Cyclic acid pickling device and method of trough type pickling tank

A technology of circulating pickling and pickling tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

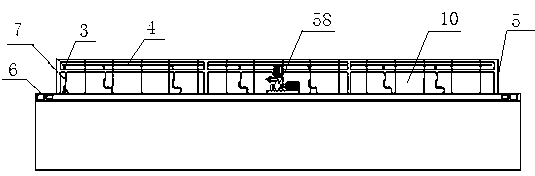

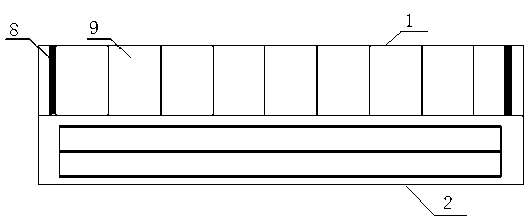

Image

Examples

Embodiment 1

[0050] Batch pickling of pipelines before construction: First, check the internal and external surface conditions of the pipelines to be pickled. If it is a newly purchased pipeline (generally a 5-9 meter straight pipe), there is no oil or paint on the surface. Open the plastic seal and keep the front and back of the pipe unblocked. If there is a lot of oil on the surface of the pipe or inside the pipe wall, degreasing operations need to be performed in advance. The pickling operation can be carried out after the oil stains on the inner and outer surfaces are removed.

[0051] Open the cover plate of the shallow pool, hang the pipeline to be pickled to the grid plate at the bottom of the shallow pickling pool, close the passage between the shallow pickling pool and the deep pool, and insert the gate into the partition groove between the shallow pickling pool and the deep pool , turn on the motor to move the triangular frame to the pickling shallow pool position, turn on the ac...

Embodiment 2

[0056] Pickling for prefabricated pipelines: In pipeline installation and production, in order to reduce the workload of on-site construction, the construction unit generally prefabricates part of the pipelines according to the drawings, and pickles and seals them before installation. The first type of pipe has many elbows and complex shapes, and it is difficult to remove impurities and rust accumulated inside the pipe. At the same time, some pipes placed in the trough pickling tank will be higher than the liquid level of the pickling solution, making it difficult to pickle. After the pipeline has been used for a period of time, the inner wall of the pipeline will be rusted and scaled, and it is necessary to pickle the inner wall of the pipeline to ensure the cleanliness of the pipeline. If online pickling is used, it will often cause on-site environmental pollution. Pipeline protection After permanent dismantling, off-line pickling can avoid the above problems, but like prefab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com