Thick steel plate capable of being welded under large heat input and method for manufacturing the same

A technology of high heat input welding and manufacturing method, which is applied in the field of thick steel plates that can be welded with large heat input and in the field of manufacturing, and can solve the problems of HAZ low temperature toughness deterioration and low temperature toughness difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

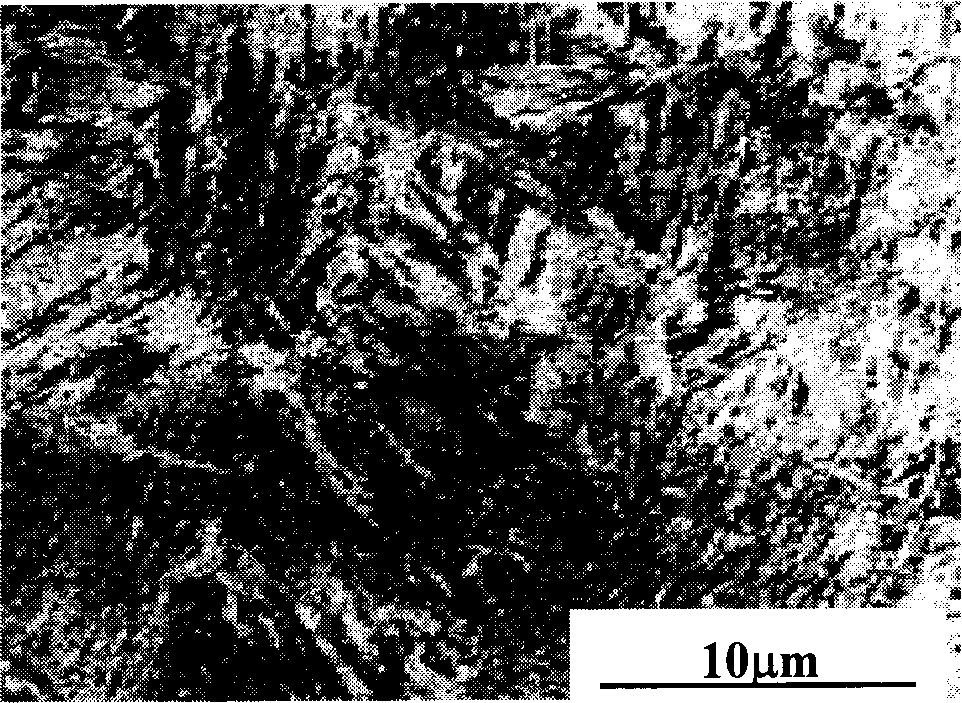

Image

Examples

Embodiment Construction

[0052] The composition of the example is shown in Table 1, the manufacturing process is shown in Table 2, and Table 3 shows the performance comparison of the steel plates of the present invention and comparative examples.

[0053] steel sample

[0054]

[0055] steel sample

[0056] According to the present invention, the alloying of precious elements such as Ni, Cr, Mo, Cu, etc., especially the alloying of Ni element is removed from the newly invented steel plate, and the TMCP process is optimized, while obtaining uniform and excellent low-temperature toughness of the base steel plate, The low temperature toughness of HAZ is also excellent during high heat input welding. This can not only reduce the manufacturing cost, shorten the production cycle, but also reduce the difficulty of production organization [steel plates with high content of Ni, Cu, and Mo elements have poor surface quality of continuous casting slabs, and generally need to go off-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com