Third-generation high-strength high-toughness automobile steel and preparation method thereof

An automotive and high-strength technology, applied in the field of new third-generation automotive steel and its high-efficiency preparation, can solve the problems of increased energy consumption, low elongation, long heat treatment time, etc., and achieves a simple and economical production process with good plasticity. and impact resistance, the effect of short heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

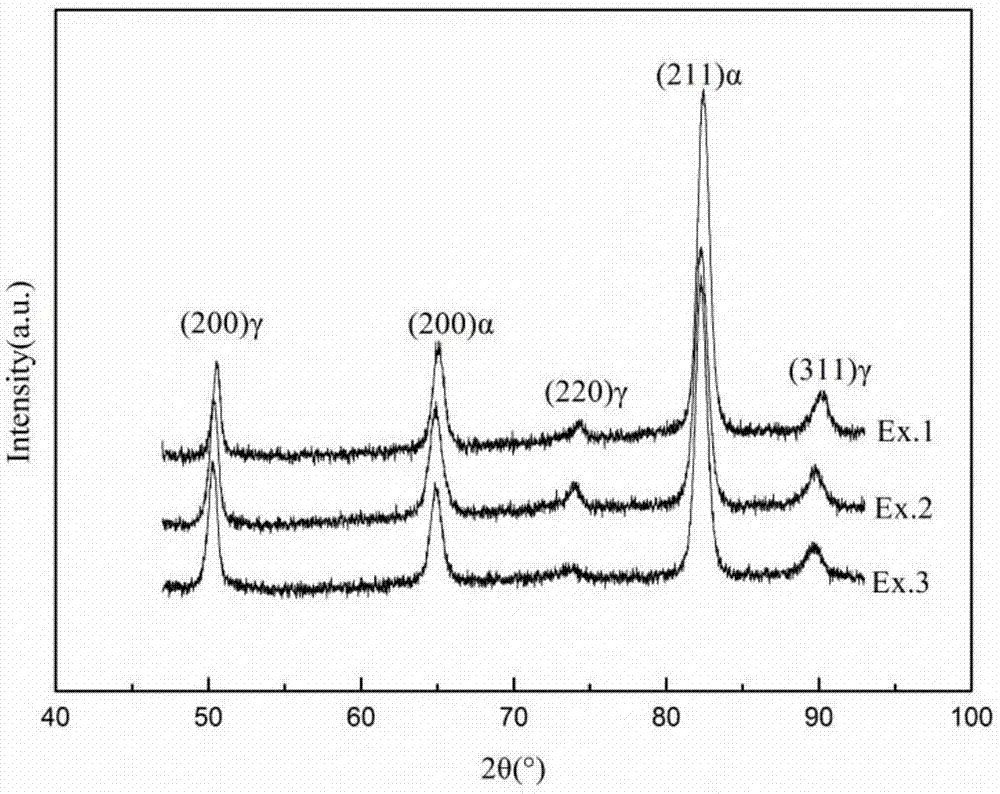

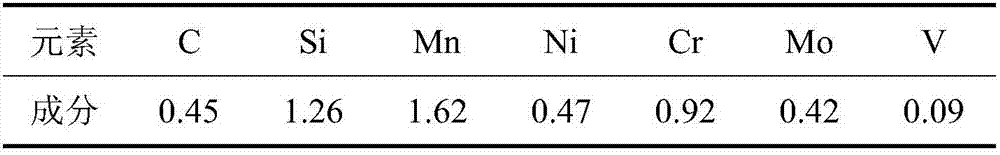

[0038] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, see Table 1.

[0039] Table 1 Slab composition (wt.%)

[0040]

[0041] Heat the 20-50mm thick billet to 1150°C for homogenization for 2 hours, and roll it at 1000°C to form a 1.5-3.5mm thick plate with a total reduction rate of 80-95%.

[0042] The specific heat treatment process parameters of the hot-rolled plate are shown in Table 2.

[0043] Table 2 heat treatment process parameters

[0044]

[0045] The mechanical properties of the high-strength automotive steel prepared according to Table 1 and Table 2 are shown in Table 3.

[0046] Table 3 mechanical properties

[0047]

[0048] Table 4 shows the dimensions of lath bainite and retained austenite in the thickness direction of the high-strength automotive steel prepared according to Table 1 and Table 2.

[0049] Table 4 Dimensions in the direction of tissue ...

Embodiment 2

[0056] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, see Table 6.

[0057] Table 6 Slab composition (wt.%)

[0058]

[0059] Heat the 20-30mm thick casting slab to 1150°C for 2h homogenization, and roll it at 1000°C to form a 1.5-3.5mm thick plate with a total reduction rate of 80-95%.

[0060] The specific heat treatment process parameters of the hot-rolled plate are shown in Table 7.

[0061] Table 7 heat treatment process parameters

[0062]

[0063] The mechanical properties of the high-strength automotive steel prepared according to Table 6 and Table 7 are shown in Table 8.

[0064] Table 8 mechanical properties

[0065]

[0066] Table 9 shows the lath bainite and retained austenite dimensions in the thickness direction of the high-strength automotive steel prepared according to Table 6 and Table 7.

[0067] Table 9 Dimensions in the direction of tissue thickn...

Embodiment 3

[0074] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, see Table 11.

[0075] Table 11 Composition of the slab (wt.%)

[0076]

[0077] Heat the 20-30mm thick casting slab to 1150°C for 2h homogenization, and roll it at 1000°C to form a 1.5-3.5mm thick plate with a total reduction rate of 80-95%.

[0078] See Table 12 for the specific heat treatment process parameters of the hot-rolled sheet.

[0079] Table 12 heat treatment process parameters

[0080]

[0081] The mechanical properties of the high-strength automotive steel prepared according to Table 11 and Table 12 are shown in Table 13.

[0082] Table 13 Mechanical properties

[0083]

[0084] Table 14 shows the dimensions of lath bainite and retained austenite in the thickness direction of the high-strength automotive steel prepared according to Table 11 and Table 12.

[0085] Table 14 Dimensions in the direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com