Water base casting coating for heavy casting and manufacturing method thereof

A technology for casting coatings and large castings, applied in casting molding equipment, coatings, molds, etc., can solve the problems of easy drop in viscosity, poor coating performance, poor resistance to microbial erosion, etc., and achieve balanced leveling and leveling. Sag resistance, mild heat release, smooth surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

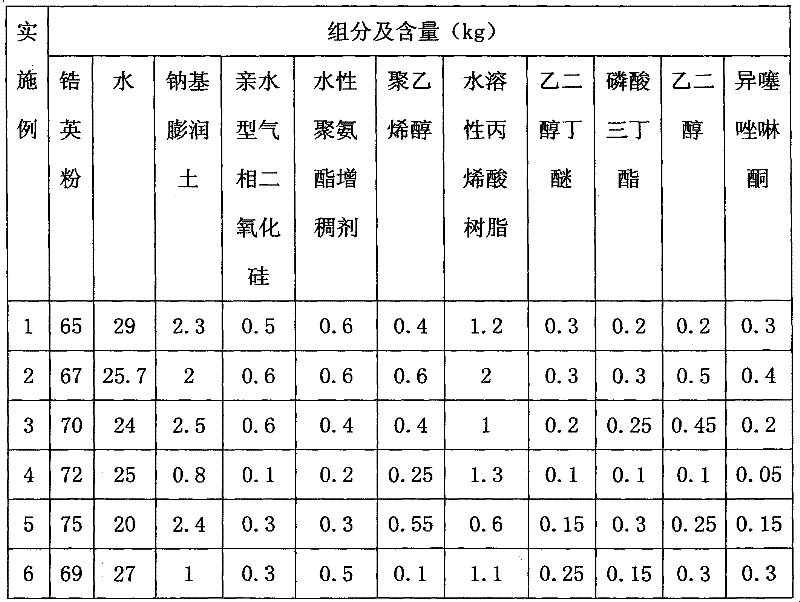

[0057] Table 1 is 6 groups of formulas (raw material components and content) of the present invention in the table below.

[0058]

Embodiment 7

[0060] 1. Take by weighing the raw material components of corresponding content according to the formula (taking Example 1 as an example).

[0061] 2. Raw material pretreatment

[0062] (1) Mix 2.3kg of sodium-based bentonite with 3.45kg of water evenly, put it in a closed container and let it stand for 30-80 hours, so that the sodium-based bentonite is fully wetted and activated; (2) Hydrophilic gas-phase dioxide Mix 0.5kg of silicon and 3kg of water evenly, put it in a closed container and let it stand for 28-100h, so that the hydrophilic fumed silica is fully wetted; (3), mix 0.4kg of polyvinyl alcohol and 3.6kg of water at 90- It dissolves at 95°C, and it is dissolved to make a 10% transparent aqueous solution.

[0063] 3. Preparation of coating

[0064] ① Weigh 0.2kg of tributyl phosphate, 1.2kg of water-soluble acrylic resin, 0.6kg of water-based polyurethane thickener, 0.3kg of ethylene glycol butyl ether, 0.2kg of ethylene glycol, 65kg of zircon powder, and isothiazo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com