Method for accurately controlling aluminum consumption of IF steel

A technology of precise control and molten steel, applied in the field of smelting, can solve the problems of large fluctuations in IF steel and aluminum consumption and poor stability, and achieve good economic benefits, low cost, and reduced fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

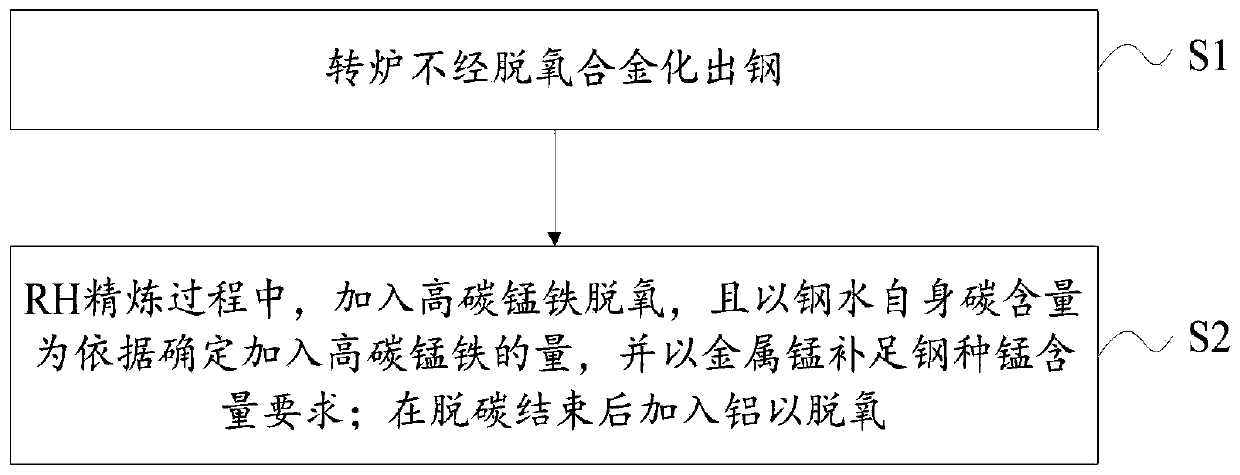

Method used

Image

Examples

Embodiment 1

[0039] A production process of high-grade automobile panel steel. The molten steel is produced through a converter-LF furnace-RH furnace-continuous casting process, and the steel output of the converter is 230 tons. During RH refining, the inbound oxygen activity is 500ppm, the inbound carbon content is 240ppm, and the steel grade Mn requirement is 0.10%. With this invention, the amount of high-carbon ferromanganese is 77kg, metal manganese is 154kg, and the time for adding high-carbon ferromanganese and metal manganese is 3 minutes, that is, adding high-carbon ferromanganese and metal manganese within 3 minutes of RH refining. At the end of RH decarburization, the oxygen activity was 248ppm, the aluminum consumption was 186kg, the RH outbound aluminum content was 0.039%, and the Mn content was 0.10%. After adopting the invention, the fluctuation of aluminum consumption between furnaces can be controlled within 10kg, and the fluctuation of Als can be controlled within 0.005%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com