High-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and preparation method

A technology of tough medium manganese steel and strong plastic product is applied in the field of hot rolled medium manganese steel and its preparation. The effect of increasing the austenite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The chemical composition of steel is: C: 0.40%, Mn: 6.25%, Al: 2.28%, Nb: 0.027%, Si: 0.074%, P: <0.005%, S: 0.011%, and the balance is Fe and unavoidable impurities. After the above ingredients were smelted in a vacuum induction melting furnace for 40 minutes, they were cold-rolled in air to room temperature to obtain steel ingots, heated to 1150°C for 2 hours, and forged into 60×45mm forging billets. The final forging temperature was controlled above 900°C, and air-cooled to room temperature.

[0023] In the laboratory Hot rolling is carried out on a four-roller single-stand reversible hot rolling mill. The forging billet is heated to 1200°C and held for 1.5h. After 5 passes, it is hot-rolled into a steel plate with a thickness of 3mm. The starting rolling temperature is 1150°C and the final rolling temperature is not lower than 900°C, water cooled to 430°C and air cooled to room temperature.

[0024] The hot-rolled steel plate was annealed in the two-phase zone i...

Embodiment 2

[0027] The chemical composition, smelting, forging, and hot-rolling processes of the steel are the same as those in Example 1, except that the annealing process in the two-phase zone is to keep the temperature at 725°C for 20 minutes, and then air-cool to room temperature.

