Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

280results about How to "Avoid microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded flexible well cementing grout and preparation method thereof

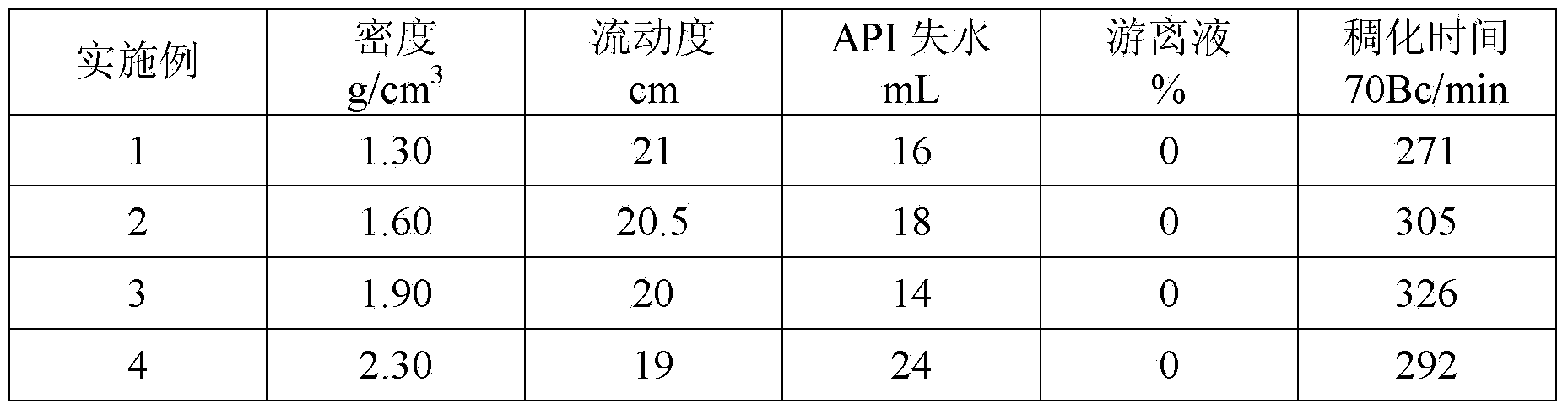

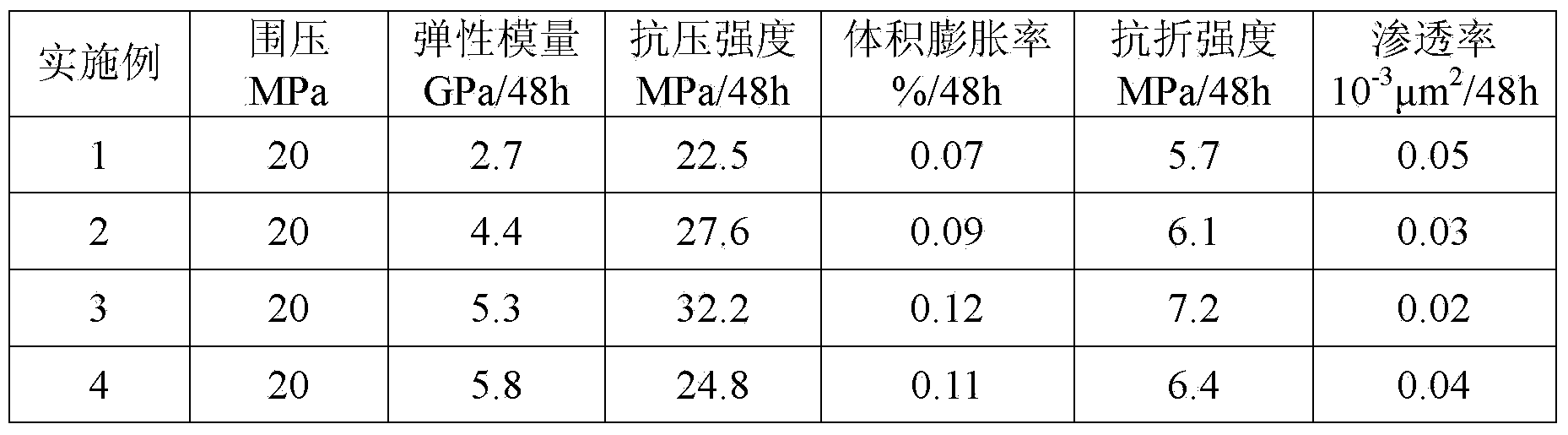

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

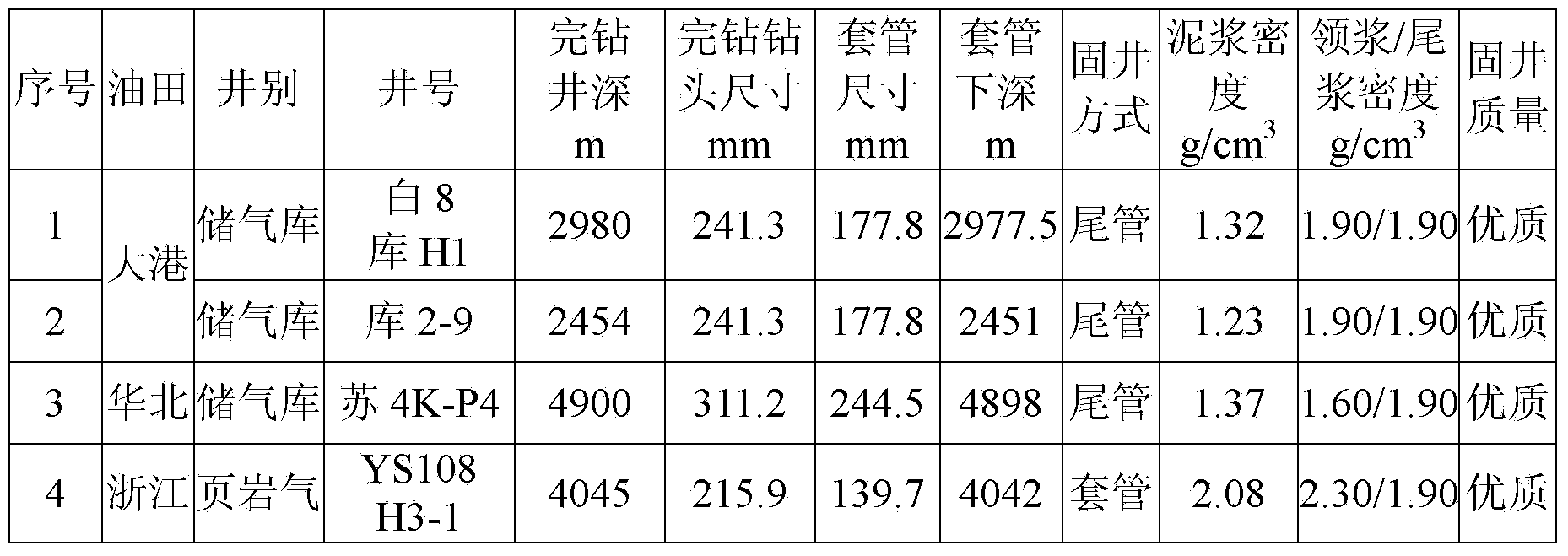

Optical device with negative thermal expansion substrate and uses therefor

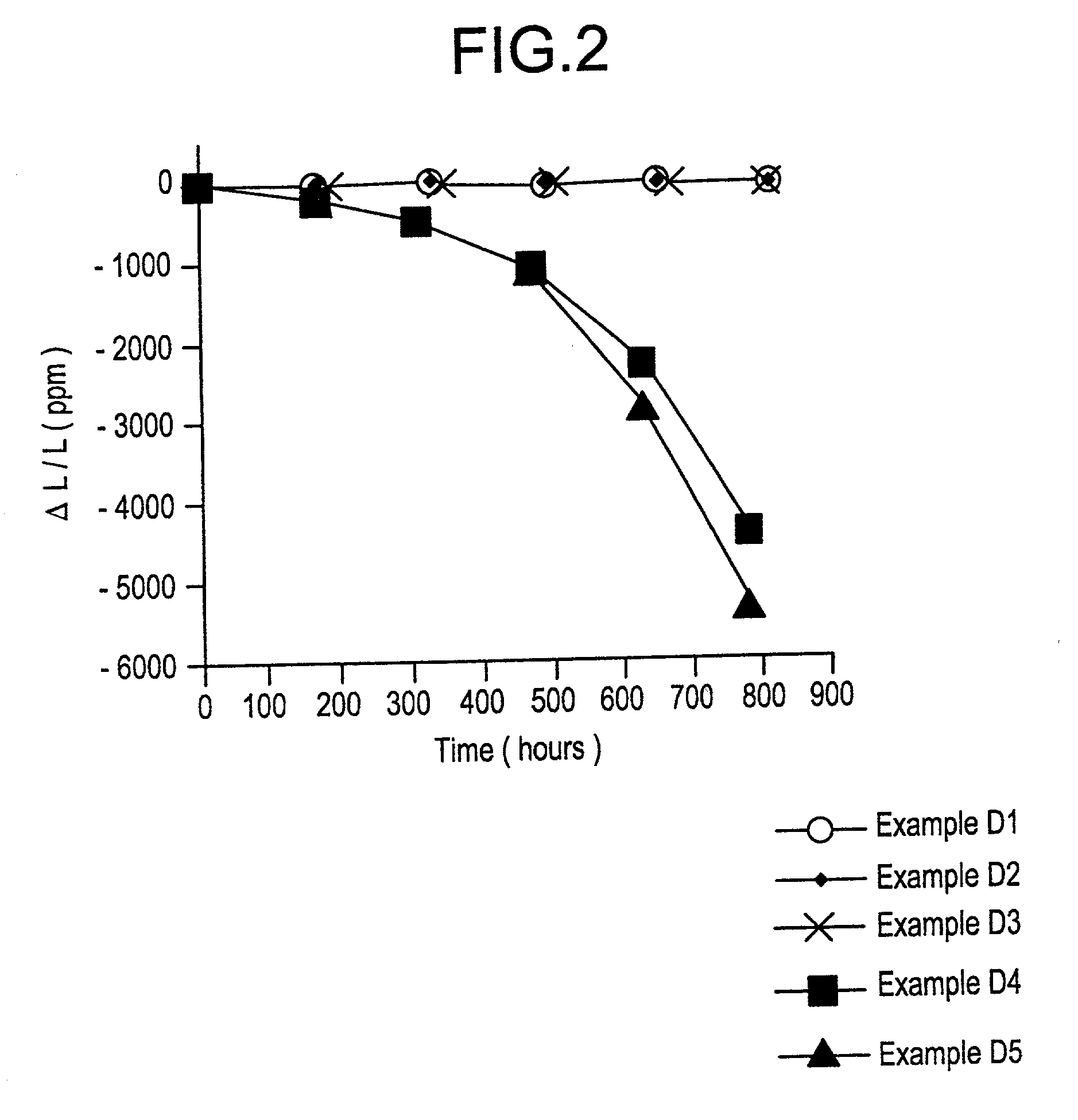

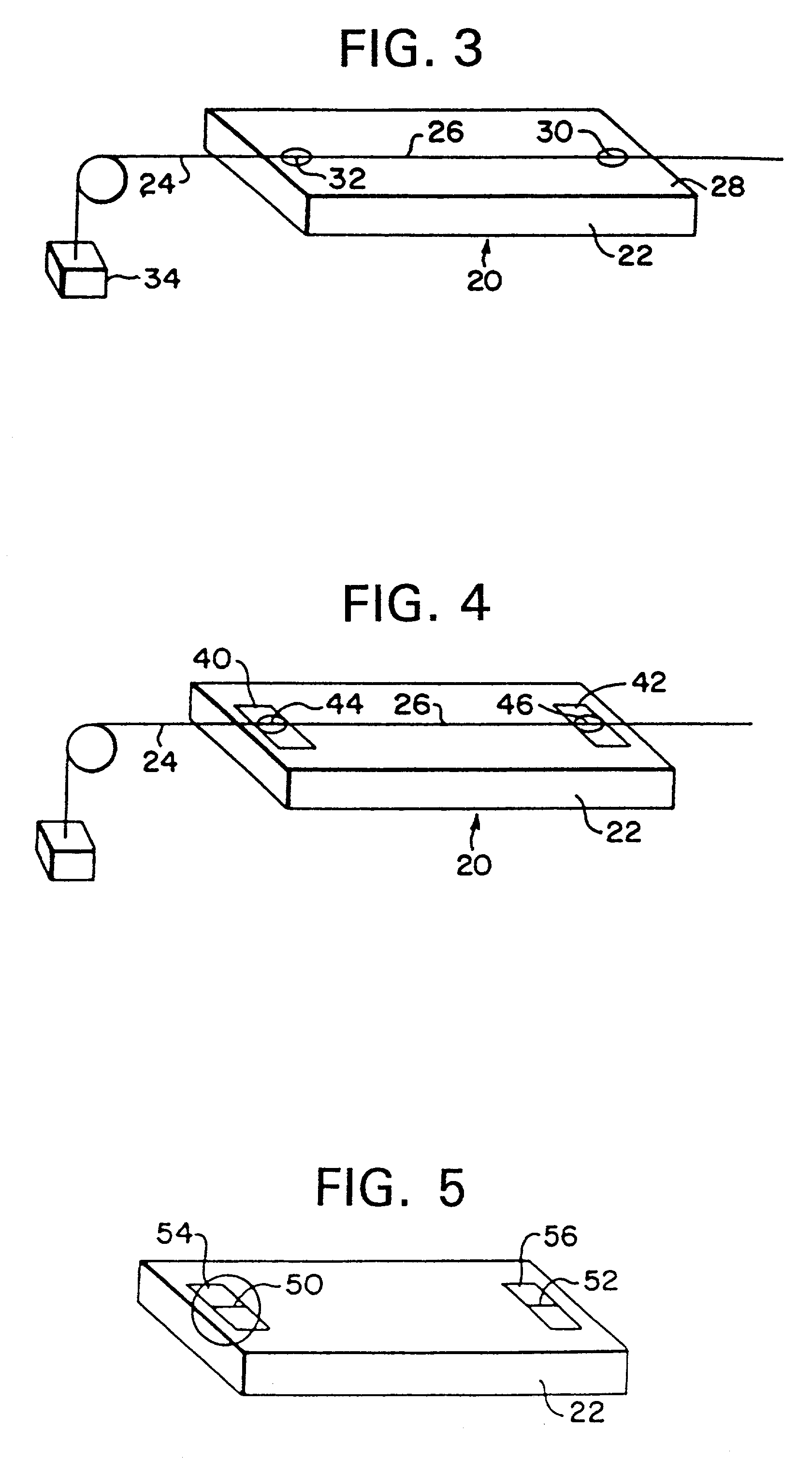

InactiveUS20010021292A1Avoid microcracksEasy to meetCladded optical fibreCoupling light guidesGratingMaterials science

Negative thermal expansion materials, methods of preparation and uses therefor are disclosed. The materials are useful for negative thermal expansion substrates, such as those used for optical fiber gratings.

