Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about How to "Increased strength and plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

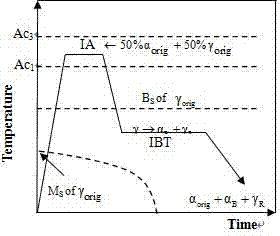

Steel plate for hot stamping, hot stamping process and hot-stamped member

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

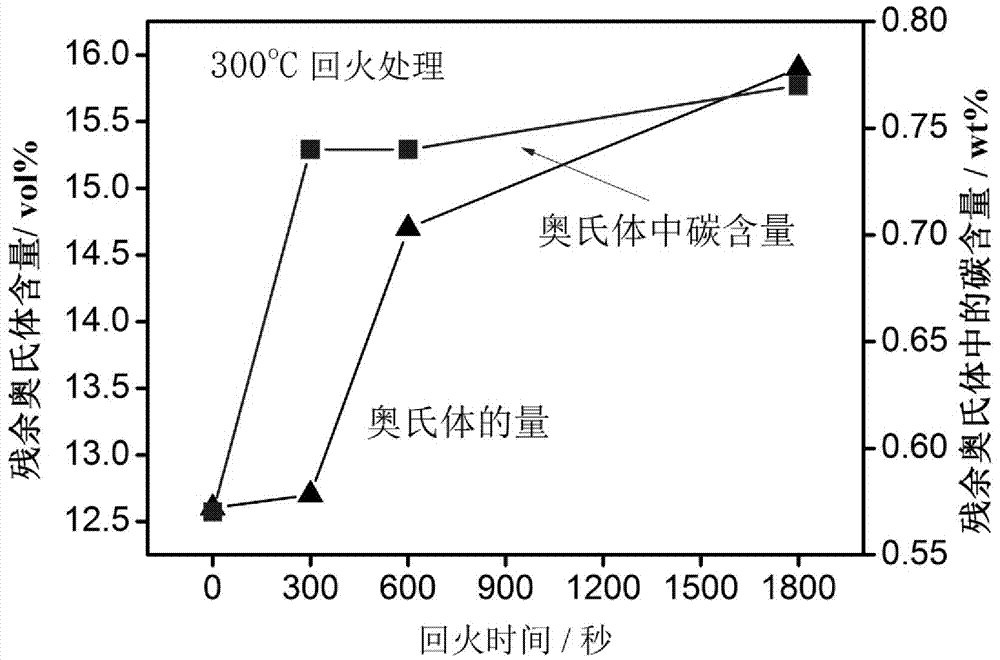

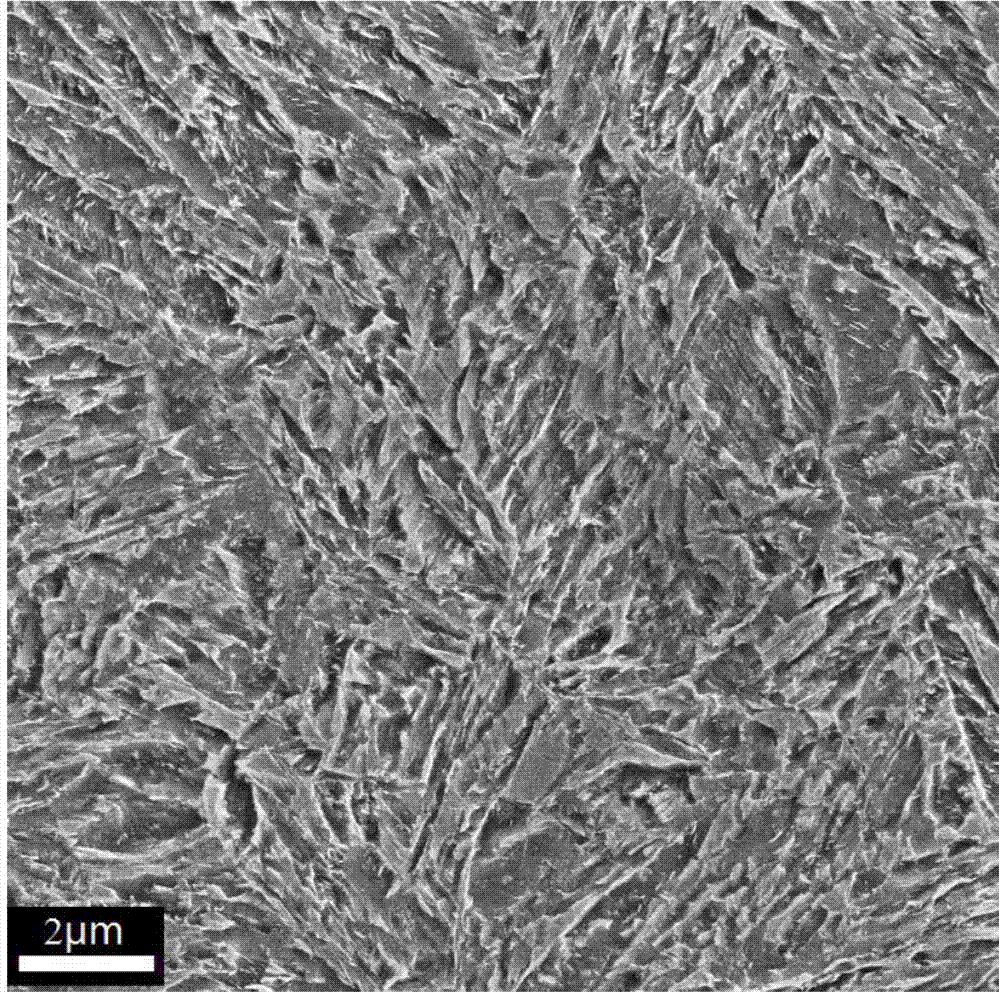

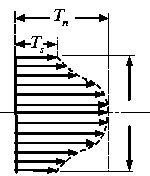

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

Production method for continuous annealing process high strength and plasticity product automobile steel plate

ActiveCN102021472AMeet continuous annealing production requirementsIncreased strength and plasticityFurnace typesHeat treatment furnacesSheet steelContinuous annealing

The invention discloses a production method for a continuous annealing process high strength and plasticity product automobile steel plate, which belongs to the technical field of automobile steel. By increasing the deformation energy storage of a cold-rolled steel plate and acquiring nonequilibrium structure, the time for reverting austenite is reduced greatly, a condition for obtaining better strength and plasticity product in an annealing and heat preservation time period of 1 to 10 minutes is created, and the process conditions of the conventional automobile steel cold-rolled plate continuous annealing and continuous galvanizing production equipment are met. In addition, through structural heredity, the strength and plasticity product of a cold-rolled reversed austenite annealing steel plate is improved by over 10 percent compared with that of reversed austenite annealing hot-rolled steel plate.

Owner:CENT IRON & STEEL RES INST

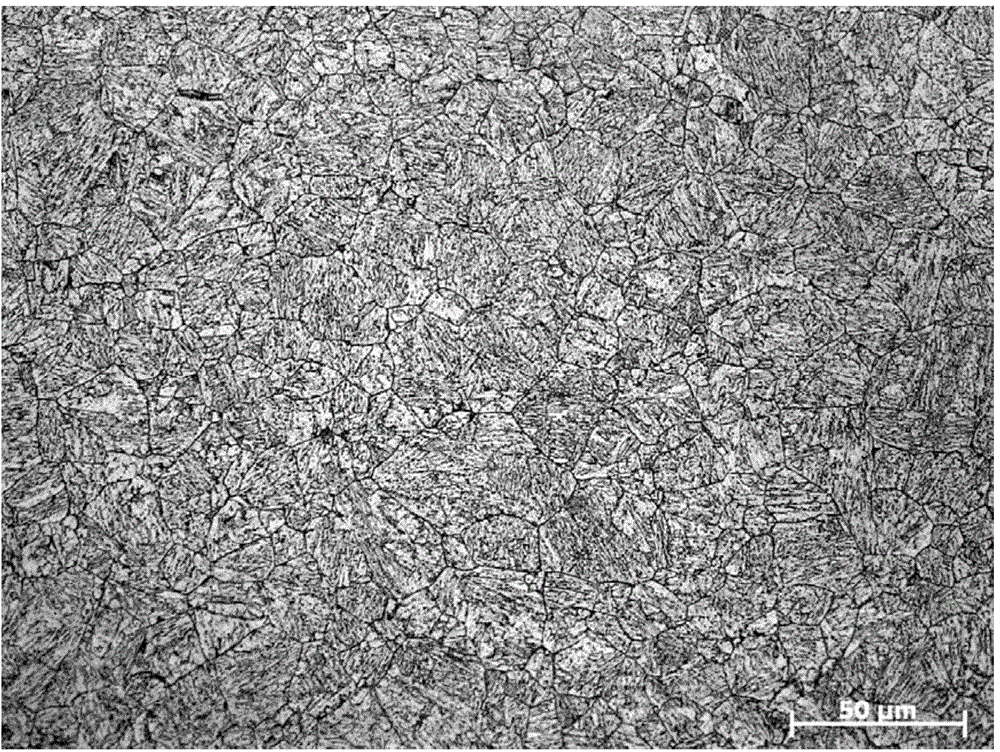

780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and preparation method thereof

The invention provides 780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and a preparation method thereof. The low-density cast steel comprises, by mass, 0.80-1.30% of C, 15.00-20.00%of Mn, 3.50-8.00% of Al, 0.05-0.25% of Si, 0.5-1.5% of Cr, 0.01-0.06% of Cu, 0.30-0.80% of Mo, 0.05-0.20% of V, 0.01-0.10% of Nb, 0.005-0.025% of Ce, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.01% of N, and the balance Fe and unavoidable impurities. Meanwhile, the weight percentage ratio of Mn to Al is no less than 2.5% and no more than 3.0%, and the sum of the weight percentages of Nb and V is no less than 0.10% and no more than 0.20%. The preparation process is simple and free of rolling, and the method can be used for manufacturing automobilestructure castings with complex shapes.

