A high strength and toughness degradable zinc alloy with high work hardening rate and its preparation method and application

A technology of work hardening and zinc alloy, which is applied in surgery, medical science, etc., can solve the problems of uneven deformation, low work hardening rate of zinc alloy, fracture or corrosion, etc., and achieve the effect of good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

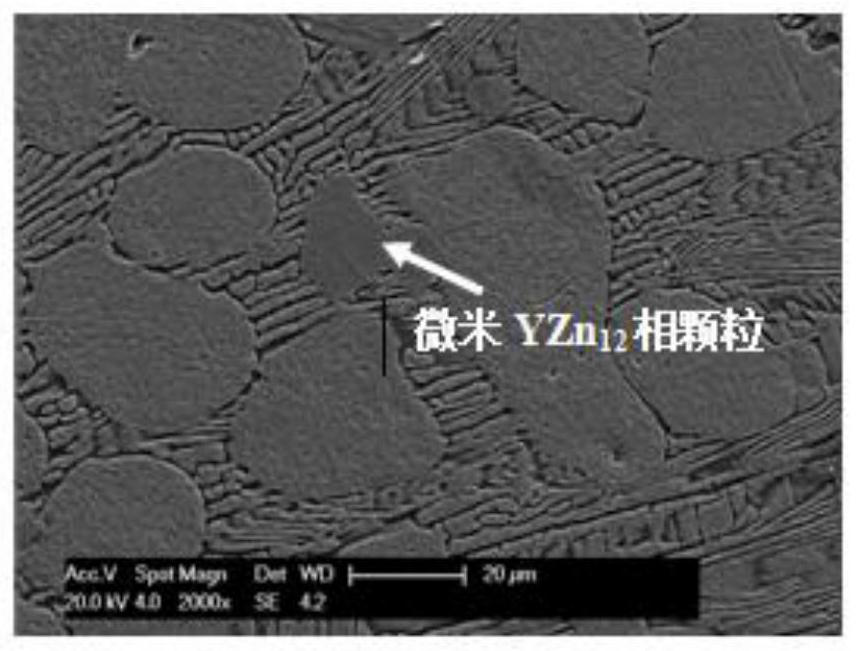

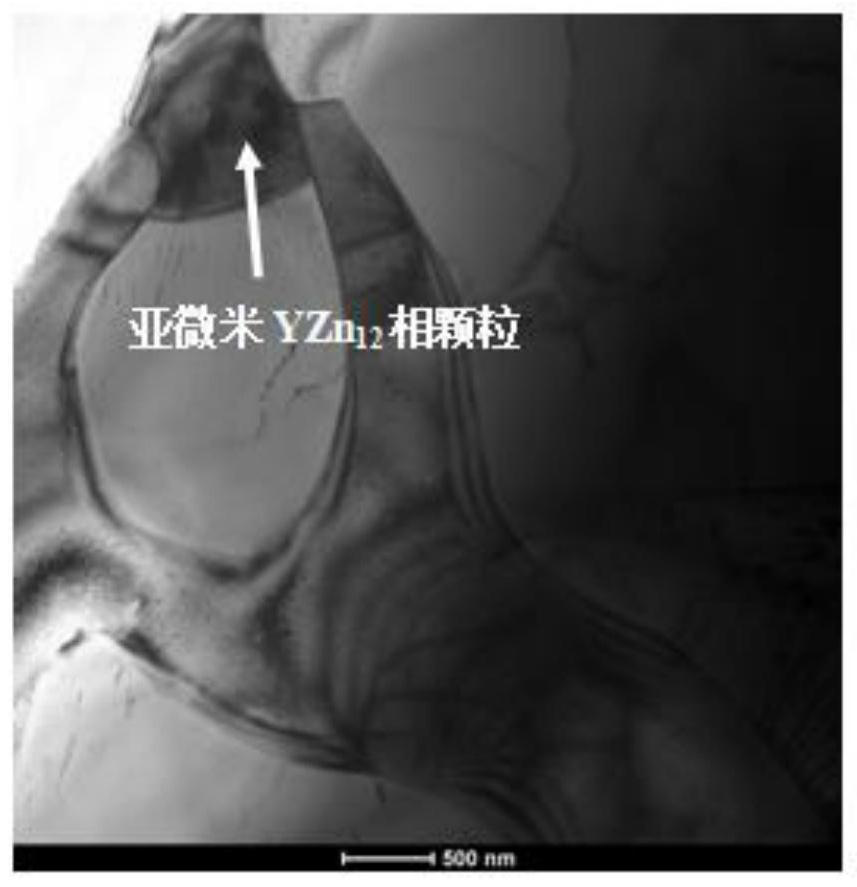

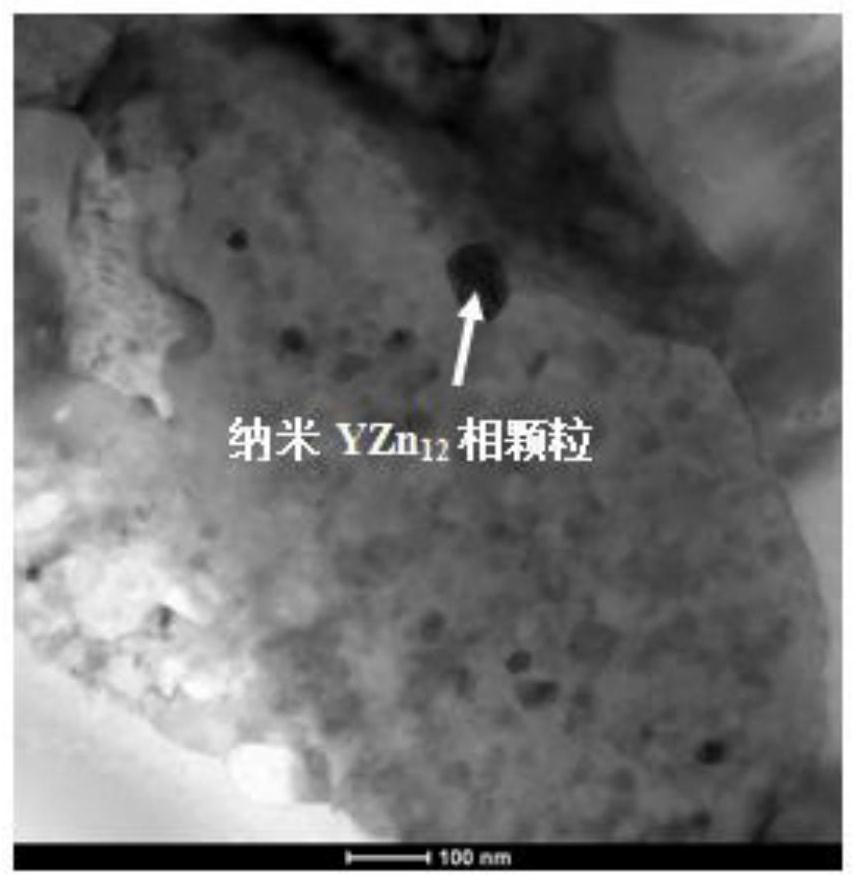

[0034] A high strength and toughness degradable zinc alloy with high work hardening rate, including Zn matrix, Zn+Mg refined and dispersed in Zn matrix 2 Zn 11 Eutectic structure, micron-sized YZn is also dispersed in the Zn matrix 12 , Zn+Mg 2 Zn 11 Submicron YZn is dispersed in the eutectic structure 12 and nanoscale YZn 12 , submicron YZn 12 and nanoscale YZn 12 The area ratio is not greater than 85:15.

[0035] The composition of the zinc alloy is: Mg: 0.8%, Y: 0.1%, the rest is Zn, and the mass ratio of Y to Mg in the alloy is not higher than 0.3.

[0036] The micron-scale YZn 12 The particle size is >2μm; the submicron YZn 12 The particle size is 0.2 ~ 1μm; the nanoscale YZn 12 The particle size is <200nm.

[0037] A method for preparing a high-strength and tough degradable zinc alloy with high work hardening rate, preparing Zn-0.8%Mg-0.1%Y alloy (mass percentage), comprising the following steps:

[0038] (1) Ingredients: weighing according to the ingredients...

Embodiment 2

[0044] A high strength and toughness degradable zinc alloy with high work hardening rate, including Zn matrix, Zn+Mg refined and dispersed in Zn matrix 2 Zn 11 Eutectic structure, micron-sized YZn is also dispersed in the Zn matrix 12 , Zn+Mg 2 Zn 11 Submicron YZn is dispersed in the eutectic structure 12 and nanoscale YZn 12 , submicron YZn 12 and nanoscale YZn 12 The area ratio is not greater than 85:15.

