Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Reduce center segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

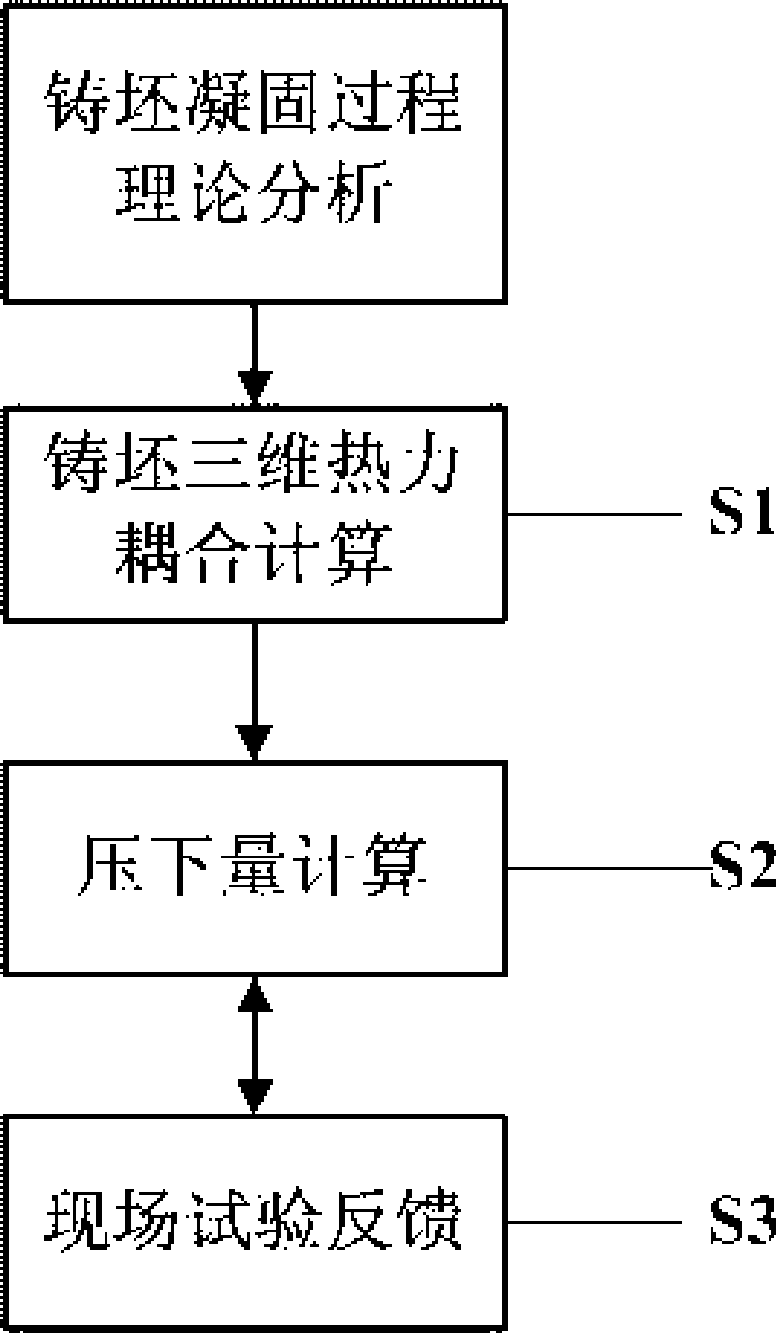

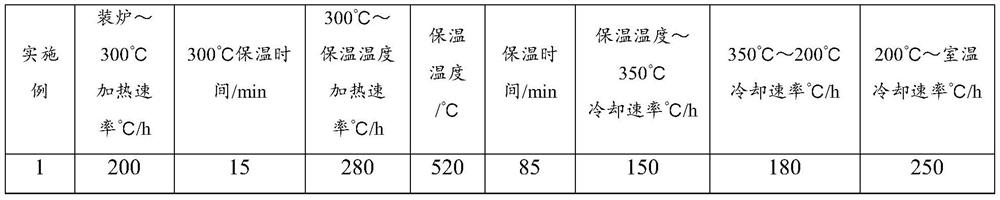

Bloom continuous-casting dynamic gentle pressure amount control method-

The invention discloses a bloom continuous casting soft depressing technology in steel production and more particularly relates to a control method of the depressing quantity of the bloom continuous casting soft depressing. The invention aims at solving the technical problem of providing a control method which can determine the depressing quantity of the bloom continuous casting dynamic soft depressing according to different steel grades and obtaining the depressing quantity Delta S by adopting the following method (see the formula). The adoption of the control method of the depressing quantity can determine the depressing quantity of the dynamic soft depressing needed in different conditions of the continuous casting technology rapidly and effectively according to changes of the steel grades, and obviously reduce the central segregation of casting billets as well as reducing or even eliminating the appearance of central crack and central porosity.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

Round steel for major diameter engineering machine hydraulic oil cylinder piston rod and manufacturing method of round steel

InactiveCN107619995AImprove mechanical propertiesCentral segregation lightFriction weldingChemical composition

The invention relates to round steel for a major diameter engineering machine hydraulic oil cylinder piston rod. The round steel comprises the following chemical components of, by mass percent, 0.35-0.55% of C, 0.10-0.50% of Si, 0.80-1.20% of M, less than or equal to 0.030% of P, 0.01-0.04% of S, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Ni, less than or equal to 0.05% of Cu, less than or equal to 0.20% of Mo, 0.01-0.05% of Al, 0.03-0.50% of V, 0.005-0.20% of N, less than or equal to 0.02% of Pb, less than or equal to 0.03% of Sn, and the balance Fe and unavoidable impurity elements. All Al and V in the round steel and N form chemical compounds correspondingly, and the chemical compounds are separated out at a grain boundary. The manufactured round steel is little in center segregation, and can meet the friction welding operation requirement, tempering heat treatment is not required in a production flow, and the mechanical properties meet the production and userequirements.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

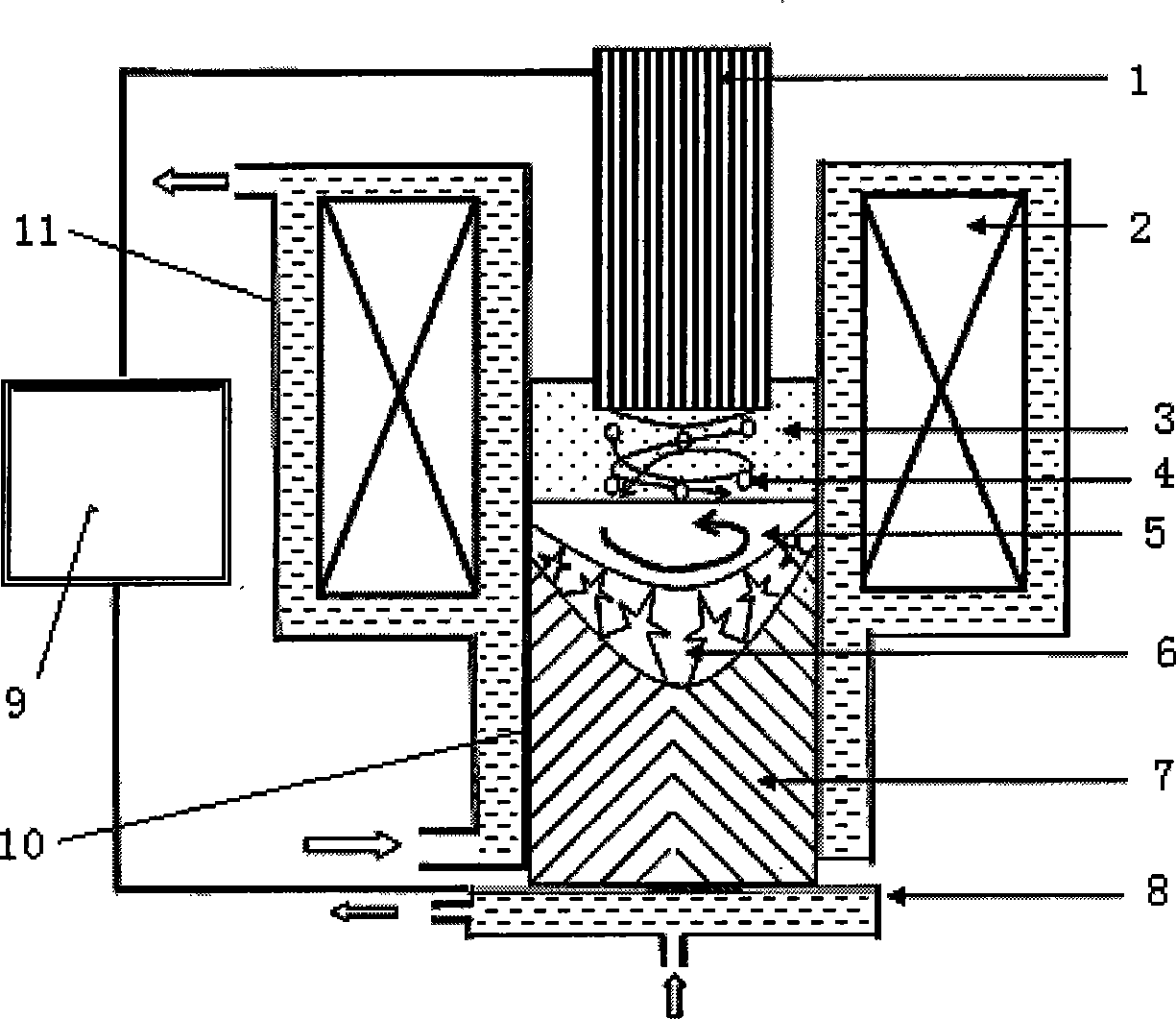

Electroslag smelting casting device with additional electromagnetic stirring and method

The invention relates to an electroslag casting device additionally provided with electromagnetic stirring and a method thereof. The electroslag casting device belongs to the technical field of special steel electroslag metallurgy and comprises a crystallizer, a crystallizer water jacket and an electromagnetic stirrer; an annular magnet is sleeved on the outer wall of the crystallizer and positioned at the middle-upper part of the crystallizer, a loop is wound on an iron core of the annular magnet, an electromagnetic stirrer water jacket is arranged at the periphery of the annular electromagnet, and the electromagnetic stirrer water jacket is communicated with the crystallizer water jacket; a melting consumable electrode forms molten steel drops which then enter a slag layer; the molten steel drops fall down in a spiral line way in the slag layer under the action of the rotary electromagnetic field and then enter a steel ingot liquid tank; the steel ingot liquid tank raises continuously and also enters into an effective magnetic field action region of the electromagnetic stirrer; and meanwhile, electric current in the molten steel is acted with the rotary magnetic field to produce the electromagnetic force which then drives the molten steel to rotate. The invention has simple equipment, and has the obvious functions of improving the surface quality, the subsurface quality and the solidifying tissue of a casting blank and the isometric crystal ratio, and lightening the internal defects, such as the center segregation, the center looseness, and the like.

Owner:NORTHEASTERN UNIV

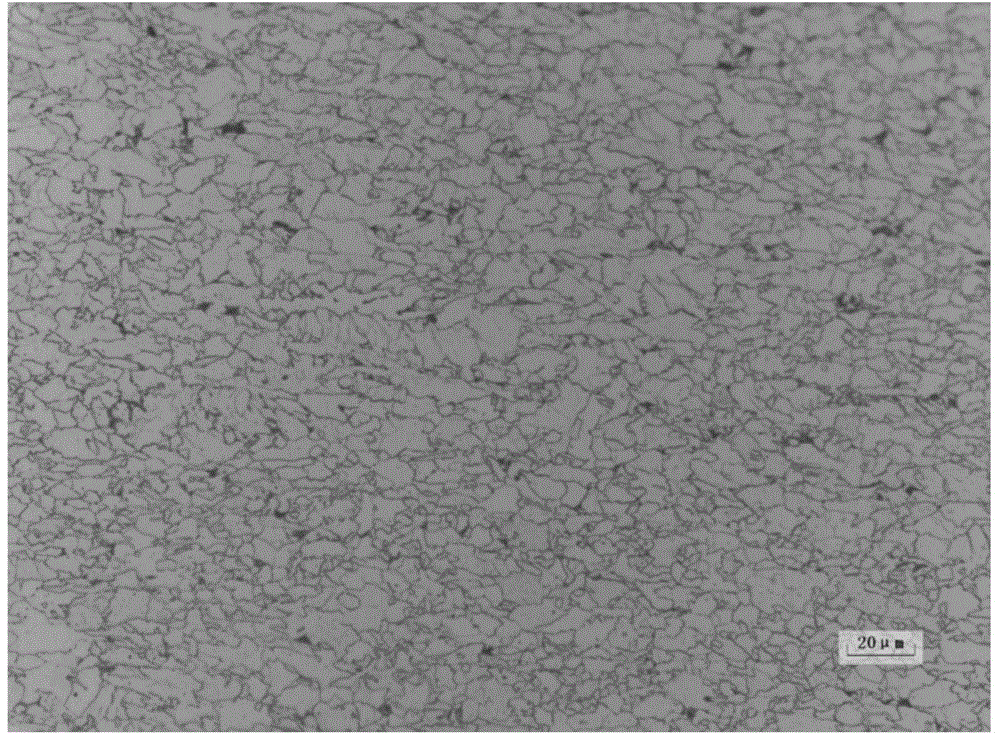

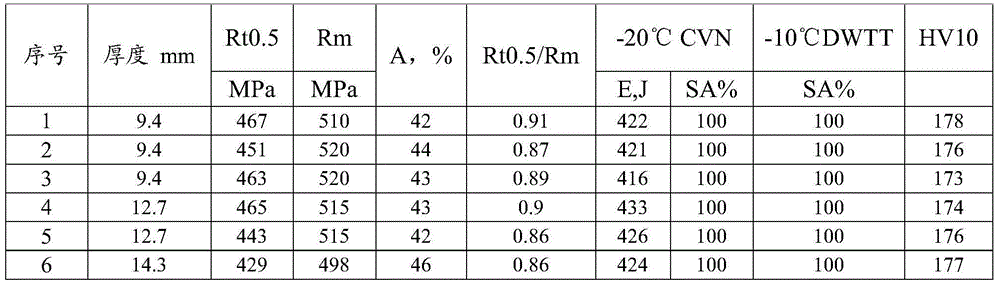

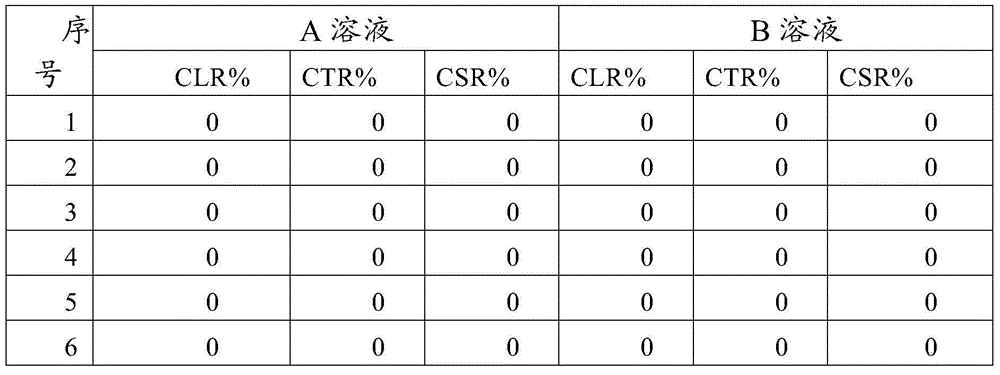

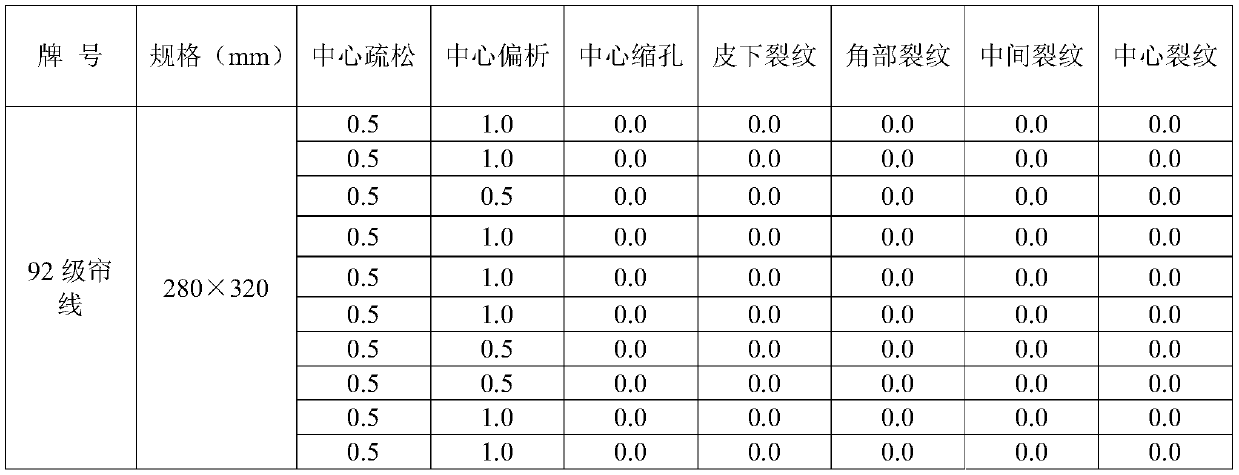

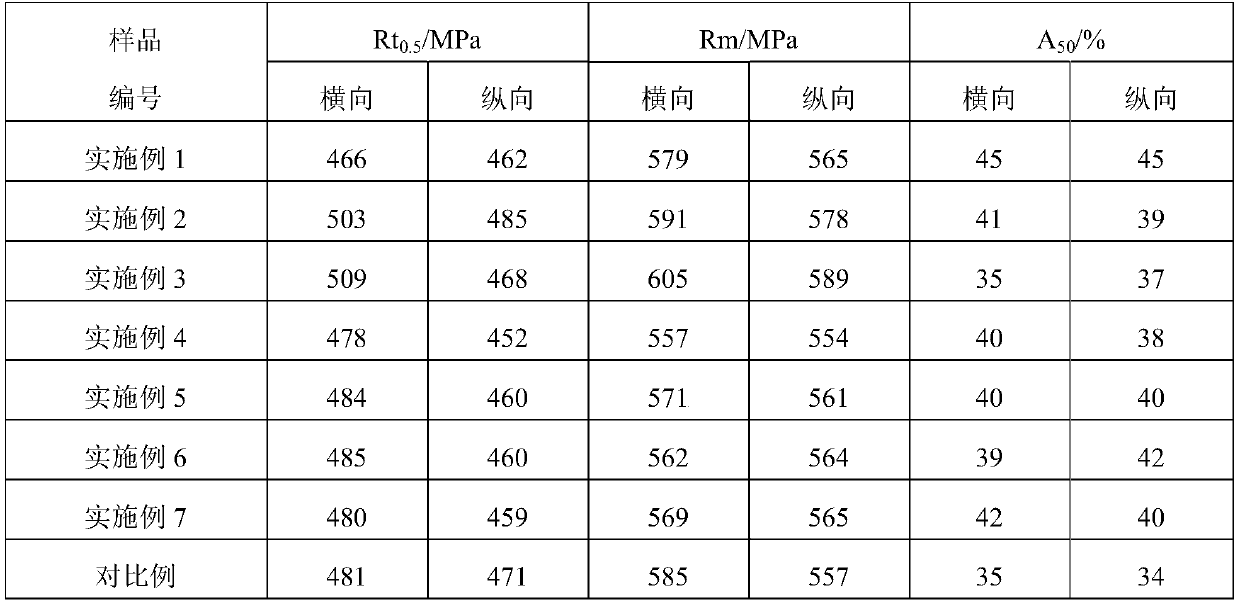

Non-copper and nickel acid resistant pipeline steel X52MS and production method of hot-rolled plate coil thereof

The invention relates to non-copper and nickel acid resistant pipeline steel X52MS. The non-copper and nickel acid resistant pipeline steel X52MS comprises the following components in percentage by weight: 0.02-0.06 wt% of C, 0.05-0.35 wt% of Si, 1.0-1.4 wt% of Mn, P not greater than 0.018 wt%, S not greater than 0.003 wt%, 0.10-0.50 wt% of Cr, 0.05-0.10 wt% of Ti, 0.005-0.10 wt% of Nb, 0-0.05 wt% of V, and the balance of Fe and inevitable trace impurities. The invention further provides a preparation method of a hot-rolled plate coil of the non-copper and nickel acid resistant pipeline steel X52MS. Part of all Cr is used for replacing original Ni / Cu elements, so that the material cost is largely reduced under the precondition of guaranteeing the material HIC resistance.

