Hyperfine automatic grinder

A grinding machine and ultra-fine technology, applied in the direction of grinding machines, machine tools suitable for grinding the edge of workpieces, machine tools for surface polishing, etc., to achieve the effects of reducing labor intensity, reducing environmental pollution, reducing energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

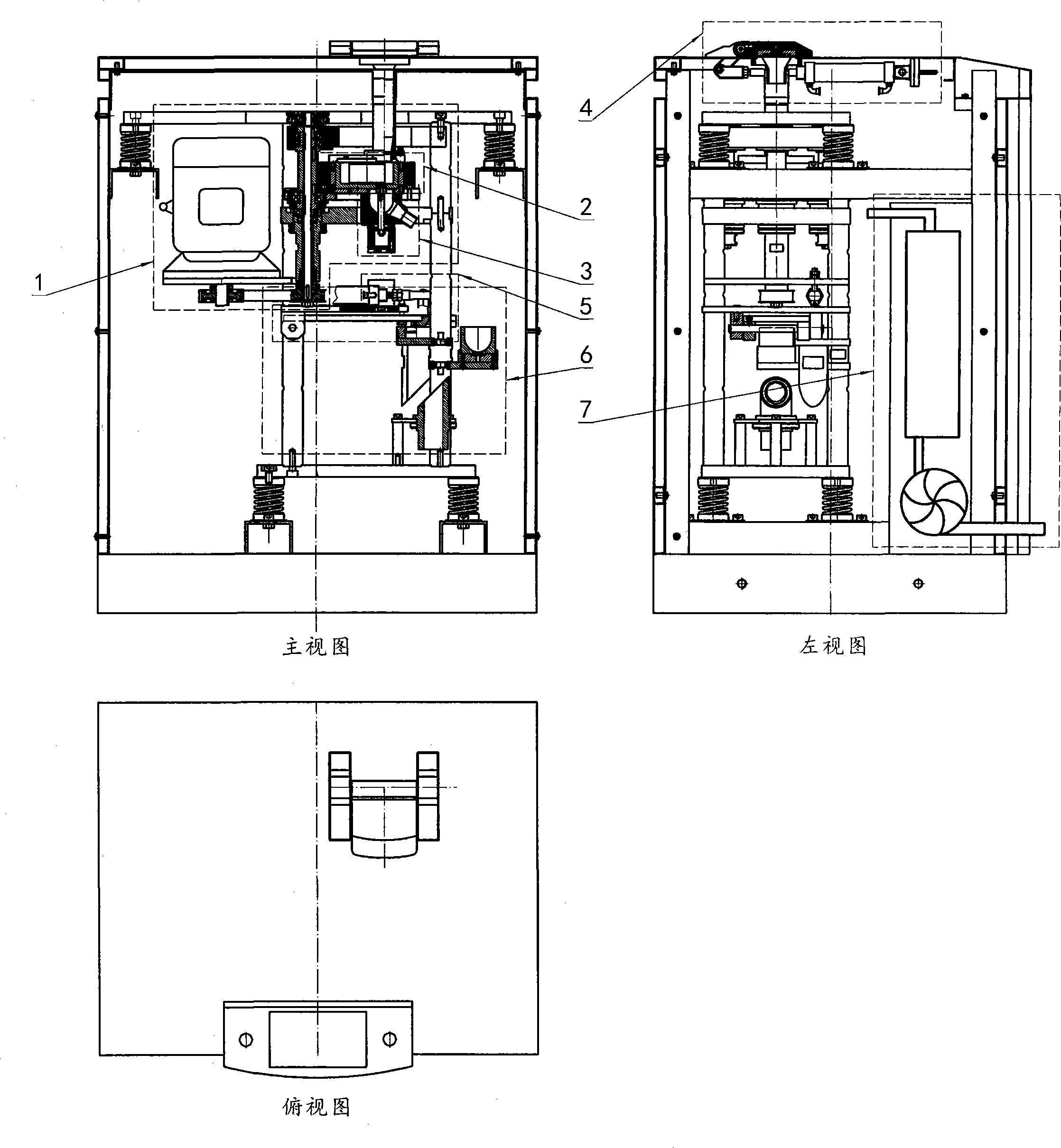

[0048] Such as figure 1 As shown, the main function setting of the ultra-fine automatic grinding machine of the present invention is to adopt the latest grinding structure: a grinding mechanism 1 is provided, a grinding box 2 is arranged above the grinding mechanism, and a feeding mechanism is connected to the top of the grinding box 2 through a hose 4. A discharge mechanism 3 is installed under the mill box 2. The discharge mechanism 3 is connected to the sealing mechanism 5. The sealing mechanism 5 is connected to the discharge dust removal conversion mechanism 6. The discharge dust removal conversion mechanism 6 and the cleaning and dust removal filter system 7 enter through the soft tube connected.

