770 MPa-stage low-welding-crack-sensitivity pressure container steel and manufacturing method thereof

A technology for low welding cracks and pressure vessels, applied in the field of 770MPa low welding crack sensitivity pressure vessel steel and its manufacturing, can solve the problems of reducing Mn and Nb content, increasing alloy content, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The 770MPa grade low welding crack sensitivity pressure vessel steel of the present invention and its manufacturing method are further described below through specific examples:

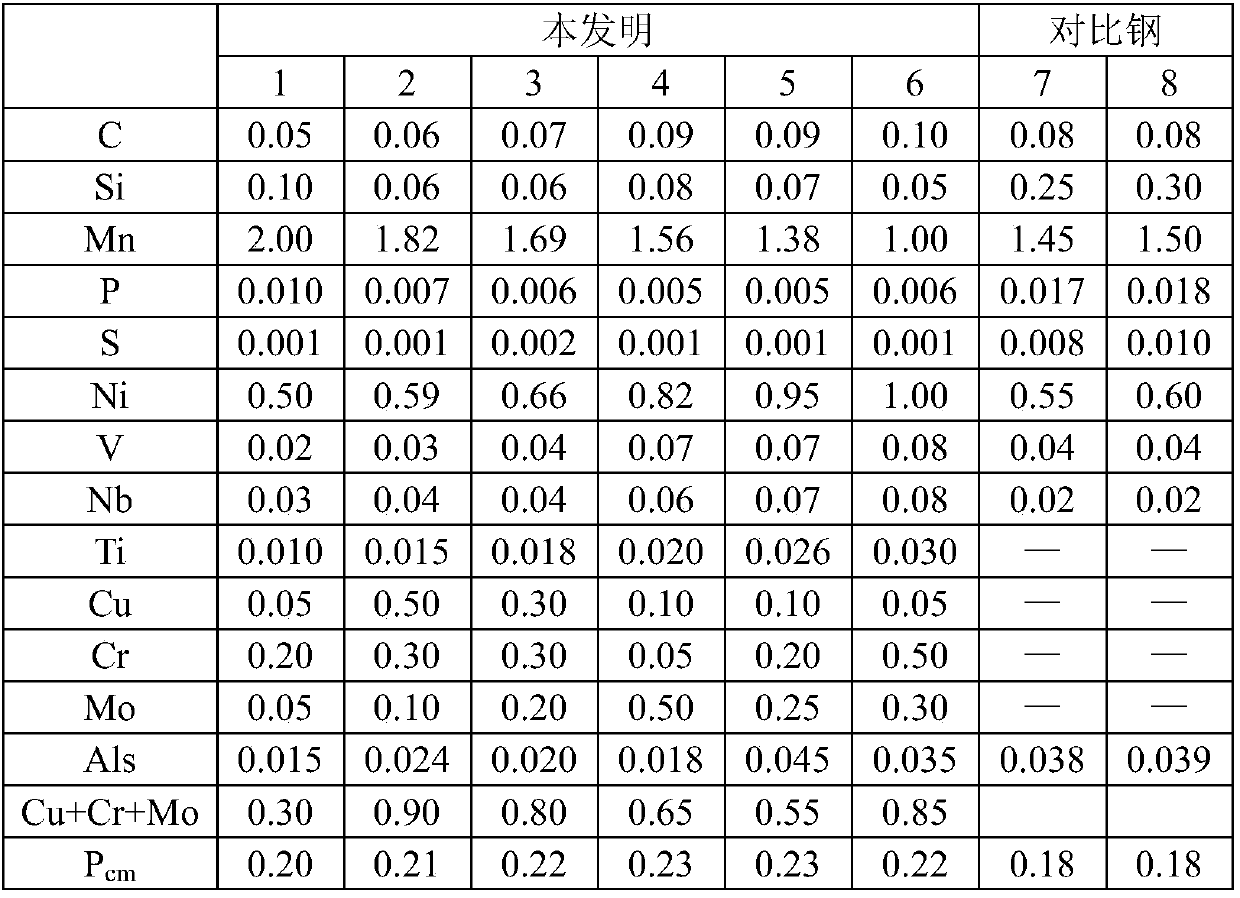

[0051] Table 1 lists the weight percentages of the chemical components of the 770MPa low weld crack sensitivity pressure vessel steels of Examples 1 to 6 with serial numbers 1 to 6 and the pressure vessel steels of Comparative Examples 1 to 2 with serial numbers 7 to 8 (The balance is Fe and unavoidable impurities).

