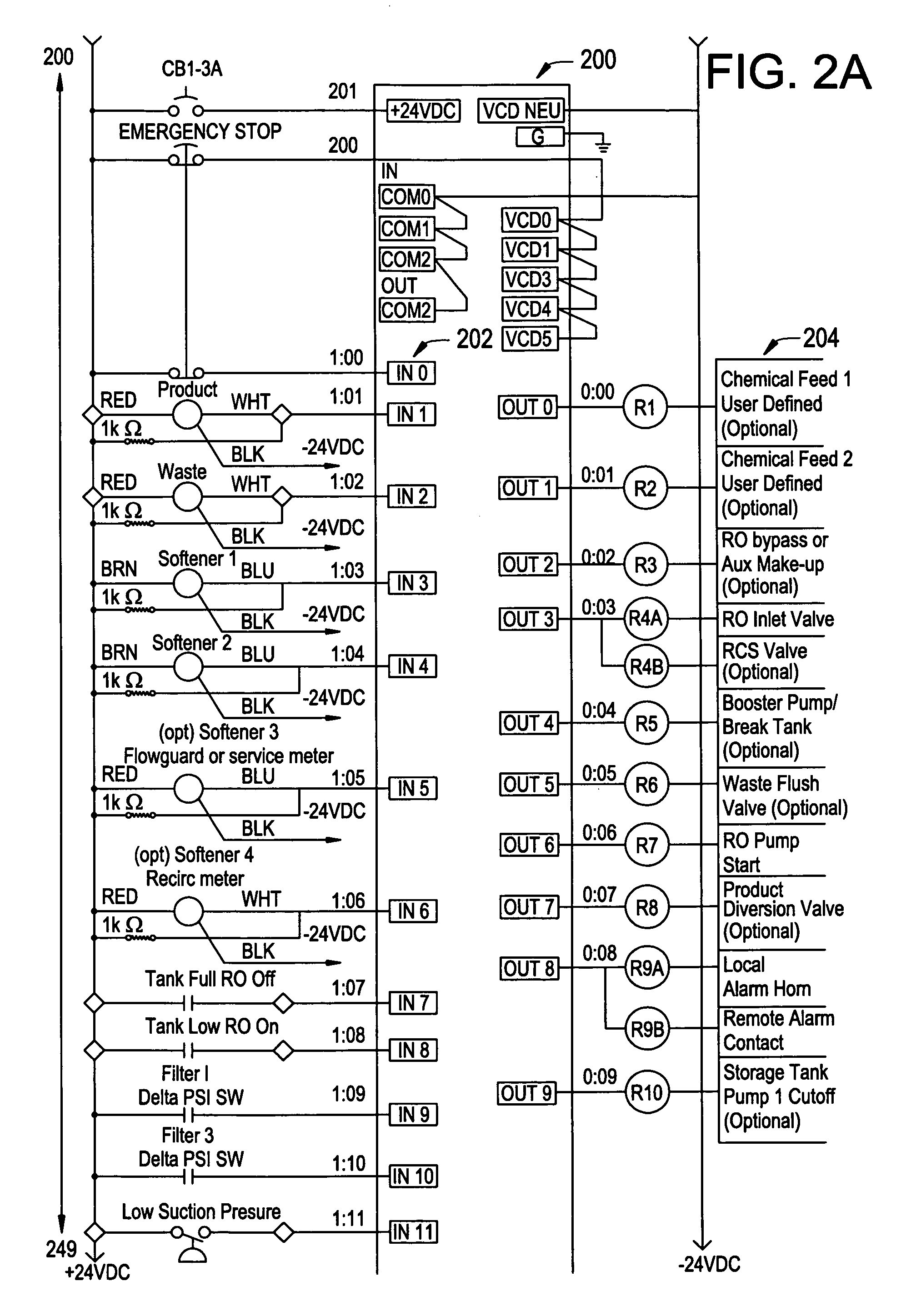

Method of integrating water treatment assemblies

ActiveUS8518262B2Effective installationEfficient manufacturingSolid sorbent liquid separationReverse osmosisElectricityControl signal

A method of integrating individual water treatment assemblies into a seamless water treatment control system. A Reverse Osmosis assembly contains a controller wherein all other pretreatment and post-treatment assemblies are electrical coupled thereto. The controller is preprogrammed for use in recognizing the coupling of the pretreatment and / or post treatment assemblies wherein and for receiving all control commands for operation thereof. The controller employs cells that allows and installer to interconnect assemblies by coupling low voltage control signal wiring having predefined inputs, set up as PnP, or by use of a personal wireless network.

Owner:NALCO CROSSBOW WATER +1

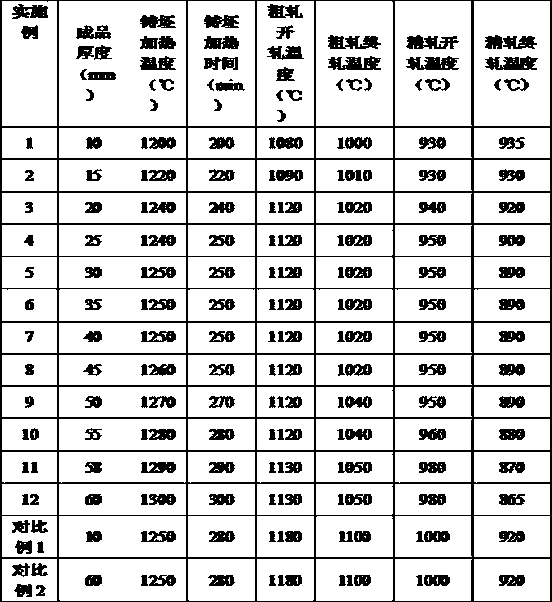

High-carbon steel wire rod inclusion control method

The invention provides a high-carbon steel wire rod inclusion control method. The method comprises converter treatment, refining, continuous casting, continuous rolling and wire rod rolling. In converter treatment, high-carbon steel is produced and after converter treatment, silicomanganese deoxidation is carried out. A LF refining temperature is in a range of 1550-1640 DEG C, refining time is in a range of 60-80min, sulfur content of a steel liquid at the refining finished point is in a range of 0.016-0.025%, oxygen activity is in a range of (10-30)*10<-6>, steel liquid acid-insoluble aluminum content is in a range of 0.0005-0.0025% and titanium content is less than or equal to 0.0010%. In continuous rolling and wire rod rolling, the steel wire rod diameter is in a range of 5-5.5mm, a spinning temperature is in a range of 880-910 DEG C and after spinning, a steel wire rod is fast cooled to 600-650 DEG C. The high-carbon steel wire rod obtained by the method contains fine oxide impurities. In steel wire rod drawing, the sulfide inclusion outside the oxide inclusion can cooperate with matrix deformation so that micro-cracks at two ends of the oxide impurity are prevented and finished product processing performances are improved.

