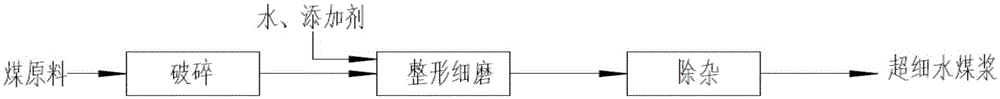

Ultrafine coal water slurry preparation method

A coal slurry and fine water technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve problems such as lag, increase system energy consumption and enterprise production costs, limit the promotion and application of coal water slurry technology, and achieve adjustment range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing ultra-fine coal-water slurry from low-rank coal in the Ordos area, the low-rank coal in the Ordos area, the analysis water is 6.5%, the total water is 15%, the ash content is 7.5%, and the particle size is less than 50mm; the method Including the following steps:

[0040] (1) crushing the low-rank coal in the Ordos area to below 13 mm to obtain the first slurry;

[0041] (2) mixing the first slurry with water at a mass ratio of 60:40 to obtain the second slurry; adding 0.4wt% naphthalenesulfonic acid formaldehyde condensate of coal raw material to the water;

[0042] (3) The second slurry is wet-processed and finely ground to obtain the third slurry, and the particle size of the third slurry is less than 1mm, and materials less than 45 μm account for more than 80% of the total material; The vertical grinding machine with the blade grinding disc is carried out, the grinding line speed of the blade grinding disc is 10m / s, and the unit volume proces...

Embodiment 2

[0046] A method for preparing superfine coal-water slurry from semi-coke in Shenmu area, wherein the analysis water of semi-coke in Shenmu area is 0.5%, the total water is 4%, the ash content is 9.5%, and the particle size is less than 25mm; the method includes Follow the steps below:

[0047] (1) Crushing the semi-coke in the Shenmu area to less than 13mm to obtain the first slurry;

[0048] (2) mixing the first slurry with water at a mass ratio of 75:25 to obtain a second slurry; adding 0.6wt% lignosulfonate of coal raw material to the water;

[0049] (3) The second slurry is wet-processed and finely ground to obtain the third slurry, and the particle size of the third slurry is less than 1mm, and materials less than 45 μm account for more than 80% of the total material; A vertical grinding machine with a blade grinding disc, the grinding line speed of the blade grinding disc is 15m / s, and the unit volume processing capacity is 2.2m 3 / h·m 3 ; Grinding medium is added in ...

Embodiment 3

[0053] A method for preparing ultra-fine coal-water slurry from low-rank coal in the Ordos area, the low-rank coal in the Ordos area, the analysis water is 6.5%, the total water is 37%, the ash content is 7.5%, and the particle size is less than 3mm; the method Including the following steps:

[0054] (1) crushing the low-rank coal in the Ordos area to below 13 mm to obtain the first slurry;

[0055] (2) mixing the first slurry with water at a mass ratio of 65:35 to obtain the second slurry; the water is added with 0.55wt% humate of coal raw material;

[0056] (3) The second slurry is wet-processed and finely ground to obtain the third slurry, and the particle size of the third slurry is less than 1mm, and materials less than 45 μm account for more than 80% of the total material; A vertical grinding machine with a blade grinding disc, the grinding line speed of the blade grinding disc is 18m / s, and the unit volume processing capacity is 2.3m 3 / h·m 3 ; Grinding medium is add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com