Clothes hanger

A hanger and main body technology, applied in the field of machinery, can solve problems such as uneven air flow, slow drying of clothes, and insufficient wind power, and achieve the effects of fast flow speed, fast drying, and accelerated water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

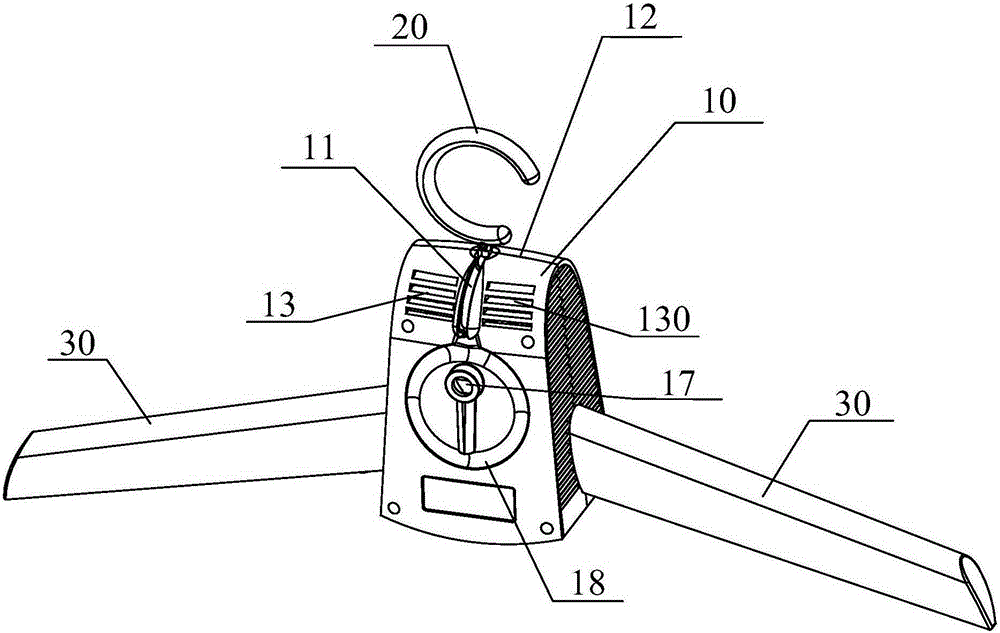

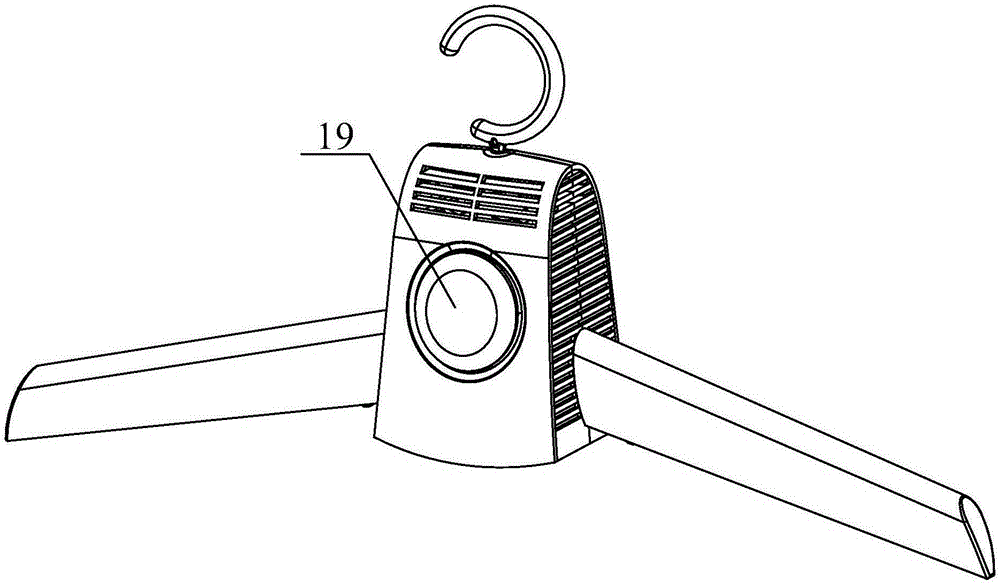

[0041] In this example, if Figure 1 to Figure 10 As shown, a kind of clothes hanger, described clothes hanger comprises clothes hanger main body 10, and described clothes hanger main body 10 is provided with air outlet 28, and described clothes hanger main body 10 is also provided with heating element 42, between described heating element 42 and air outlet 28 An air outlet channel 60 is arranged between them, and the cross-sectional area of the air outlet channel 60 gradually decreases as the air outlet channel 60 approaches the air outlet 28 .