Owner:HEBEI UNIV OF TECH

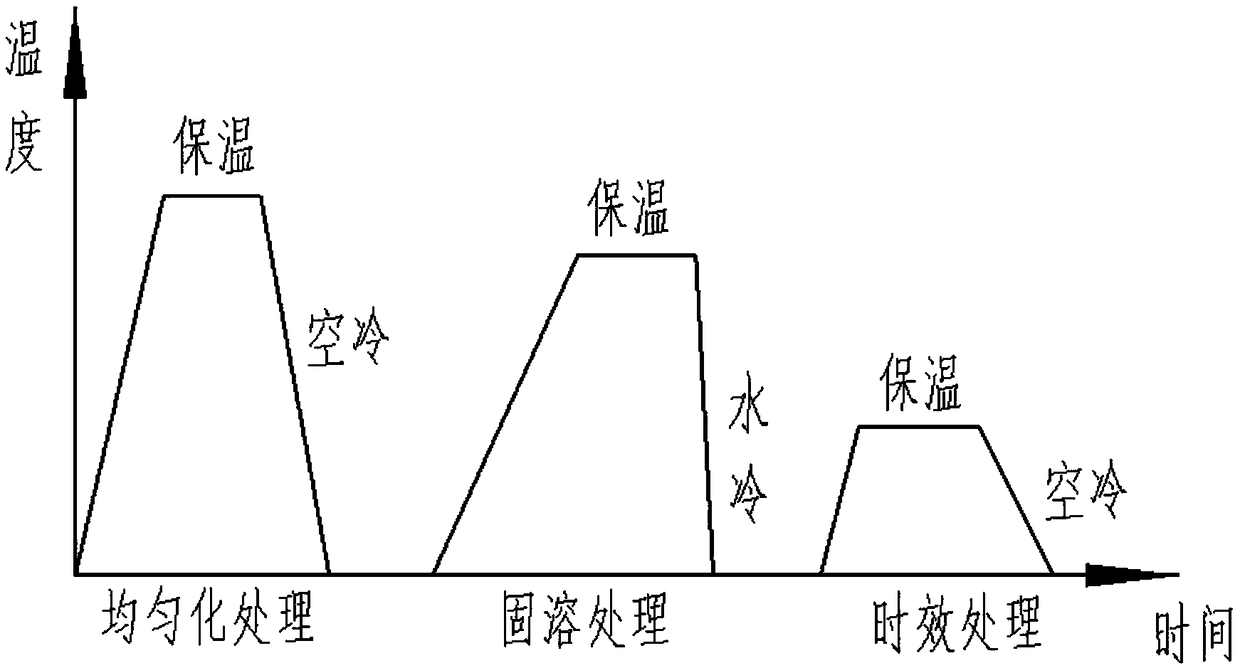

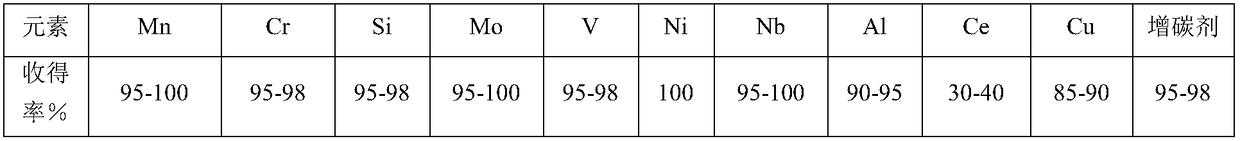

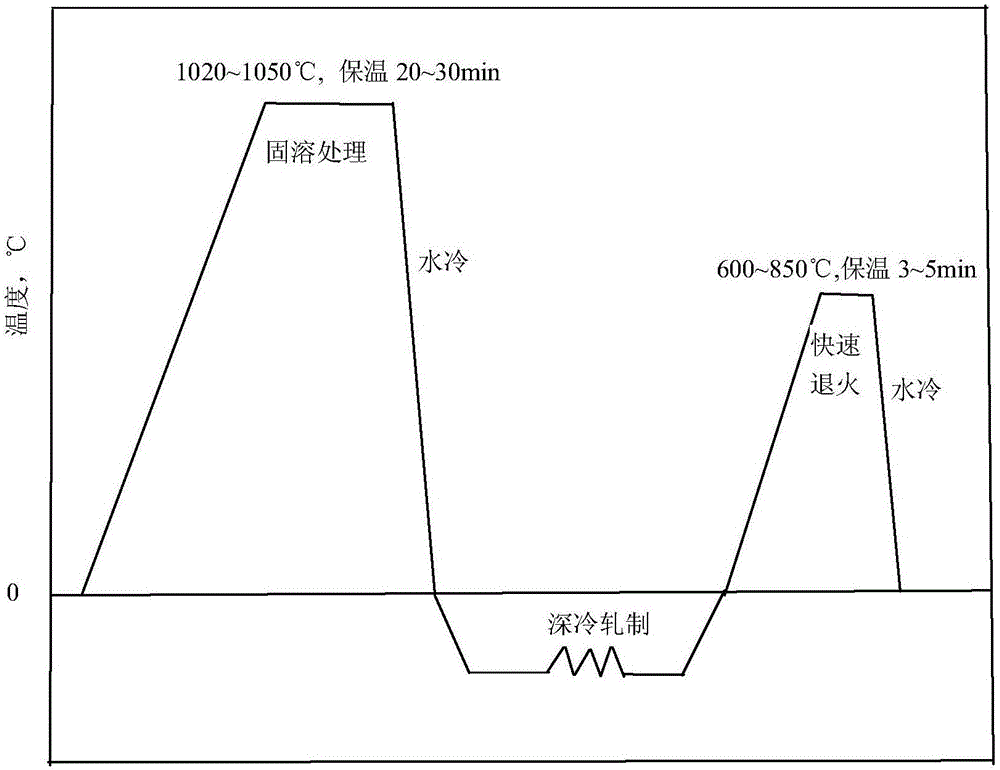

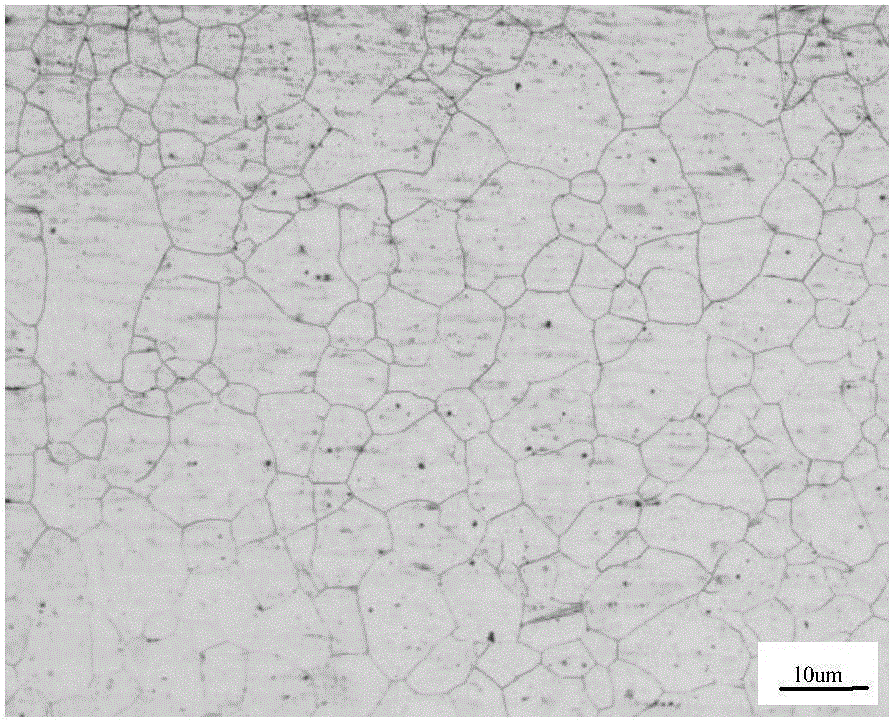

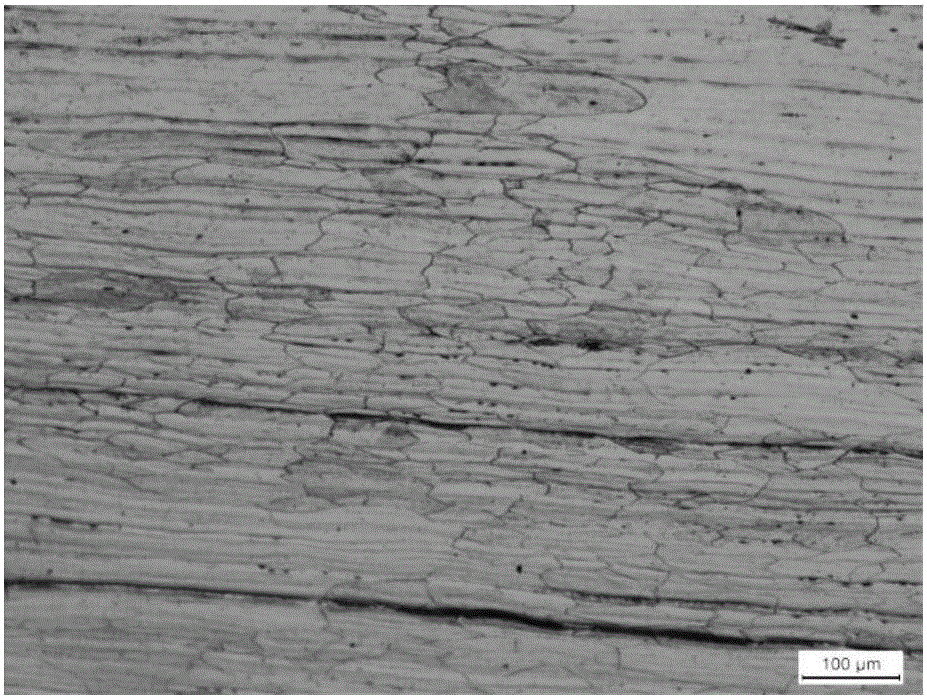

Method for preparing nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing

ActiveCN106435131ARemarkable grain refinement effectIncreased strength and plasticitySteel platesAustenitic stainless steel

The invention provides a method for preparing a nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing and belongs to the field of stainless steel manufacturing. The method comprises the steps that (1) an austenitic stainless steel blank is hot-rolled after being subjected to heat preservation at the temperature of 1150 DEG C-1250 DEG C and then is air-cooled to the room temperature after being water-cooled to 150 DEG C-200 DEG C, and a hot-rolled plate is prepared; (2) deep cooling rolling is conducted, specifically, the hot-rolled plate is subjected to solid solution treatment, after an oxide layer on the surface is removed, deep cooling rolling is conducted, the steel plate is subjected to liquid nitrogen treatment before cold rolling per pass, and a deep cooling rolled stainless steel plate is prepared; and (3) the deep cooling rolled stainless steel plate is air-cooled to the room temperature after being subjected to heat preservation at the temperature of 600 DEG C-850 DEG C, so that the nanocrystalline austenitic stainless steel plate is prepared. The yield strength of the stainless steel plate prepared by the method is 956-1170 MPa, the tensile strength is 1130-1380 MPa, the percentage elongation after fracture is 18%-52%, and the product of strength and elongation is 55000-58080 MPa.%. According to the method for preparing the nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing, the time is short; the efficiency is high; energy sources are saved; the cost is low; and a sample piece large in section size is easy to produce.

Owner:NORTHEASTERN UNIV

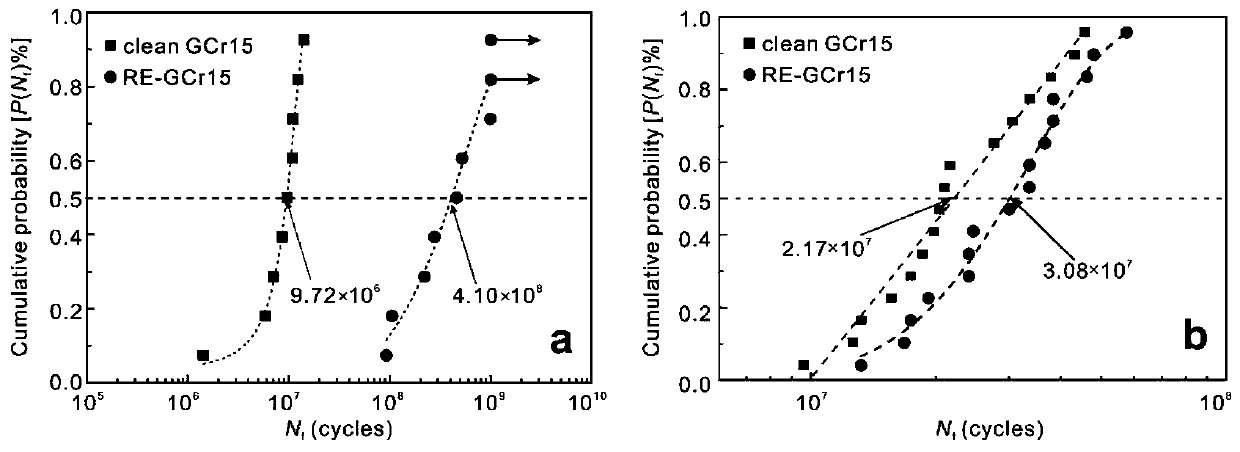

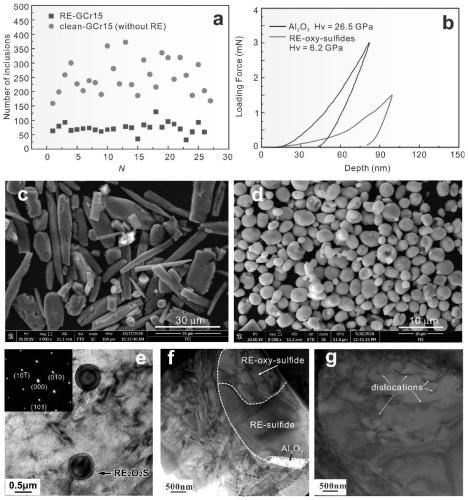

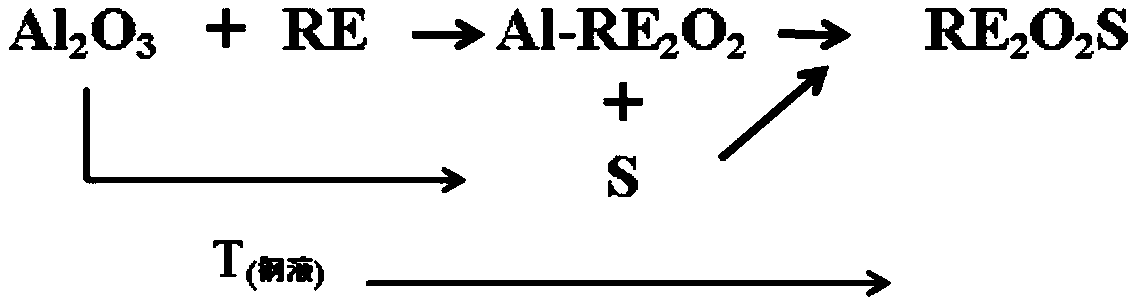

Ultra-clean rare earth steel and occluded foreign substance modification control method

