Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "High uniform elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and manufacturing method thereof

The invention discloses ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and a manufacturing method of the ultralow yield ratio 980 MPa-grade cold rolling two-phase steel, and belongs to the technical field of two-phase steel. Chemical components of the steel comprise, by weight, 0.13-0.18% of C, 0.3-0.6% of Si, 1.7-2.4% of Mn, 0.03-0.06% of Als, 0-0.05% of Nb, 0.3-0.5% of Cr and the balance Fe and inevitable impurities. In composition design, the composite strengthening way mainly comprising phase transformation strengthening and combining solid solution strengthening, refined crystalline strengthening, phase change strengthening and precipitation strengthening is adopted, the cold rolling two-phase steel plate can be used as an automobile anti-collision part, a structural part and an inner plate material. The steel has the advantages that DP980 has the ultralow yield ratio YS / TS which is smaller than 0.50, good ductility A50 which is larger than or equal to 14%, the high n value, the small mechanical property fluctuation range, the low process sensitivity and other property characteristics, can reduce springback after stamping and is beneficial to follow-up deep processing of the automobile industry.

Owner:CENT IRON & STEEL RES INST

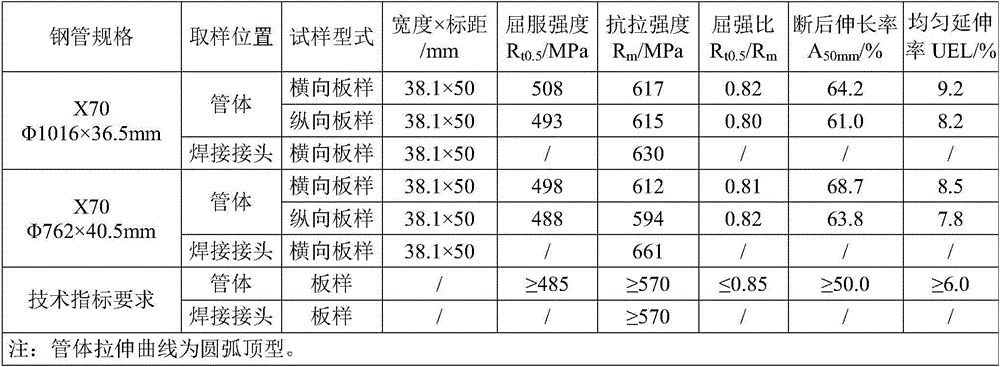

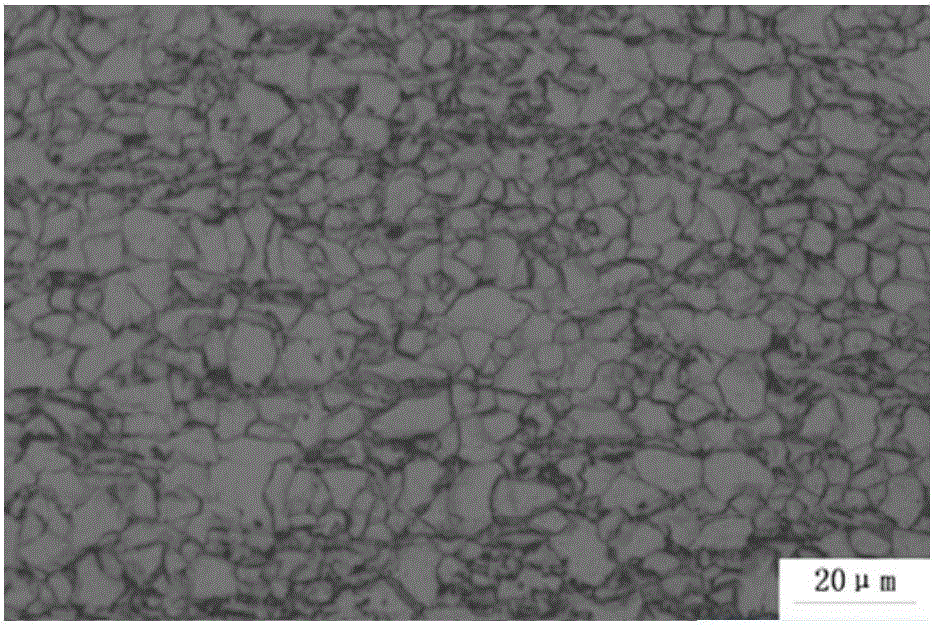

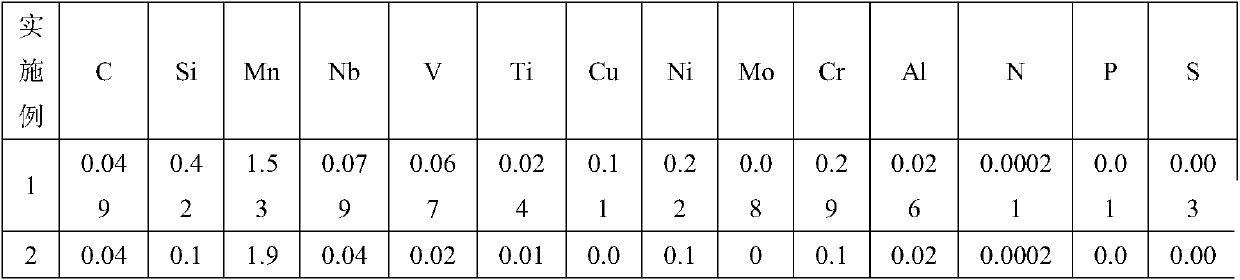

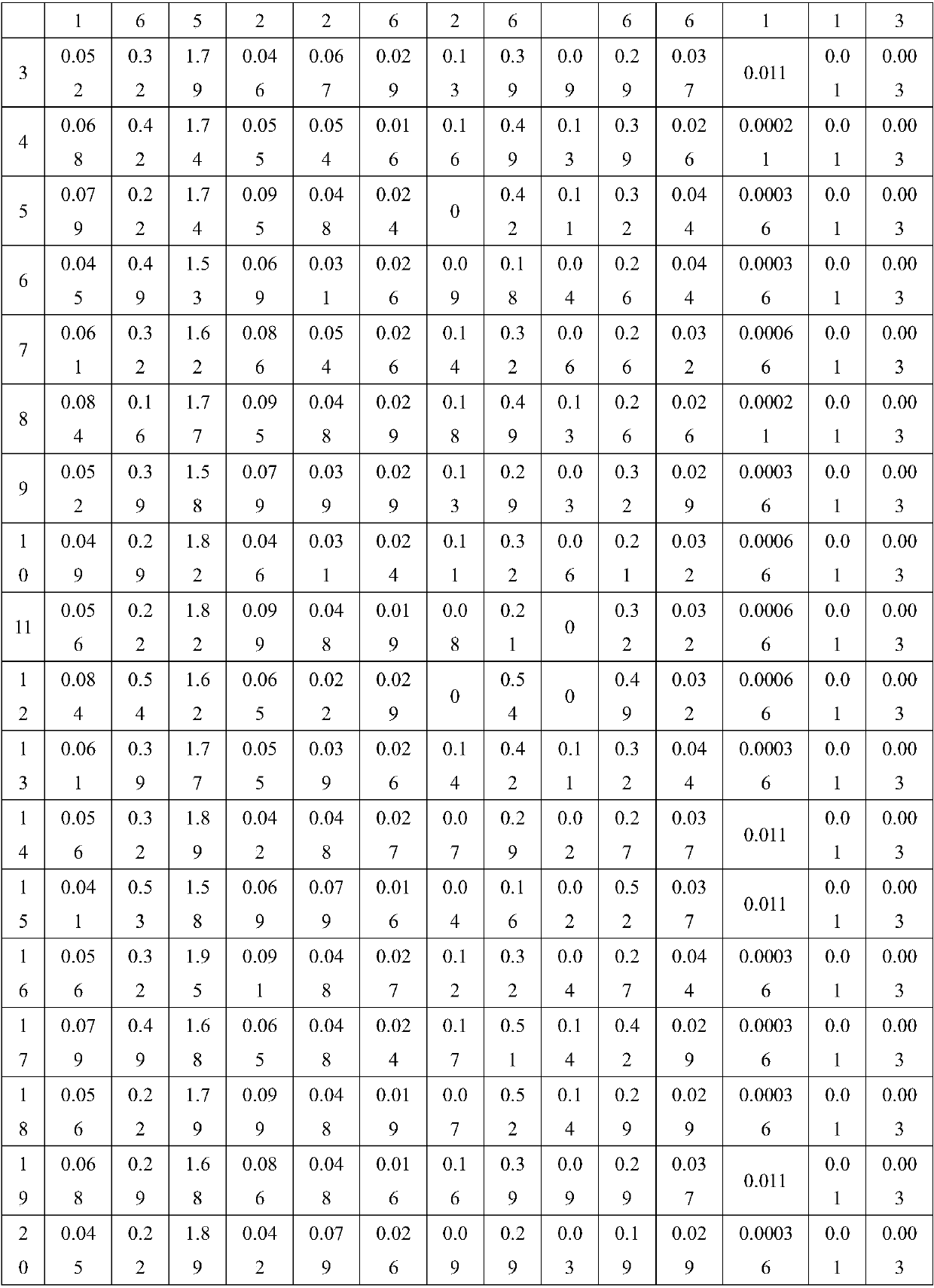

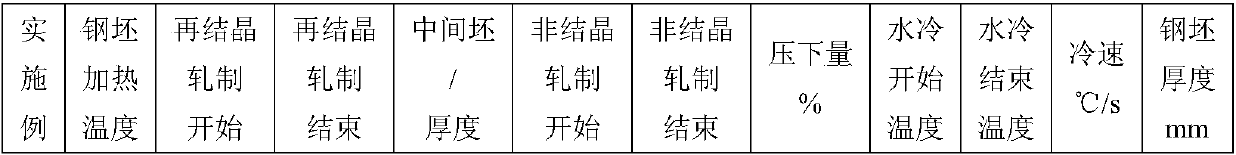

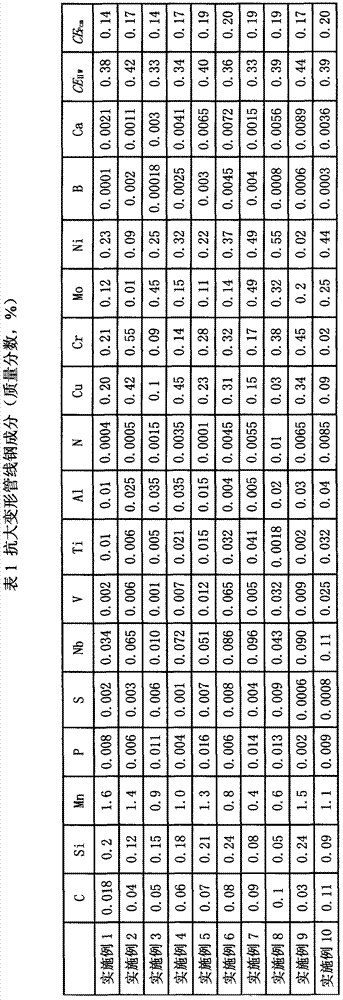

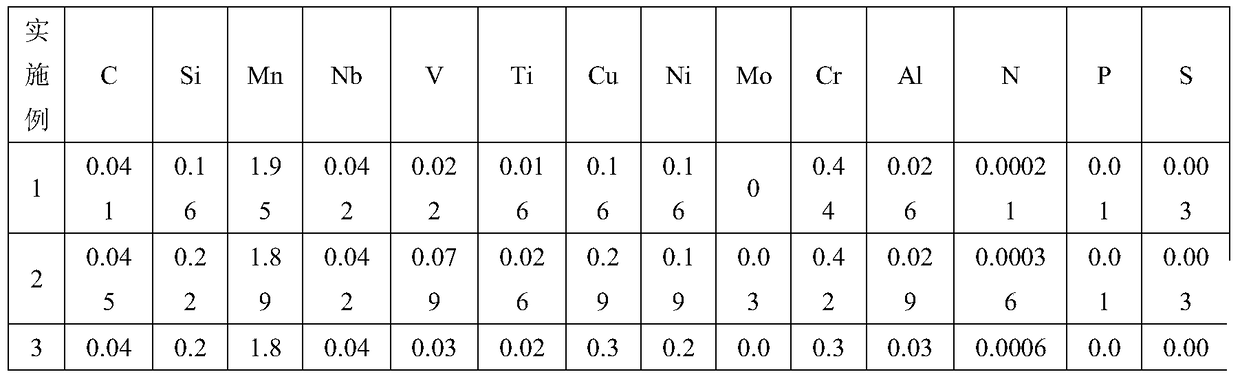

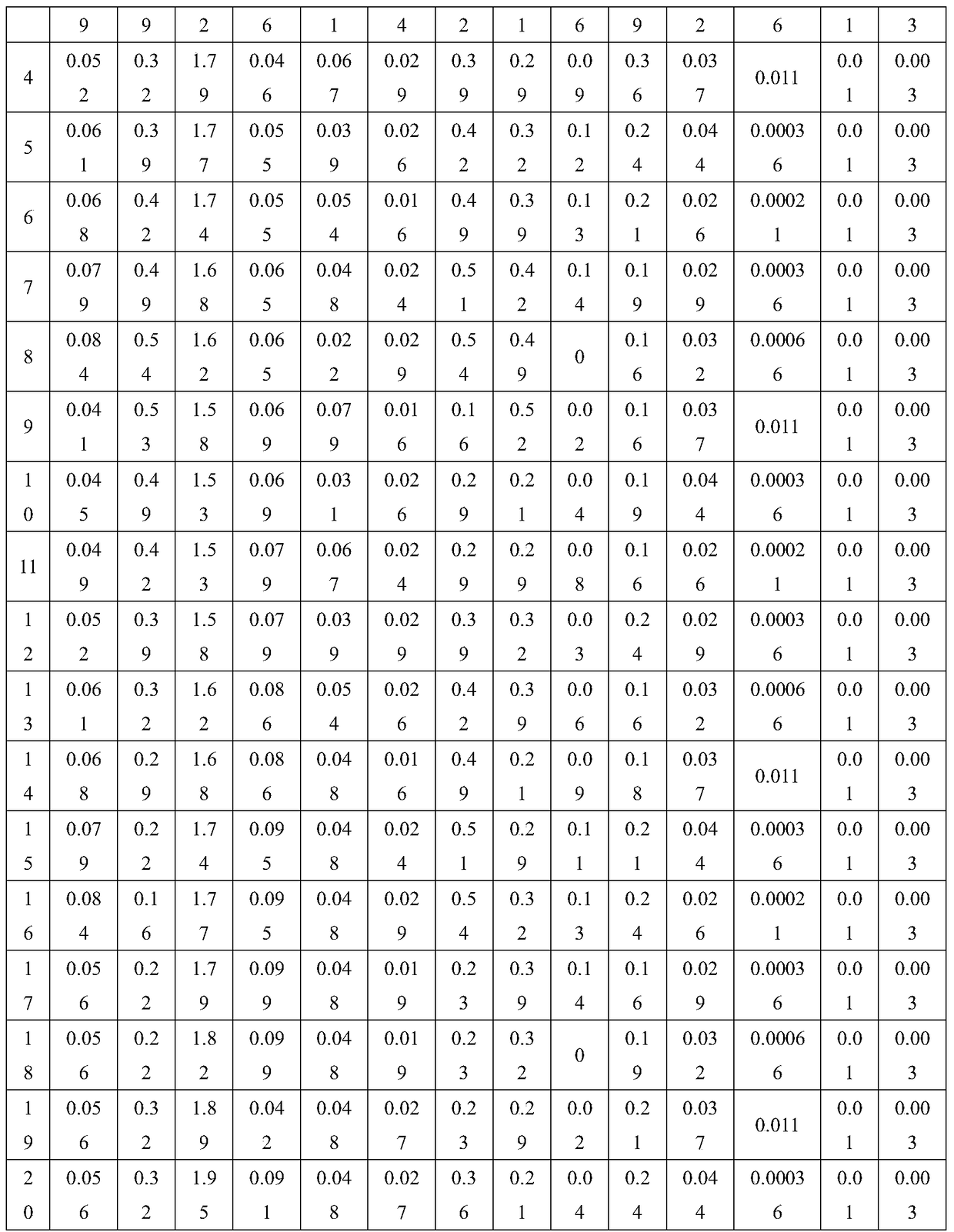

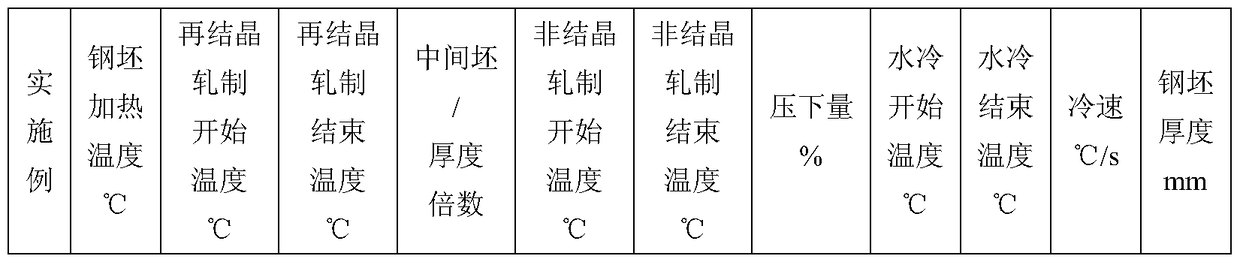

X70 large deformation resisting pipeline steel and manufacturing method

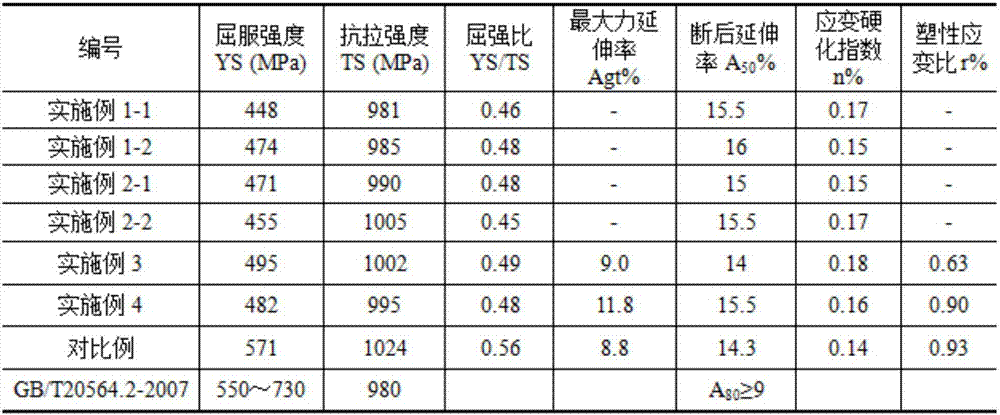

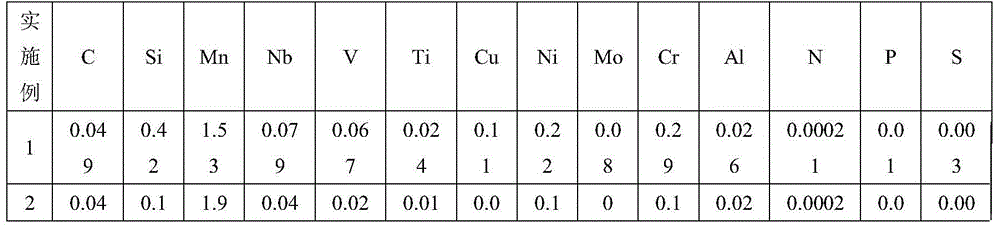

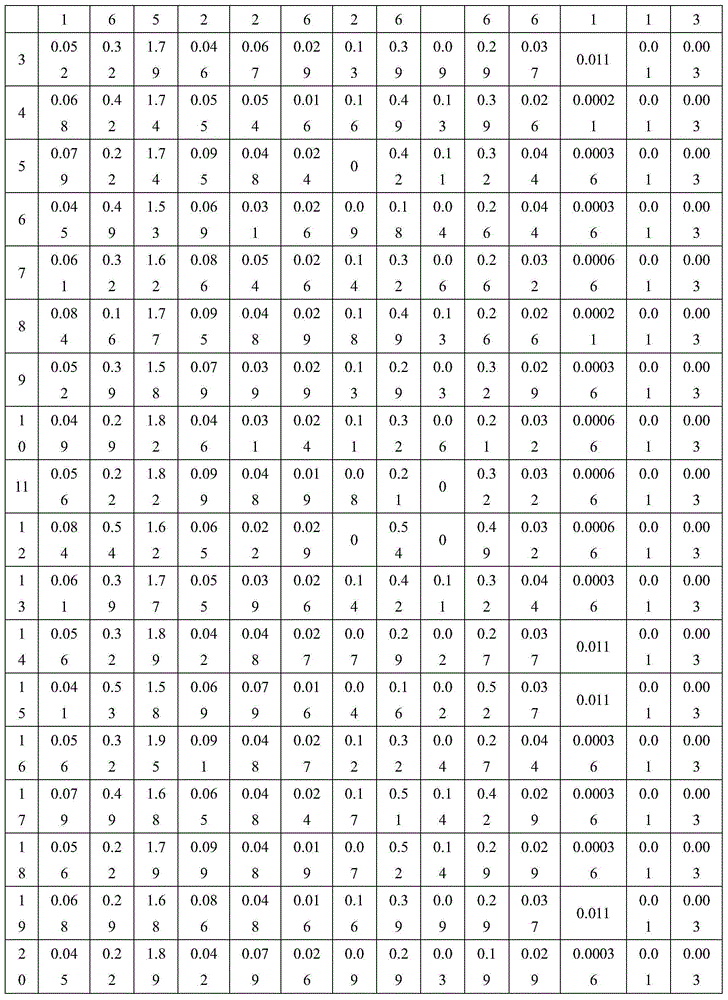

The invention discloses an X70 large deformation resisting pipeline steel and a manufacturing method. The steel comprises chemical components including, by mass percent, 0.04%-0.09% of C, 0.15%-0.55% of Si, 1.45%-1.75% of Mn, 0.04%-0.10% of Nb, 0.02%-0.08% of V, 0.01%-0.03% of Ti, 0%-0.20% of Cu, 0.15%-0.55% of Ni, 0%-0.15% of Mo, 0.15%-0.45% of Cr, 0.025%-0.045% of Al, 0.0002%-0.011% of N, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, and the balance Fe and other inevitable impurity elements. Production of the X70 large deformation resisting pipeline steel comprises the following process routes of material preparing, converter or electric furnace smelting, furnace exterior refining, casting, slab reheating, controlled rolling and controlled cooling, and after two-phase region quenching, tempering is conducted or the tempering technology is not adopted. Compared with the prior art, the X70 large deformation resisting pipeline steel and the manufacturing method have the beneficial effects that the yield ratio is lower, the uniform ductility is higher, tenacity matching is better, the steel plate and copper plate performance difference is small, the structure uniformity in the thickness direction is high, and the strip-shaped level is low.

Owner:ANGANG STEEL CO LTD

Method for improving elongation of cold-rolled dual-phase steel by utilizing retained austenite

InactiveCN104862597AHigh strengthImprove plasticityProcess efficiency improvementChemical compositionHigh intensity

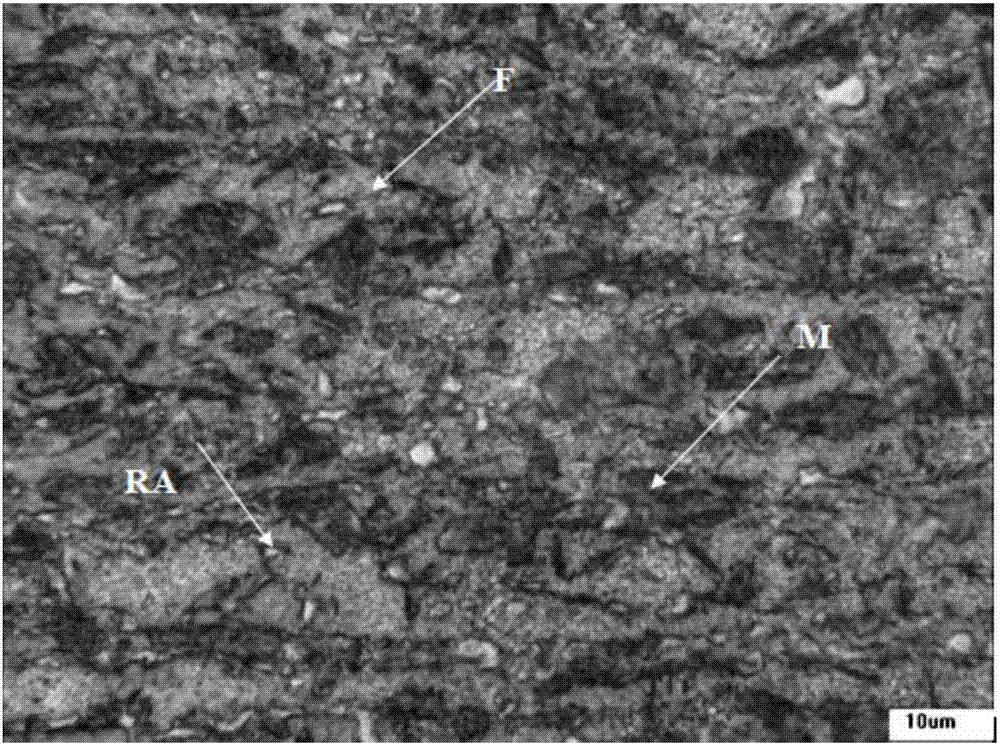

The invention discloses a method for improving the elongation of cold-rolled dual-phase steel by utilizing retained austenite and belongs to the technical field of steel materials. By the combination of the unique chemical component design, a hot-rolled ausforming TMCP (Thermal Mechanical Control Process) and a flexible continuous annealing process, complex-phase tissues including island martensite scattered and distributed on refined ferrite serving as a matrix and 2-7 percent of the retained austenite are obtained, so that dual-phase steel tissues include the ferrite, the martensite and the retained austenite. The content of the retained austenite is controlled through a component-continuous annealing process, the hardening performance of the generated martensite is highly superior to that of the austenite before phase changing, the uniform deformability of a material is improved, and the plasticity of the material is improved accordingly. A checking result for mechanical performance shows that high strength and high plasticity are obtained at the same time, and the elongation is improved by 4-5 percent in comparison with a conventional process.