[0045] The composition of the zinc alloy is: Mg: 1.7%, Y: 0.5%, the rest is Zn, and the mass ratio of Y to Mg in the alloy is not higher than 0.3.

[0046] The micron-scale YZn 12 The particle size is >2μm; the submicron YZn 12 The particle size is 0.2 ~ 1μm; the nanoscale YZn 12 The particle size is <200nm.

[0047] A preparation method of a high-strength and tough degradable zinc alloy with a high work hardening rate, prepares Zn-1.7%Mg-0.5%Y alloy (mass percentage), and its preparation method is as follows:

[0048] (1) Ingredients: weighing according to the...

Embodiment 3

[0052] A high strength and toughness degradable zinc alloy with high work hardening rate, including Zn matrix, Zn+Mg refined and dispersed in Zn matrix 2 Zn 11 Eutectic structure, micron-sized YZn is also dispersed in the Zn matrix 12 , Zn+Mg 2 Zn 11 Submicron YZn is dispersed in the eutectic structure 12 and nanoscale YZn 12 , submicron YZn 12 and nanoscale YZn 12 The area ratio is not greater than 85:15.

[0053] The composition of the zinc alloy is: Mg: 1.5%, Y: 0.3%, the rest is Zn, and the mass ratio of Y to Mg in the alloy is not higher than 0.3.

[0054] The micron-scale YZn 12 The particle size is >2μm; the submicron YZn 12 The particle size is 0.2 ~ 1μm; the nanoscale YZn 12 The particle size is <200nm.

[0055] A preparation method of a high-strength and tough degradable zinc alloy with a high work hardening rate, prepares Zn-1.5%Mg-0.3%Y alloy (mass percentage), and its preparation method is as follows:

[0056] (1) Ingredients: weighing according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com