Owner:SHOUGANG CORPORATION

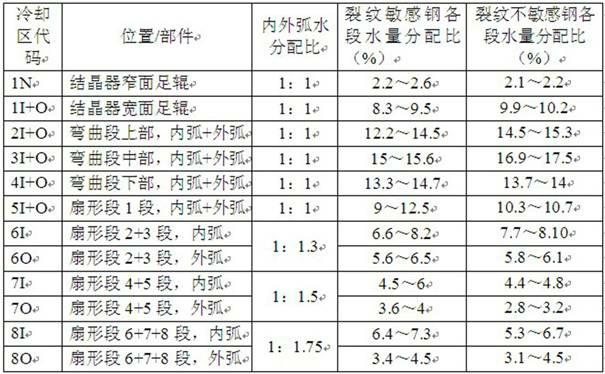

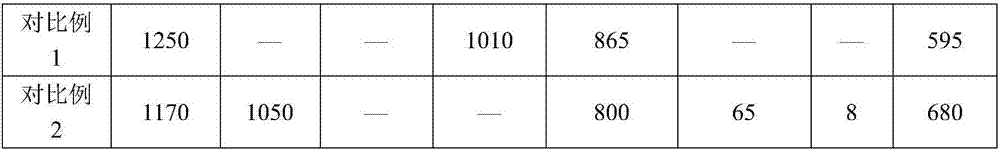

Method for adjusting secondary cooling water amount and roll gap value of double-flow slab casting machine

The invention discloses a method for adjusting the secondary cooling water amount and the roll gap value of a double-flow slab casting machine. In the double-flow slab casting machine, 12 cooling regions are formed for secondary cooling; 10 cooling water meters are provided; five grades, i.e., strong cooling: the secondary cooling water amount is 1.0-1.1 L / kg, medium cooling: the secondary cooling water amount is 0.8-0.9 L / kg, weak cooling: the secondary cooling water amount is 0.7-0.8 L / kg, medium-weak cooling: the secondary cooling water amount is 0.45-0.6 L / kg, and slight cooling: the secondary cooling water amount is 0.4-0.45 L / kg are divided to adapt to the cooling requirements of different types of steel respectively; the roll gap of a secondary cooling region support roll is consistent with the linear shrinkage rule of a casting blank from top to bottom, and decrease continually; and the roll opening between the outlet of a previous fan-shaped section and the inlet of a next fan-shaped section is kept consistent. By adopting the method, the internal cracking rate is lowered, the macrostructure of the casting blank is optimized, and the performance yield of steel is increased.

Owner:ANYANG IRON & STEEL

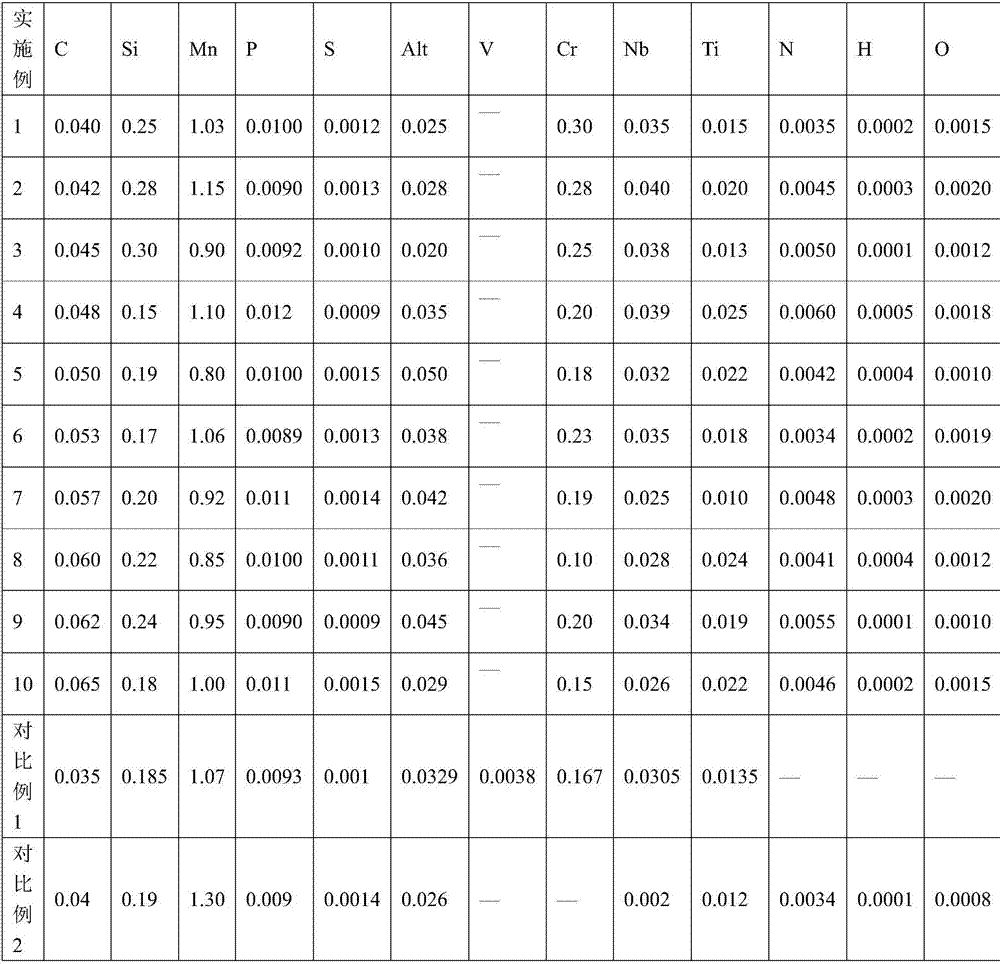

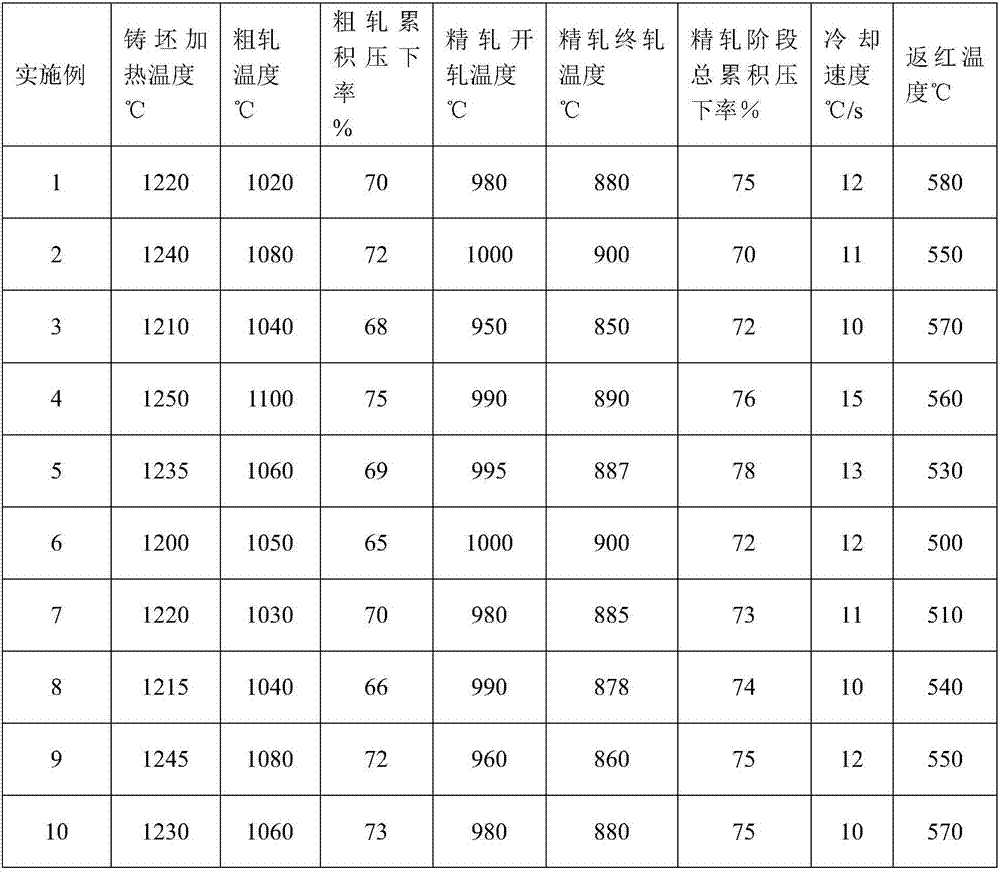

Low-yield-ratio thin-gauge high-strength and acid-resistant pipeline steel hot rolled coil plate and manufacturing method thereof

The invention provides a low-yield-ratio thin-gauge high-strength and acid-resistant pipeline steel hot rolled coil plate. The hot rolled coil plate comprises the chemical components, by mass, of 0.04%-0. 065% of C, 0.15%-0.30% of Si, 0.8%-1.15% of Mn, 0.012% of P or the less, 0.0015% of S or the less, 0.006% of N or the less, 0.025%-0.04% of Nb, 0.010%-0.025% of Ti, 0.1%-0.3% of Cr, 0.02%-0.05% of Als and the balance Fe and inevitable impurities. Through combination control over the components and the technique, the high strength, low yield ratio, excellent HIC resistance and excellent SSCC resistance of thin-gauge high-strength and acid-resistant pipeline steel can be achieved, the cost is lower, strength is higher, the thinner gauge can be achieved, control over the smelting and rolling processes is relatively simple, the production efficiency is greatly improved, and control over the process cost is greatly strengthened.