Owner:CENT IRON & STEEL RES INST

High-strength thick-wall welded steel pipe for deep sea pipeline and production method thereof

InactiveCN105734444AHigh strengthImprove toughnessArc welding apparatusMetal working apparatusHigh intensityThick wall

The invention discloses a high-strength thick-wall welded steel pipe for a deep sea pipeline and a production method thereof. The steel pipe plate contains the following components in percentage by mass: 0.03-0.07% of C, 0.10-0.40% of Si, 1.20-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0015% of S, 0.10-0.35% of Ni, 0.10-0.35% of Cr, less than or equal to 0.35% of Cu, 0.10-0.35% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of V, 0.005-0.025% of Ti, 0.01-0.06% of Al, 0.0020-0.0060% of N, 0.0005-0.0035% of Ca, 1.5-4.0% of Ti / N and the balance of Fe and inevitable impurities. The steel pipe disclosed by the invention has high plasticity and corrosion resistance and can be used for conveying the deep sea oil gas in a complicated working condition of deep sea service.

Owner:BAOJI PETROLEUM STEEL PIPE

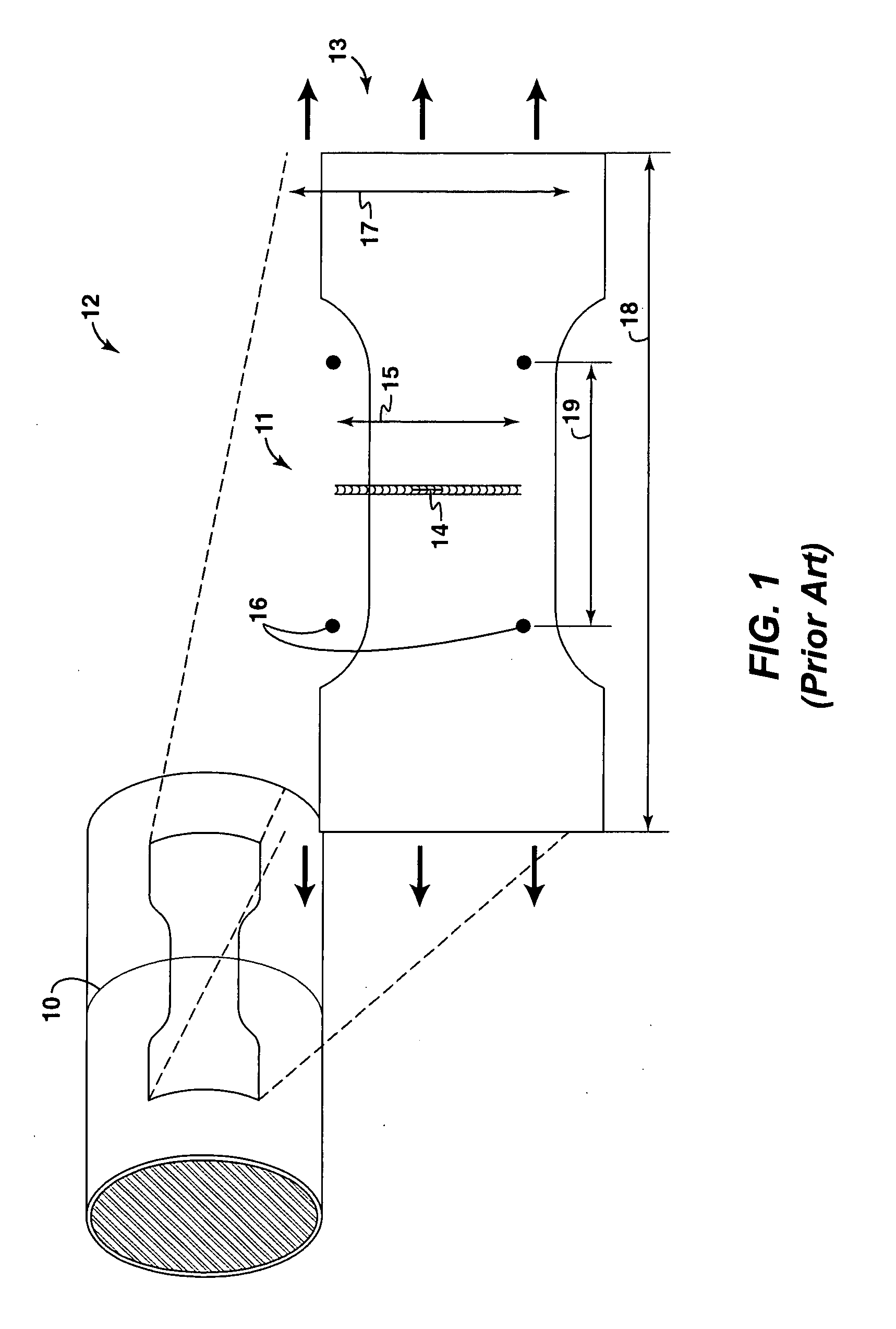

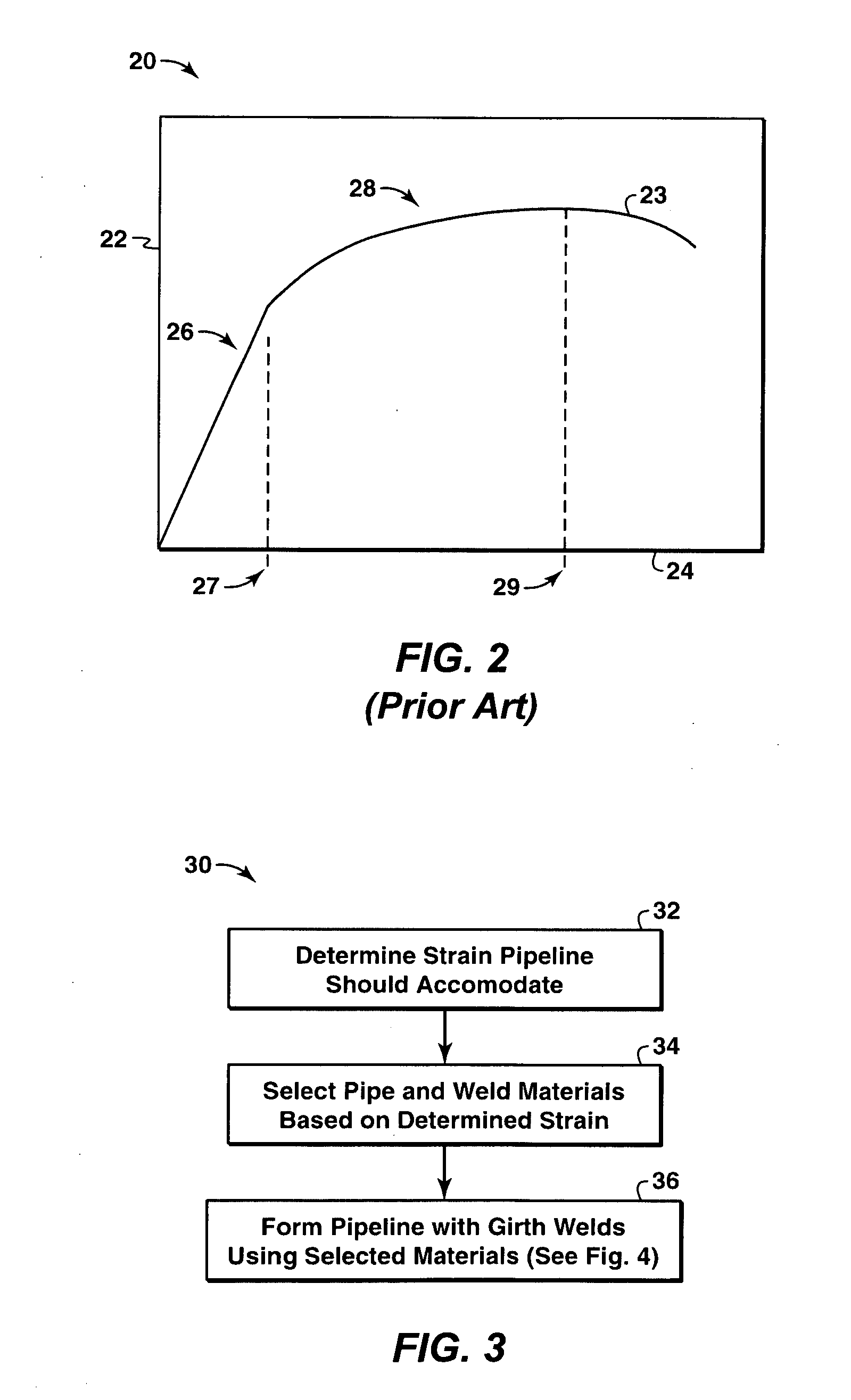

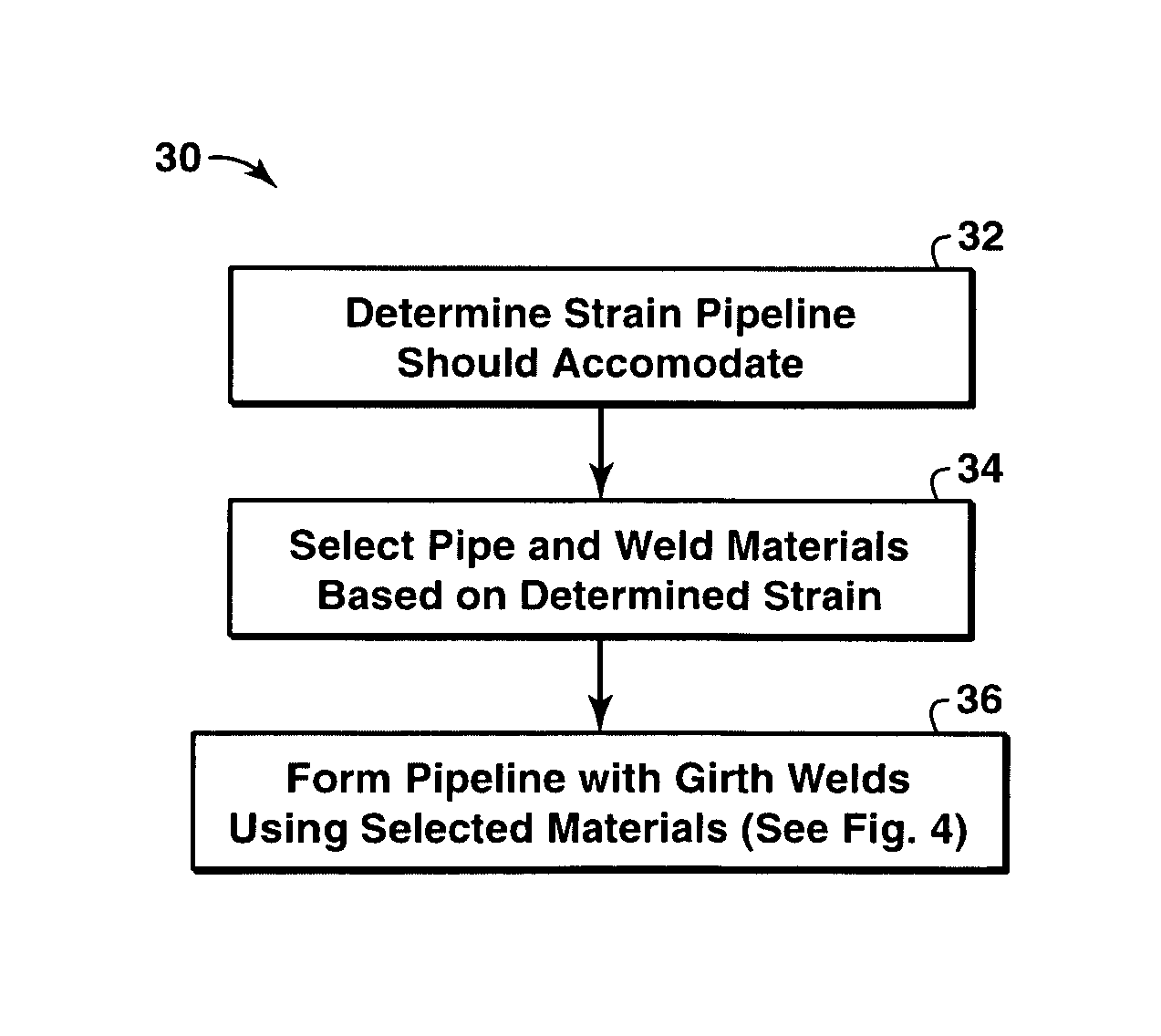

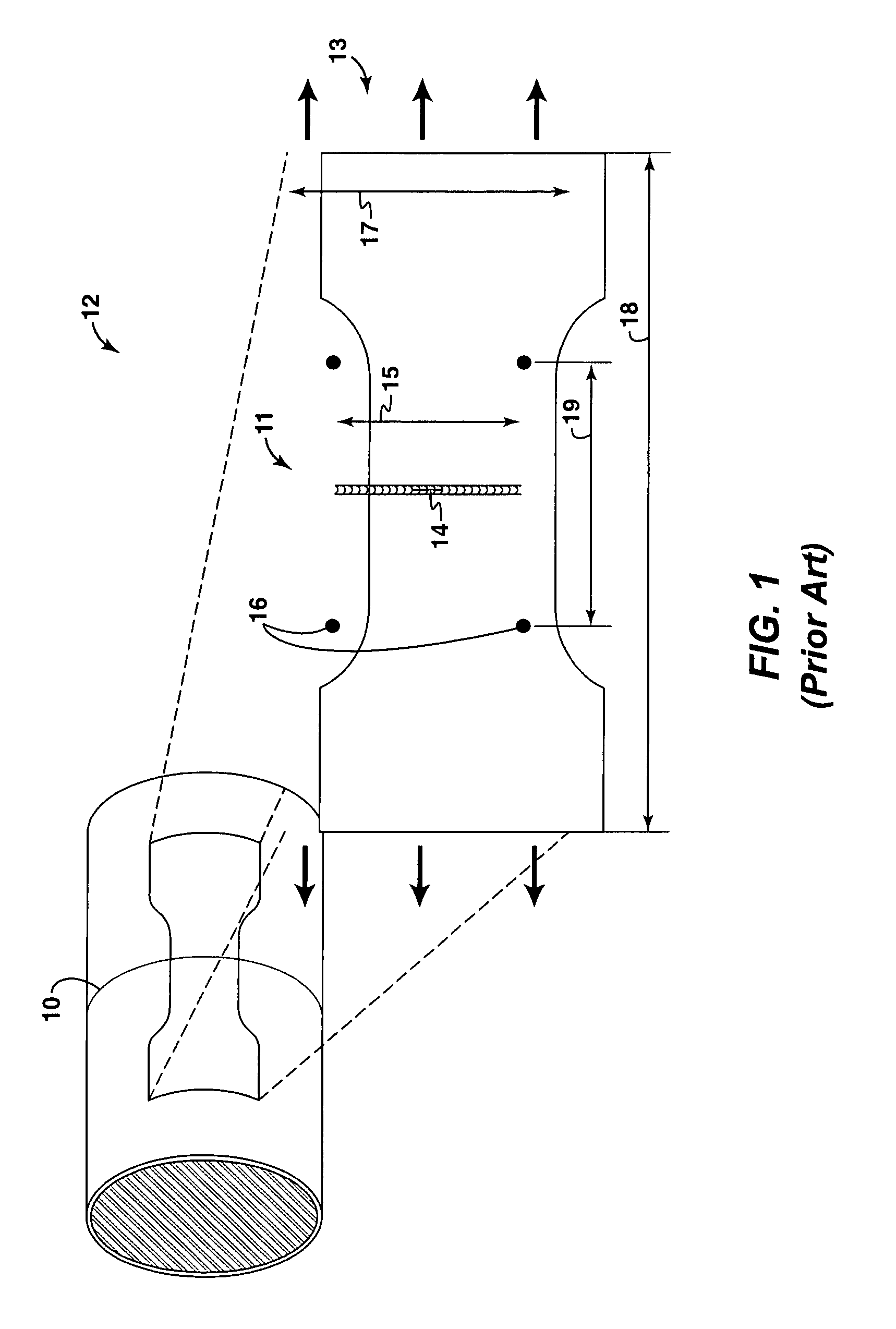

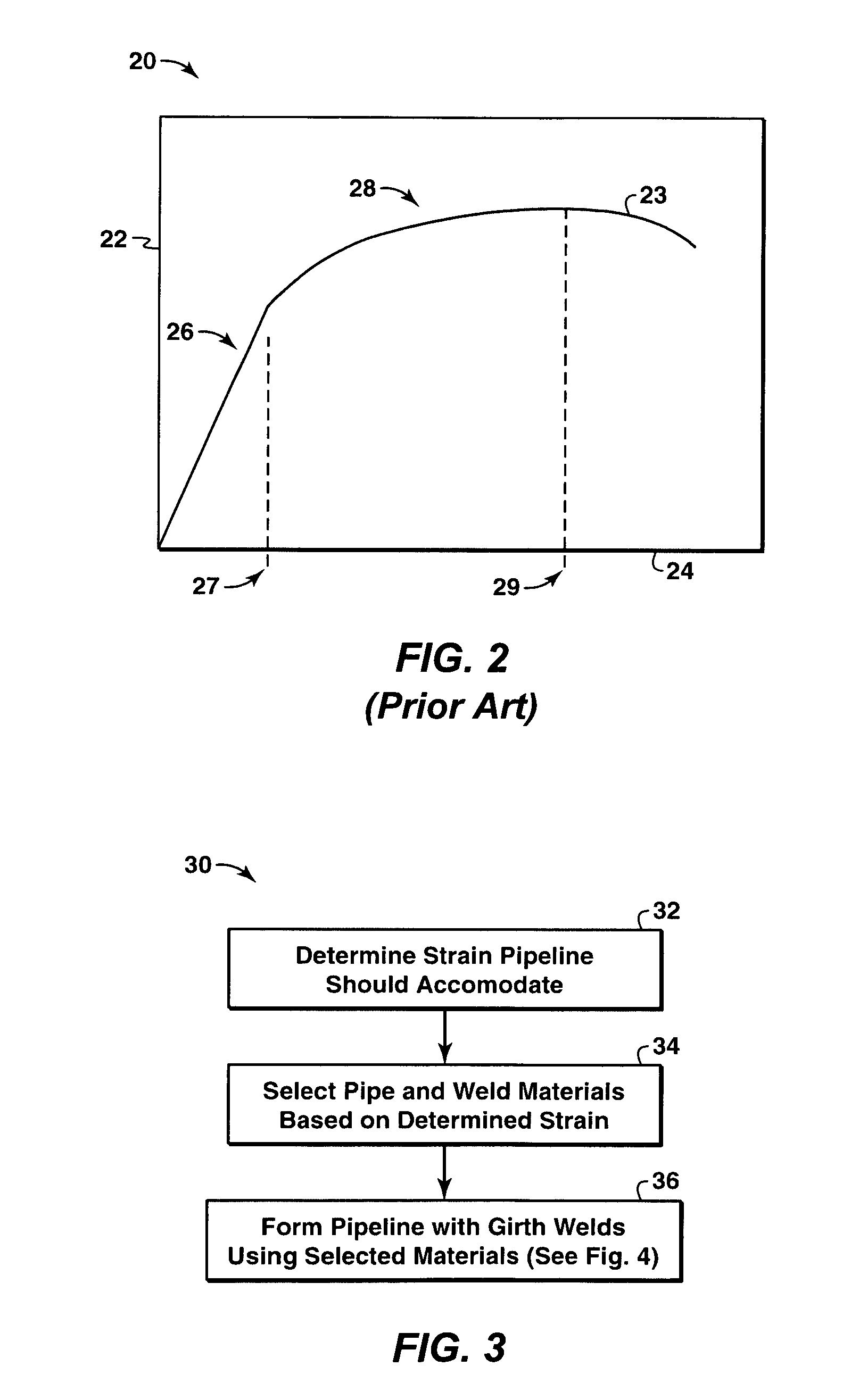

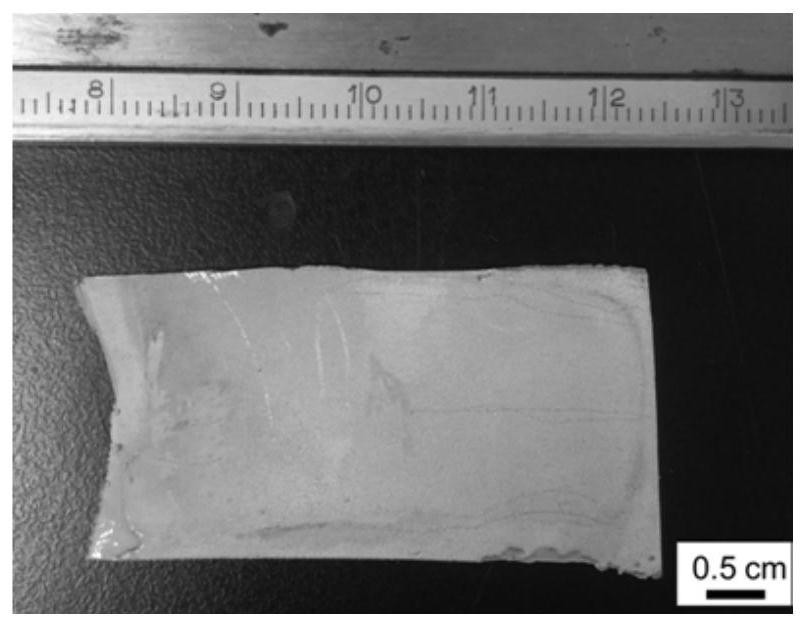

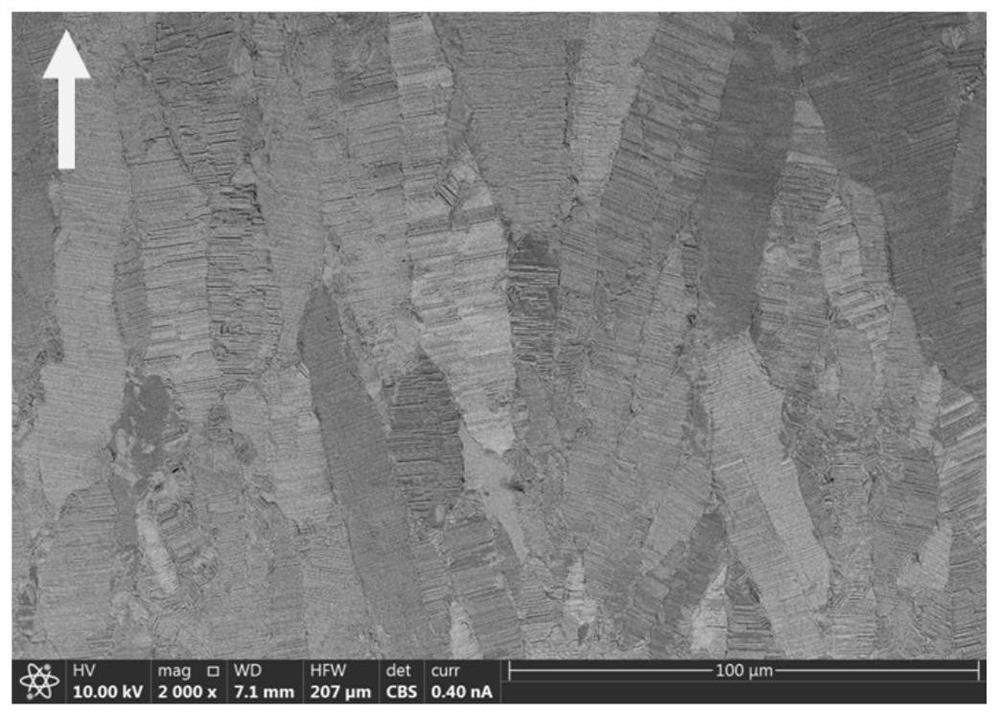

Corrosion Resistant Alloy Weldments In Carbon Steel Structures and Pipelines To Accommodate High Axial Plastic Strains

ActiveUS20100089463A1Simplifies its qualificationSimple designCooking-vessel materialsArc welding apparatusCorrosion resistant alloyTear resistance

A method and apparatus for joining materials having primarily ferritic properties is described. The method includes joining the ferritic materials using a welding process and a weld material having a primarily austenitic microstructure. The resulting weldment enhances the properties of yield ratio, uniform elongation, toughness and tearing resistance thereby producing superior strain capacity. High strain capacity produces a structure that accommodates high axial loading. The weldment can also accommodate larger than conventional weld flaws while maintaining sufficient strength, tearing resistance, and fracture toughness under high axial loading.

