Non-autoclaved foam concrete material and preparation method thereof

A foamed concrete, autoclaved-free technology, applied in the field of building materials and foamed concrete preparation, can solve the problems of complex preparation process, hidden dangers, product burst cracks, etc., achieve uniform pore structure, reduce hydration heat, and prevent fine cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

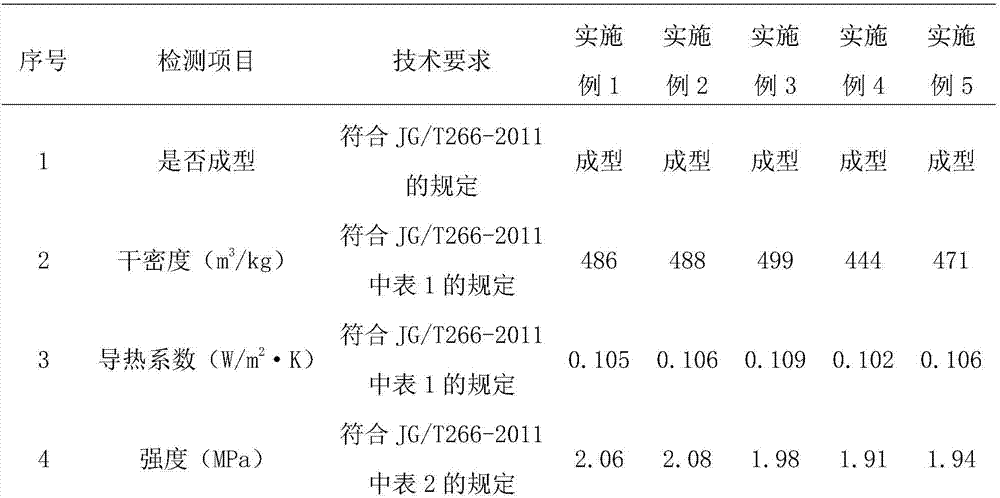

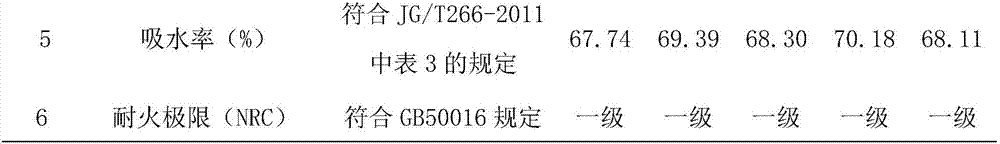

Examples

Embodiment 1

[0029] In terms of parts by mass, prepare 88 parts of cement (86 parts of PO42.5 ordinary Portland cement and 2 parts of R·SAC52.5 sulfoaluminate cement), 2 parts of quartz sand, and a specific surface area of 800m 2 10 parts / kg slag powder, 1.4 parts of aluminum powder chemical foaming agent with a mass fraction of 60%, 1.2 parts of admixture (0.6 part of rosin acid soap foam stabilizer, 0.2 part of polycarboxylate water reducer, early strength agent MgCl 2 0.4 parts), polypropylene fiber 0.6 parts, NaOH 1.4 parts.

[0030] First, mix cement, quartz sand, slag powder and water evenly under the condition of mechanical stirring, add fiber, additives and water reducer in the admixture to the mixer and mix for 2 minutes at a stirring speed of 1000rpm; then add the foam stabilizer in the admixture Add foaming agent, early strength agent and other admixtures, mix with cement slurry for 40s, the mixer speed is 1500rpm; finally add foaming agent and cement slurry and mix for 20s, s...

Embodiment 2

[0032] In parts by mass, prepare 92 parts of cement (88 parts of PO42.5 ordinary Portland cement and 4 parts of R·SAC52.5 sulfoaluminate cement), 2 parts of quartz sand, 800m 2 / kg 6 parts of slag powder, 2 parts of chemical foaming agent, 0.8 part of admixture (0.2 part of rosin acid soap foam stabilizer, 0.2 part of polycarboxylate superplasticizer, early strength agent MgCl2 0.4), 0.5 parts of polypropylene fiber, and 1.3 parts of NaOH as an auxiliary agent.

[0033] First, mix the cement and water evenly under the condition of mechanical stirring, add the fiber, additives and water reducing agent in the admixture to the mixer and mix for 3 minutes, and the stirring speed is 1200rpm; then add the foam stabilizer, early strength agent and admixture in the admixture Mix other additives, mix with cement slurry for 60s, the mixer speed is 1500rpm; finally add foaming agent and cement slurry and mix for 30s, stirring speed is 1200rpm, continue stirring for 30s, mixer speed is 300...

Embodiment 3

[0035] In parts by mass, prepare 92 parts of PO42.5 ordinary Portland cement, 5 parts of quartz sand, 800m 2 / kg 6 parts of slag powder, 2 parts of chemical foaming agent, 1.4 parts of admixture (0.6 part of rosin acid soap foam stabilizer, 0.3 part of polycarboxylate water reducer, early strength agent MgCl 2 0.5 parts), polypropylene fiber 0.6 parts, NaOH 1.4 parts.

[0036] First, mix cement, quartz sand, slag powder and water evenly under the condition of mechanical stirring, add fiber, additives and water reducer in the admixture to the mixer and mix for 3 minutes at a stirring speed of 1200rpm; then add the foam stabilizer in the admixture Add foaming agent, early strength agent and other additives, mix with cement slurry for 50s, the mixer speed is 1600rpm; finally add foaming agent and cement slurry and mix for 30s, stirring speed is 1200rpm, continue to stir for 30s, mixer speed is 3000rpm; The material mass ratio is 0.56. Inject the stirred foam concrete slurry int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com