Flow field structure for improving effective area of bipolar plate waveform flow channel flow filed of fuel cell

A wave-shaped, flow channel technology, applied in the field of fuel cells, can solve problems such as reducing the power generation capacity of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The flow field structure of the present invention for increasing the effective area of the flow field of the corrugated flow channel of the bipolar plate of the fuel cell will be further specifically described below in conjunction with specific embodiments.

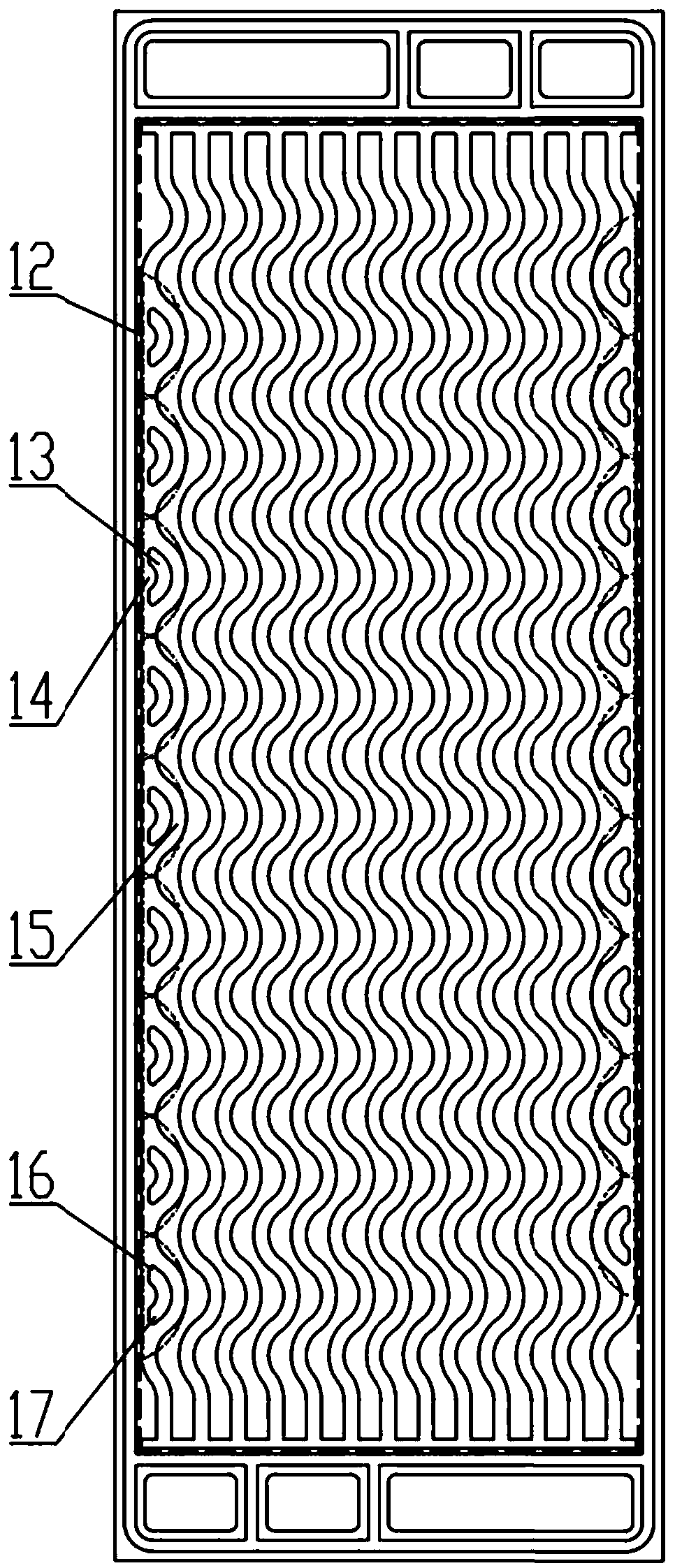

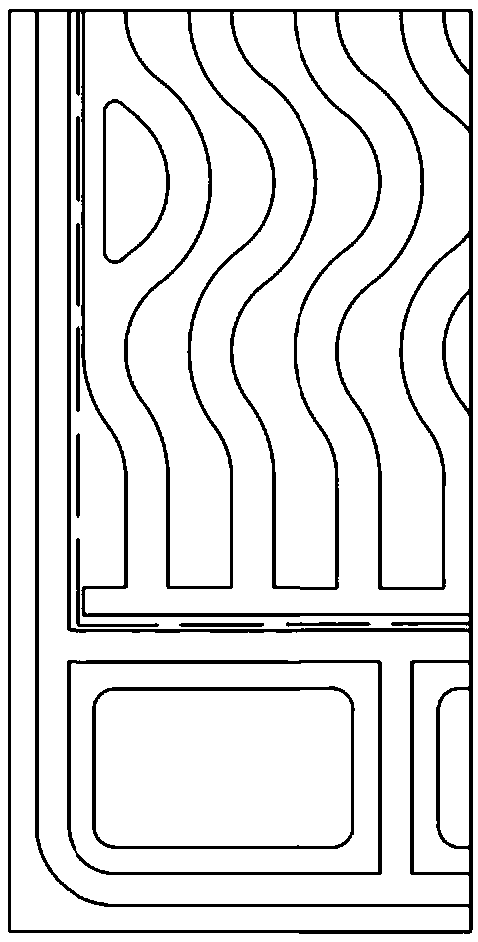

[0024] Such as figure 1 with figure 2 As shown, the wave-shaped channel flow field structure has a wave-shaped flow channel 5 composed of several parallel bosses 2 extending in a wave state in the flow field. The edge a of the flow field that is consistent with the extending direction of the boss is Straight line; the edge a does not meet with the adjacent boss b, forming several connected gaps X; the gap X is provided with a half-moon-shaped boss 13 suitable for the structure of the gap X; the bow of the half-moon-shaped boss 13 The side is close to the boss b, and the chord side is close to the edge a; there is a gap A14 between the chord side and the edge a; there is a gap B15 between the bow side and the boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com