Owner:EXXONMOBIL UPSTREAM RES CO

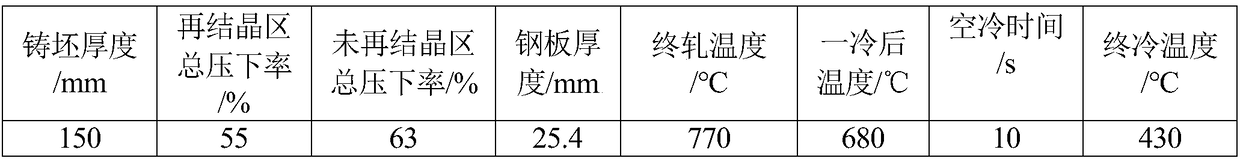

Continuous casting type large-wall-thickness hot-rolled steel plate for deep sea pipelines and production method thereof

The invention discloses a continuous casting type large-wall-thickness hot-rolled steel plate for deep sea pipelines and a production method thereof, and belongs to the technical field of pipeline steel. The hot-rolled steel plate is composed of, by weight, 0.03-0.06% of C, 0.15-0.30% of Si, 1.20-1.35% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.0012% of S, 0.01-0.05% of Alt, 0.03-0.05% of Nb, 0.00-0.05% of V, 0.005-0.016% of Ti, 0.25-0.40% of Ni, 0.00-0.30% of Cr, 0.00-0.20% of Cu, 0.00-0.15% of Mo and the balance Fe and inevitable impurity elements. Continuous castings with the thickness being 400 mm are adopted for producing the steel plate with the thickness being 41-48 mm. The steel plate and the production method thereof have the advantages that good metallographic structures are obtained, the Charpy impact toughness at -20 DEG C, the drop hammer toughness at -20 DEG C, the low yield ratio, the high uniform elongation rate, the anti-fracture toughness property CTOD, the A solution acid resistance HIC and SSCC, and the like of the large-wall-thickness hot-rolled steel plate for the deep sea pipelines are realized, and therefore the construction requirement of conveying pipelines of oil and gas fields of deep seas can be met.

Owner:SHOUGANG CORPORATION

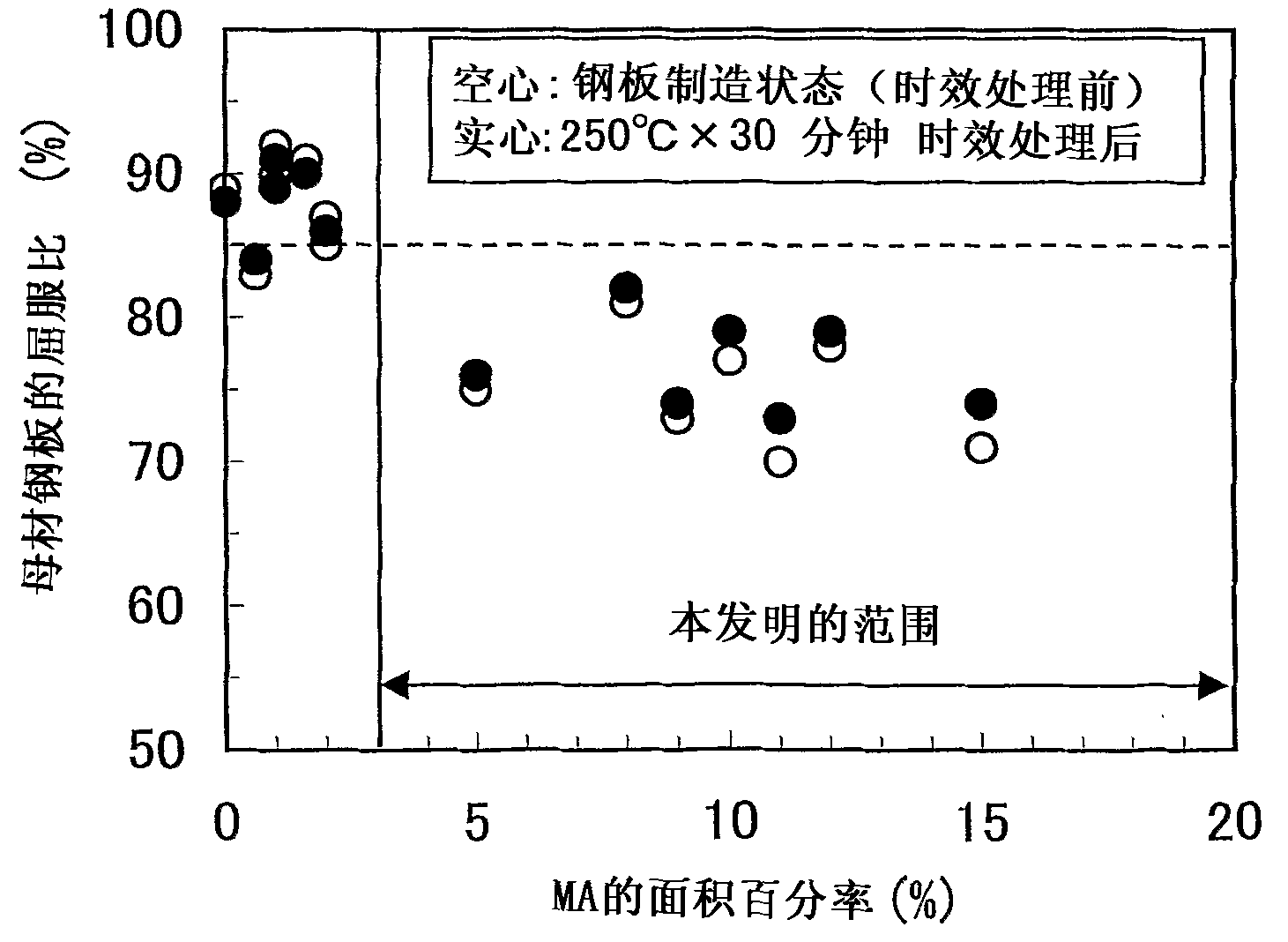

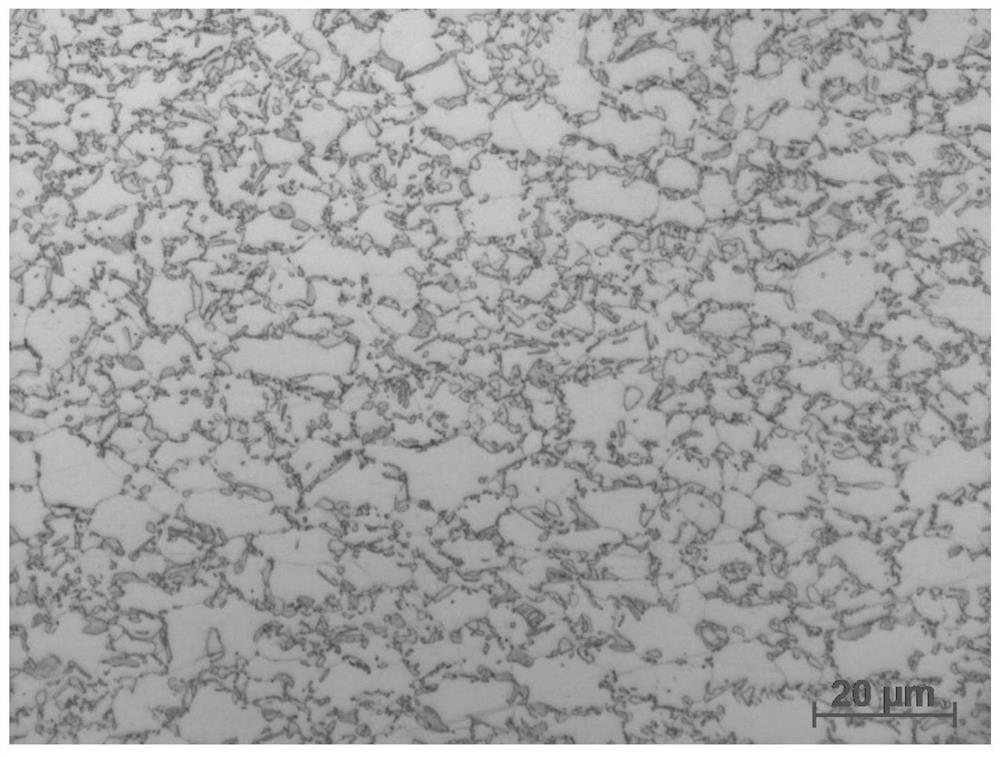

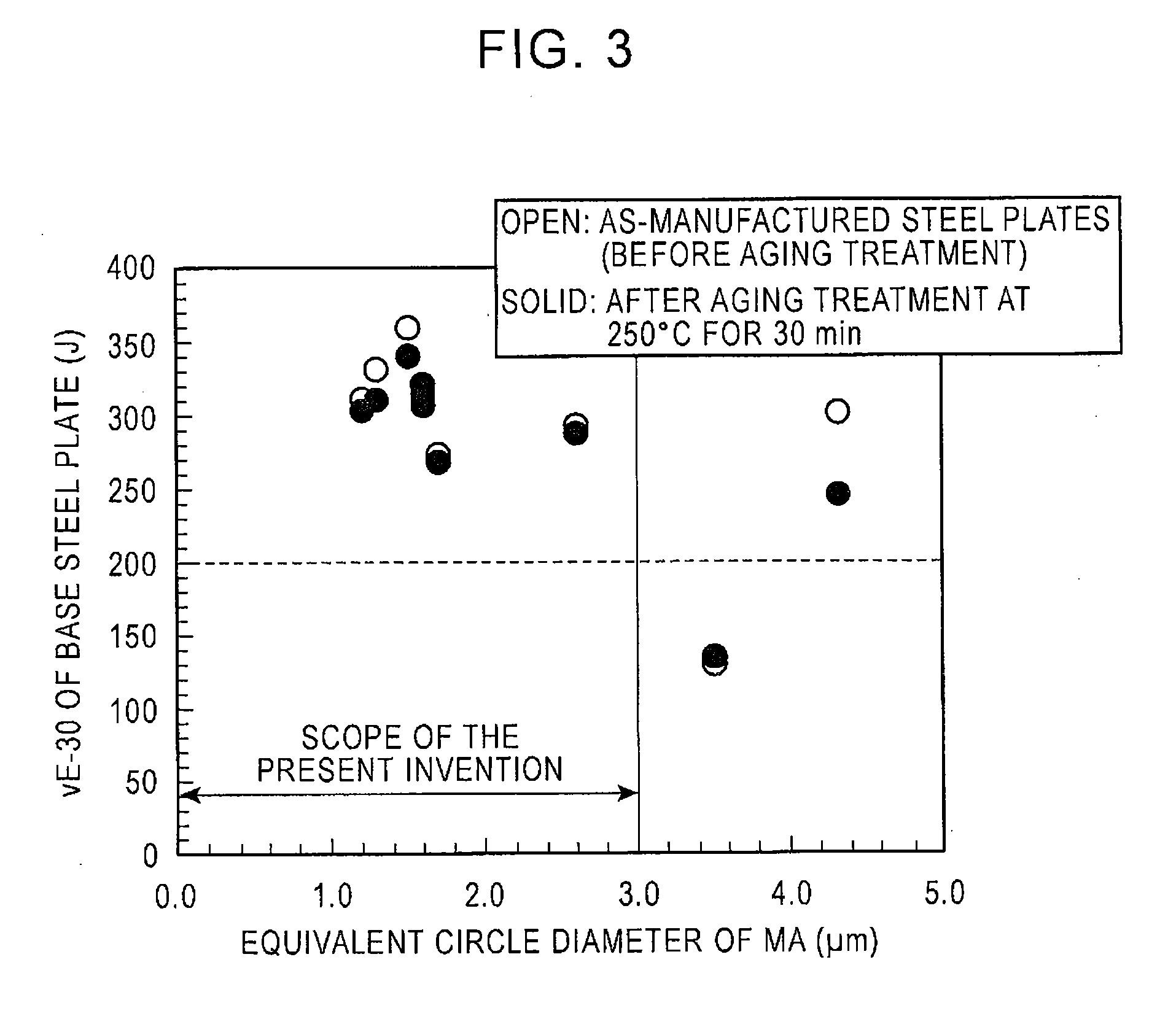

Low yield ratio, high strength and high uniform elongation steel plate and method for manufacturing the same

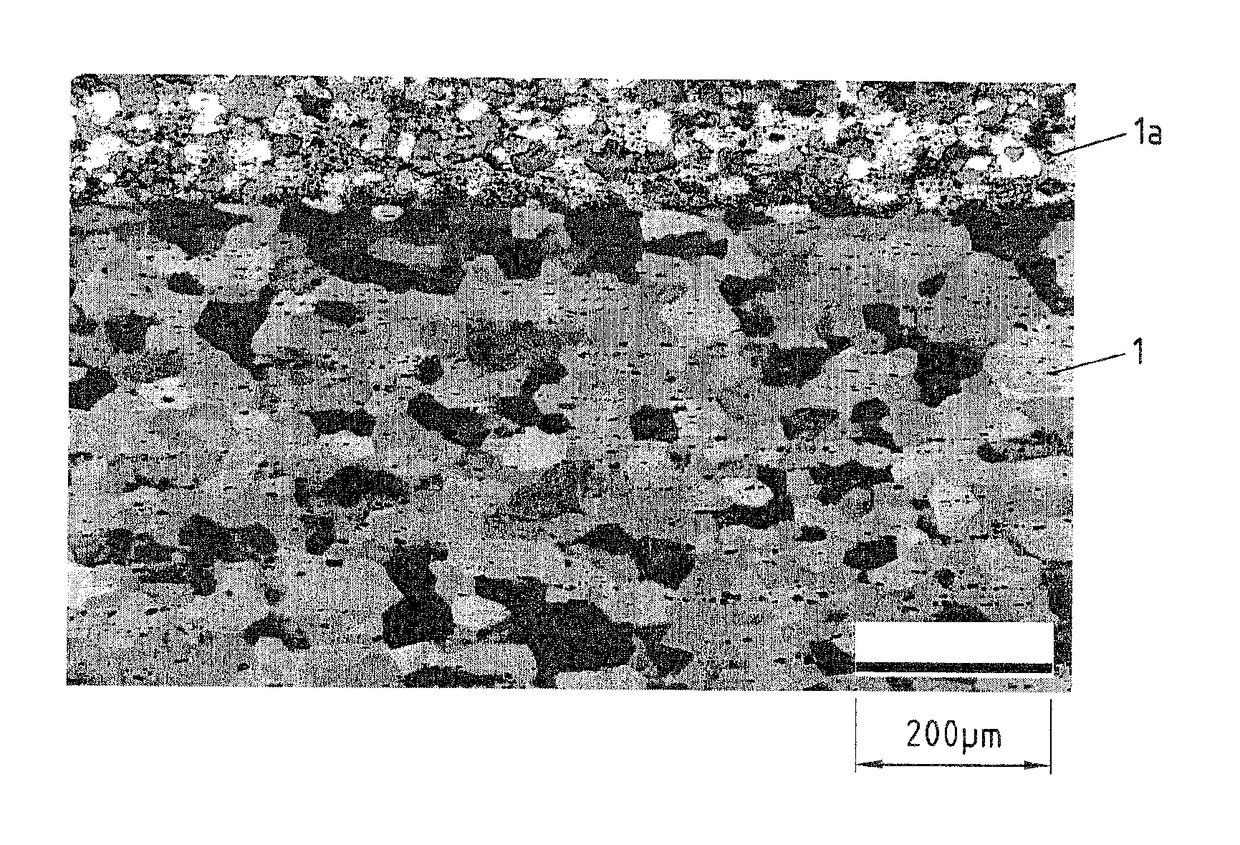

Provided is a low yield ratio, high strength and high uniform elongation steel plate having excellent strain ageing resistance equivalent to API 5L X70 Grade or lower and a method for manufacturing the same. In particular, the steel plate contains 0.06% to 0.12% C, 0.01% to 1.0% Si, 1.2% to 3.0% Mn, 0.015% or less P, 0.005% or less S, 0.08% or less Al, 0.005% to 0.07% Nb, 0.005% to 0.025% Ti, 0.010% or less N, and 0.005% or less O on a mass basis, the remainder being Fe and unavoidable impurities. The low yield ratio, high strength and high uniform elongation steel plate has a metallographic microstructure that is a two-phase microstructure consisting of bainite and M-A constituent, the area fraction of the M-A constituent being 3% to 20%, the equivalent circle diameter of the M-A constituent being 3.0 μm or less.

Owner:JFE STEEL CORP

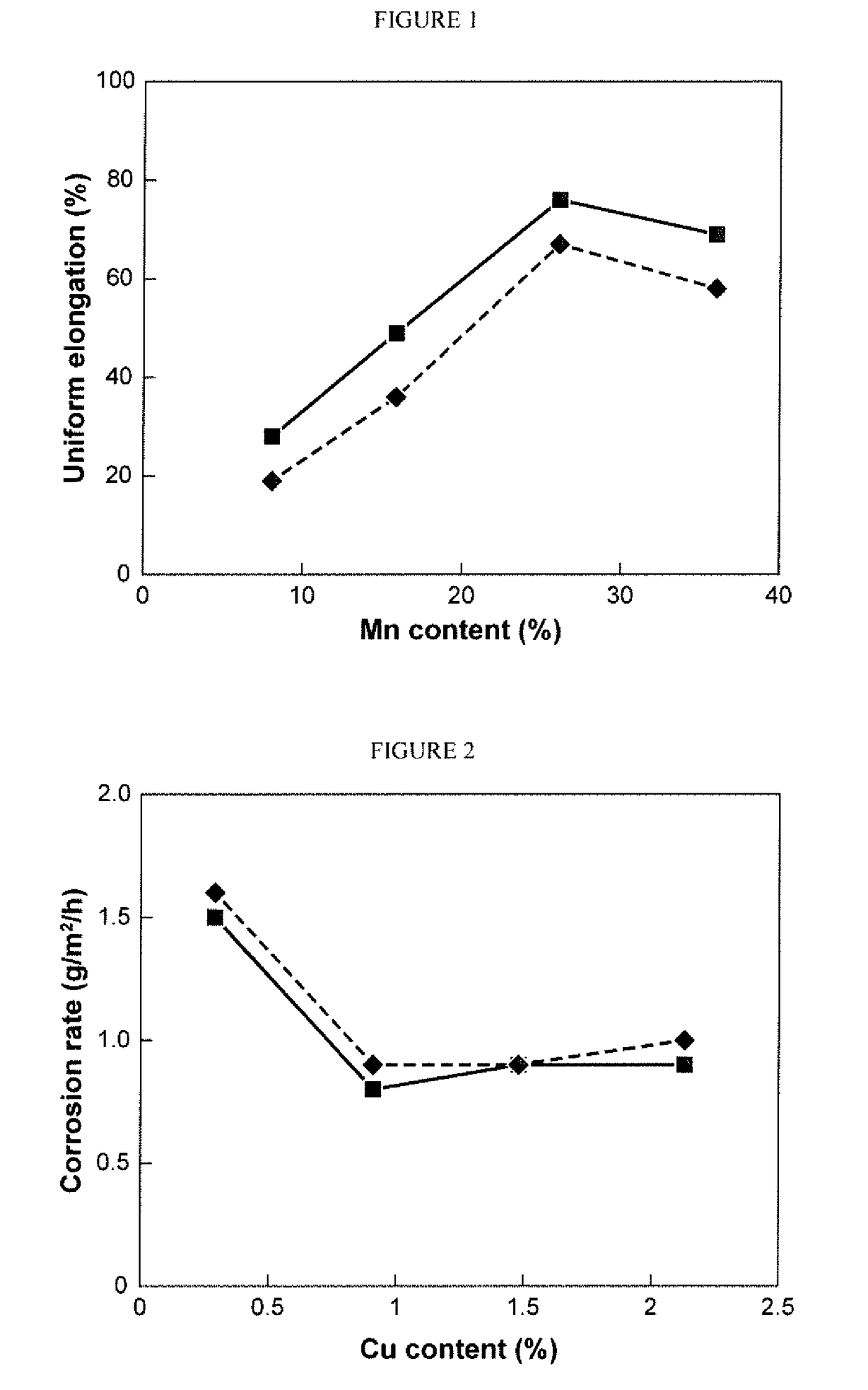

24-30% Mn-containing alloy pipe material and manufacture method thereof

ActiveCN101798658AHigh uniform elongationUniform elongationTemperature control deviceFurnace typesElectrical resistance and conductanceAlloy

The invention relates to a 24-30% Mn-containing alloy pipe material and a manufacture method thereof. The pipe material comprises the following components of: 0.001-0.35% of C, 24-30% of Mn, 0-5% of Si, 1.0-3.5% of Al, P which is less than and equal to 0.015%, S which is less than and equal to 0.010%, and Fe in balance amount, or one or two of 1-6% of Cr, 0.1-0.5% of Cu, 0.01-0.9% of Nb, 0.01-0.1% of Ti and 0.01-0.3% of V. The manufacture method comprises the following steps of: vacuum smelting and casting, annealing in a homogenizing way, hot rolling to obtain a steel plate or a bar material, electric resistance welding or hot rolling to obtain a pipe blank, and performing solid solution and aging treatment to obtain the alloy pipe material with good expansibility performance. The even elongation coefficient is more than or equal to 60%, and the yield strength is 250-400MPa. After performing 30-40% of plastic deformation, the even elongation coefficient is more than or equal to 25%, and the yield strength is 500-630MPa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