[0042] With this structure, after the air flow through the heating element 42 reaches the air outlet channel 60, the air flow is squeezed due to the gradual reduction of the cross-sectional area of the air outlet channel 60, and the speed of the air flow gradually increases at this time, and the air outlet channel 60 The closing-shaped setting also makes the air flow denser and more impactful. When this air flow rushes out from t...

Embodiment 2

[0048] In this example, if Figure 1 to Figure 10 As shown, the hanger body 10 is provided with a hook 20 and a sliding groove 11 for installing the hook 20, the hook 20 can slide in the sliding groove 11, and the hook 20 can move along the sliding groove 11 to the The top 12 of the hanger main body 10 moves or moves along the sliding groove 11 to fit the hanger main body 10, the hanger main body 10 is provided with an air inlet 13, and the sliding groove 11 passes through the air inlet 13, The air inlet 13 is divided into air inlet through holes 130 respectively located on two sides of the sliding groove 11 .

[0049] With this structure, the hook 20 is slidably installed on the sliding groove 11, and the hook 20 can move to the top 12 along the sliding groove 11, so that the hook 20 can be moved to the top 12 when needed to hang the hanger. Thereby, the clothes are dried, and when the clothes hanger is not needed, the hook 20 is moved to the state where it fits with the han...

Embodiment 3

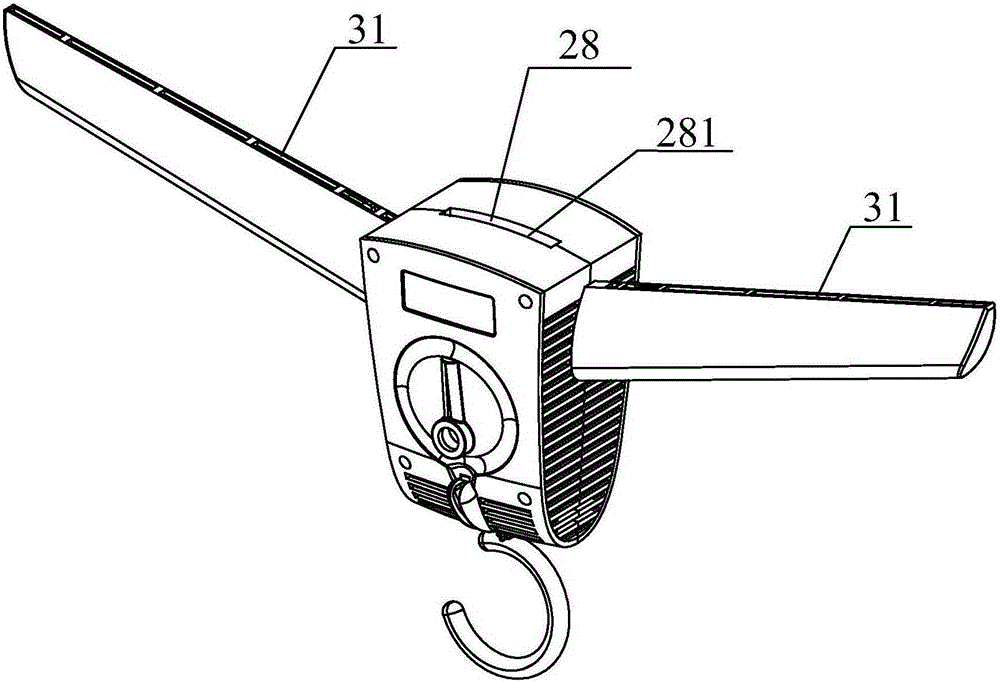

[0063] In this example, if Figure 11 shown, combined with Figure 1 to Figure 10 , the hanger main body 10 is also provided with an air outlet pipe 29, a support arm 30 is installed on the air outlet pipe 29, and the support arm 30 is sleeved on the air outlet pipe 29, and the air outlet pipe 29 and The support arms 30 are connected by a clamping device, the clamping device includes a first elastic arm 50 fixed on the hanger main body 10, and the air outlet pipe 29 and the support arm 30 pass through the The first elastic arm 50 is clamped and fixed with the support arm 30 .

[0064] With this structure, the air outlet duct 29 is set on the hanger main body 10, and the supporting arm 30 is set on the air outlet duct 29, so that the clothes can be hung by the supporting arm 30, which is convenient for drying the clothes. A clamping device is arranged between the support arms 30 to connect, and the clamping device comprises a first elastic arm 50, so that the support arm 30 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com