Pressure vessel steel resistant to acid corrosion at medium temperature of 600 DEG C and preparation method thereof

A technology for acid corrosion resistance and pressure vessel, which is applied in the field of acid corrosion resistance pressure vessel steel at 600°C and its preparation field, and can solve the problems of failing to meet design requirements and low acid corrosion resistance.

Inactive Publication Date: 2018-09-28

WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to solve the problem that the service temperature of the current acid corrosion-resistant pressure vessel steel is limited within 500°C, and the acid corrosion resistance is too low to meet the design requirements. Preparation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

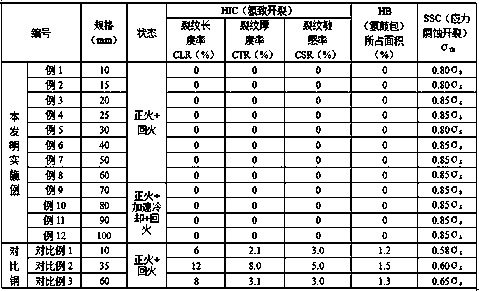

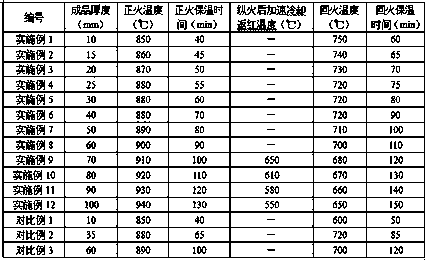

[0057] The present invention will be further described in detail below in conjunction with the examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

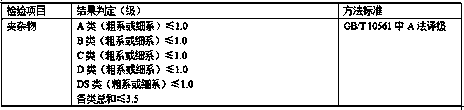

The invention discloses pressure vessel steel resistant to acid corrosion at medium temperature of 600 DEG C and a preparation method thereof. The pressure vessel steel comprises 0.05-0.15% of C, 0.20-0.50% of Si, 0.50-1.00% of Mn, 0.008% or less of P, 0.002% or less of S, 0.050% of less of Alt, 0.30-0.80% of Cu, 0.30-1.00% of Ni, 0.80-1.50% of Cr, 0.20-0.50% of Mo, 0.01-0.05% of V, 0.0070% or less of N and the balance Fe and unavoidable impurities. During preparation, the mass percentage of the chemical components is adjusted in a molten iron tank first, aluminum wires are added into an LF furnace and a RH furnace and continuously cast into a casting blank, the casting blank is rolled in two stages including rough rolling and finishing rolling, then subjected to heat treatment of normalization and tempering and finally cooled, and the pressure vessel steel is obtained. Through composition design, inclusion control, rolling and heat treatment, the obtained pressure vessel steel has good toughness, a low yield ratio and good welding performance and can be used for supercritical thermal power, high-efficiency boilers, nuclear power and other industries.

Description

technical field [0001] The invention relates to the technical field of low-alloy steel manufacturing, in particular to a 600°C medium-temperature acid-resistant corrosion-resistant pressure vessel steel and a preparation method thereof. Background technique [0002] At present, similar technical products in the field of acid-resistant corrosion pressure vessel steel manufacturing mainly adopt Cr-Mo series steel grades in the GB / T713-2014 standard in China, such as 15CrMoR, 14Cr1MoR, 12Cr2Mo1R, etc., but the service temperature of the above-mentioned types of steel is limited to 500 ℃, and the acid corrosion resistance is low, far from meeting the design requirements. [0003] The Chinese invention patent application number is CN201710971946.6, which discloses a low-alloy high-strength steel plate for corrosion resistance and a production method. The chemical composition and mass percentage of the steel plate are: C 0.07-0.10%, Si 0.30-0.40% , Mn 0.65~0.85%, P≤0.010%, S≤0.00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/42C22C38/44C22C38/46C21D8/02C21D1/28

Inventor 刘文斌梁宝珠余宏伟王宪军李书瑞杨秀利郭斌卜勇

Owner WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com