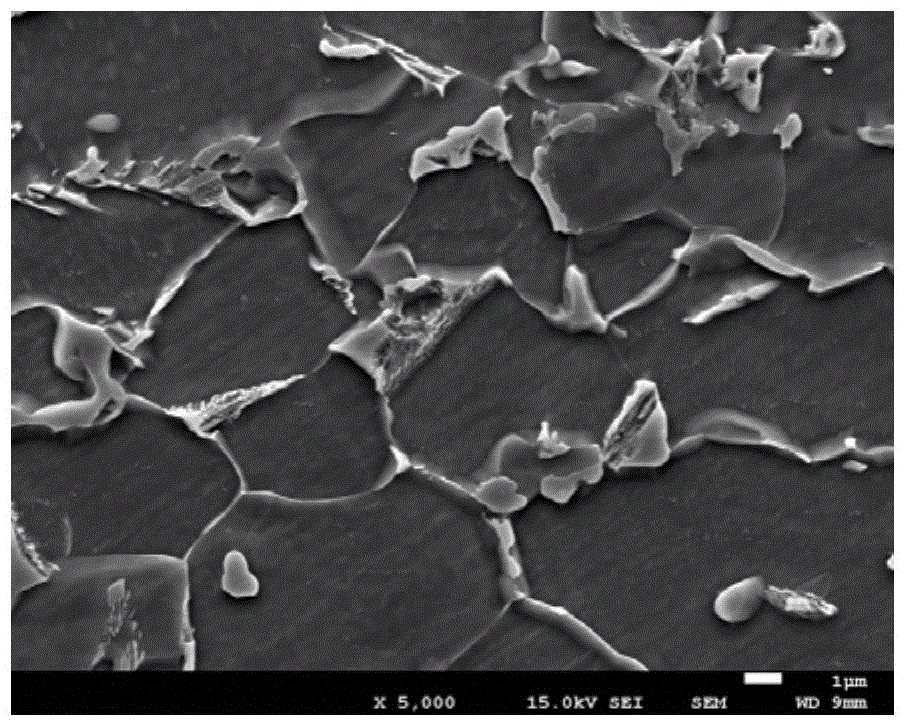

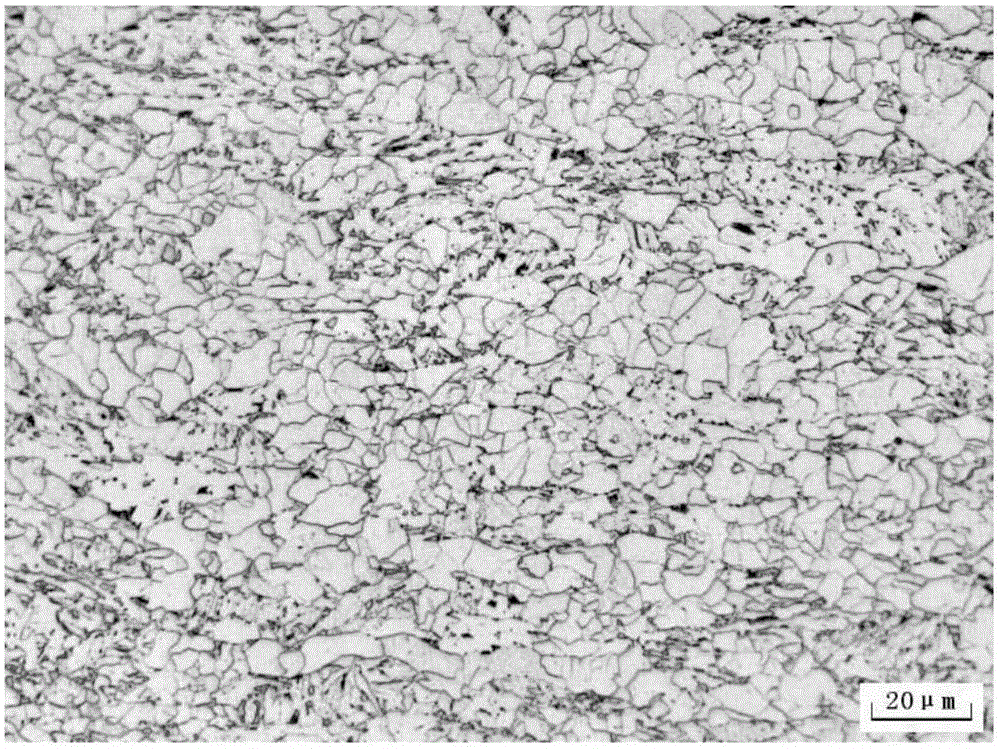

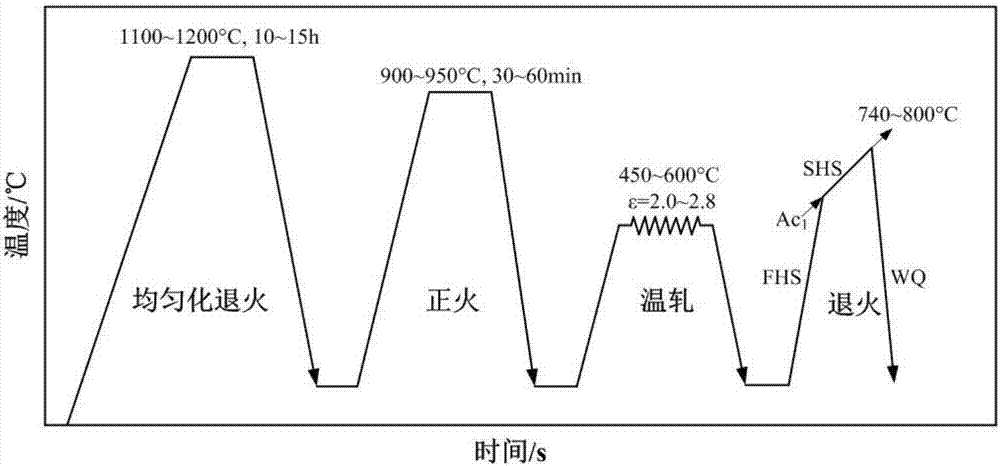

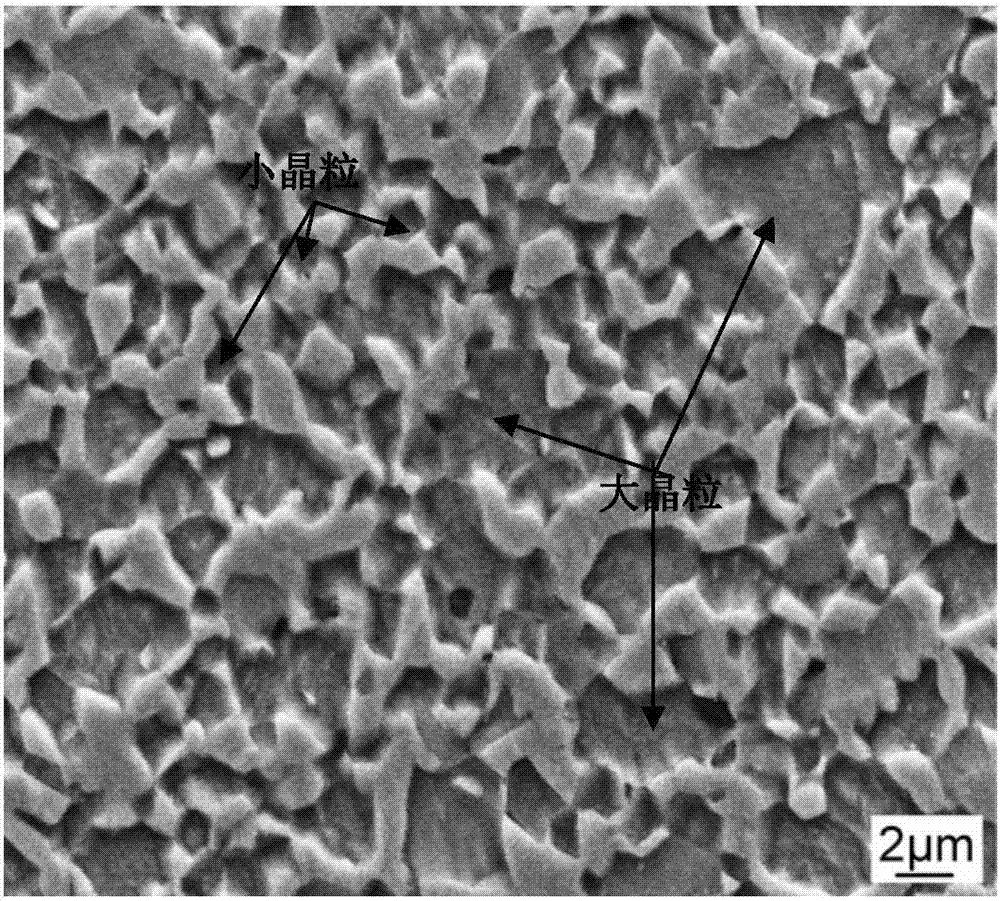

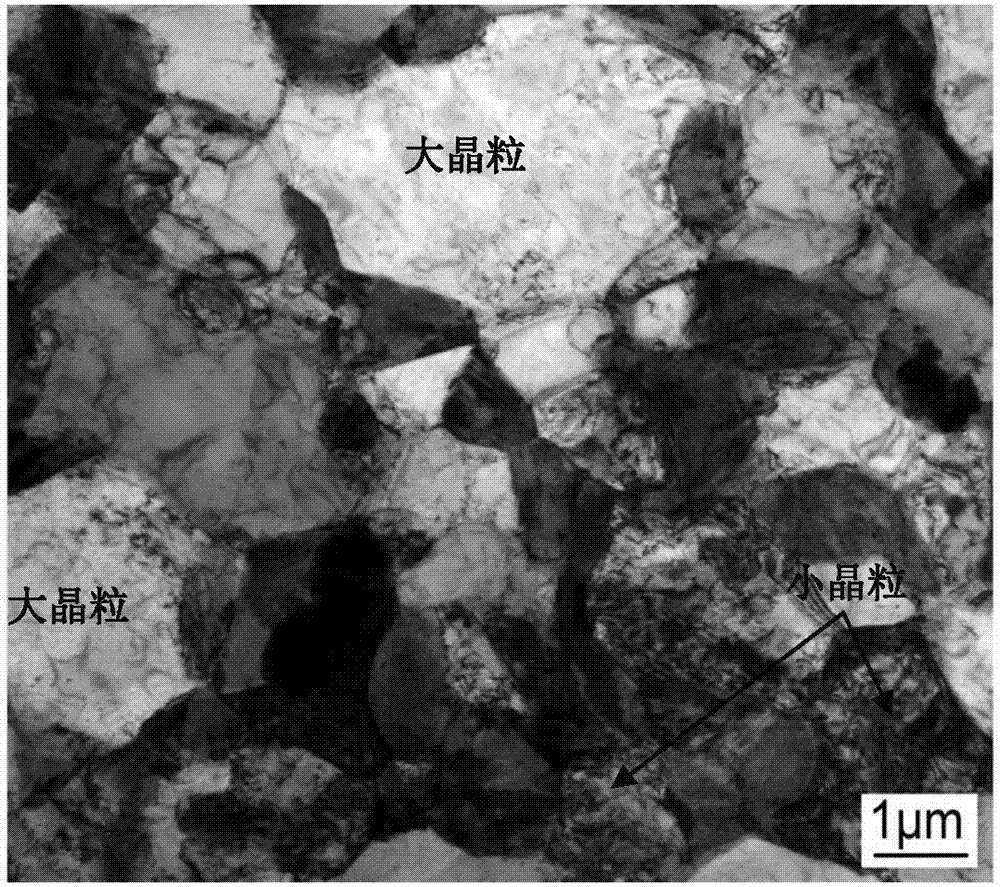

Ultra-fine grain martensite ferrite dual-phase steel with two-peak ferrite grains distributed and production process of ultra-fine grain martensite ferrite dual-phase steel

The invention discloses ultra-fine grain martensite ferrite dual-phase steel with two-peak ferrite grains distributed and a production process of the ultra-fine grain martensite ferrite dual-phase steel. After billet steel is obtained through smelting, casting, forging and hot rolling, the billet steel is subjected to heat treatment which comprises the following working procedures of homogenizing annealing, normalizing, warm rolling and continuous annealing, and continuous annealing comprises three stages that firstly, the billet steel is heated to the temperature of Ac1 at the speed of 40 DEG C / s-80 DEG C / s, secondly, the billet steel continues to be heated to 740 DEG C-800 DEG C at the speed of 1 DEG C / s-5 DEG C / s, and thirdly, quenching is carried out. By means of the process, austenite grains are refined, the ferrite gains are distributed in a two-peak size manner, the uniform elongation of the steel is greatly increased when the steel is pulled at the room temperature, and the yield ratio is smaller than 0.5.