Owner:武汉钢铁有限公司

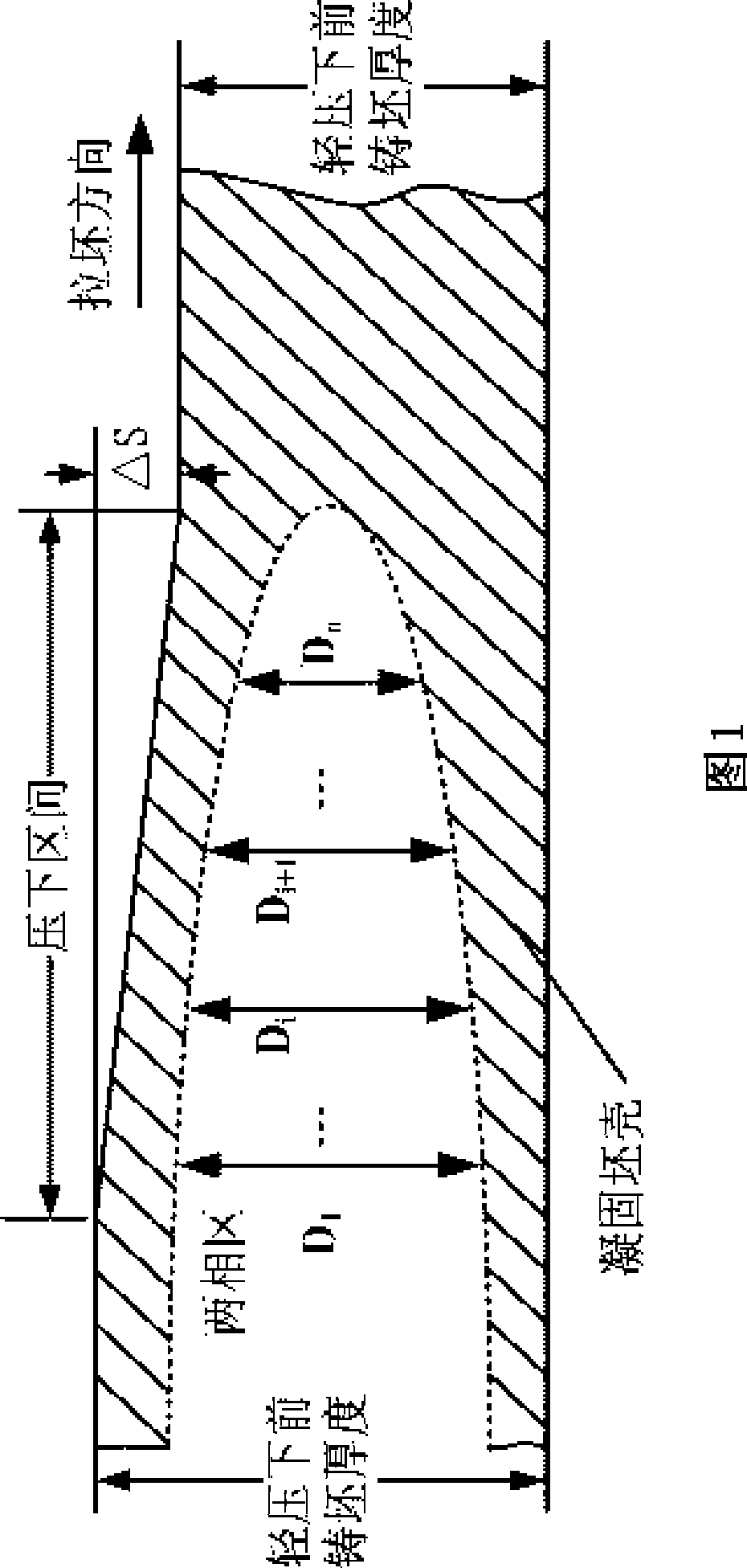

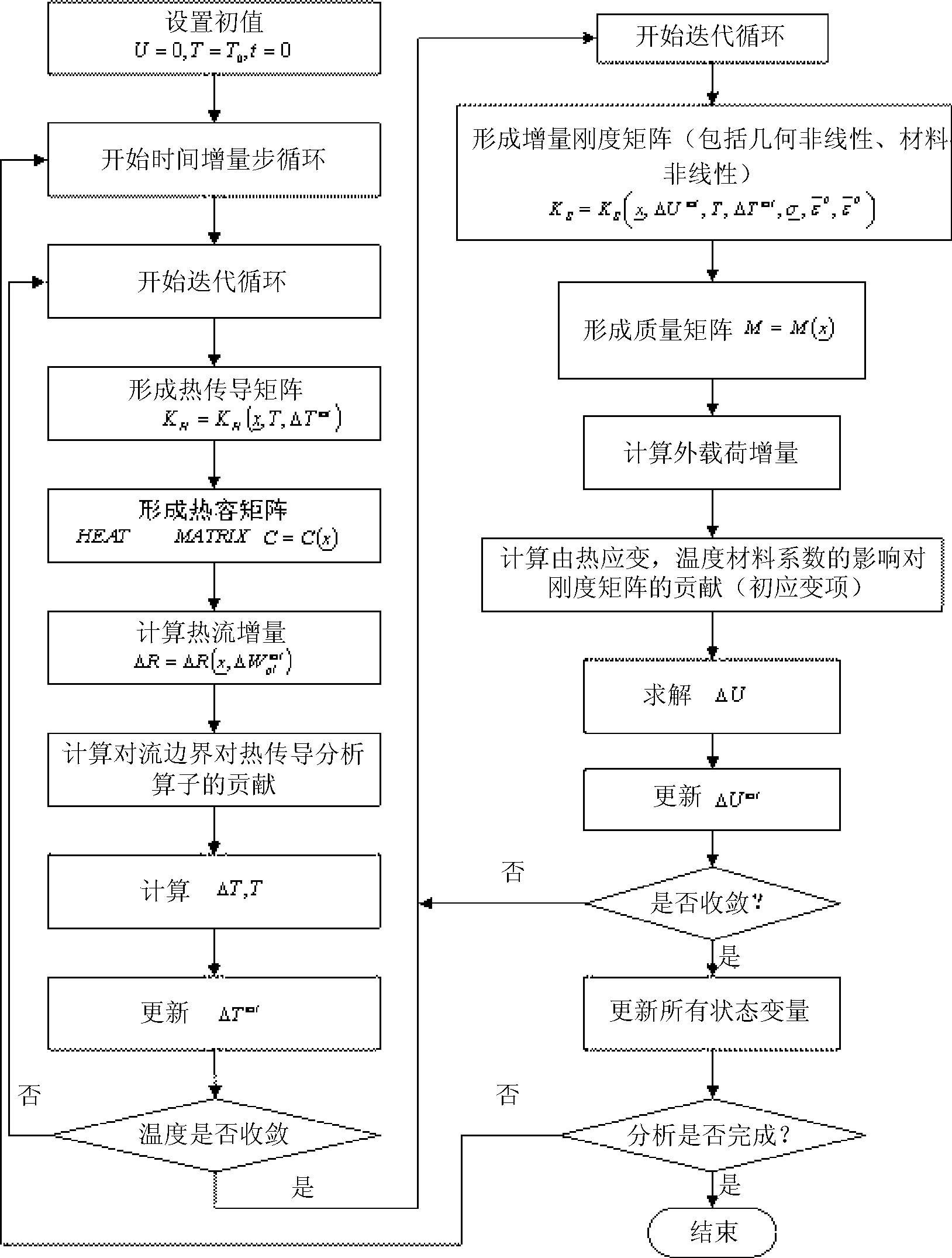

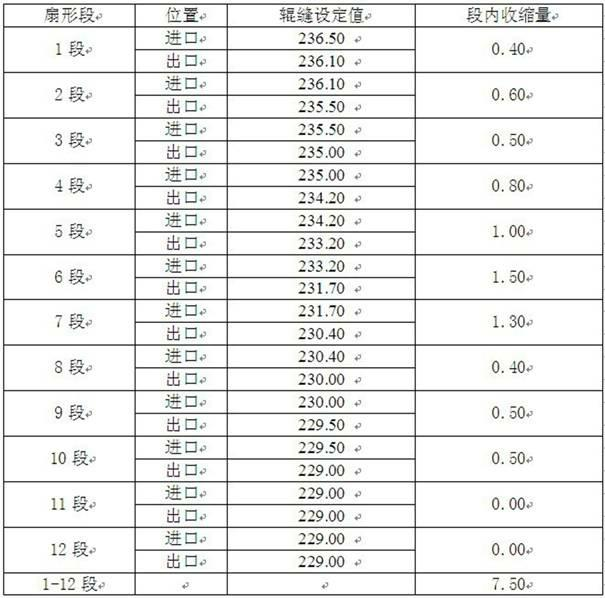

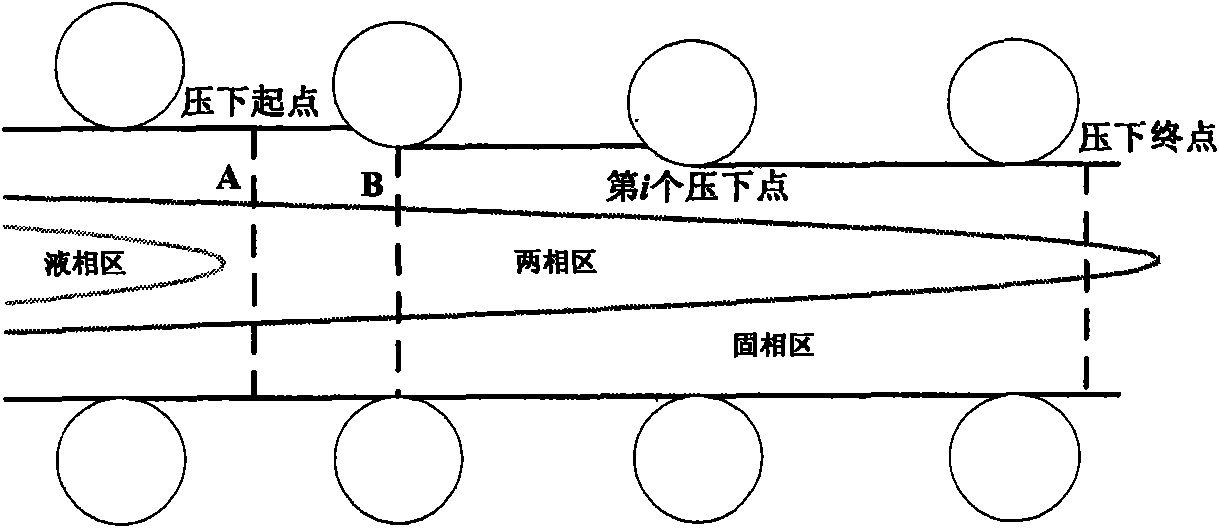

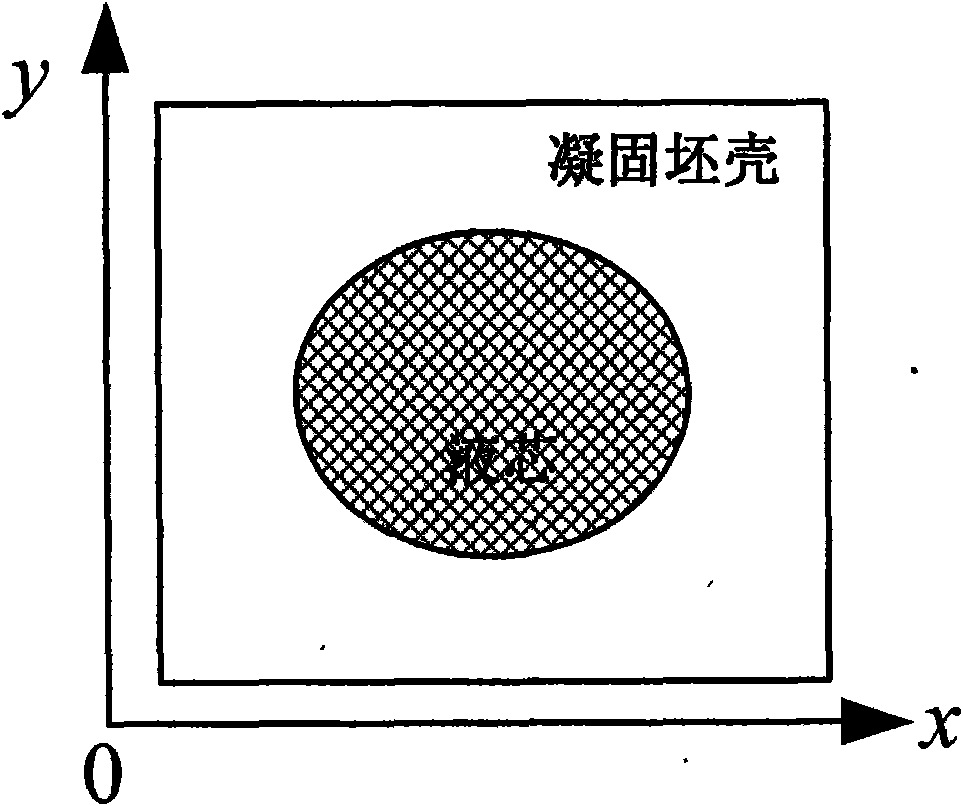

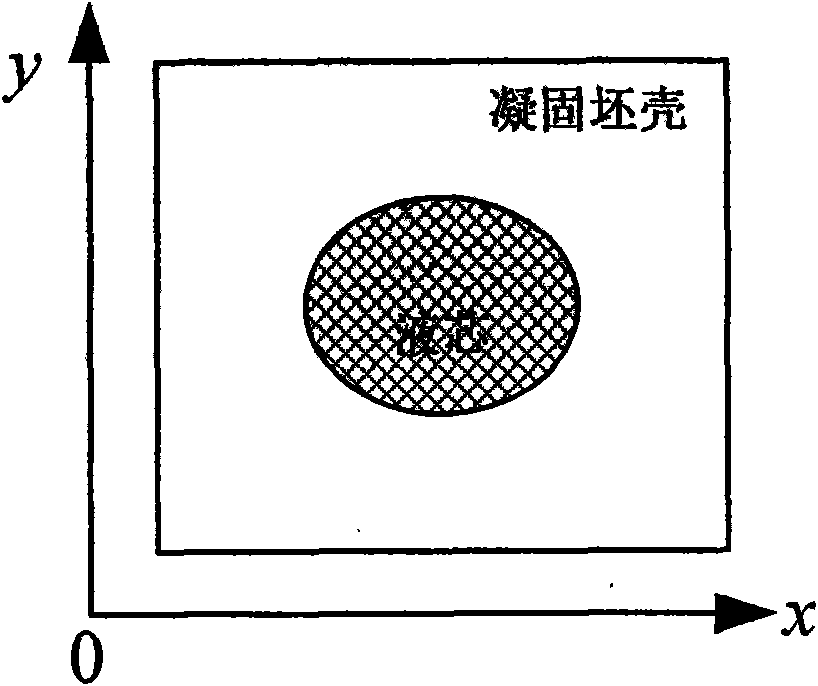

Continuous-casting dynamic soft-reduction pressing quantity on-line control method of large square blank

InactiveCN101658911ACentral shrinkage cavity improvementReduce center segregationEngineeringPorosity

The invention relates to a continuous-casting dynamic soft-reduction pressing quantity on-line control method of a large square blank, in particular to a continuous-casting dynamic soft-reduction process of the large square blank in iron and steel production; the method is as follows: casting blank surface pressing quantity of all pressing points is calculated in an on-line way according to basicprinciples that center segregation and porosity can be eliminated by solidifying contraction of a soft-reduction pressing quantity compensating liquid core, so as to determine the roll gap setting value of racks of all tension levelers; the roll gap setting value is transmitted to a one-level basic automation control system, so as to adjust the roll gap of the tension leveler remotely and realizesoft reduction. After adopting the invention, the special indexes for improving the quality of a casting piece are that: the center segregation of the casting blank is less than or equal to 1.0 grade,center carbon segregation index of the casting blank is 0.95-1.10, and the average is 1.05; center porosity and center line shrinkage of the steel casting blank of a bearing can be obviously improved, the center porosity of the casting blank is less than or equal to 1.0 grade, the proportion thereof can reach more than 90 percent, and the center line shrinkage is less than or equal to 0.5 grade;by adopting the invention, the disadvantages of center segregation, center porosity and center line shrinkage of the large square blank can be remarkably alleviated.

Owner:NORTHEASTERN UNIV

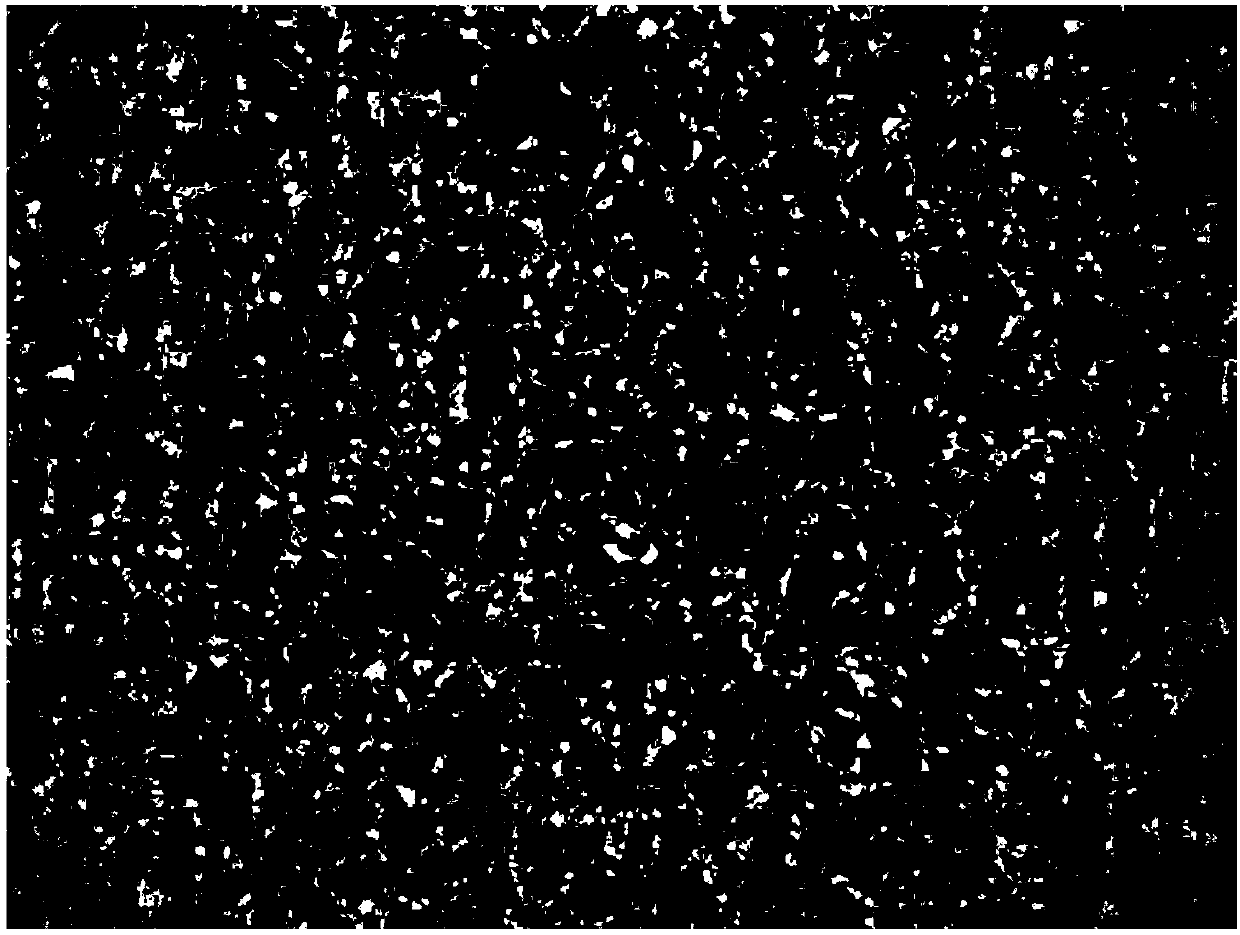

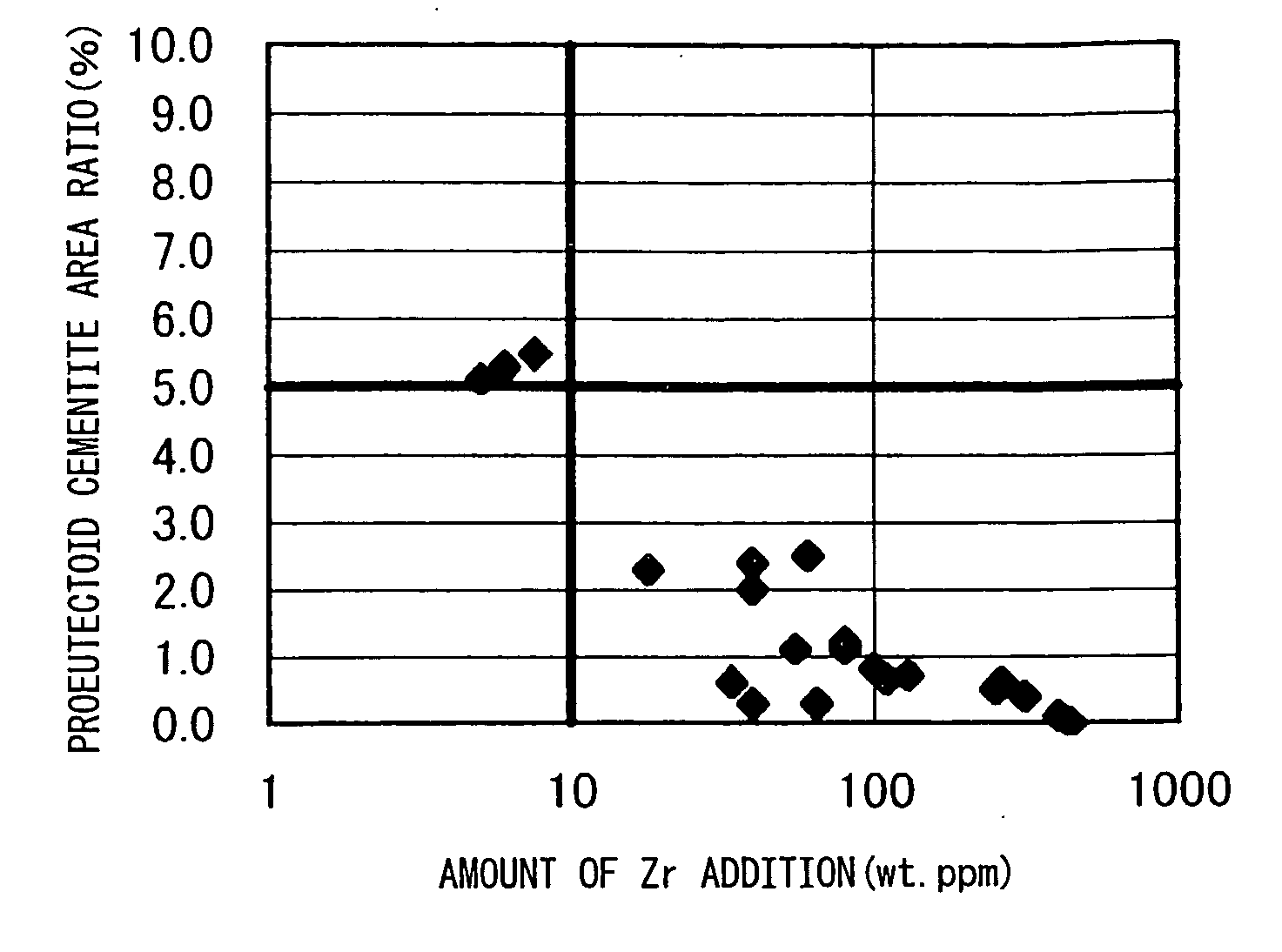

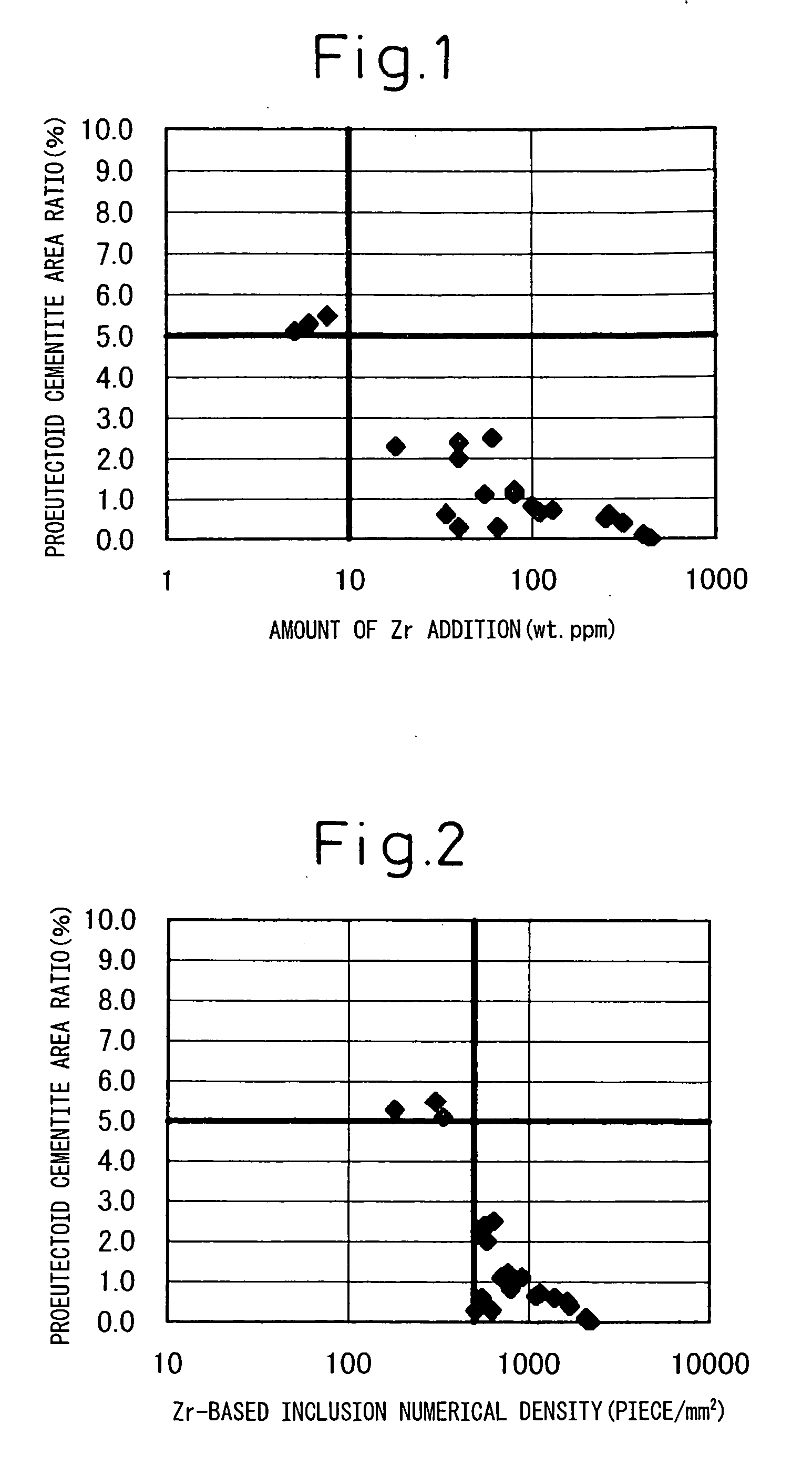

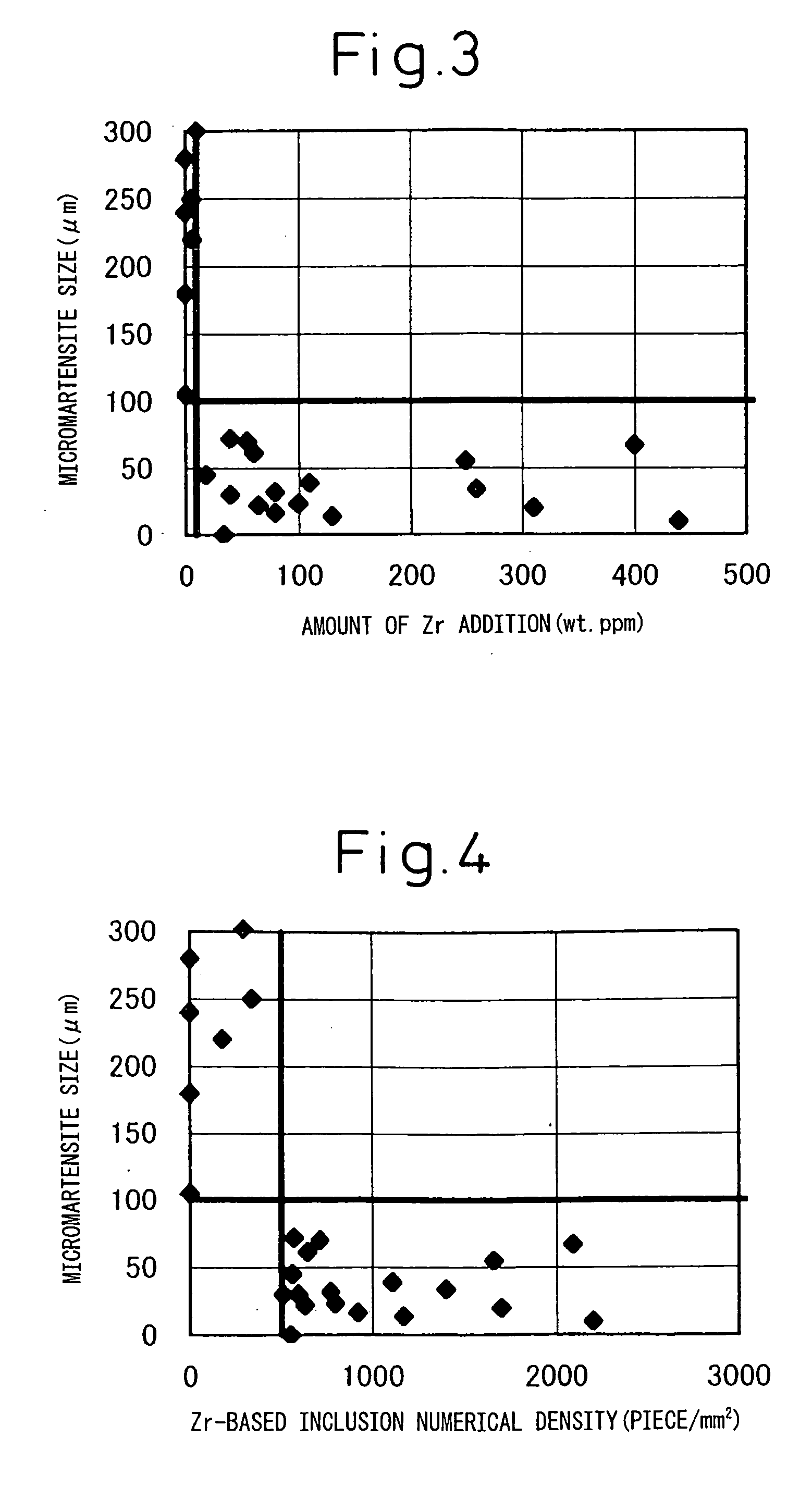

High strength, high toughness, high carbon steel wire rod and method of production of same

InactiveUS20060137776A1High strengthImprove toughnessHot-dipping/immersion processesFurnace typesHigh carbonNumerical density

The present invention provides a high strength, high toughness steel wire rod useful for a PC steel wire, galvanized steel strands, spring use steel wire, cables for suspension bridges, etc. By hot rolling, then directly patenting or reaustenitizing, then patenting a high carbon steel wire rod of a specific chemical composition of the steel and chemical composition, size, and numerical density of inclusions, piano wire rod or high carbon steel wire rod having a structure of mainly pearlite, having an average value of the proeutectoid cementite area ratio of 5% or less in a center region of less than 20% of the wire rod diameter from the center of the wire rod, having a micromartensite size of the C section of 100 μm or less, having a tensile strength of the 170 kgf / mm2 class or more, and having a drawing ratio at break of 30% or more is obtained.