Owner:CORNING INC

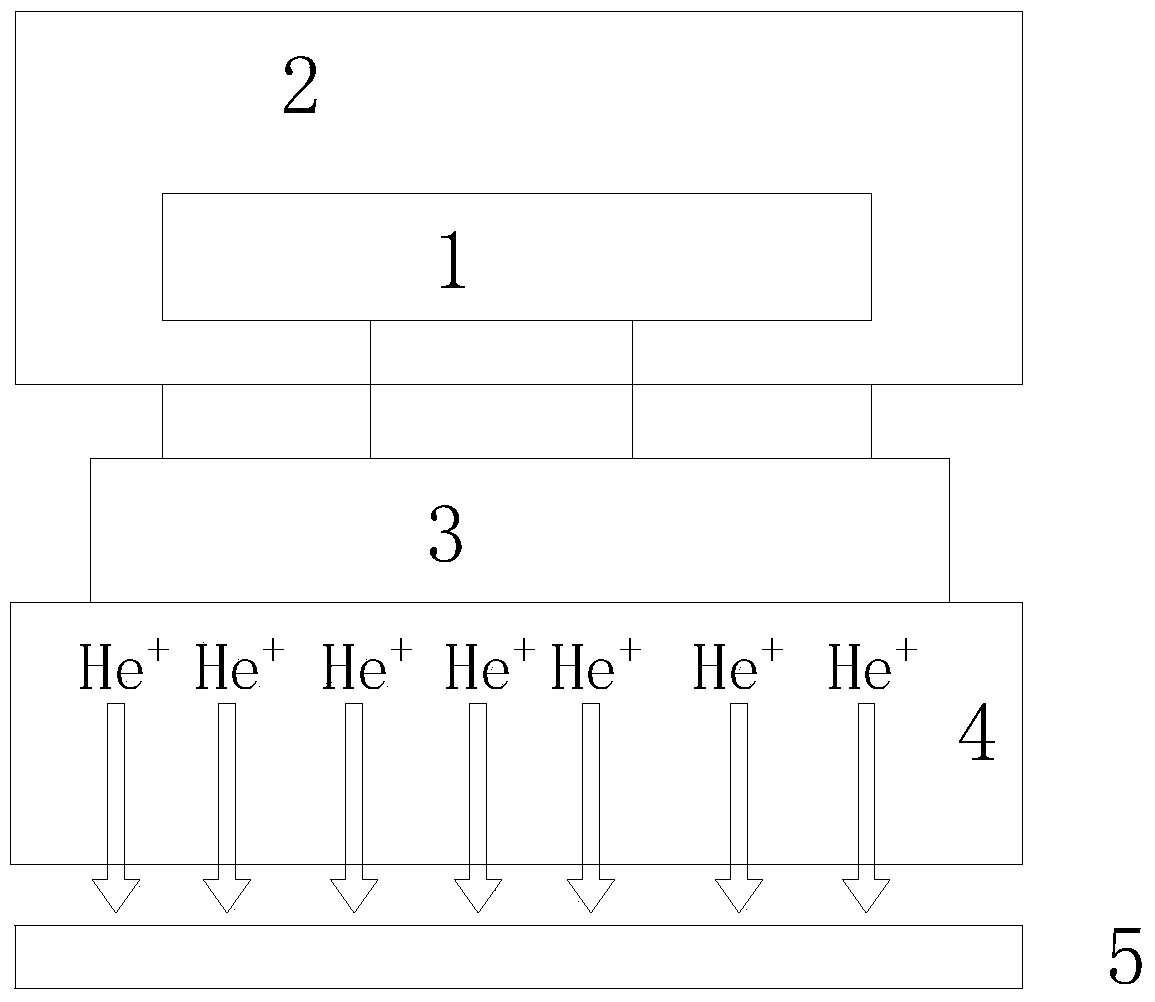

Preparation method of sapphire-glass laminated sheet

ActiveCN103707578AReduce reworkAvoid microcracksGlass/slag layered productsMaterials preparationSapphire

The invention discloses a preparation method of a sapphire-glass laminated sheet. The preparation method comprises the following steps: (1) injecting a He<+> ion layer on the surface of a sapphire material; (2) peeling the He<+> ion layer to obtain an ultrathin sapphire material with at least one damage-free and ultra-smooth face; (3) roasting and welding to obtain a laminated sheet with one damage-free face and the other glass face; and (4) processing. The preparation method disclosed by the invention has the beneficial effects that (1) the processing speed is relatively fast, a lot of re-work in the sapphire material preparation and loading process is saved, and the production cost is lowered; (2) the ultra-smooth laminated sheet with characteristics of glass material and sapphire material is obtained, microcracks in the conventional sapphire processing process are avoided, and the application range of sapphire is expanded, so that the preparation method can be widely applied to the fields of optics, display and substrates.

Owner:贵阳嘉瑜光电科技咨询中心

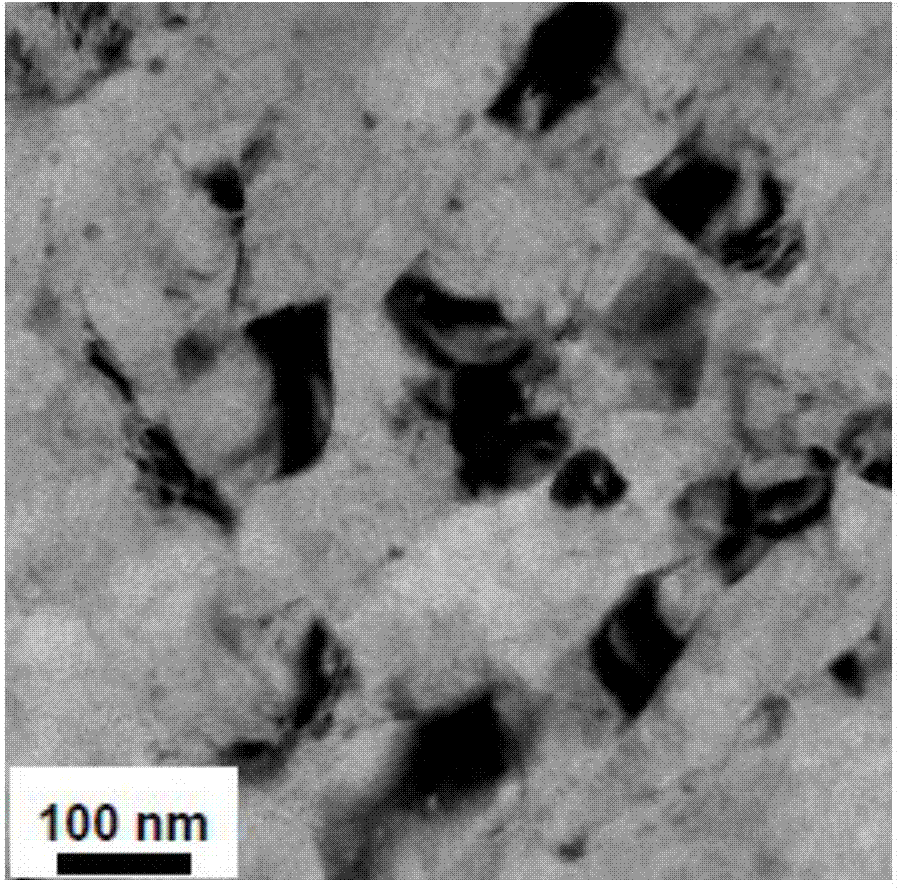

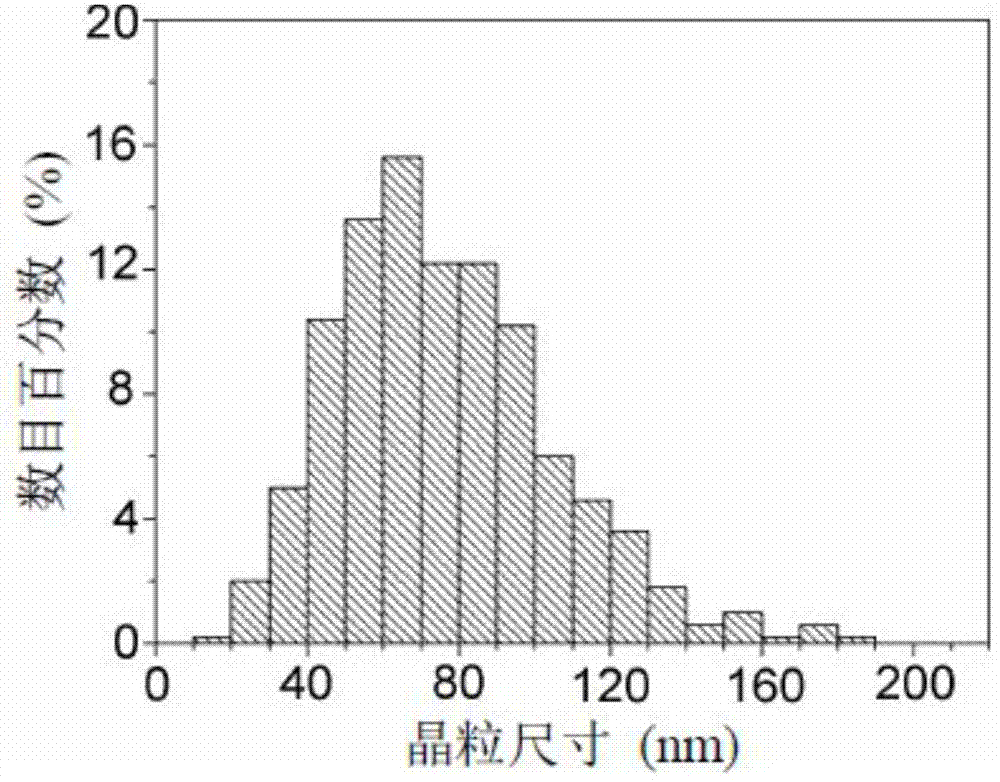

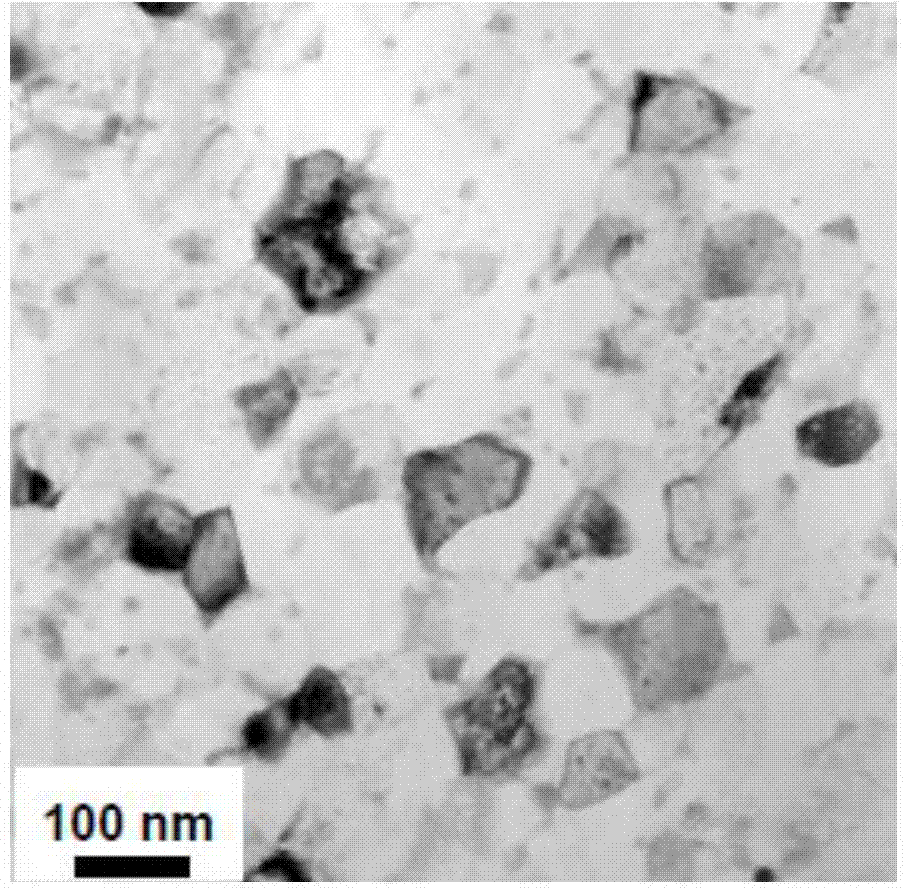

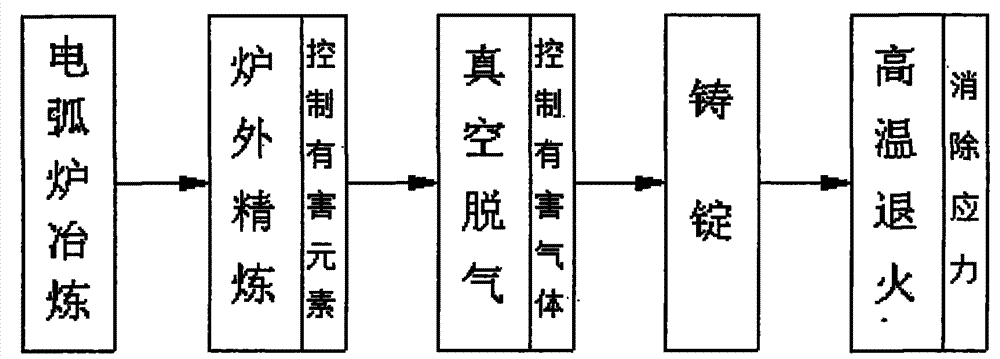

Method for preparing nanocrystalline metal material containing nano-sized precipitates within crystal

The invention provides a method for preparing a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method comprises the following steps of firstly, performing high-temperature solution treatment on a coarse crystalline metal material, thereby obtaining single phase solid solution with supersaturated and dissolved alloy element, wherein the coarse crystalline metal material contains alloy element in a matrix, and the solid solubility is reduced as the temperature is reduced; then, performing severe plastic deformation and high-pressure reverse processing at or below the room temperature, thereby obtaining single phase solid solution nanocrystalline material composed of nanocrystalline grains with supersaturated and dissolved alloy element; and finally, ageing the obtained nanocrystalline material at a pressure of 3-25 GPa and at a temperature of 100-800 DEG C, and holding the temperature for 5-8 h, thereby obtaining a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method provided by the invention is wide in suitable material component range, and can be used for effectively avoiding severe plastic deformation to produce microcrack in a material, and the prepared nano-sized precipitates in the nanocrystalline material are distributed uniformly.

Owner:YANSHAN UNIV

Method for machining forge piece of large-scale single-flange anti-explosion motor main shaft of all-fiber texture

ActiveCN103894792AIntegrity guaranteedImprove mechanical propertiesMetal-working apparatusFiberEconomic benefits

The invention discloses a method for machining a forge piece of a large-scale single-flange anti-explosion motor main shaft of an all-fiber texture. The method comprises the specific steps of raw material smelting, heating, first heating number twice upsetting and swaging, second heating number flange and step shaft forging, normalization treatment after forging, workblank detection, nondestructive inspection, mechanical property and metallographic examination, semi-finishing, stabilized heat treatment and the like. According to the method, the all-fiber texture of the forged single-flange anti-explosion motor main shaft is even, the flange root is high in impact-resistant mechanical property, and operation is balanced and free of noise. Meanwhile, the method greatly reduces production cost and is good in economic benefit.

Owner:陕西华威科技股份有限公司

Laser induced low pressure jet flow combined etching processing method and device

InactiveCN103317234AEasy to cleanImprove surface finish qualityLaser beam welding apparatusHigh energy laser beamHigh pressure

The invention discloses laser induced low pressure jet flow combined etching processing method and device thereof. The method comprises the following steps: the operations of cutting, drilling and slotting are performed on a workpiece by utilizing high-energy laser beams generated by a laser processing system, and meanwhile erosion is performed on the material surface subjected to laser ablation through high-speed jet flow beams generated by a corrosive medium jet flow device, so that the purpose of removing the material is achieved; the device comprises a laser device and a power source, and further comprises a jet flow generation device and a corrosion liquid circulating reflux device, wherein the jet flow device comprises a corrosion liquid tank, a plunger piston high pressure pump, a pressure gauge, an accumulator, a one-way control valve, a corrosion-resistant spray nozzle and a jet flow device fixed fixture. The method disclosed by the invention has the advantages that the laser ablation is mainly performed, the cooling of high-speed corrosive medium jet flow beams, synchronous erosion and combined processing effect of the cooling and the erosion are added on the basis of the laser ablation, so that the laser induced low pressure jet flow combined etching processing of the material is realized; the invention provides an efficient, clean and combined etching processing process.