Owner:NORTHEASTERN UNIV

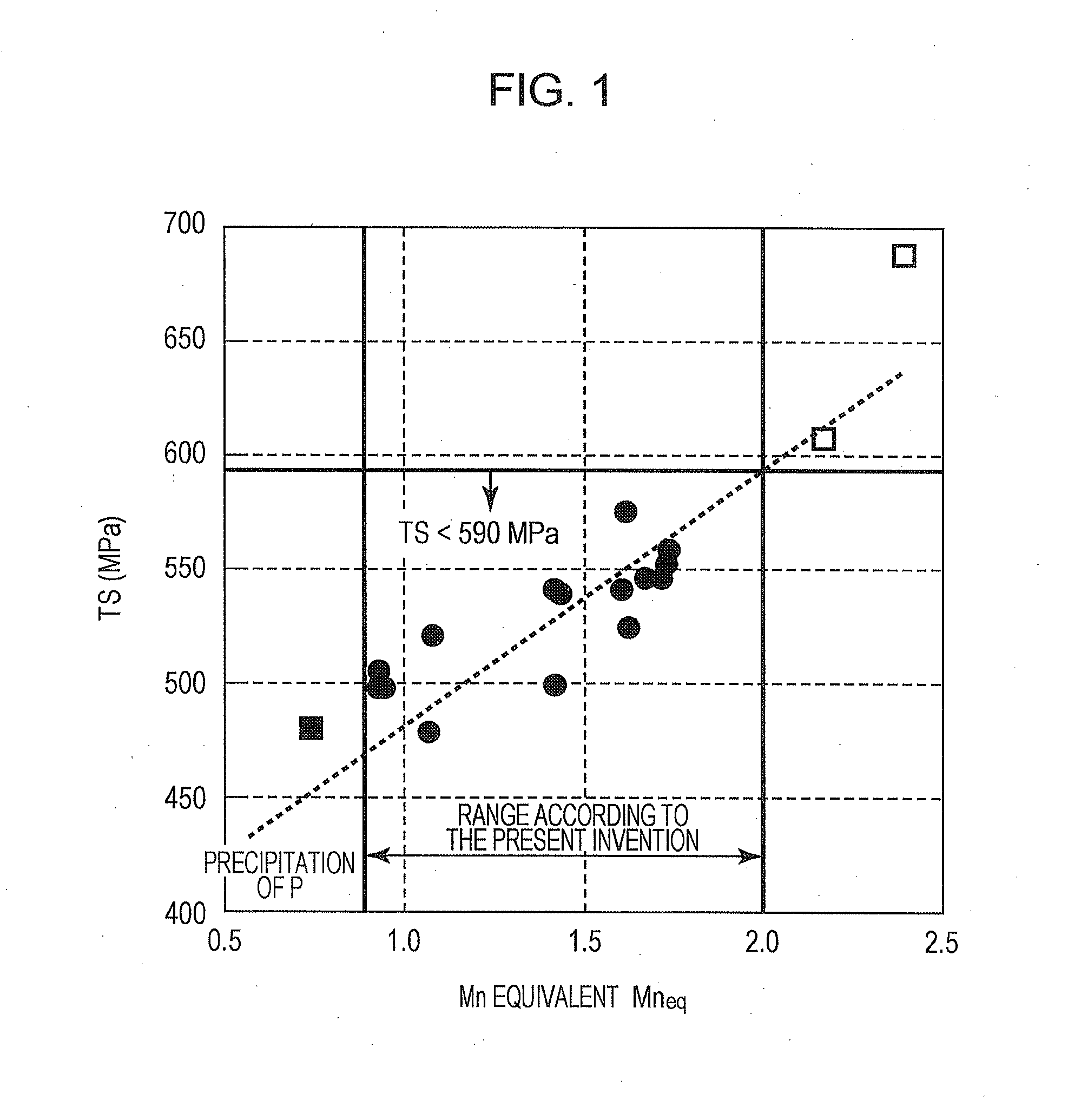

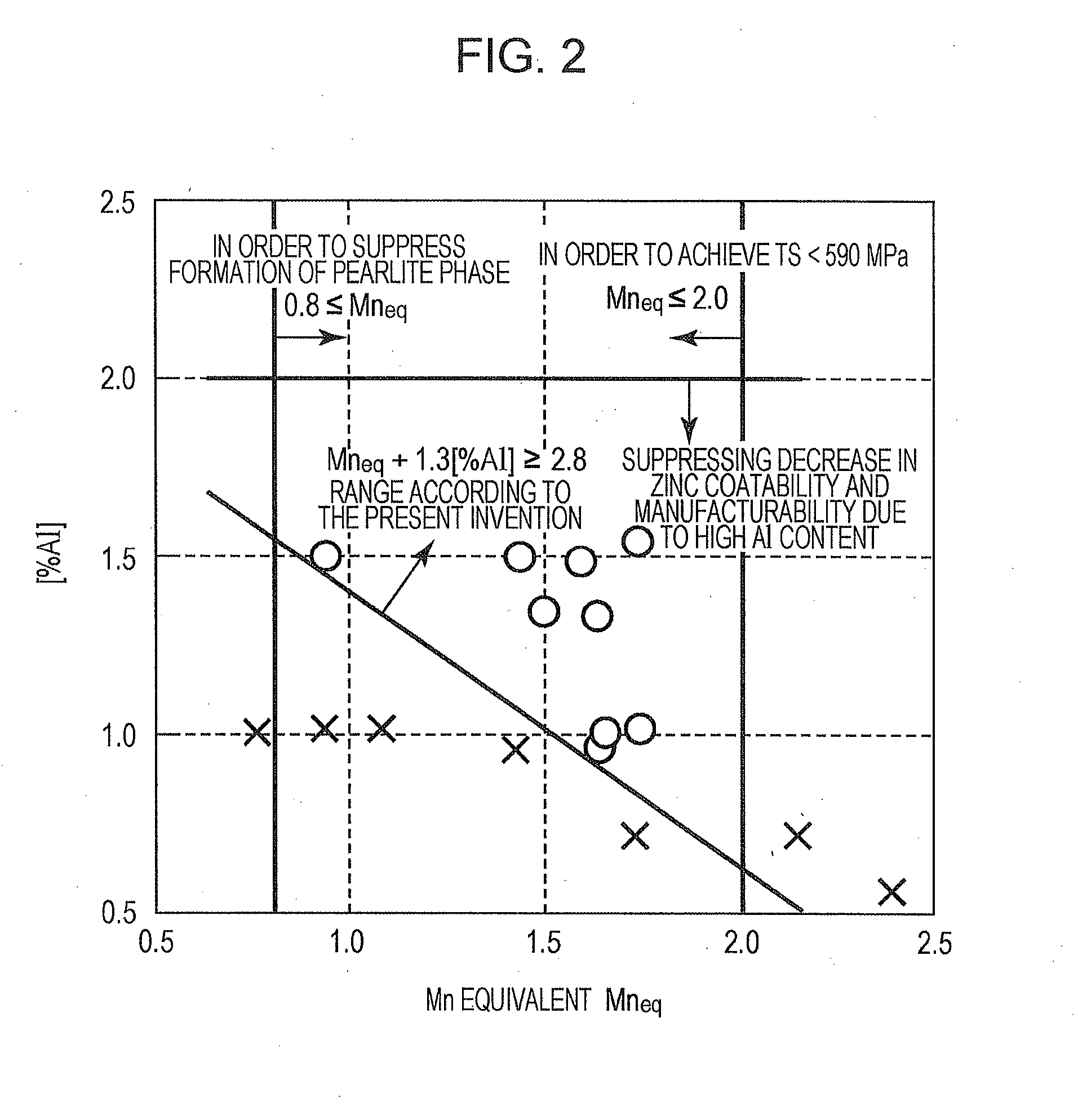

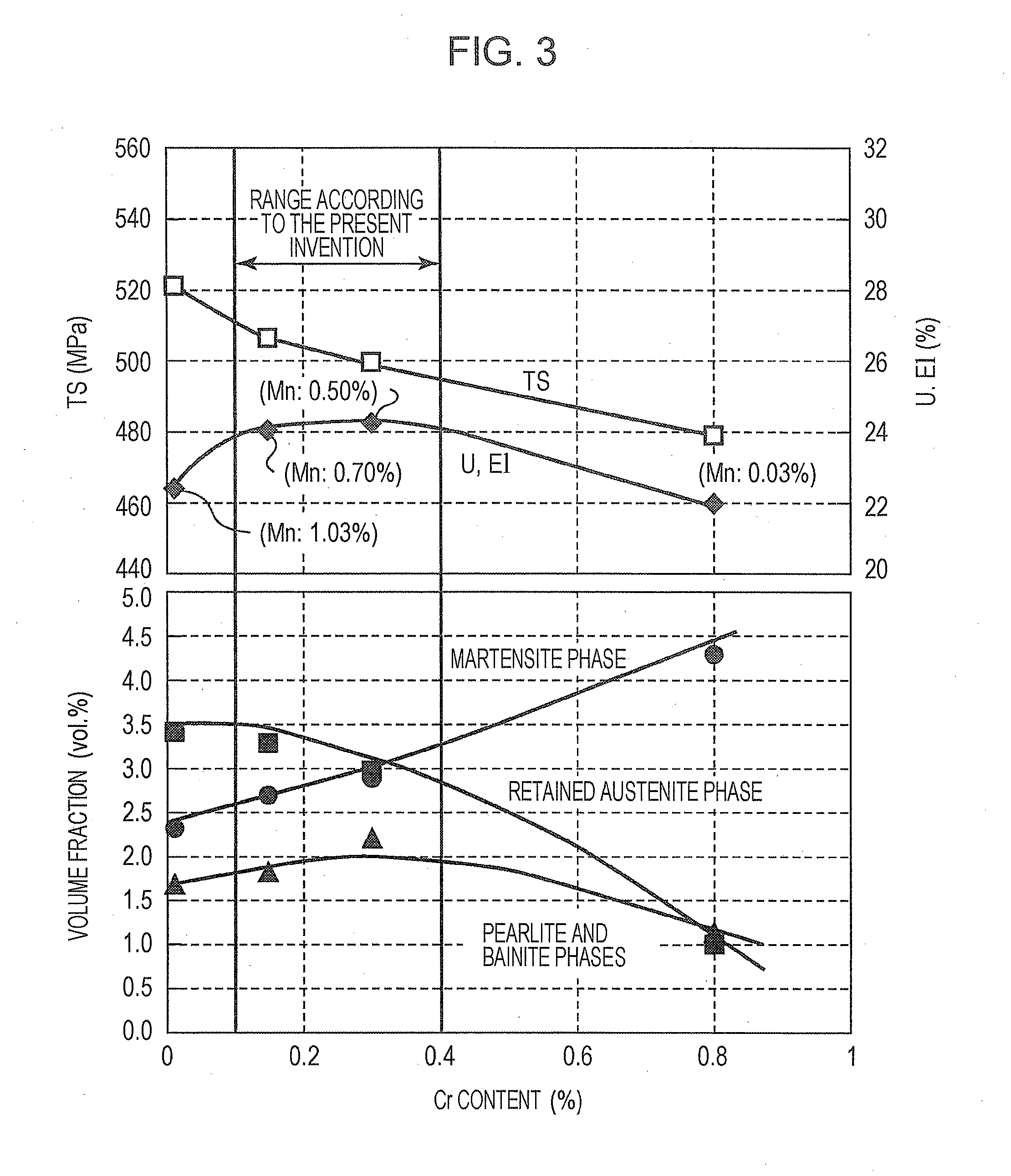

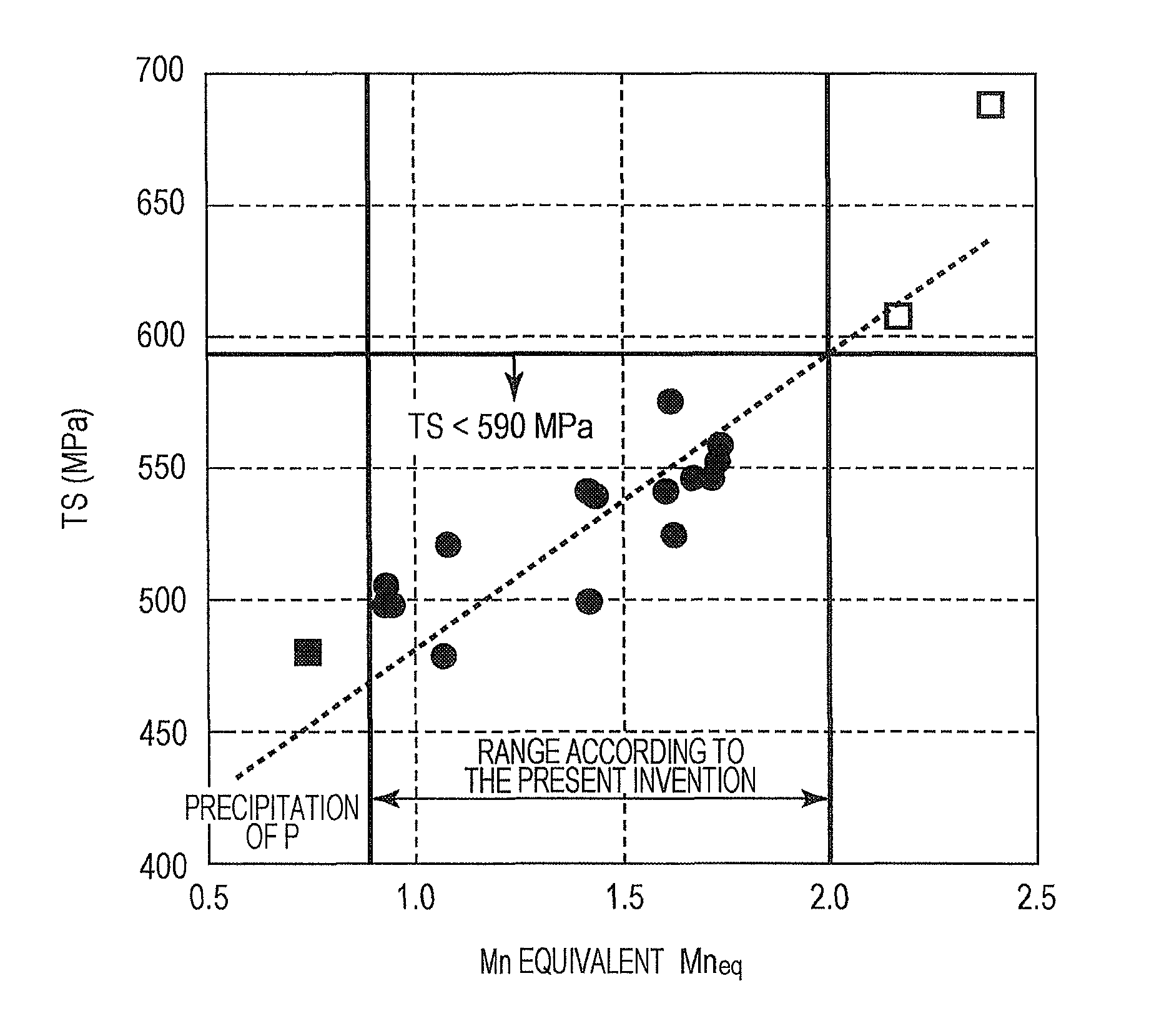

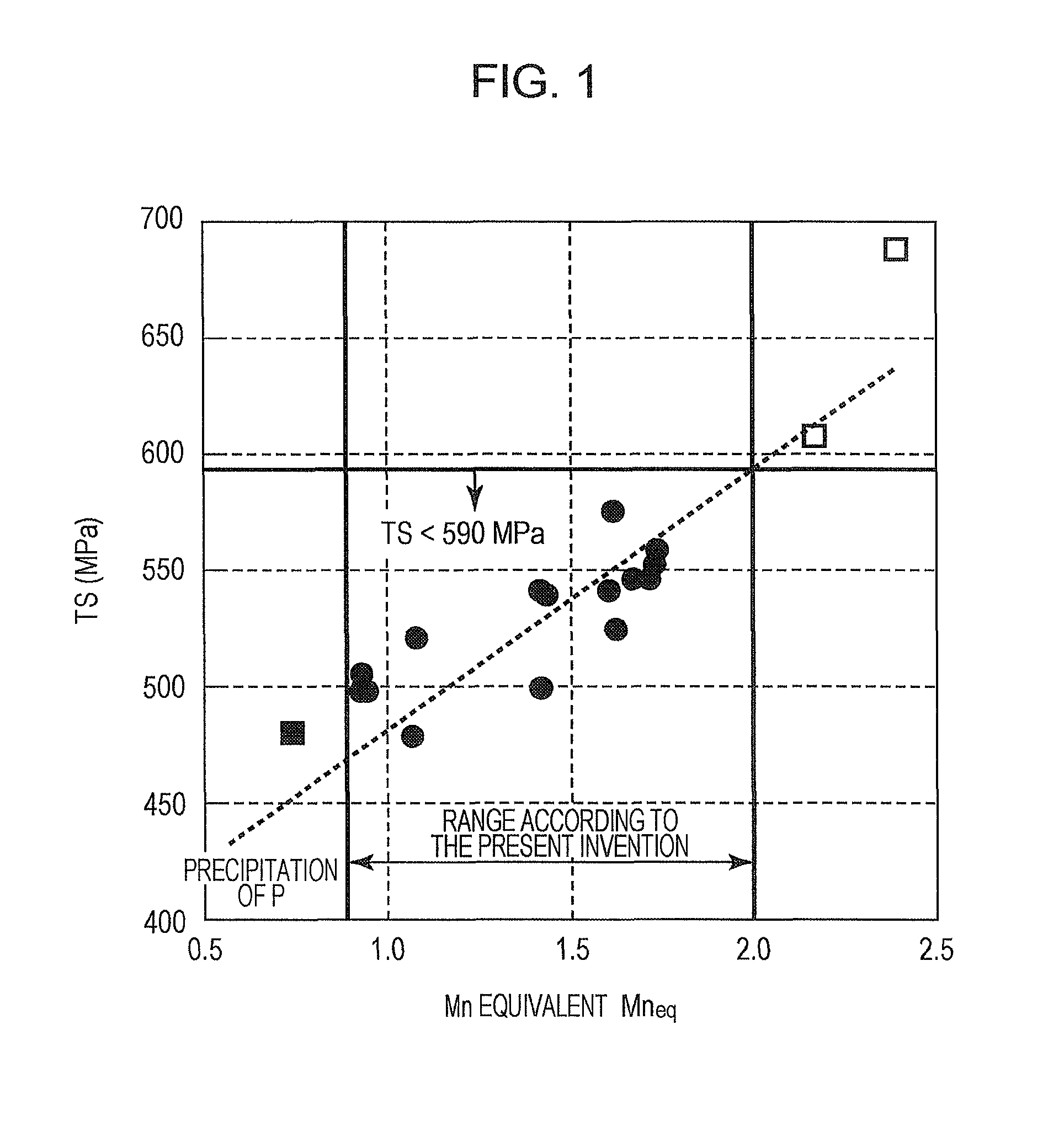

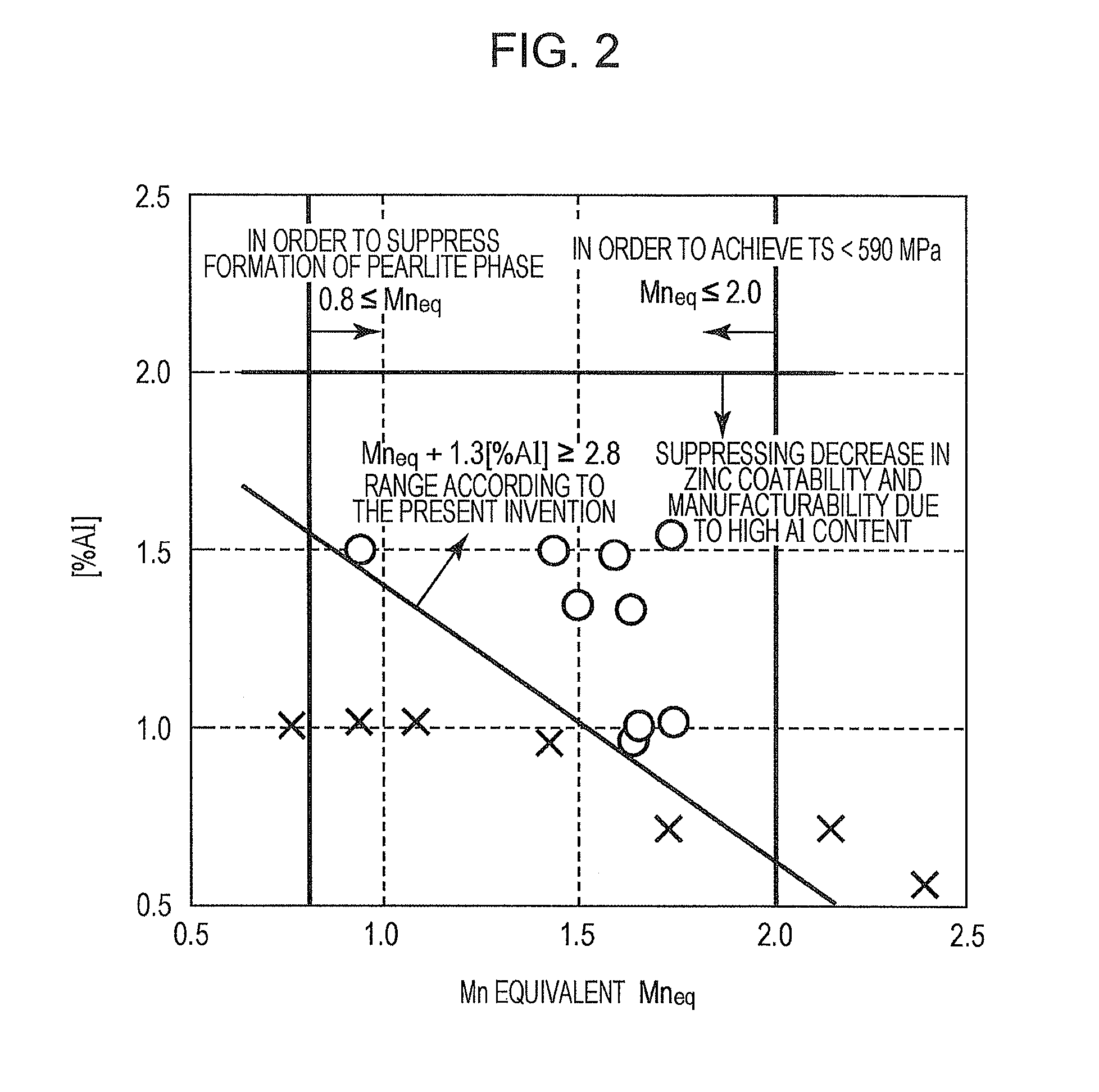

High strength galvanized steel sheet having excellent uniform elongation and zinc coatability and method for manufacturing the same

ActiveUS20130295410A1Increase in costHighly balanceHot-dipping/immersion processesFurnace typesPearliteSteel plates

A high strength galvanized steel sheet is provided comprising steel containing C: 0.06% or more and 0.20% or less, Si: less than 0.50%, Mn: 0.5% or more and less than 2.0%, P: 0.05% or less, S: 0.02% or less, Al: 0.60% or more and 2.00% or less, N: less than 0.004%, Cr: 0.10% or more and 0.40% or less and B: 0.003% or less, satisfying the relationships 0.8≦Mneq≦2.0 and Mneq+1.3[% Al]≧2.8, and a microstructure containing a ferrite phase and a second phase whose volume fraction is 15% or less, the second phase having a martensite phase whose volume fraction is 3% or more, a retained austenite phase whose volume fraction is 3% or more and a sum of the volume fractions of a pearlite phase and a bainite phase being equal to or less than the volume fraction of the martensite phase and the volume fraction of the retained austenite phase.

Owner:JFE STEEL CORP

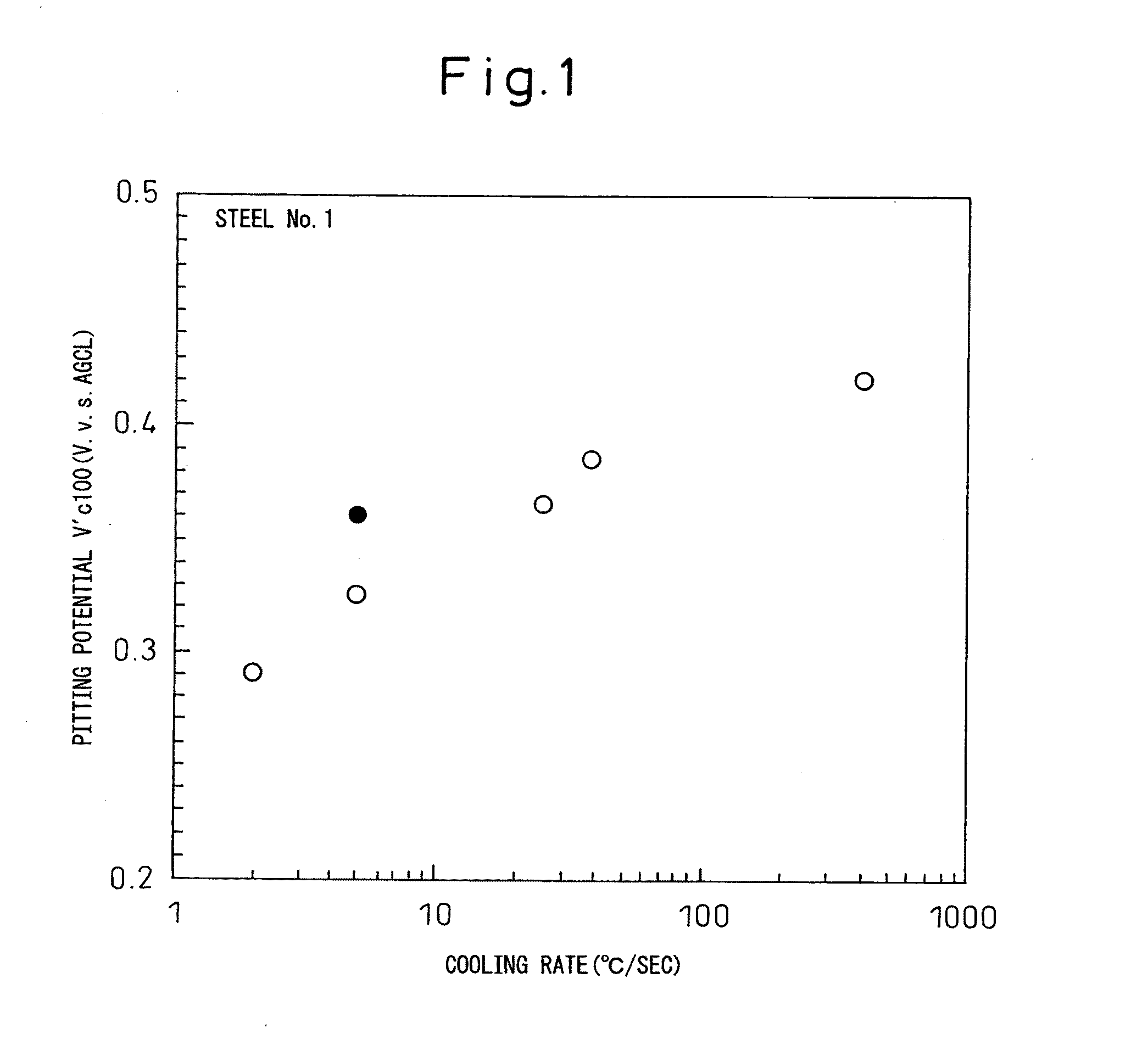

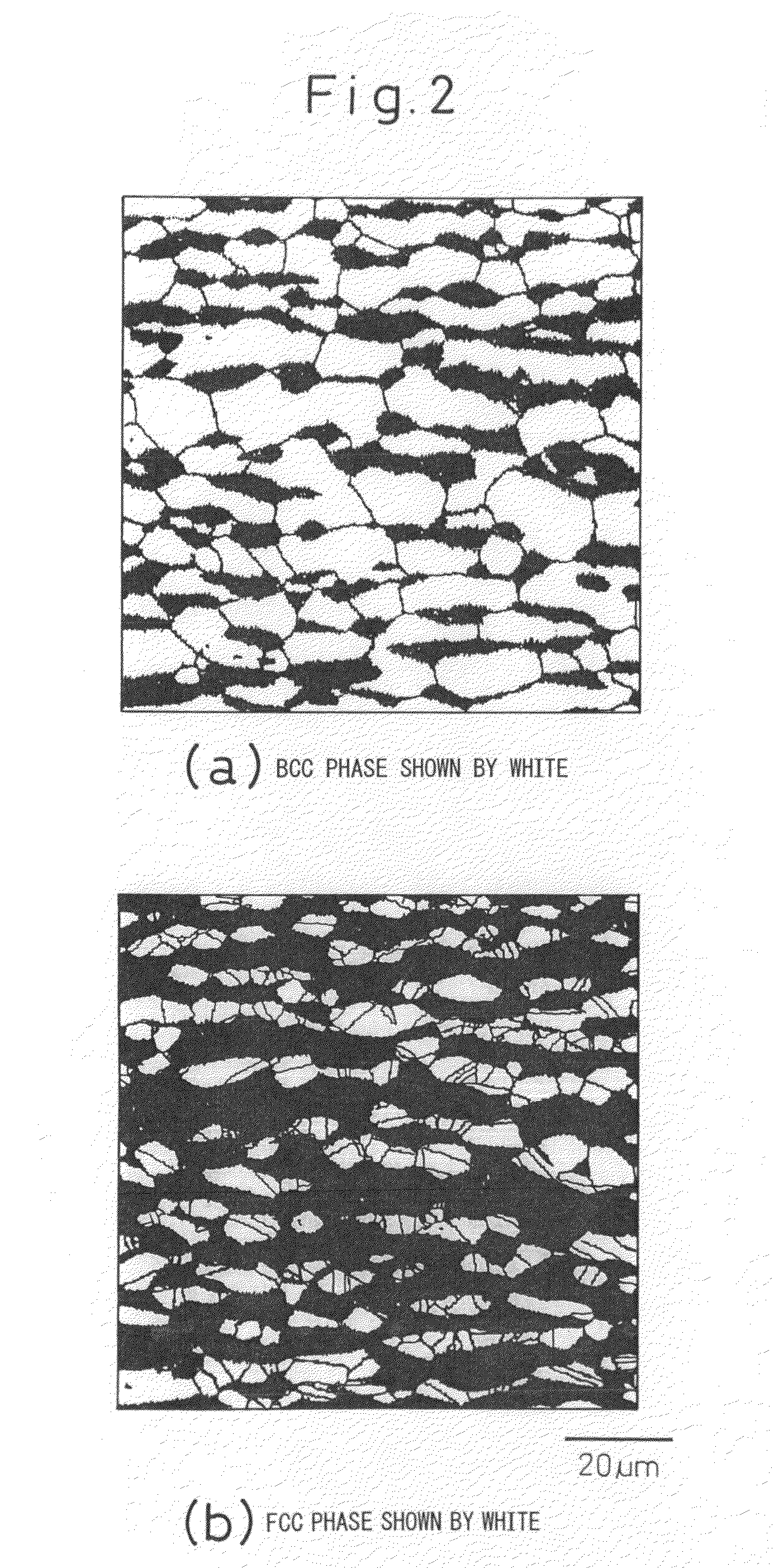

Ferritic-austenitic stainless steel excellent in corrosion resistance and workability andmethod of production of same

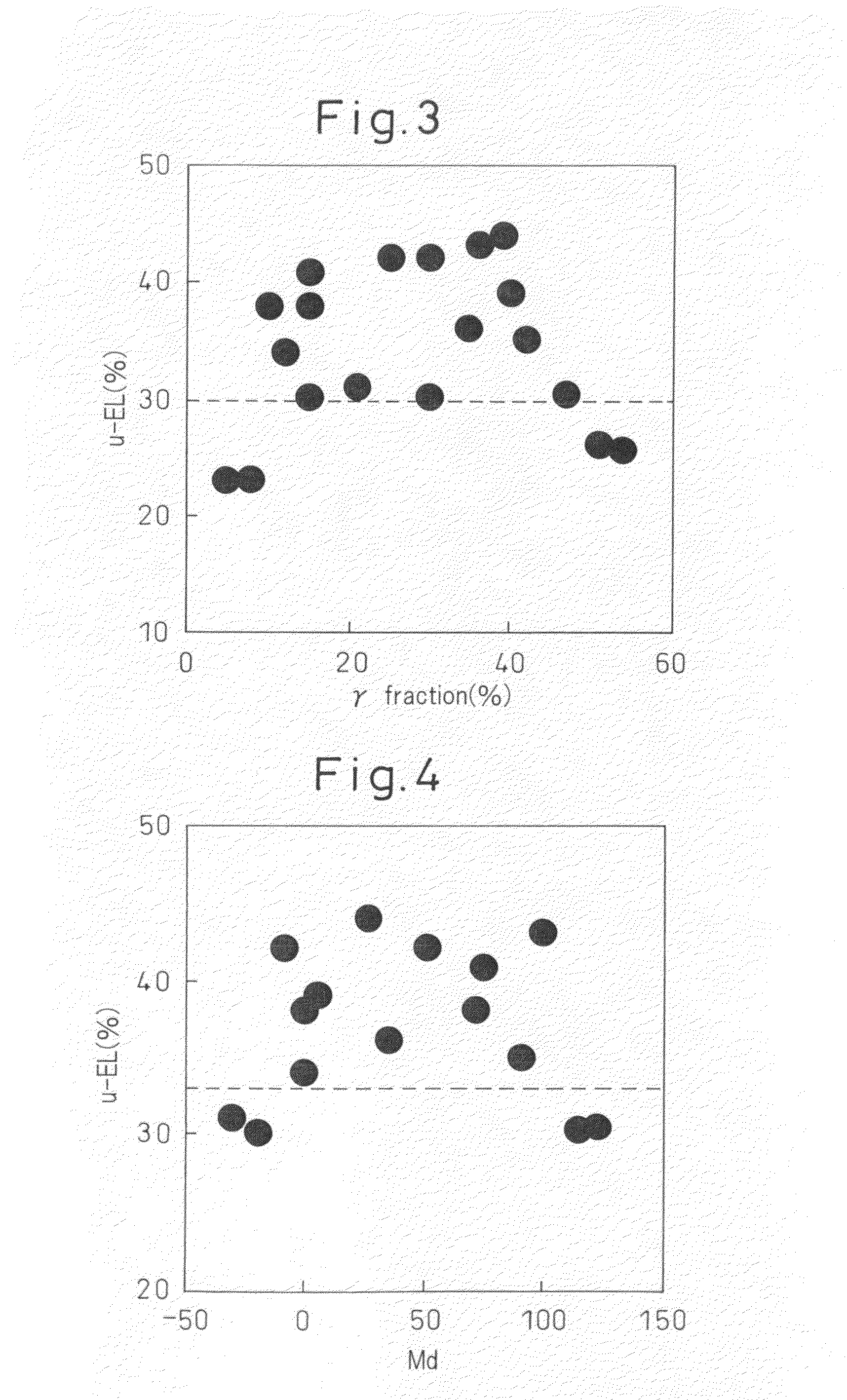

The present invention relates to ferritic-austenitic stainless steel oriented to have low Ni which is excellent in corrosion resistance, particularly in corrosion resistance in a neutral chloride environment, and has high “uniform elongation”—a factor governing workability—and a method of production for the same.There are independently provided ferritic-austenitic stainless steels and methods of production for the same particularly having a corrosion resistance in a neutral chloride environment satisfyingPI value(=Cr+3Mo+10N—Mn)≧18% and having a uniform elongation satisfying−10≦Md≦110 (where Md=551−462({C}+[N])−9.2[Si]−8.1[Mn]−13.7[Cr]−29[Ni]−29[Cu]−18.5[Mo], where [ ] is composition (mass %) in the austenite phase, and { } is average composition (mass %))

