High product of strength and elongation alloy steel in columnar crystal/isometric crystal composite crystal structure and preparation method thereof

A composite crystal and high-strength plastic product technology, which is applied in the field of microstructure and performance control of high-strength plastic product alloy steel, can solve problems such as inability to achieve strength and plasticity, and limited control range, so as to increase strength, improve axial plasticity, and high-strength Plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

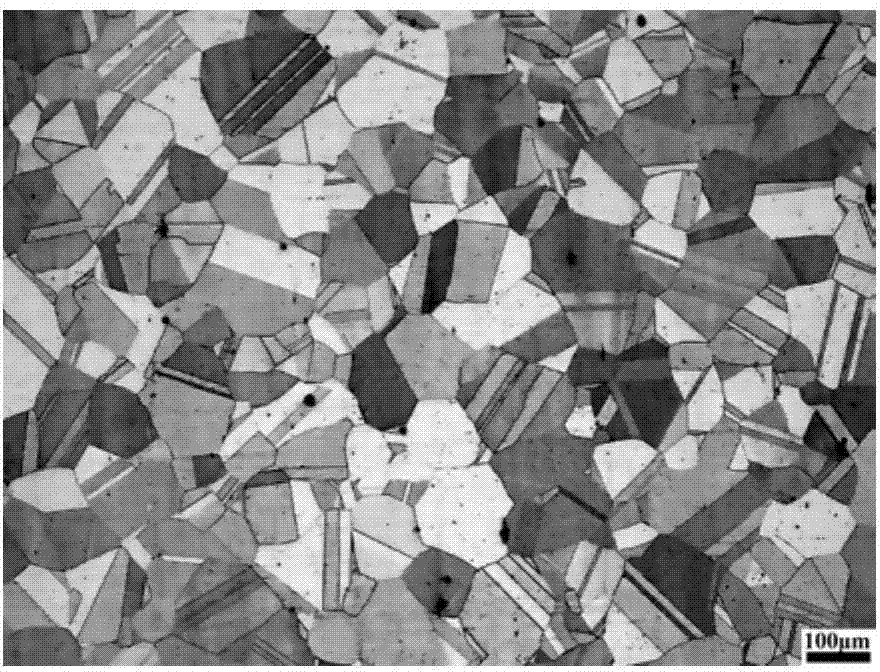

[0021] Example: a high-strength plastic alloy steel with a columnar crystal / equiaxed crystal composite crystal structure, its main chemical composition is (wt%): Mn29.5, Al2.75, Si3.10, C0.05, and the rest is Fe.

[0022] The preparation method is as follows:

[0023] (1) Dosing according to the target ingredients, smelting in a vacuum induction furnace under the protection of argon, and pouring into ingots after smelting;

[0024] (2) The amount of turning on the surface of the steel ingot is 2mm, and the size of the forging billet is 40×40×600mm;

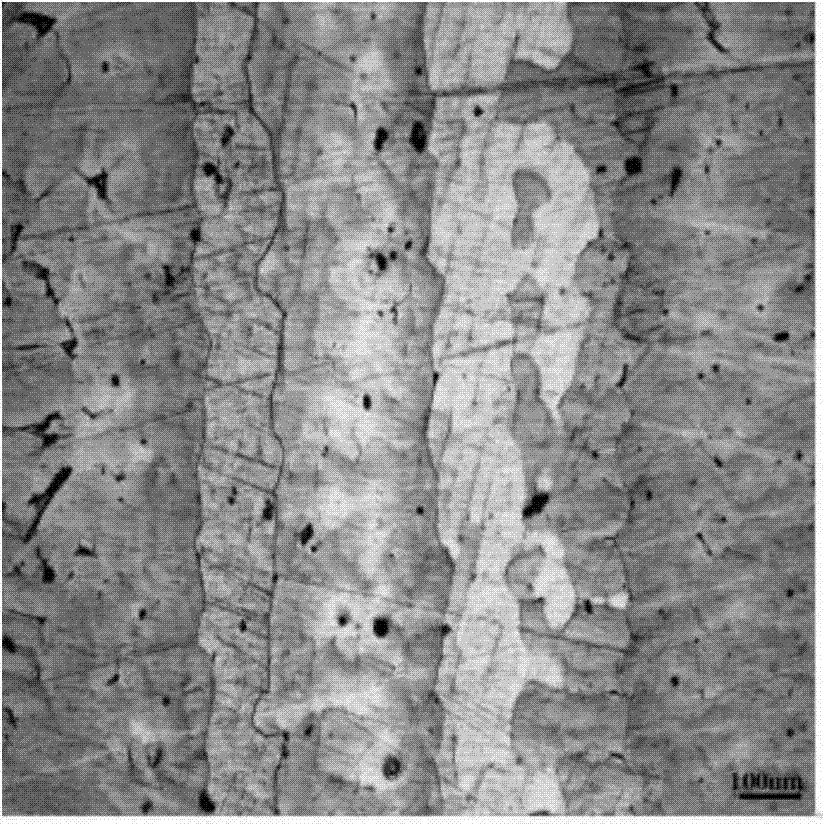

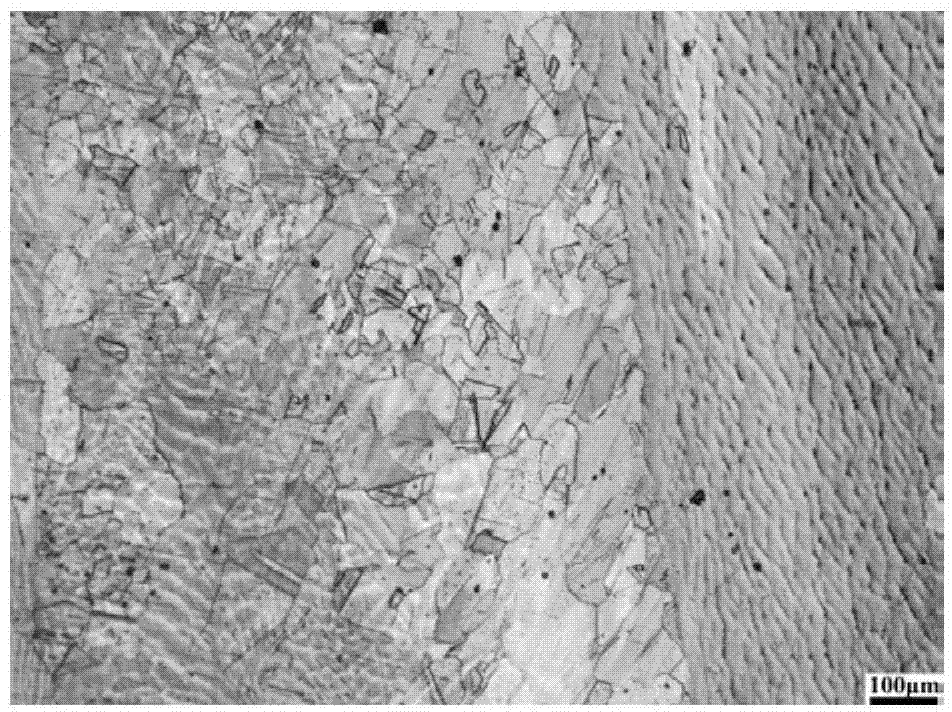

[0025] (3) Melt the processed billet in a directional solidification furnace under argon protection, the melting temperature is 1500°C, the crucible descending speed is 2mm / min during directional solidification, and the temperature gradient in the solidification area is 30°C / cm;

[0026] (4) Cut the directionally solidified billet into plates with a size of 40×10×500mm, and then carry out drawing deformation along the columnar cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com