Owner:JIANGNAN UNIV

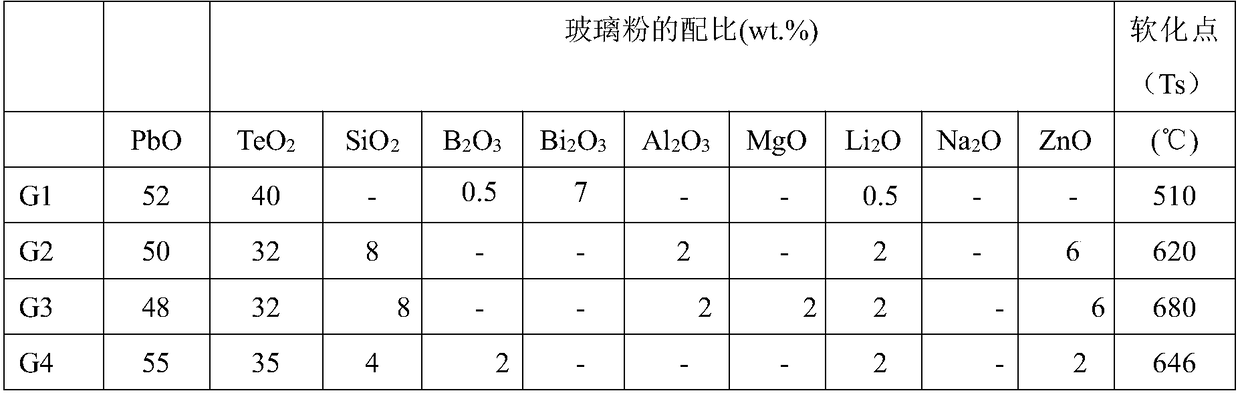

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

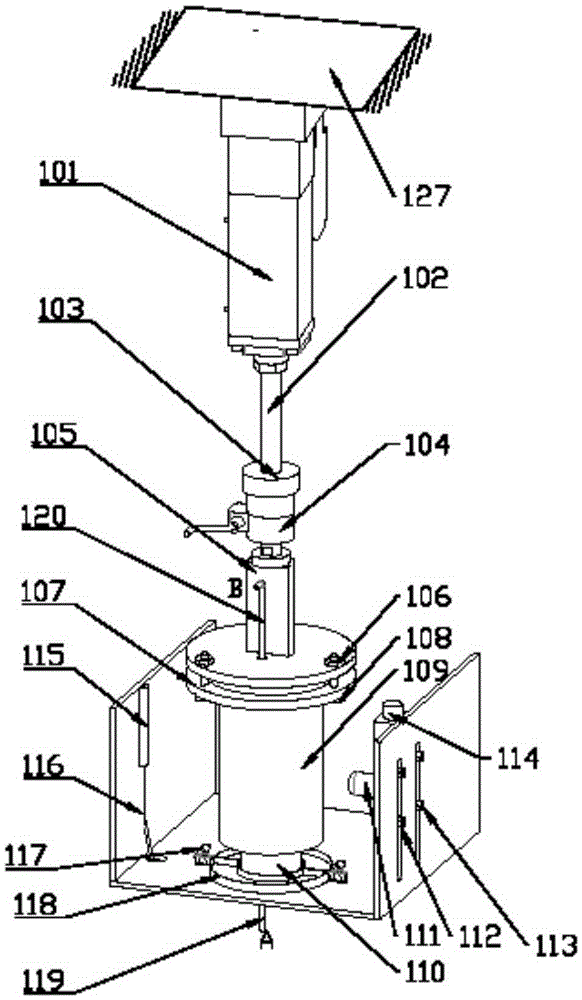

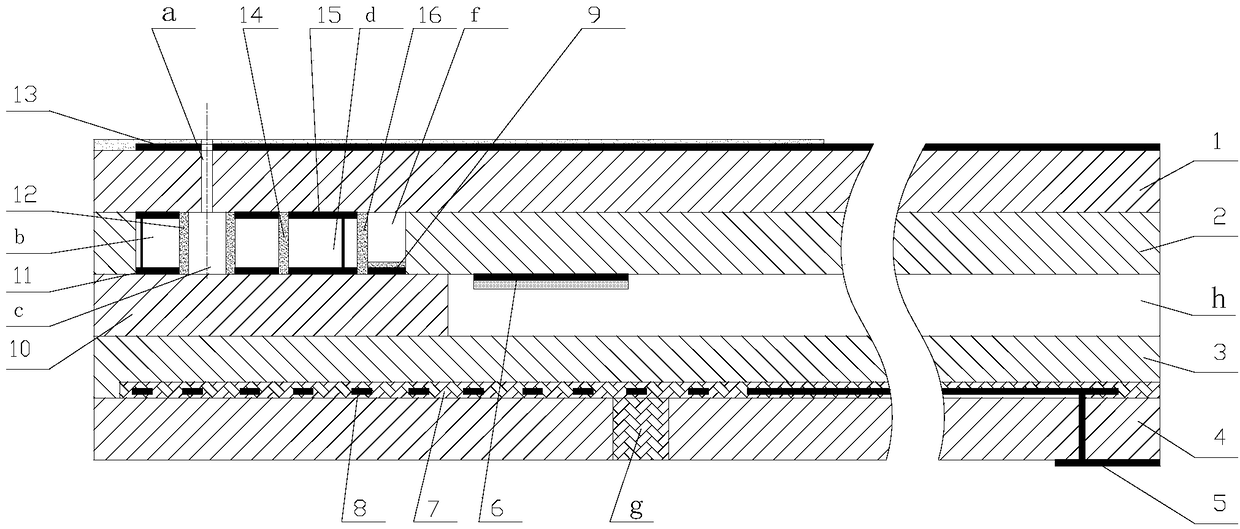

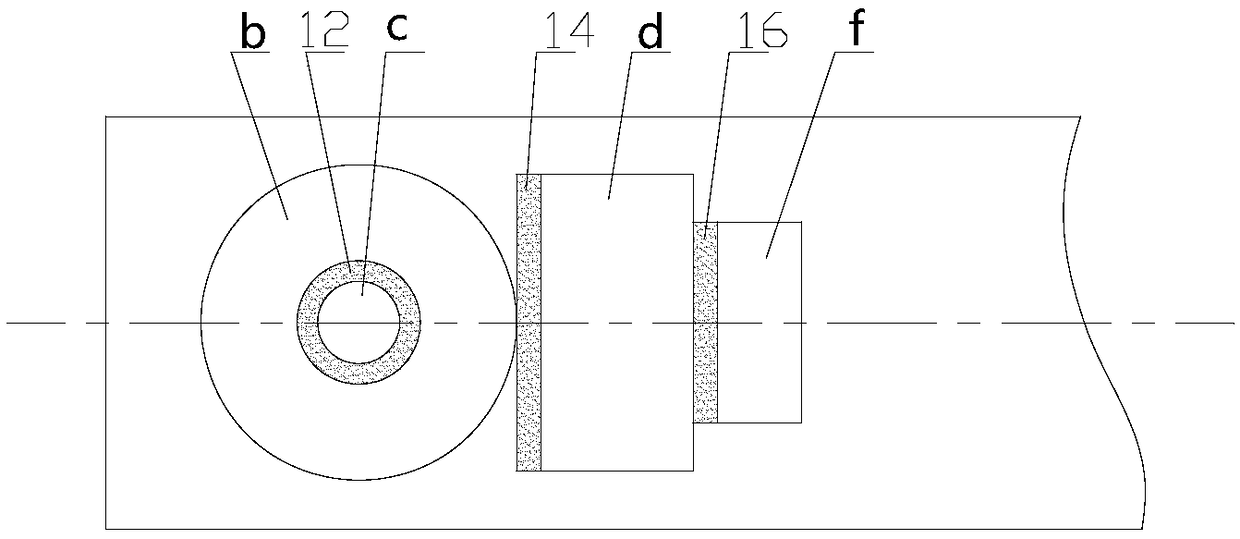

Closed oil film visualization device capable of measuring leakage of reciprocating sealing piston

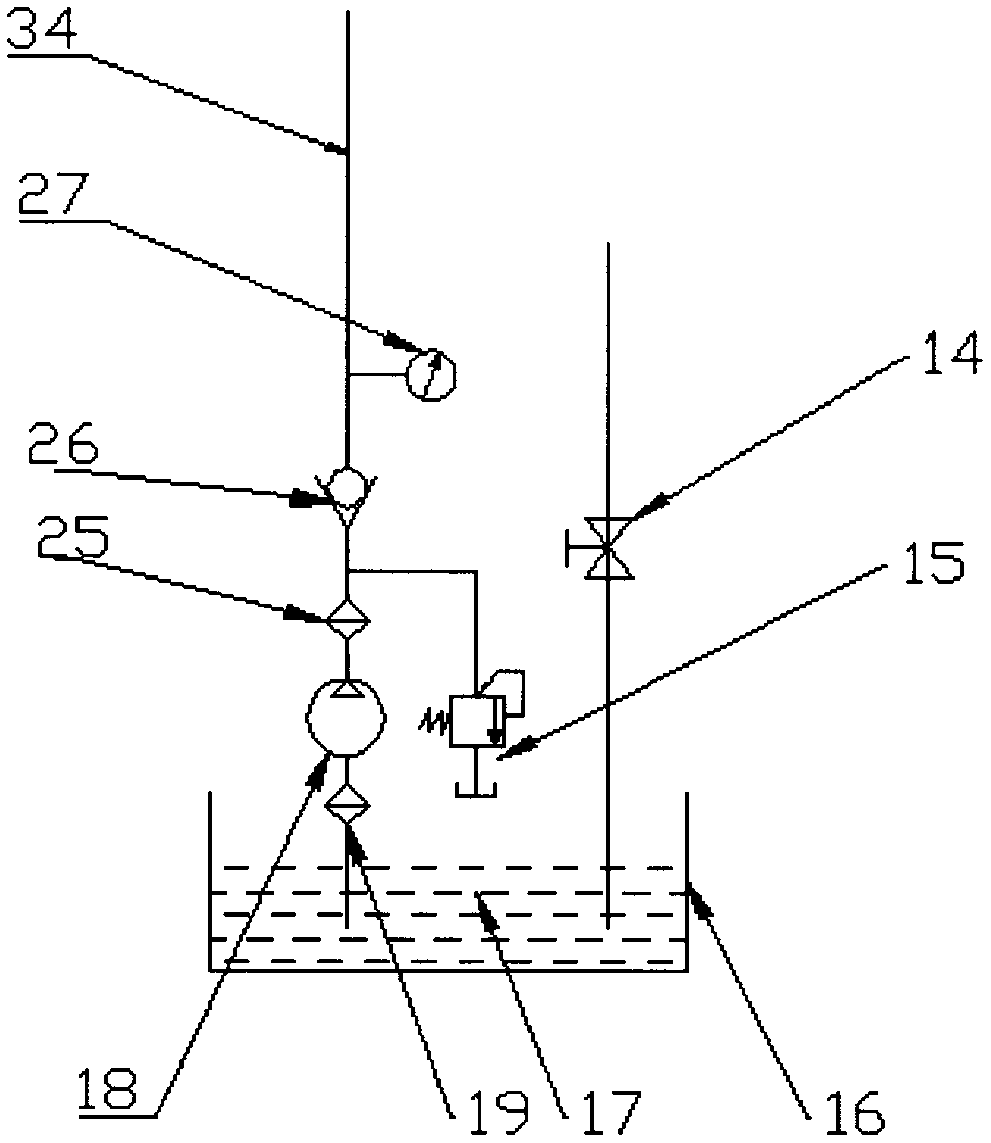

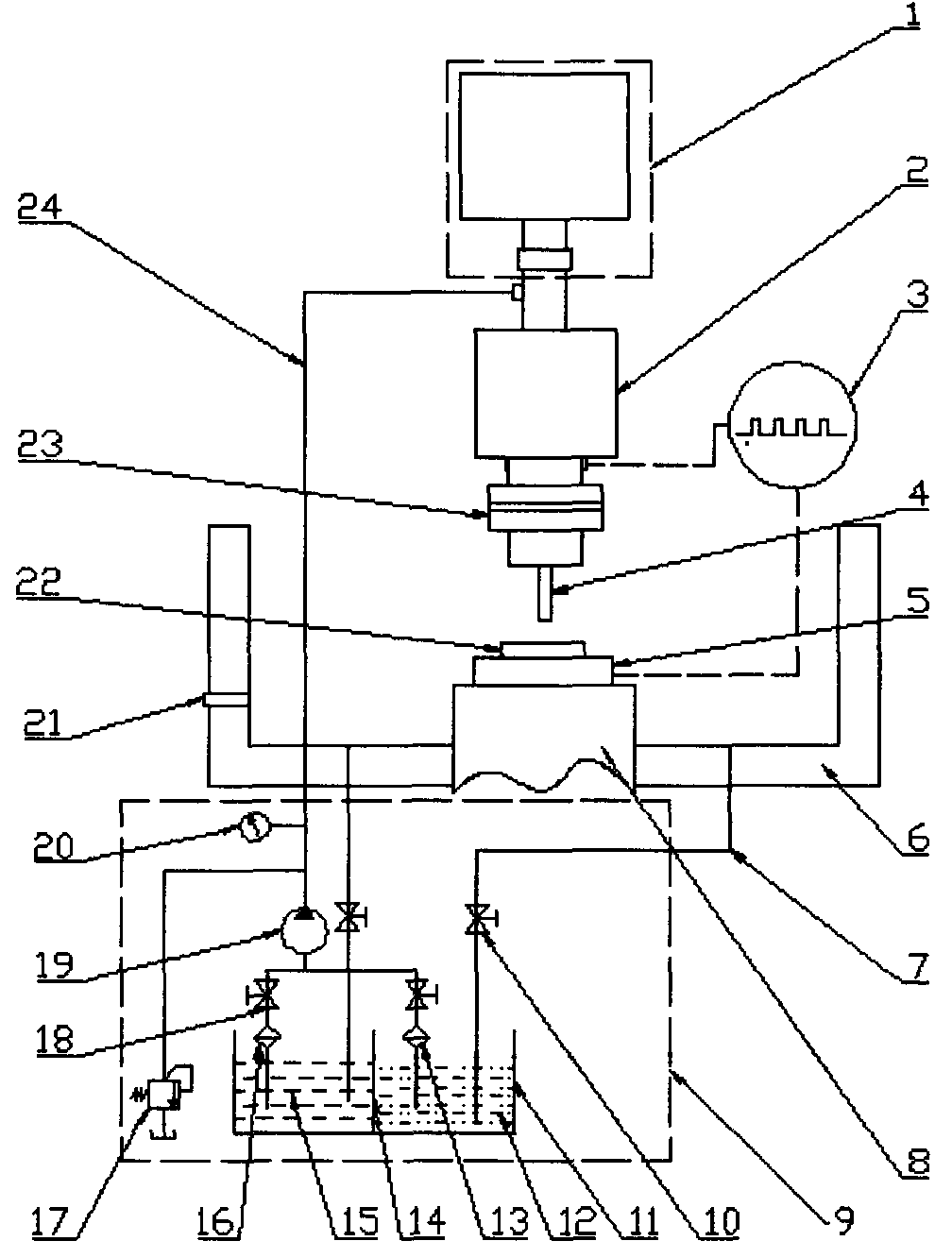

ActiveCN105257618AStable liquid pressureAvoid destructionFluid-pressure actuator testingFluid-pressure actuator componentsLiquid heightLinear actuator

The invention discloses a closed oil film visualization device capable of measuring leakage of a reciprocating sealing piston. The device comprises a tabletop visualization mechanism and an oil supply system, wherein the tabletop visualization mechanism comprises a top plate, a base frame, a linear actuator, a pull pressure sensor, a piston and a transparent cylinder; lower leaked liquid detecting components are arranged around the bottom of the piston; an upper leaked liquid height detecting component and a microscope observation component are arranged on the side wall of the base frame; a vertical oil way and a horizontal oil way are arranged in the piston; the two ends of the horizontal oil way penetrate through the side wall of the piston; the vertical oil way is connected and communicated with the upper leaked liquid height detecting component; an annular groove is peripherally formed in the middle part of the piston to serve as an oil closed cavity to be connected to the oil supply system; and gaps are formed in the side surface of the piston and the inner wall of the transparent cylinder. The device solves the technical difficulties in a traditional device, supplies stable liquid pressure, guarantees the bearing capacity and the service life of a glass cylinder, and detects the sealing leakage quantity or the magnitude of pumping back quantity.

Owner:ZHEJIANG UNIV

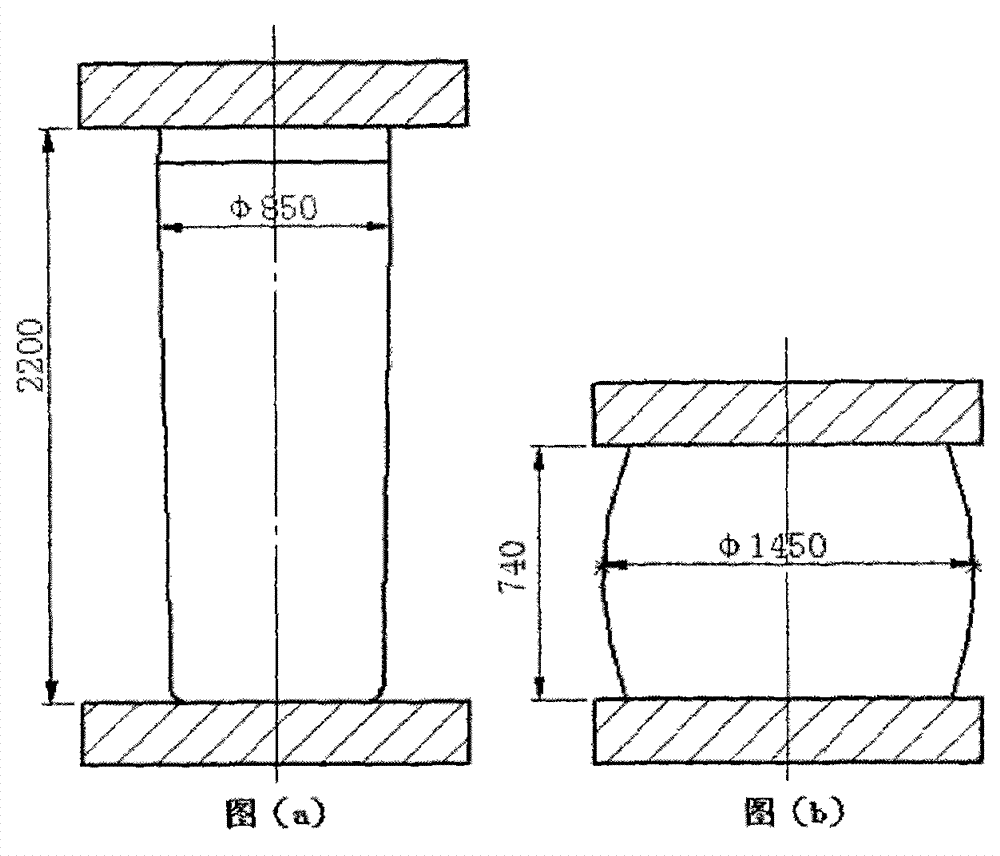

All-fiber-texture large-size double-flange fan main shaft forging method

ActiveCN104175062AGood economic benefitsEliminate poor impact mechanicsShaftsEngine componentsQuality controlForging

The invention discloses an all-fiber-texture large-size double-flange fan main shaft forging method which comprises the steps of raw material smelting quality control, heating, primary firing twice-upsetting and drawing out, number printing, blanket making, secondary firing finish forging forming until a technical dimension of a forged piece is obtained, wherein after being forged, a double-flange fan main shaft forged piece is subjected to primary supercooling, normalizing and tempering heat treatment, rough turning, ultrasonic flaw detection, mechanical property testing, semi finish turning processing, deep hole drilling, stable heat treatment and packaging. The double-flange motor main shaft forged by the all-fiber-texture large-size double-flange fan main shaft forging method is of an all-fiber-texture structure, so that the natural defects that a flange formed by cutting is easy to deform and low in structural balance property and the root is easy to break are completely overcome; the impact mechanical property of the root is improved, the material consumption is reduced, and a requirement of a large-size motor on the main shaft design is met; furthermore, compared with the conventional forging method, the main forging process has the advantages that another operation of firing is reduced, and the economical benefit is improved.