Owner:ANGANG STEEL CO LTD

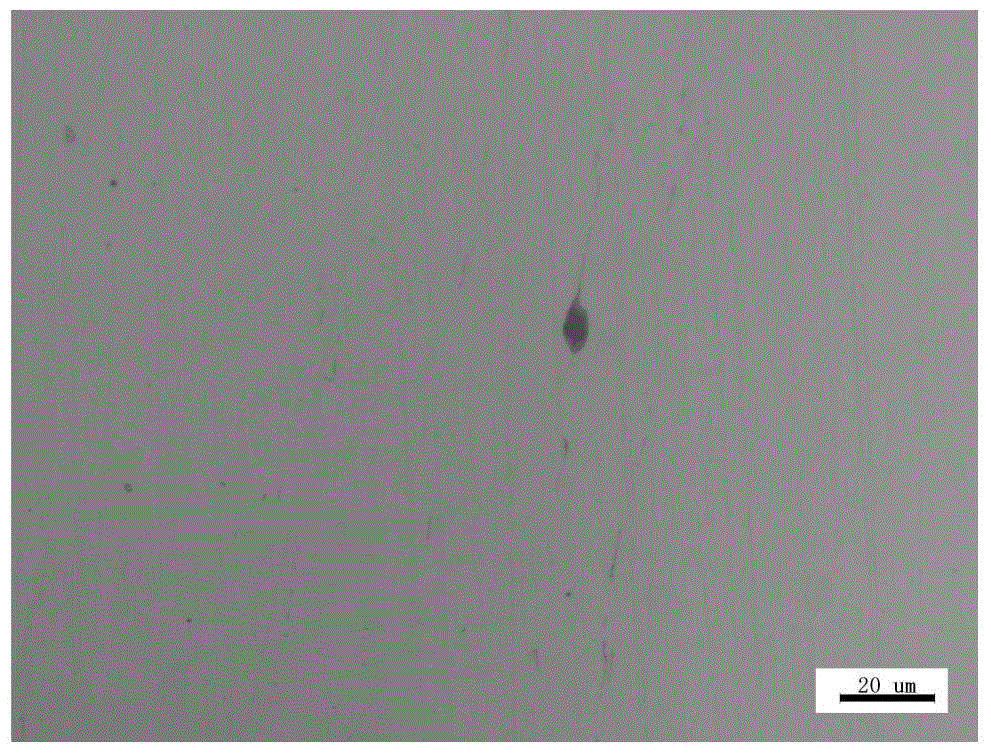

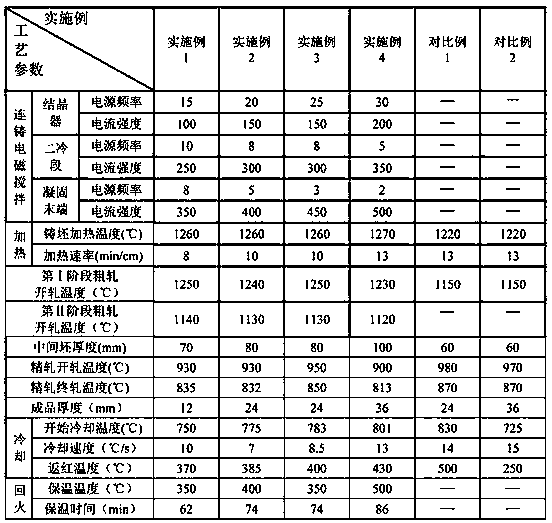

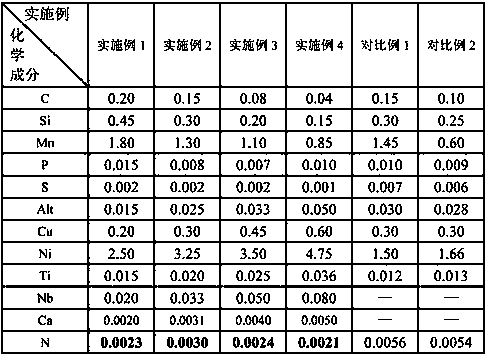

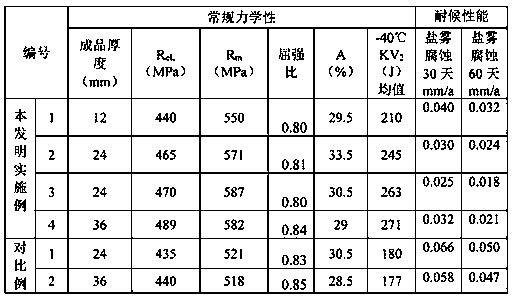

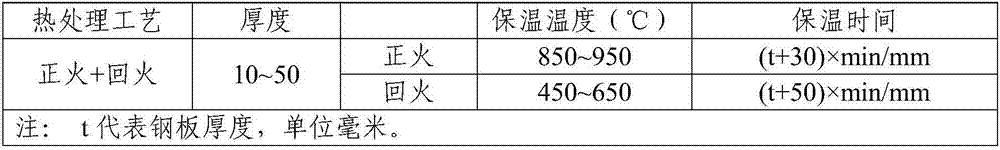

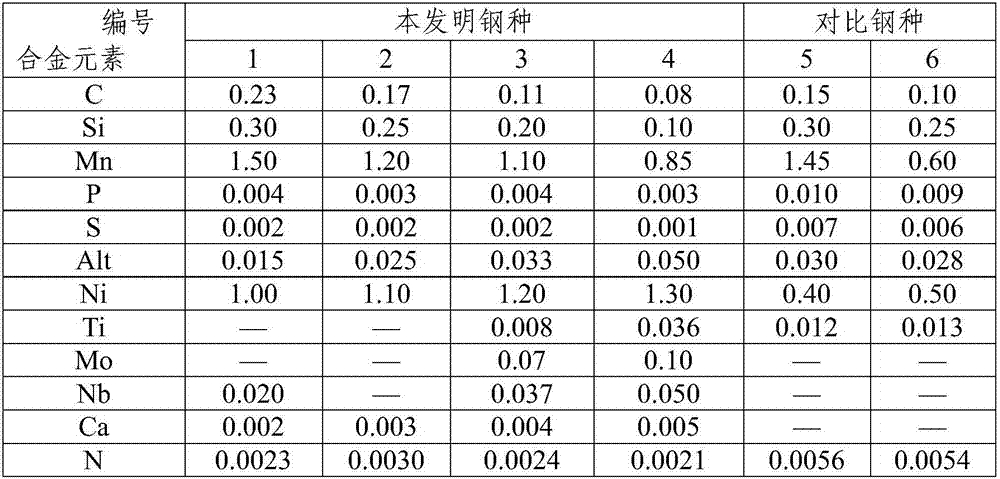

420 MPa grade low yield strength ratio resistance to marine atmospheric corrosion bridge steel and production method thereof

ActiveCN109136752AImprove low temperature impact toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesChemical compositionImpurity

The invention discloses a steel 420MPa grade low yield ratio marine atmospheric corrosion resistant bridge and a production method thereof, the steel comprises the following chemical components in percentage by mass: 0.04-0.20% of C, 0.15-0.45% of Si, 0.85-1.80% of Mn, 0.015-0.050% of Alt, 2.50-4.75% of Ni, 0.20-0.60% of Cu, 0.020-0.080% of Nb, 0.015 to 0.036 percent of Ti, 0.0020 to 0.0050 percent of Ca, less than or equal to 0.020%of P, less than or equal to 0.002%of S, less than or equal to 0.004%of N and the balance of Fe and other inevitable impurities; after the steel of passes the composition design, the inclusion control, the controlled rolling , the controlled cooling and heat treatment, the steel has the advantages of high strength, low yield strength, and can be used for manufacturing various bridges under the ocean atmospheric environment, and the safety of use is greatly improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