ActiveCN110484811AReduce hardnessImprove fatigue lifeProcess efficiency improvementRare-earth elementMicrometer

The invention provides ultra-clean earth steel and an occluded foreign substance modification control method. 10-200 ppm of rare earth elements are included in the steel, and 50% or more occluded foreign substances in the steel are dispersed RE-oxygen-sulfide with the average equivalent diameter Dmean ranging from 1 micrometer to 5 micrometers in a spherical shape or a spheroidal shape or a granular shape. According to the method, at least 80%, preferably at least 90%, of Al2O3 occluded foreign substances in the steel are modified into RE-oxygen-sulfide, compared with steel with the same components without rare earth, the total amount of the occluded foreign substances in the steel is reduced by 18% or higher, the cracking probability caused by occluded foreign substances such as Al2O3 intraditional pure steel is reduced, the mechanical and chemical performance such as the fatigue life of the steel is remarkably improved, precise control over the modification type, distribution and dimension of the occluded foreign substances in the steel is achieved, and the method is suitable for researching and producing of high-performance steel in more varieties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

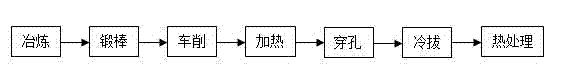

Method for producing transformation induced plasticity (TRIP) seamless tube

InactiveCN102407245AAustempering achievedReduce contentFurnace typesHeat treatment furnacesAustemperingChemical composition

The invention belongs to the field of preparation of steel tubes, and in particular relates to a method for producing a transformation induced plasticity (TRIP) seamless tube. The method comprises the following steps that: a smelted ingot is forged into a rod, turned, heated, punched and subjected to cold drawing to obtain a seamless cold drawing steel tube, and the seamless cold drawing steel tube is placed in a resistor furnace for critical region isothermal annealing for 180-1200 seconds at the temperature of 780-850 DEG C, and then is rapidly placed in a salt bath furnace for bainite region isothermal annealing for 120-1800 seconds at the temperature of 380-470 DEG C so as to obtain the TRIP seamless tube. According to the technical scheme in the invention, the chemical components of common low carbon steel can be used for producing the TRIP seamless tube with good comprehensive mechanical properties, high yield strength up to 580MPa, high tensile strength up to 763MPa and high product of strength and elongation up to 22029MPa.%. The method is easy to realize in industrialized production, has the advantages of relatively stable process and relatively low cost, and is suitable for producing TRIP seamless steel tubes with different chemical components and sizes.

Owner:NORTHEASTERN UNIV LIAONING

Medium-manganese TRIP (Transformation-Induced Plasticity) steel and preparation method thereof

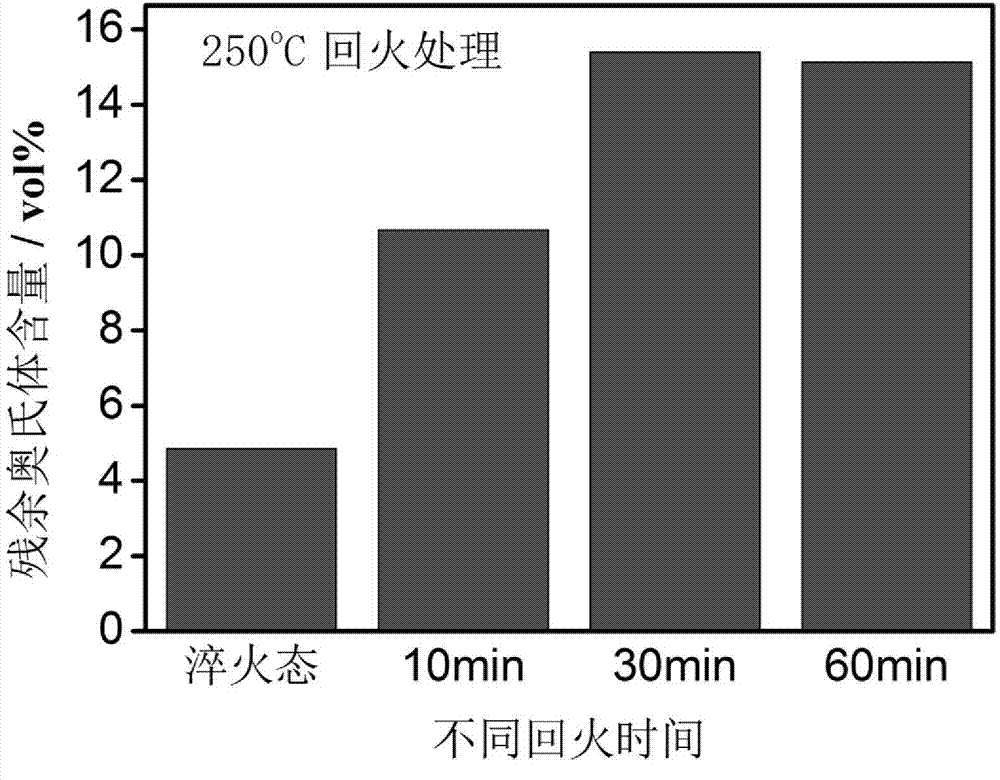

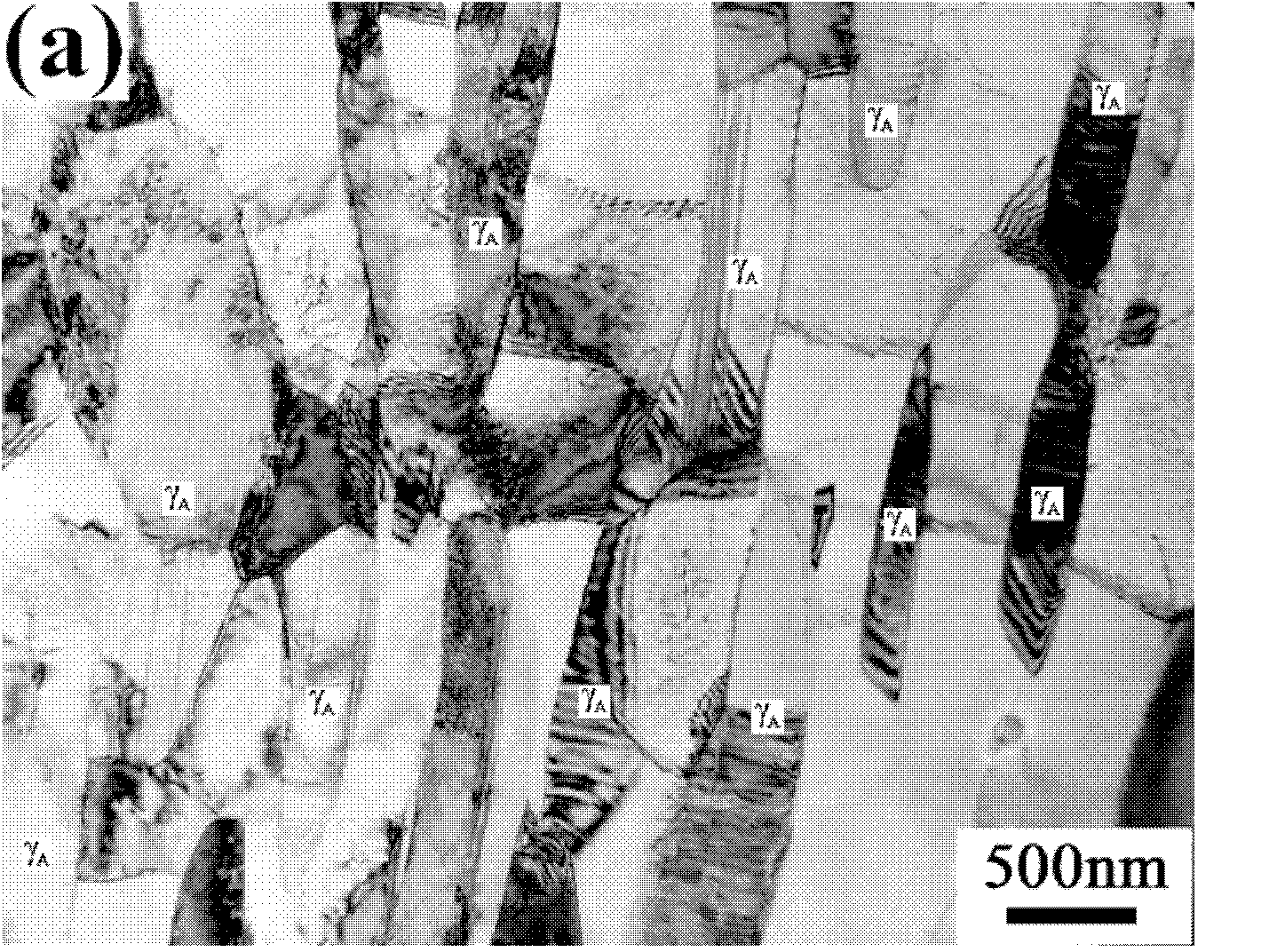

The invention provides medium-manganese TRIP (Transformation-Induced Plasticity) steel and a preparation method thereof. According to the medium-manganese TRIP steel and the preparation method thereof, medium-manganese cold rolled steel is taken as a raw material; the cost is low; the performance of a final product is realized by adopting critical region heat preserving, quenching cooling and partitioning processes; the structure of the medium-manganese steel is controlled by utilizing an over-aging stage in a continuous annealing production line, and the residual austenite volume fraction of the structure is improved in a relatively short critical annealing time, so that mechanical properties of a product are ensured, and meanwhile, the cost is reduced as much as possible; the performance of the steel is stable, the process fluctuation has little influence on performance, and industrial production is facilitated; and the prepared medium-manganese TRIP steel is high in strength, high in elongation and good in forming property, can be widely applied to reinforcing structural parts, such as a B-pillar reinforcing plate, to improve the collision safety of an overall vehicle, and achieves the effects of reducing weight and reducing emission.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

High-strength and high-plasticity medium manganese cold-roll steel sheet and manufacturing method thereof

InactiveCN103103438AImprove mechanical propertiesSimple and economical ingredientsTime rangeSheet steel

The invention discloses a high-strength and high-plasticity medium manganese cold-roll steel sheet and a manufacturing method thereof, and belongs to the technical field of metal material manufacturing. The high-strength and high-plasticity medium manganese cold-roll steel sheet comprises the following main components in percentage by mass: 0.15-0.25% of C, 7-8% of Mn, 1.2-1.8% of Si, and less than or equal to 0.05% of Al. The components are smelted and cast into a blank, and then the casting blank is subjected to multi-pass hot rolling so as to obtain a hot-rolled plate; the hot-rolled plate is subjected to intermediate heat treatment two times and two stages of cold rolling; the temperature of the intermediate heat treatment is 80-120 DEG C larger than Ar1, and the heat preservation time is 8 hours and above; in the two stages of cold rolling, the deformation is 30-50%; and the temperature of final heat treatment of the cold-roll steel sheet is Ar1+70 DEG C and above, and the annealing time ranges from 10 minutes to 2 hours. The cold-roll steel sheet disclosed by the invention is simple in preparation method, low in cost, and wide in application prospect. A prepared high-strength and high-plasticity medium manganese cold-roll steel sheet has excellent mechanical properties, and the product of strength and elongation of the cold-roll steel sheet can be up to 44.9 GPa*%.

Owner:UNIV OF SCI & TECH BEIJING

Annealing preparation process for enhancing product of strength and elongation of twinning-induced plasticity high-manganese steel board

The invention belongs to the field of metal material processing, and relates to an annealing preparation process for enhancing a product of strength and elongation of a twinning-induced plasticity (TWIP) high-manganese steel board. The high-manganese TWIP cold-rolled steel board comprises the following components in percentage by mass: 0.06-0.6% of C, not more than 3% of Si, not more than 3% of Al, 22-30% of Mn, not more than 0.1% of P, not more than 0.02% of S, and the balance of iron or inevitable impurities. The high-manganese TWIP cold-rolled steel board is prepared by the preparation steps of: smelting, carrying out die casting or continuous casting, hot rolling, cold rolling and heat treatment, carrying out heat insulation on the cold-rolled board in a heating furnace at 800-1000 DEG C for 0.1-0.5 hour, carrying out short-time heat treatment and rolling process multiple times, and carrying out air cooling to room temperature. According to the invention, by component and process control, the prepared material has superhigh strength and plasticity ratio, the tensile strength can reach 900-1020 MPa, the elongation can reach 70-80% and the strength and plasticity ratio can reach 80000 MPa.%; and the preparation process is simple and feasible as well as economical.