Owner:NIPPON STEEL CORP

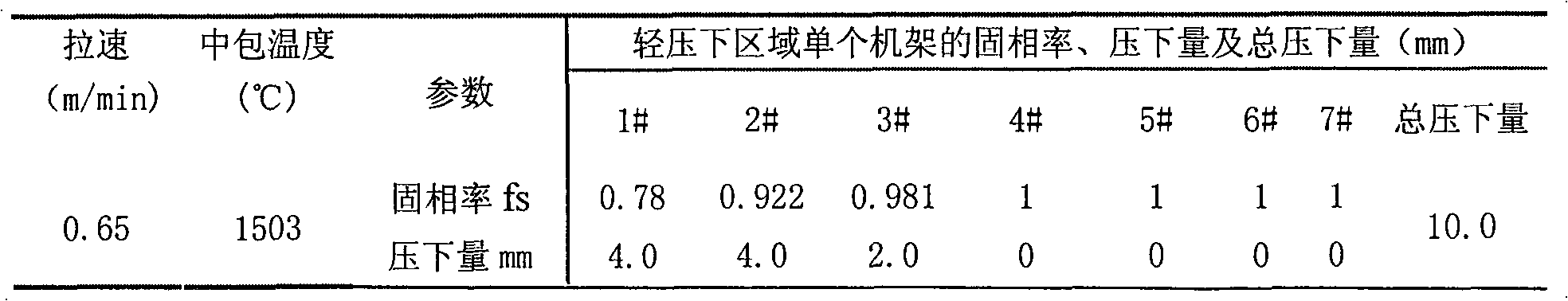

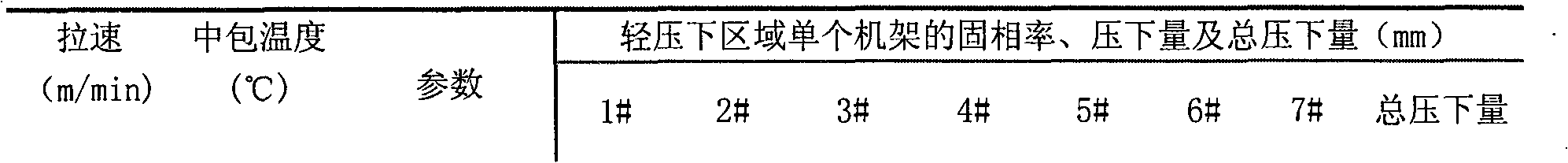

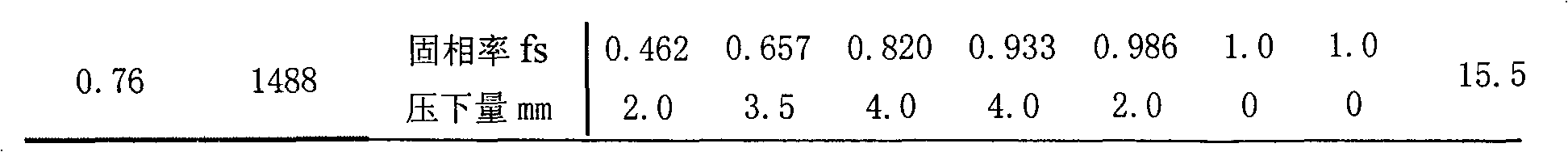

Bloom continuous casting dynamic soft reduction process for high-quality tire cord steel

The invention relates to a bloom continuous casting dynamic soft reduction process for high-quality tire cord steel, belonging to the technical field of metallurgy continuous casting and used for solving the problems of internal quality defects of casting billets such as central segregation, central porosity, central contraction cavity and the like which are easy to occur in tire cord steel bloomcontinuous casting. The invention adopts the technical scheme that in a continuous casting soft reduction region, the reduction amount is controlled by the variation of casting billet central solid phase rate fs, and a quantitative relationship of the reduction amount of a soft reduction stand and the casting billet central solid phase rate is given. By adopting the dynamically controlled soft reduction process, the central segregation of tire cord steel casting billets can be remarkably lightened with the casting billets center carbon segregation index controlled between 0.96 to 1.05 and theaverage value of 1.03; and the central porosity and the central contraction cavity of the tire cord steel casting billets can also be remarkably improved with the casting billet central porosity of nomore than 1.0 level and the central pipe of no more than 0.5 level. The technical requirements for manufacturing the high-quality tire cord steel are satisfied by wires rolled by the processed continuous casting billets.

Owner:XINGTAI IRON & STEEL +1

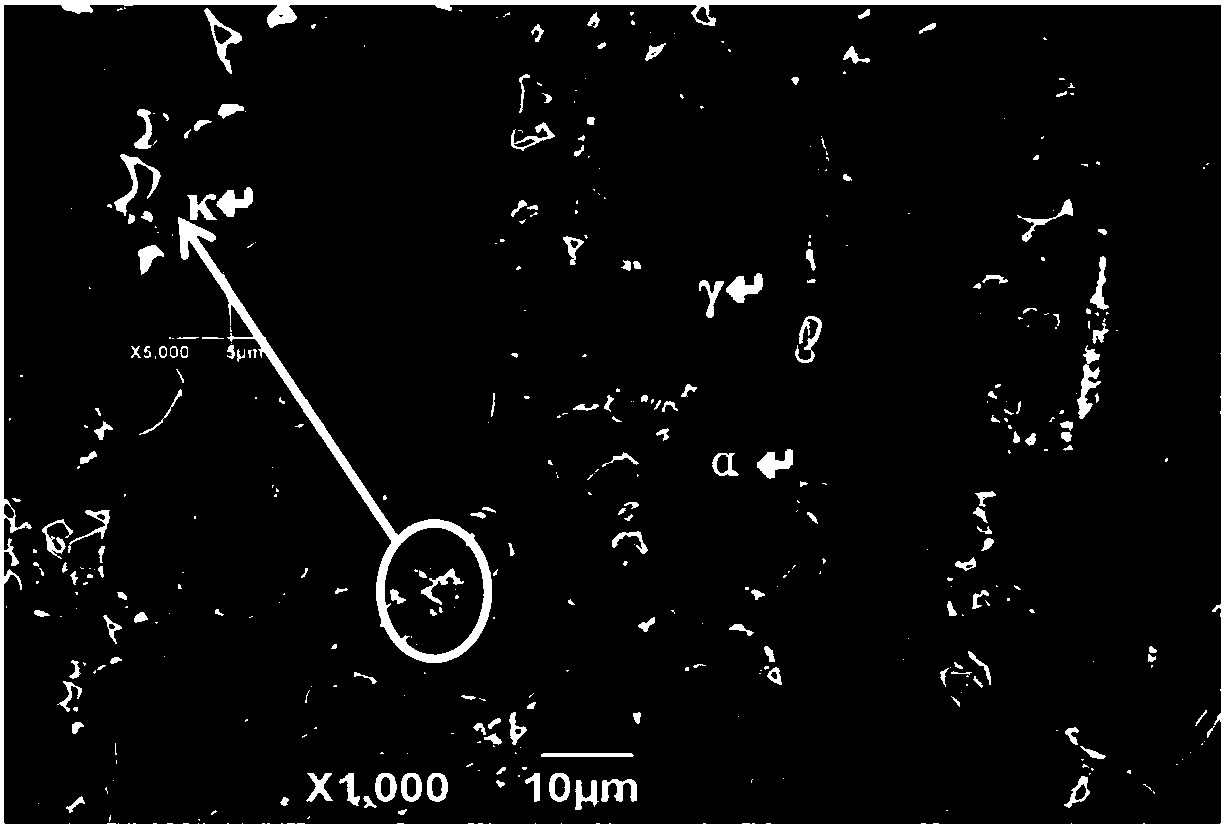

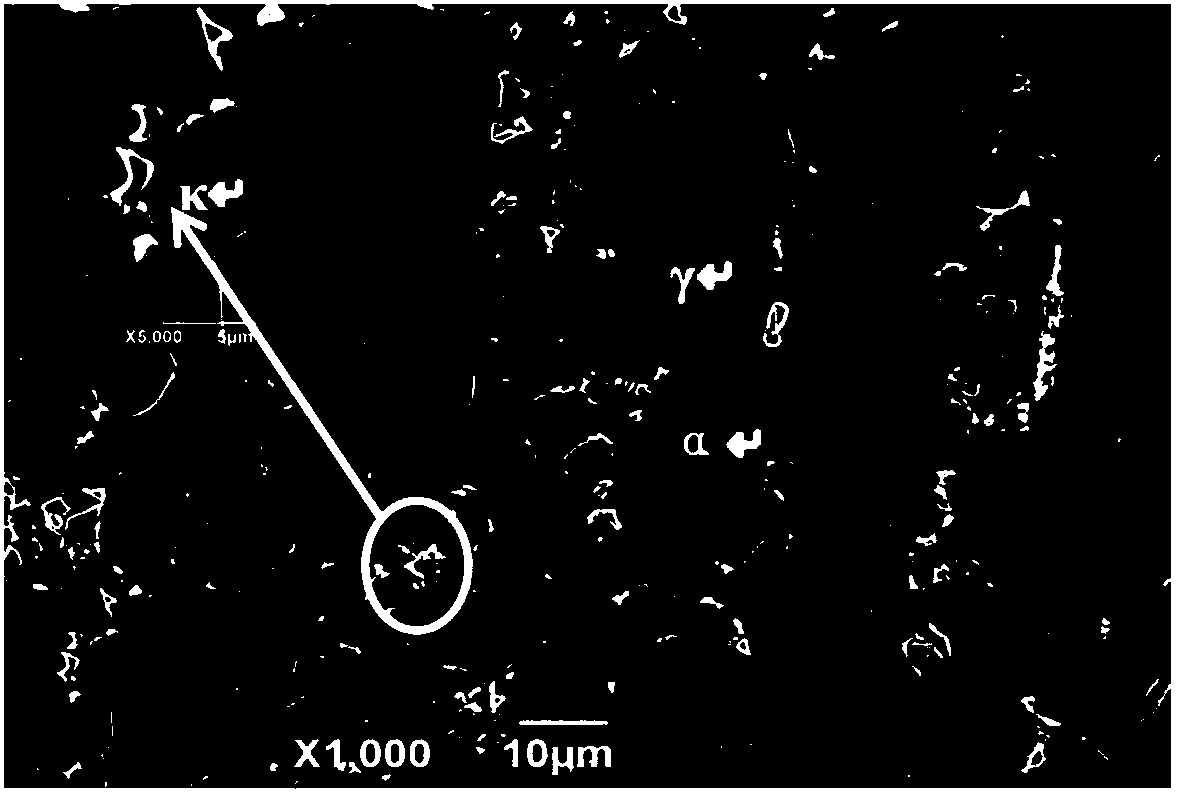

Low-density high manganese steel with high product of strength and elongation

InactiveCN107641763AHigh strengthImprove plasticityProcess efficiency improvementSolution treatmentCarbide

The invention provides low-density high manganese steel with high product of strength and elongation, and belongs to the field of low-density steel. The sum of the mass percents of Mn and Al in low-density steel exceeds 28%. The low-density high manganese steel is prepared through the following steps: smelting, namely, smelting on the basis of the alloy component system; casting; hot rolling, namely, heating a casting blank to be 1150-1250 DEG C; maintaining the temperature; then performing hot rolling at least twice; performing solution treatment, namely, maintaining the temperature of 1000-1100 DEG C of the casting blank, and then quenching; cold rolling, namely, performing cold rolling on the obtained low-density steel at least twice; annealing and then cooling to obtain the low-densitysteel. According to the low-density high manganese steel with high product of strength and elongation, a certain amount of Al is added to the steel, and the alloy component and the processing technology are adjusted, so as to obtain Fe-Mn-Al-C series low-density steel; the low-density steel is of an appearance of an austenite, ferrite and k carbide multi-phase structure, so that the low-density steel is high in strength and high in plasticity.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

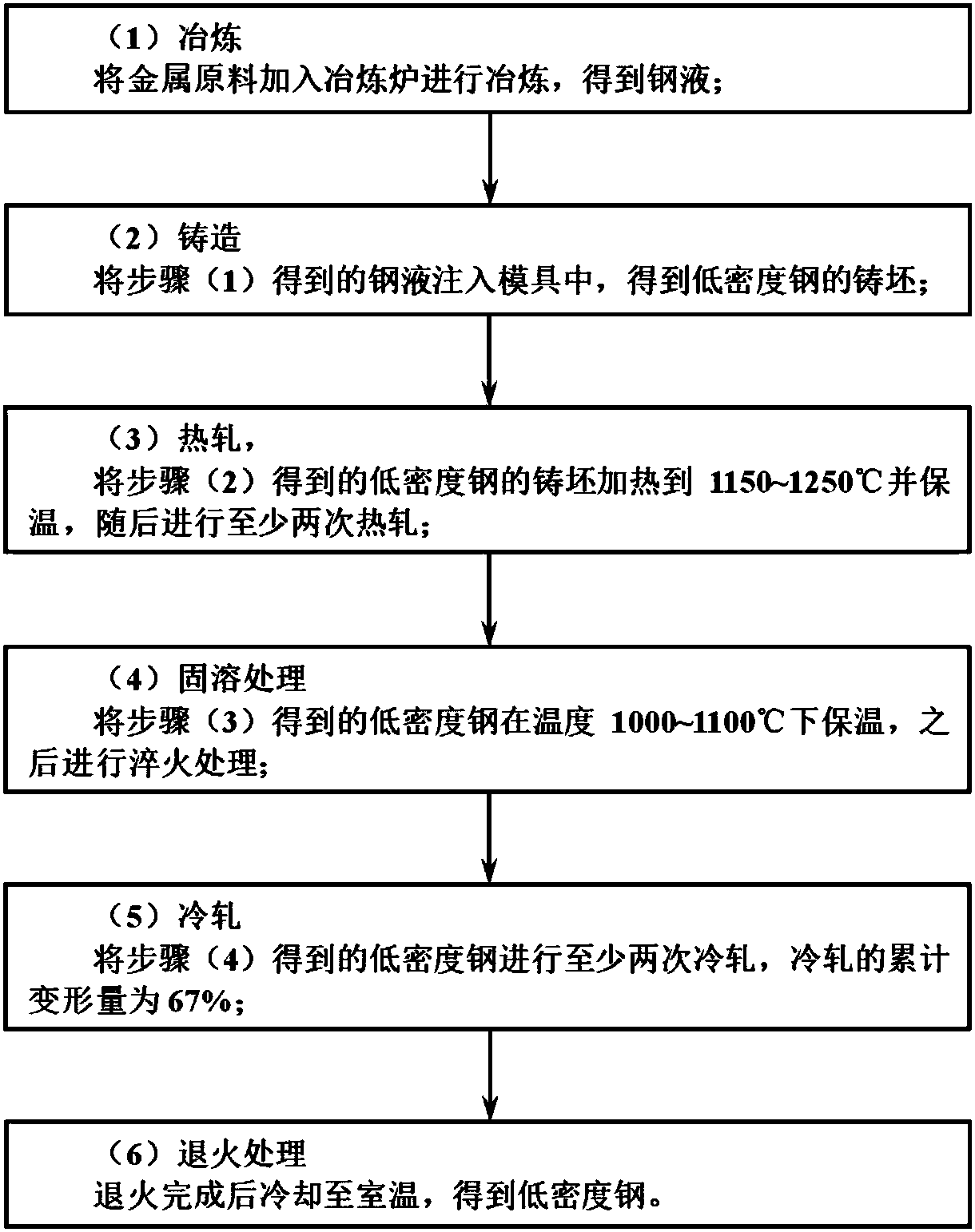

Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

The invention relates to a preparation method for low-density steel with the strength and elongation product larger than 50 GPa.%, and belongs to the field of low-density steel. The preparation methodincludes the following steps of smelting, specifically, raw materials are put into a smelting furnace for smelting; casting, specifically, obtained molten steel is poured into a mold, and low-densitysteel ingots are obtained after cooling; hot rolling, specifically, the obtained low-density steel ingots are heated to 1150-1250 DEG C, heat preservation is carried out, and then at least two timesof hot rolling are carried out; solution treatment, specifically, the obtained low-density steel is subjected to heat preservation at the temperature of 1000-1100 DEG C, and quenching treatment is carried out; cold rolling, specifically, the obtained low-density steel is subjected to at least two times of cold rolling; and cooling after annealing treatment. In this way, the low-density steel is obtained. Through regulation of alloy elements and the machining process, the Fe-Mn-Al-C system low-density steel is obtained, and the morphology of the low-density steel is of a multi-phase structure including austenite, ferrite and kappa carbide, so that the low-density steel has high strength and good plasticity, and the strength and elongation product is larger than 50 GPa.%.