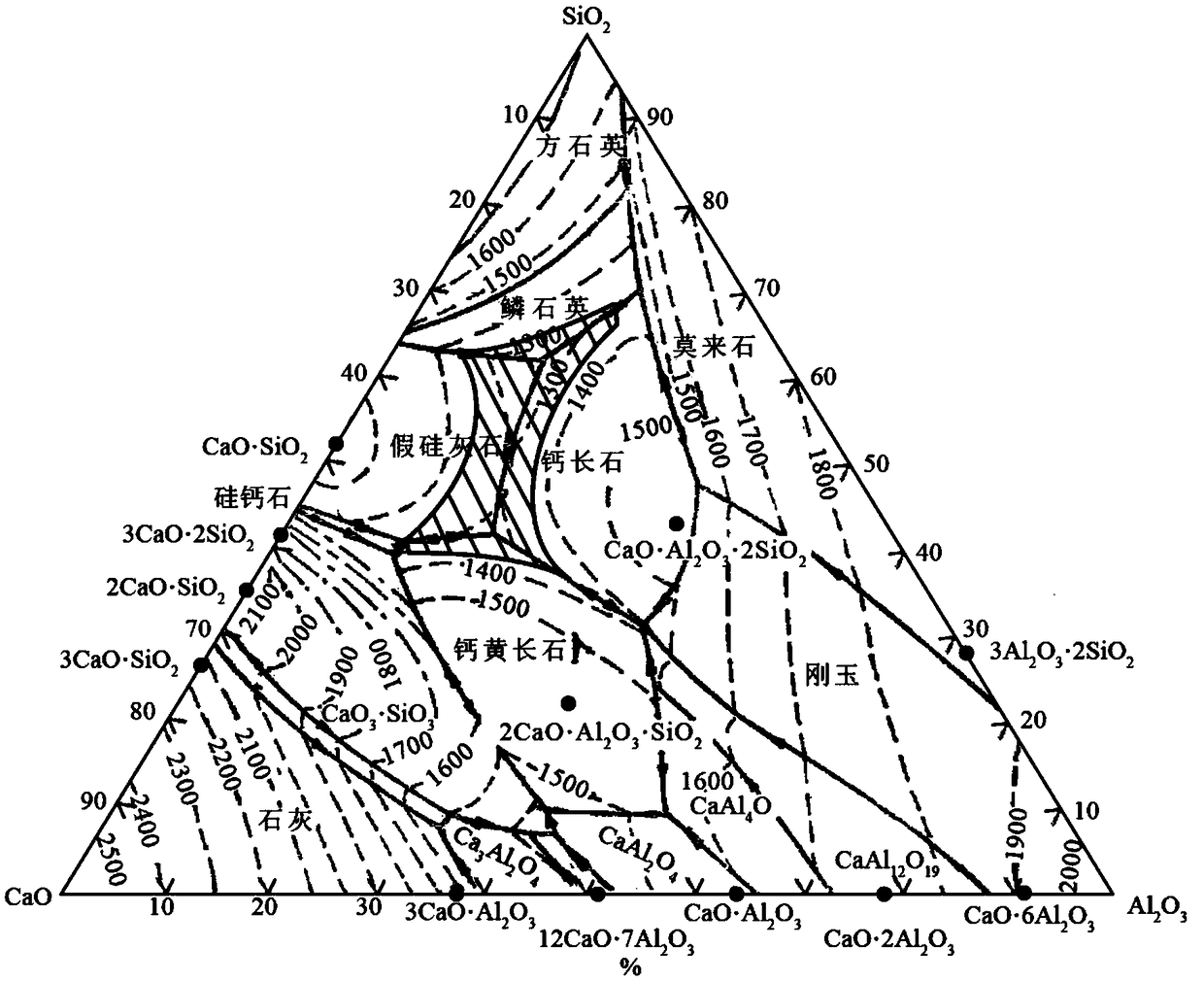

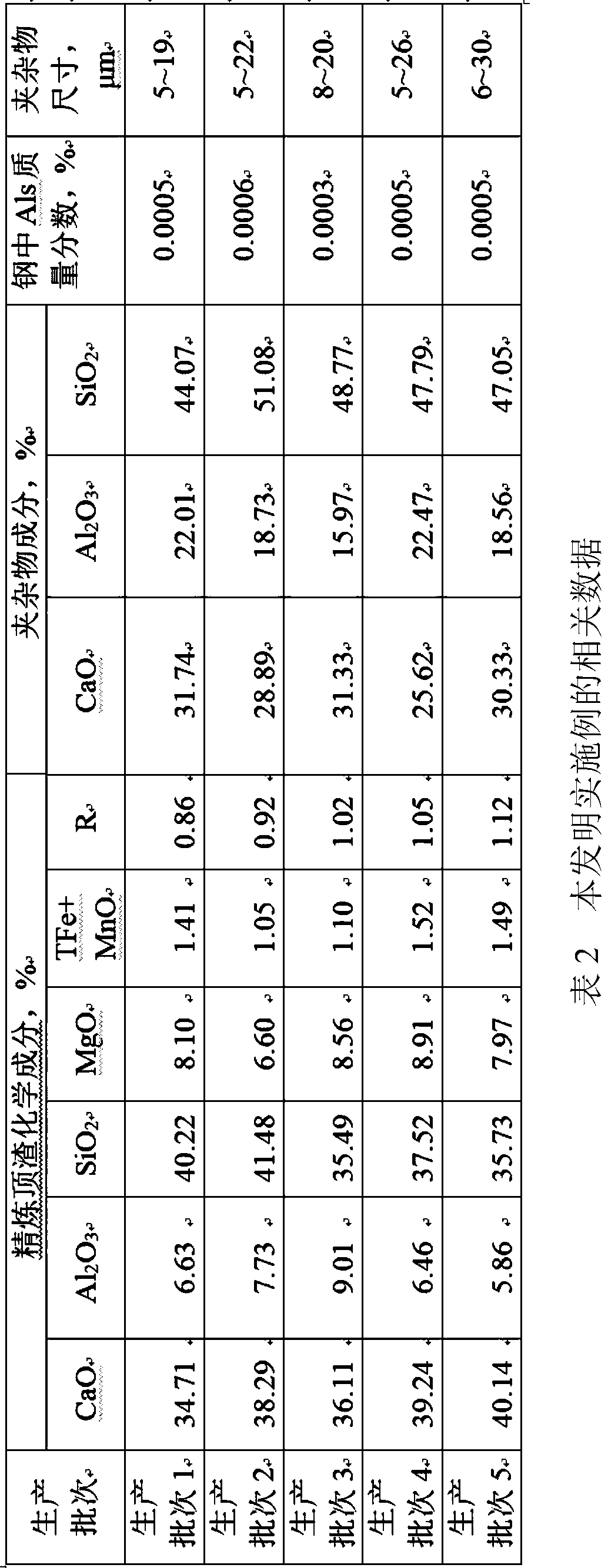

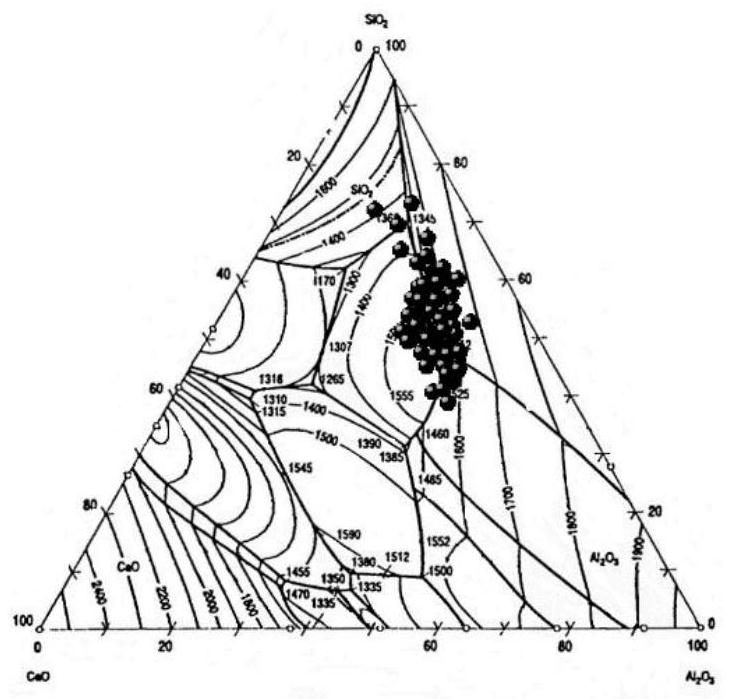

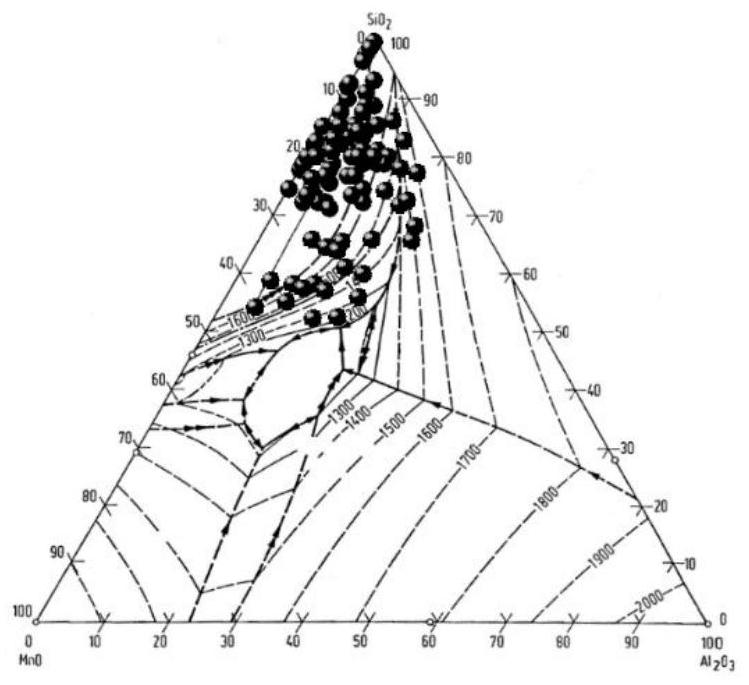

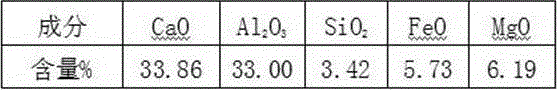

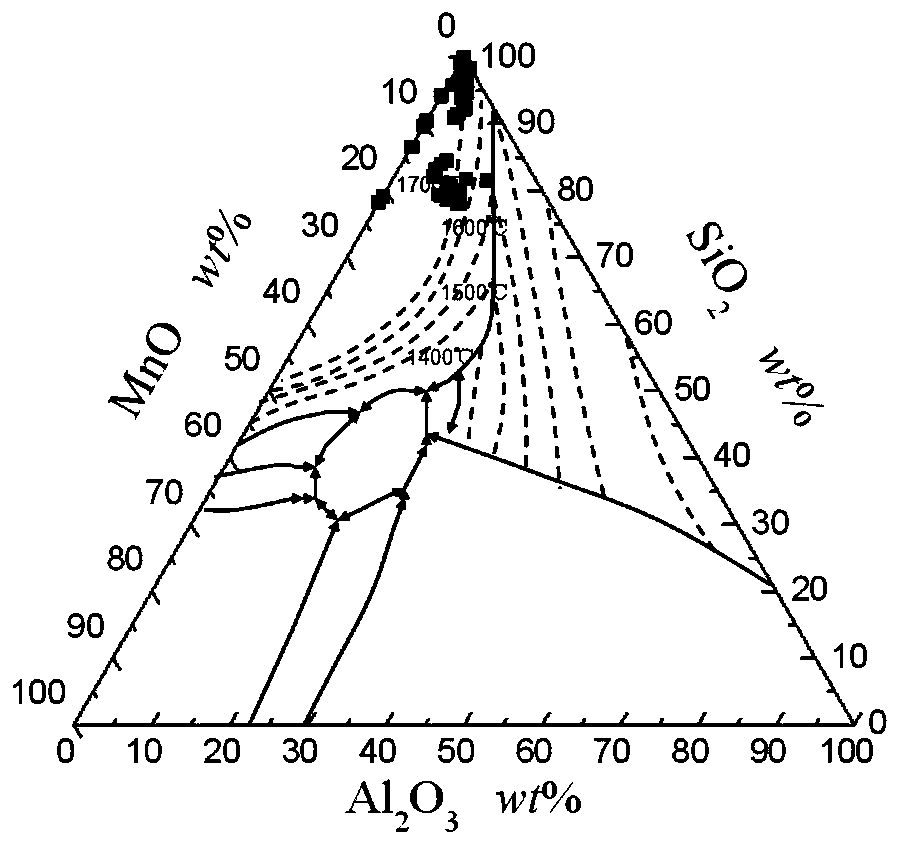

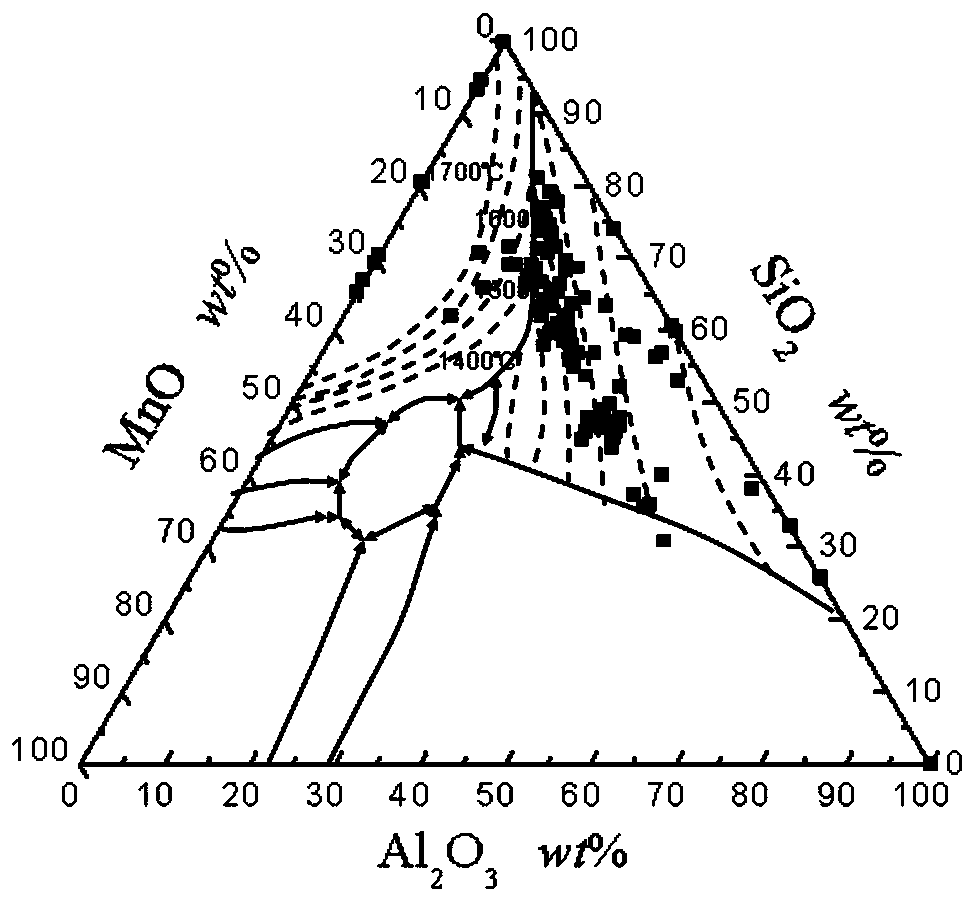

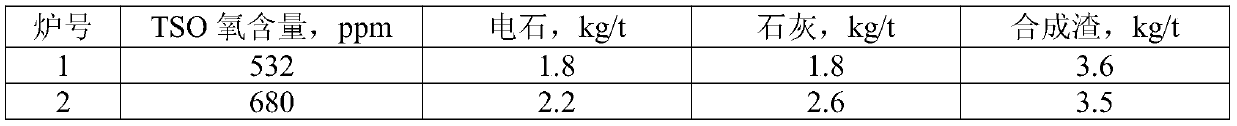

Inclusion control method for SWRH82B steel produced by carbon-free steel ladle

The invention provides an inclusion control method for SWRH82B steel produced by a carbon-free steel ladle. The inclusion control method for the SWRH82B steel produced by the carbon-free steel ladle comprises the following steps that step A, slag system target components of refining top slag are determined and the slag system target components comprise, by mass, 35%-45% of CaO, 6%-8% of AL2O3, 35%-45% of SiO2, 4%-9% of MgO and less than or equal to 1.6% of TFe + MnO; step B, the vacuum degree of RH vacuum refining is controlled at 300 Pa; step C, steel ladle bottom argon blowing time after acid slag is produced is controlled to be greater than 20 min; and step D, the sedation time from the end of refining treatment to the beginning of pouring is greater than 20 min, and binary basicity ofthe refining top slag is further controlled at 0.8-1.2. According to the inclusion control method for the SWRH82B steel produced by the carbon-free steel ladle, the cleanliness of the steel is improved, transformable inclusions with a low melting point are obtained, the problem that AL2O3 and other brittle inclusions increase due to the fact that the SWRH82B steel is produced by the carbon-free steel ladle is solved, and economic benefits are increased.

