Full-penetration welding device for weld joint of welded part and welding method of device

A welding device and full penetration technology, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low quality qualification rate, low work efficiency and high cost of the reverse root cleaning method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

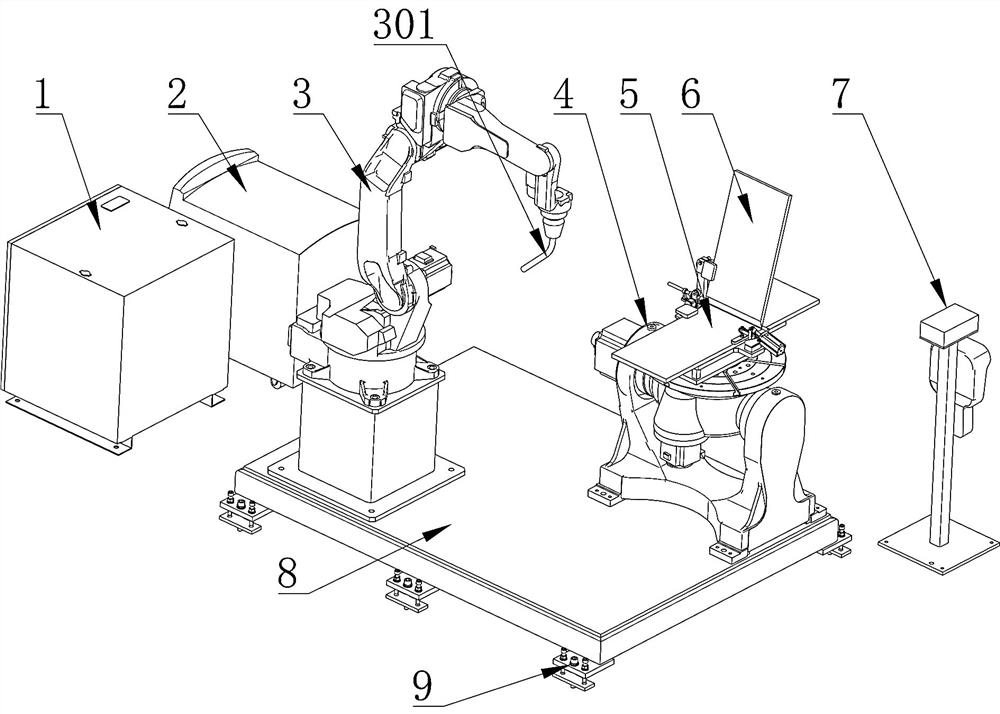

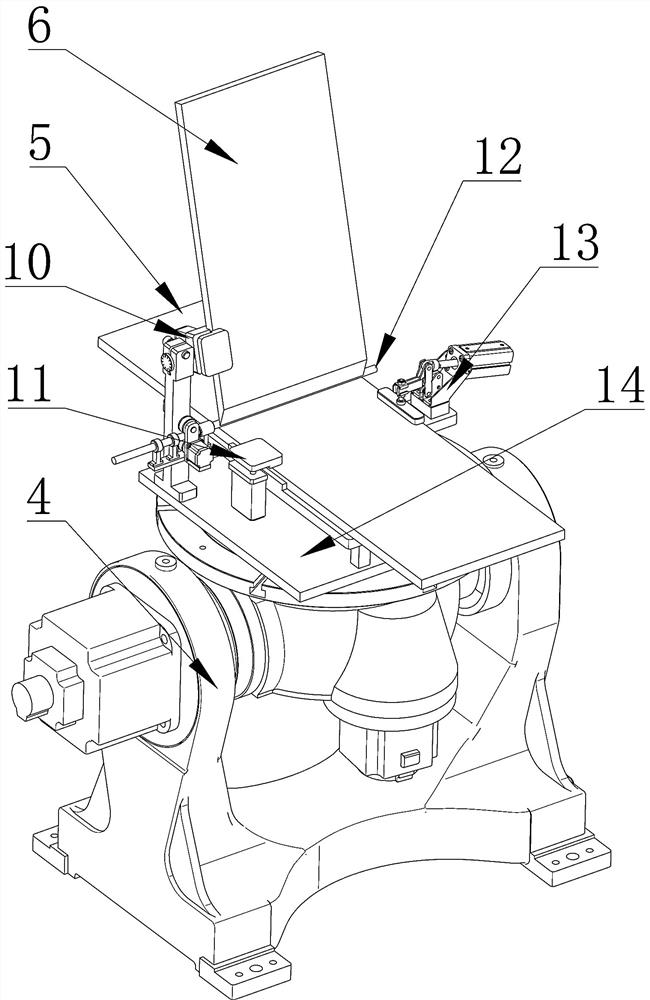

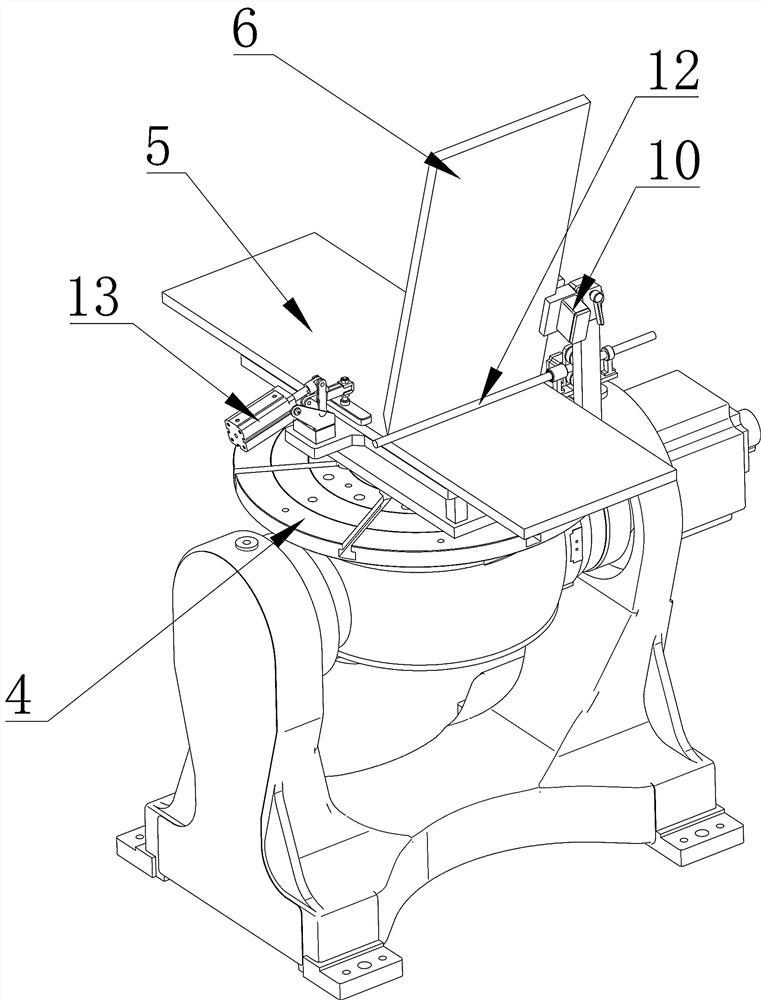

[0046] Such as Figure 1~12 Shown, a kind of weldment seam full-penetration welding device, the first welding base metal 5 and the second welding base metal 6 weld seam side are provided with liner 12, liner 12 and first welding base material 5 and The second welding base material 6 is in contact with the weld seam. The preferred circular ceramic pad in this program is placed on one side of the first welding base material 5 and the second welding base material 6 welds, such as Figure 4-5 The shown structure reduces the work of cleaning the root of the weld seam on the other side of the weld seam, makes the welding steps on the other side simpler, and does not need to perform effective root cleaning work on the other side.

[0047] Also be provided with welding base plate 14, be provided with at least two clamping devices on welding base plate 14, the first welding base metal 5 is located on welding base plate 14, the first welding base material 5 is clamped by clamping device...

Embodiment 2

[0058] Further illustrate in conjunction with embodiment 1, as Figure 1~12 As shown, the first welding base metal 5 is placed on the welding bottom plate 14, the first welding base metal 5 is positioned against the first side positioning plate 1401 for side positioning, and the first welding base material 5 is clamped by the pneumatic clamp 11 and the pneumatic turning clamp 13. Welding base metal 5.