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

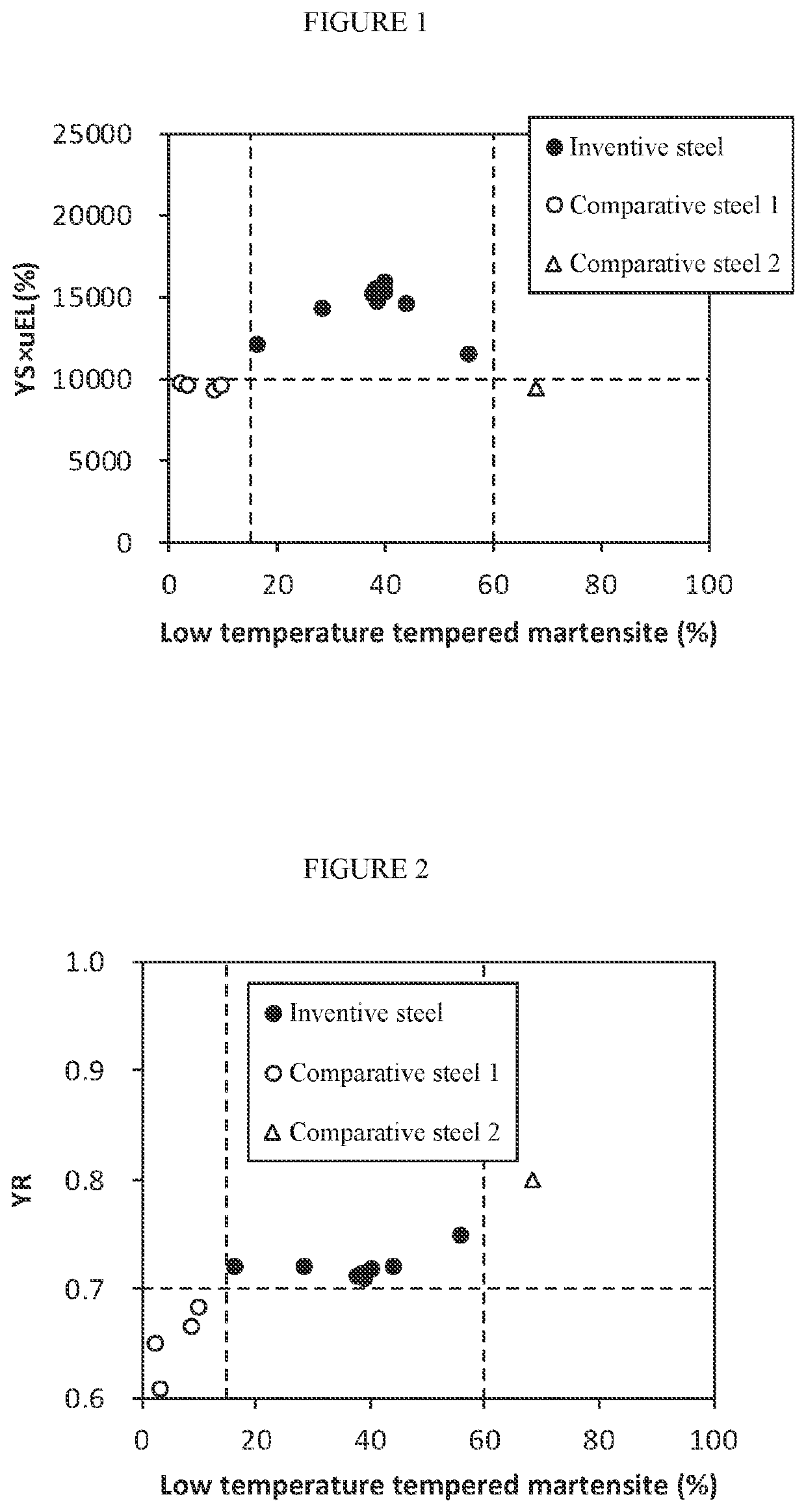

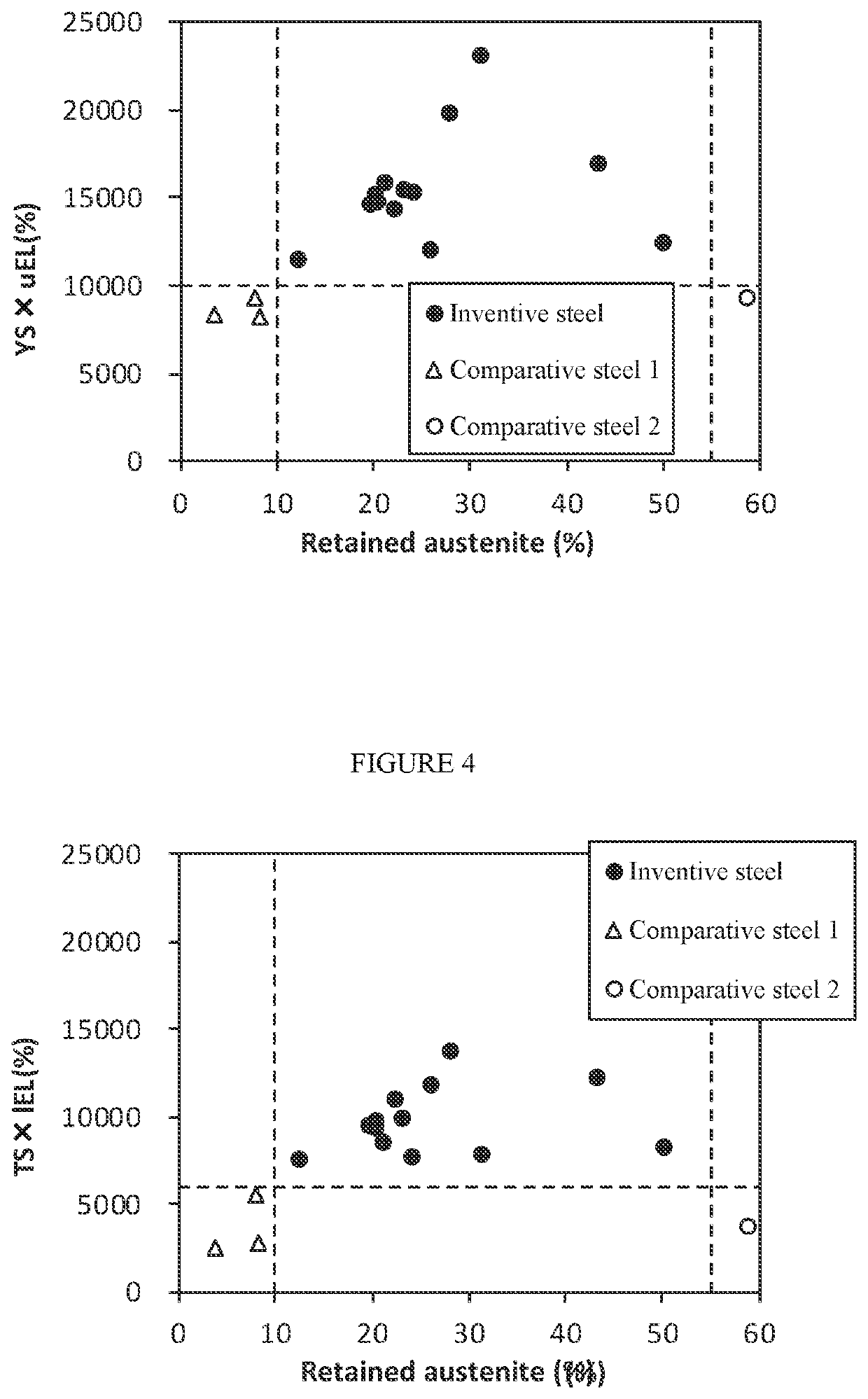

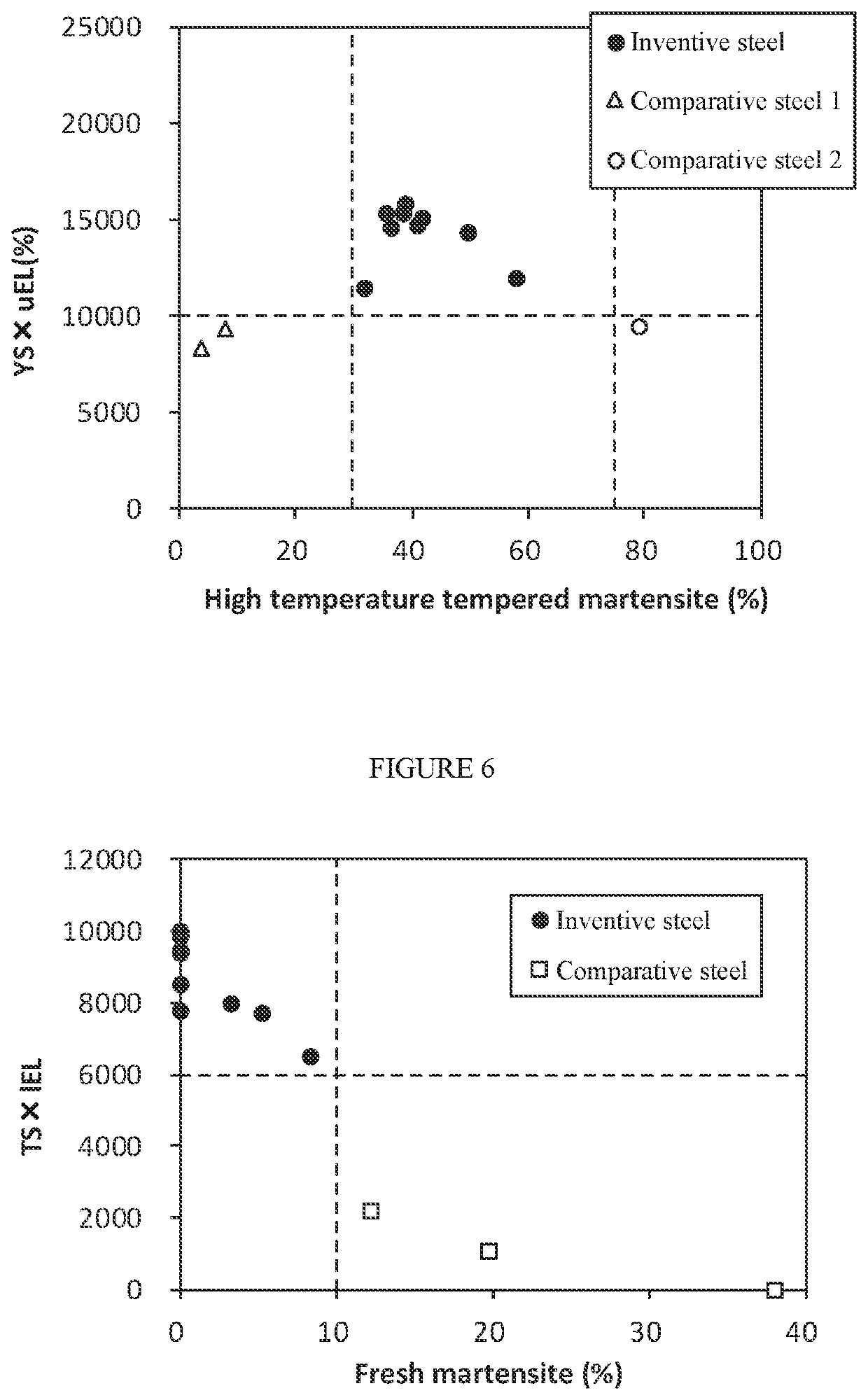

High-strength steel sheet

InactiveUS20200087764A1High uniform elongationHigh local elongationHot-dipping/immersion processesFurnace typesChemical compositionPearlite

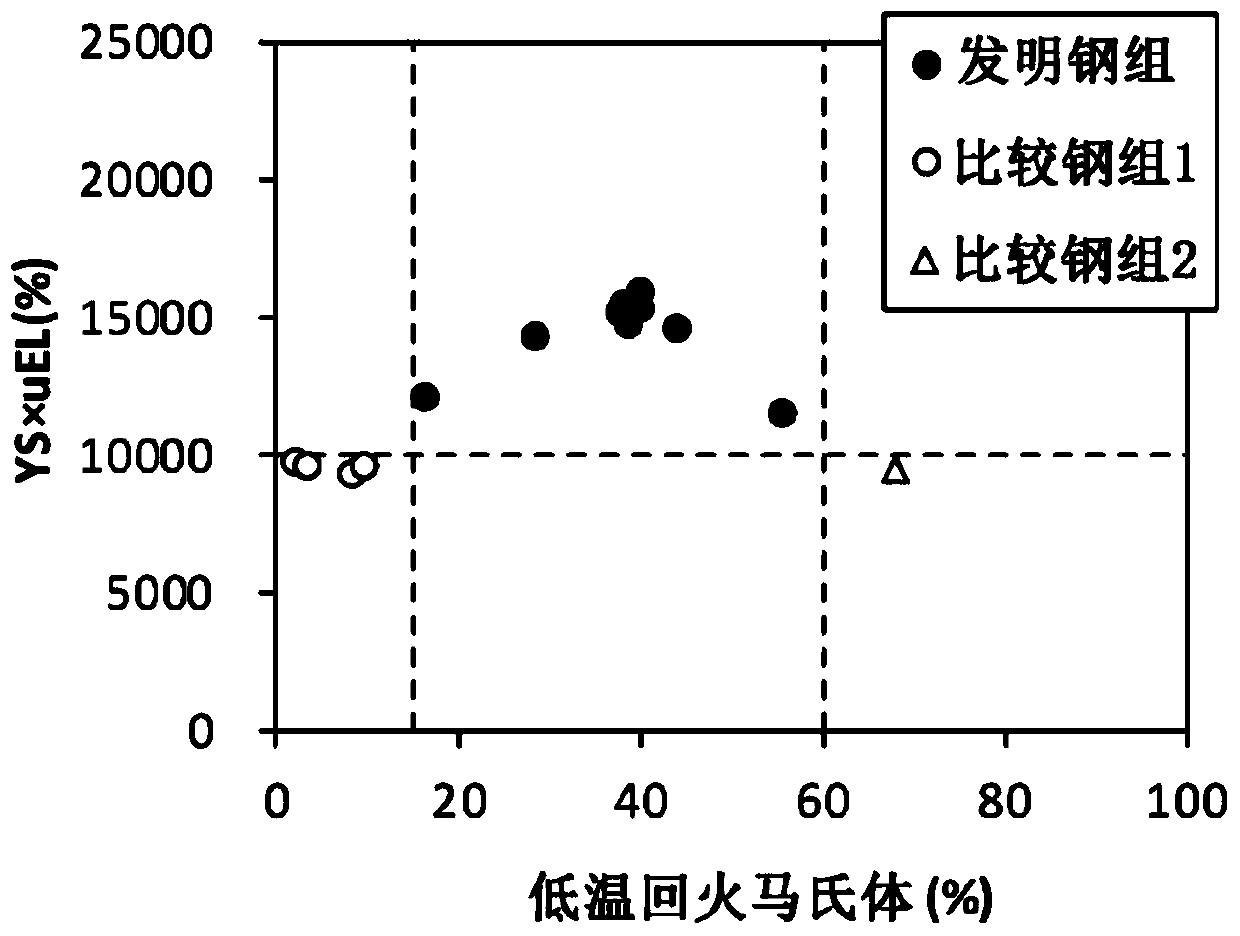

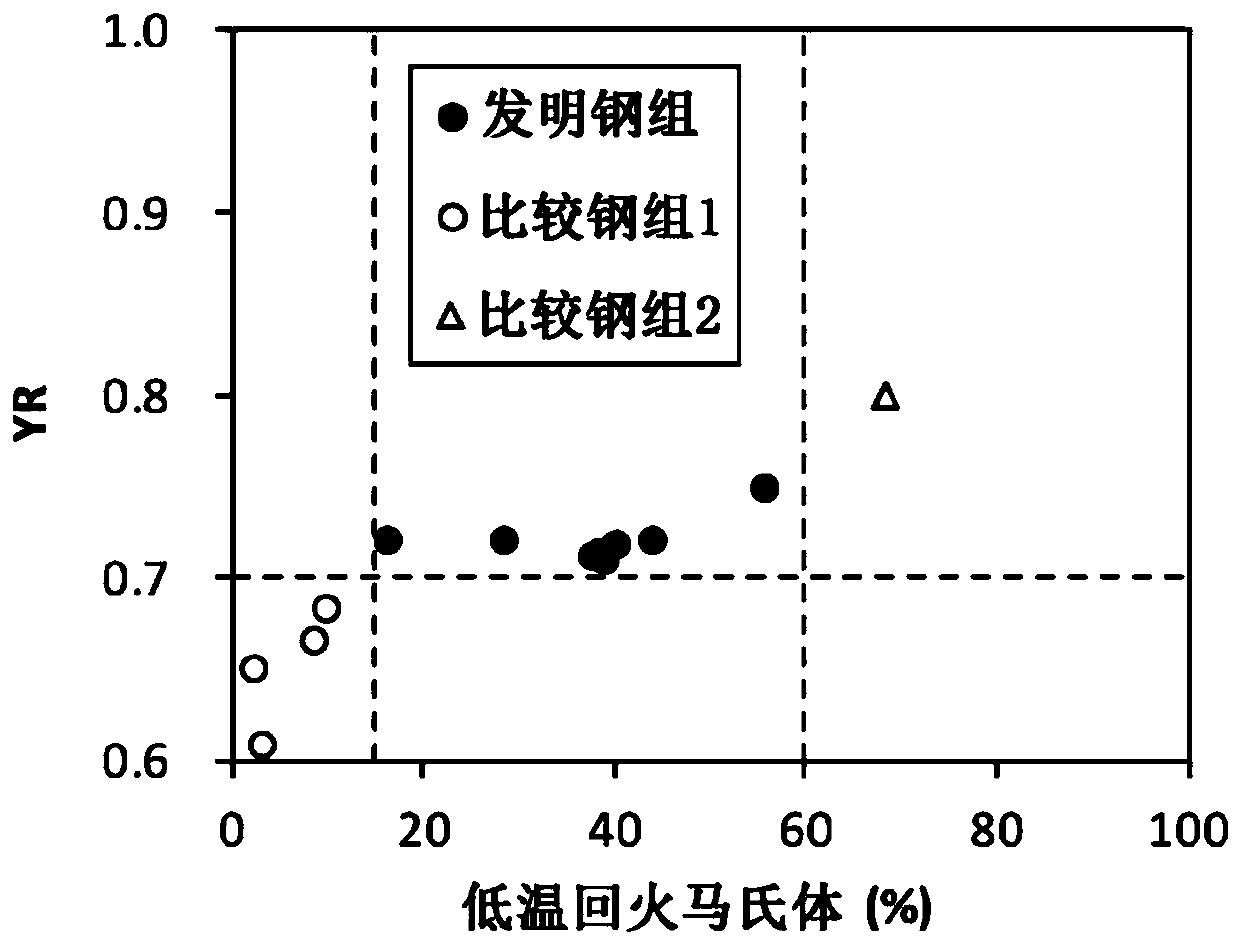

A high-strength steel sheet has a chemical composition consisting of, in mass percent, C: 0.10 to 0.24%, Mn: 3.50 to 12.00%, Si: 0.005 to 5.00%, Al: 0.005 to 5.00%, P: 0.15% or less, S: 0.030% or less, N: 0.020% or less, O: 0.010% or less, Cr: 0 to 5.00%, Mo: 0 to 5.00%, Ni: 0 to 5.00%, Cu: 0 to 5.00%, Nb: 0 to 0.50%, Ti: 0 to 0.50%, W: 0 to 0.50%, B: 0 to 0.010%, Ca: 0 to 0.05%, Mg: 0 to 0.05%, Zr: 0 to 0.05%, REM: 0 to 0.05%, Sb: 0 to 0.50%, Sn: 0 to 0.50%, As: 0 to 0.05%, and V: 0 to 2.0%, with the balance: Fe and impurities, and a steel micro-structure at a ¼ sheet-thickness position includes, in area percent, retained austenite: 10.0 to 55.0%, high temperature tempered martensite: 30.0 to 75.0%, and low temperature tempered martensite: 15.0 to 60.0%, with the balance including fresh martensite: 0 to 10.0%, pearlite: 0 to 5.0%, and bainite: 0 to 5.0%.

Owner:NIPPON STEEL CORP

High strength steel sheet

PendingCN110036128AHigh uniform elongationHot-dipping/immersion processesFurnace typesChemical compositionMetal

Owner:NIPPON STEEL CORP

Steel sheet

InactiveUS20190211427A1Improve solderabilityTensile strength highHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

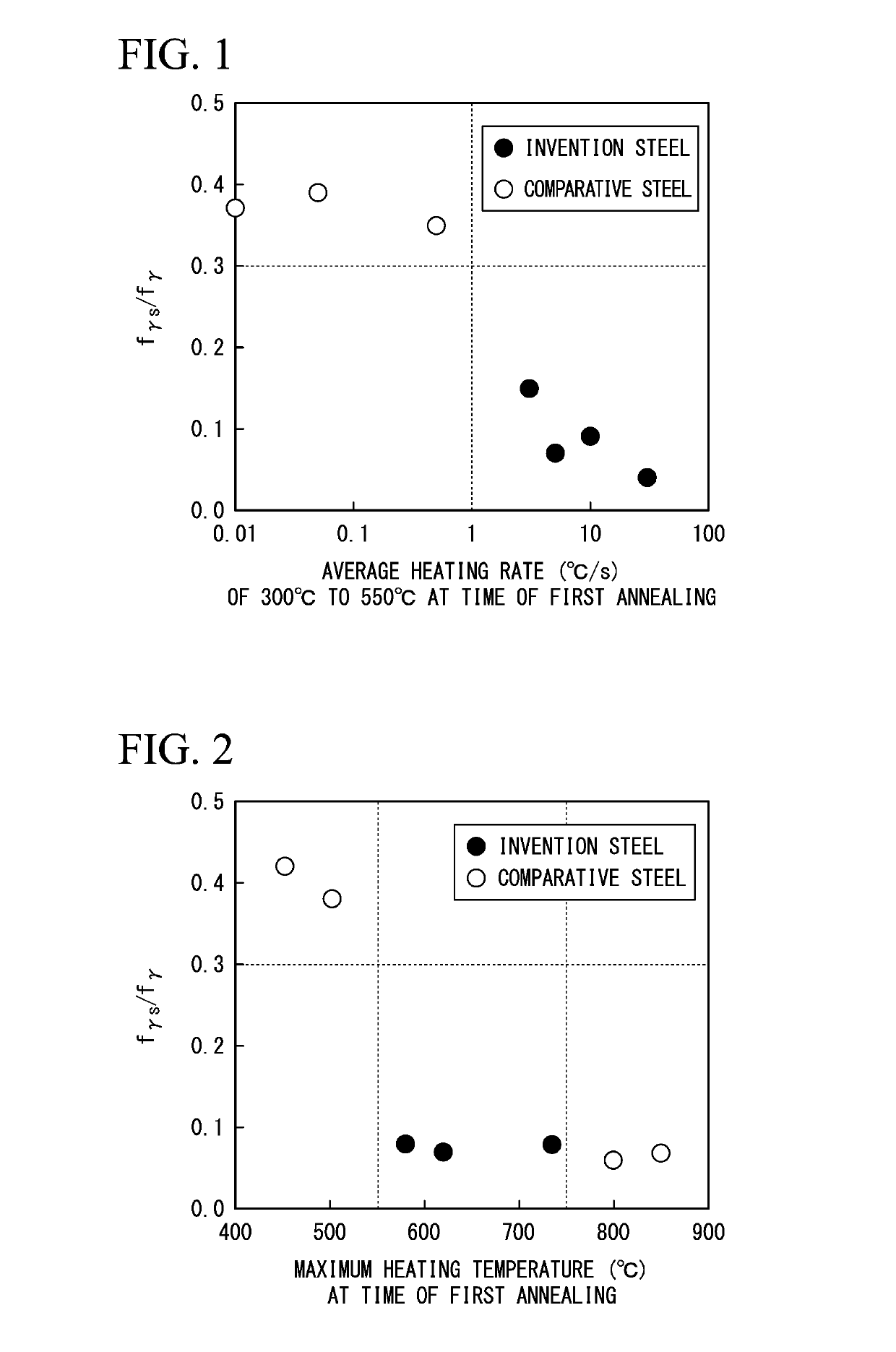

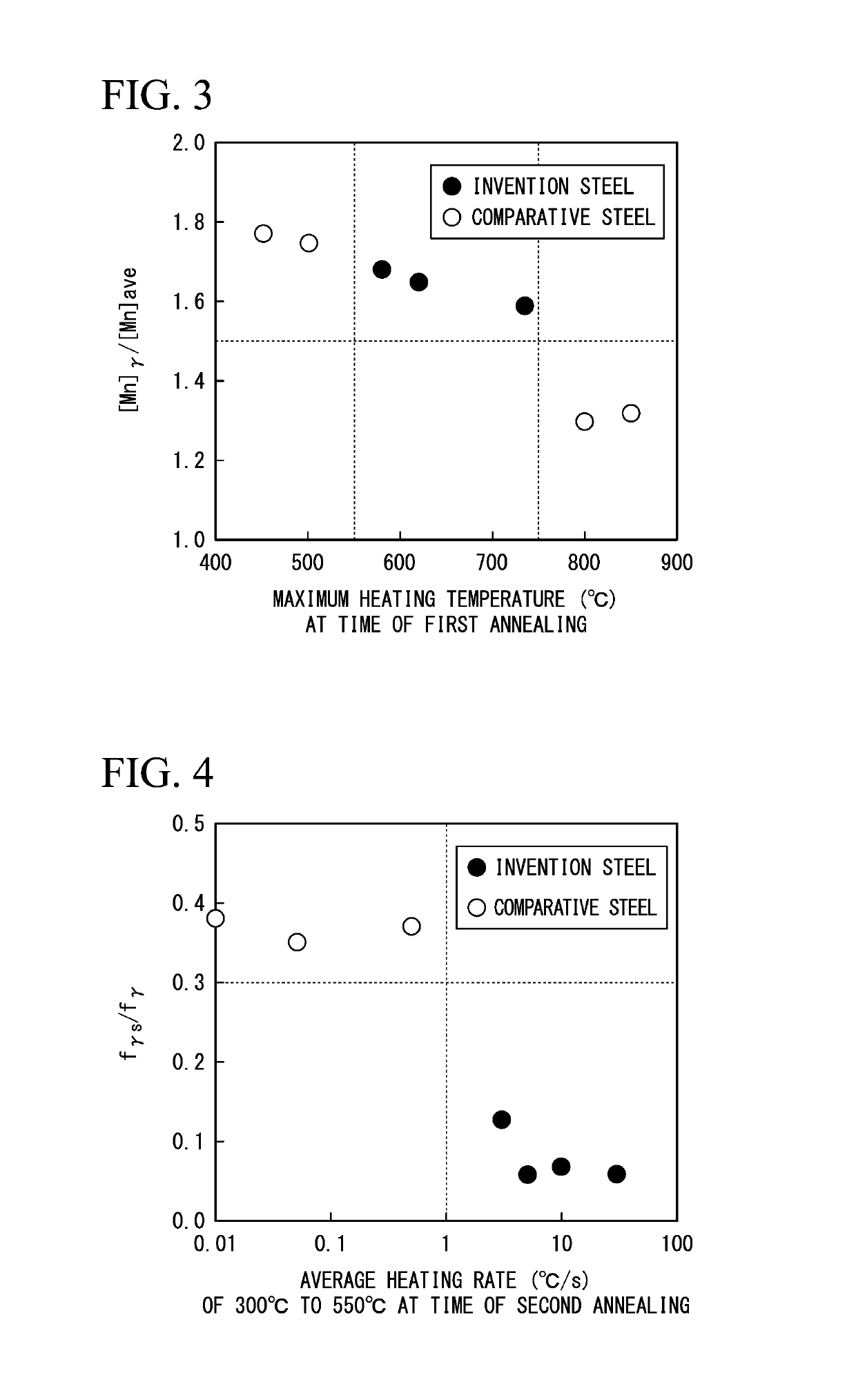

A steel sheet according to an aspect of the present invention includes a predetermined chemical composition; in which a metallographic structure in a ¼ t portion contains residual austenite of 4 volume % to 70 volume %; [Mn]γ / [Mn]ave>1.5 is satisfied in the ¼ t portion; fγs / fγ≤0.30 and [C]×[Mn]≥0.15 are satisfied in the ¼ t portion.

Owner:NIPPON STEEL CORP

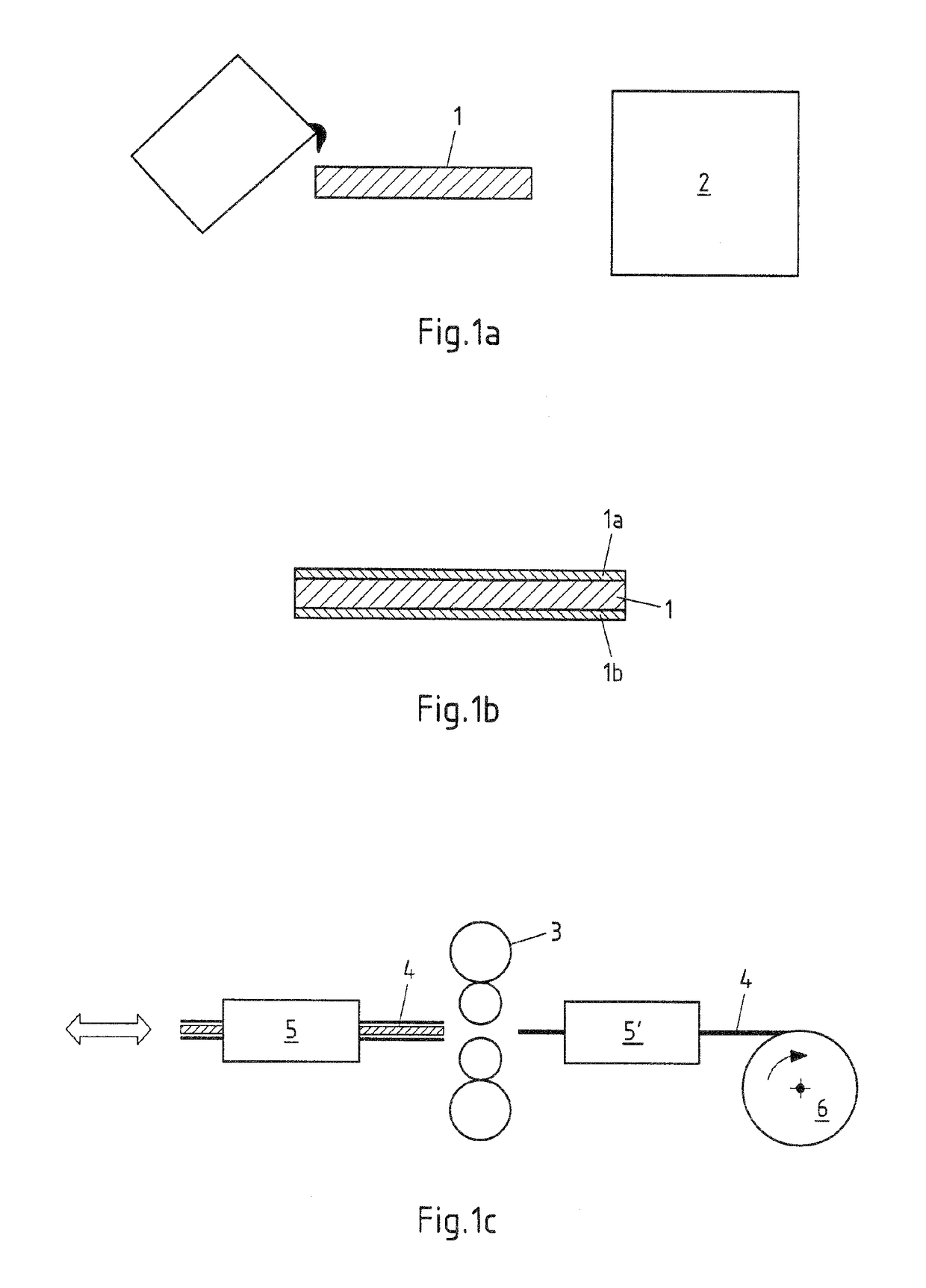

Aluminium Composite Material with AlMgSi Core Layer

ActiveUS20170259529A1Low tensile strengthImprove bending performanceThin material handlingMetal layered productsAluminum compositesUltimate tensile strength

The invention relates to a strip consisting of an aluminum material for producing components with improved bending behavior and exacting shaping requirements, a method for producing the strip and the use of sheets produced from the strip according to the invention. The strip has a core layer of an AlMgSi alloy and at least one outer aluminum alloy layer arranged on one or both sides, made from a non-hardenable aluminum alloy, wherein the at least one outer aluminum layer has a lower tensile strength in the (T4) state than the AlMgSi layer, wherein the strip has a uniform strain (Ag) in the (T4) state of more than 23% transverse to the rolling direction and, at a thickness of 1.5 mm-1.6 mm, achieves a bending angle of less than 40° in a bending test.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

High strength galvanized steel sheet having excellent uniform elongation and zinc coatability

ActiveUS9028973B2High strengthImprove galvanizing effectHot-dipping/immersion processesFurnace typesHigh intensityZinc

A high strength galvanized steel sheet is provided comprising steel containing C: 0.06% or more and 0.20% or less, Si: less than 0.50%, Mn: 0.5% or more and less than 2.0%, P: 0.05% or less, S: 0.02% or less, Al: 0.60% or more and 2.00% or less, N: less than 0.004%, Cr: 0.10% or more and 0.40% or less and B: 0.003% or less, satisfying the relationships 0.8≦Mneq≦2.0 and Mneq+1.3[% Al]≧2.8, and a microstructure containing a ferrite phase and a second phase whose volume fraction is 15% or less, the second phase having a martensite phase whose volume fraction is 3% or more, a retained austenite phase whose volume fraction is 3% or more and a sum of the volume fractions of a pearlite phase and a bainite phase being equal to or less than the volume fraction of the martensite phase and the volume fraction of the retained austenite phase.