Owner:LIUZHOU IRON & STEEL

Ultralow-aluminum non-oriented silicon steel inclusion control method

ActiveCN112899552AReduce oxidationControl componentManufacturing convertersNon-metallic inclusionsFerrosilicon

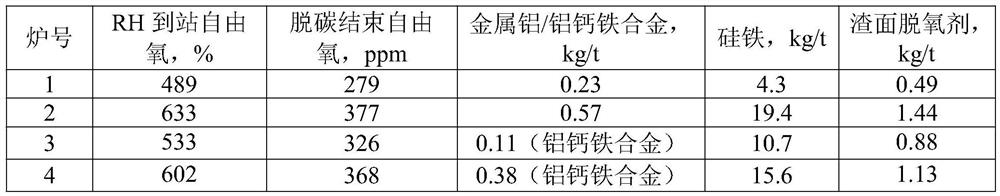

The invention provides an ultralow-aluminum non-oriented silicon steel inclusion control method. Chemical components of the steel type comprise, by mass percent, not larger than 0.005% of C, 0.25%-1.50% of Si, 0.15%-0.55% of Mn, 0.02%-0.06% of P, not larger than 0.005% of S, not larger than 0.005% of Als and the balance Fe and inevitable impurities. The technological process comprises the steps of KR, BOF, RH and continuous casting. The slag amount is strictly controlled during converter tapping, and lime and a slag surface deoxidizer are added to adjust slag after tapping is finished; and after RH decarburization is finished, low-carbon and low-sulfur ferrosilicon, metal aluminum or an aluminum-calcium-iron alloy are firstly added for complex deoxidation, finally metal manganese and ferrophosphorus are added for alloying, then clean circulation is carried out for 6-10 min, and vacuum breaking and tapping are carried out to continuous casting pouring. Obtained molten steel mainly contains SiO2-Al2O3 series inclusions, so that the situation that low-melting-point SiO2-MnO series inclusions are generated, rolling extension and lengthening are caused, and grain growth is affected is avoided; and meanwhile, refractory material corrosion caused by generation of acidic inclusions of high SiO2 components is also avoided. The types of non-metallic inclusions in steel can be remarkably improved, the performance of non-oriented silicon steel is improved, and the pouring performance of the molten steel is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