Owner:UNIV OF SCI & TECH BEIJING

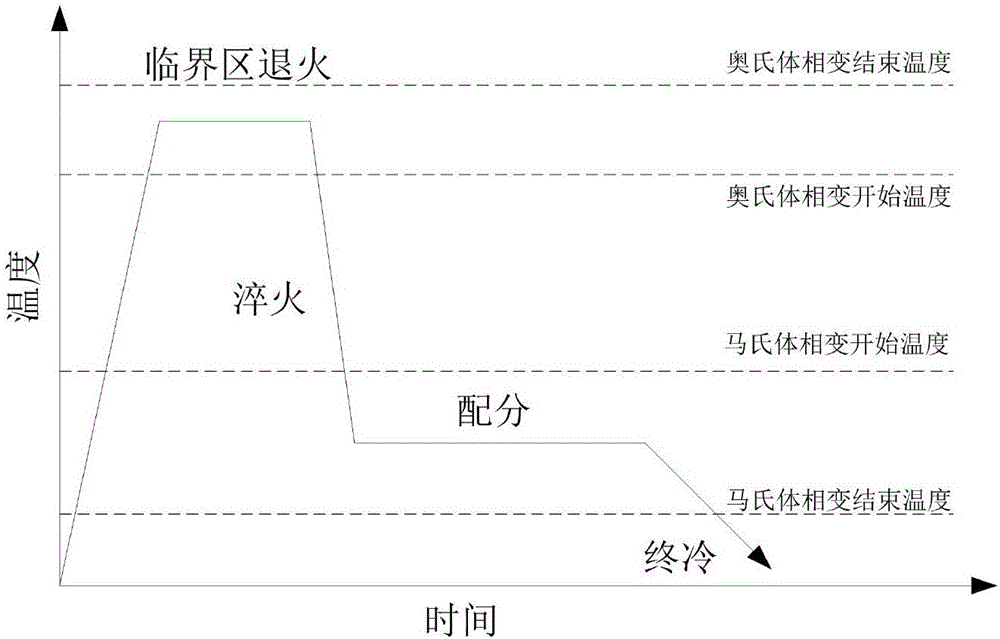

Hot stamping forming process based on Q&P one-step method

The invention relates to a hot stamping forming process based on a Q&P one-step method. The process is a process which integrates a Q&P hot processing process and hot stamping process and specifically includes the following steps of cutting a sheet according to the size of a hot stamping part, heating a die with a heating plate to a temperature ranging from 230 DEG C to 410 DEG C, placing the sheet into a heating furnace, conducting vacuum pumping, heating the sheet to a temperature ranging from 850 DEG C to 950 DEG C at a heating speed not lower than 15 DEG C per second, conducting heat preservation for 3min to 6min so that the sheet can be even in an austenitized mode, quickly moving the heated sheet to a preheated hot stamping die to be stamped, formed and quenched, enabling the die to be kept in a closed state, conduct heat preservation for 10s to 180s, quickly placing the hot stamping part into water and enabling the hot stamping part to be quenched to the room temperature after carbon distribution heat preservation, conducting de-scaling, and removing the oxide skin of the formed part through shot blasting or acid dipping. Compared with the prior art, the hot stamping forming process based on the Q&P one-step method can ensure that a finally manufactured part has high strength and has good plasticity (ductility) at the same time, and therefore the shock resistance of the manufactured part is improved.

Owner:SHANGHAI JIAO TONG UNIV

Production method of quenched and tempered high-intensity Q890D super-thick steel plate

ActiveCN103589969AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingSteel plates

A production method of a quenched and tempered high-intensity Q890D super-thick steel plate comprises processing steps as follows: liquid iron pretreatment, converter steelmaking, secondary refining, continuous casting including dynamic soft reduction and electromagnetic stirring, heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance examination and ultrasonic flaw detection. Steel comprises chemical composition in percentage as follows: not more than 0.16% of C, 0.20%-0.40% of Si, 1.30%-1.40% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03%-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.35%-0.45% of Cr, 0.45%-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and unavoidable impurities. The produced high-performance quenched and tempered high-intensity Q890D super-thick steel plate with a thickness ranging from 100 mm to 120 mm can meet the manufacturing requirement of heavy machinery for a mine, a port and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

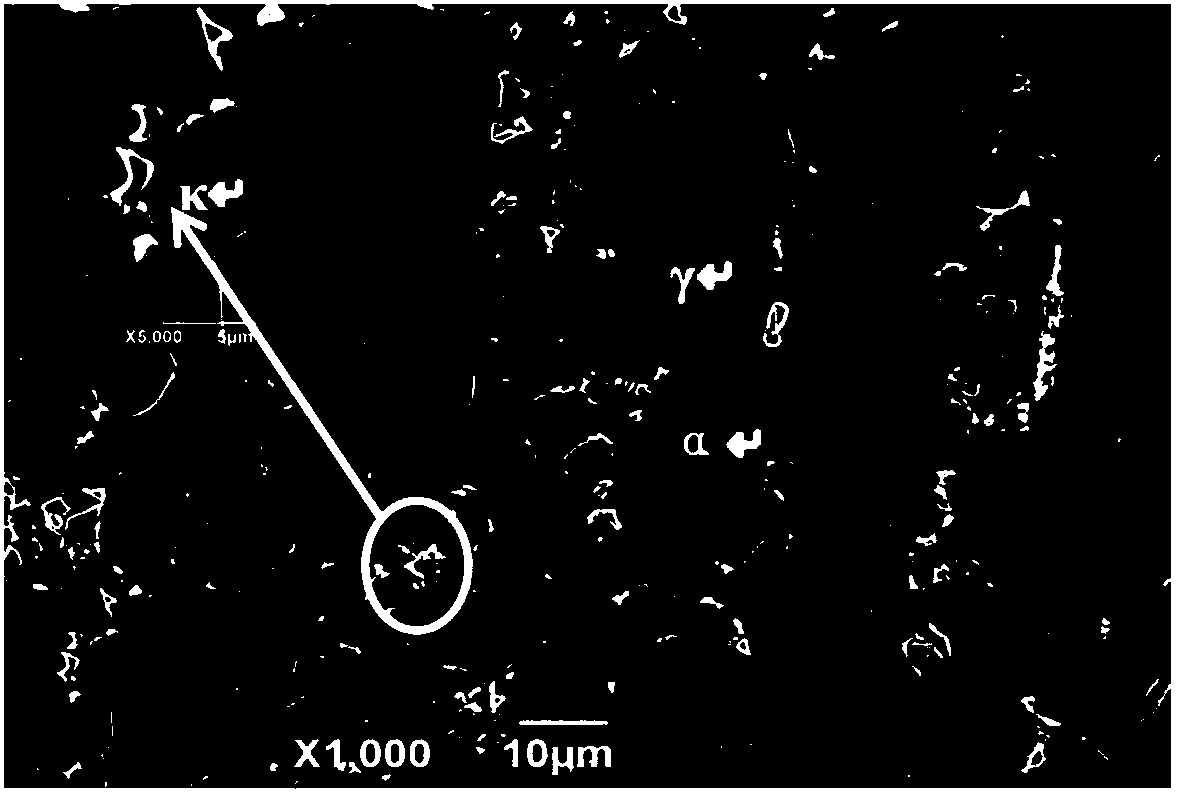

Low-density high manganese steel with high product of strength and elongation

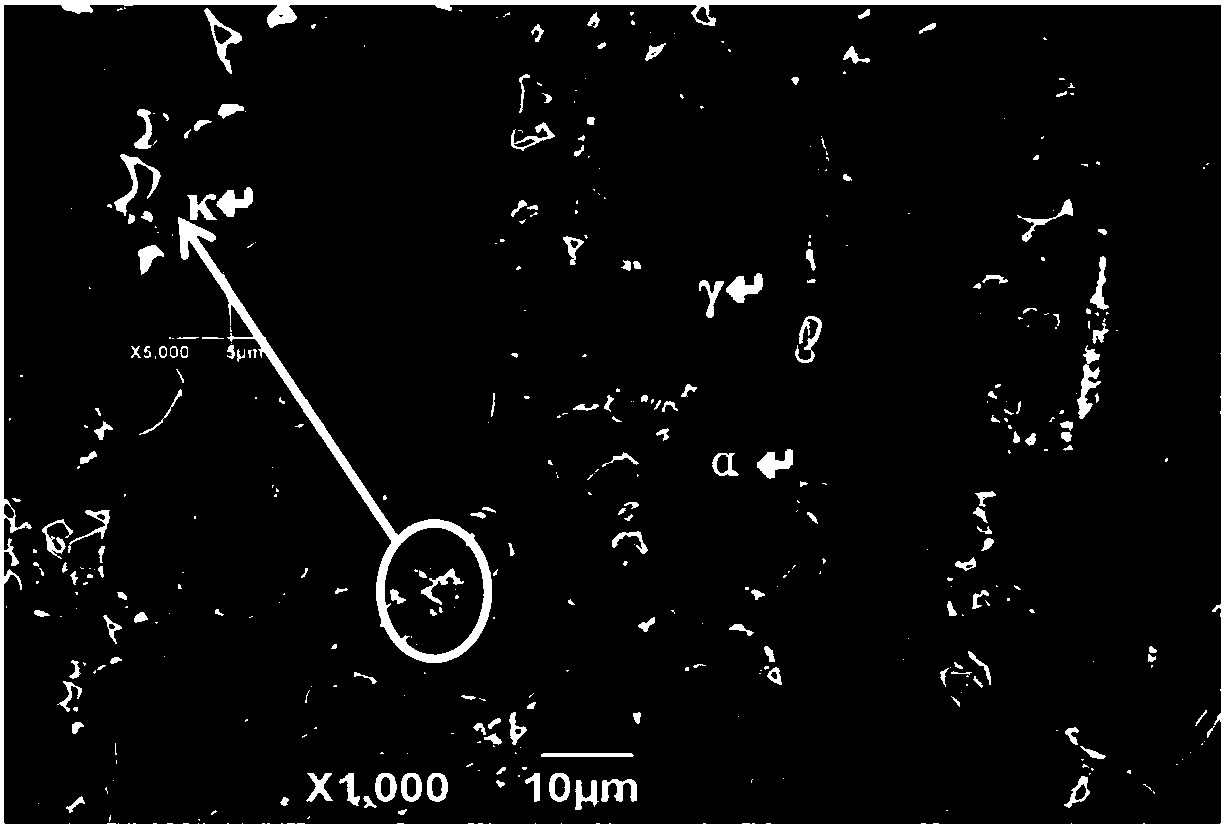

InactiveCN107641763AHigh strengthImprove plasticityProcess efficiency improvementSolution treatmentCarbide

The invention provides low-density high manganese steel with high product of strength and elongation, and belongs to the field of low-density steel. The sum of the mass percents of Mn and Al in low-density steel exceeds 28%. The low-density high manganese steel is prepared through the following steps: smelting, namely, smelting on the basis of the alloy component system; casting; hot rolling, namely, heating a casting blank to be 1150-1250 DEG C; maintaining the temperature; then performing hot rolling at least twice; performing solution treatment, namely, maintaining the temperature of 1000-1100 DEG C of the casting blank, and then quenching; cold rolling, namely, performing cold rolling on the obtained low-density steel at least twice; annealing and then cooling to obtain the low-densitysteel. According to the low-density high manganese steel with high product of strength and elongation, a certain amount of Al is added to the steel, and the alloy component and the processing technology are adjusted, so as to obtain Fe-Mn-Al-C series low-density steel; the low-density steel is of an appearance of an austenite, ferrite and k carbide multi-phase structure, so that the low-density steel is high in strength and high in plasticity.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