Owner:陕西华威科技股份有限公司

Cement sealing and solidifying agent and construction technique thereof

InactiveCN104016714APlugging structural voidsImprove hardened wear resistanceSodium silicateMagnesium fluorosilicate

The invention relates to a construction paint, particularly a lithium-base permeable crystallization cement sealing and solidifying agent. The cement sealing and solidifying agent is composed of 15-20 parts of sodium silicate, 8-15 parts of lithium metasilicate, 3-5 parts of magnesium fluosilicate, 2-4 parts of sodium dihydrogen phosphate, 0-6 parts of water-based color paste for paint and 50-70 parts of water. The construction technique comprises the following steps: new ground: troweling the new ground, carrying out primary hardening, coating the solidifying agent, completely drying and curing, flushing the ground with clear water, naturally drying, and sanding and polishing with a sander; and old ground: sanding and cleaning the old ground, coating the solidifying agent, naturally drying, cleaning the ground, naturally drying, and sanding and polishing (or additionally coating solidifying agent, cleaning the ground, naturally drying, and sanding and polishing). By using the solidifying agent and construction technique, the strength, hardness and compactness of the concrete are greatly enhanced, and the durability and weathering resistance of the concrete are effectively improved.

Owner:HARBIN UNIV OF SCI & TECH

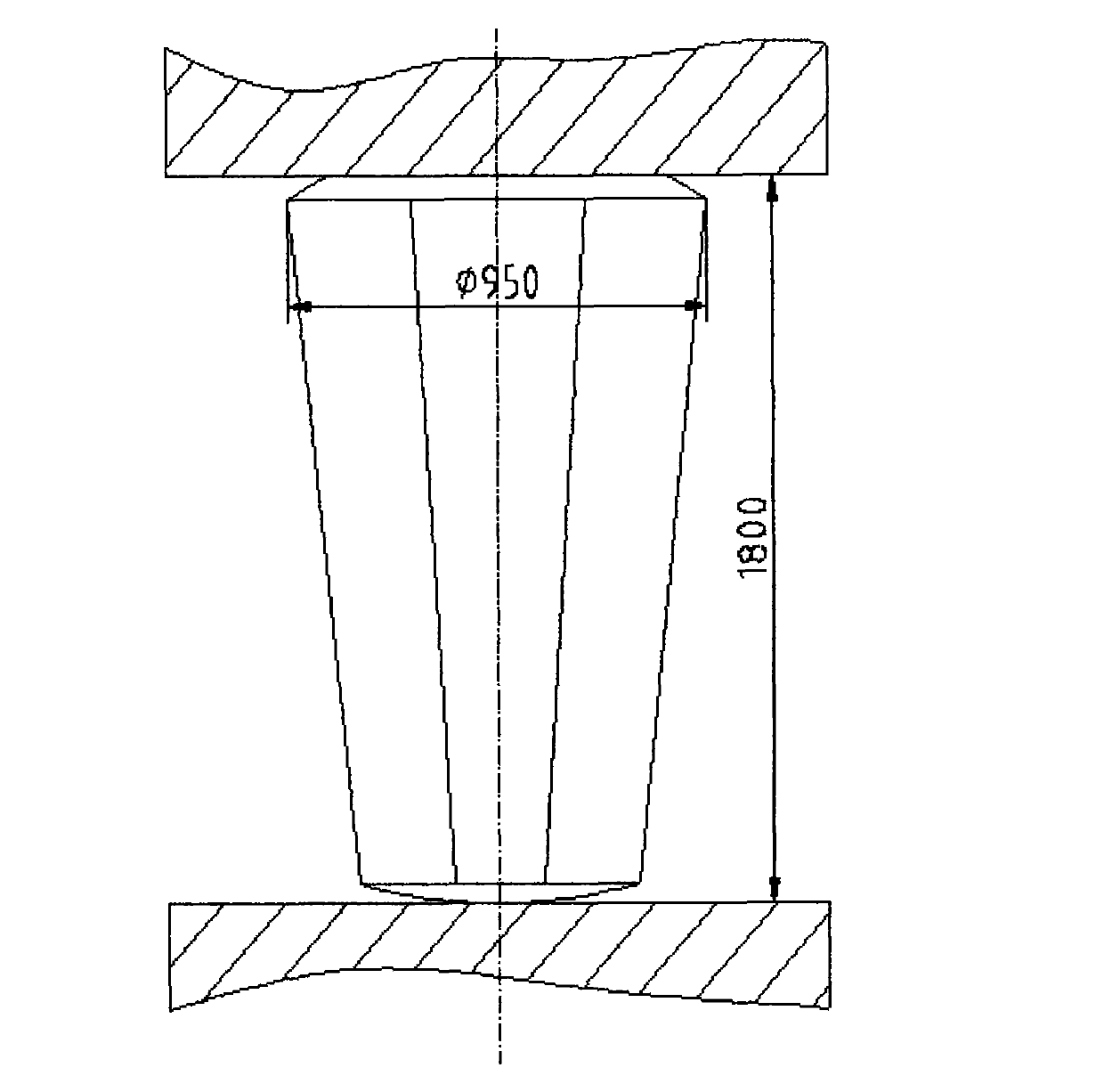

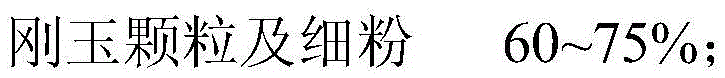

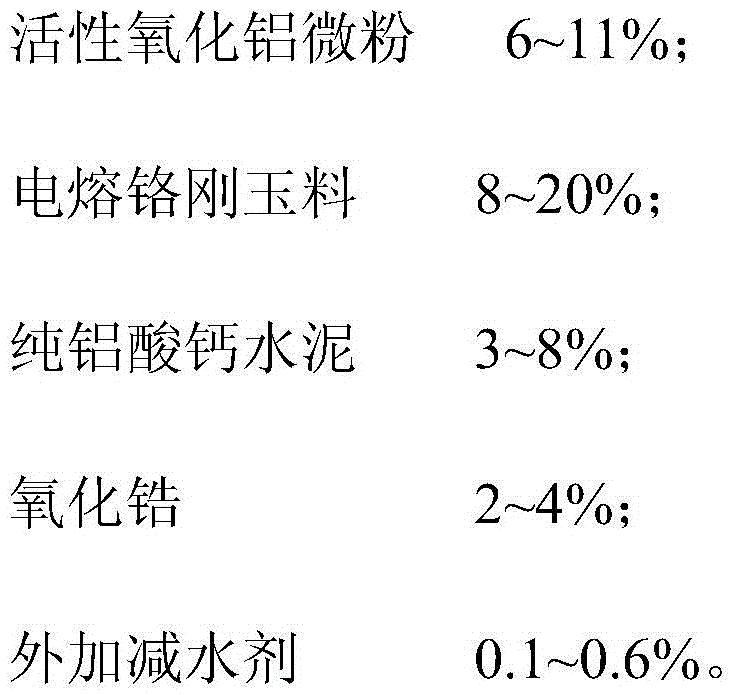

Air brick for special steel refining and preparation method thereof

InactiveCN105645977AReduce the amount of water addedImprove liquidityMelt-holding vesselsBrickCalcination

The invention relates to an air brick for special steel refining, particularly an air brick for special steel refining and a preparation method thereof. The air brick is composed of the following components in percentage by mass: 60-75% of corundum particle and fine powder, 6-11% of activated alumina micropowder, 8-20% of electrofused chrome corundum material, 3-8% of pure calcium aluminate cement, 2-4% of zirconium oxide and 0.1-0.6% of additional water reducing agent. The air brick is suitable for smelting of special steel grades, and has the advantages of excellent high-temperature properties, excellent air permeability, low breaking possibility, favorable high-temperature folding strength and favorable thermal shock resistance. By adopting the curing schedule, the cement in the material can be sufficiently hydrated, thereby enhancing the strength of the semifinished product, and avoiding generating microcracks of possible collisions in the transportation process (the cracks can further extend in the high-temperature calcination process). The firing schedule is adopted to prevent the air brick cracks from generation and enhance the yield of the air bricks.

Owner:LUOYANG LIER REFRACTORY MATERIAL

Scatheless grinding method for rigid, fragile crystal wafer

ActiveCN1958233AImprove grinding accuracyReduce processing costsAbrasion apparatusSemiconductor/solid-state device manufacturingIonCooling fluid

A nondestructive grinding method for the hard and crisp crystal substrate of semiconductor or photoelectric crystal features used of a special abrasive disc prepared from the grinding material chosen from CeO2, SiO2 and barium carbonate and the filler containing activator, oxidant and pH regulator, a finishing disc composed of metallic substrate and electroplated diamond particles, and a deionized water as cooling liquid. Its grinding parameters are also disclosed.

Owner:DALIAN UNIV OF TECH

Electromagnetic field regulation and control method of surface residual stress of aero-engine component

ActiveCN107299217AEliminate deformationAvoid damageProcess efficiency improvementManufacturing cost reductionPeak current

The invention discloses an electromagnetic field regulation and control method of surface residual stress of an aero-engine component. The regulation and control method comprises the following step: performing electromagnetic field regulation and controlling on the new-made aero-engine component at normal temperature for 3-600s, wherein the electromagnetic field is formed by coupling an alternating magnetic field and a pulsed electric field; the intensity of the alternating magnetic field is 500-30,000A / m; the frequency of the alternating magnetic field is 1-1,000Hz; the maximum peak current of the pulsed electric field is 5-20,000A; the pulse period of the pulsed electric field is 0.01-1.0s. According to the method, the traditional shot blasting process is canceled, and the distribution of residual stress of a surface layer and a near-surface layer of a material of the component is regulated and controlled by an electromagnetic field, so that the manufacturing accuracy and the surface roughness can be improved, the technological process is shortened, the manufacturing cost is lowered, and the manufacturing period is shortened.

Owner:WUHAN UNIV OF TECH

Gypsum base swelling perlite heat-insulating mortar dry powder and its usage method

InactiveCN1807337AImprove thermal insulation performanceReduce energy consumptionSolid waste managementCoalMaterials science

The invention relates to a gypsum base swelling perlite heat-insulating mortar dry powder, wherein each unit of the thermal insulating mortar dried powder comprises the following raw material as the components: expanded perlite 0.9-1.1m3, beta CaSO4*1 / 2H2O 145-165kg, common silicate cement 18-22kg, grade I coal ash and / or grade II coal ash and / or high calcium ash 45-65kg, polypropylene fiber 0.4-1kg, 80-100 mesh heavy calcium powder and / or calcium carbonate powder 1.3-1.7kg, cellulose methyl and / or methylcellulose propylene glycol ether 1.5-2.5kg, gypsum retarder 3.0-5.0kg and sodium dodecyl silicate 0.008-0.013kg.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

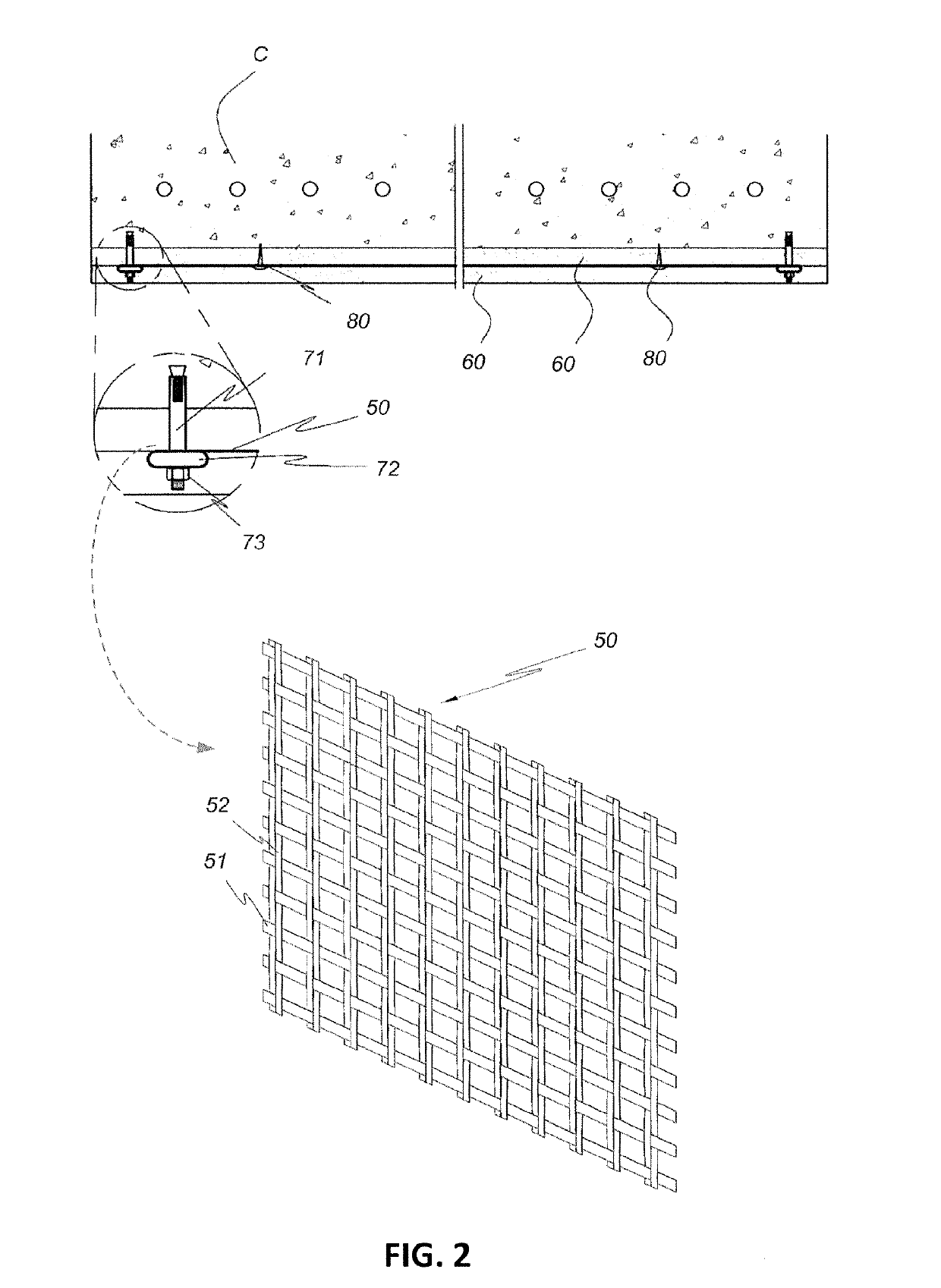

Concrete structure using reinforcing panel including embedded reinforcing grid and method of repairing and reinforcing the same

ActiveUS20190153728A1Improve the immunitySimple structureConstruction materialBuilding repairsRepair materialHardness

Reinforcing panel having high durability, high strength, and high hardness is applied such that a concrete structure may be repaired to have excellent resistance to an external environment and to be structurally excellent. In comparison to existing bonding methods, a concrete structure and a reinforcing panel may be completely attached to each other as a whole using a repairing material with high fluidity as a cement-based material injected into a repair cross section. Part with microcracks is completely filled with repairing cement mortar injected at high pressure. Since reinforcing panel is precast-fabricated in a factory, embossing, intaglio, color, and the like may be easily added to an external surface of the reinforcing panel and an excellent exterior may be provided after repair due to an aesthetic cross section thereof The reinforcing panel fabricated in a factory is applied as to reduce labor costs and construction costs.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

Preparation method of anti-shrinkage autoclaved aerated concrete block dry powder masonry mortar

The invention provides a preparation method of novel anti-shrinkage dry powder masonry mortar special for autoclaved aerated concrete blocks, and the components and ratios are: 15%-20% of anhydrite, 25%-35% of portland cement, 5%-16% of lime powder, 33%-54% of dry sand (20-40 meshes), 0.6%-0.8% of redispersable latex powder, 0.3%-0.5% of cellulose ether, and 0.4%-0.6% of calcium formate. The dry shrinkage value of the dry powder mortar is adjusted by adding cement and gypsum, and thus is close to a dry shrinkage value of an autoclaved aerated concrete block; the dry shrinkage value of a material for bonding the mortar is close to the dry shrinkage value of the autoclaved aerated concrete block; the synchronization of the shrinkage and the expansion overcomes quality accidents of empty drum, sun crack, and even shedding of masonry and floated coats caused by excessively rapid water loss of walls; and the invention has good value for popularization and application.