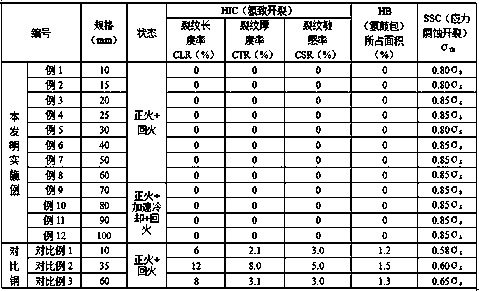

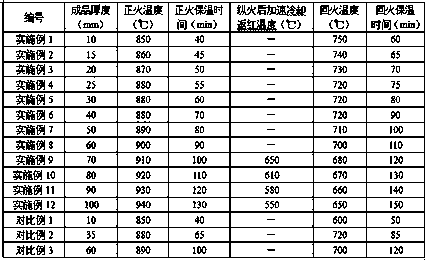

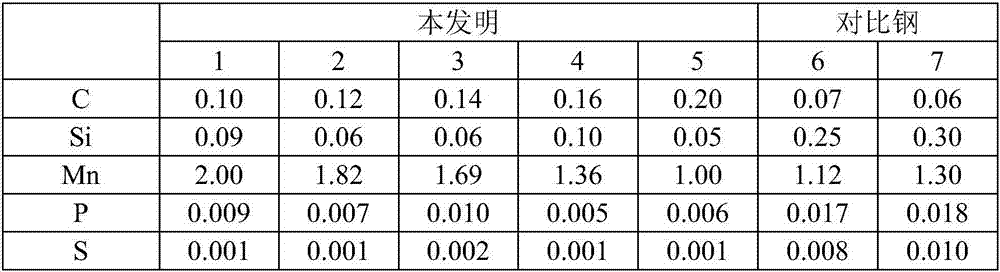

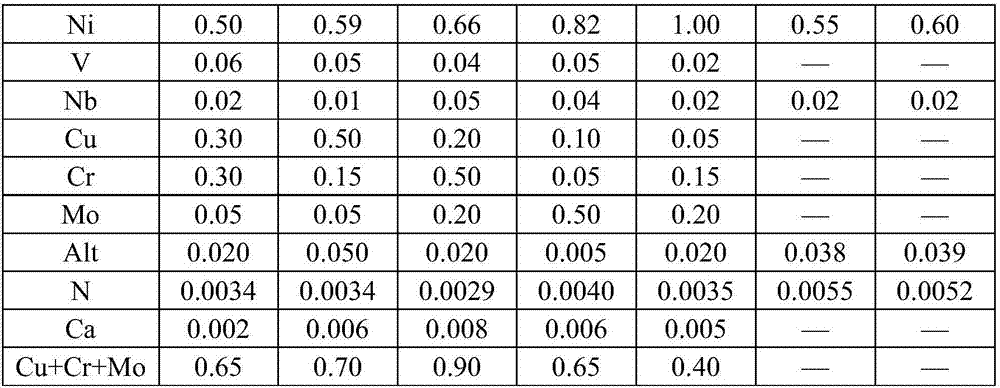

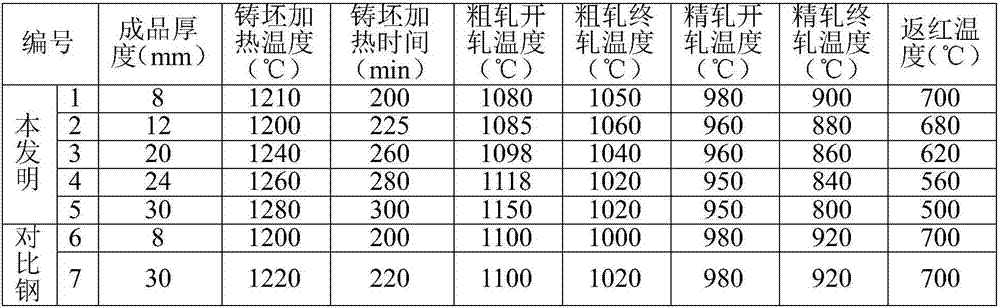

770 MPa-stage low-welding-crack-sensitivity pressure container steel and manufacturing method thereof

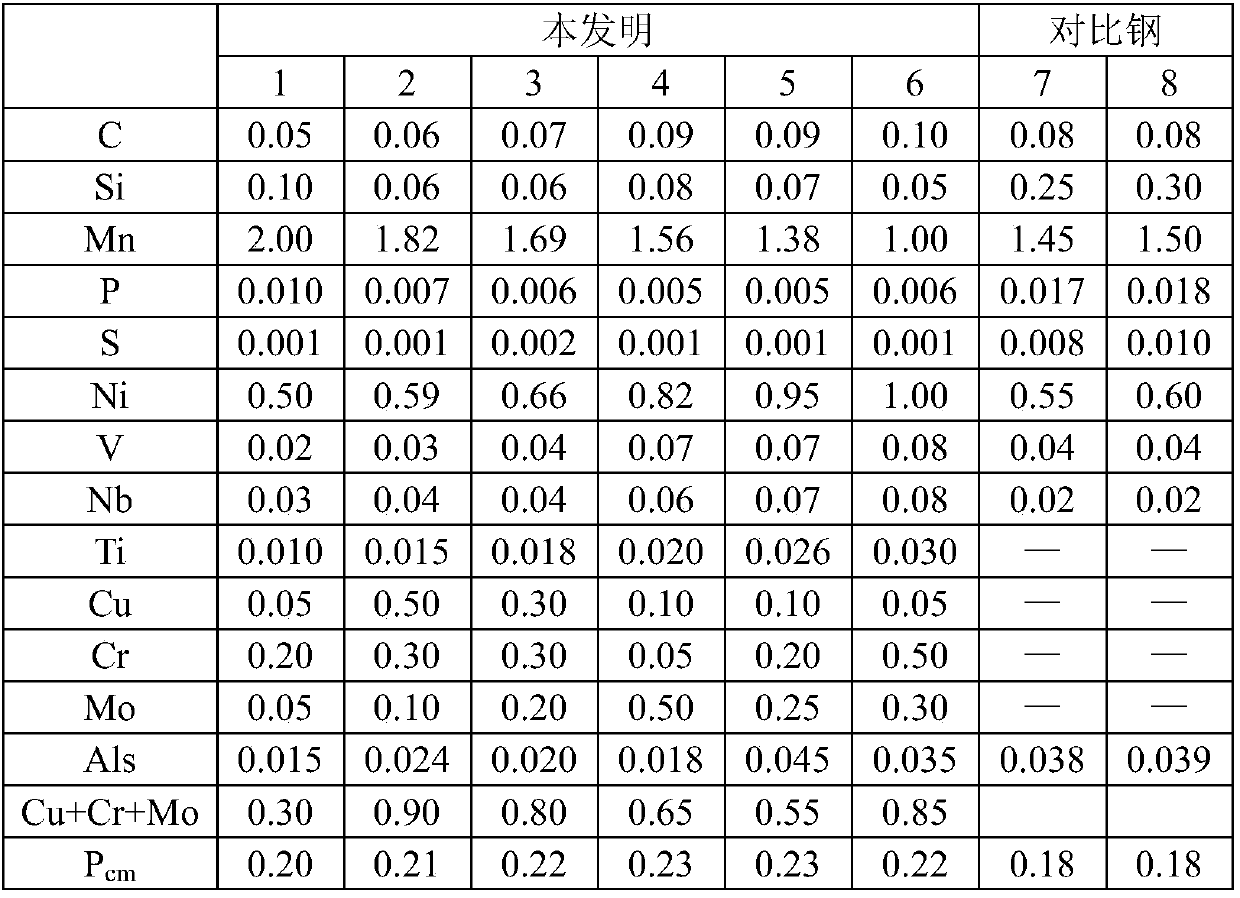

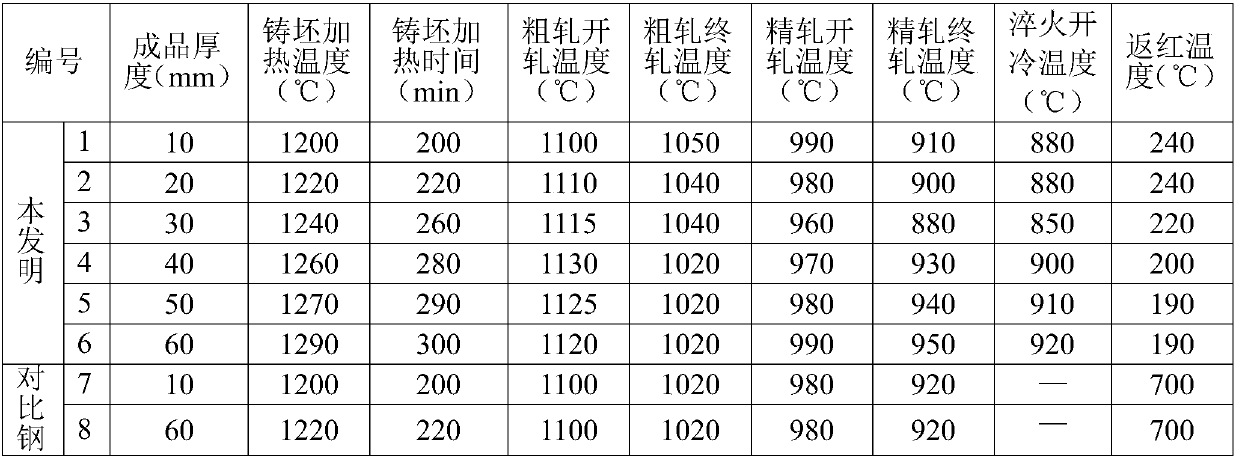

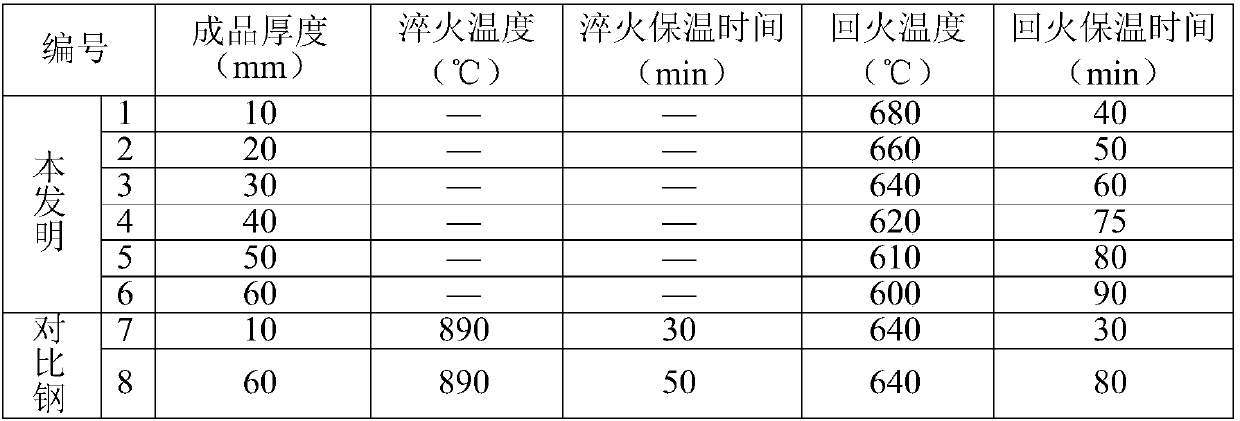

ActiveCN107937807AImprove low temperature toughnessGood welding performanceChemical compositionHigh intensity

The invention provides 770 MPa-stage low-welding-crack-sensitivity pressure container steel. The 770 MPa-stage low-welding-crack-sensitivity pressure container steel comprises the following chemical components in percentage by mass: 0.05-0.10 of C, Si not more than 0.10, 1.00-2.00 of Mn, P not more than 0.010, S not more than 0.002, 0.015-0.045 of Als, 0.50-1.00 of Ni, 0.03-0.08 of Nb, 0.02-0.08 of V, 0.010-0.030 of Ti, Cu not more than 0.50, Cr not more than 0.50, Mo not more than 0.50, and the balance of Fe and inevitable impurities, wherein the mass percentages of Cu, Cr and Mo meet that [Cu]+[Cr]+[Mo] is not more than 0.90 and not less than 0.30. Through component design, inclusion control, rolling and heat treatment, the steel achieves high strength, high toughness and low welding crack sensitivity, and can be used for manufacturing various liquefied petroleum gas storage tank equipment.

Owner:武汉钢铁有限公司

Production method of ultra-low silicon peritectic steel

Owner:TANGSHAN IRON & STEEL GROUP +1

Equipment and tail gas treatment method for synchronously treating tail gas of multiple graphitization furnaces

ActiveCN103007711ARealize one-drag multi-functionReduce the number of buildsDispersed particle separationElectricityAir volume

The invention discloses equipment and a tail gas treatment method for synchronously treating tail gas of multiple graphitization furnaces. The equipment comprises draft fans for controlling the air pressure and the air quantity of a main graphitization furnace tail gas pipe, and further comprises a fresh air system, a turbulent flow absorbing system, monitoring systems and a control system, wherein the fresh air system is arranged in an external furnace cover and the main tail gas pipe of each graphitization furnace; the input end of the turbulent flow absorbing system is connected with the main graphitization furnace tail gas pipe through a pipeline; the output end of the turbulent flow absorbing system is connected with an external gas discharge device through a pipeline; the monitoring systems are arranged in the fresh air system and the turbulent flow absorbing system; and the control system is connected with the fresh air system, the monitoring systems and the turbulent flow absorbing system, and is used for controlling the working of the fresh air system and the turbulent flow absorbing system through monitoring signals transmitted by the monitoring systems. By utilizing the equipment, the construction number of the tail gas treatment equipment is reduced, the equipment construction cost is saved to a large extent, and operation personnel and electricity consumption are reduced, so that the production cost is greatly saved; the tail gas is cooled and at the same time the air pressure in the graphitization furnaces is precisely adjusted and controlled; and the graphitization furnace gas supply process is improved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

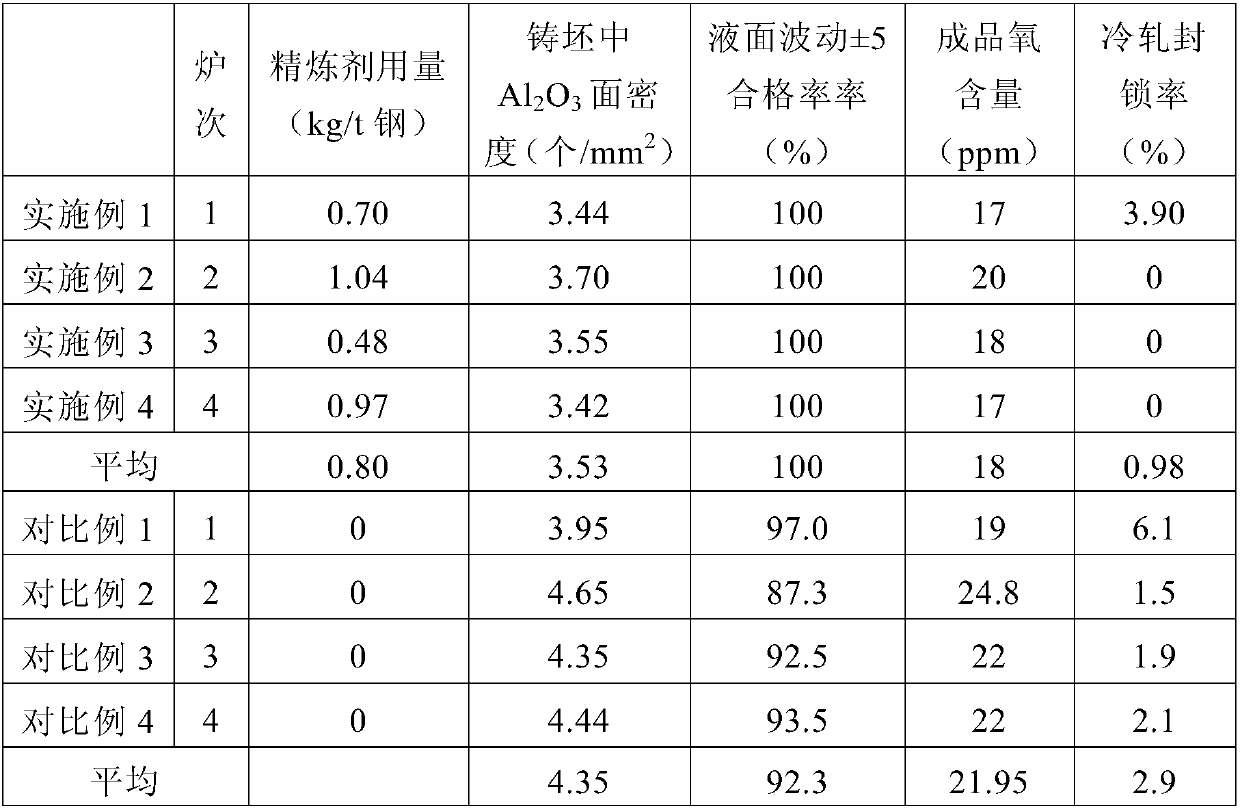

Oxide inclusion control method for producing ultra-low-carbon steel by using LD-RH process

ActiveCN109554605AReduce the number of inclusionsReduce the oxygen content of the finished productManufacturing convertersProcess efficiency improvementOxygen contentCarbon steel

