Gas plasma sulfurizing process

A technology of plasma infiltration and gas, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem that the quality of sulfurization is difficult to control, and achieve the effect of appropriate quantity, uniform distribution and uniform depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: For general small and medium-sized bearings, the material is GCr15, and the sulfurizing depth is 2-3 μm, the operating procedures and process parameters of the sulfurizing process are set as follows:

[0033] 1. Preparation for sulfurizing:

[0034] Prepare the site and the workpiece of the bearing ring to be infiltrated, and check whether the furnace, vacuum pump, control system, temperature system, and vacuum system are normal.

[0035] 2. Cleaning and loading furnace:

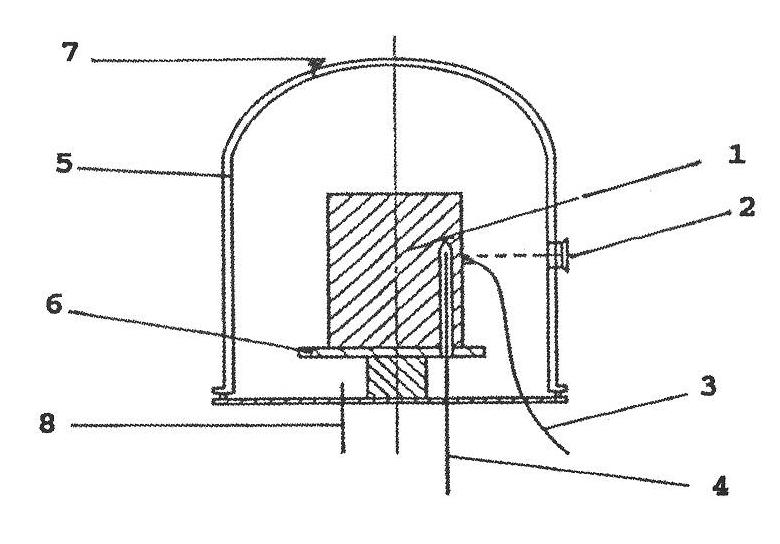

[0036] Lift the furnace hood, blow out the furnace chamber, work table and sealing ring, and scrub them with acetone. Clean the bearing ring with gasoline first, and then scrub it with acetone. Place the workpiece on the workbench, lift the furnace cover and cover it, as attached figure 1 .

[0037] 3. Start the power supply, turn on the computer, and set the relevant process parameters.

[0038] Voltage: 0 Volts, Current: 0A. Sulfurizing temperature: 140°C.

[0039] Sulfurization ti...

example 2

[0047] Example 2: High temperature tempered bearing, high carbon chromium bearing steel material, when the sulfurizing depth is 3-5μm, the sulfurizing process operating procedures and process parameters are set as follows:

[0048] 1. Preparation for sulfurizing:

[0049] Prepare the site and the workpiece of the bearing ring to be infiltrated, and check whether the furnace, vacuum pump, control system, temperature system, and vacuum system are normal.

[0050] 2. Cleaning and loading furnace:

[0051] Lift the furnace hood, blow out the furnace chamber, work table and sealing ring, and scrub them with acetone. Clean the bearing ring with gasoline first, and then scrub it with acetone. Place the workpiece on the workbench, lift the furnace cover and cover it, as attached figure 1 .

[0052] 3. Start the power supply, turn on the computer, and set the relevant process parameters.

[0053] Voltage: 0 Volts, Current: 0A. Sulfurizing temperature: 250°C.

[0054] Sulfurizati...

example 3

[0062] Example 3: For high temperature resistant bearings, the material is M50, and when the depth of the sulfurized layer is 6-8 μm, the operating procedures and process parameters of the sulfurized process are set as follows:

[0063] 1. Preparation for sulfurizing:

[0064] Prepare the site and the workpiece of the bearing ring to be infiltrated, and check whether the furnace, vacuum pump, control system, temperature system, and vacuum system are normal.

[0065] 2. Cleaning and loading furnace:

[0066] Lift the furnace hood, blow out the furnace chamber, work table and sealing ring, and scrub them with acetone. Clean the bearing ring with gasoline first, and then scrub it with acetone. Place the workpiece on the workbench, lift the furnace cover and cover it, as attached figure 1 .

[0067] 3. Start the power supply, turn on the computer, and set the relevant process parameters.

[0068] Voltage: 0 Volts, Current: 0A. Sulfurizing temperature: 550°C.

[0069] Sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com