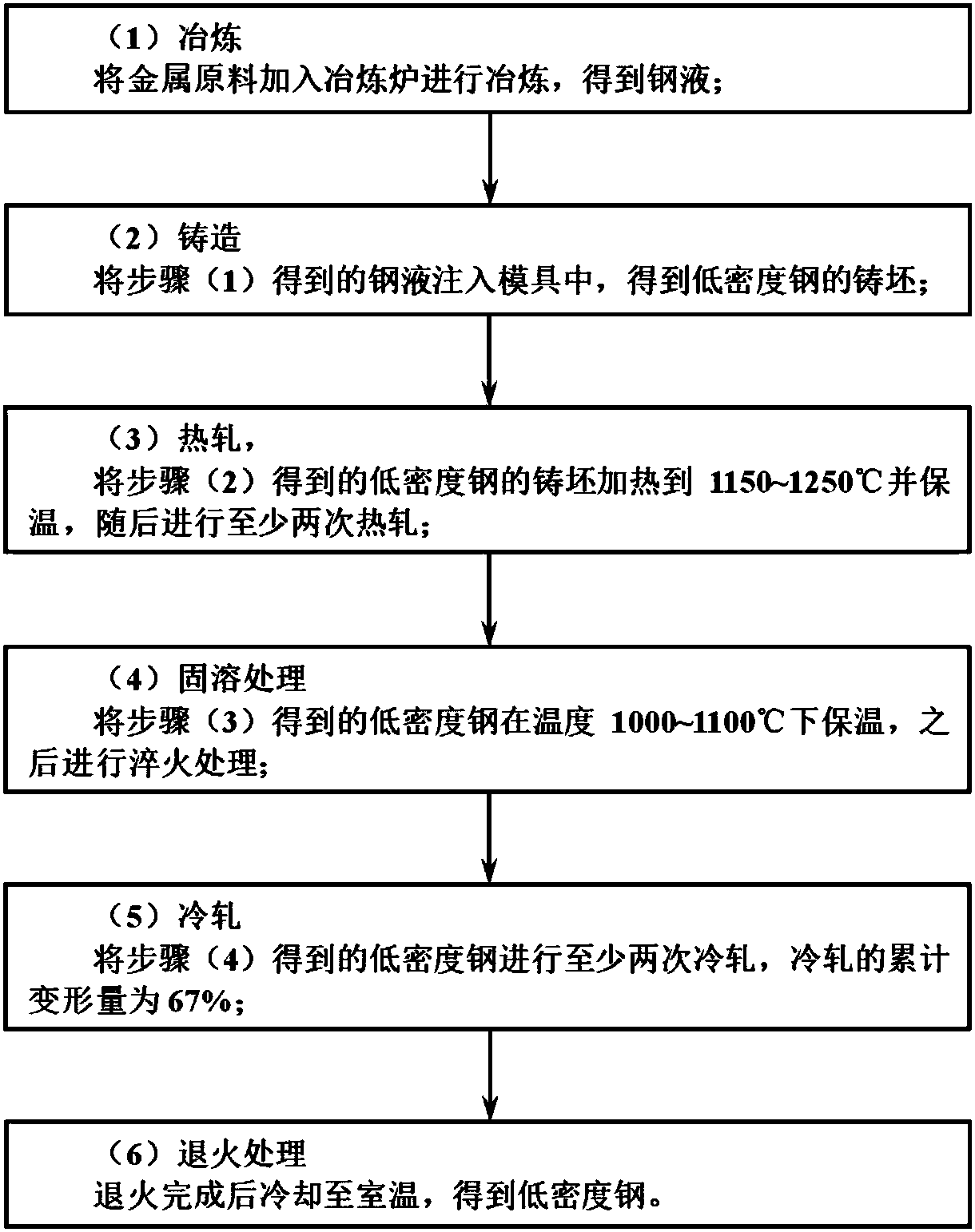

Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

The invention relates to a preparation method for low-density steel with the strength and elongation product larger than 50 GPa.%, and belongs to the field of low-density steel. The preparation methodincludes the following steps of smelting, specifically, raw materials are put into a smelting furnace for smelting; casting, specifically, obtained molten steel is poured into a mold, and low-densitysteel ingots are obtained after cooling; hot rolling, specifically, the obtained low-density steel ingots are heated to 1150-1250 DEG C, heat preservation is carried out, and then at least two timesof hot rolling are carried out; solution treatment, specifically, the obtained low-density steel is subjected to heat preservation at the temperature of 1000-1100 DEG C, and quenching treatment is carried out; cold rolling, specifically, the obtained low-density steel is subjected to at least two times of cold rolling; and cooling after annealing treatment. In this way, the low-density steel is obtained. Through regulation of alloy elements and the machining process, the Fe-Mn-Al-C system low-density steel is obtained, and the morphology of the low-density steel is of a multi-phase structure including austenite, ferrite and kappa carbide, so that the low-density steel has high strength and good plasticity, and the strength and elongation product is larger than 50 GPa.%.

Owner:马鞍山学院

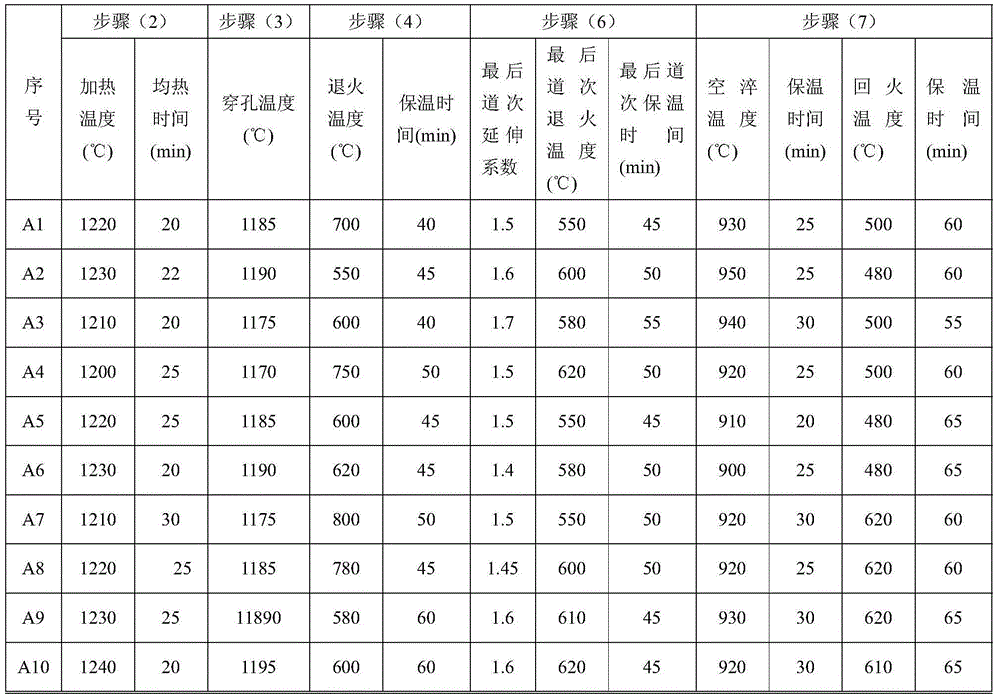

High-strength steel, high-strength plastic seamless steel pipe for automotive driver shafts and manufacturing method of high-strength plastic seamless steel pip

The invention discloses high-strength steel. The high-strength steel comprises the following chemical elements in percentage by mass: 0.07% to 0.15% of C, 0.1% to 1.0% of Si, 2.0% to 2.6% of Mn, 0.05% to 0.6% of Ni, 0.2% to 1.0% of Cr, 0.1% to 0.6% of Mo, 0.001% to 0.006% of B, 0.05% to 0.50% of Cu, 0.015% to 0.060% of Al, 0.02% to 0.1% of Nb, 0.02% to 0.15% of V, and the balance Fe and unavoidable impurities. Correspondingly, the invention further discloses a high-strength plastic seamless steel pipe for automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is manufactured by the high-strength steel. In addition, the invention further discloses a manufacturing method of the high-strength plastic seamless steel pipe for the automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is high in strength, high in strength and ductility product and good in anti-torsion fatigue performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing method for improving extensibility of commonly-cooled ferrite lightweight steel

ActiveCN104928456AOptimizing the Manufacturing ProcessIncreased elongation and strength-plastic productSteel platesDuctility

Owner:BAOSHAN IRON & STEEL CO LTD

Ultra-low-carbon cryogenic steel and heat treatment technique thereof

The invention provides ultra-low-carbon cryogenic steel and a heat treatment technique thereof. The ultra-low-carbon cryogenic steel comprises the elements of, by mass, 0.005-0.01% of C, 1.0-4.5% of Ni, 6.0-12.0% of Mn, 1.0-3.0% of Al, 0.5-3.0% of Cu, 0.005% or less of P, 0.003% or less of S, 0.005-0.008% of N, 0.0005-0.002% of O and the balance Fe. According to the ultra-low-carbon cryogenic steel and the heat treatment technique thereof, through the TRIP effect of retained austenite and precipitation hardening of a nano-precipitate phase, the high-strength ultra-low-carbon nickel-saving nano-precipitate reinforced cryogenic steel is prepared and obtained, has good strength, excellent plasticity and good weldability and is low in cost, and the heat treatment technique is simple.

Owner:SHANGHAI JIAO TONG UNIV

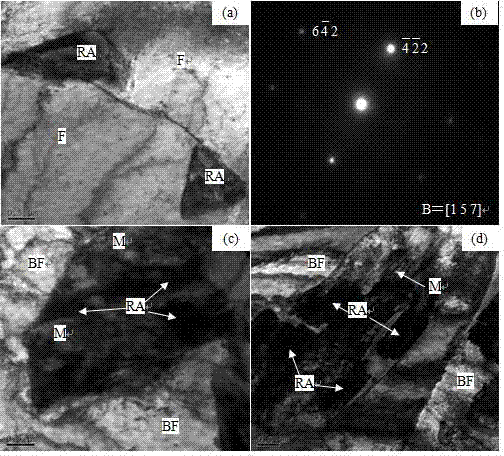

Heat treatment process for 980 MPa grade automotive steel with high product of strength and elongation

InactiveCN103555902AIncrease productivityShort heat treatment process timesPartitioned systemsHeat treated

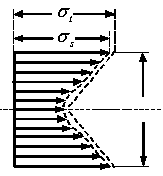

The invention belongs to the technical field of heat treatment of materials, and particularly relates to a heat treatment process for 980 MPa grade automotive steel with a high product of strength and elongation. The heat treatment process disclosed by the invention comprises the following steps: carrying out heat preservation on a TRIP780 cold-rolled steel plate subjected to pretreatment for 2-5 min at a temperature of 820-840 DEG C; then, after the heat preservation is completed, rapidly cooling the steel plate to 230-250 DEG C, and carrying out heat preservation on the steel plate for 5-10 s; and after the steel plate is quenched, rapidly heating the steel plate, controlling the partitioning temperature at 400-420 DEG C and controlling the partitioning time at 30-60 s; and finally, carrying out water quenching on the steel plate so as to obtain 980 MPa grade automotive steel with a product of strength and elongation of 26300-26800 MPa % and a percentage elongation of 23.8-24.2%. According to the technical scheme of the invention, through the reasonable mutual cooperation of austenitizing, quenching and partitioning systems, automotive steel with a higher product of strength and elongation is produced.

Owner:NORTHEASTERN UNIV

Heat treatment process for Q&P980 steel

InactiveCN103555894AIncreased strength and plasticityIncrease contentPartitioned systemsHeat treated

The invention belongs to the technical field of heat treatment of materials, and particularly relates to a heat treatment process for Q&P980 steel. The heat treatment process for Q&P980 steel comprises the following specific steps that firstly, carrying out heat preservation on a Q&P980 cold-rolled steel plate subjected to pretreatment for 2-5 min at a temperature of 800-820 DEG C; then, after the heat preservation is completed, rapidly cooling the steel plate to 230-250 DEG C, carrying out heat preservation on the steel plate for 5-10 s, and after the steel plate is quenched, carrying out partitioning on the steel plate, wherein the partitioning temperature is 380-420 DEG C, and the partitioning time is 30-60 s; and finally, carrying out water quenching on the steel plate so as to obtain steel with a product of strength and elongation of 25000-25100 MPa % and a percentage elongation of 23.8-24%. According to the technical scheme of the invention, through the reasonable mutual cooperation of austenitizing, quenching and partitioning systems, the product of strength and elongation of the Q&P980 steel is improved.

Owner:NORTHEASTERN UNIV

Q&P steel with gradient structure and manufacturing method thereof

InactiveCN105463307AIncreased strength and plasticityEnsure process stabilitySolid state diffusion coatingCarburizingAustenite

The invention discloses Q&P steel with a gradient structure. The Q&P steel comprises, by weight percent, 0.14-0.29% of C, 1.1-2.8% of Si, 1.8-3.0% of Mn, 0.5-1.9% of Cr, 1.5-3.1% of Al, smaller than or equal to 0.01% of S, smaller than 0.01% of P and the balance Fe. A manufacturing method of the Q&P steel includes the steps of austenitizing, carburizing, quenching, tempered carbon distributing and quenching. According to the Q&P steel and the manufacturing of the Q&P steel, technology stability and organization gradient can be ensured in production of large-size products, strength of the steel is improved, good toughness of the steel is also ensured, and low alloying cost is low.