Owner:马鞍山学院

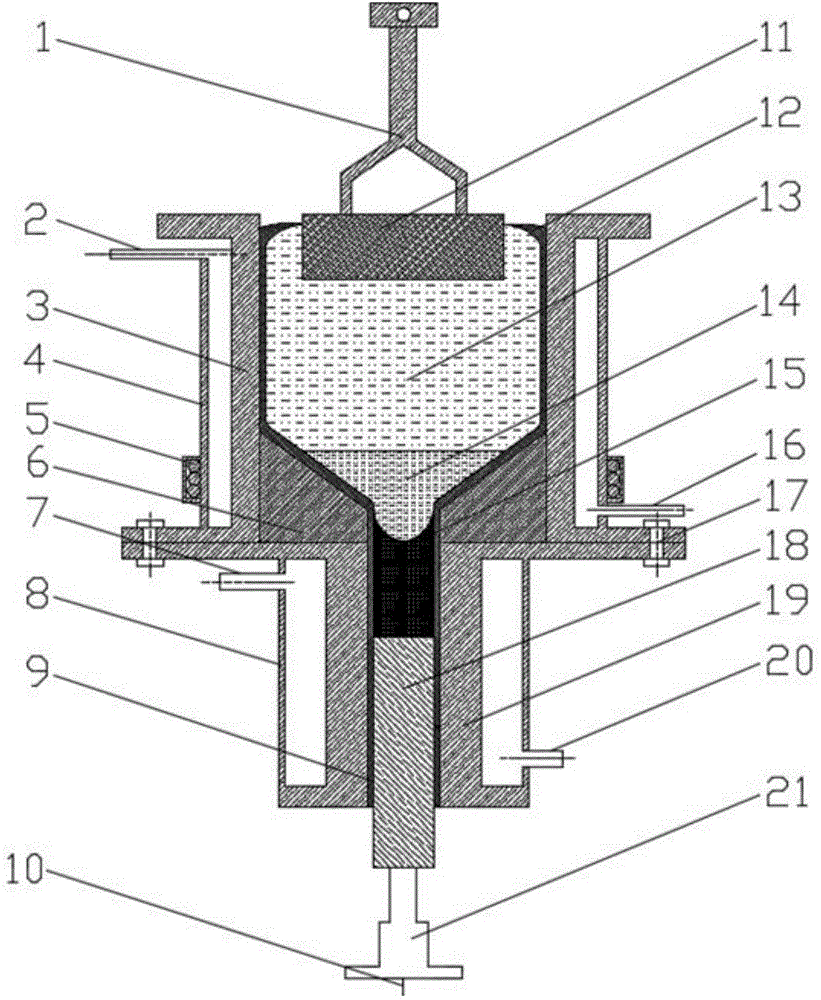

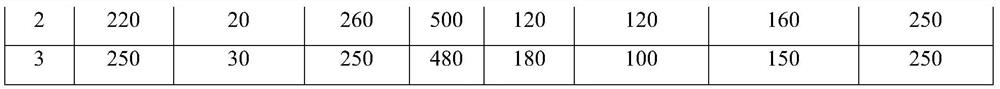

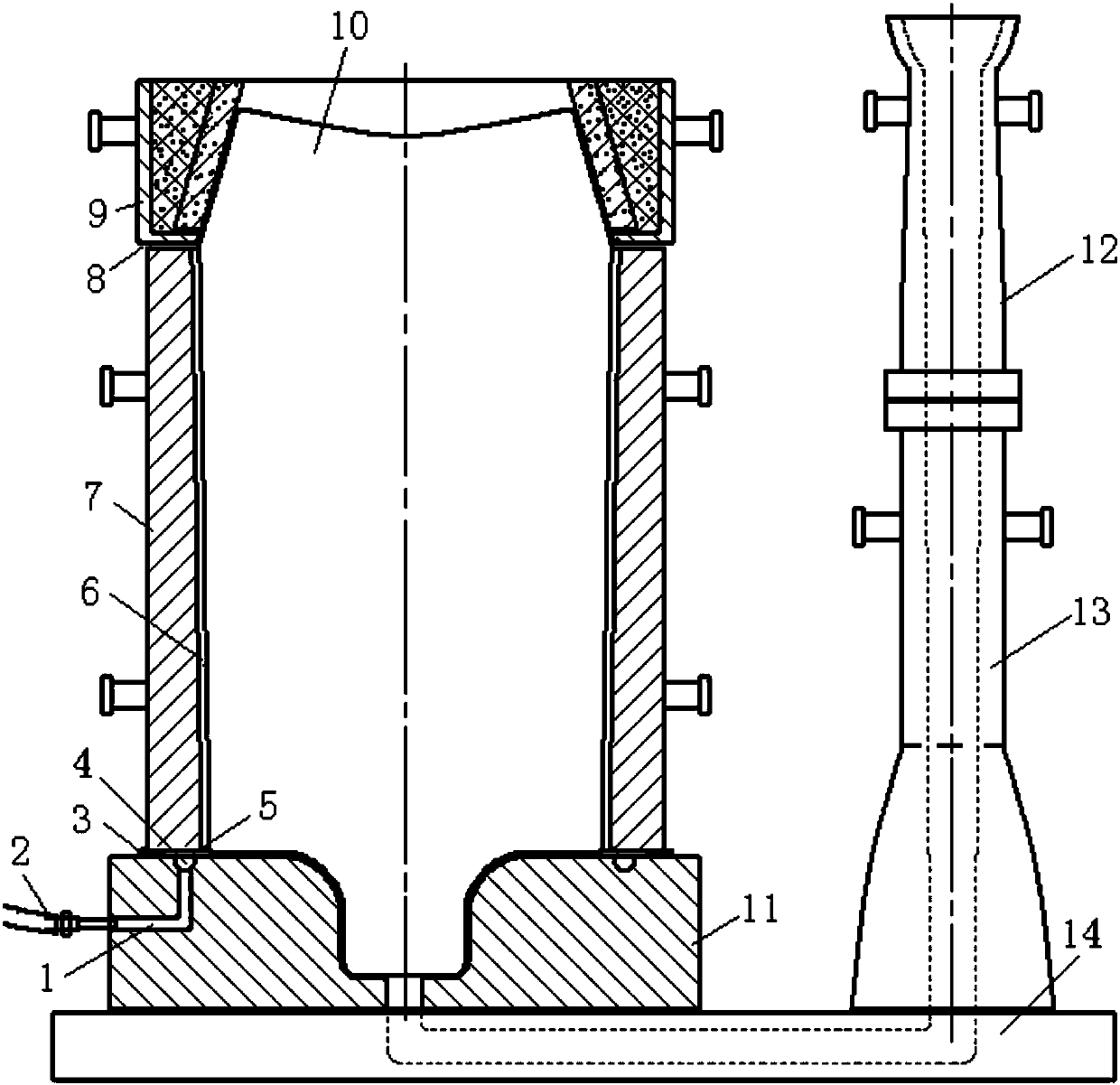

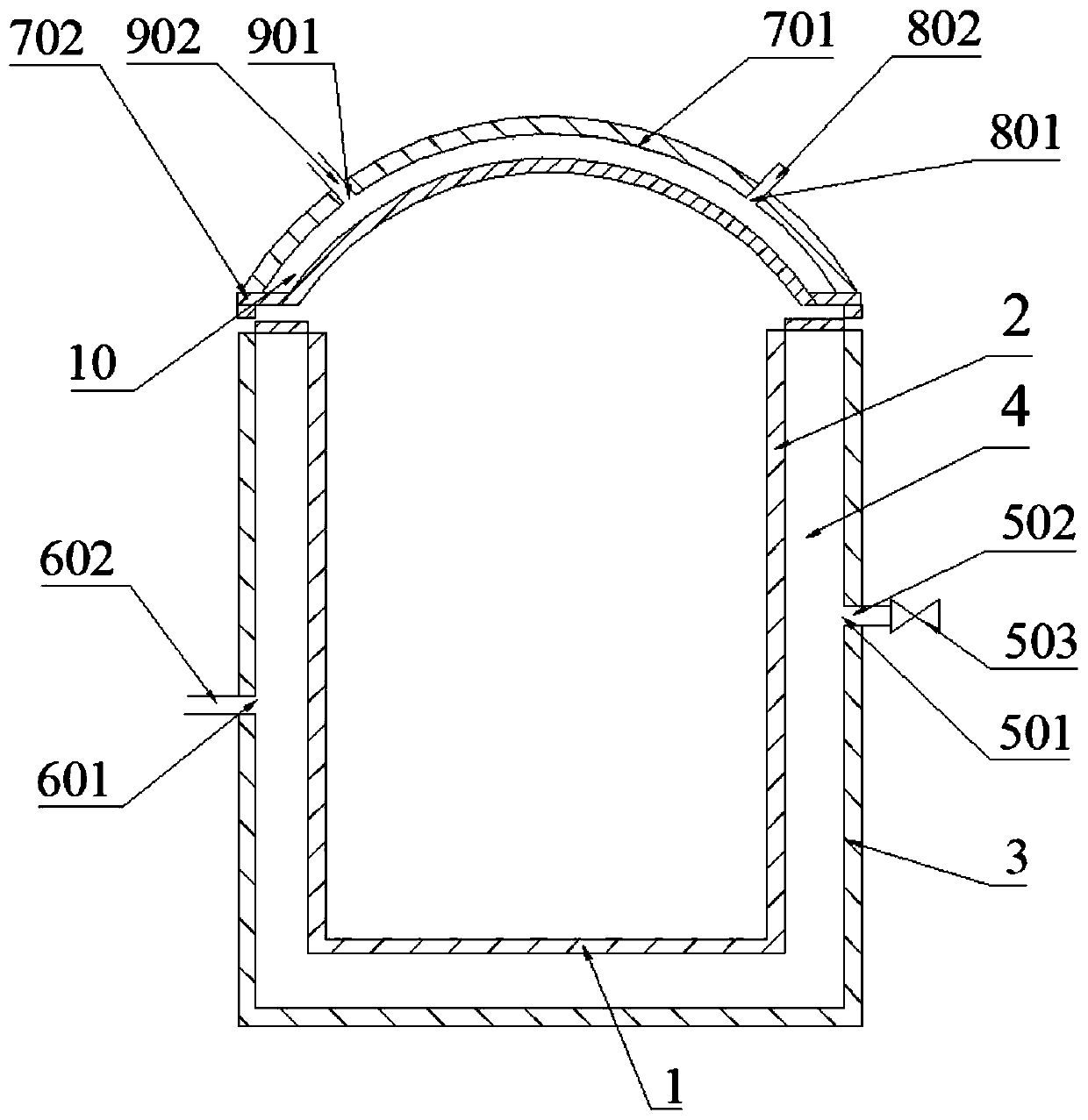

Method and device for preparing rare-earth metal through lower cathode electrolysis and in-situ ingot casting synchronization

The invention relates to a method and a device for preparing rare-earth metal through lower cathode electrolysis and in-situ ingot casting synchronization. The device comprises an electrolysis furnace and an ingot casting furnace which are arranged on a machine frame, wherein a carbon anode is hung at a hearth opening of the electrolysis furnace through an anode conducting rod and is communicated with a positive electrode of a power supply; the anode conducting rod is fixedly arranged on an automatic ascending and descending feeding device arranged on the machine frame; the lower part of a hearth of the electrolysis furnace is provided with a funnel-shaped insulation inner liner; an upper cooling water jacket is arranged outside the furnace wall of the electrolysis furnace; the lower part of the outer side of the upper cooling water jacket is provided with an electromagnetic stirring device; an ingot casting cavity is arranged on the ingot casting furnace; the ingot casting cavity is centered with an outlet of the funnel-shaped insulation inner liner; the lower part of the ingot casting cavity is provided with a sliding ingot guide rod in a matched way; the bottom of the ingot guide rod is connected with an ingot drawing rod and is communicated with the cathode of the power supply through a conducting wire; a lower cooling water jacket is arranged outside the furnace wall of the ingot casting furnace. Constant-voltage or constant-current electrolysis is carried out under the conditions that the temperature is 900 to 1200 DEG C, the voltage is 5 to 30V, and the current is 1000 to 10000A. The rare-earth metal can be continuously and automatically prepared.

Owner:JIANGXI UNIV OF SCI & TECH

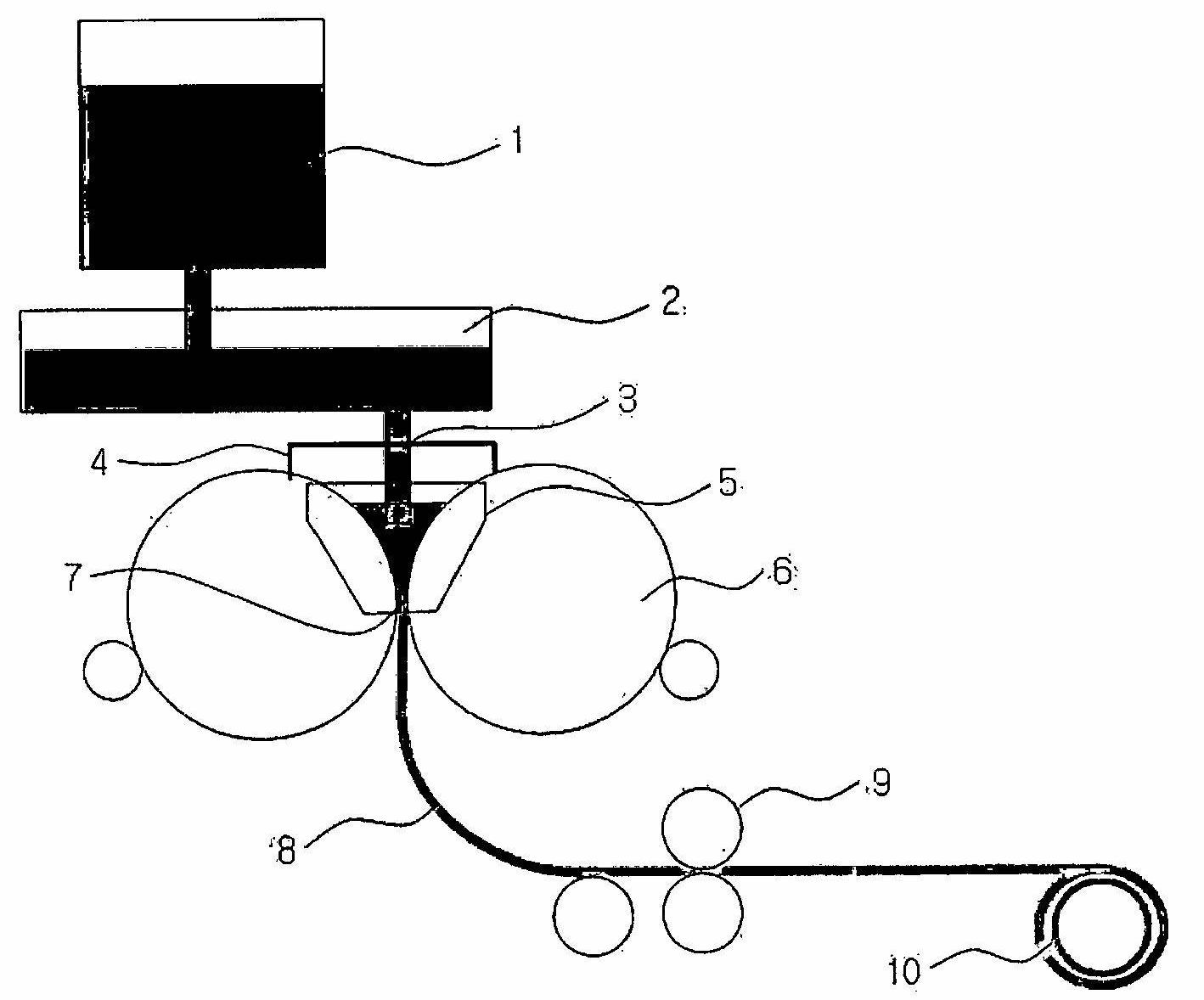

Martensitic stainless steel and a production method therefor

InactiveCN102665963AUniform hardnessReduce center segregationThin material handlingMartensitic stainless steelCarbide

The present invention relates to a martensitic stainless steel as used in tableware, knives, scissors and the like, which contains, as percentages by weight, from 0.10 to 0.50% of carbon and from 11 to 16% of chromium, and relates to a production method therefor; and the invention relates to a production method for mid-carbon martensitic stainless steel in a strip-casting device comprising a pair of rollers which rotate in opposite directions, an edge dam which is provided so as to form a molten steel pool at both side surfaces, and a meniscus shield for supplying inert nitrogen gas to the upper surface of the molten steel pool, wherein steel for stainless steel containing, as percentages by weight, from 1.10 to 0.50% of carbon and from 11 to 16% of chromium is supplied from a tundish, via a nozzle to the molten steel pool in such a way that a stainless-steel thin sheet is cast,; and the cast stainless-steel thin sheet is made into hot-rolled annealed strips using in-line rollers to a rolling reduction of from 5 to 40%, and relates to martensitic stainless steel produced by means of the production method. The present invention suppresses lamination defects by reducing carbide centre segregation and makes it possible to obtain martensitic stainless steel with little difference in hardness between carbide-segregated zones and non-segregated zones and hence with uniform hardness overall.

Owner:POHANG IRON & STEEL CO LTD

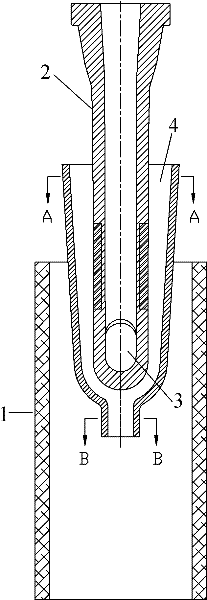

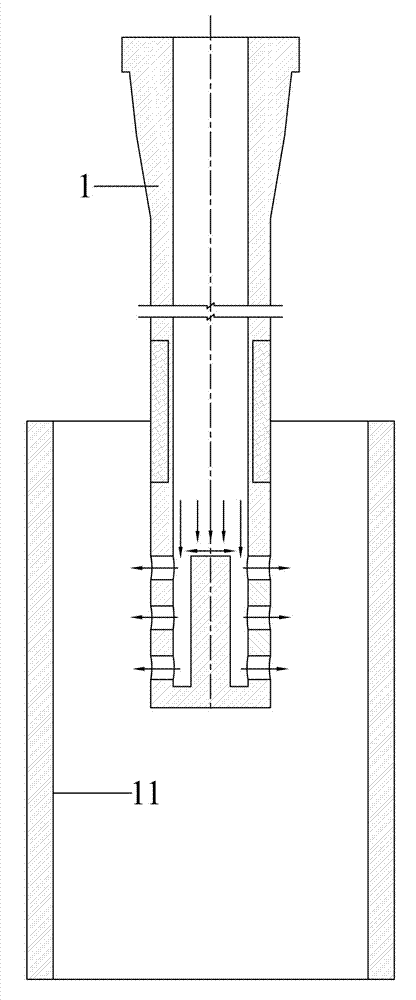

Method for improving internal quality of continuous casting and submerged nozzle for implementing method

The invention relates to a method for improving the internal quality of a continuous casting and a submerged nozzle for implementing the method. The submerged nozzle mainly comprises a long-barrel flat annular body submerged nozzle body with the bottom sealed, two arc surfaces at the upper end of the bottom of the nozzle are provided with symmetrical side holes; the two opposite side surfaces and hollow surfaces respectively arranged at the periphery are connected in a closing way to form an integrated feeding guide pipe; each hollow surface is inclined downward and extends while a certain distance is kept with each side surface of the nozzle body, thus all the feeding guide pipe are communicated at the bottom and form an exit section at the bottom of the nozzle body. In a continuous casting process, granular or bead-like, piece-like and strap-like part steel or iron product is continuously fed from the feeding guide pipes of the submerged nozzle and creeps down to the center of a molten pool of a crystallizer, degree of superheat of molten steel can be reduced, the cooling speed at the center is increased, formation of a central isometric crystal is promoted, enrichment and segregation of solute element at the center of a cast blank are prevented, solidification structure at the center of the cast blank is effectively optimized, and the density at the center of the cast blank is strengthened.