The invention discloses an oxide inclusion control method for producing ultra-low-carbon steel by using an LD-RH process. The method comprises the following steps that 2.0-3.5 kg of lime is added intoper ton of steel at the early stage of steel tapping of an LD converter, and 0.3-2 kg of Al modifiers are added into per ton of steel at the end of steel tapping; then the mixture enters an RH furnace to be subjected to vacuum treatment and decarbonization; after decarbonization is finished, deoxidizing is carried out, and 0.3-2.0 kg of refining agents are added int per ton of steel, wherein therefining agent comprises the following components of, by weight, 50-60wt% of CaO, 30-40wt% of Al2O3, 2-6wt% of MgO, less than or equal to 3wt% of SiO2, less than 0.08wt% of TiO2, less than or equal to1wt% of FeO and less than or equal to 0.5wt% of H2O; and alloying is carried out, wherein molten steel is circulated for 3-12 minutes, and then the vacuum refining process is finished. According to the method, the number of oxide inclusions in the casting blank and the oxygen content of a finished product are greatly reduced, the cold rolling blocking rate is reduced, and the quality of the ultra-low carbon steel product is remarkably improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Pressure vessel steel resistant to acid corrosion at medium temperature of 600 DEG C and preparation method thereof

InactiveCN108588570AImprove low temperature toughnessGood welding performanceNuclear powerAcid corrosion

The invention discloses pressure vessel steel resistant to acid corrosion at medium temperature of 600 DEG C and a preparation method thereof. The pressure vessel steel comprises 0.05-0.15% of C, 0.20-0.50% of Si, 0.50-1.00% of Mn, 0.008% or less of P, 0.002% or less of S, 0.050% of less of Alt, 0.30-0.80% of Cu, 0.30-1.00% of Ni, 0.80-1.50% of Cr, 0.20-0.50% of Mo, 0.01-0.05% of V, 0.0070% or less of N and the balance Fe and unavoidable impurities. During preparation, the mass percentage of the chemical components is adjusted in a molten iron tank first, aluminum wires are added into an LF furnace and a RH furnace and continuously cast into a casting blank, the casting blank is rolled in two stages including rough rolling and finishing rolling, then subjected to heat treatment of normalization and tempering and finally cooled, and the pressure vessel steel is obtained. Through composition design, inclusion control, rolling and heat treatment, the obtained pressure vessel steel has good toughness, a low yield ratio and good welding performance and can be used for supercritical thermal power, high-efficiency boilers, nuclear power and other industries.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

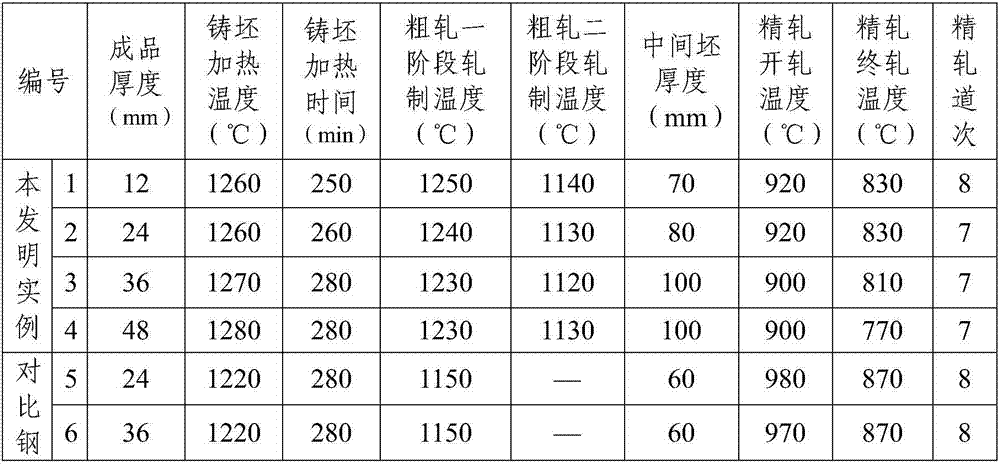

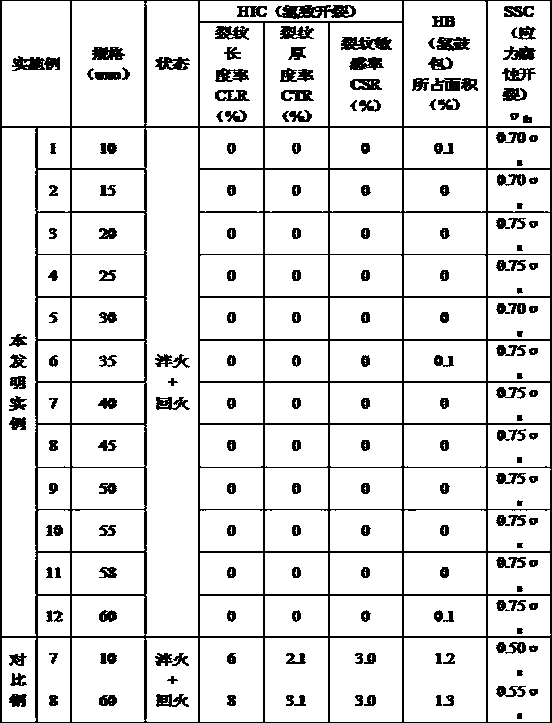

High-toughness low-yield ratio low-temperature steel for LPG ship storage tank and manufacturing method thereof

InactiveCN107974625ALow yield ratioGuaranteed low temperature impact toughnessSteel platesInclusion control

The invention belongs to the field of manufacturing of low alloy steel, and particularly relates to high-toughness low-yield ratio low-temperature steel for an LPG ship storage tank and a manufacturing method thereof. The low-temperature steel comprises the following raw material chemical components by mass percent: 0.08% to 0.23% of C, 0.30% or less of Si, 0.85% to 1.50% of Mn, 0.004% or less ofP, 0.002% or less of S, 0.015% to 0.050% of Alt, 1.00% to 1.30% of Ni and 0.004% or less of N, and further comprises at least one of 0.10% or less of Mo, 0.05% or less of Nb, 0.036% or less of Ti and0.005% or less of Ca, and the balance being Fe and unavoidable impurities. The method for manufacturing the low-temperature steel comprises a steel-making technology, a steel rolling technology and aprocessing and thermal treatment technology. According to the high-toughness low-yield ratio low-temperature steel, through component design, inclusion control, rolling and thermal treatment, a steelplate has excellent low-temperature toughness and good welding performance, the yield ratio is relatively low, the steel plate can be utilized to manufacture the storage tank for an LPG ship, and utilization safety performance is greatly improved.

Owner:武汉钢铁有限公司

Inclusion control method for ultrapure austenitic stainless steel for cold-rolled sheets

InactiveCN108559818AStrong resistance to salt spray corrosionReduce in quantitySS - Stainless steelDeoxidization

The invention discloses an inclusion control method for ultrapure austenitic stainless steel for cold-rolled sheets. The preparation method comprises the following steps: I, performing decarburizationblowing, silicon iron reduction and preliminary dexidation on stainless steel mother liquid in an AOD furnace, and adjusting basicity of slag to 1.8 or higher; II, performing slagging-off treatment on ladle slag after tapping; III, performing refining treatment on an LF furnace; IV, performing continuous casting to obtain a continuous casting billet; V, performing hot rolling and cold rolling onthe continuous casting billet, thereby obtaining the stainless steel plate. According to the control method disclosed by the invention, deep deoxidization of aluminum is adopted, and the total oxygencontent is lower than 20 ppm; due to a small amount of inclusion, the prepared stainless steel is high in salt spray resistance and corrosion resistance; the inclusion type in the stainless steel prepared in the invention is mainly fine magnesium aluminate spinel, and the stainless steel does not extend in a rolling process and does not form defects on the cold drawing surface.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

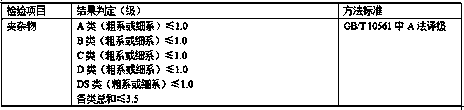

Acid corrosion resistant quenching and tempering high-strength pressure vessel steel and production method

Acid corrosion resistant quenching and tempering high-strength pressure vessel steel comprises the components of, by weight, 0.05%-0.10% of C, 0.15%-0.50% of Si, 0.50%-1.20% of Mn, 0-0.008% of P, 0-0.002% of S, 0.015%-0.045% of Als, 0.20%-0.80% of Ni, 0.010%-0.030% of Ti, 0.22%-0.50% of Cu, 0.50%-1.50 % of Cr, 0.23%-0.50% of Mo and 0.002%-0.006% of Ca. A production method comprises the steps of molten iron pretreatment and converter smelting, LF furnace external refining, RH vacuum treatment, tapping and continuous casting blank forming, segmented hot rolling, quenching and tempering. According to the acid corrosion resistant quenching and tempering high-strength pressure vessel steel, after composition design, inclusion control, rolling and heat treatment, yield strength is larger than orequal to 450 MPa, tensile strength is larger than or equal to 540 MPa, elongation is larger than or equal to 20%, -40 DEG C KV2 is larger than or equal to 60 J, no hydrogen induced cracking phenomenon is generated, and stress corrosion cracking is not lower than 0.70 sigma s.

