A kind of 6061 aluminum alloy surface treatment method

A technology of aluminum alloy surface and treatment method, applied in the direction of metal material coating process, coating, etc., can solve the problems of high thermal conductivity, jagged interface, poor control of cladding interface, etc., to inhibit the expansion of cracks, The effect of improving uniform elongation and improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

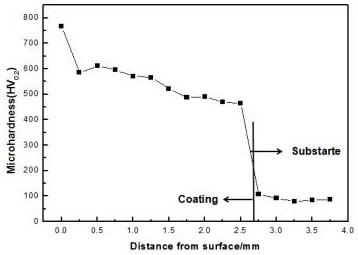

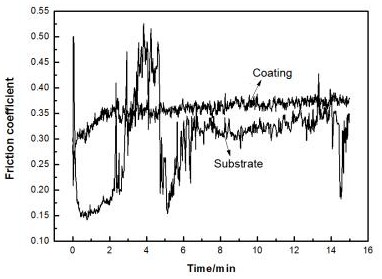

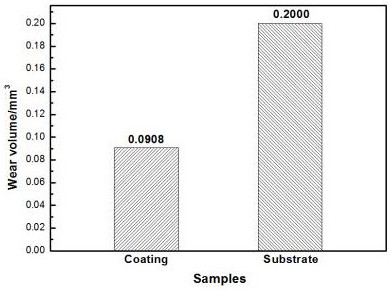

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of 6061 aluminum alloy surface treatment method, the steps are as follows:

[0036] 1) Mix 50 parts of Fe powder, 29 parts of Mn powder, 8 parts of Si powder, 3 parts of Al powder and 2 parts of C powder with a purity greater than 99.7% and a particle size of 200 mesh to obtain TWIP steel powder raw material;

[0037] 2) Put the TWIP steel powder raw material into a planetary ball mill for dry grinding. The ball mill jar and balls of the planetary ball mill are made of stainless steel or corundum, the abrasive ratio is 7:1, the speed is 210 rpm, and the ball milling time is 4 After dry grinding, put the powder into a vacuum oven and dry at 120°C for 2 hours to obtain pretreated TWIP steel powder;

[0038] 3) The pretreated TWIP steel powder was pre-placed on the surface of 6061 aluminum alloy with a thickness of 0.7 mm, and then under the protection of argon, the laser power was 2.7 kW, the laser spot diameter was 4 mm, and the laser scanning speed ...

Embodiment 2

[0040] Embodiment 2: a kind of 6061 aluminum alloy surface treatment method, the steps are as follows:

[0041] 1) Mix 44 parts of Fe powder, 27 parts of Mn powder, 7 parts of Si powder, 3 parts of Al powder and 2 parts of C powder with a purity greater than 99.7% and a particle size of 140 mesh to obtain the raw material of TWIP steel powder;

[0042]2) Put the TWIP steel powder raw material into a planetary ball mill for dry grinding. The ball mill tank and balls of the planetary ball mill are made of stainless steel or corundum, the abrasive ratio is 6:1, the speed is 180 rpm, and the ball milling time is 2 After dry grinding, put the powder into a vacuum oven and dry at 110°C for 1 hour to obtain pretreated TWIP steel powder;

[0043] 3) The pretreated TWIP steel powder was pre-placed on the surface of 6061 aluminum alloy with a thickness of 0.4 mm, and then under the protection of argon, the laser power was 2.2 kW, the laser spot diameter was 3 mm, and the laser scanning ...

Embodiment 3

[0045] Embodiment 3: a kind of 6061 aluminum alloy surface treatment method, the steps are as follows:

[0046] 1) Mix 56 parts of Fe powder, 31 parts of Mn powder, 9 parts of Si powder, 4 parts of Al powder and 3 parts of C powder with a purity greater than 99.7% and a particle size of 280 mesh to obtain TWIP steel powder raw material;

[0047] 2) Put the TWIP steel powder raw material into a planetary ball mill for dry grinding. The ball mill tank and balls of the planetary ball mill are made of stainless steel or corundum, the abrasive ratio is 8:1, the speed is 240 rpm, and the milling time is 5 After dry grinding, put the powder into a vacuum oven and dry at 130°C for 3 hours to obtain pretreated TWIP steel powder;

[0048] 3) The pretreated TWIP steel powder was pre-placed on the surface of 6061 aluminum alloy with a thickness of 1.0 mm, and then under argon protection, the laser power was 3.2 kW, the laser spot diameter was 6 mm, and the laser scanning speed was 8 mm / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com