Owner:WISDRI ENG & RES INC LTD

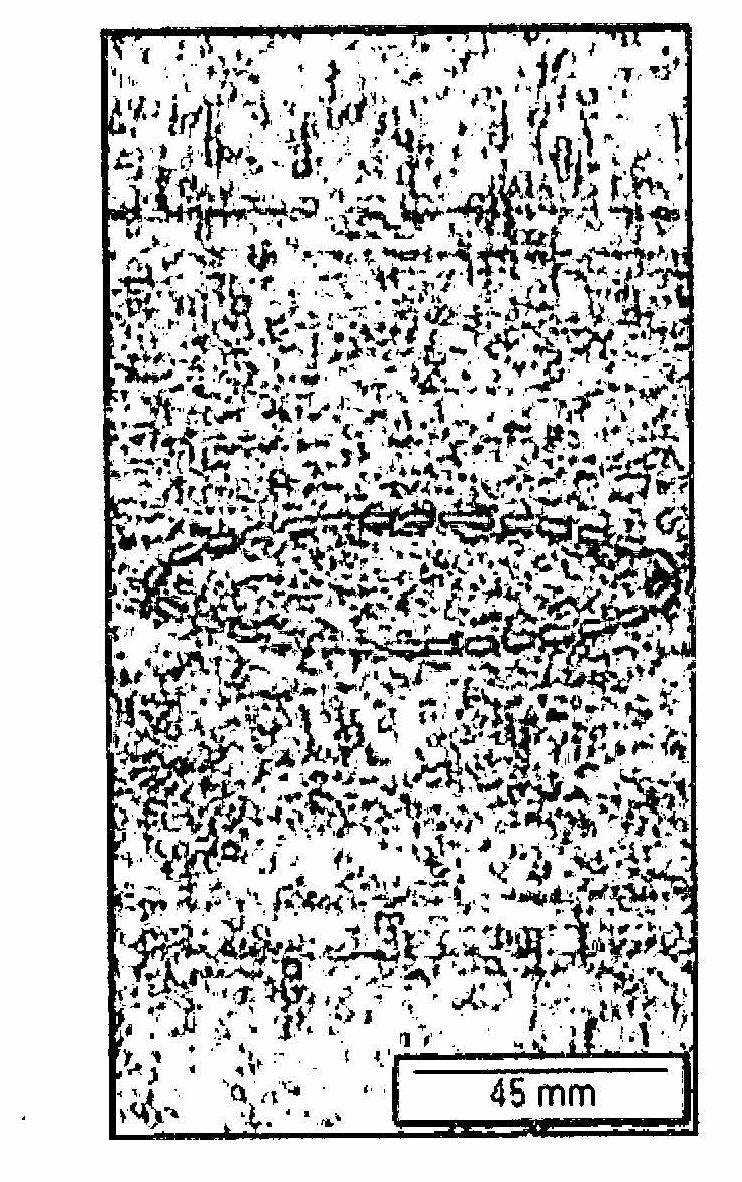

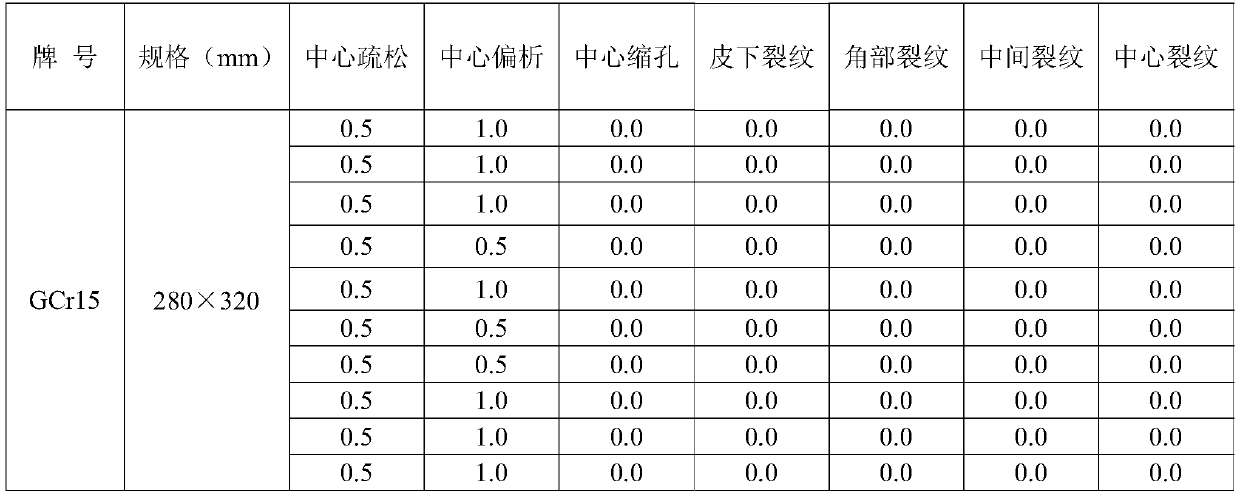

Method for removing center line shrinkage and controlling center segregation of 280mm*320mm fracture surface high-carbon steel

The invention discloses a method for removing center line shrinkage and controlling center segregation of 280mm*320mm fracture surface high-carbon steel. Continuous casting secondary cooling adopts alow cooling mode; the relation between the rolling reduction of a soft reduction machine frame and the solid phase rate fs of the center of a cast blank is as follows: when fs is larger than or equalto 0 but smaller than 0.55, the rolling reduction is 0mm, when fs is larger than or equal to 0.55 but smaller than 0.70, the single-roller rolling reduction is 2.0mm, and when fs is larger than or equal to 0.7 but smaller than or equal to 1, the single-roller rolling reduction is 4-5mm; when the temperature of the core of a solidified cast blank is lower than the solidification temperature 110 DEGC, the single-roller rolling reduction is 4-5mm; when the temperature of the core of the solidified cast blank is lower than the solidification temperature 150 DEG C, the single-roller rolling reduction is 2mm; and when the temperature of the core of the solidified cast blank is lower than the solidification temperature 180 DEG C, the single-roller rolling reduction is 0mm. By means of the method, the rolling reduction is controlled through change of the solid phase rate of the center of the cast blank and the temperature of the core of the solidified cast blank, the center line shrinkage isremoved, the central carbon segregation index of the cast blank is controlled to be 0.98-1.10 with the average being 1.06, the center porosity is smaller than or equal to 0.5 grade, and the center line shrinkage is 0 grade.

Owner:ZENITH STEEL GROUP CORP +1

Method for continuous casting of steel, and method for manufacturing bar steel

This method for continuous casting is provided with an extraction step for extracting a cast slab in a solid-liquid coexisting state from a cylindrical casting mold, a first rolling reduction step for performing rolling reduction of the cast slab in the solid-liquid coexisting state in a first rolling reduction direction perpendicular to the longitudinal direction of the cast slab after the extraction step, and a second rolling reduction step for molding the cast slab, in a completely solidified state in which the temperature of a center part thereof is higher than the temperature of a surface part thereof after the first rolling reduction step, into a rounded rectangle having rounded corner parts as viewed in cross-section perpendicular to the longitudinal direction of the cast slab, while performing rolling reduction alternately in the first rolling reduction direction and a second rolling reduction direction, the second rolling reduction direction being a rolling reduction direction orthogonal to both the first rolling reduction direction and the longitudinal direction of the cast slab.

Owner:NIPPON STEEL CORP

Production method for medium-high carbon high-strength steel homogenized casting blank

The invention relates to a production method for a medium-high carbon high-strength steel homogenized casting blank. The invention adopts the technical scheme that the production method comprises the step that a compound filler cored wire is fed into medium-high carbon high-strength molten steel in a continuous casting crystallizer or an ingot mold, wherein the fed compound filler cored wire accounts for 0.3 to 1.2 percent by weight of the medium-high carbon high-strength molten steel, the feeding speed Vband of the compound-filled cored wire is equal to A*Vcasting*(Ttundish -Tliqudus) / Tliqudus, and the vibrating frequency of a band feeding machine is 50-35,000 Hz; the compound filler cored wire is a mixture of passivated iron sand and a high-melting-point carbonitride, the carbonitride accounts for 1-10 percent by weight of the compound filler cored wire, and the high-melting-point carbonitride is a carbonitride formed by Zr and / or Nb. The production method provided by the invention is simple in process, low in cost and convenient to operate; the macrostructure of the produced medium-high carbon high-strength steel homogenized casting blank is obviously improved, and axial / central segregation and internal cracks caused by chemical elements are remarkably reduced or eliminated, so that the plasticity and toughness of a rolled steel plate are improved.

Owner:WUHAN UNIV OF SCI & TECH

Low-internal-stress steel for bridge structure and production method of low-internal-stress steel

ActiveCN112501511ASimple welding processGood resistance to welding coldUltimate tensile strengthInternal stress

The invention discloses low-internal-stress steel for a bridge structure and a production method of the low-internal-stress steel. A steel plate comprises the following chemical components in percentage by weight: 0.10-0.15% of C, 0.25-0.50% of Si, 1.00-1.50% of Mn, less than than or equal to 0.002% of P, less than than or equal to 0.0010% of S, less than than or equal to 0.025% of Al, 0.010-0.070% of V, 0.040-0.060% of Nb, 0.01-0.05% of Ti, less than than or equal to 0.0065% and the balance of Fe and inevitable impurities, and meanwhile, V+Nb+Ti< / = 0.18, C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+ 5B < / = 0.35, and C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15 < / = 0.50. The steel plate is the low-internal-stress steel for the bridge structure, the yield strength is larger than or equal to 400 MPa, the tensile strength is 600-700 MPa, the ductility is larger than or equal to 25%, the structure is ferrite and pearlite, ferrite and pearlite are evenly distributed, the ferrite grain size reaches the 11-14 level, the internal stress of the steel plate is low after the steel plate is flattened, and the average stress of the steel plate is smaller than 40 MPa.

Owner:武汉钢铁有限公司

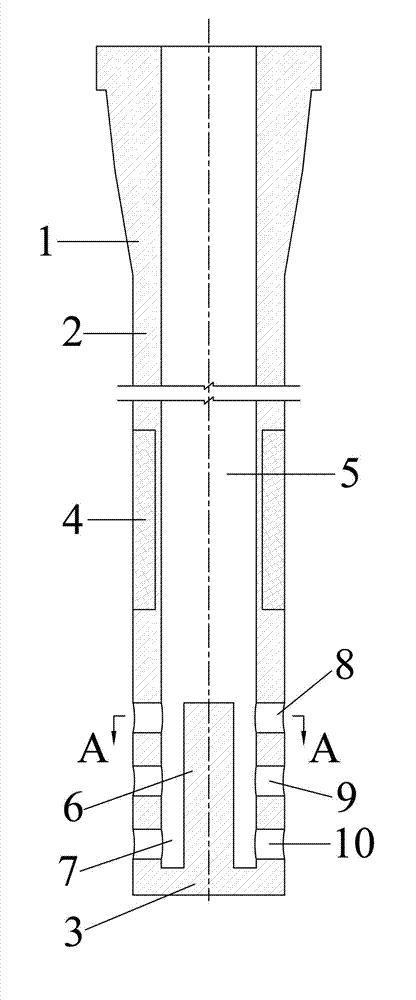

Multi-hole continuous-casting submersed nozzle for square and round billets

ActiveCN102950275AHigh reverse frictionReduce impact speedMelt-holding vesselsEngineeringLiquid steel

The invention belongs to the technical field of continuous casting of steel and particularly relates to a multi-hole submersed nozzle device for a continuous casting crystallizer of square and round billets. The multi-hole submersed nozzle device comprises a nozzle body, wherein the nozzle body is surrounded by a side wall and a sealed base plate, and the upper end of the nozzle body is opened; a vertical inner cavity is defined by the body; side holes penetrating through the side wall are formed in the parts, close to the upper part of the base plate, of the side wall; a boss protruding towards the inner cavity is arranged at the center of the upper surface of the base plate; and an annular gap capable of changing a linear flow manner of liquid steel into an annular flow manner is defined between the boss and the side wall; and a plurality of side holes are uniformly formed in the side wall higher than the upper surface of the base plate and lower or equal to the upper surface of the boss. According to a multi-hole continuous-casting submersed nozzle, the poured liquid steel can flow uniformly and stably out from the side holes, so that the uniform temperature field and flow field of the crystallizer can be transversely maintained, and the impact of the liquid steel on primarily-generated solidified billet housings at the wall surface of the crystallizer can be further lightened so as to facilitate the reasonable solidification and the quality improvement of the casting billets.

Owner:启东市长江船舶工业投资发展有限公司

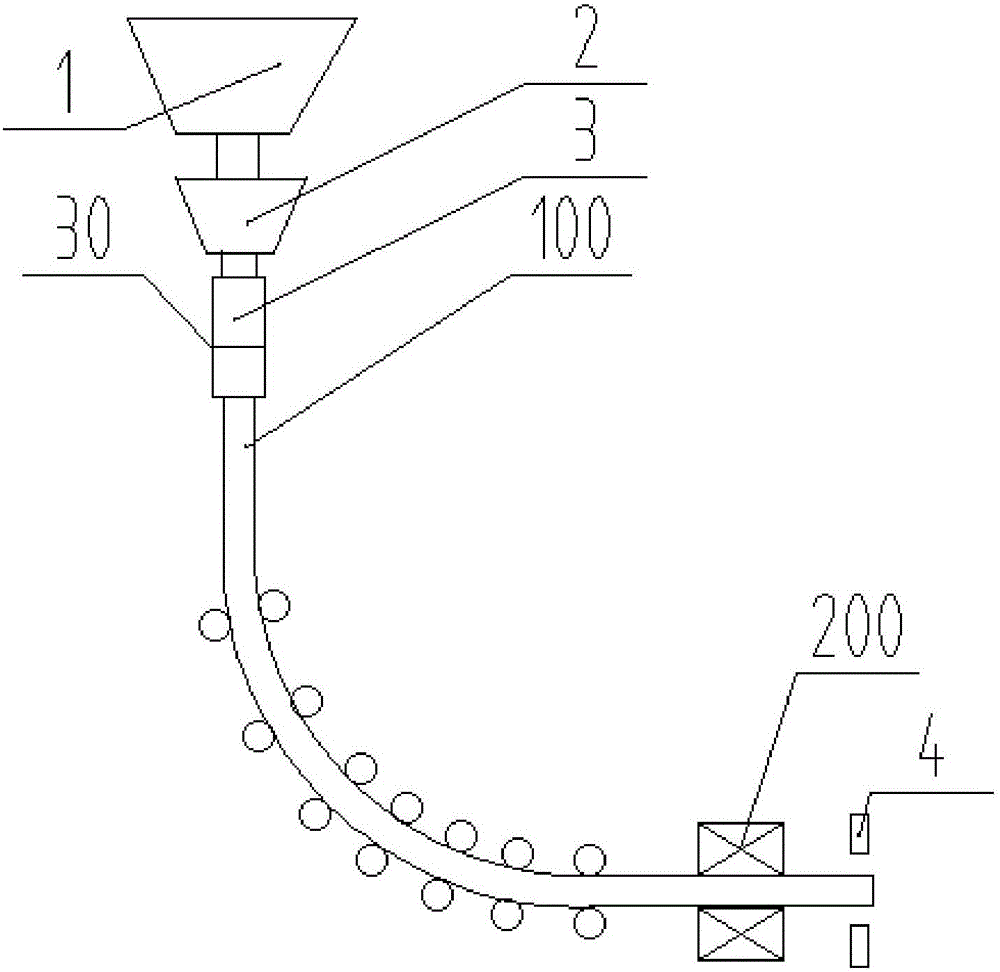

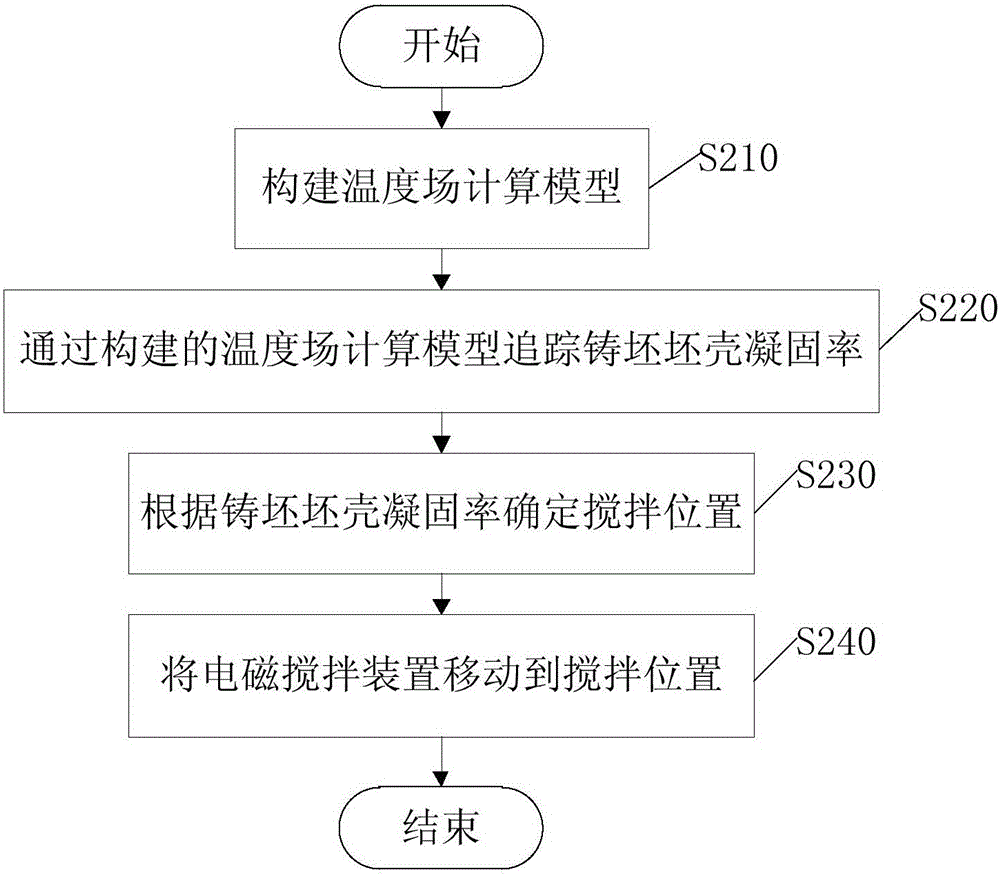

Electromagnetic stirring control method and system for continuous casting

ActiveCN105127390AReduce central porosityReduce center segregationElectromagnetic stirringElectromagnetic field

The invention provides an electromagnetic stirring control method and system for continuous casting. The method comprises the steps that a temperature field calculation model is built; the casting blank shell solidification rate is tracked through the temperature field calculation model; a stirring position is determined according to the casting blank shell solidification rate, wherein the position where the casting blank shell solidification rate is 45%-70% is determined as the stirring position; an electromagnetic stirring device is moved to the stirring position to apply an electromagnetic field to a casting blank. The system comprises an inputting unit, a model building unit, a tracing unit, a determining unit and a moving device; the inputting unit is used for inputting a technological parameter of continuous casting production, the model building unit is used for building the temperature field calculation model, the tracing unit is used for tracing the casting blank shell solidification rate according to the input technological parameter and the temperature field calculation model, the determining unit is used for determining the position where the casting blank shell solidification rate is 45%-70% as the stirring position, and the moving device is used for moving the electromagnetic stirring device to the stirring position. According to the electromagnetic stirring control method and system for continuous casting, a temperature field, the stirring device and the moving device are combined, electromagnetic stirring on the casting block at the best stirring position is achieved, and the internal quality of the casting blank is improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Production method of medium-low carbon high-strength steel homogenized casting blank

The invention relates to a production method of a medium-low carbon high-strength steel homogenized casting blank. The invention adopts the technical scheme as follows: the production method comprises the following step: feeding a cold steel belt into medium-low carbon high-strength molten steel inside a continuous casting machine crystallizer or an ingot mold, wherein the cold steel belt accounts for 0.3-1.0% of the medium-low carbon high-strength molten steel by weight; the cold steel belt feeding speed Vband is equal to A*Vcasting*(Ttundish-Tliqudus) / Tliquidus; the vibration frequency of a belt feeder is 50-35000 Hz; the cold steel belt comprises 0.2-0.65% of C or 1-3% of silicon by weight; the melting point of the cold steel belt is 3-30 DEG C lower than that of the cast casting blank; the surface of the cold steel belt is coated with anti-rusting oil; the thickness of the cold steel belt is 1-6 mm. The production method disclosed by the invention is simple in process, low in cost and convenient to operate; the macrostructure of the produced medium-low carbon high-strength steel homogenized casting blank is obviously improved, the axial / center segregation and internal cracks caused by chemical elements are obviously weakened or eliminated, the ductility and the toughness of the rolled steel plate are improved, the HIC detection qualification rate of the engineering structure steel and the corrosion-resisting steel is increased.