Owner:汤建新 +1

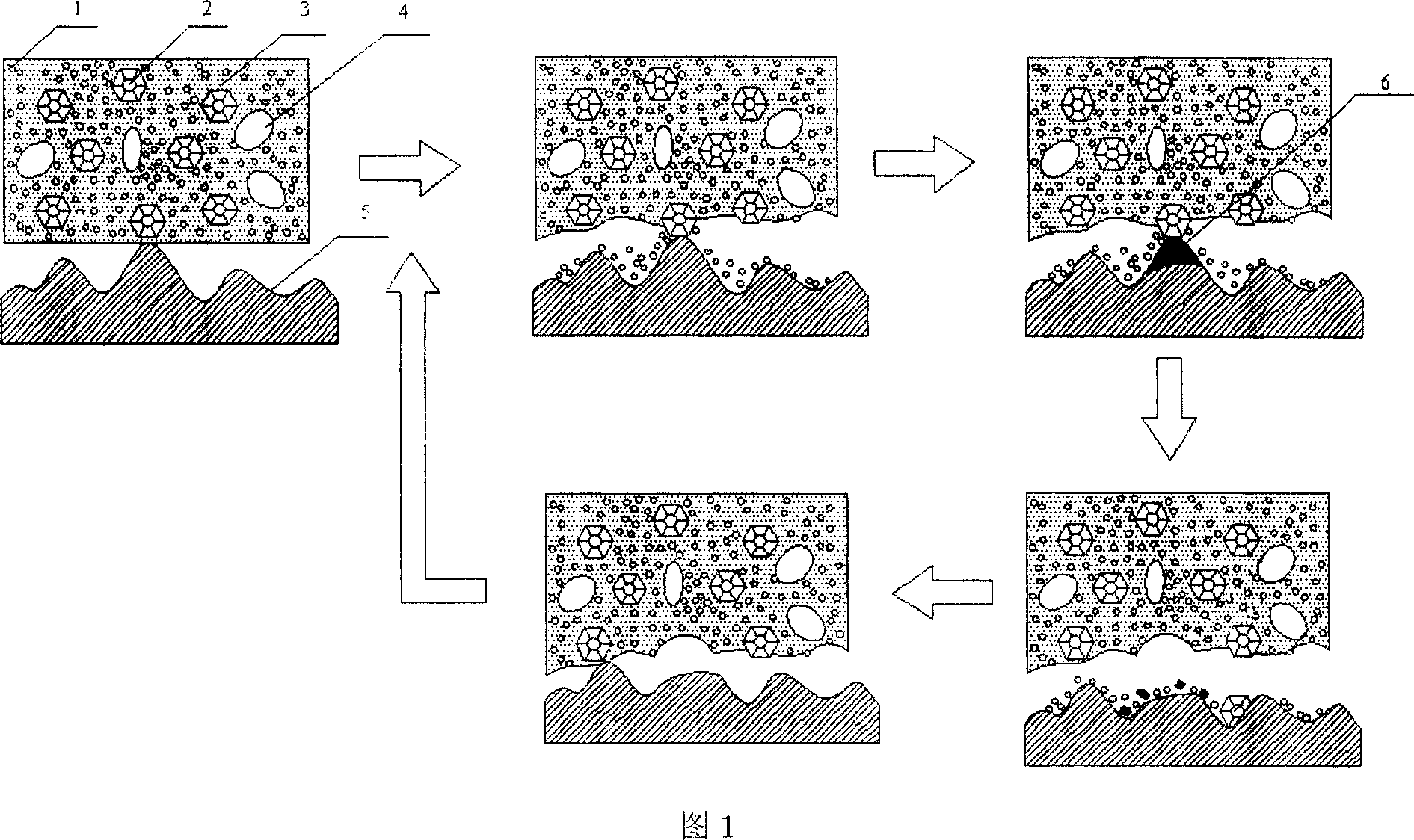

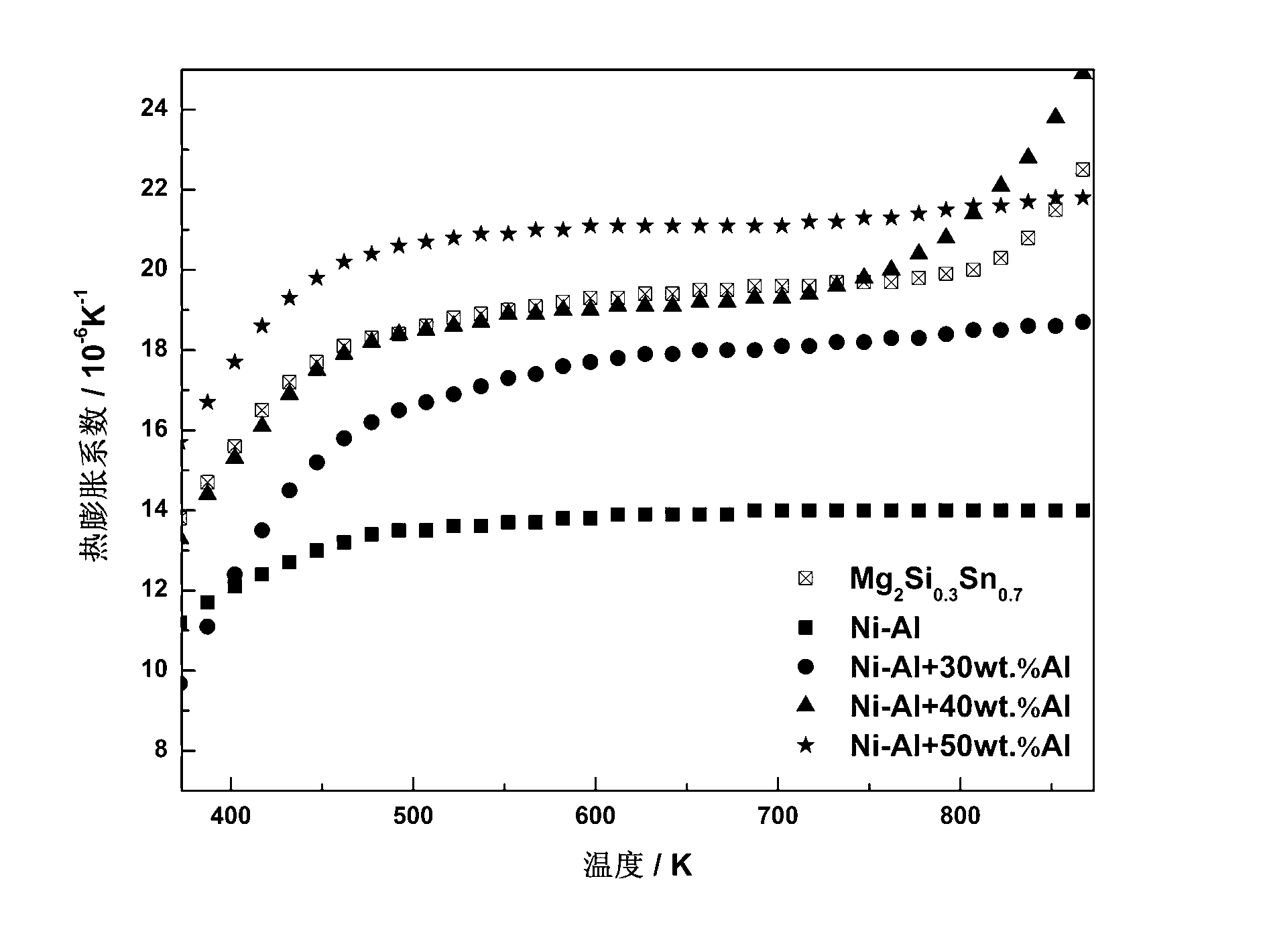

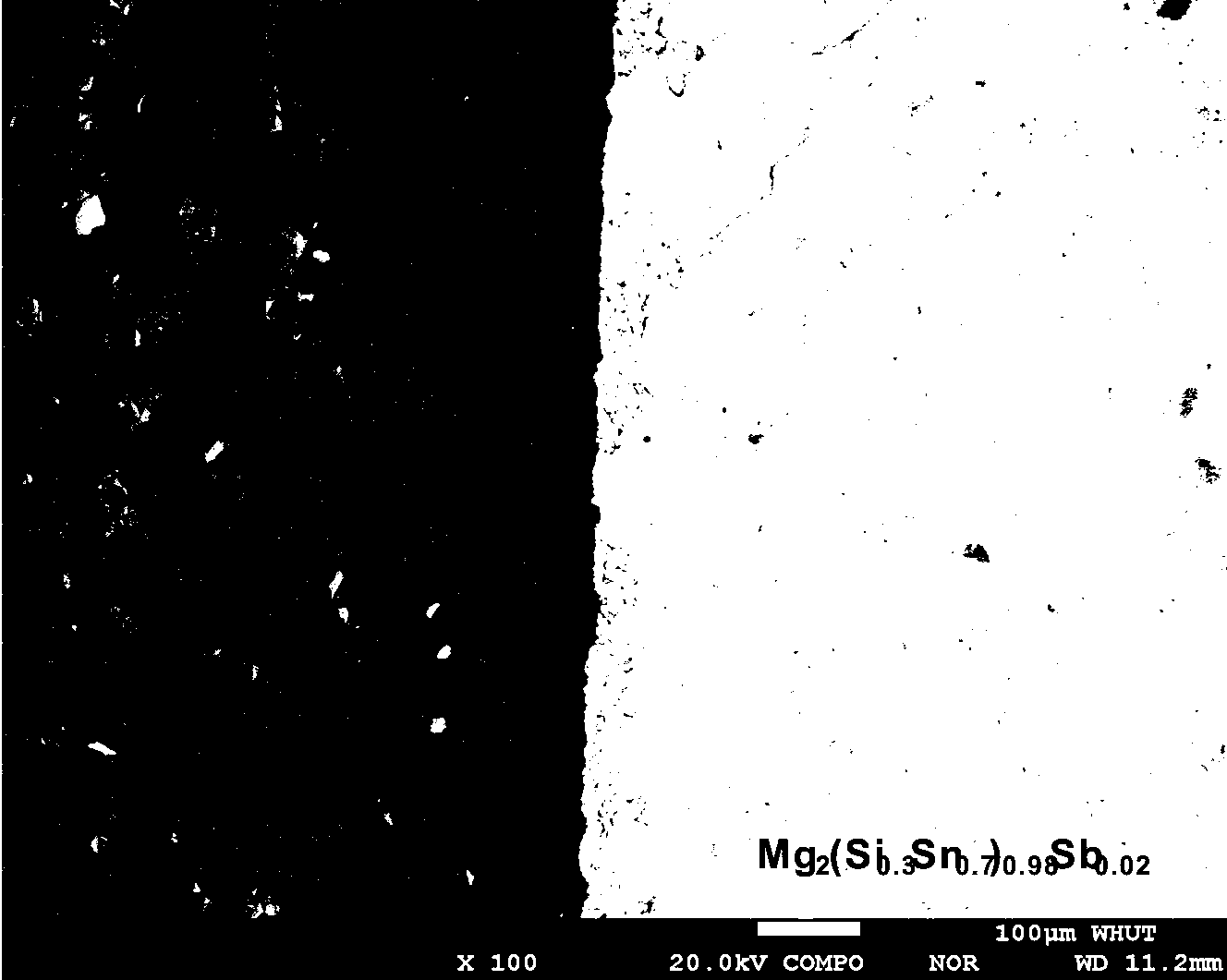

Electrode matched with Mg-Si-Sn-based thermoelectric element and connecting process thereof

ActiveCN103219456ALow costSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsEngineering

The invention relates to an electrode matched with an Mg-Si-Sn-based thermoelectric element and a connecting process thereof. The electrode is a mixture consisting of the following components in percentage by mass, 30 to 50 percent of metal elementary substance Al and the balance of Ni-Al alloy. The electrode and a thermoelectric material interface are well combined, the reliability is high, the technical operation is simple and convenient, and the service life can be prolonged due to the fact that the good thermal match between the electrode and the thermoelectric material reduces the thermal stress at an interface to the greatest degree.

Owner:WUHAN UNIV OF TECH

Hurricane-proof glass manufacturing technique

InactiveCN1990402AAvoid ignoring other aspects of performanceAvoid destructionGlass tempering apparatusThin material handlingAcid etchingGlass manufacturing

The invention relates to a process of preparing anti-hurricane glass, comprising following steps: cutting and edging glass; heating glass in the tempering furnace to softening point; feeding the glass into cooling room at speed of 25-50 cm / s, the air pressure in cooling room should be controlled at 6.5-7.5 * 103 Pa to make the surface compressive stress reach to more than 150 MPa; putting glass into acid-etching slot for suitable acid etching; washing glass surface with clean water; coating the surface with organic silicon protecting membrane. The invention is characterized by low production cost and short producing time.

Owner:庄大建 +1

Ceramic chip of NOx sensor

ActiveCN109001284AImprove stress concentrationHigh strengthMaterial electrochemical variablesNitrogen oxide sensorSlurry

The invention discloses a ceramic chip of a NOx sensor. An oxygen pump anode covered with a protective layer on the surface is arranged on a first-layer membrane, an acquisition cavity is formed on the oxygen pump anode and the first-layer membrane, second to fourth through holes are formed in a second-layer membrane, a first diffusion barrier is formed in the second through hole and divides the second through hole into a first measurement chamber and a buffer cavity, a main oxygen pump cathode is arranged in the first measurement chamber, a second diffusion barrier is arranged between the second through hole and a third through hole, the third through hole is a second measurement chamber, an auxiliary pump cathode is arranged in the second measurement chamber, a third diffusion barrier isarranged between the third through hole and the fourth through hole, the fourth through hole is a third measurement chamber, a measurement electrode covered with a protective layer on the surface isarranged in the third measurement chamber, a reference channel is formed in a third-layer membrane, a reference electrode covered with a protective layer on the surface is arranged in the reference channel, a heating electrode wrapped in a heating electrode insulating layer is arranged between the fourth-layer membrane and a fifth-layer membrane, an outer lead of the heating electrode penetrates through the fifth-layer membrane to be located on the lower surface of the fifth-layer membrane, and a stress release hole filled with heating electrode insulating layer slurry is formed in the fifth-layer membrane.

Owner:西安创研电子科技有限公司

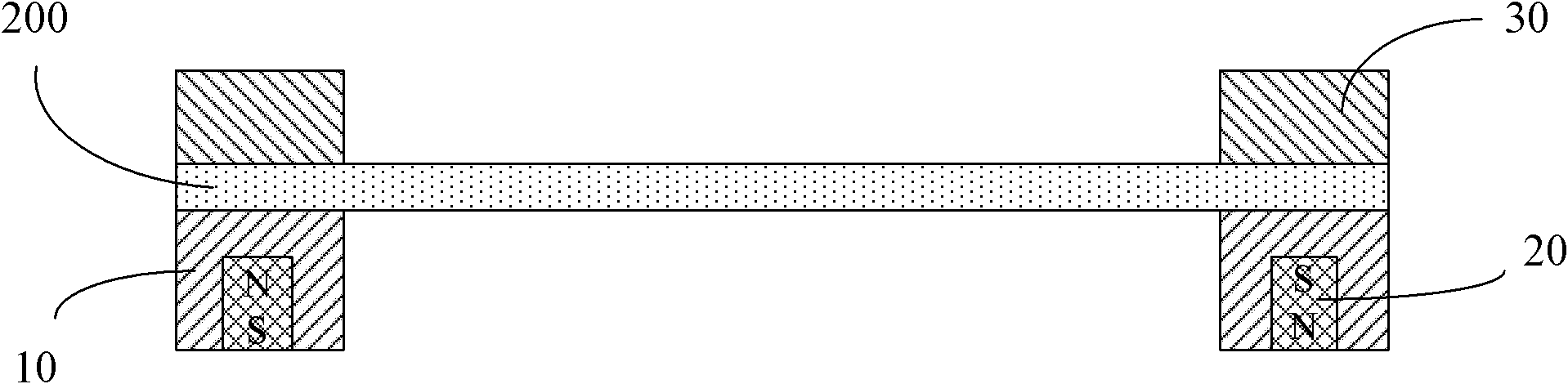

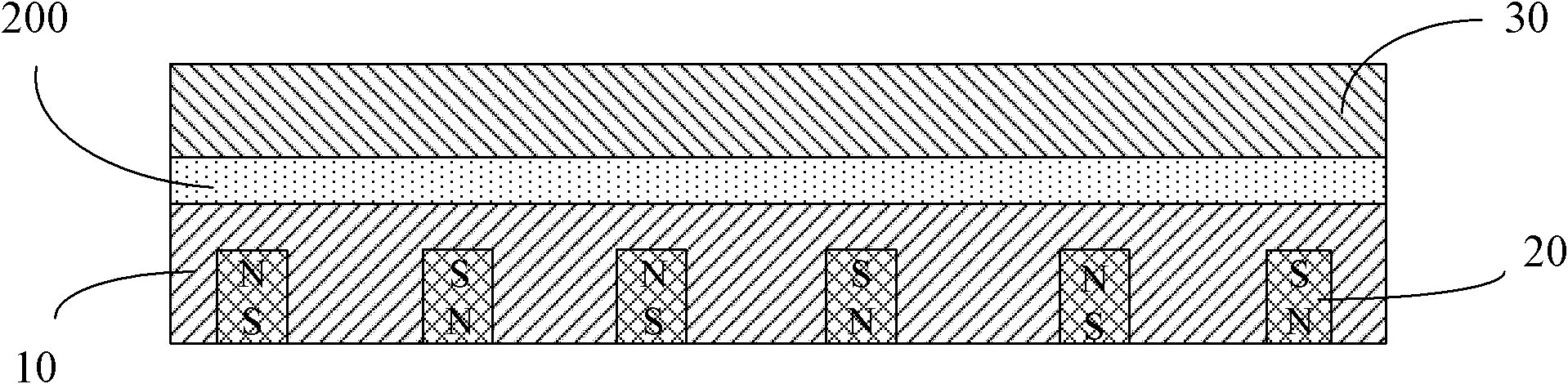

Glass clamp, glass conveying device and glass fixing method

The invention provides a glass clamp, a glass conveying device and a glass fixing method. The glass clamp comprises a non-magnetic conduction frame which is arranged vertically, a plurality of magnets and a magnetic conduction frame corresponding to the non-magnetic conduction frame in shape; the plurality of magnets are uniformly arranged on the non-magnetic conduction frame; and the glass plate is vertically clamped between the non-magnetic conduction frame and the magnetic conduction frame, and shape of the non-magnetic conduction frame and the glass plate are adaptive. The glass clamp can clamp the relatively thin glass plates and is difficult to break.

