800 MPa grade high-strength plastic product Q&P steel plate and preparation method thereof

A high-strength plastic product and steel plate technology, which is applied in the direction of improving process efficiency, can solve the problems of difficulty in batch production, difficulty in implementation, and high soaking temperature requirements, and achieve simple and easy process control, easy implementation and control , the effect of consistent quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

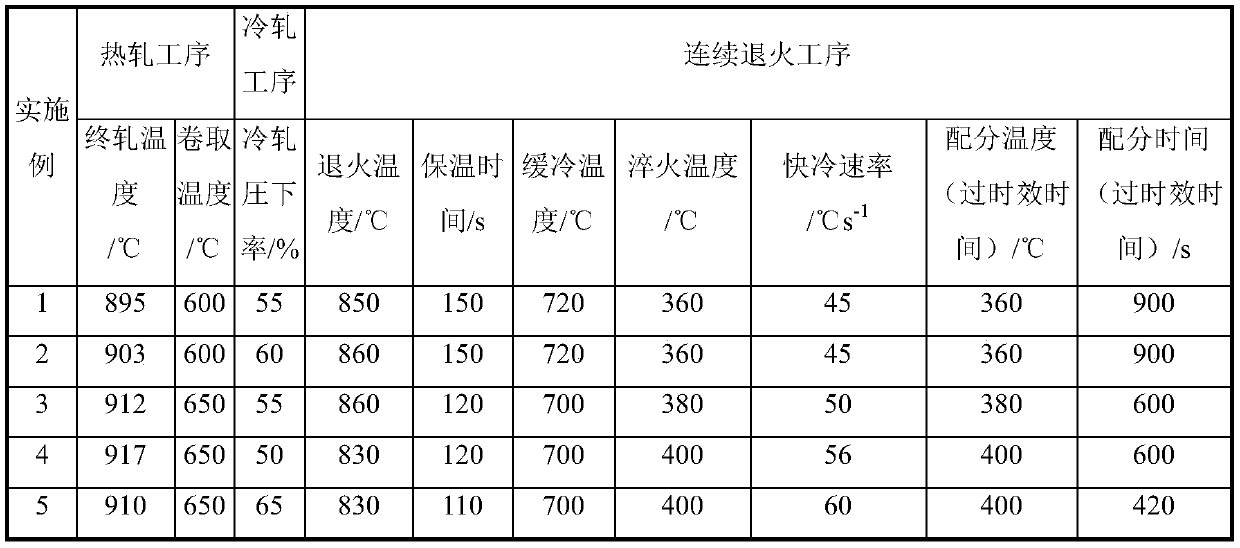

[0035] The present invention will be described in further detail below in conjunction with specific embodiments.

[0036] Smelt in a vacuum induction melting furnace according to the chemical composition ratio in Table 1, and pour into ingots, then forge the ingots into 80mm thick slabs, and carry out hot rolling, pickling, cold rolling and continuous annealing simulations in the laboratory. The process is shown in Table 2. The hot-rolled coiling is simulated by a box-type resistance furnace (the set temperature of the box-type furnace is consistent with the coiling temperature, and it is slowly cooled with the furnace after holding for 2 hours); continuous annealing is carried out on a continuous annealing simulator. Carry out with the set process.

[0037] According to GB / T228-2010 "Metallic Materials Tensile Test Part 1: Room Temperature Test Method", the mechanical properties of the steel plates of Examples 1-5 of the present invention were measured, and the results are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com