Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

A technology of tensile strength and ultra-high toughness, applied in the field of ultra-high-strength steel, can solve problems such as low-temperature impact work difference, high dislocation density, and fracture failure, and achieve good strength, good low-temperature impact toughness, and tensile properties. The effect of reducing production costs and carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

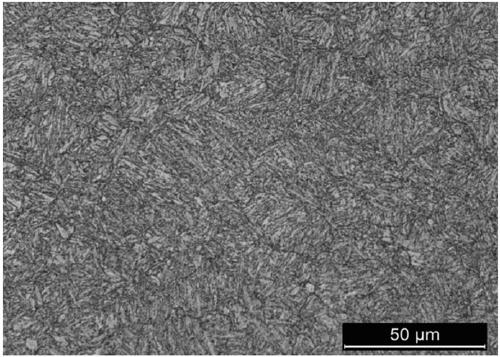

Image

Examples

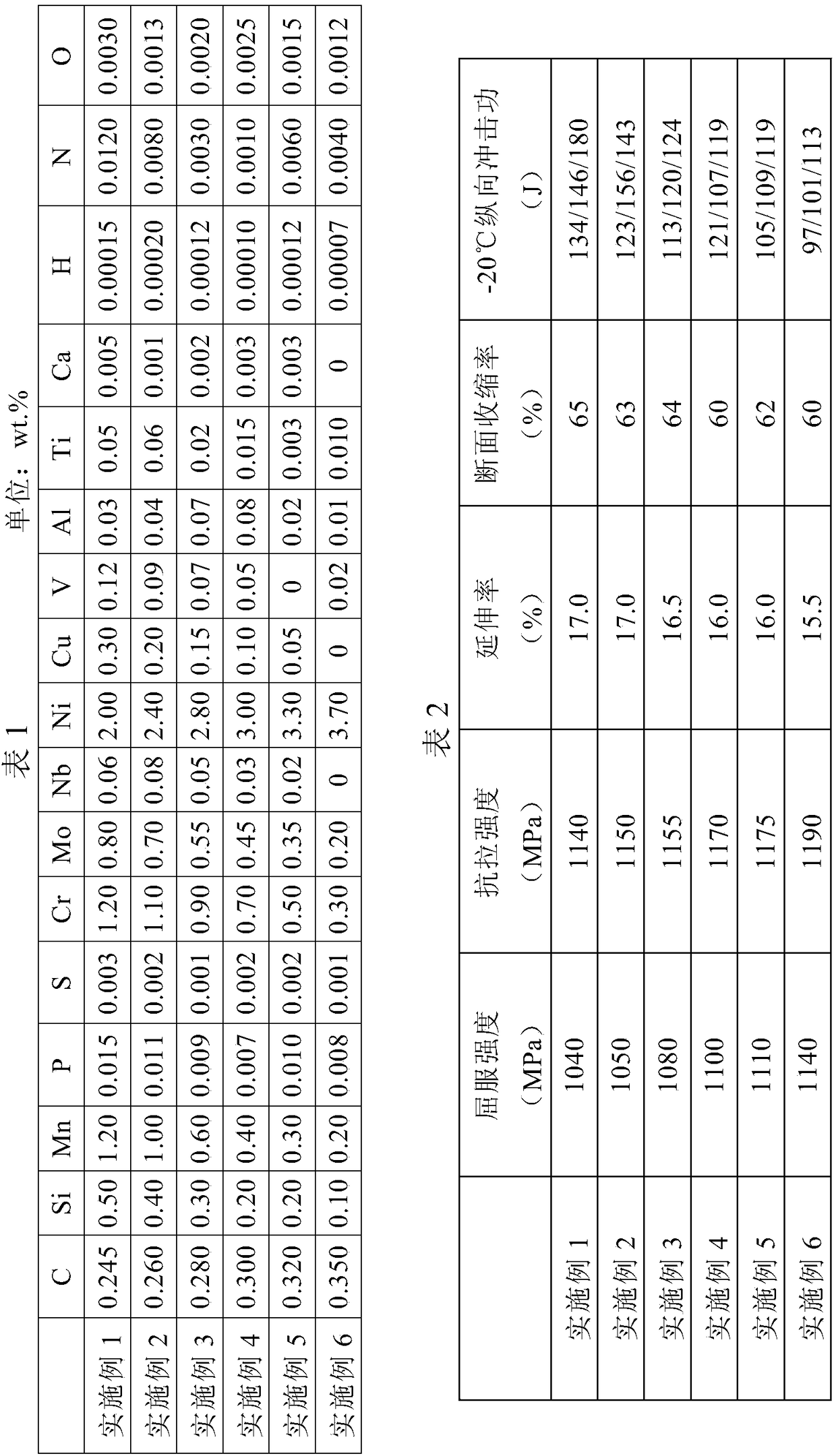

Embodiment 1

[0055] Smelt in electric furnace or converter according to the chemical composition shown in Table 1, and cast into continuous casting slab or steel ingot, heat the continuous casting slab or steel ingot to 1050°C, finish rolling temperature at 800°C, intermediate billet size 220*220mm. The intermediate billet is heated to 1070°C, the final rolling temperature is 760°C, and the specification of the finished bar is Cool in air after rolling. The quenching heating temperature is 840°C, and the heating time is 30 minutes; the tempering temperature is 500°C, and the tempering time is 30 minutes, and air-cooled after tempering.

Embodiment 2

[0057] The implementation method is the same as that in Example 1, wherein the heating temperature is 1080°C, the finish rolling temperature is 840°C, and the size of the intermediate billet is 215*215mm. The intermediate billet is heated to 1100°C, the final rolling temperature is 830°C, and the specification of the finished bar is Cool in air after rolling. The quenching heating temperature is 870°C, the heating time is 100 minutes, the tempering temperature is 530°C, the tempering time is 60 minutes, and air cooling after tempering.

Embodiment 3

[0059] The implementation is the same as in Example 1, wherein the heating temperature is 1120°C, the finish rolling temperature is 920°C, and the finished bar specification is Cool in air after rolling. The quenching heating temperature is 900°C, the heating time is 150 minutes, the tempering temperature is 550°C, the tempering time is 100 minutes, and air-cooled after tempering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com