Owner:ZHONGBEI UNIV

Production method of quenched and tempered high-strength Q890E super-thick steel plate

ActiveCN103555911AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q890E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.30-1.40% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.30-0.50% of Cr, 0.45-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q890E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

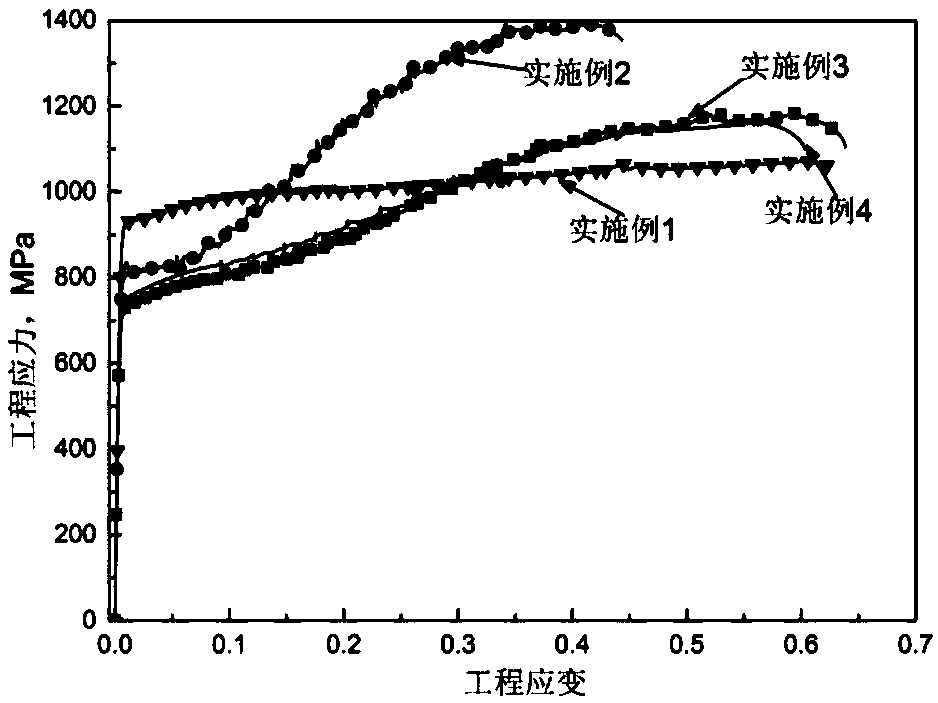

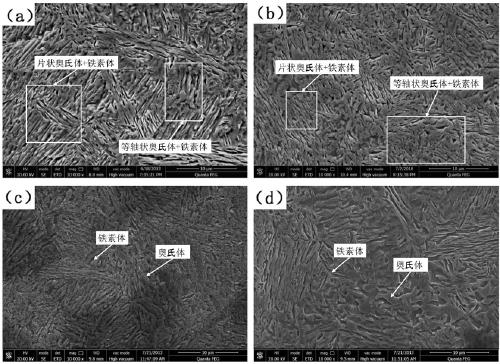

High-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and preparation method

ActiveCN109666862AHigh work hardening rateIncreased strength and plasticityChemical compositionPerformance index

The invention discloses high-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and a preparation method, and belongs to the field of high-toughness automobile steel. The steel comprises the following chemical components of, in percentage by weight, 0.35-0.40% of C, 6.00 -6.30% of Mn, 2.20-2.35% of Al, 0-0.027% of Nb, 0.030 -0.074% of Si, 0.05% of P,0.02% of S, and the balance Fe and inevitable impurities. The preparation method comprises the steps of raw material preparation, smelting, casting, forging, hot rolling and two-phase region annealing. According to the high-toughness hot-rolled medium manganese steel, strength of extension is 1039-1183 MPa, after-fracture elongation rate is 43.5-64.8%, strength-ductility balance can reach more than 60 GPa.%, but not greater than 72GPa.%. Through reasonable component proportion and optimized two-phase region annealing process, morphology and proportion of a two-phase structure are controlled, TRIP and TWIP effects are effectively simulated to reach a high work hardening rate, the strength and the toughness of the medium manganese steel are greatly improved, and performance indexes of different components of an automobile are met.

Owner:UNIV OF SCI & TECH BEIJING

Automobile steel with high toughness and high product of strength and elongation and preparation method thereof

ActiveCN111575580AIncreased strength and plasticityHigh alloy contentMechanical propertyImpact toughness

The invention discloses automobile steel with high toughness and high product of strength and elongation and a preparation method thereof, and belongs to the technical field of preparation of automobile steel with high toughness and high product of strength and elongation. The steel comprises, by weight, 0.15%-0.60% of C, 0%-2.0% of Si, 0%-2.0% of Ni, 3.0-6.0% of Mn, 2.0-6.0% of Al, and the balance of Fe and inevitable impurity elements. On this basis, one or more of the following microalloying elements can be added: by weight, 0-0.10% of Nb, 0-0.10% of V, 0-0.10% of Ti, 0-0.10% of Mo, 0-0.50%of Cu, and 0.0005-0.005% of B. The automobile steel and the preparation method have the advantages that a multi-phase, multi-layer and metastable microstructure is formed through alloying of C, Mn, Al and the like and rolling and annealing of a two-phase region; at -40 DEG C, the V-type impact toughness is not smaller than 120 J, the product of strength and elongation is not lower than 50 GPa%, the cost is far lower than that of traditional high manganese steel, the comprehensive mechanical property is far higher than that of medium manganese steel, and low cost and high performance are achieved. The automobile steel can be applied to the field of white automobile body and transmission part manufacturing in the form of bars or plates.

