Acid corrosion resistant quenching and tempering high-strength pressure vessel steel and production method

A technology of acid corrosion resistance and pressure vessel, which is applied in the field of low-alloy high-strength steel manufacturing, and can solve the problems of inability to meet the manufacturing requirements of large fixed spherical tanks and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below:

[0048] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

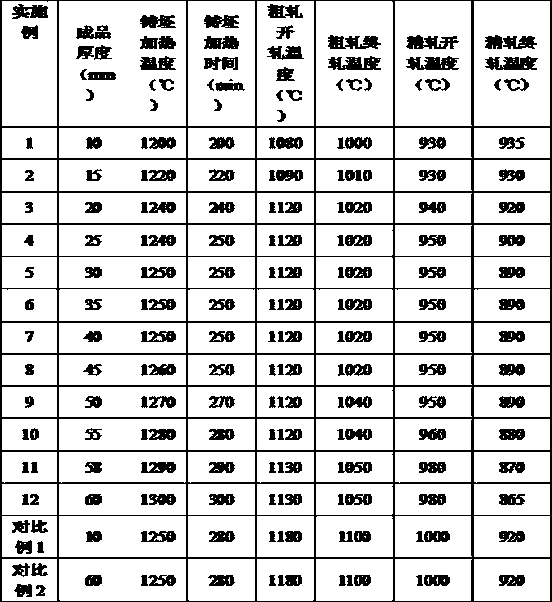

[0049] Table 2 is the smelting and rolling process parameter list of each embodiment of the present invention and comparative examples;

[0050] Table 3 is the heat treatment process parameter list of each embodiment of the present invention and comparative example;

[0051] Table 4 is the mechanical test result of each embodiment of the present invention and comparative example;

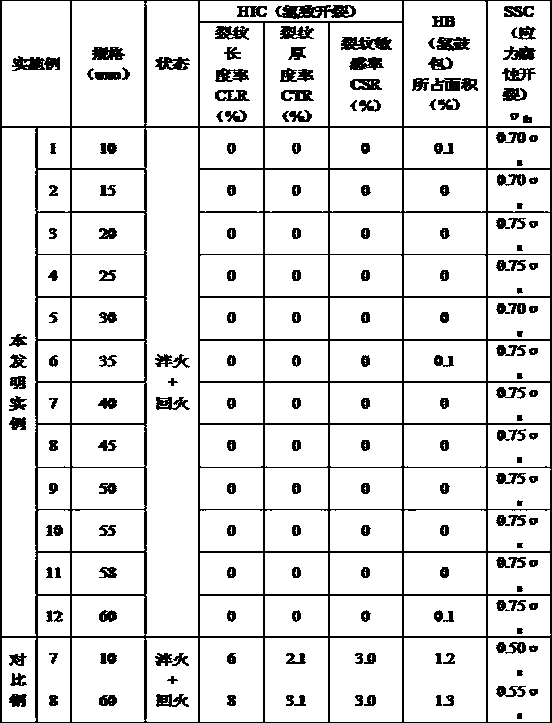

[0052] Table 5 is the anti-hydrogen sulfide corrosion inspection result of each embodiment of the present invention and comparative example;

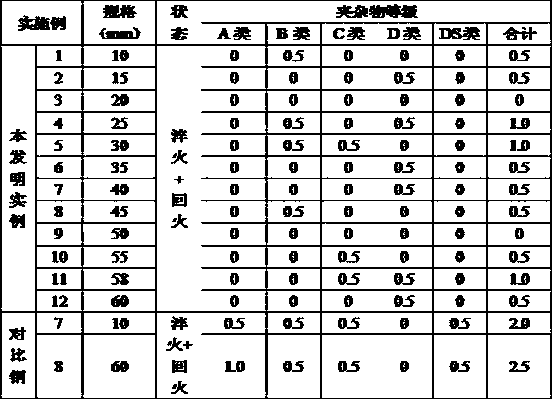

[0053] Table 6 shows the inclusion inspection results of the various embodiments and comparative examples of the present invention.

[0054] Each implementation case of the present invention all produces according to the following steps:

[0055] 1) Conventional hot metal pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com