Owner:WUHAN UNIV OF SCI & TECH

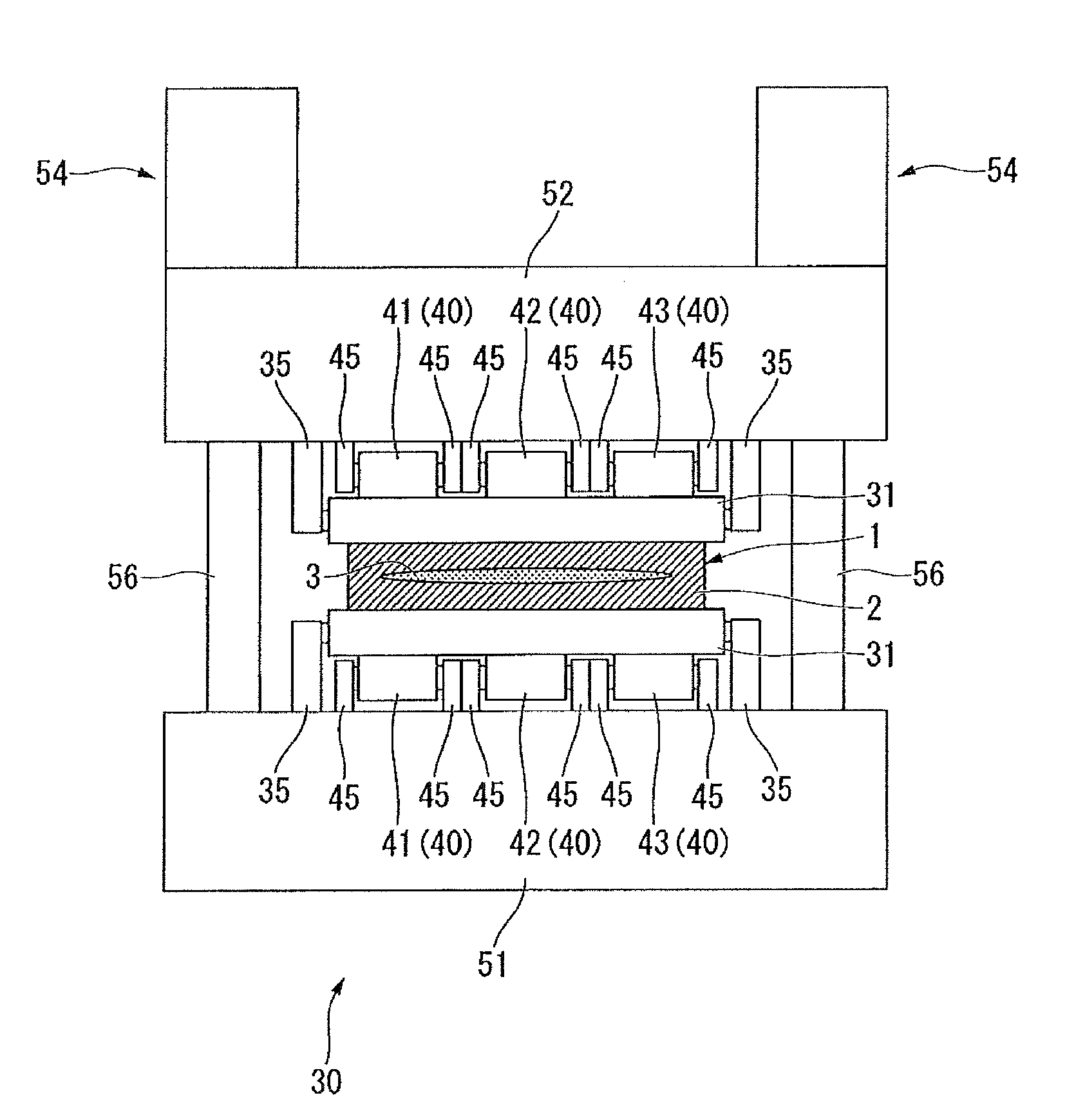

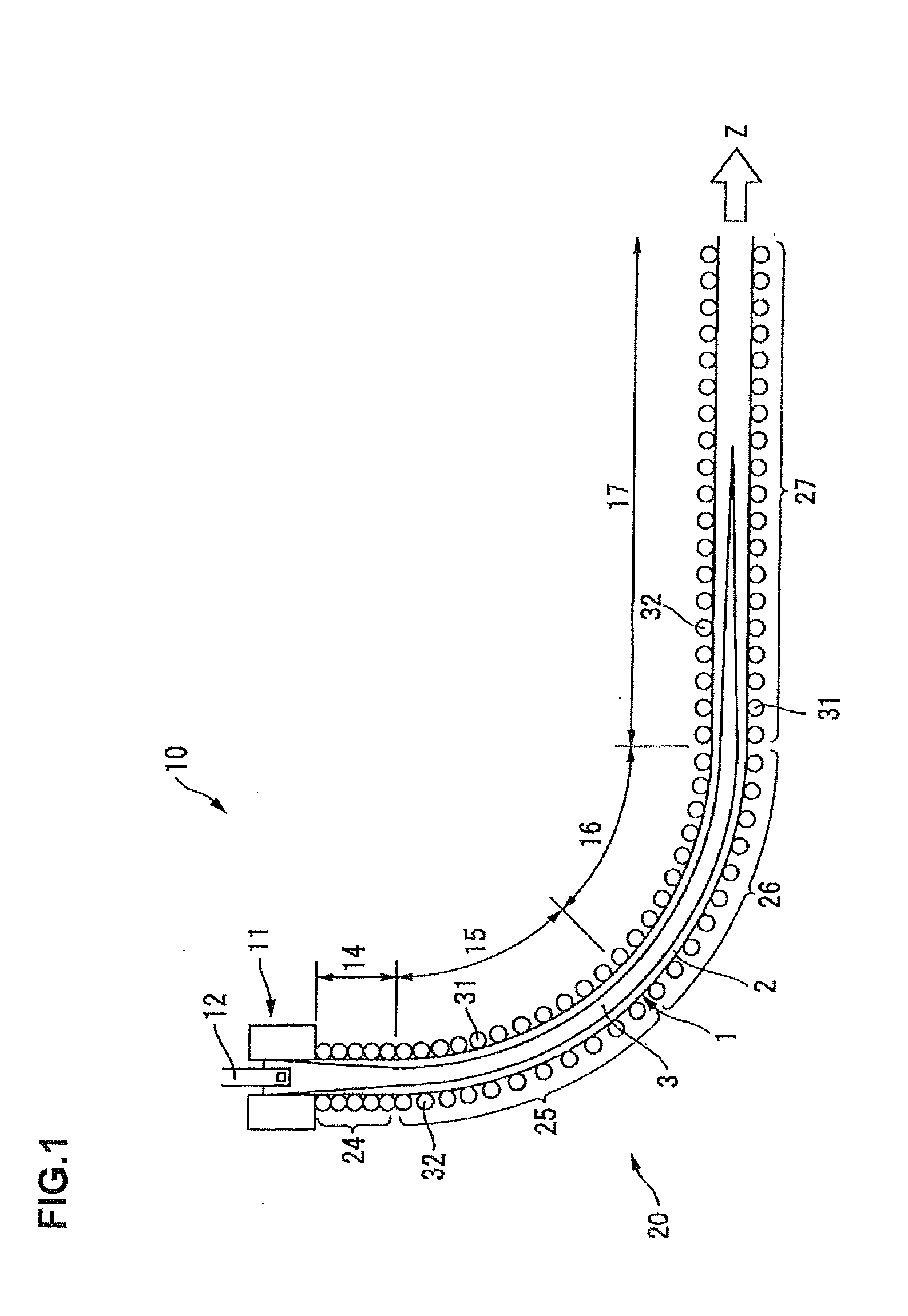

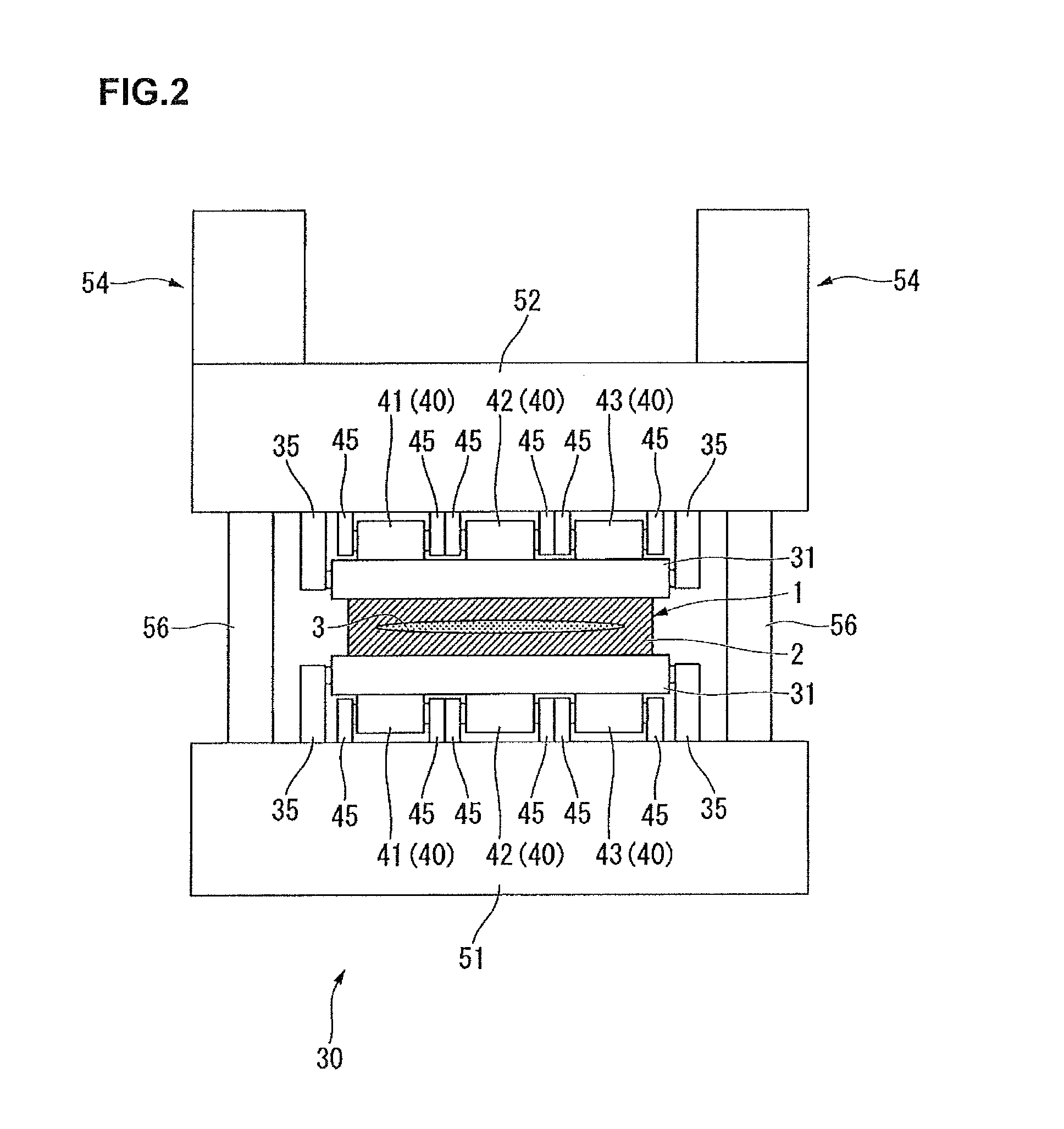

Casting product reduction apparatus

ActiveUS20150047403A1Reduce center segregationReduce porosityMetal rolling stand detailsRollsBackup rollMetallurgy

The present invention is a casting product reduction apparatus that applies reduction to a casting product drawn from a mold with a sufficient reduction force and thereby can surely decrease center segregation and porosity and suppress occurrence of internal cracks so as to manufacture a high-quality casting product and includes: a pair of casting product press rolls that hold and press the casting product therebetween; backup rolls that support the casting product press rolls; and a pair of frames arranged to face each other, wherein three or more sets of the casting product press roll and the backup roll are arranged in a casting product drawing direction on each of the frames, and wherein a reduction means that decreases and increases a distance between the frames is provided at two or more places on the pair of frames.

Owner:NIPPON STEEL CORP

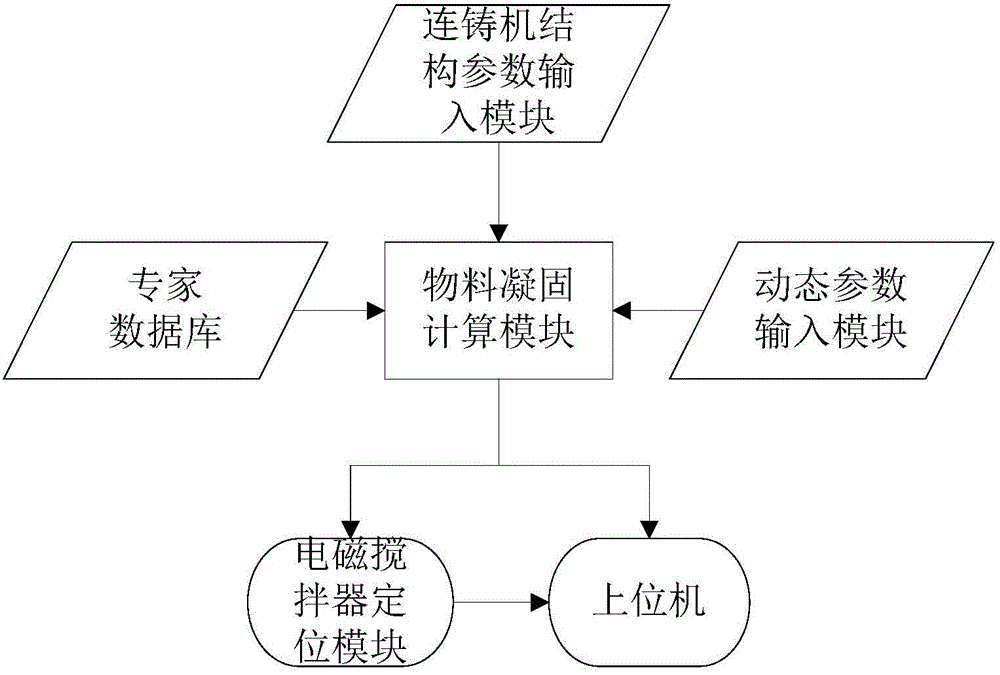

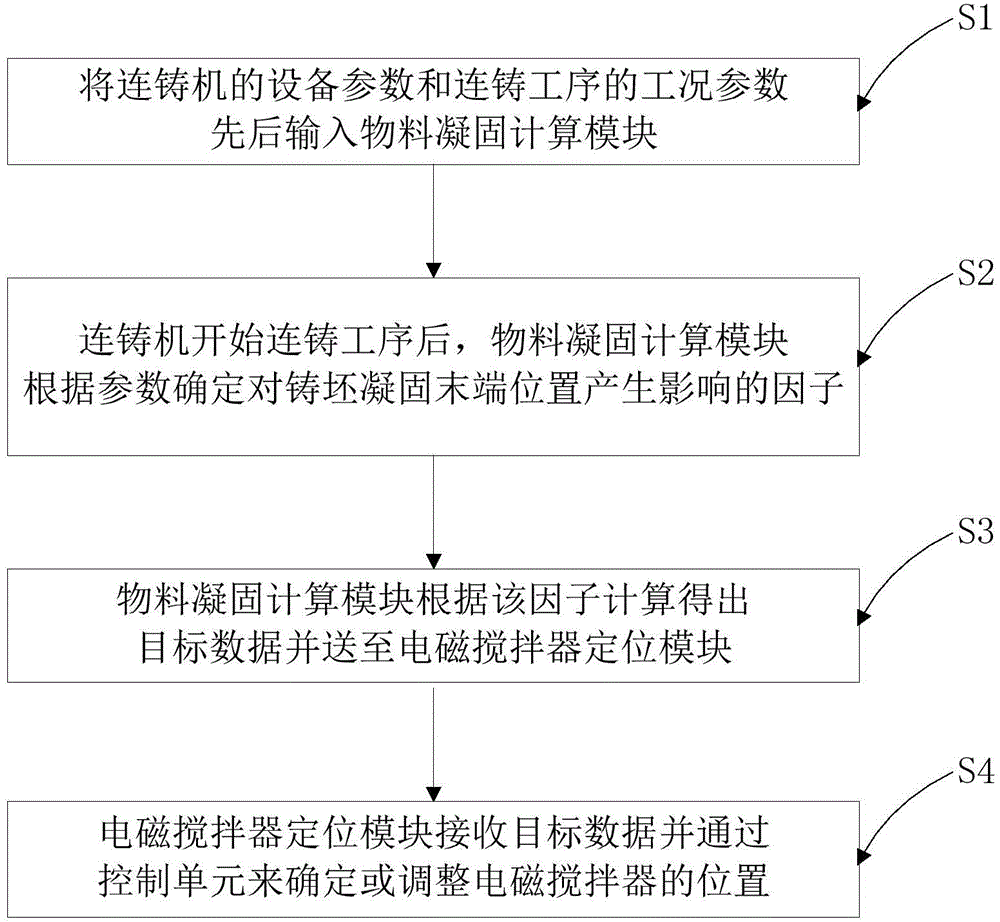

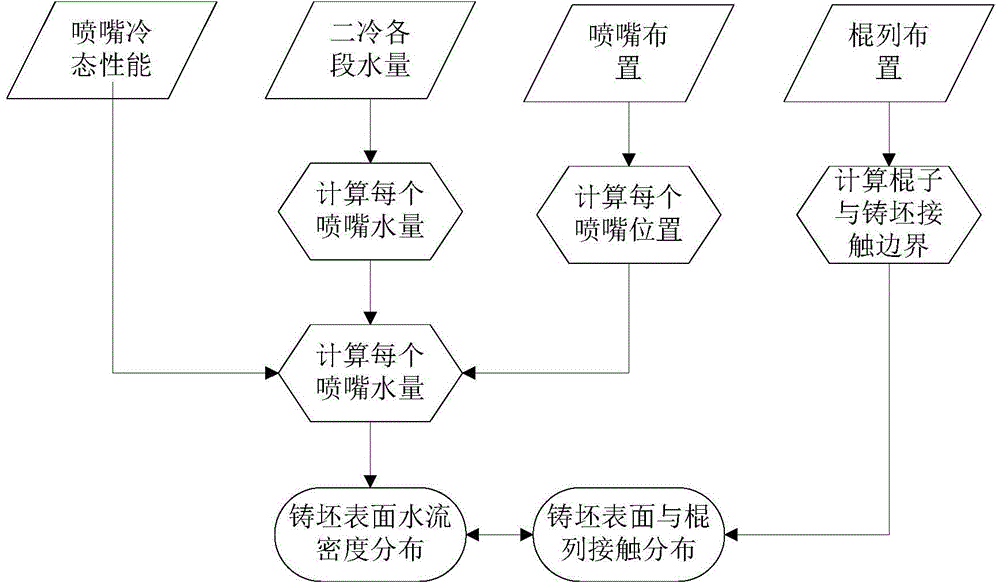

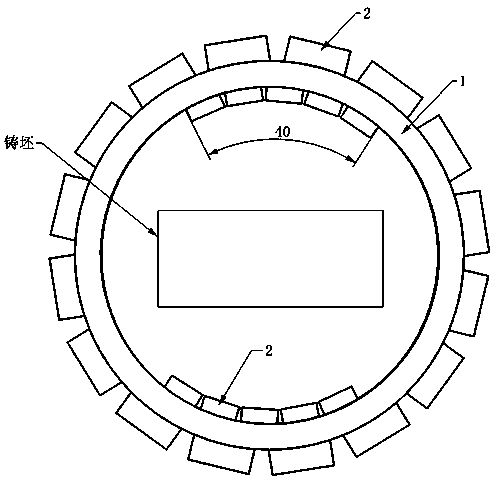

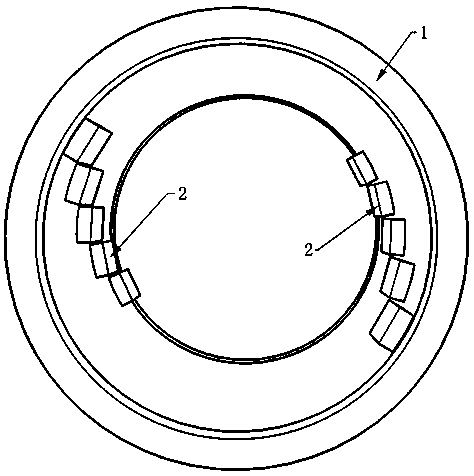

Control system and method for regulating electromagnetic stirrer in continuous casting process

The invention discloses a control system for regulating an electromagnetic stirrer in a continuous casting process. The control system comprises a material solidification calculating module and an electromagnetic stirrer positioning module; the material solidification calculating module is configured to determine factors generating influences on the tail solidification end of a casting blank according to received parameters, target data are calculated and obtained according to the factors and sent to the electromagnetic stirrer positioning module, and the parameters comprise the equipment parameters of a continuous casting machine and the work condition parameters of the continuous casting process; the electromagnetic stirrer positioning module comprises a control unit which is electrically connected with the electromagnetic stirrer, and the electromagnetic stirrer positioning module is configured to receive the position of the electromagnetic stirrer and determine or regulate the position of the electromagnetic stirrer according to the target data. According to the control system and method for regulating the electromagnetic stirrer in the continuous casting process, the problem that in the prior art, the purpose of ideal stirring is difficult to achieve caused by the fact that the position of the electromagnetic stirrer cannot be regulated in electromagnetic stirring is solved.

Owner:BEIJING MINGCHENG TECH DEV

Method for improving homogeneous degree of low-alloy high-tensile structural steel wide and thick plate continuous casting billets

The invention discloses a method for improving the homogeneous degree of low-alloy high-tensile structural steel wide and thick plate continuous casting billets. In the continuous casting process, the pulling speed of a casting machine is controlled to range from 0.78m / min to 0.90 m / min, and the superheat degree of tundish molten steel ranges from 20 DEG C to 30 DEG C; and dynamic secondary cooling control and solidification tail end heavy downward pressing are adopted. According to the method, the center segregation of the low-alloy high-tensile structural steel wide and thick plate continuous casting billets is reduced by mainly and comprehensively taking technical measures such as casting machine pulling speed stabilization, tundish superheat degree lowering, secondary cooling dynamic control and solidification tail end heavy downward pressing control, and the homogeneous degree of the continuous casting billets is improved. After the method is implemented, the effect is superior to the effect of an existing light downward pressing technology, the center segregation is well improved, the overall quality is good, the homogeneous degree is high, and the requirement for using low-alloy and high-strength structural steel can be well met.