Owner:JFE STEEL CORP

Steel plate having low yield ratio, high strength and high uniform elongation and method for producing same

Owner:JFE STEEL CORP

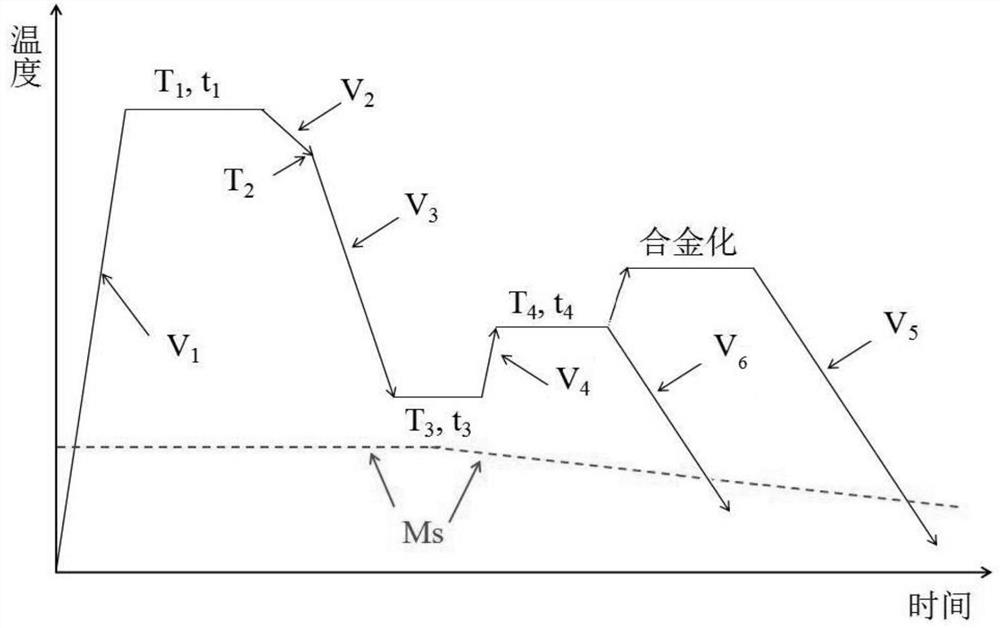

Cold-rolled hot-dip galvanized steel and manufacturing method thereof

ActiveCN112301293AGood formabilityHigh elongationHot-dipping/immersion processesThermal insulationHeat conservation

The invention discloses cold-rolled hot-dip galvanized steel. The cold-rolled hot-dip galvanized steel comprises the following chemical elements of, in percentage ration by mass, 0.06%-0.14% of C, 1.3%-2.4% of Mn, 0.1%-1.0% of Si, and the balance Fe and inevitable impurities; and the microstructure of the cold-rolled hot-dip galvanized steel is ferrite + martensite + bainite + retained austenite.In addition, the invention further discloses a manufacturing method of the above cold-rolled hot-dip galvanized steel. The manufacturing method comprises the steps that (1) smelting and casting are carried out; (2) hot rolling is carried out; (3) acid pickling is carried out; (4) cold rolling is carried out; (5) hot galvanizing recrystallization annealing is carried out, specifically, a cold-rolled sheet is heated to the soaking temperature T1 for thermal insulation for a period of time; and then the soaked steel plate is cooled to the intermediate temperature T2 at the first cooling speed andthen cooled to T3 at the second cooling speed, thermal insulation is carried out for a period of time, then the temperature is increased to the zinc pool temperature T4 for thermal insulation for a period of time, wherein the cooling speed is less than the second cooling speed, T2 is larger than or equal to 640 DEG C and less than or equal to T1, and T3 is larger than Ms and less than or equal toT4; and (6) cooling is carried out to the room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

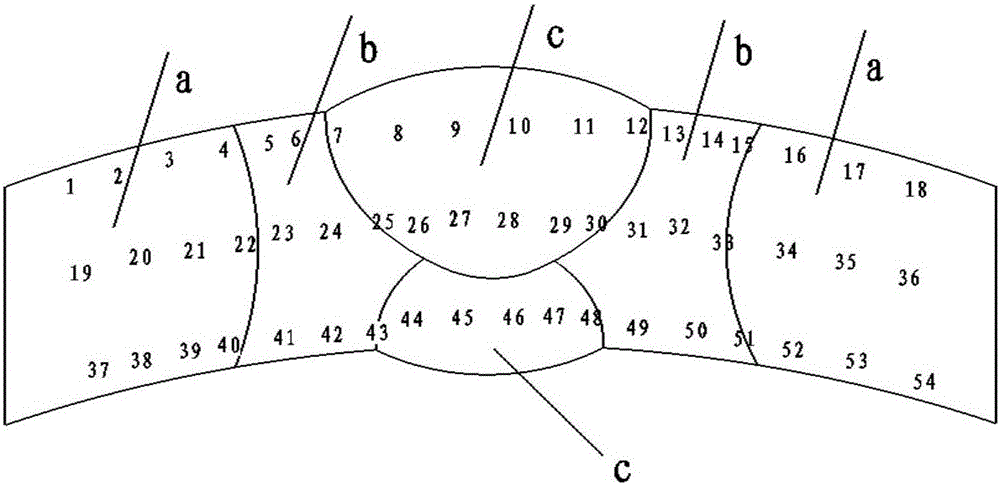

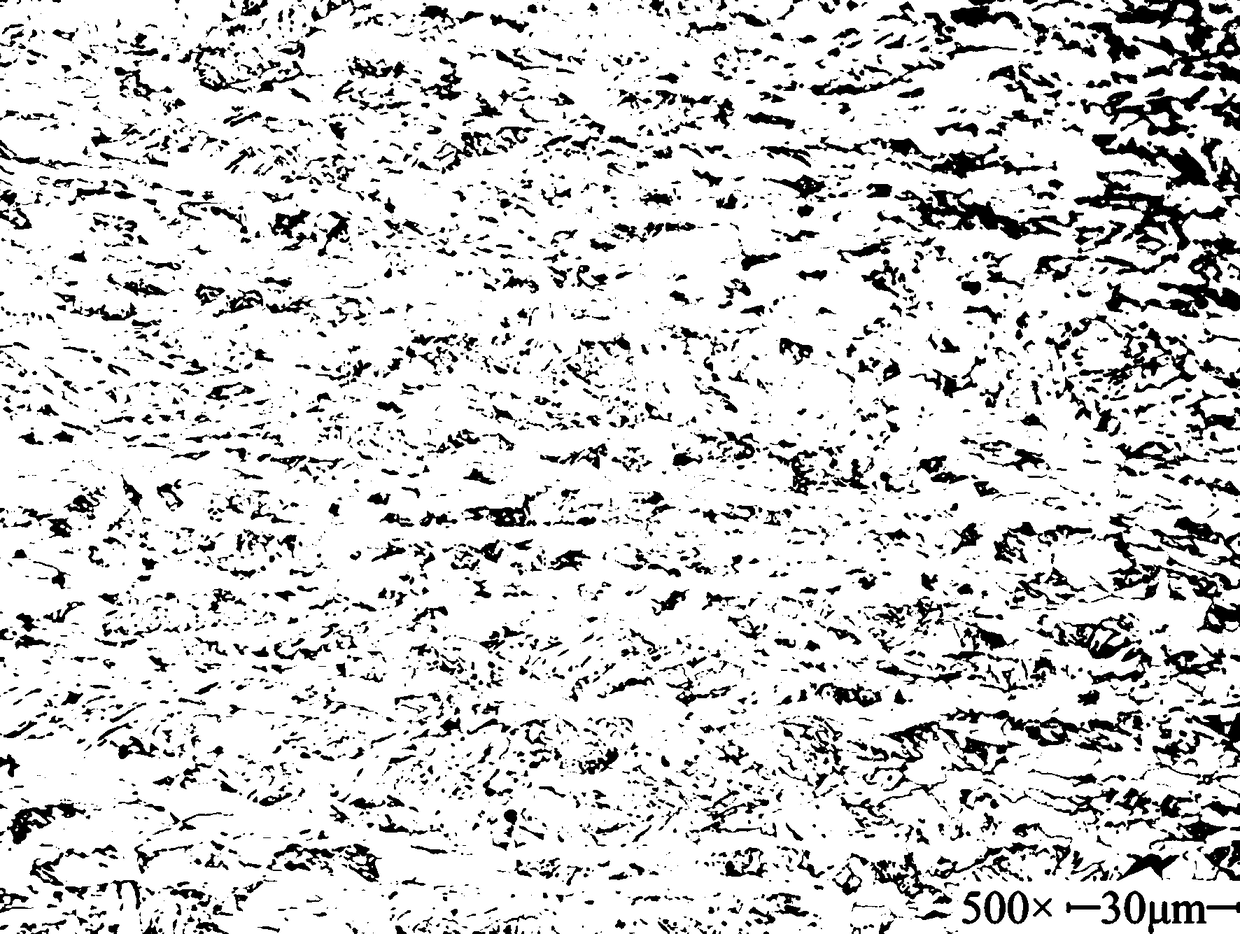

Pipeline steel X70 steel plate in low compression ratio, and production method thereof

ActiveCN109161813AImprove material uniform elongationImprove drop weight performanceSteel platesSheet steel

The invention provides a pipeline steel X70 steel plate in low compression ratio, and a production method thereof. The pipeline steel X70 steel plate in low compression ratio is prepared from the following components in weight percent: C is 0.030-0.080%, Mn is 1.55-1.75%, Si is 0.10-0.40%, S is not more than 0.0050%, P is not more than 0.015%, Nb is 0.035-0.060%, Ti is 0.008-0.025%, V is not morethan 0.10%, Alt is 0.020-0.060%, Cr is not more than 0.30%, Mo is not more than 0.20%, and the balance of Fe and unavoidable impurities. In the production method of the steel plate provided by the invention, the X70 pipeline steel with low compression rate and thick specification is produced in batch by adopting laminar subsection cooling process, and the engineering technical requirement is satisfied.

Owner:ANYANG IRON & STEEL

Alloy pipe containing 18-24% of Mn and manufacturing method thereof

The invention relates to an alloy pipe containing 18-24% of Mn and a manufacturing method thereof. The alloy pipe comprises: 0.002-0.2% of C, 18-24% of Mn, 0-4% of Si, 0-5% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, or one or more of 1-6% of Cr, 0.1-0.5% of Cu, 0.01-0.6% of Nb, 0.01-0.1% of Ti and 0.01-0.3% of V, and balance of Fe. The manufacturing method comprises the following steps: casting the raw materials by vacuum melting, carrying out homogenizing annealing and hot-rolling on the casted materials so as to be manufactured into steel plates or bars; carrying out resistance-welding or hot-rolling on the steel plates or balls so as to be manufactured into pipe blanks; carrying out solid solution treatment and ageing treatment on the pipe blanks, wherein the obtained product has a uniform elongation percentage no less than 50% and a yield strength of 300-400MPa; and carrying out dilatational strain of 30% on the pipe blanks, wherein the obtained product has the uniform elongation percentage no less than 20%, the yield strength of 560-760MPa and the yield ratio of 0.62-0.80.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low yield ratio, high strength and high toughness steel plate and method for manufacturing the same

ActiveUS20120241057A1Yield ratio decreaseIncrease of uniform elongationFurnace typesHeat treatment furnacesAbsorbed energyCharpy impact test

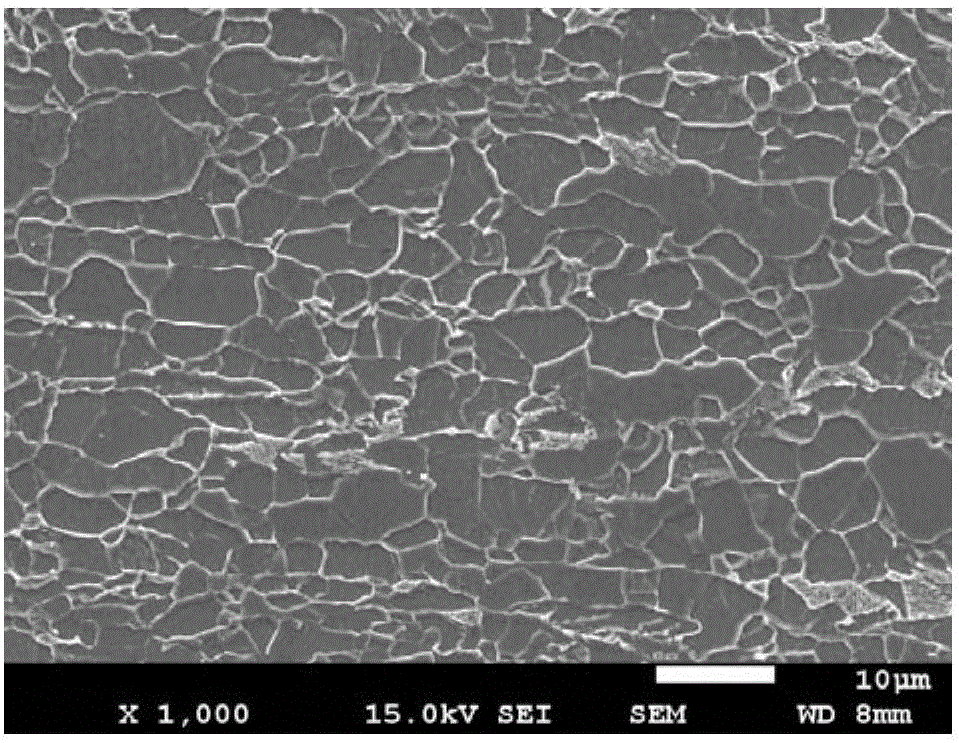

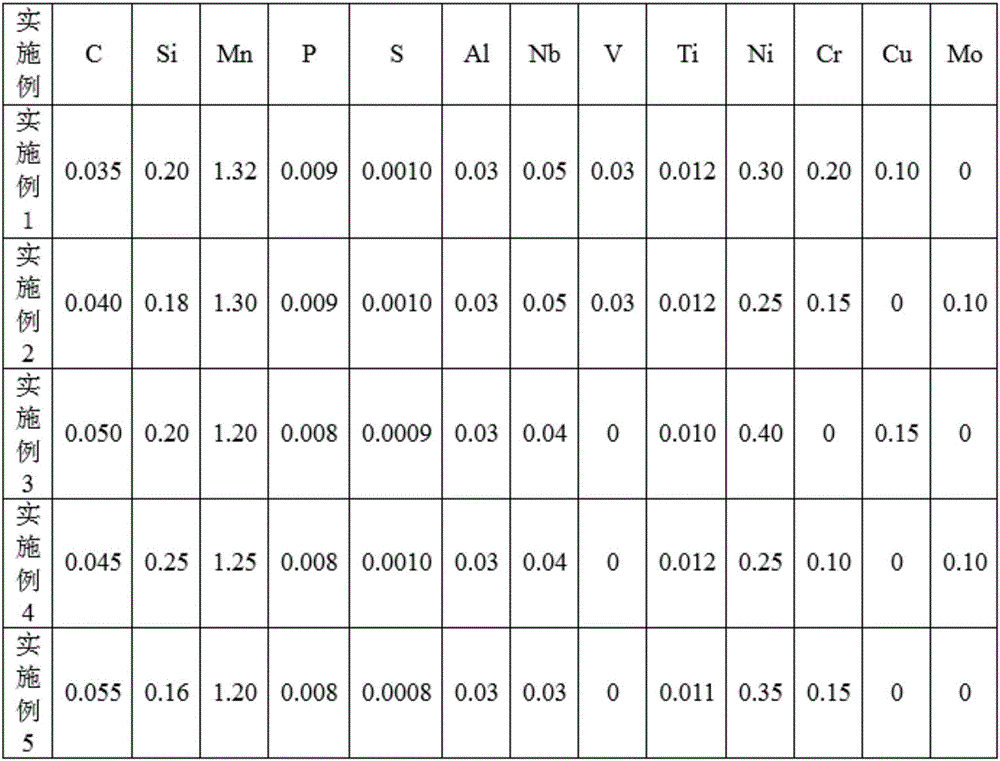

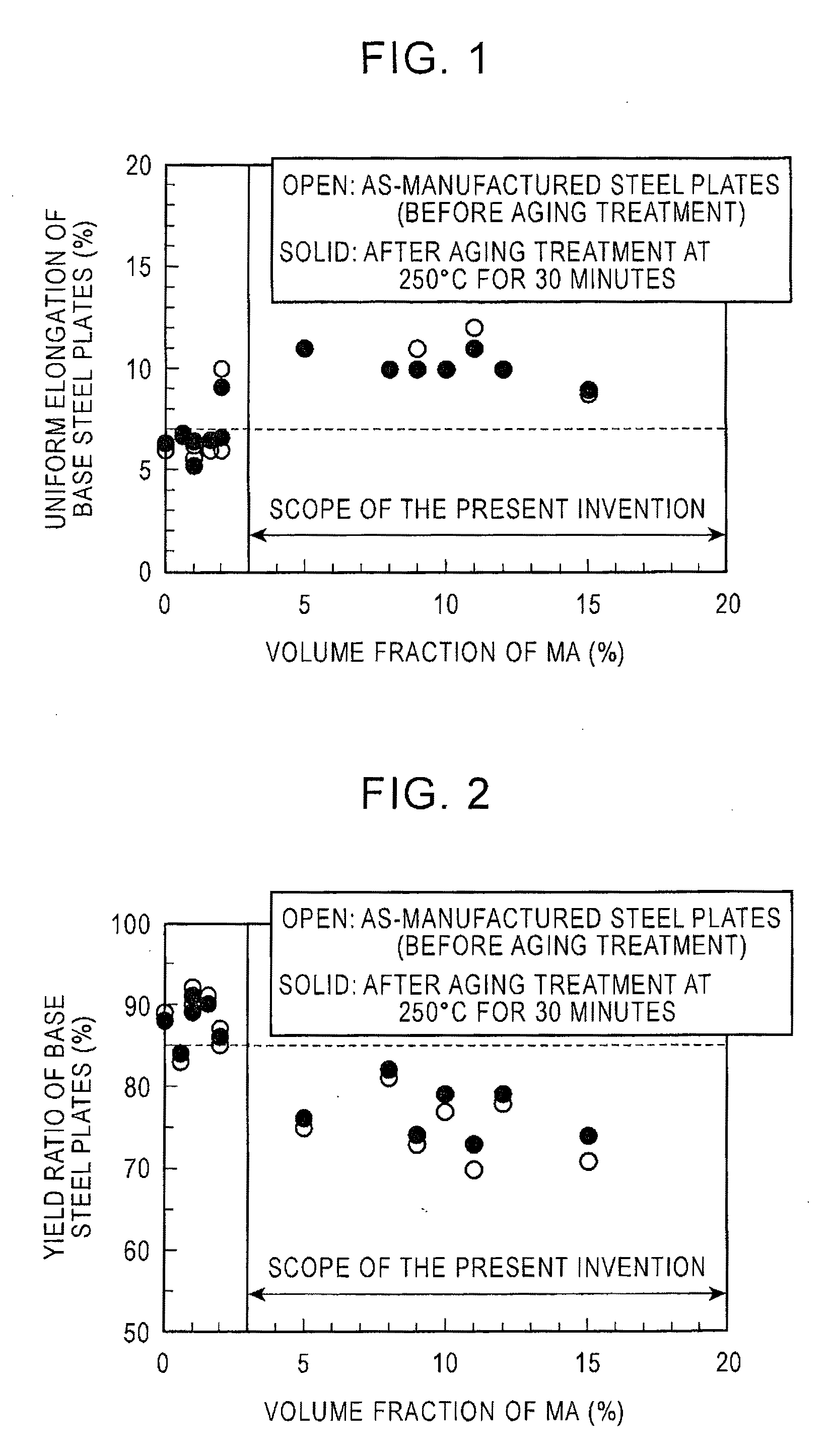

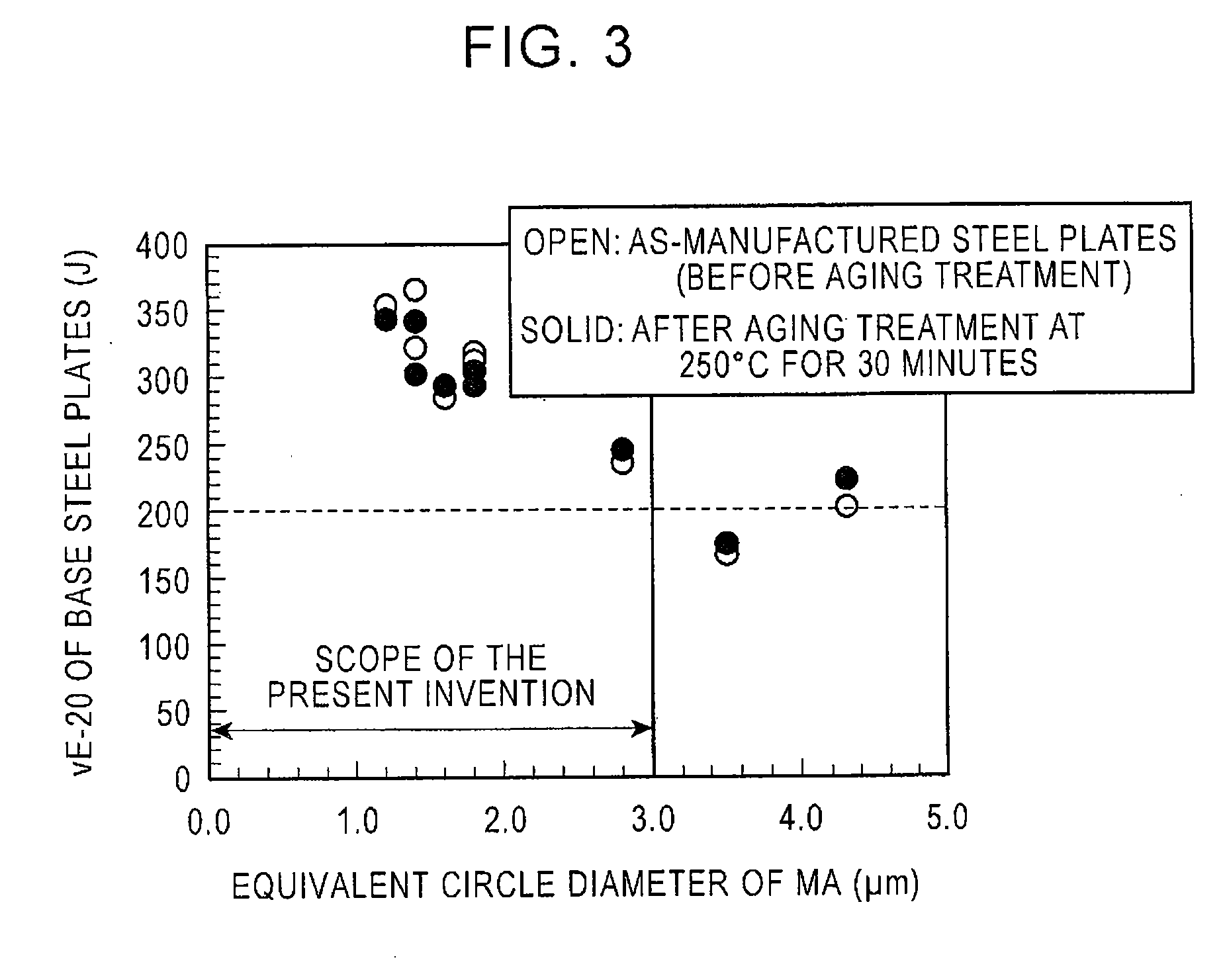

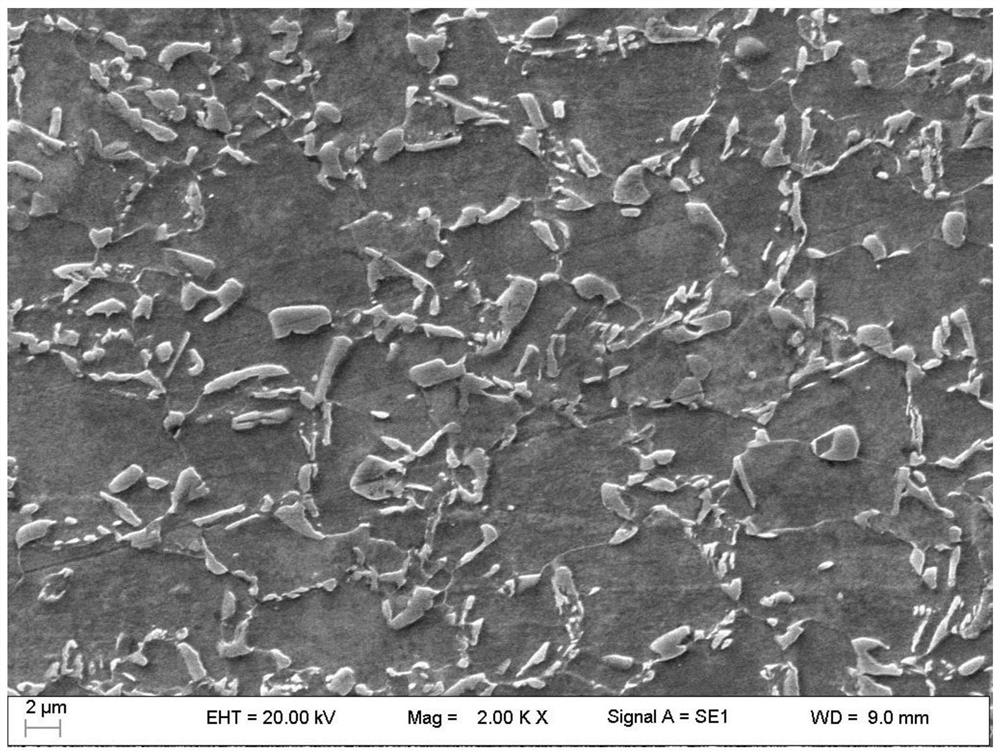

Provided is a low yield ratio, high strength and high toughness steel plate having excellent strain ageing resistance equivalent to API 5L X70 Grade or lower and a method for manufacturing the same. The steel plate has a metallographic microstructure that is a three-phase microstructure consisting of bainite, M-A constituent, and quasi-polygonal ferrite, the area fraction of the bainite being 5% to 70%, the area fraction of the M-A constituent being 3% to 20%, the remainder being the quasi-polygonal ferrite, the equivalent circle diameter of the M-A constituent being 3.0 μm or less. The steel plate has a yield ratio of 85% or less and a Charpy impact test absorbed energy of 200 J or more at −30° C. before or after being subjected to strain ageing treatment at a temperature of 250° C. or lower for 30 minutes or less.