Owner:武汉钢铁有限公司

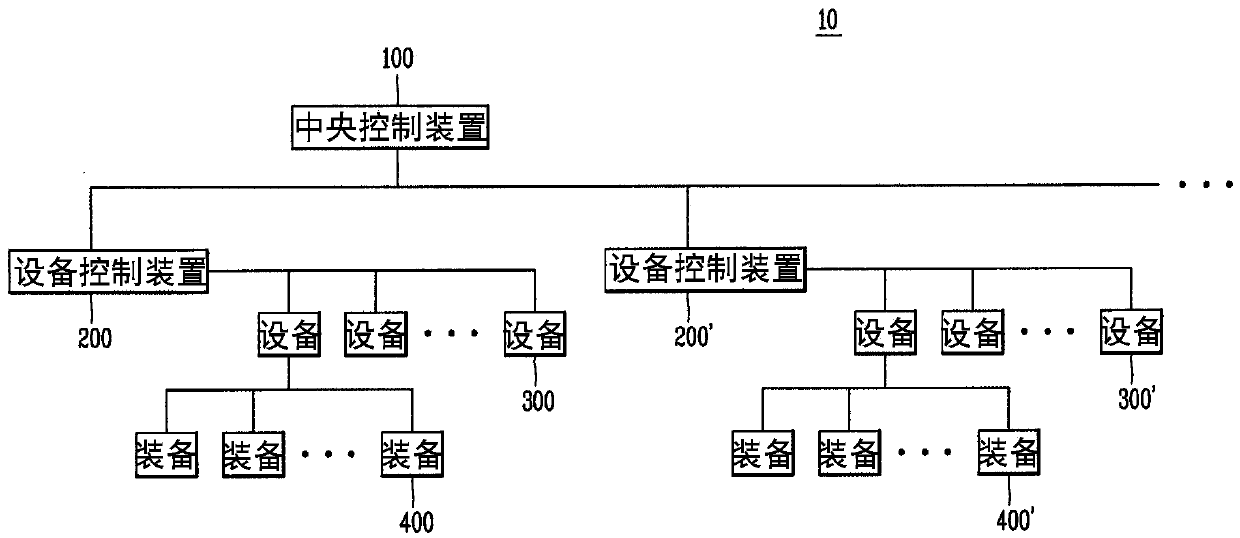

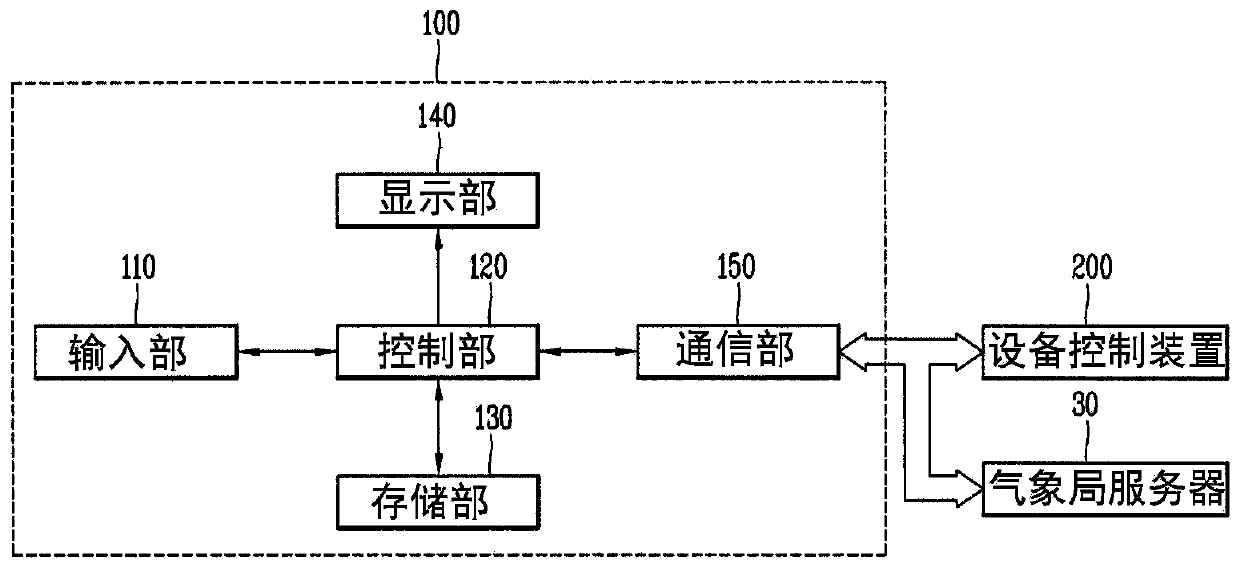

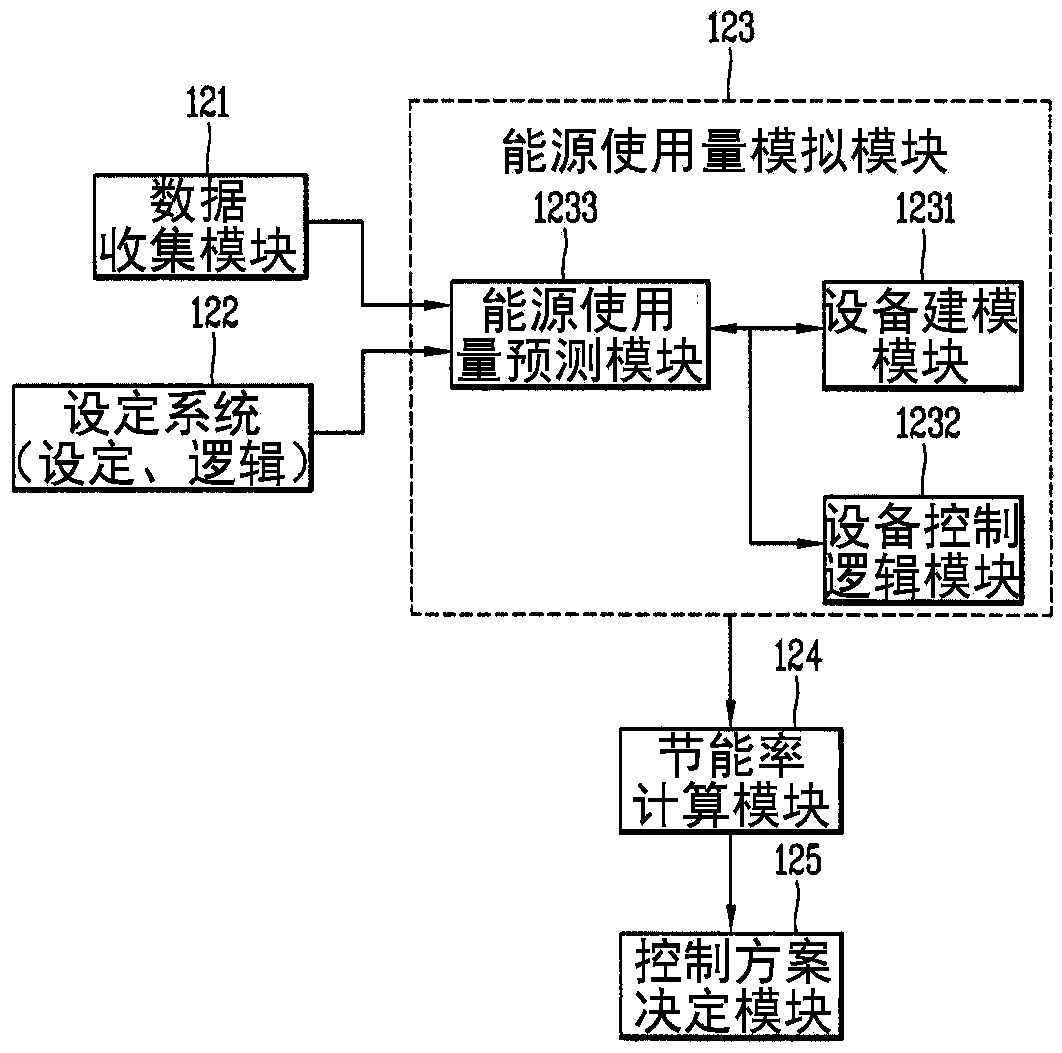

Central control apparatus, and facility control system and method

The invention provides a central control apparatus, and a facility control system and method. The central control apparatus includes: a controller that performs control over facilities or equipment; and a display unit that displays information processed by the controller on the screen, wherein the central control apparatus further includes a communication unit that communicates with a meteorological office server, and the controller includes: a data collection module that collects predicted environmental data about a target control area through the communication unit; a system setting module that sets information about at least one facility within the target control area; and an energy usage simulation module that models the facility based on based on the facility information and simulates the power consumption of the facility model according to a control scenario, the energy usage simulation module including an energy reduction calculation module for calculating the energy reduction of the facility or target control area based on a simulation result of the power consumption of the facility model according to a combination of at least one control scenario.

Owner:LG ELECTRONICS INC

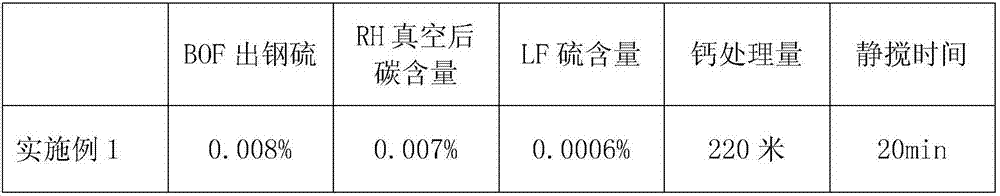

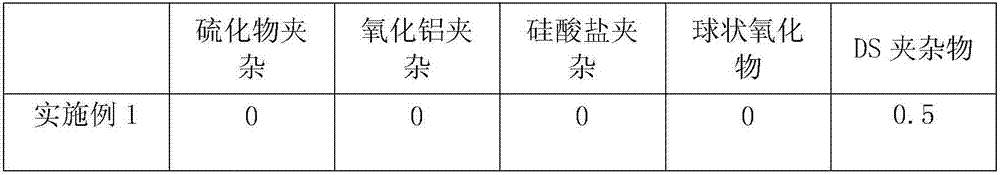

Production process for controlling large inclusions in acid-resistant pipeline steel

ActiveCN107099747AControl quantityDeterioration of mechanical propertiesProcess efficiency improvementSulfurEconomic benefits

The invention discloses a production process for controlling large inclusions in acid-resistant pipeline steel. Through systematic analysis on a pipeline steel inclusion control mechanism adopting a BOF-RH-LF production process, the component design is reasonably performed; the pipeline steel comprises the following components in percentage by weight: 0.02-0.04 percent of C, 0.10-0.30 percent of Si, 1.00-1.30 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0010 percent of S, 0.030-0.070 percent of Nb, 0.006-0.020 percent of Ti, 0.10-0.30 percent of Ni, 0.10-0.30 percent of Cr, 0.10-0.30 percent of Cu, 0.015-0.050 percent of Al and the balance of Fe. The production process disclosed by the invention has the benefits that the content of sulfurs in molten steel before calcium treatment is ensured to be less than 10 ppm; the quantitative calcium treatment is performed after the end of LF; the purpose of improving the purity of the molten steel is achieved, so that the internal quality of steels is improved, and the economic benefits are improved.