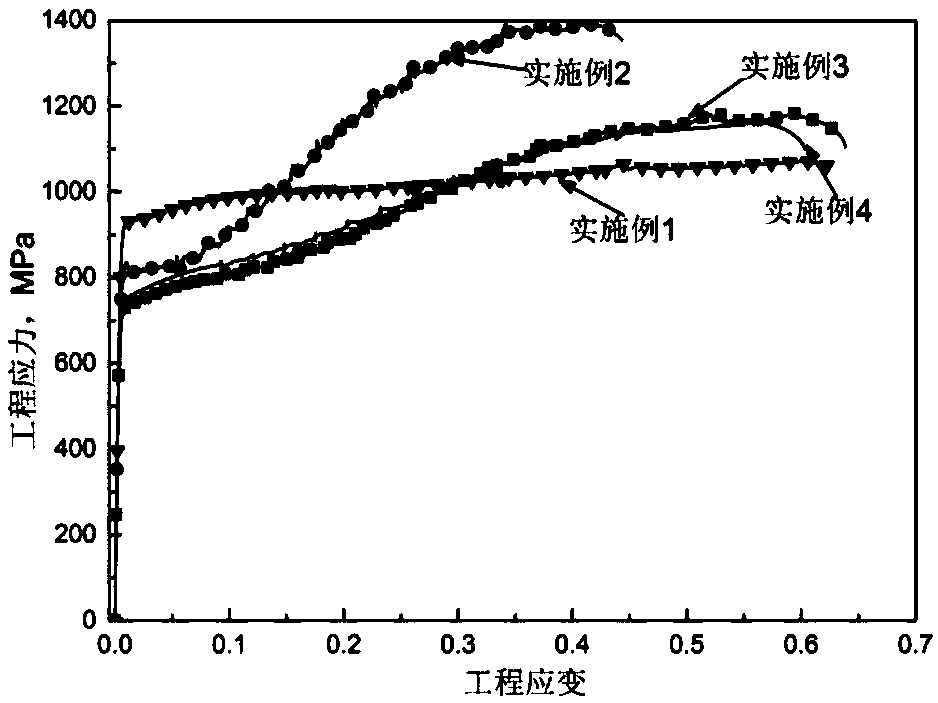

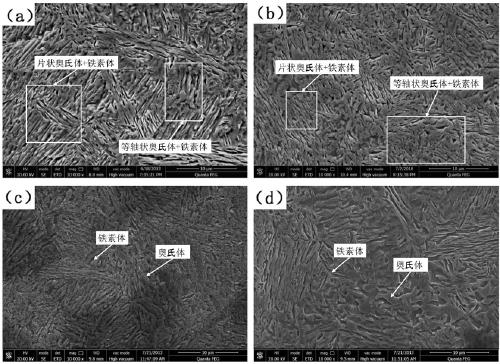

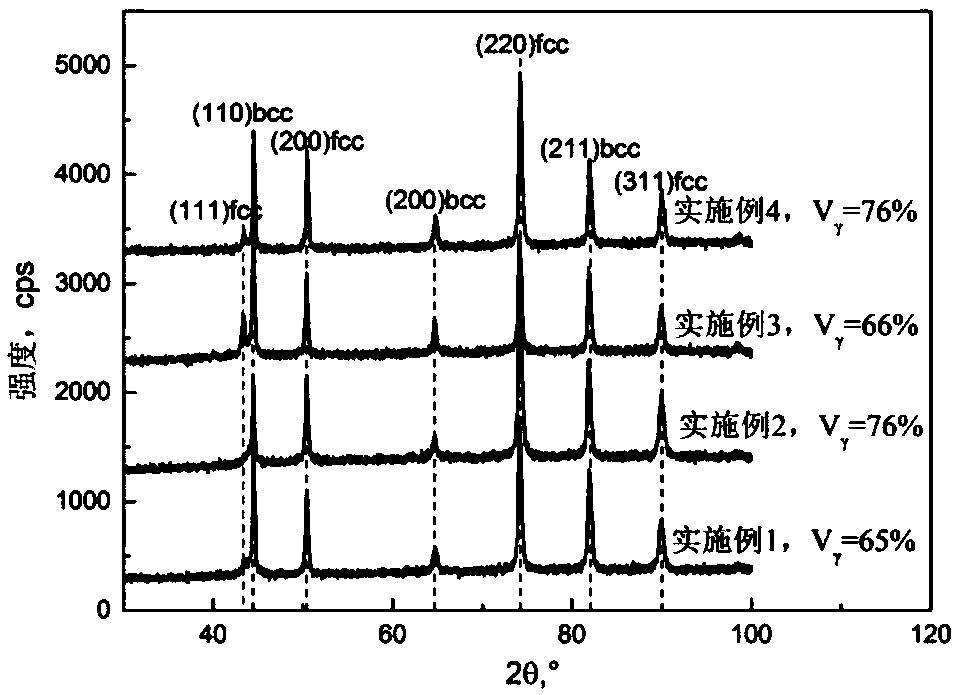

[0028] Perform related performance tests on the hot-rolled medium-manganese steel prepared in this example, and process the heat-treated steel plate into a standard tensile sample according to GB / T228-2002 "Metallic Materials Tensile Test Method at Room Temperature", and the tensile speed is fixed at 2mm / min. The results of mechanical properties are shown in Table 1, and the engineering stress-strain curve is shown in figure 1 As shown, the SEM structure morphology is as figure 2 As shown in (b), the XRD characterization results are as follows image 3 shown. It can be seen that the austenite content of the hot-rolled medium-manganese steel after annealing in the two-phase zone is 76%, the tensile str...

Embodiment 3

[0030] The chemical composition of the steel is: C: 0.39%, Mn: 6.08%, Al: 2.31%, Si: 0.031%, P: <0.005%, S: 0.011%, and the balance is Fe and unavoidable impurities . The above components are smelted and cast into steel ingots in a vacuum induction furnace. The steel ingots are heated to 1150°C for 2 hours, forged into 60×45mm forging billets, and air-cooled to room temperature.

[0031] Heat the forging billet to 1200°C for 1.5h, and hot-roll it into a steel plate with a thickness of 3mm after 5 passes.

[0032]The hot-rolled steel plate was annealed in the two-phase zone in a heating furnace, kept at 700°C for 180min, and air-cooled to room temperature.

[0033] Relevant performance tests were carried out on the hot-rolled medium-manganese steel prepared in this example, and the tensile test was carried out according to GB / T228-2002 "Metal Materials Tensile Test Method at Room Temperature". The results of mechanical properties are shown in Table 1, and the engineering stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com