Owner:YICHANG NANBO DISPLAY

High-carbon steel wire rod inclusion control method

The invention provides a high-carbon steel wire rod inclusion control method. The method comprises converter treatment, refining, continuous casting, continuous rolling and wire rod rolling. In converter treatment, high-carbon steel is produced and after converter treatment, silicomanganese deoxidation is carried out. A LF refining temperature is in a range of 1550-1640 DEG C, refining time is in a range of 60-80min, sulfur content of a steel liquid at the refining finished point is in a range of 0.016-0.025%, oxygen activity is in a range of (10-30)*10<-6>, steel liquid acid-insoluble aluminum content is in a range of 0.0005-0.0025% and titanium content is less than or equal to 0.0010%. In continuous rolling and wire rod rolling, the steel wire rod diameter is in a range of 5-5.5mm, a spinning temperature is in a range of 880-910 DEG C and after spinning, a steel wire rod is fast cooled to 600-650 DEG C. The high-carbon steel wire rod obtained by the method contains fine oxide impurities. In steel wire rod drawing, the sulfide inclusion outside the oxide inclusion can cooperate with matrix deformation so that micro-cracks at two ends of the oxide impurity are prevented and finished product processing performances are improved.

Owner:ANGANG STEEL CO LTD

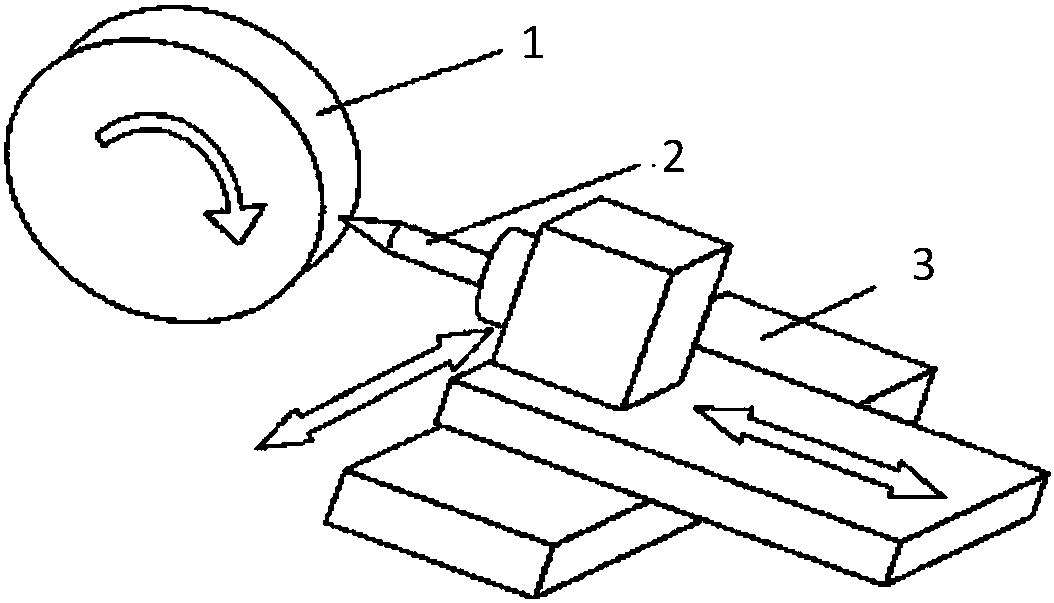

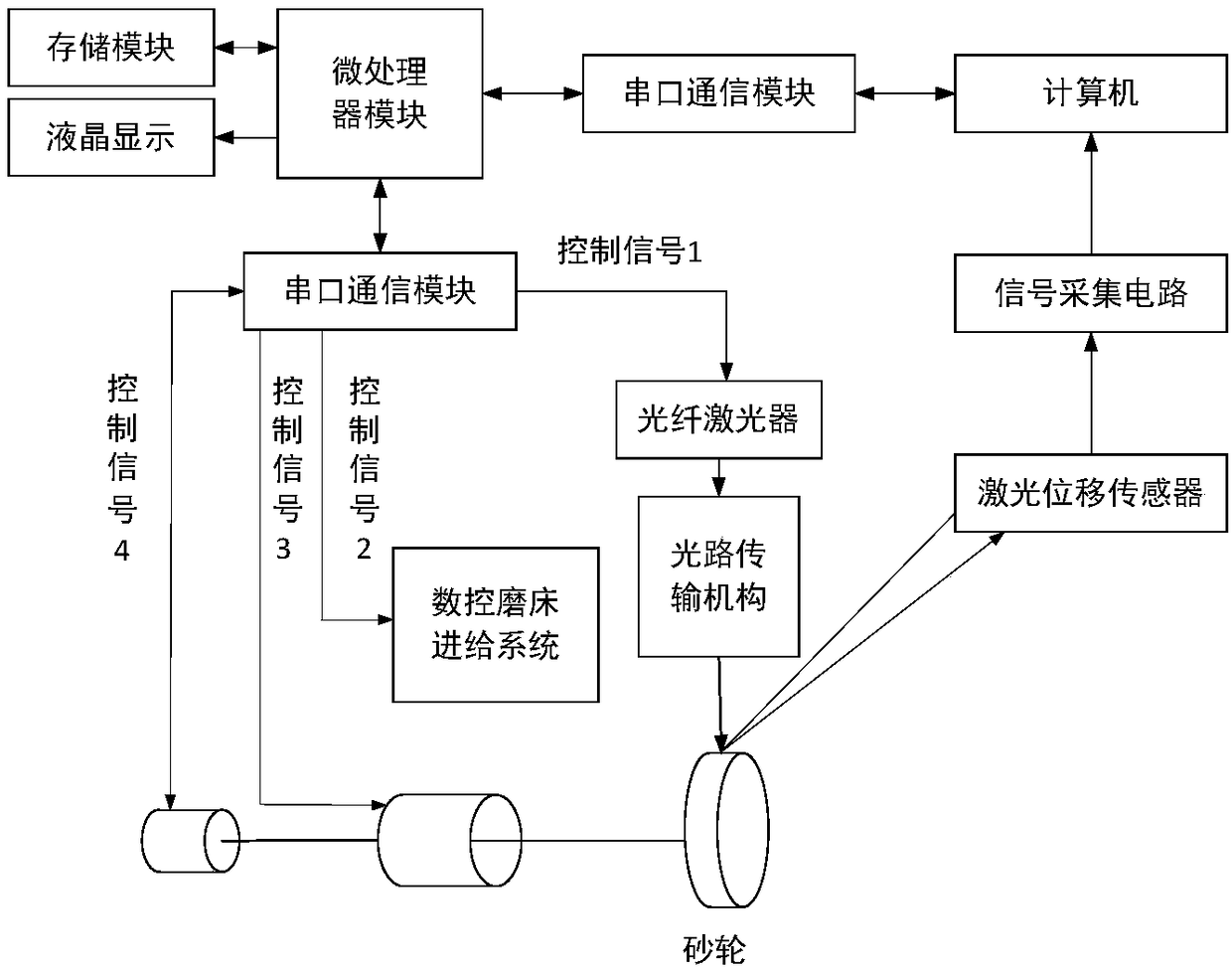

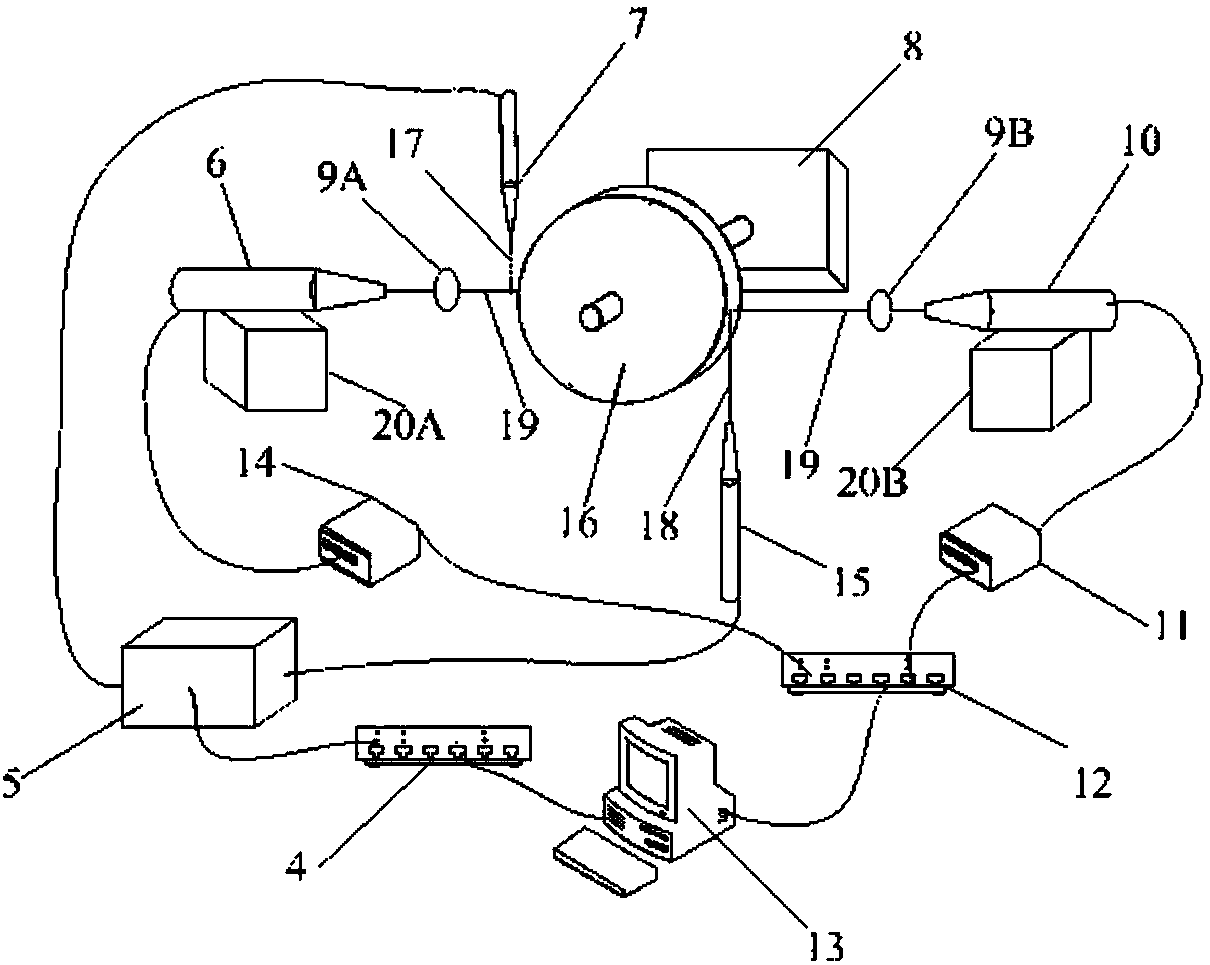

Gas-liquid parallel tube type grinding wheel double laser trimming device and method

ActiveCN108081137AReduced chip spaceAvoid Coulomb ExplosionsAbrasive surface conditioning devicesAutomatic grinding controlPicosecond laserFemto second laser

The invention discloses a gas-liquid parallel tube type grinding wheel double laser trimming device. The gas-liquid parallel tube type grinding wheel double laser trimming device comprises gas-liquidcontrol equipment, a gas-liquid control operating platform, a picosecond laser ablation head, a gas-guide flexible pipe, a grinding machine, focusing lenses, a femtosecond laser ablation head, a femtosecond laser device, a laser device control operating platform, control equipment, a picosecond laser device, a fine water-guide pipe, a superhard grinding-material grinding wheel, a gas column flow,a liquid column flow, laser beams and three-dimensional moving platforms. By means of the gas-liquid parallel tube type grinding wheel double laser trimming device and method, the auxiliary gas-liquidparallel tube type grinding wheel double laser trimming device is provided, the situations that diamond grinding particle chip tolerance space of the grinding wheel is reduced and the height of highlighted binder is not enough caused by plasma particles and phase explosion effect are avoided, and the defects of microcracks, graphite metamorphic layers and the like generated by peripheral heat accumulation during diamond grinding are overcome; and by means of the gas-liquid parallel tube type grinding wheel double laser trimming device and the method, the generation of coulomb explosion can beavoided, the surface grating and micro-cone structure of the grinding wheel are reduced, the utilization efficiency of laser energy is improved, and the grinding wheel trimming efficiency and the trimming surface quality are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

