Tubular ventilation cooling type five-core flexible cable and manufacturing method thereof

A ventilation cooling and core soft technology, applied in the direction of coaxial cables, circuits, electrical components, etc., can solve problems such as accelerated insulation, sheath aging speed, shortened cable service life, fire and communication interruption, etc., so as to be easy to grasp and reduce The effect of less cross-sectional area and conductor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

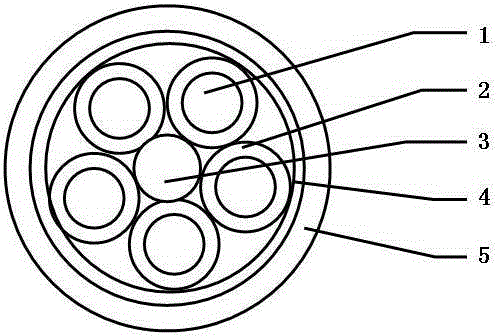

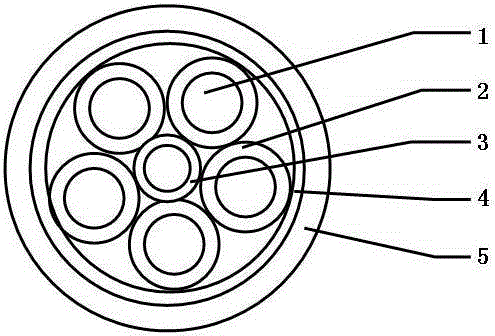

[0026] please see figure 2 , a tubular ventilation-cooled five-core flexible cable, which is composed of five insulated wires distributed around the filling element 3, a tape layer 4 covering the insulated wires, and an outer sheath covered outside the tape layer 5, each insulated wire is composed of a conductor 1 and an insulating layer 2 covering the conductor; it is characterized in that the filling element is a pipe structure with a through hole inside, and the outer diameter of the pipe is 6-20 mm. The wall thickness of the pipeline is 0.6-0.8mm.

Embodiment 2

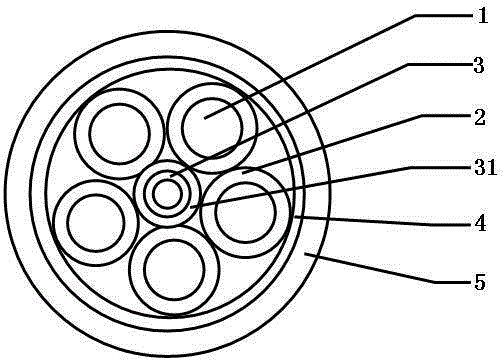

[0028] please see image 3 , a tubular ventilation-cooled five-core flexible cable, which is composed of five insulated wires distributed around the filling element 3, a tape layer 4 covering the insulated wires, and an outer sheath covered outside the tape layer 5, each insulated wire is composed of a conductor 1 and an insulating layer 2 covering the conductor; it is characterized in that the filling element is a pipe structure with a through hole inside, and the outer diameter of the pipe is 6-20 mm. The wall thickness of the pipeline is 0.6-0.8mm; the outer wall of the pipeline has an insulating protective layer 31 .

[0029] A tubular ventilated and cooled five-core flexible cable described in any of the above implementation examples is characterized in that the material of the wall of the pipe is brass or white copper or red copper or aluminum or steel or an alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com