Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

A low-density steel, strong plastic product technology, applied in the field of low-density steel preparation, can solve problems such as inability to meet demand, achieve high strength, good plasticity, and prevent laminar tearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

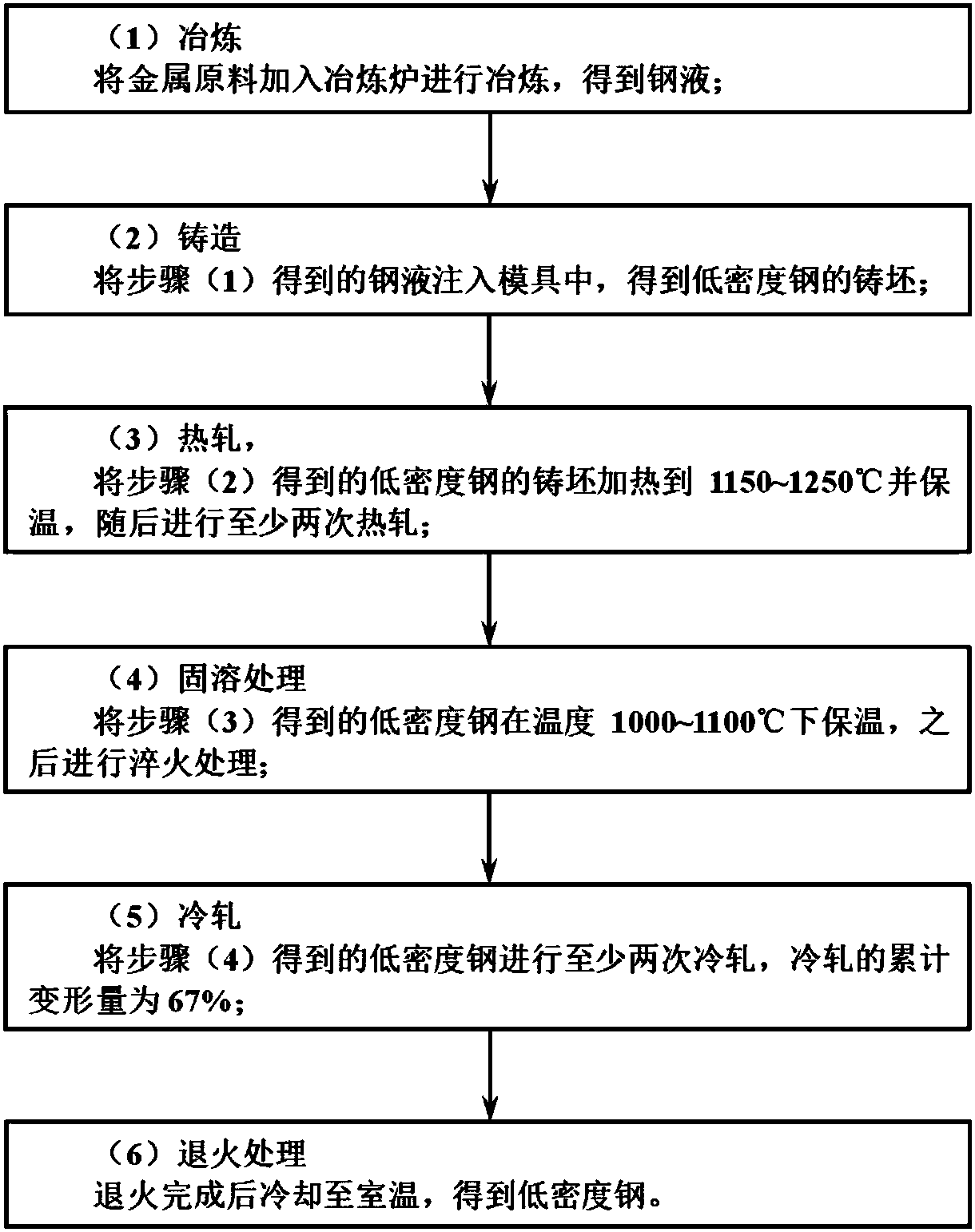

[0039] A preparation method of a low-density steel with a strength-plastic product greater than 50GPa·% in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.4%, Al: 9.82%, C: 0.99%, P: 0.003 %, S: 0.003%, the rest are Fe and other unavoidable impurities, and the sum of the mass percentages of Mn and Al in the low-density steel>28%, which is 29.22% in this embodiment; and the mass percentage of Mn in the low-density steel The percentage is 19.40~20%, the ratio of Mn to Al mass is 1.8~2.0, the mass percentage of Mn of this embodiment is 19.4%, the ratio of Mn to Al mass is 1.98; In addition, it is worth noting that the low density of this method The mass ratio of Al to C in the steel is 9.5-10.5, and it is 9.9 in this embodiment. like figure 1 Shown, concrete preparation method is as follows:

[0040] Step (1) smelting: use low-carbon Mn-Fe as the matrix, add Al-Fe alloy and carbon powder, smelt through the vacuum induction melting f...

Embodiment 2

[0048] A preparation method of a low-density steel with a strength-plastic product greater than 50GPa·% in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.00%, Al: 9.80%, C: 0.98%, P: 0.003 %, S: 0.003%, the rest are Fe and other unavoidable impurities, and the preparation method is basically the same as in Example 1. Then the tensile strength, elongation after fracture and strong-plastic product of the low-density steel were tested, and the test results were recorded in Table 1.

Embodiment 3

[0050] A preparation method of a low-density steel whose strength-plasticity product is greater than 50GPa·% in this embodiment, the chemical composition mass percentage of the low-density steel is: Mn: 19.8%, Al: 9.97%, C: 1%, P: 0.003 %, S: 0.003%, the rest are Fe and other unavoidable impurities, and the preparation method is basically the same as in Example 1. Then the tensile strength, elongation after fracture and strong-plastic product of the low-density steel were tested, and the test results were recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com