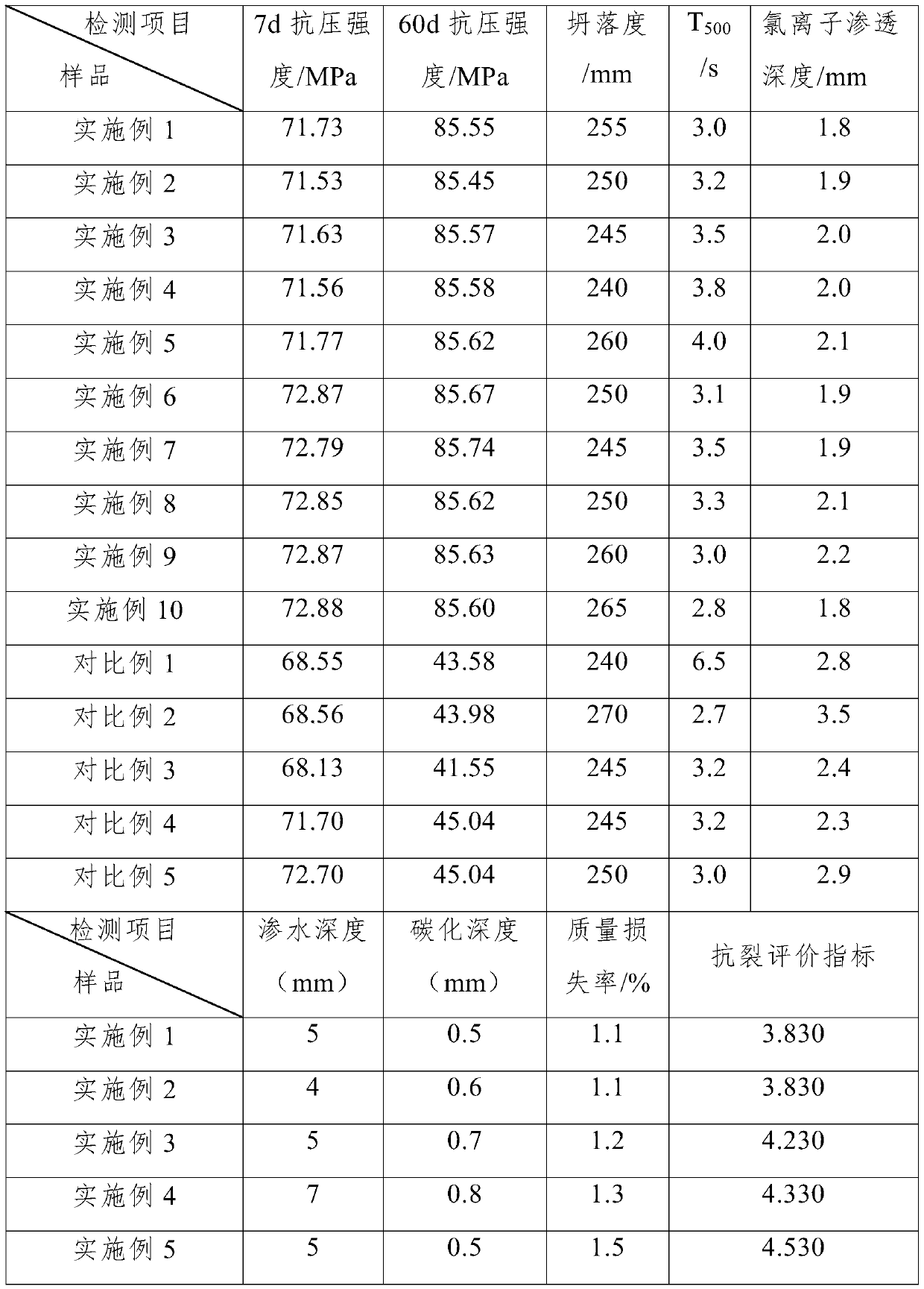

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

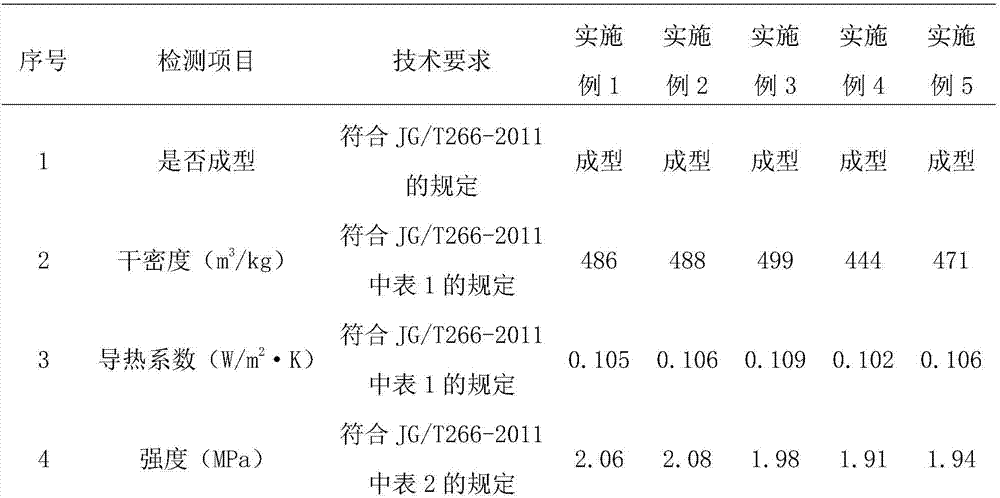

Non-autoclaved foam concrete material and preparation method thereof

The invention relates to a non-autoclaved foam concrete material and a preparation method of the material. The non-autoclaved foam concrete material is characterized by comprising the following raw material ingredients in parts by weight: 85-96 parts of cement, 2-8 parts of fine sand, 2-10 parts of slag powder, 1.4-2.2 parts of chemical foaming agent, 0.7-1.5 parts of additive, 0.5-1.0 part of fiber and 1-1.5 parts of assistant, wherein the additive is a foam stabilizer, a water reducer and an early strength agent, and a water-material mass ratio is 0.55-0.6. The prepared foam concrete material can reach various performance indexes (foam concrete JG / T 266-2011); various performance is excellent; and the method is simple and practicable, low in cost, obvious in energy conservation effect and appropriate for large-scale popularization and application.

Owner:NANJING UNIV OF TECH

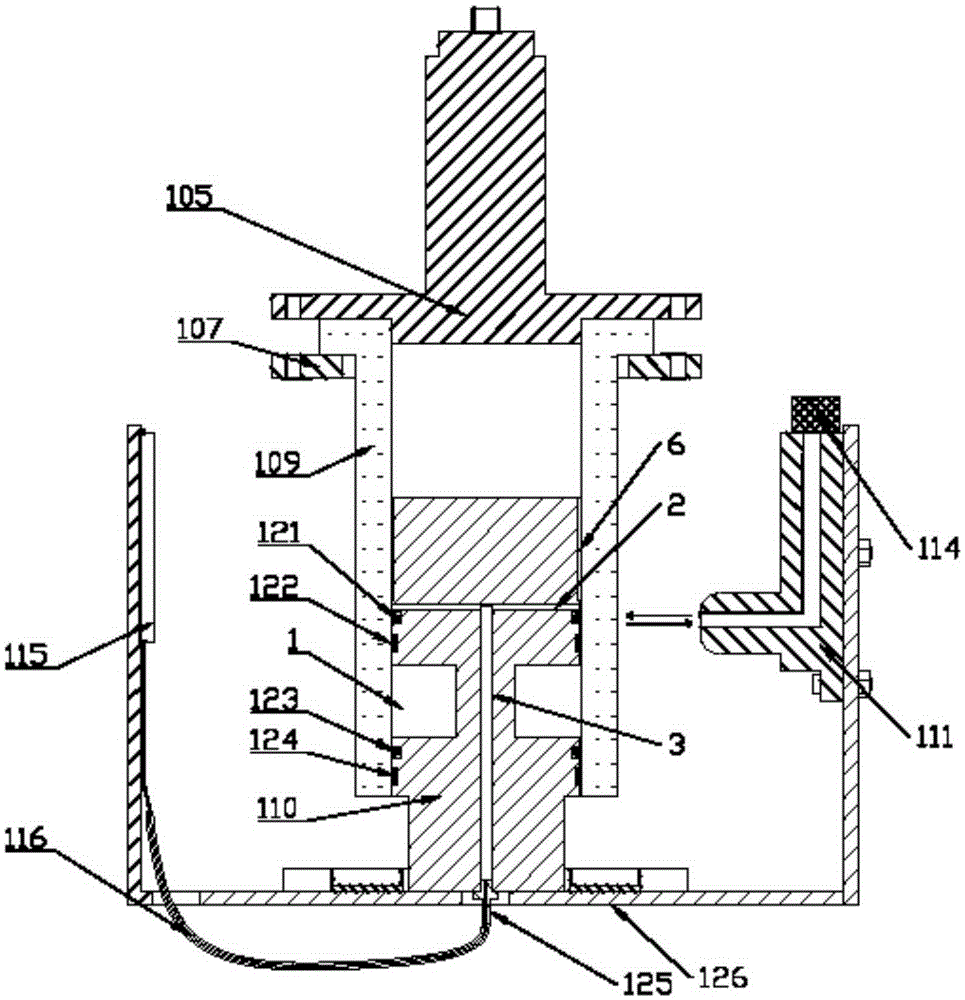

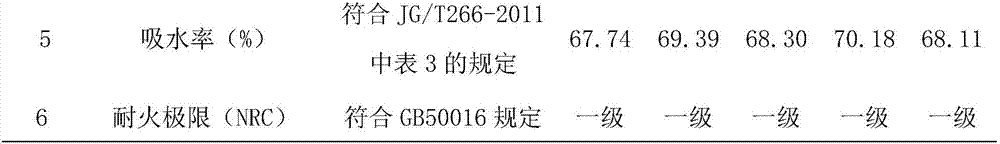

Combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads

The invention relates to a combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads. The method comprises the steps: carrying out through hole pre-machining on the micro holes with the countersunk heads on a workpiece through a laser beam, carrying out electric spark machining on the countersunk heads of the micro holes through a tubular copper electrode to achieve needed precision of the shape of the countersunk heads basically, and carrying out electrolytic machining electrolysis machining on the whole micro holes with the countersunk heads through a high-speed jet electrolyte beam coaxial with the electric spark machining electrode to remove recast layers remaining after the former two machining steps. The device comprises a laser generation device, a combined electric spark machining and electrolysis machining device, a machining mode conversion device, a working solution circulation system, a power supply and a control system. According to the method, laser machining and electric spark machining are the main machining modes and supplemented by electrolysis machining, and the high speed, high precision and high quality can be achieved at the same time. By means of the method and device, rapid machining of the micro holes with the various special-shaped countersunk heads can be achieved, and various shortcomings caused by the adoption of a single specific machining mode in the prior art can be overcome.

Owner:JIANGNAN UNIV

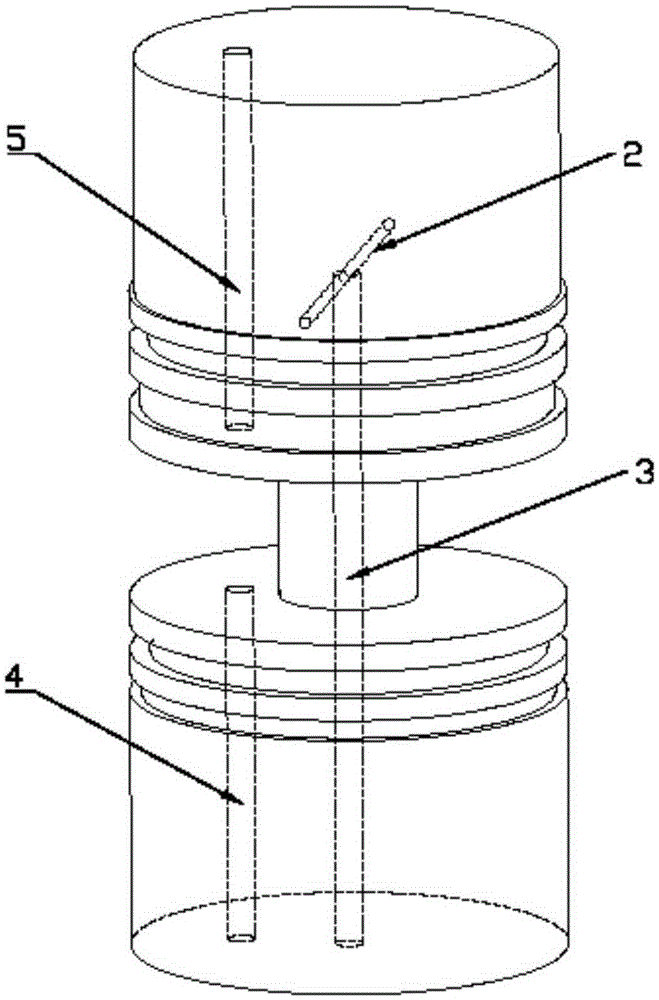

Jet-flow-guided laser-spark-electrolysis combined machining device

The invention relates to a jet-flow-guided laser-spark-electrolysis combined machining device, and belongs to the field of non-traditional machining. The jet-flow-guided laser-spark-electrolysis combined machining device adopts the structure integrating three non-traditional machining methods, and is composed of a laser generator, a machining module, a working solution circulation system and a power supply module, wherein the laser generator is placed above the machining module, and laser beam machining and spark machining are ensured to be coaxial; an electrode in the machining module for sparking machining can be stationary or rotary; the working solutions for jet-flow-guided laser machining and spark machining employ deionized water, and form a set of working solution circulation system with the working solution for electrolytic machining. When the device is used for machining, the jet-flow-guided laser machining and spark machining are employed as the main means for removing material, being accompanied by electrolytic machining; speed, accuracy and surface quality of part manufacturing are all taken into consideration; thereby, rapid machining of various micro holes with abnormal countersunk heads, and various defects caused by using single non-traditional machining method are overcome.

Owner:JIANGNAN UNIV

Substrate optical detection method and apparatus

InactiveCN101408572AAvoid FragmentsAvoid microcracksContactless testingContactless circuit testingArray data structureInductor

The invention relates to an optical detection method and a device thereof which are used for detecting the defects of a substrate. The optical detection device comprises an optical unit used for generating a light source to radiate the substrate and a plurality of groups of receiving inductor units of more than one dimension used for receiving an image generated by the radiated substrate, wherein, the light wave of the image contains a specific wavelength section as well as an image capture processing unit for capturing the image.

