C70 mass concrete and preparation process thereof

A large-volume concrete and cement technology, applied in the field of concrete, can solve the problems of high-strength concrete self-drying, self-shrinkage control effect is not obvious, self-shrinkage and brittleness increase, wet curing effect is weak, etc., to improve workability and pumping Performance, reduce water loss, improve the effect of sulfate attack and chloride dialysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

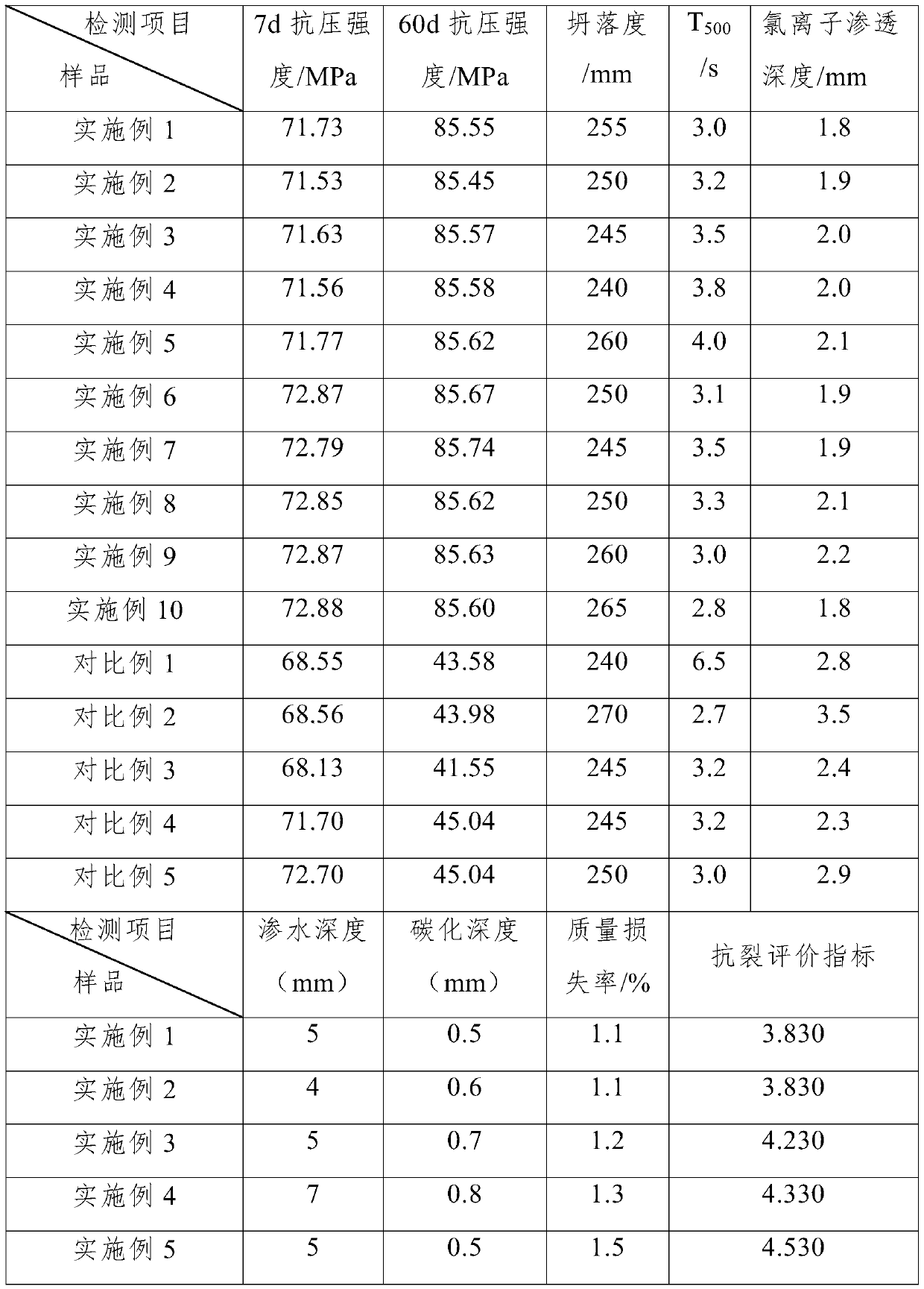

Embodiment 1

[0030] The C70 mass concrete in this example is prepared from the following components by mass: 140 parts of water, 400 parts of P.O52.5R cement, 1000 parts of crushed stone, 550 parts of sand and gravel, and 70 parts of Class II fly ash , 60 parts of S95 mineral powder, 30 parts of silica fume, 8 parts of polycarboxylate pumping agent, 35 parts of SY-K fiber toughened concrete anti-cracking agent, 0.3 part of superabsorbent resin internal curing agent; The diameter is 10mm to 20mm.

[0031] The preparation method of the C70 mass concrete of the present embodiment may further comprise the steps:

[0032] Step 1. Mix 550 parts of gravel, 1000 parts of gravel and 140 parts of water at a temperature of 5° C. to obtain a mixture;

[0033] Step 2. Add 400 parts of P.O52.5R cement, 70 parts of Ⅱ grade fly ash, 60 parts of S95 mineral powder, 30 parts of silica fume, 8 parts of polycarboxylic acid pumping agent, 35 parts of the mixture obtained in step 1. One part of SY-K fiber tou...

Embodiment 2

[0045] The C70 mass concrete in this example is prepared from the following components by mass: 143 parts of water, 405 parts of P.O52.5R cement, 1020 parts of crushed stone, 560 parts of sand and gravel, and 74 parts of Class II fly ash , 63 parts of S95 mineral powder, 34 parts of silica fume, 8.2 parts of polycarboxylic acid pumping agent, 36 parts of SY-K fiber toughened concrete anti-cracking agent, 0.31 part of superabsorbent resin internal curing agent; The diameter is 10mm to 20mm.

[0046] The preparation method of the C70 mass concrete of the present embodiment may further comprise the steps:

[0047] Step 1. Mix 560 parts of gravel, 1020 parts of gravel and 143 parts of water at a temperature of 5° C. to obtain a mixture;

[0048] Step 2. Add 405 parts of P.O52.5R cement, 74 parts of Ⅱ grade fly ash, 63 parts of S95 mineral powder, 34 parts of silica fume, 8.2 parts of polycarboxylic acid pumping agent, 36 parts of the mixture obtained in step 1. One part of SY-K ...

Embodiment 3

[0050] The C70 mass concrete in this example is prepared from the following components by mass: 146 parts of water, 410 parts of P.O52.5R cement, 1040 parts of crushed stone, 570 parts of sand and gravel, and 78 parts of Class II fly ash , 66 parts of S95 mineral powder, 38 parts of silica fume, 8.4 parts of polycarboxylate pumping agent, 37 parts of SY-K fiber toughened concrete anti-cracking agent, 0.32 part of superabsorbent resin internal curing agent; The diameter is 10mm to 20mm.

[0051] The preparation method of the C70 mass concrete of the present embodiment may further comprise the steps:

[0052] Step 1. Mix 570 parts of gravel, 1040 parts of gravel and 146 parts of water at a temperature of 5° C. to obtain a mixture;

[0053] Step 2: Add 410 parts of P.O52.5R cement, 708 parts of grade II fly ash, 66 parts of S95 mineral powder, 38 parts of silica fume, 8.4 parts of polycarboxylic acid pumping agent, 37 parts of the mixture obtained in step 1 One part of SY-K fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com