Owner:CENT IRON & STEEL RES INST

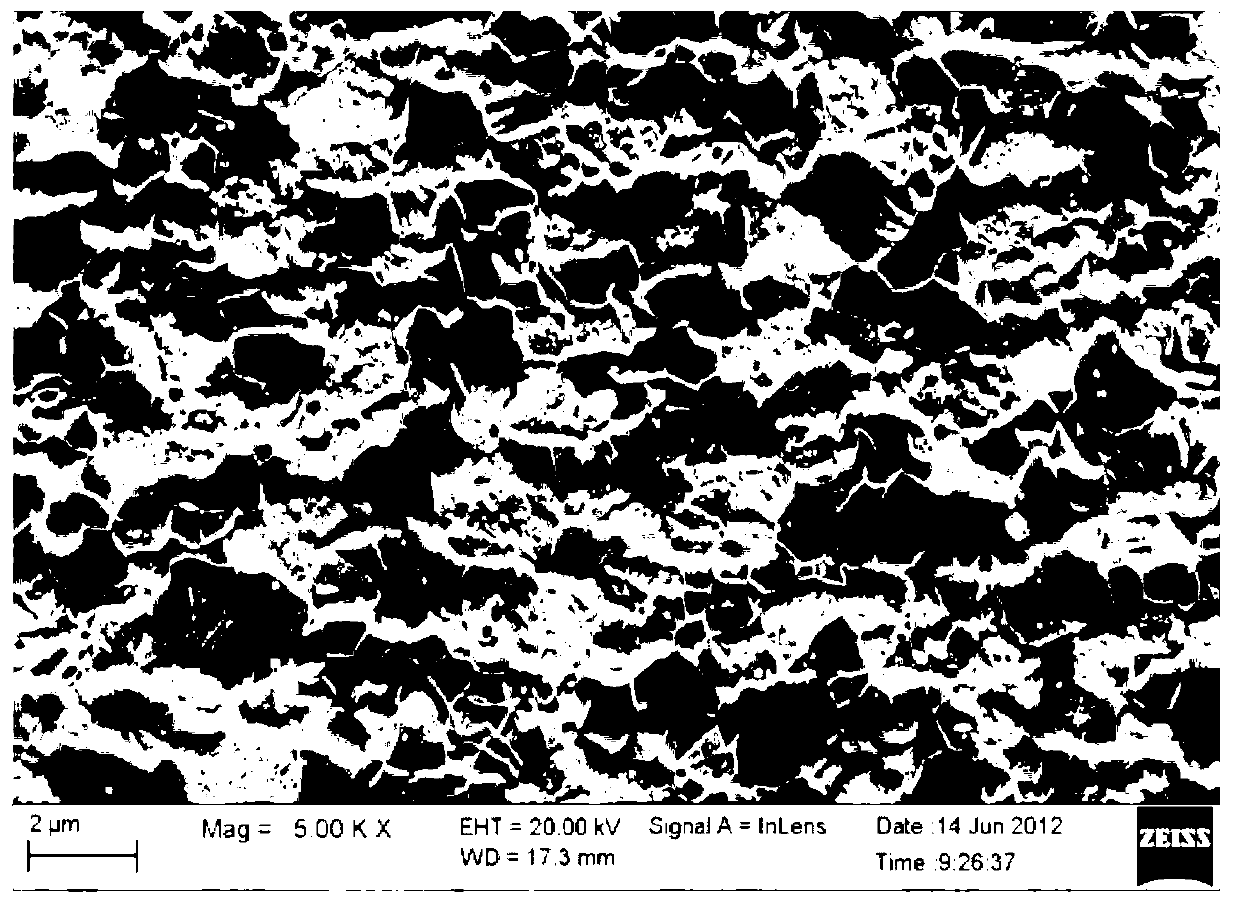

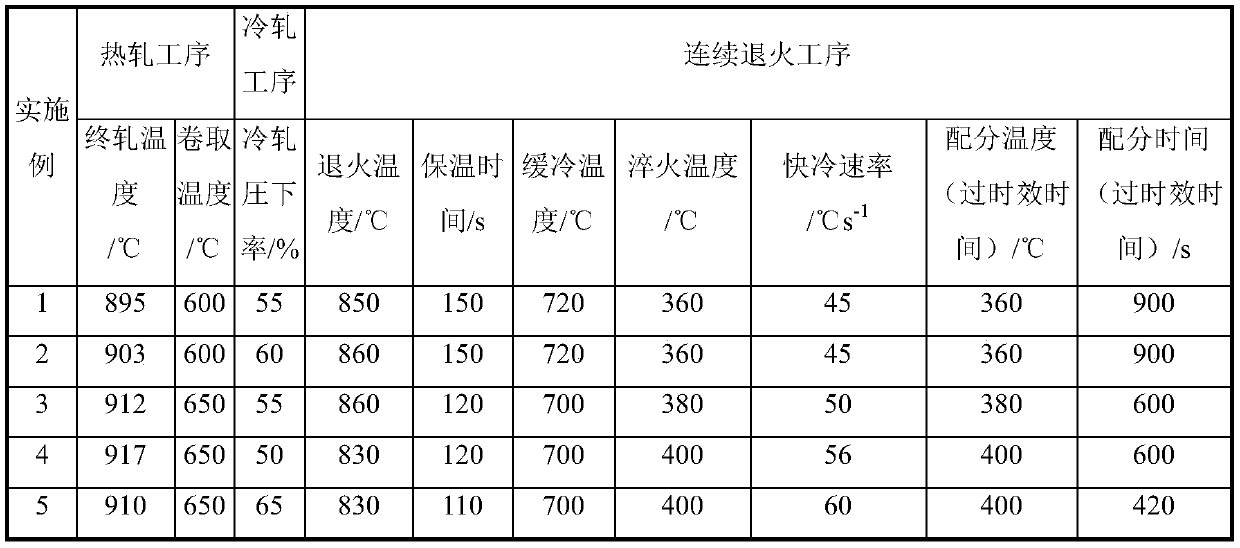

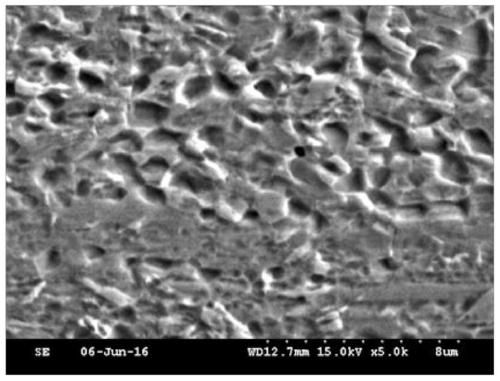

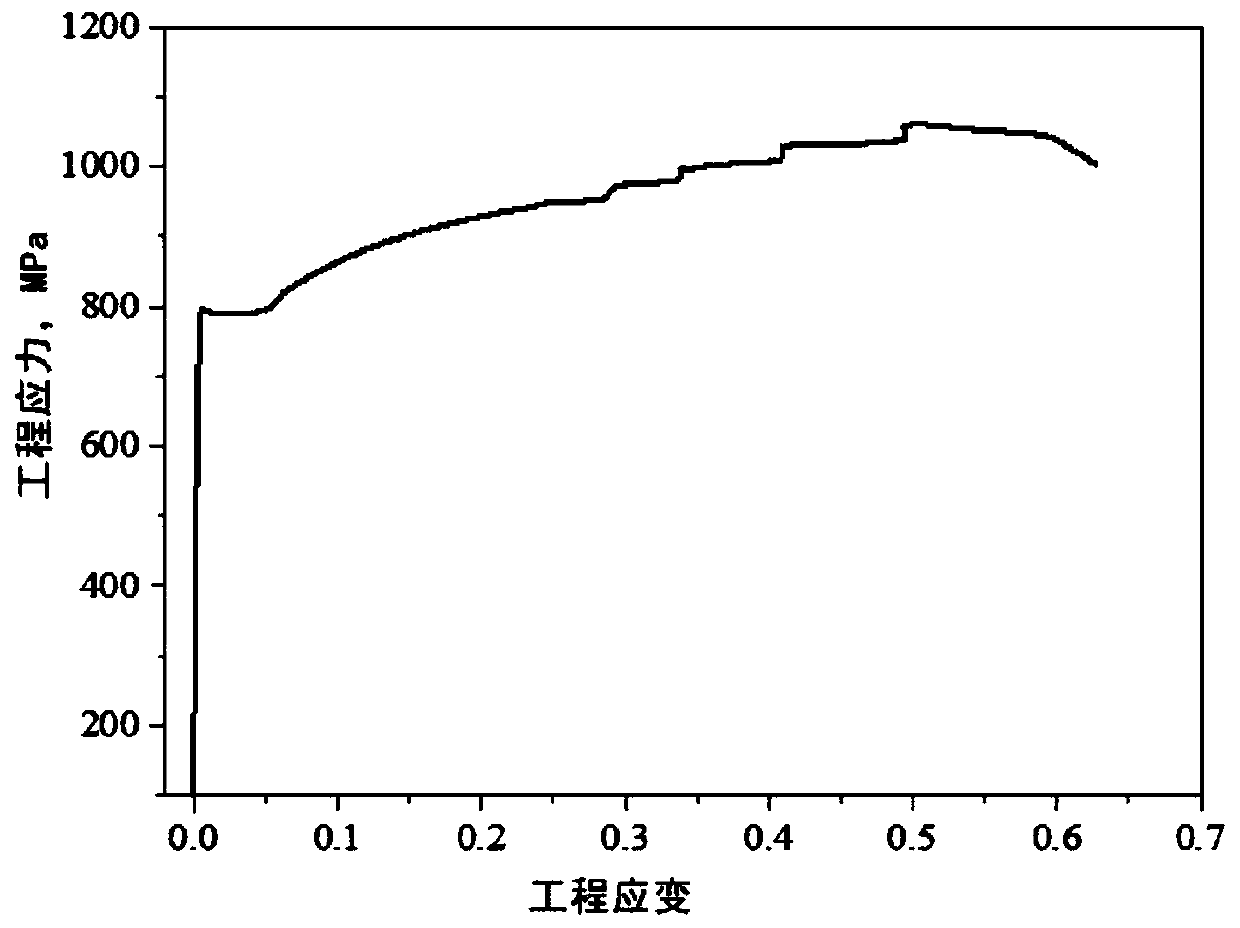

800 MPa grade high-strength plastic product Q&P steel plate and preparation method thereof

ActiveCN110129673AEasy to implementEasy to controlProcess efficiency improvementProduction lineCold formed

The invention discloses a 800 MPa grade high-strength plastic product Q&P steel plate and a preparation method thereof, and belongs to the technical field of cold-rolled automobile steel production. The steel plate comprises the following chemical components of, in percentage by weight, 0.38%-0.42% of C, 0.10%-0.30% of Si, 0.80%-1.20% of Mn, 2.80%-3.20% of Al, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, less than or equal to 0.0060% of N, the balance Fe and inevitable impurity elements. The preparation method comprises the following steps of smelting; continuous casting; hot rolling; acid pickling; cold rolling; and continuous annealing, specifically, heating a cold-rolled plate to 830-860 DEG C during continuous annealing, then slowly cooling to 700-730 DEG C, finally, rapid cooling cold-rolled plate to 350-400 DEG C at 40-60 DEG C per second cooling rate to carry out overaging distribution treatment. The Q&P steel plate has advantages that the mechanical property is excellent, the yield strength is larger than or equal to 480 MPa, the tensile strength is larger than or equal to 800 MPa, the elongation percentage is greater than or equal to 25%, the n isgreater than or equal to 0.20, the yield ratio is less than or equal to 0.75, and the cold forming property is good. The Q&P steel plate and the preparation method have low requirements on process equipment, and are suitable for production of an existing continuous annealing production line.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

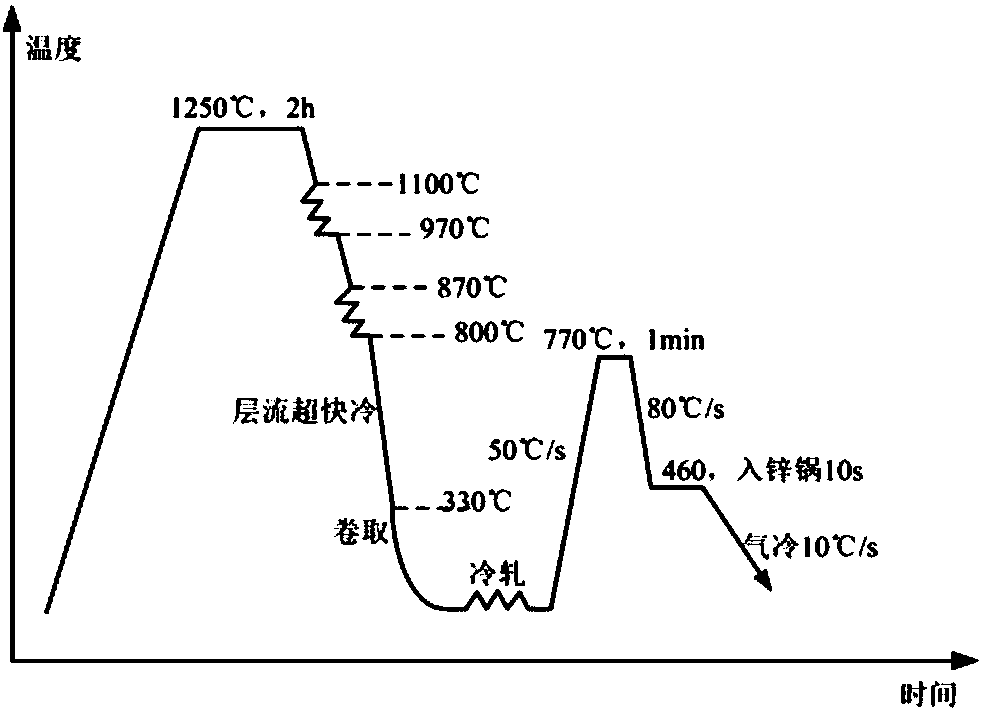

Preparation method of high-strength hot galvanizing Q&P steel

InactiveCN104630647AIncreased strength and plasticitySimple processHot-dipping/immersion processesQuenchingCarbon alloy

The invention discloses a preparation method of high-strength hot galvanizing Q&P steel. The preparation method is characterized by comprising the following steps: preparing low-carbon alloy steel into a to-be-used steel product; heating the to-be-used steel product to an austenitizing temperature and keeping the temperature for 3-5 minutes; performing primary quenching cooling in a cooling cavity with a protective gas until the temperature is between an Ms point and an Mf point, and keeping the temperature for 0.5-3 minutes; heating to 450-500 DEG C, performing distribution processing, keeping the temperature for 0-5 minutes, quickly adding into a constant-temperature galvanizing bath isothermal with the steel product, performing hot galvanizing, further performing distribution processing, and keeping the temperature for 10-60 seconds; and performing secondary quenching cooling until the temperature is reduced to the room temperature. By adopting the preparation method disclosed by the invention, the aim of simultaneously finishing a Q&P process and hot galvanizing treatment is achieved, the process flow is simplified, the production efficiency is improved, and high-strength hot galvanizing alloy steel is prepared.

Owner:DALIAN UNIV OF TECH

Cold-rolling medium Mn steel with low Mn content and high product of strength and ductility, and preparation method for same

The invention provides cold-rolling medium Mn steel with a low Mn content and a high product of strength and ductility, and a preparation method for the same. The steel contains, by weight, the chemical components including 0.15%-0.6% of C, 3.0%-6.0% of Mn, 1.0%-3.0% of Al, 0.0%-2.0% of Si, 0%-5.0% of Cr, 0%-2.0% of Ni and the balance being Fe and inevitable impurities. Preparation of the cold-rolling medium Mn steel with the high product of strength and ductility comprises the steps that molten steel is smelted by a converter, and a continuous casting blank is obtained through continuous casting; the continuous casting black is heated by a heating furnace, and a hot-rolling plate roll is obtained after hot rolling; the hot-rolling roll is treated with softening annealing by a bell furnace, and cold and hard belt steel is obtained after cold rolling; and the cold and hard belt steel is treated with continuous annealing, and the finished product of the cold-rolling medium Mn steel withthe high product of strength and ductility is obtained. The cold-rolling medium Mn steel and the preparation method provided by the invention have the beneficial effects that the Mn steel has the highproduct of strength and ductility on the premise that good ductility is ensured during cold rolling; and the significance of practical application is high.

Owner:SHOUGANG CORPORATION

Production method of quenched and tempered high-strength Q500D super-thick steel plate

ActiveCN103556075BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

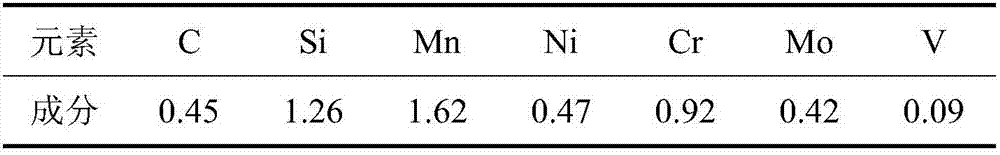

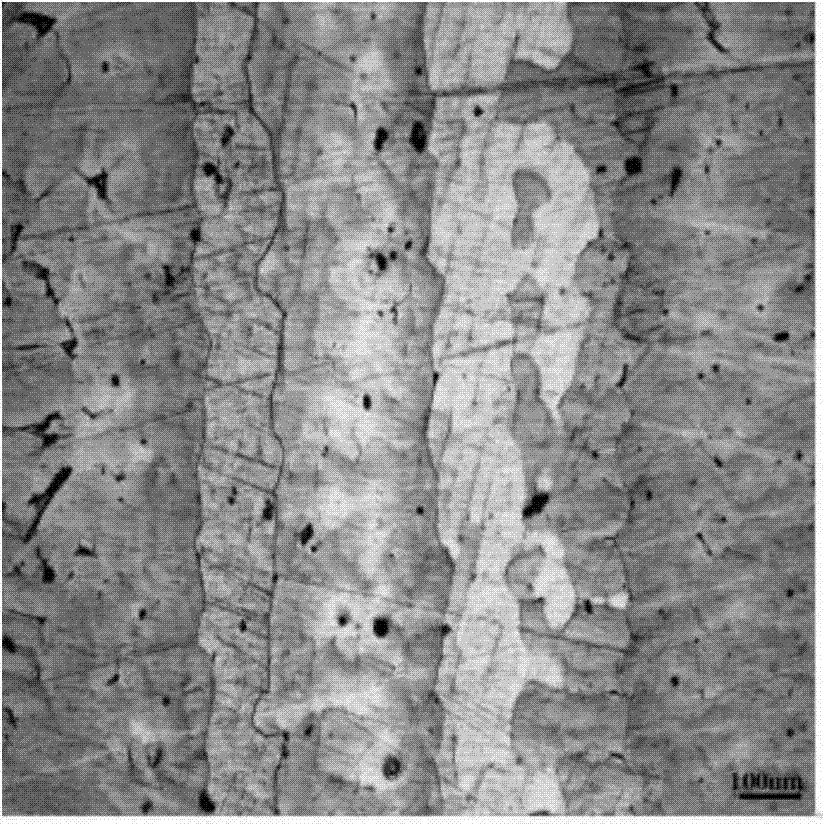

Third-generation high-strength high-toughness automobile steel and preparation method thereof

The invention provides third-generation high-strength high-toughness automobile steel and a preparation method thereof, and belongs to the technical field of metal material processing. The automobile steel comprises the following alloy components in percentage by weight: 0.40-0.60% of C, 1.00-2.00% of Si, 1.50-3.00% of Mn, 0-0.60% of Ni, 0.50-1.50% of Cr, 0.30-0.60% of Mo, 0-0.20% of V, 0-1.50% of Co, 0-1.50% of Al, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: carrying out casting after vacuum smelting, and then carrying out hot rolling at a total reduction rate of 80-95% to obtain a hot-rolled plate; heating the obtained hot-rolled plate to 900-970 DEG C at the speed of 5-20 DEG C / s, and carrying out austenitization for 10-20 min; and then, carrying out air cooling to 250-320 DEG C and carrying out heat preservation for 2-12 h. According to the automobile steel provided by the invention, the yield strength, the tensile strength and the elongation after fracture exceed 1000 MPa, 1500 MPa and 20% correspondingly, and both the strength and the plasticity are high; meanwhile, the preparation process is simple, the welding performance is good, and the formability is high; and accordingly, the automobile steel is suitable for industrialized production, and applicable to cross beams of front and rear bumpers in an automobile body structure, thereby guaranteeing the automobile safety.