Owner:DELTA ELECTRONICS INC

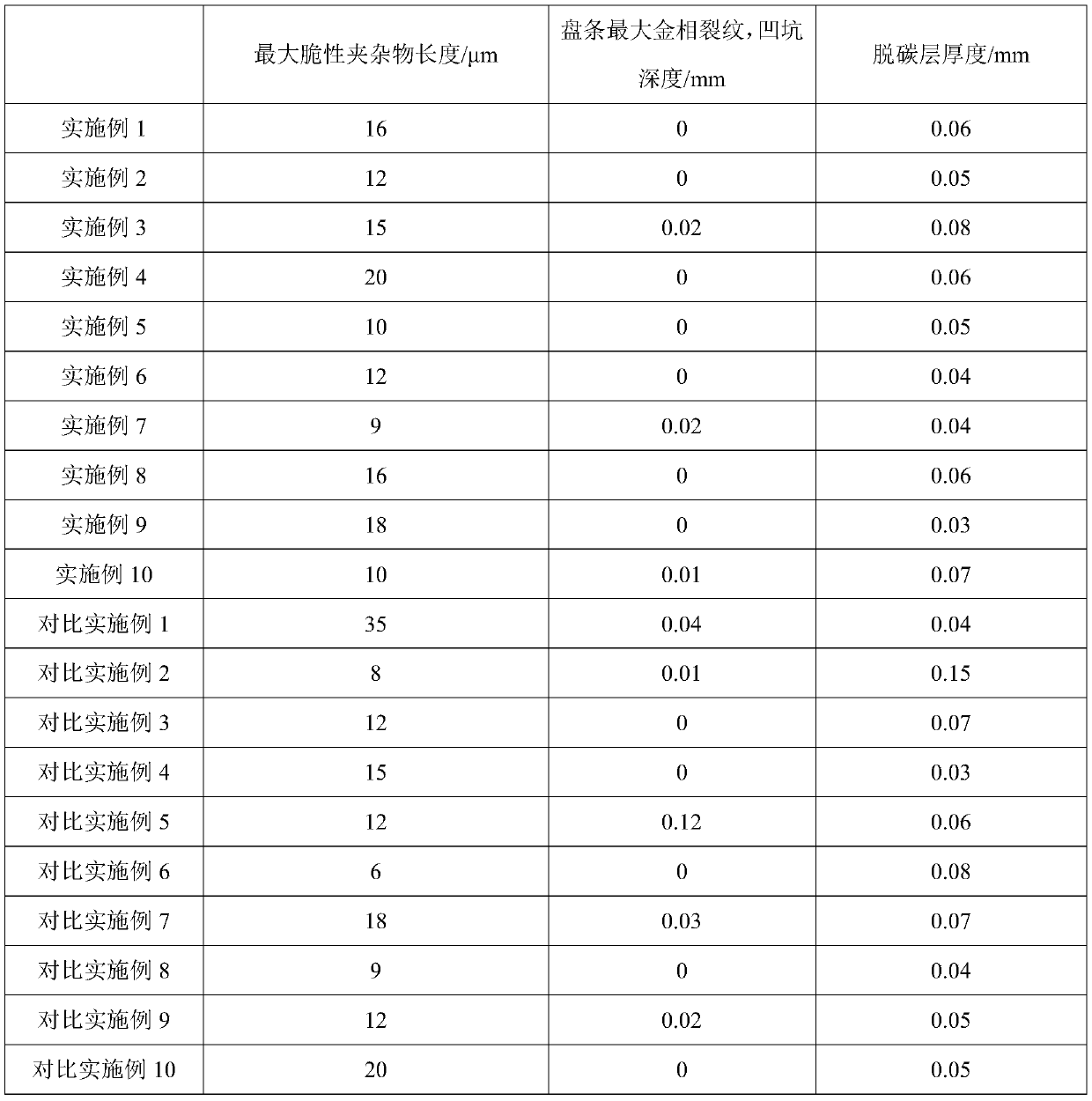

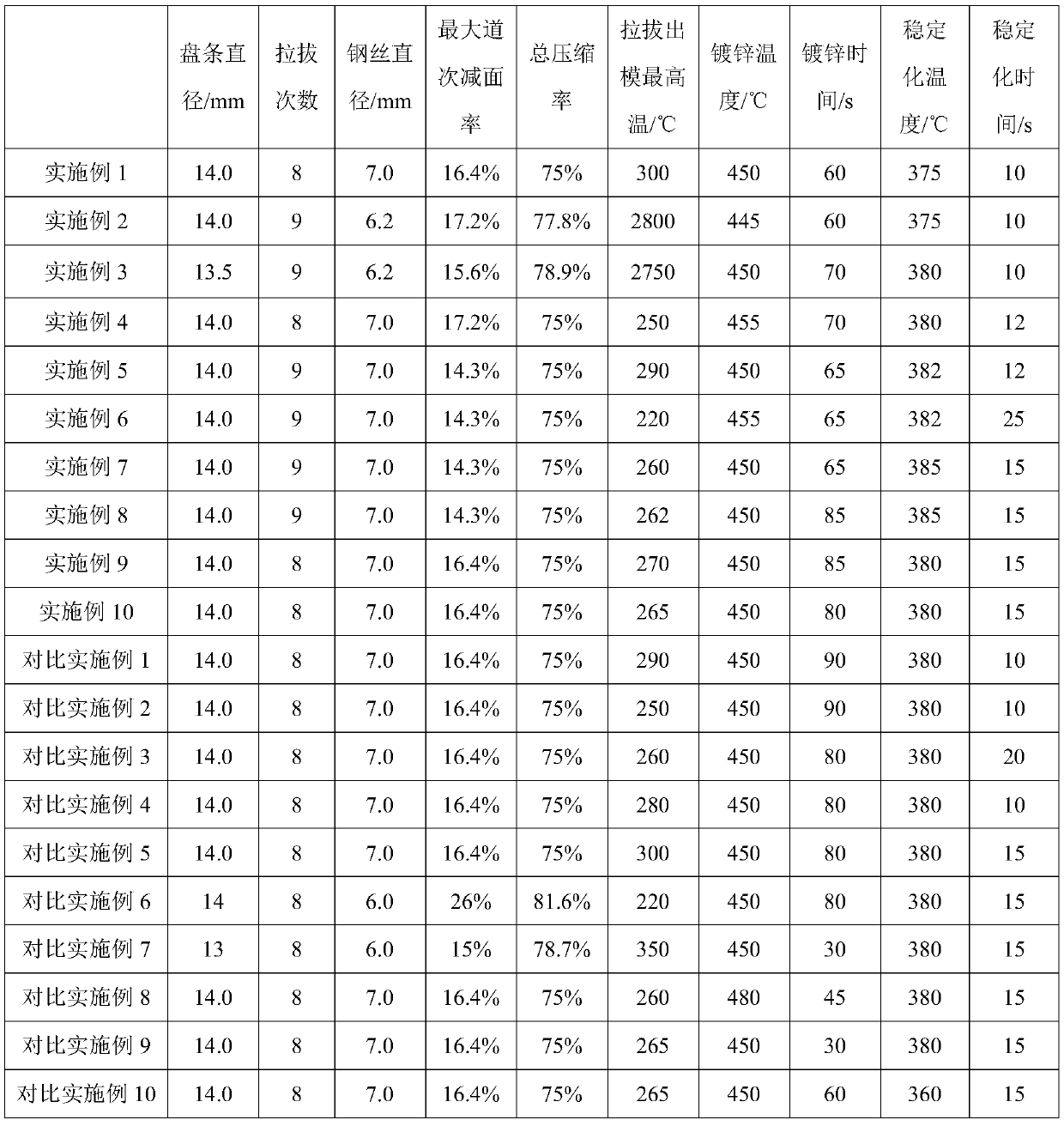

2000 MPa-grade bridge cable galvanized steel wire and preparation method thereof

ActiveCN110066963AAvoid rapid scalingReduce the impactHot-dipping/immersion processesPre treatmentChemical composition

The invention relates to a 2000 MPa-grade bridge cable galvanized steel wire and a preparation method thereof. The steel wire comprises the following chemical components of, in percentage by weight, 0.88%-0.94% of C, 1.05%-1.35% of Si, 0.40%-0.50% of Mn, 0.25%-0.35% of Cr, less than or equal to 0.07% of Cu, and the balance Fe and inevitable impurity elements; and the steel wire further comprises one or more than one of the following components of, in percentage by weight, 0.0005%-0.0015% of B, 0.01%-0.03% of Nb and 0.01%-0.03% of Mo; and the preparation method of the steel wire comprises the following steps of steel wire rod pre-treatment, drawing and hot galvanizing stabilization. The twisting performance of the galvanized steel wire is improved by strictly controlling of the chemical components of the steel wire rod, the surface quality and inclusion as well as optimizing the drawing and a hot galvanizing process; and the tensile strength of the galvanized steel wire produced by themethod can reach the 2000 MPa or above , and the torsion value is not less than 18 circles.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

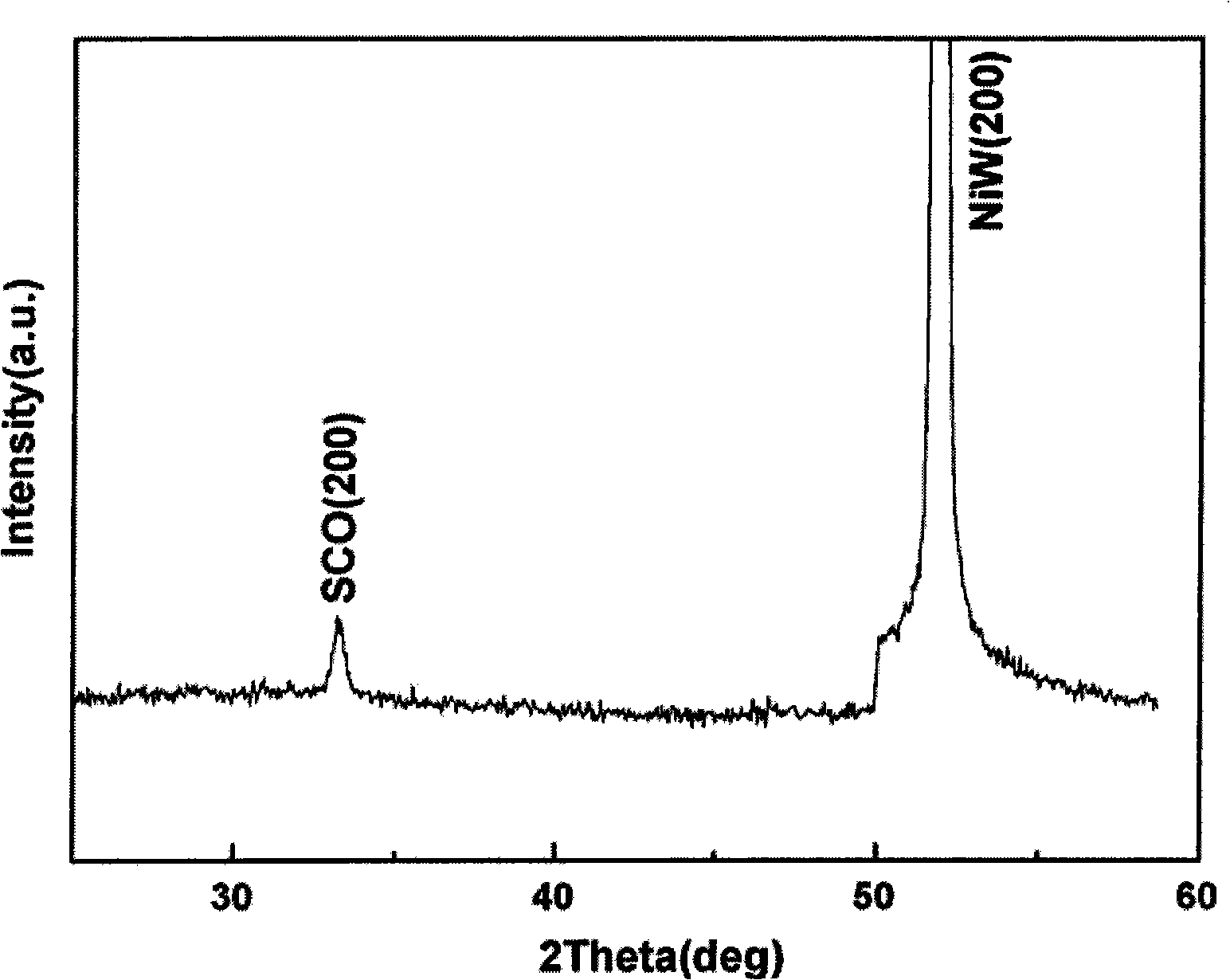

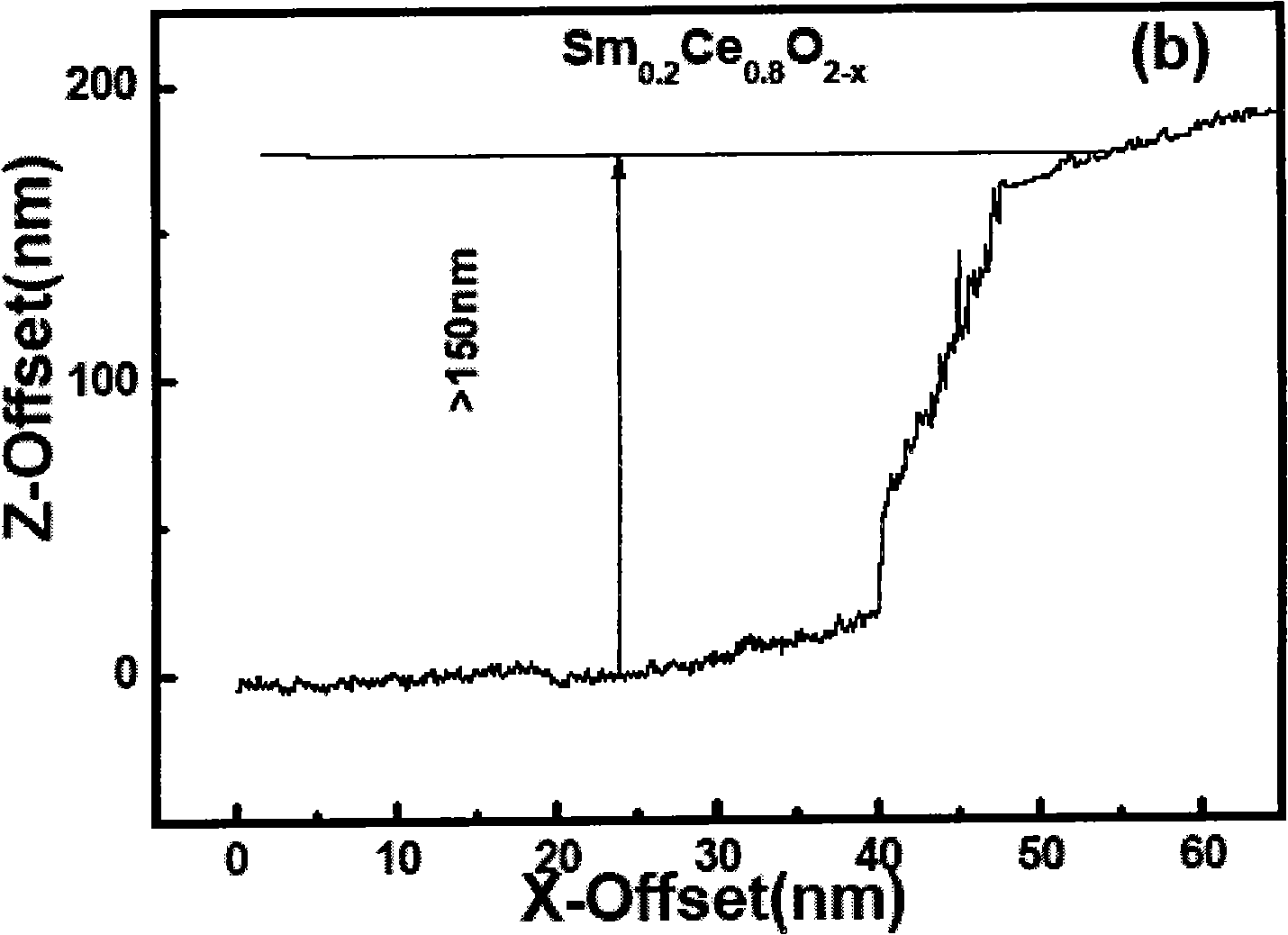

Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary azotate deposition

InactiveCN101281805AImprove textureFlat and dense surfaceSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorCerium nitrate

The present invention provides a method for producing the buffer layer of a conductor coated with high temperature superconducting coating by means of macromolecule assisted nitrate deposition, a. producing a waterless weigh rare earth nitrate or zirconium nitrate and cerous cerium nitrate at an ionic ratio of rare-earth or zirconium: cerium as x:1-x (0.01<=x<=0.5), and dissolve the elements in N,N-dimethyl formamide to form a waterless solution; b. preparing colloid: add polyacrylic acid or polymethacrylic acid to the waterless solution prepared in step a; c. coating the colloid and drying: coat the colloid prepared in step b on a substrate and the dry the substrate. d. sintering: load the dry substrate into a sintering oven, heat up to 850-1150 DEG C at 5-100 DEG C / min speed, hold for 0.25-2h, and then drop the oven temperature to room temperature. The method is characterized in simple process, easy operation control, low cost, and free of environment pollution; the single-layer cerium oxide buffer layer obtained can be in thickness up to 150-200nm.

Owner:SOUTHWEST JIAOTONG UNIV

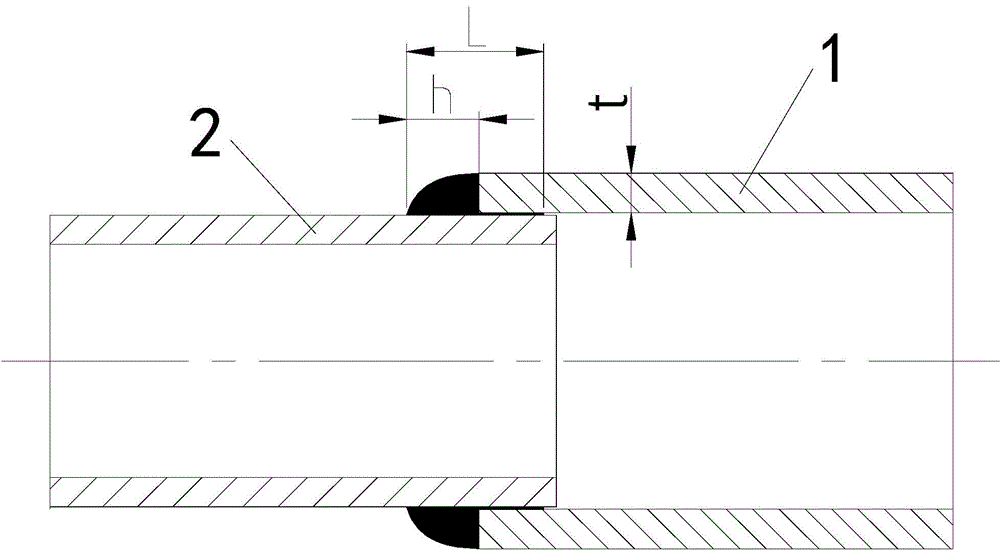

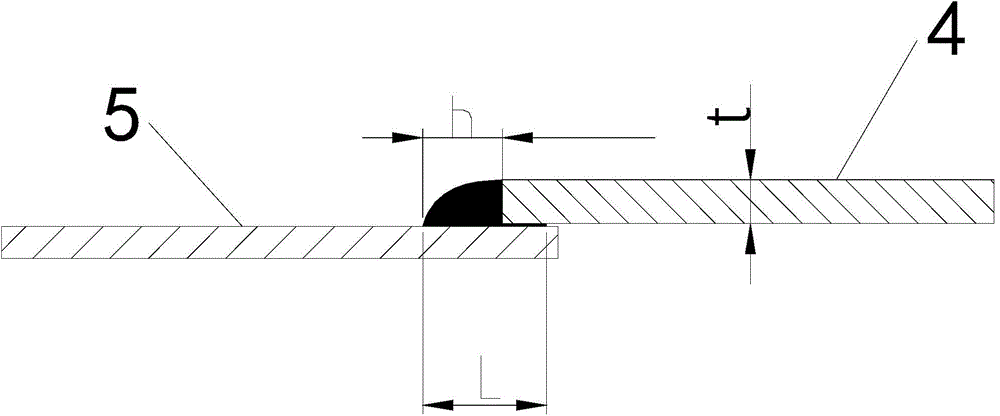

Welding method, product and application of dissimilar metal

ActiveCN104551431AAvoid microcracksWeld bead brittleness decreasedWelding/soldering/cutting articlesMetal working apparatusElectric arcHigh frequency

The invention relates to a welding method, a product and an application of a dissimilar metal. The welding method of the dissimilar metal comprises a high-melting-point material to be welded and a low-melting-point material to be welded, the high-melting-point material and the low-melting-point material are mutually overlapped or connected in a sleeving manner to form a welding seam, the welding seam is welded by the aid of electric arc welding, electron beam welding, laser welding or high-frequency welding, the welding temperature is lower than the melting temperature of the high-melting-point material and higher than the melting temperature of the low-melting-point material, the low-melting-point material is melted to serve as a welding material to seal the welding beam and cooled to form a welding channel, and the width L of the welding channel is larger than or equal to 1.5mm. The melted low-melting-point material directly serves as the welding material to seal the welding beam to form the welding channel with a certain width, so that the melted low-melting-point material and the high-melting-point material are mutually permeated in a certain area range to form solid solution, the permeation quantity of high-melting-point metal to low-melting-point metal is controlled, overall strength sufficiently meets use requirements, more importantly, frangibility of the welding channel is reduced, mechanical properties are improved, the requirements for a welding process are low when welding is performed, and the welding method is easier to control.

Owner:佛山晓世科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com