Metallic catalyst for synthesizing dimethoxym ethane and methyl formate and production method thereof and use

A technology of metal catalyst and methyl formate, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, carboxylate preparation, molecular sieve catalyst, etc., can solve the problem of low production capacity of methyl formate, harsh reaction conditions and pollution and other problems, to achieve the effect of uniform distribution of active components, good stability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 5mlTiCl under nitrogen protection atmosphere 4 , 3.1gNH 4 VO 3 and 0.12g (NH 4 ) 2 WO 4 In 26ml concentrated HNO 3 , stir to make it completely dissolve, add 23g urea and 14gMCM-41, and then rapidly roast at 500°C for 10min under air atmosphere to get V 2 o 5 -TiO 2 The content is 30wt% (V 2 o 5 / TiO 2 The mass ratio is 40 / 60), WO 3 The content is 0.5wt%, MCM-41 content is 69.5wt% of WO 3 -V 2 o 5 -TiO 2 / MCM-41 catalyst.

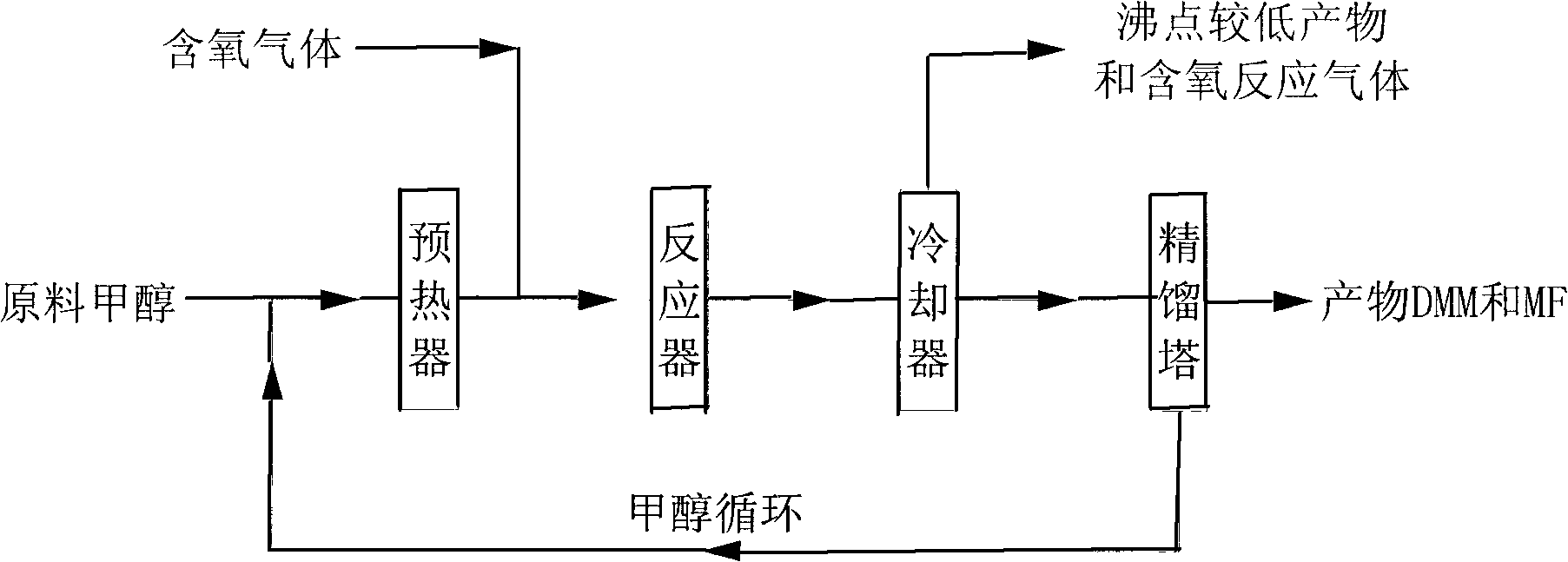

[0022] Catalyst at 10vol% O 2 / Ar atmosphere is activated at 400°C for 1.5h, and lowered to a reaction temperature of 130°C, then methanol is preheated to 120°C by a preheater and then gasified and mixed with oxygen-containing gas to form a raw material gas. The volume ratio composition of the raw material gas is CH 3 OH / O 2 / Ar=10.0 / 9.0 / 81.0, the space velocity of the raw material gas in the reaction gas is 11300ml / g cat .h, the reaction is carried out under the condition of working pressure of 0.1MPa. After the reaction produ...

Embodiment 2

[0024] Add 5mlTiCl under nitrogen protection atmosphere 4 and 0.70gNH 4 VO 3 In 11.33ml concentrated HNO 3 After stirring to dissolve completely, add 68g of citric acid, and then quickly roast at 450°C for 15min under air atmosphere to get V 2 o 5 / TiO 2 Catalyst with a mass ratio of 20 / 80.

[0025] The catalyst is activated at 350°C for 2.0 hours in an air atmosphere, and then lowered to a reaction temperature of 125°C, then methanol is preheated to 110°C by a preheater and gasified, and then mixed with oxygen-containing gas to form a raw material gas. The volume ratio of the raw material gas is as follows: CH 3 OH / air=5.2 / 94.8, the space velocity of raw material gas in reaction gas is 8100ml / g cat .h, the reaction is carried out under the condition of working pressure of 0.1MPa. After the reaction product is cooled and separated, the oxygen-containing reaction gas and the product with low boiling point are separated for recovery and purification, and the product with ...

Embodiment 3

[0027] Add 10ml TiCl under nitrogen protection atmosphere 4 , 4.01gNH 4 VO 3 and 0.41gCu(NO 3 ) 2 In 50ml concentrated HNO 3 In, stir to make it dissolve completely, then add 100g citric acid and 7.0g ZrO 2zirconium sol, and then rapidly calcined at 550 ° C for 8 min in an air atmosphere to obtain V 2 o 5 -TiO 2 The content is 60wt% (V 2 o 5 / TiO 2 Mass ratio is 30 / 70), CuO content is 1.0wt%, ZrO 2 39 wt% CuOV 2 o 5 -TiO 2 / ZrO 2 catalyst.

[0028] Activate the catalyst at 500°C for 1.0h in the air atmosphere, and lower it to the reaction temperature of 155°C, then methanol is preheated to 140°C by the preheater and gasified, then mixed with oxygen-containing gas to form the raw material gas, the volume ratio composition of the raw material gas is CH 3 OH / air=3.0 / 97.0, the space velocity of the raw material gas in the reaction gas is 2000ml / g cat .h, the reaction is carried out under the condition of working pressure of 0.3MPa. After the reaction product is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com