Owner:UNIV OF SCI & TECH BEIJING

Ultrahigh-strength and ductility low-cost titanium alloy and preparation method and application thereof

The invention relates to ultrahigh-strength and ductility low-cost titanium alloy. The titanium alloy is prepared from Ti, Mo, Cr, Al and Fe, wherein the mass of Ti is more than 75% of the total massof the titanium alloy. The invention further provides a preparation method of the titanium alloy. In order to reduce the total cost of the titanium alloy, preferably, Mo, Cr, Al and Fe elements in thealloy are added in the form of intermediate alloy of Al-Mo, Mo-Fe and Cr-Fe. The ultrahigh-strength and ductility low-cost titanium alloy has ultrahigh strength and ductility, has ideal yield strength, high ductility and good work hardening rate, can be processed into rods, plates, profiles and the like, has the advantage of low use cost and has high application values in the field of aviation, aerospace, marine exploration, shipbuilding and / or automobile making.

Owner:BEIHANG UNIV

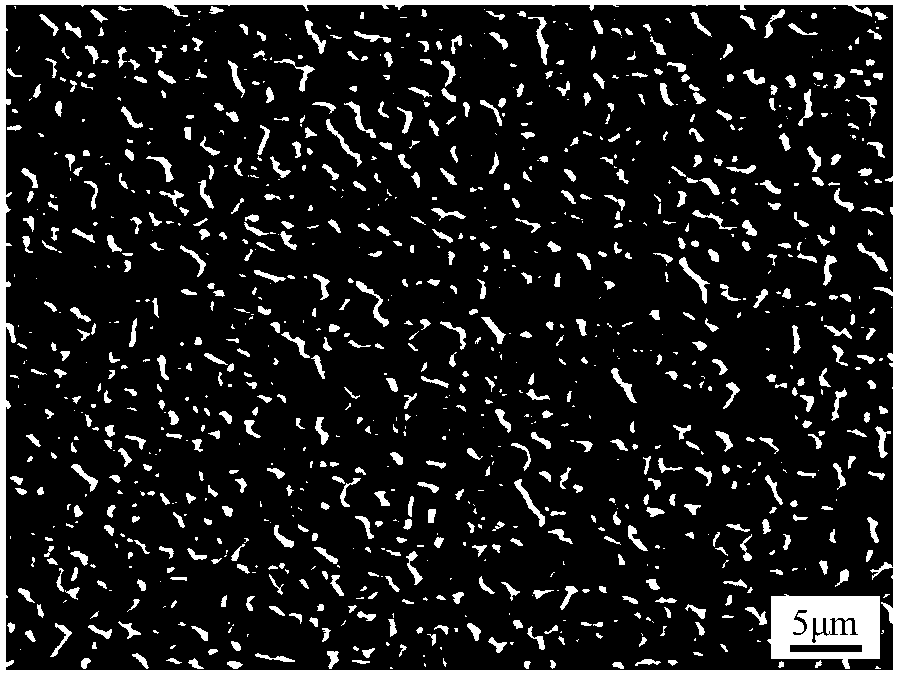

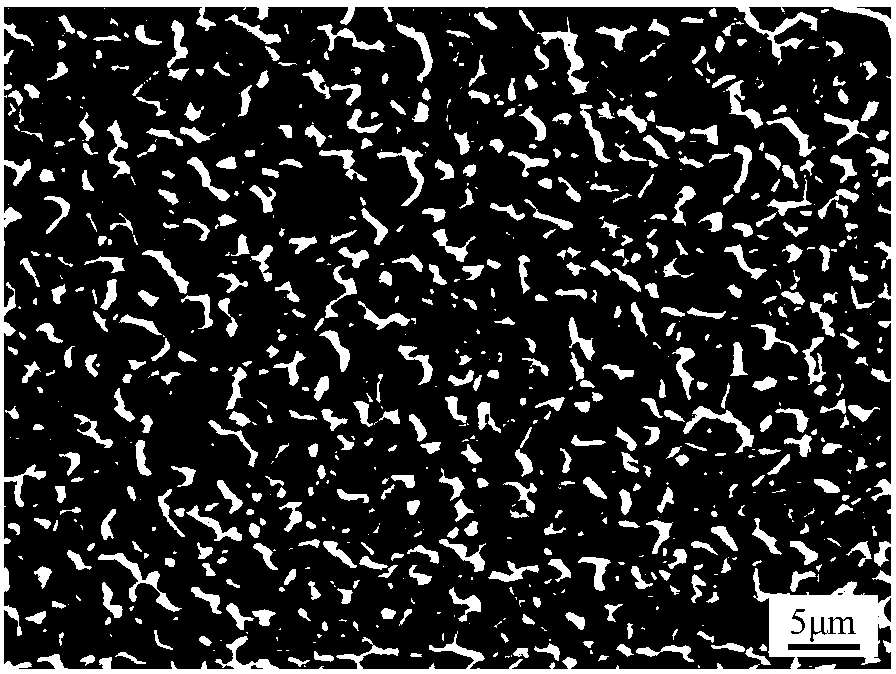

High-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and production method thereof

ActiveCN107829038ALow costReduce selective oxidationHot-dipping/immersion processesChemical compositionStrip steel

The invention discloses a high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and a production method thereof, and belongs to the field of metallurgy materials. Thechemical components of the high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel are, by weight, 0.08%-0.12% of C, 1.8%-2.5% of Mn, less than 0.005% of Si, 0.3%-0.5% of Al, 0.04%-0.08% of P, 0.03%-0.06% of Nb, 0.02%-0.05% of Ni, less than 0.005% of S and the balance iron. The production method comprises the steps of vacuum smelting, blank forging, first-stage austenite recrystallization zone rolling, second-stage two-phase zone hot rolling, multi-pass cold rolling and rapid annealing. According to the high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and the production method thereof, the selective oxidation of alloy elements in the annealing process can be greatly reduced, platability of the steel is improved, and the structure and the performance of the strip steel are optimized.

Owner:NORTHEASTERN UNIV LIAONING

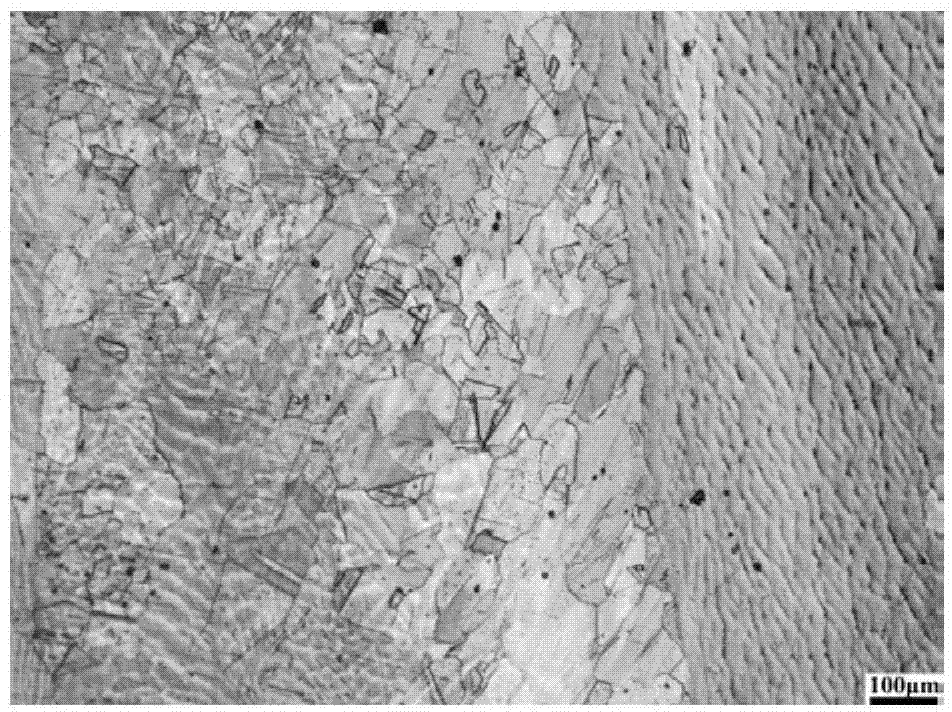

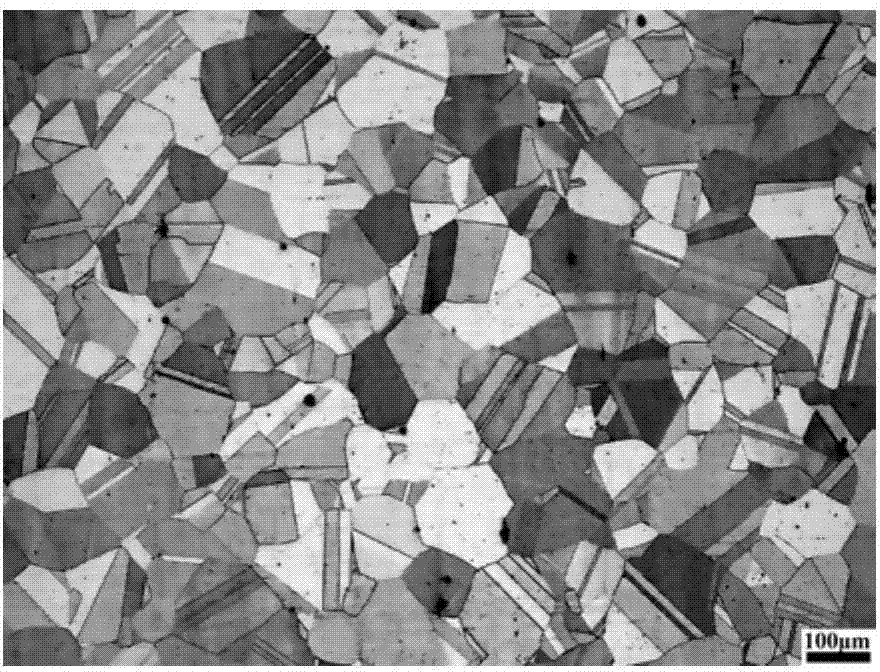

High product of strength and elongation alloy steel in columnar crystal/isometric crystal composite crystal structure and preparation method thereof

The invention discloses a high product of strength and elongation alloy steel in a columnar crystal / isometric crystal composite crystal structure and a preparation method thereof. The alloy steel is composed of the following chemical components by mass percent: 25-35 of Mn, 2.5-3.5 of Al, 2.7-3.4 of Si, 0.05-0.50 of C, and the balance of Fe. The formation principle of the complex tissue is as follows: growing a certain amount of isometric crystals on the basis of directionally solidified and formed columnar crystal tissue through plastic deformation and recrystallization annealing, wherein the columnar crystal is in favor of improving the axial plasticity, and the isometric crystal is in favor of improving the whole intensity of the material so as to simultaneously improve the material strength and the plasticity; the specific value can regulated by changing a relative number of two crystal tissues. Compared with the normal isometric crystal product of strength and elongation alloy steel, the material obtained by virtue of the preparation method disclosed by the invention can be simultaneously provided with high strength and plasticity and high product of strength and elongation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com