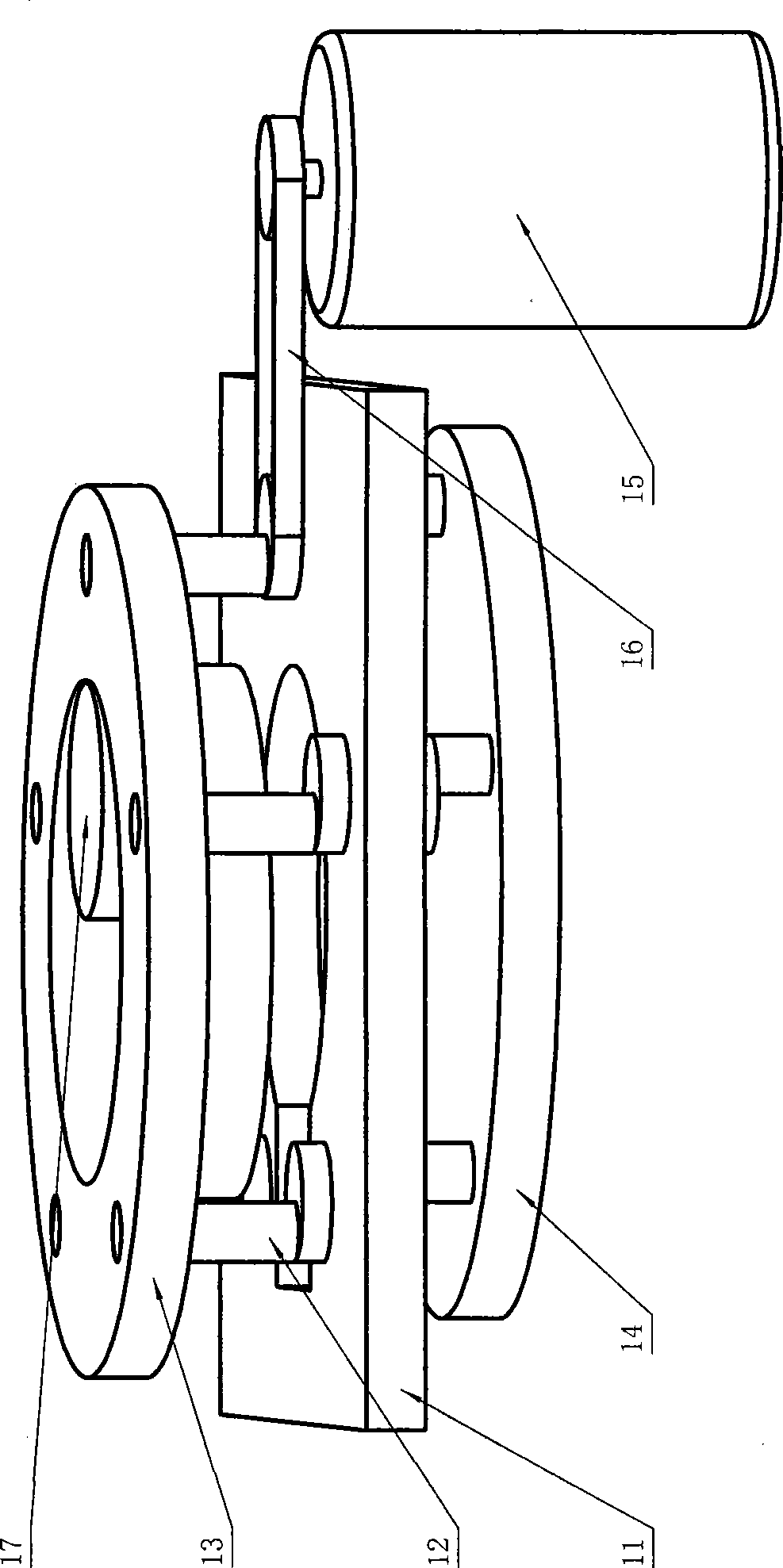

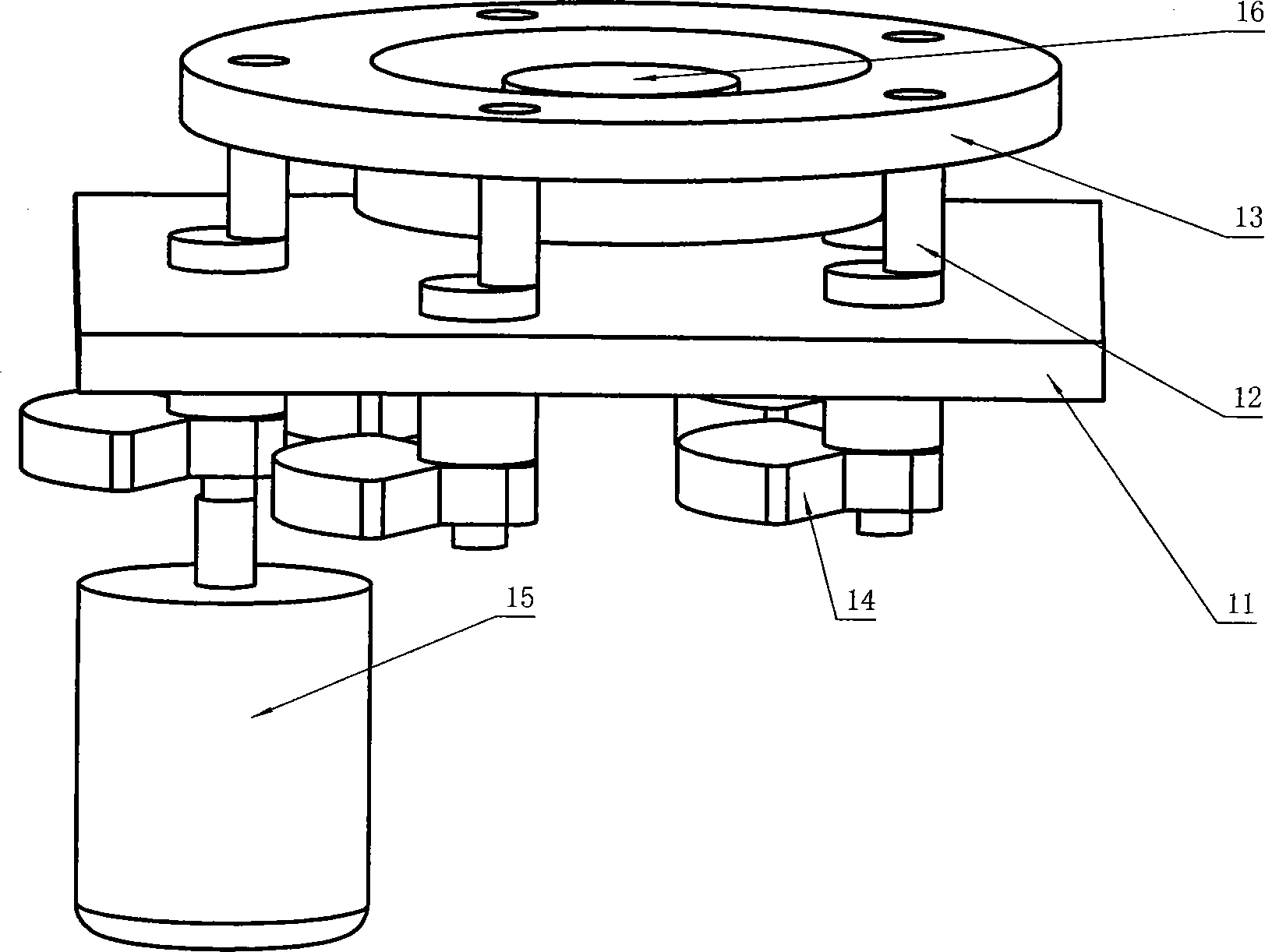

[0049] The grinding mechanism adopts the fixed-magnitude eccentric vibration technology with synchronous rotation of multiple eccentric shafts, and can adopt a counterweight mechanism in which counterweights and eccentric counterweights are arranged symmetrically with the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com