Owner:NANJING IRON & STEEL CO LTD

Method for accurately controlling aluminum consumption of IF steel

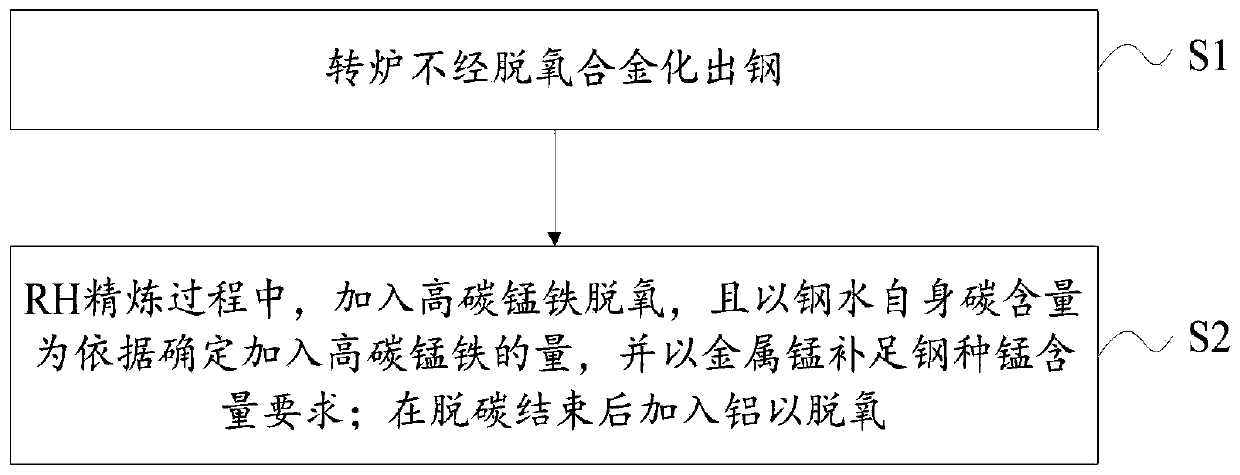

The invention discloses a method for accurately controlling the aluminum consumption of IF steel. The method comprises the following steps of tapping steel by a converter without deoxidation alloying;in the RH refining process, adding high-carbon ferromanganese for deoxidation, wherein the amount of the added high-carbon ferromanganese is determined on the basis of the carbon content of molten steel, and complementing the manganese content requirement of the steel grade through metal manganese; adding aluminum for deoxidization after the decarburization is finished. According to the method for accurately controlling the aluminum consumption of the IF steel, the amount of the added high-carbon ferromanganese for deoxidation is determined according to the carbon content of the molten steel,accurate control over oxygen inhibition in molten steel decarburization can be achieved, then the aluminum consumption of the IF steel can be accurately controlled, fluctuation of the aluminum consumption is reduced, and the inclusion control level is stabilized.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Normalized high-strength low-yield-ratio pressure vessel steel with temperature of minus 70 DEG C and manufacturing method thereof

ActiveCN107974643AImprove low temperature toughnessGood welding performanceChemical compositionHigh intensity

The invention provides normalized high-strength low-yield-ratio pressure vessel steel with the temperature of minus 70 DEG C. The normalized high-strength low-yield-ratio pressure vessel steel with the temperature of minus 70 DEG C comprises, by mass percentage, 0.10-0.20 of C, not larger than 0.10 of Si, 1.00-2.00 of Mn, not larger than 0.010 of P, not larger than 0.002 of S, 0.005-0.050 of Alt,not larger than 0.50 of Cu, not larger than 0.50 of Cr, not larger than 0.50 of Mo, 0.01-0.05 of Nb, 0.02-0.06 of V, 0.50-1.00 of Ni, not larger than 0.004 of N and the balance Fe and unavoidable inclusions, wherein Cu, Cr, and Mo satisfy the condition that, by mass percentage, the sum of [Cu], [Cr] and [Mo] is larger than or equal to 0.40 and smaller than or equal to 0.90. By the adoption of thenormalized high-strength low-yield-ratio pressure vessel steel with the temperature of minus 70 DEG C and a manufacturing method of the normalized high-strength low-yield-ratio pressure vessel steel with the temperature of minus 70 DEG C, through composition design, inclusion control, rolling and heat treatment, the steel is high in strength, high in low-temperature obdurability and low in yield ratio and can be used for manufacturing various low-temperature movable pressure vessels.

Owner:武汉钢铁有限公司

Smelting method for high-surface-quality IF steel

ActiveCN111485068ASolve problemsReduce joinManufacturing convertersProcess efficiency improvementMolten steelDecarburization

The invention relates to a smelting method for high-surface-quality IF steel. According to the provided smelting method of the high-surface-quality IF steel in the scheme, the BOF-LF-RH-CC manufacturing process is adopted, and an LF is used for heating molten steel to solve the problem that a semi-steel heat source is insufficient; and after the molten steel is subjected to BOF treatment and tapping and before RH treatment deoxidation, except the fact that submerged arc is added and necessary slag needed by inclusion adsorption is added in the LF treatment heating process, addition of the slagis reduced, so that the situations that oxygen in the molten steel is transferred into the slag in the process, the oxygen in the slag is transferred into steel again in the molten steel carrying andcontinuous casting process after decarburization and deoxidation of the molten steel are completed, then secondary oxidation of the molten steel is caused, and the molten steel is polluted by generated endogenous inclusions are avoided. By adopting the smelting method, the inclusion control level can be improved, and the production cost can be reduced.

Owner:攀钢集团西昌钢钒有限公司

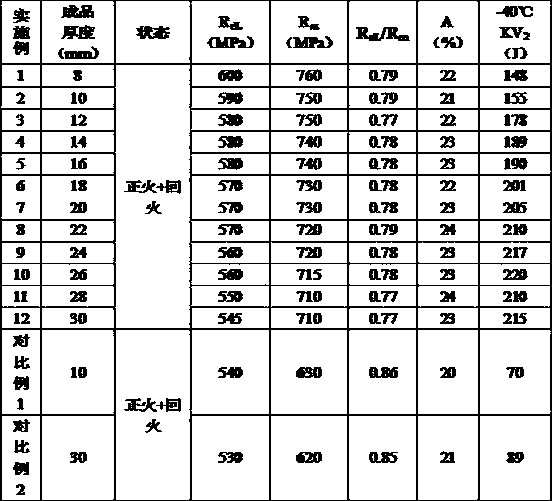

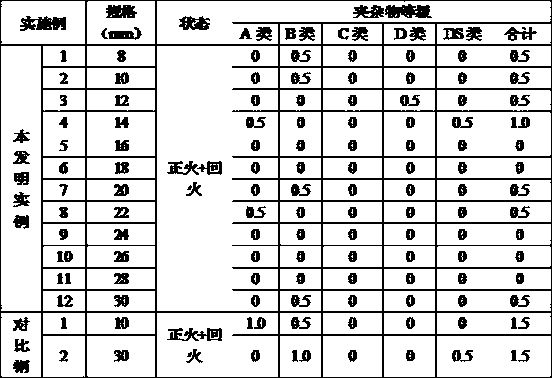

Steel with tensile strength being of 680MPa grade and used for large transportable pressure vessel and production method

The invention relates to steel with the tensile strength being of the 680MPa grade and used for a large transportable pressure vessel. The steel comprises the components including, by weight, 0.10-0.20% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, not greater than 0.008% of P, not greater than 0.002% of S, 0.005-0.050% of Alt, 0.10-0.50% of Cu, 0.01-0.05% of Nb, 0.10-0.20% of V, 0.20-1.00% of Ni, 0.002-0.008% of Ca and 0.010-0.020% of N. A production method comprises the steps that molten iron pretreatment and converter smelting are performed conventionally; LF furnace external refining and RH vacuum treatment are performed in sequence; tapping and continuous casting cogging are performed; segmental hot rolling is performed; normalizing is performed; and tempering is performed. According to the steel which is subjected to component designing, inclusion control, rolling and heat treatment, the tensile strength is 680-830 MPa, KV2 under the minus 40 DEG C condition is greater than or equalto 47 J, the yield ratio ReL / Rm is smaller than or equal to 0.83, and the thickness of a steel plate is 8-30 mm; and by means of the steel, requirements of preparation of the transportable vessel withhigher performance requirements can be met, and furthermore, the self weight can be reduced by 15%.

Owner:武汉钢铁有限公司

A method for controlling inclusions in silicon-manganese killed non-oriented silicon steel

ActiveCN108660294BOxygen Potential StabilizationReduce oxidationProcess efficiency improvementMetallic aluminumChemical composition

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

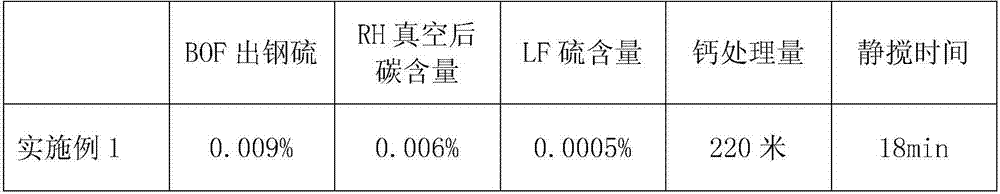

A production process for controlling large inclusions in acid-resistant pipeline steel

ActiveCN107099747BControl quantityDeterioration of mechanical propertiesProcess efficiency improvementCalcium handlingMetallurgy

The invention discloses a production process for controlling large inclusions in acid-resistant pipeline steel. Through systematic analysis on a pipeline steel inclusion control mechanism adopting a BOF-RH-LF production process, the component design is reasonably performed; the pipeline steel comprises the following components in percentage by weight: 0.02-0.04 percent of C, 0.10-0.30 percent of Si, 1.00-1.30 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0010 percent of S, 0.030-0.070 percent of Nb, 0.006-0.020 percent of Ti, 0.10-0.30 percent of Ni, 0.10-0.30 percent of Cr, 0.10-0.30 percent of Cu, 0.015-0.050 percent of Al and the balance of Fe. The production process disclosed by the invention has the benefits that the content of sulfurs in molten steel before calcium treatment is ensured to be less than 10 ppm; the quantitative calcium treatment is performed after the end of LF; the purpose of improving the purity of the molten steel is achieved, so that the internal quality of steels is improved, and the economic benefits are improved.

Owner:NANJING IRON & STEEL CO LTD

Defect control method in solidification of molten aluminum alloy

InactiveCN106893870AReduce solidification defectsImprove mechanical propertiesFoundry mouldsFoundry coresInclusion controlProcess control

The invention discloses a defect control method in solidification of a molten aluminum alloy. The defect control method consists of a melting process control method and a solidification insulation control method, wherein the melting process control method includes a molten aluminum gas content control method and a slag inclusion control method; and the solidification insulation control method includes a riser feeding method, a sequential solidification method and a crack control method. The defect control method comprehensively uses gas and slag removal, riser feeding, sequential solidification and aging treatment methods, can effectively reduce the solidification defect probability in cast aluminum alloy, improves the mechanical performances of the cast aluminum alloy, and widens the application range of the cast aluminum alloy.

Owner:泉州市中知信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com