Owner:TANGSHAN IRON & STEEL GROUP +2

Preparation method of high-temperature-resisting, abrasion-resisting, corrosion-resisting and antimagnetic material

InactiveCN102174666AReduce consumptionReduce center segregationProcess efficiency improvementElectric furnaceChemical compositionSulfur

The invention discloses a preparation method of a high-temperature-resisting, abrasion-resisting, corrosion-resisting and antimagnetic material, which is used for solving the problems that the existing antimagnetic material has poorer strength and hardness, is easy to corrode and has higher cost in using. The antimagnetic material is composed of the following raw materials by weight percent: 7-10% of Mn, 11-14% of Cr, 7-10% of Ni, 1-2% of V, 1-2% of Si, 1-2% of Mo, 0.5-1% of Nb, 0.1-1% of Ti, 0.3-0.4% of C and the balance of steel materials. The preparation method comprises the following steps: 1) preheating by an electric furnace; smelting by adding the steel material; 2) adding the following raw materials by weight percent: 7-10% of Mn, 11-14% of Cr, 7-10% of Ni, 1-2% of V, and smelting for 25-30 minutes; 3) then adding the following raw materials by weight percent: 1-2% of Si, 1-2% of Mo, 0.5-1% of Nb, 0.1-1% of Ti and 0.3-0.4% of C in the electric furnace, and smelting; 4) sampling and analyzing the chemical components in the electric furnace, and carrying out desulfuration, dephosphorus and carbon determination; and controlling the content of the carbon by weight percent to be 0.3-0.4%; and 5) heating and smelting by the electric furnace, and cooling; remelting and refining to remove impurities, and cooling and controlling the content of the sulfur and the phosphorus by weight percent to be less than or equal to 3%. By the preparation method provided by the invention, the center segregation is reduced, thick columnar crystals are reduced, stable casting blanks are obtained, and meanwhile the casting blank capacity is increased, and the continuous casting efficiency is effectively improved.

Owner:SHANXI BUYEASY MACHINERY MFG

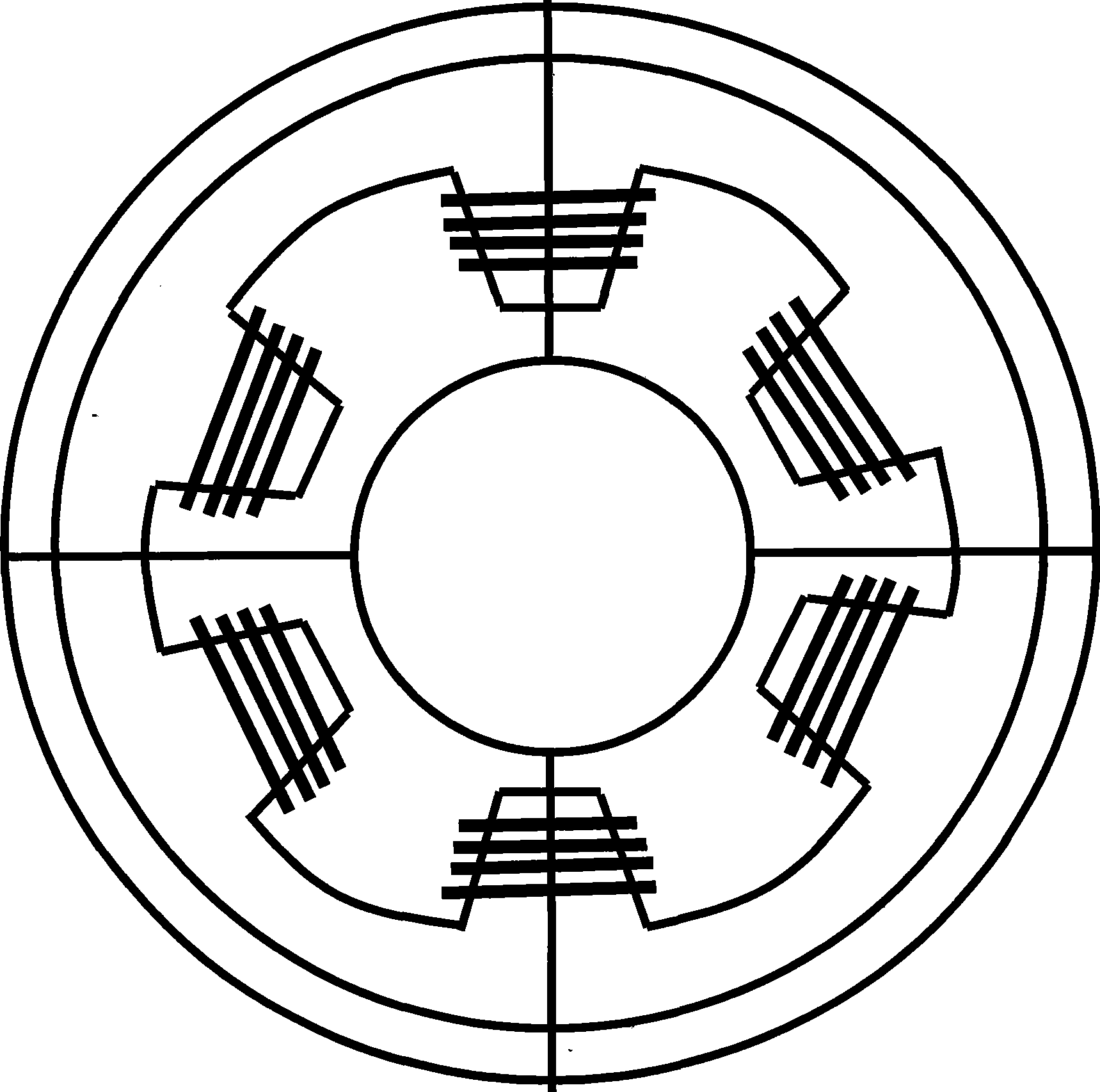

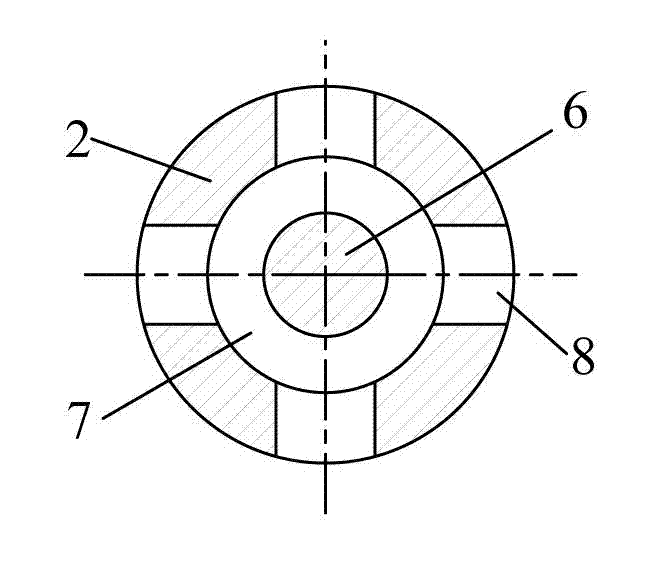

Continuous casting permanent magnet spiral magnetic field stirrer

ActiveCN110152545AReduce volumeReduce weightTransportation and packagingMixer accessoriesMetallurgyMagnetic poles

The invention discloses a continuous casting permanent magnet spiral magnetic field stirrer which comprises a steel cylinder, magnetic steel, a stator iron core and a shell. The continuous casting permanent magnet spiral magnetic field stirrer is characterized in that the shell is of a topless bottomless tubbish structure; the steel cylinder is of a topless bottomless tubbish structure; the steelcylinder is sleeved by the shell in a concentric manner; the stator iron core is fixed on the inner wall of the shell; a coil is embedded into the stator iron core to form a stator winding; the magnetic steel is fixed on the outer wall of the steel cylinder in a manner of surrounding the steel cylinder to form a rotor magnetic pole; two pieces of magnetic steel arranged in a spiral line are fixedon the inner wall of the steel cylinder; the two pieces of magnetic steel arranged in the spiral line mutually form an angle of 180 degrees in symmetry with the steel cylinder as a center; an includedangle of 40 degrees is formed by a head block and a tail block of each piece of magnetic steel to form an internal spiral magnetic field; and both ends of the stator iron core are assembled inside the shell through bearings. The stirrer is small in size, light in weight, simple in transmission, flexible to control, stable in performance, low in energy consumption, good in practicability and easyto popularize.

Owner:包钢集团电气有限公司

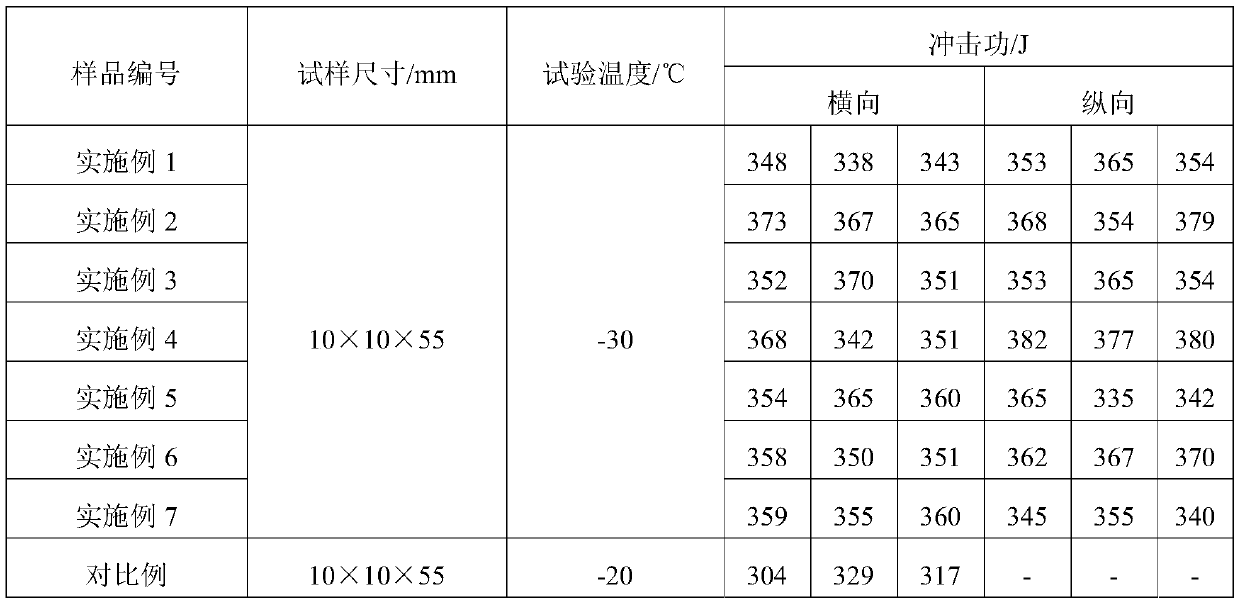

ERW submarine pipeline steel plate coil and production process thereof

InactiveCN110863145AHigh strengthUniform transverse mechanical propertiesManufacturing convertersPearliteNon-metallic inclusions

The invention discloses an ERW submarine pipeline steel plate coil and a production process thereof, and belongs to the technical field of submarine pipeline steel. The ERW submarine pipeline steel plate coil comprises the following main components of, in percentage by mass, 0.040% to 0.070% of C, 0.10% to 0.20% of Si, 1.40% to 1.60% of Mn, 0.020% to 0.040% of Nb, 0.020% to 0.040% of V, 0.010% to0.030% of Ti, 0.08% to 0.15% of Mo, 0.020% to 0.050% of Als, less than or equal to 0.0020% of S, less than or equal to 0.013% of P, and the balance Fe and inevitable impurity elements; developing theERW submarine pipeline steel plate coil, which applies small pipe diameter ( such as phi 219.1 to phi 273.1 mm ), with very low carbon content and very low S content ( less than or equal to 0.0020%) and P content ( less than or equal to 0.013%) is carried out. Under a TMCP process system, rolling is adjusted and controlled and the cooling processes is controlled, an uniform ferrite plus pearlite structure is obtained, materials has grain size of 10 to12 grades, band structure of no more than 3.0 grades, and low non-metallic inclusions, so that the ERW submarine pipeline steel plate coil has yield strength higher than or equal to 450 MPa, percentage of elongation greater than 30%, impact energy greater than 300 J at minus 30 DEG C, and good toughness.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for improving steel ingot cooling conditions

The invention provides a method for improving steel ingot cooling conditions. An annular air outlet groove and an air inlet channel communicated with the annular air outlet groove are machined in a chassis, an ingot mold is placed on the chassis, the exterior of the contact position of the ingot mold and the chassis is sealed through refractory mortar, a compression air pipe is inserted into the air inlet channel, and all components are sealed through the refractory mortar and an asbestos cord. After pouring is carried out, when an air gap is generated between a steel ingot and the ingot mold,an insulation cap is prized to enable an air gap to be generated between the insulation cap and the ingot mold. A valve is opened, compressed air enters the air outlet groove from the air inlet channel from the compression air pipe, then enters the air gap between the ingot mold and the chassis and the air gap between the steel ingot and the ingot mold, and is finally discharged from the gap between the insulation cap and the ingot mold, and continuous flowing and replacement between cold air and hot air are achieved. By means of the method, the problem that heat transferring is limited by the gaps can be effectively solved, the cooling rate of the steel ingot and the ingot mold is increased, sequent setting of the steel ingot from bottom to top is promoted, the defects of center segregation, loosening and the like of the steel ingot are reduced, and the steel ingot quality is improved.

Owner:ANGANG STEEL CO LTD

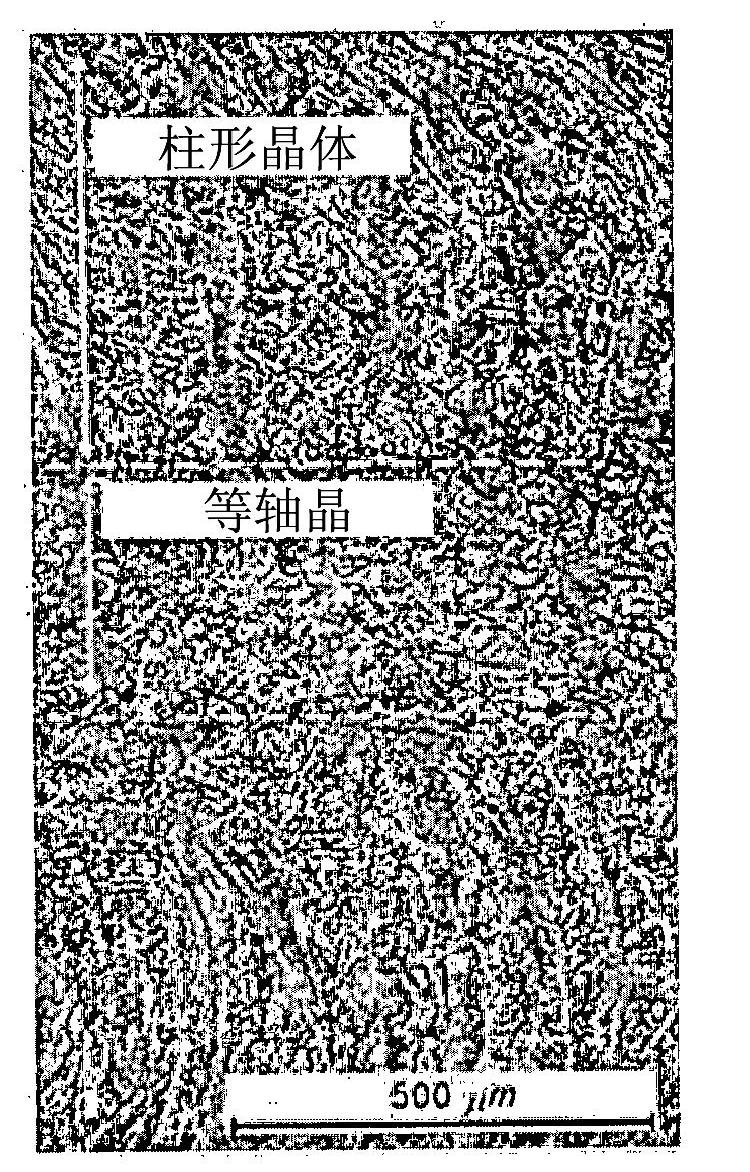

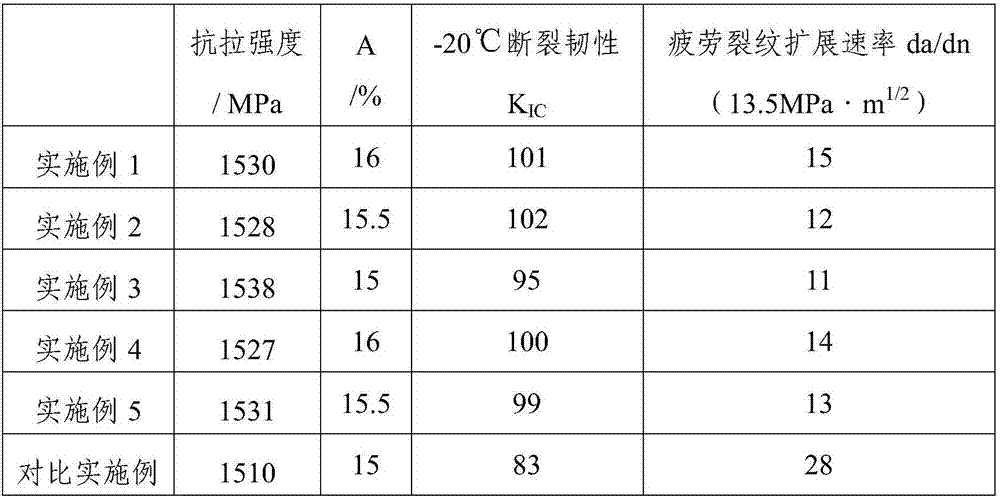

Production method capable of reducing fatigue crack growth rate of bainite steel rail

The invention discloses a production method capable of reducing the fatigue crack growth rate of a bainite steel rail. The production method specifically comprises the steps as follows: during smelting and deoxidation, the slag basicity of refining slag is controlled in the range of 1.8-2.3, and slag inclusions are controlled in the plastic range of anorthite; the temperature of a continuous casting tundish is 10-20 DEG C higher than the liquidus, and the pulling rate is controlled to range from 0.3 m / min to 0.5 m / min; a casting blank is obtained with a liquid core reduction technology, and the equiaxial crystal ratio of the casting blank is controlled to be higher than 95%. The composition and the size of the inclusions are controlled with the technology, tiny total-equiaxial crystal continuous casting is formed, the center segregation is reduced, in the later period, the bainite steel rail produced finally with the heating technology, the proper cooling technology and the heat treatment technology is higher in strength than a bainite steel rail prepared with a conventional smelting method, the fracture toughness KIC at subzero 20 DEG C is up to 102 MPa*m<1 / 2>, and for the fatigue crack growth rate, when deltak is equal to 13.5 MPa*m<1 / 2>, da / dn is as low as 11 m / Gc.

Owner:武汉钢铁有限公司

Molten metal solidification device and heat preservation method thereof

InactiveCN109877281AReduce center segregationReduce defects such as loose centerPorosityNonferrous metal

The invention discloses a molten metal solidification device and a heat preservation method thereof. A hollow cavity body is mounted on the periphery of an ingot mold, the cooling rate of a molten metal is adjusted by adjusting a cooling medium in the hollow cavity body to solidify the molten metal, the heat transferring uniformity of a temperature field is higher in the molten metal solidifying process by adjusting the cooling medium, thus the defects such as dendritic segregation and center porosity of a metal ingot are advantageously reduced, and the quality of the metal ingot is improved;meanwhile the hollow cavity body is mounted on the periphery of the ingot mold, thus the temperature difference of the inner surface and the outer surface of the ingot mold can be reduced, heat stressof the ingot mold in the cooling process of the molten metal is greatly reduced, and the service life of the ingot mold is advantageously prolonged; and the molten metal solidification device and theheat preservation method thereof are suitable for preparation of metal ingots of all the tonnages, the range of application is wide, the molten metal solidification device and the heat preservation method thereof can be suitable for preparation of carbon steel, alloy steel and non-ferrous metals, the technology is simple, easy to operate, reliable and safe, and the costs of investment and maintenance are low.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com