Owner:JFE STEEL CORP

A kind of x70 anti-large deformation pipeline steel and its manufacturing method

The invention discloses an X70 large deformation resisting pipeline steel and a manufacturing method. The steel comprises chemical components including, by mass percent, 0.04%-0.09% of C, 0.15%-0.55% of Si, 1.45%-1.75% of Mn, 0.04%-0.10% of Nb, 0.02%-0.08% of V, 0.01%-0.03% of Ti, 0%-0.20% of Cu, 0.15%-0.55% of Ni, 0%-0.15% of Mo, 0.15%-0.45% of Cr, 0.025%-0.045% of Al, 0.0002%-0.011% of N, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, and the balance Fe and other inevitable impurity elements. Production of the X70 large deformation resisting pipeline steel comprises the following process routes of material preparing, converter or electric furnace smelting, furnace exterior refining, casting, slab reheating, controlled rolling and controlled cooling, and after two-phase region quenching, tempering is conducted or the tempering technology is not adopted. Compared with the prior art, the X70 large deformation resisting pipeline steel and the manufacturing method have the beneficial effects that the yield ratio is lower, the uniform ductility is higher, tenacity matching is better, the steel plate and copper plate performance difference is small, the structure uniformity in the thickness direction is high, and the strip-shaped level is low.

Owner:ANGANG STEEL CO LTD

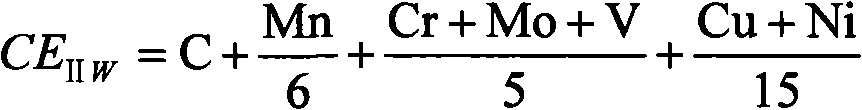

Anti-large-deformation pipe line steel prepared by thermal treatment method and preparation method thereof

The invention discloses anti-large-deformation pipe line steel prepared by a thermal treatment method and a preparation method thereof. The steel comprises the following chemical components of: not less than 0.02% and not greater than 0.12% of C, not less than 0.5% and not greater than 2.0% of Mn, not more than 0.25% of Si, not more than 0.02% of P, not more than 0.01% of S, not more than 0.11% of Nb, not more than 0.08% of V, not more than 0.05% of Ti, not more than 0.06% of Al, not more than 0.012% of N, not more than 0.50% of Cu, not more than 0.60% of Cr, not more than 0.50% of Mo, not more than 0.60% of Ni, not more than 0.005% of B, not more than 0.01% of Ca and the balance of Fe and inevitable impurities, wherein the CEIIW is not less than 0.3% and not greater than 0.45%, and the CEPcm is not more than 0.2%. The preparation method comprises the following steps of: heating steel at 700-950 DEG C in a thermal treatment furnace, maintaining the temperature for 6-15 min, cooling with the rate of 1-400 DEG C / s to room temperature, and simultaneously tempering from room temperature to 500 DEG C to obtain steel with ferrite as a first phase and bainite, martensite, degenerate perlite or any mixture thereof as a second phase. The steel has the advantages of high tensile strength, low yield strength, low yield ratio, high uniform elongation rate and high strain hardening exponent, thereby having good toughness and deformation performance.

Owner:NANJING IRON & STEEL CO LTD

A kind of x80 anti-large deformation pipeline steel and its manufacturing method

The invention discloses X80 large deformation resisting pipeline steel and a manufacturing method. The steel comprises the following chemical components in percentage by mass: 0.04-0.09% of C, 0.15-0.55% of Si, 1.50-1.75% of Mn, 0.04-0.10% of Nb, 0.02-0.08% of V, 0.01-0.03% of Ti, 0.15-0.55% of Cu, 0.15-0.55% of Ni, 0-0.15% of Cr, 0.15-0.45% of Mo, 0.025-0.045% of Al, 0.0002-0.011% of N, P not more than 0.015%, S not more than 0.005%, and the balance of Fe and inevitable impurity elements. The manufacturing method adopts the process route of: material preparation-converter or electric furnace smelting-furnace external refining-casting-plate blank reheating-control rolling-control cooling; and the tempering process is adopted or not adopted after two-phase area quenching. Compared with the prior art, the steel has such advantages as lower yield ratio, higher uniform ductility, better toughness matching, low identical plate performance difference of steel plates, high thickness direction structure uniformity and low belt-shaped grade.

Owner:ANGANG STEEL CO LTD

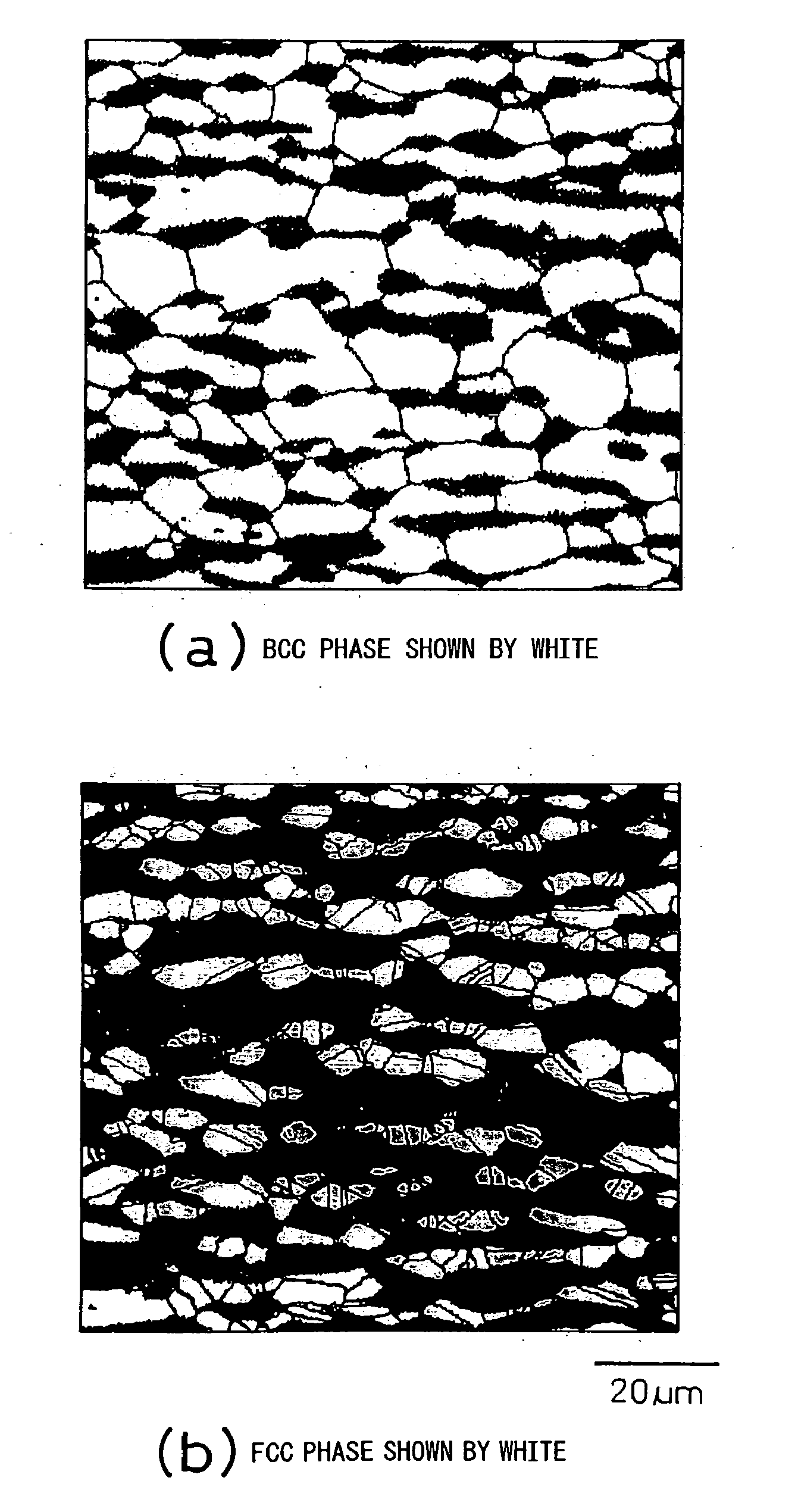

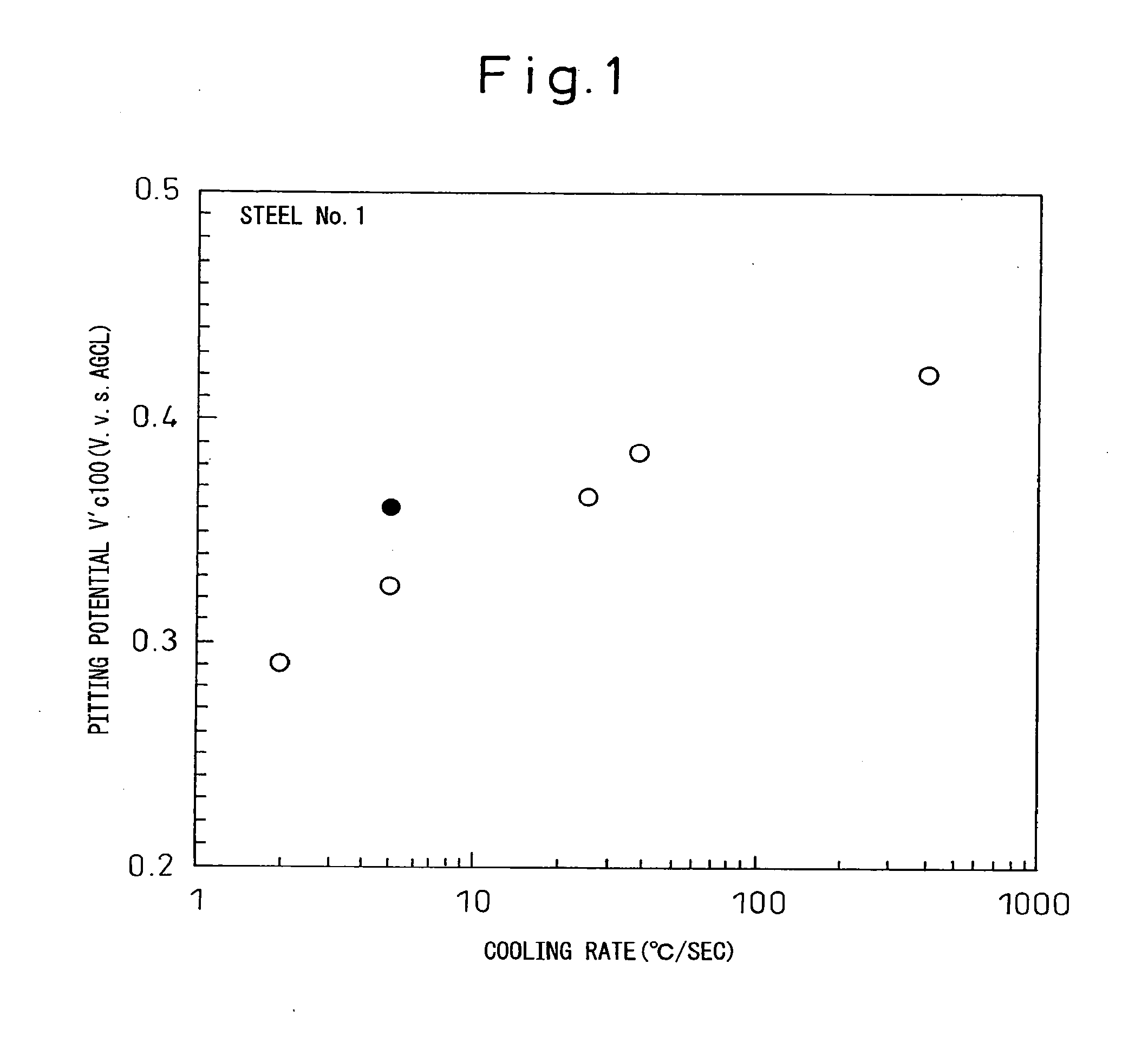

Ferritic-austenitic stainless steel excellent in corrosion resistance and workability and method of production of same

InactiveUS20130118650A1Improve corrosion resistanceHigh “uniform elongation”ChlorideMethods of production

The present invention relates to ferritic-austenitic stainless steel oriented to have low Ni which is excellent in corrosion resistance, particularly in corrosion resistance in a neutral chloride environment, and has high “uniform elongation”—a factor governing workability—and a method of production for the same.There are independently provided ferritic-austenitic stainless steels and methods of production for the same particularly having a corrosion resistance in a neutral chloride environment satisfyingPI value(=Cr+3Mo+10N−Mn)≧18% and having a uniform elongation satisfying−10≦Md≦110 (where Md=551−462({C}+[N])−9.2[Si]−8.1[Mn]−13.7[Cr]−29[Ni]−29[Cu]−18.5[Mo], where [ ] is composition (mass %) in the austenite phase, and { } is average composition (mass %))

Owner:NIPPON STEEL CORP

Steel material and expandable oil country tubular goods

InactiveUS20170349982A1High uniform elongationExcellent SSC resistanceFurnace typesHeat treatment furnacesMicro structureChemical composition

There is provided a steel material having a chemical composition consisting, by mass percent, of C: 0.6-1.8%, Si: 0.05-1.00%, Mn: >25.0-45.0%, Al: 0.003-0.06%, P: ≦0.03%, S: ≦0.03%, Cu: 0.5-3.0%, N: ≦0.10%, V: 0-2.0%, Cr: 0-3.0%, Mo: 0-3.0%, Ni: 0-1.5%, Nb: 0-0.5%, Ta: 0-0.5%, Ti: 0-0.5%, Zr: 0-0.5%, Ca: 0-0.005%, Mg: 0-0.005%, REM: 0-0.01%, B: 0-0.015%, the balance: Fe and impurities, and satisfying [0.6<C−0.18V<1.44], wherein a metal micro-structure is consisting of an austenite single phase, a yield strength is 241 MPa or higher, and a uniform elongation is 40% or higher.

Owner:NIPPON STEEL CORP

Corrosion resistant alloy weldments in carbon steel structures and pipelines to accommodate high axial plastic strains

ActiveUS9040865B2Simplifies its qualificationSimple designCooking-vessel materialsArc welding apparatusCorrosion resistant alloyTear resistance

A method and apparatus for joining materials having primarily ferritic properties is described. The method includes joining the ferritic materials using a welding process and a weld material having a primarily austenitic microstructure. The resulting weldment enhances the properties of yield ratio, uniform elongation, toughness and tearing resistance thereby producing superior strain capacity. High strain capacity produces a structure that accommodates high axial loading. The weldment can also accommodate larger than conventional weld flaws while maintaining sufficient strength, tearing resistance, and fracture toughness under high axial loading.

Owner:EXXONMOBIL UPSTREAM RES CO

Method for preparing nano-twinned copper layer by high-frequency pulse

ActiveCN110592621BExtended service lifeLow costElectroforming nanostructuresCopper sulfateElectroforming

The invention discloses a method for preparing a nano-twinned copper layer by using high-frequency pulses. The method utilizes a high-frequency pulse electroforming technique to prepare columnar nano-twinned copper in an additive-free, low-concentration copper sulfate electroforming solution. The nano-twinned copper layer prepared by the present invention guarantees high mechanical properties, and at the same time, the deposition speed of the cast copper layer is faster, the concentration of copper sulfate used is low, and no additives are added, the maintenance cost of the electroforming solution is greatly reduced, and the The impact of the electroforming process on the environment is conducive to the large-scale preparation of nano-twinned copper layers.

Owner:NANJING UNIV OF SCI & TECH

A kind of 6061 aluminum alloy surface treatment method

ActiveCN110396691BImprove bindingHigh uniform elongationMetallic material coating processesAl powderAluminium alloy

The invention discloses a 6061 aluminum alloy surface treatment method, which is to synthesize a TWIP steel coating in situ on the 6061 aluminum alloy surface by adopting a laser cladding method; the TWIP steel coating comprises 44-56 parts of Fe powder in parts by weight, 27‑31 parts of Mn powder, 7‑9 parts of Si powder, 3‑4 parts of Al powder and 2‑3 parts of C powder. The invention has the characteristics of good surface physical and chemical properties of the treated 6061 aluminum alloy and little damage to the base material.

Owner:GUIZHOU UNIV

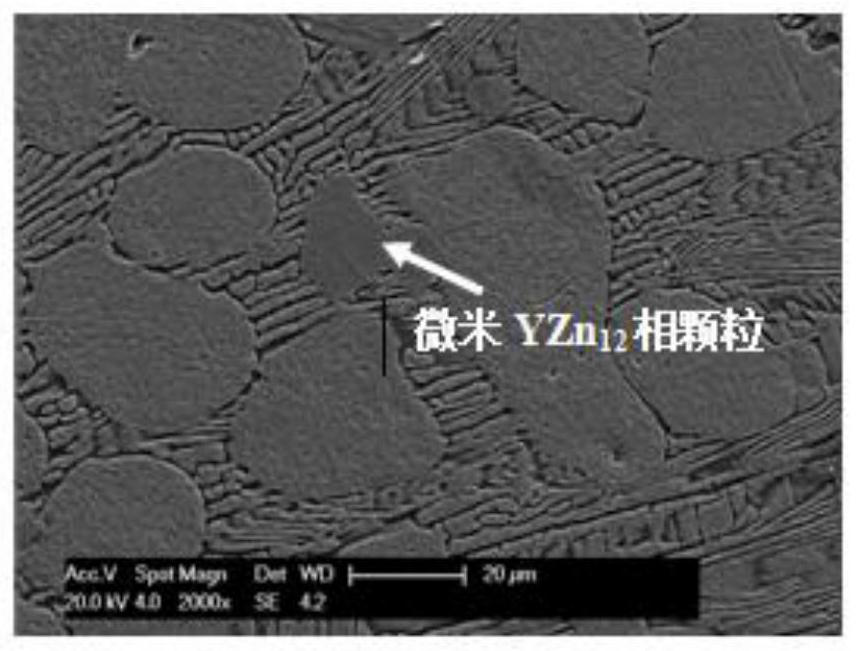

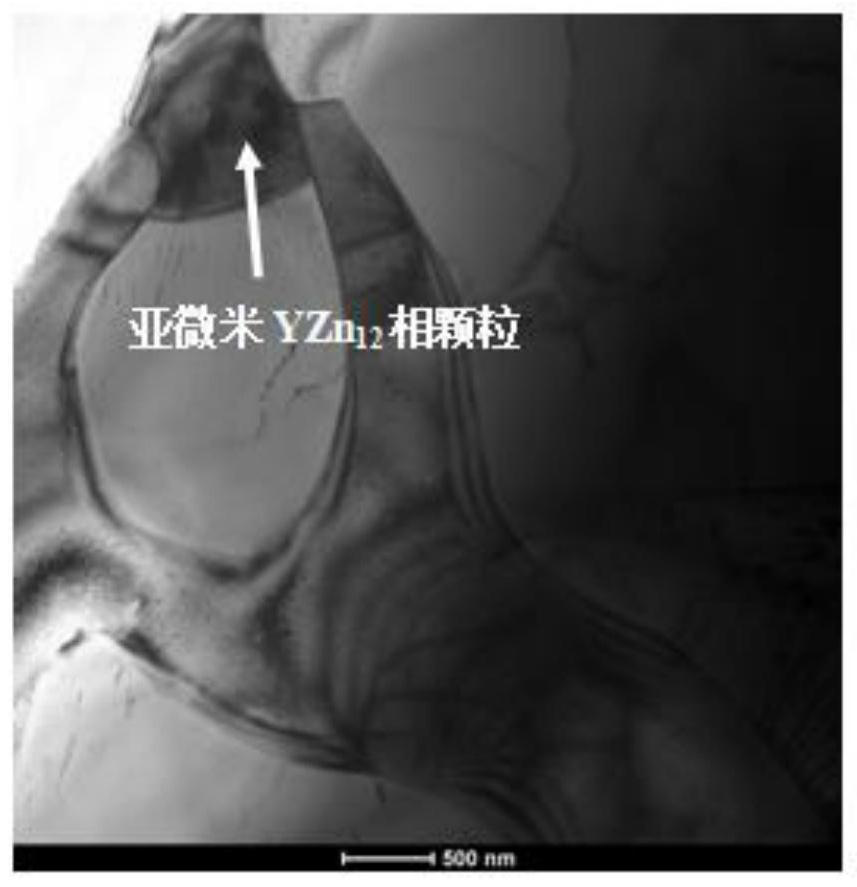

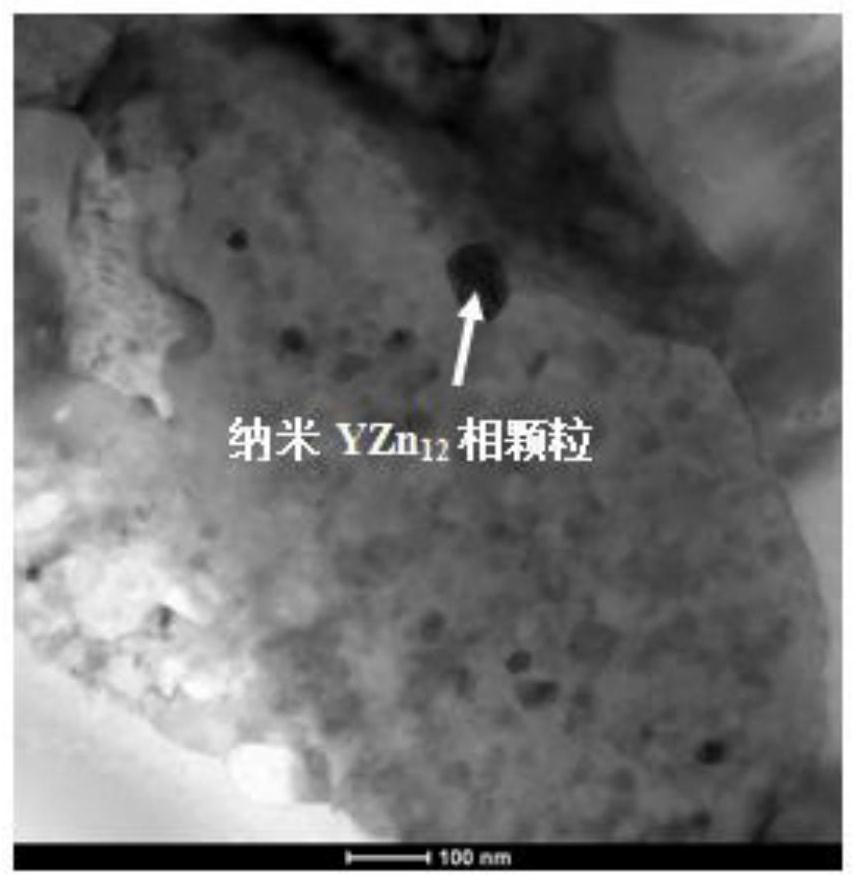

A high strength and toughness degradable zinc alloy with high work hardening rate and its preparation method and application

ActiveCN113186427BHigh work hardening rateHigh uniform elongationSurgeryMicron scaleMetallic materials

The invention discloses a high-strength, tough and degradable zinc alloy with high work hardening rate, including a Zn matrix, Zn+Mg refined and dispersed in the Zn matrix 2 Zn 11 Eutectic structure, micron-sized YZn is also dispersed in the Zn matrix 12 , Zn+Mg 2 Zn 11 Submicron YZn is dispersed in the eutectic structure 12 and nanoscale YZn 12 , submicron YZn 12 and nanoscale YZn 12 The area ratio is not greater than 85:15. The invention also discloses a preparation method of a high-strength and tough degradable zinc alloy with high work hardening rate and its application in biomedical degradable metal materials. The zinc alloy of the invention has both high strength and high toughness, its tensile strength is 340-530MPa, and its elongation is 10-32%, which can meet the requirements of different medical devices on the mechanical properties of the zinc alloy.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com