[0059] The second welding base material 6 leans against the second side positioning plate 1003 on the first cylinder 1002 for side positioning, and the second welding base material 6 is pressed by the pressing plate 1004 .

[0060] Then select the second welding base material 6 to rotate the entire vertical fixture 10 on the support column 1001, select the angle of rotation through the angle dial 1007, and lock the vertical fixture by rotating the locking handle 1005 after rotating the appropriate angle 10, release the vertical clamp 10 to adjust the weld distance between the ...

Embodiment 3

[0064] Further description in conjunction with embodiment 1 or embodiment 2, as Figure 1~12 As shown, the full penetration method includes: the ultrasonic flaw detection of the first welding base metal 5 and the second welding base metal 6 is qualified, and there must be no lack of fusion, air holes, slag inclusions, undercuts, welding flashes, weld fillet heights, and weld gap widths. Nonconforming defects.

[0065] Determine the weld groove, the first welding base metal 5 and the second welding base metal 6 are k-shaped grooves or x-shaped grooves.

[0066] Select the circular liner 12 to stick to the large groove side of the k-shaped groove, and the diameter of the circular liner 12 is 5-10mm.

[0067] According to the welding principle that welding current × welding voltage ÷ welding speed is equal to linear energy, determine welding current, welding voltage, welding speed, root welding: 300 ~ 320A, 30 ~ 32V, 30 ~ 36cm / min, filling welding: 280 ~ 300A, 30~32V, 30~36cm / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com