Ultralow-aluminum non-oriented silicon steel inclusion control method

A technology of oriented silicon steel and control method, applied in the direction of manufacturing converters, etc., can solve problems such as affecting the quality of molten steel and the normal progress of production, corrosion of refractory materials of smelting RH dip pipes, affecting the magnetic properties of non-oriented silicon steel, etc., to improve non-metallic Types of inclusions, improved service life, effect of improved pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

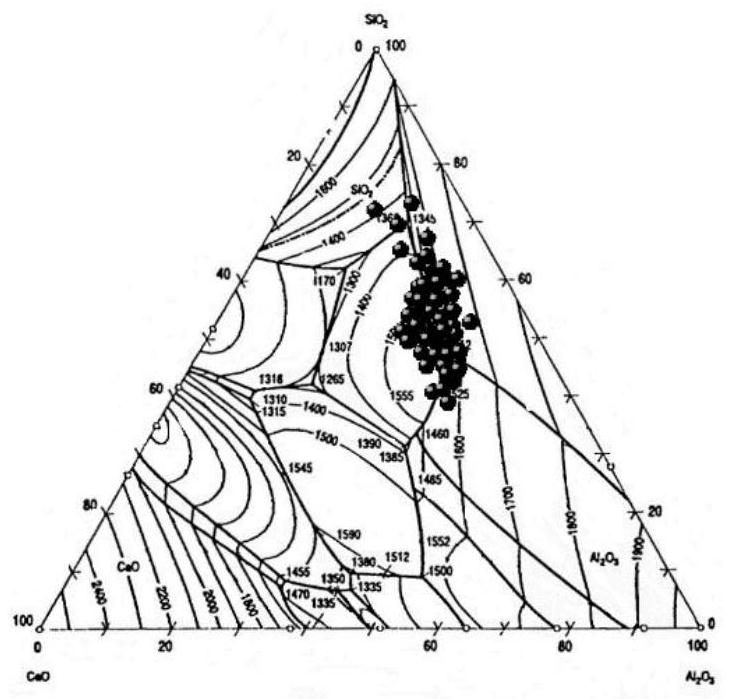

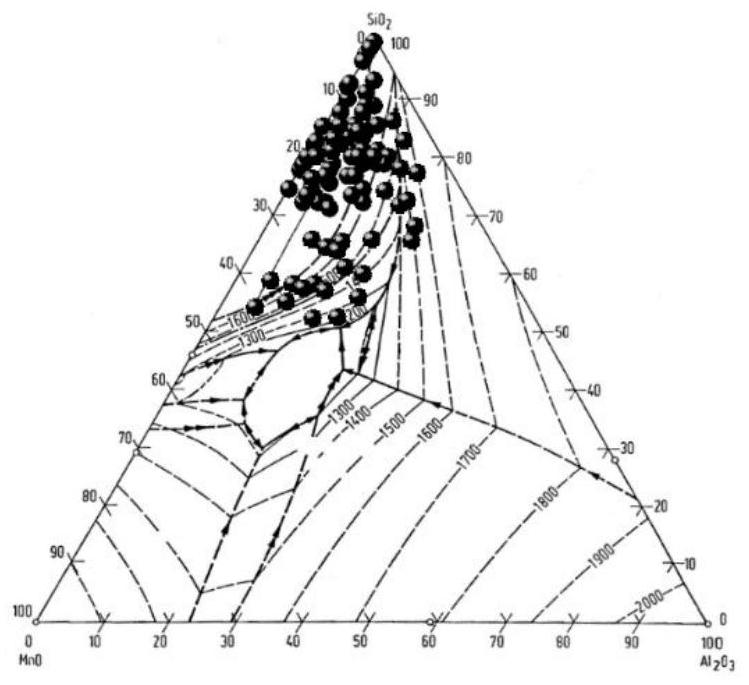

Image

Examples

Embodiment

[0027] It is produced on the ultra-low aluminum non-oriented silicon steel production line of a steel plant. Its technological process is: converter smelting→RH vacuum refining→continuous casting. Taking the process of the present invention as an example, the present invention will be further described.

[0028] (1) After the molten iron has been desulfurized by KR, the requirements for the molten iron when entering and exiting the station are shown in Table 1 below. After the treatment is completed, it is transported to the converter for blowing.

[0029] Table 1 KR incoming and outgoing hot metal conditions

[0030] furnace number Entry temperature, ℃ Si,% Ex-S, % After S, % 1 1352 0.25 0.027 0.0011 2 1383 0.50 0.040 0.0015 3 1366 0.37 0.032 0.0011 4 1375 0.44 0.038 0.0012

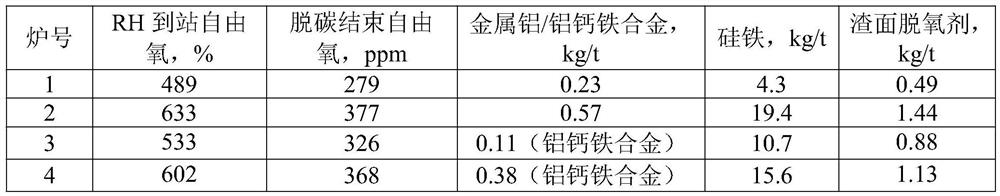

[0031] (2) Converter slag-stop tapping, strictly control the slag drop, and evenly add slag surface deoxidizer and lime to the slag surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com