[0052] The chemical composition (wt, %) of the embodiment of table 1

[0053]

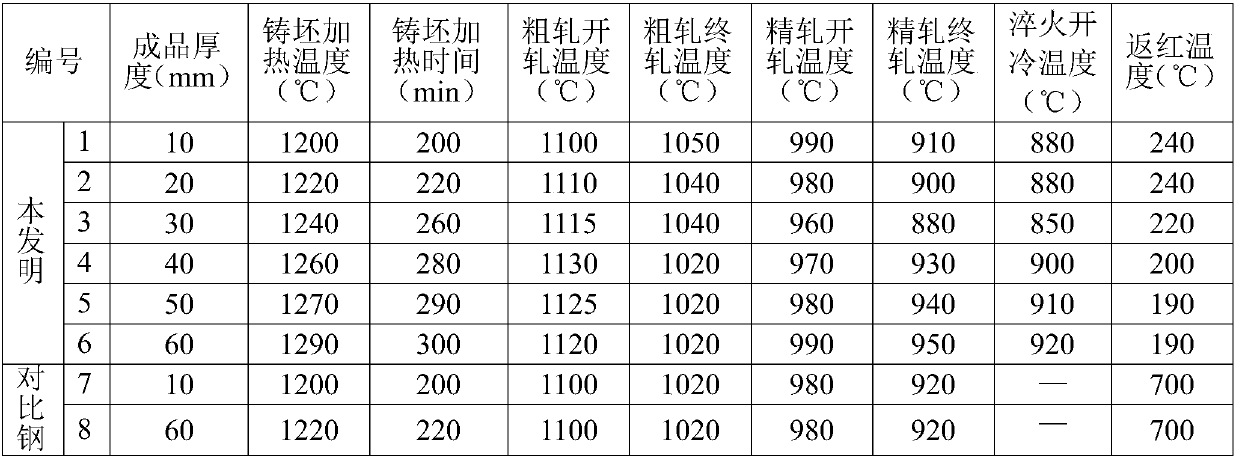

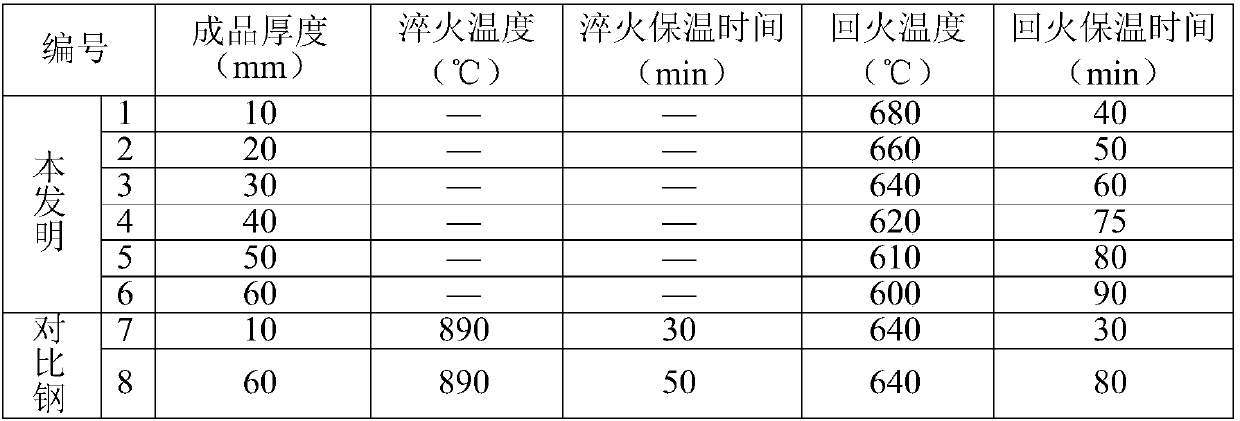

[0054] The 770MPa grade low weld crack sensitivity pressure vessel steels of Examples 1 to 6 with serial numbers 1 to 6 of the present invention and the pressure vessel steels of Comparative Examples 1 to 2 with serial numbers 7 to 8 are manufactured according to the following methods, mainly Process parameter is as described in table 2, and heat treatment process parameter is as shown in table 3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com