High strength steel sheet

A technology for high-strength steel plates and steel plates, applied in the directions of coating, furnace type, hot-dip plating process, etc., can solve the problems of large difference in hardness, local elongation and deterioration of hole expandability, etc., and achieve high uniform elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0214] A slab having a chemical composition shown in Table 1 and having a thickness of 240 mm was produced. The slabs were hot-rolled under the conditions shown in Tables 2 and 3 to produce hot-rolled steel sheets. During this process, rolling at a high pressure of 10% or more per pass is carried out at least three times. The hot-rolled steel sheet is cooled to the coiling temperature by spraying water and coiled. The produced hot-rolled steel sheets were pickled to remove scale, and then cold-rolled under the conditions shown in Tables 2 and 3 to prepare cold-rolled steel sheets with a thickness of 1.2 mm.

[0215] [Table 1]

[0216] Table 1

[0217]

[0218] * Indicates that it is not within the limits of the present invention.

[0219] [Table 2]

[0220]

[0221] [table 3]

[0222]

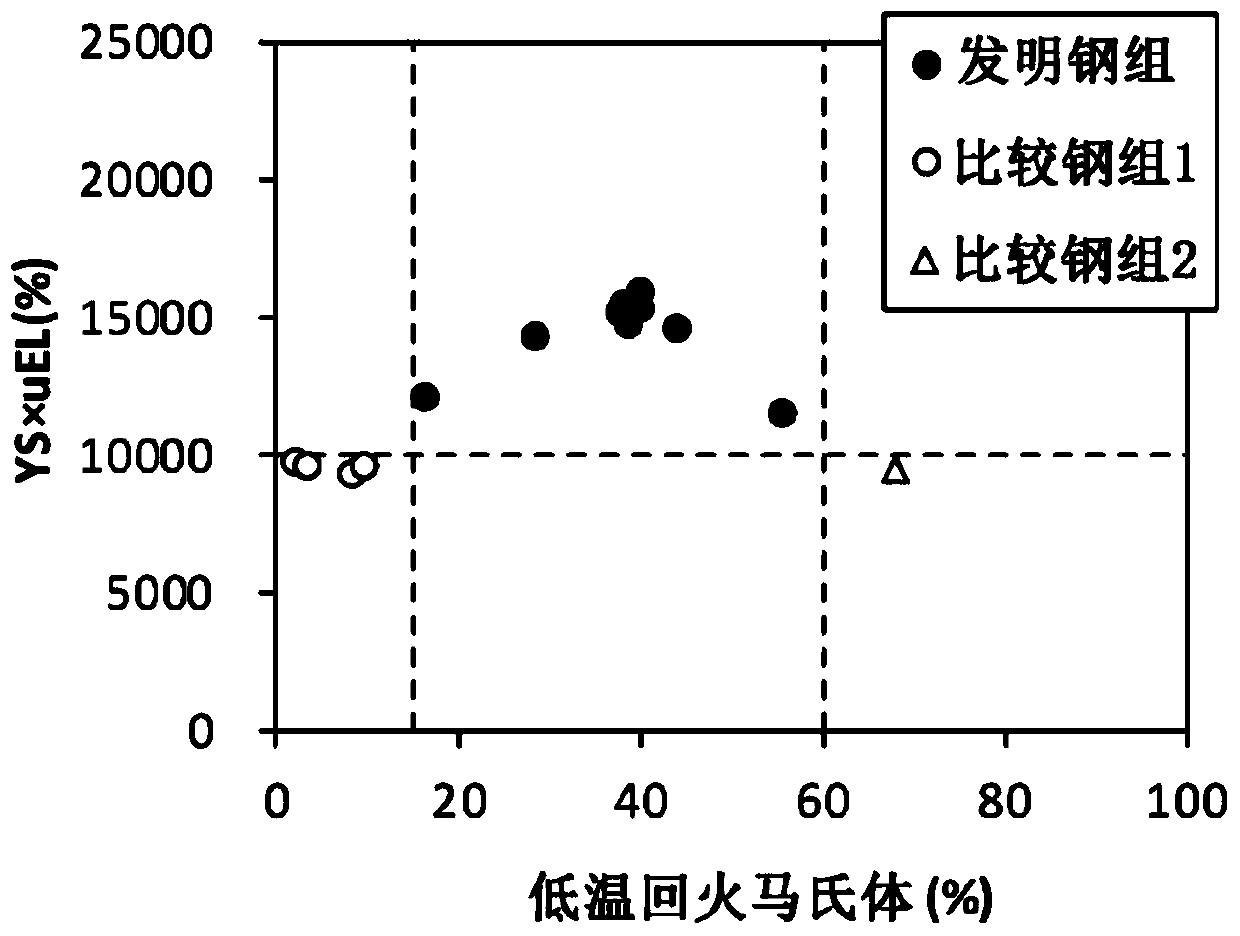

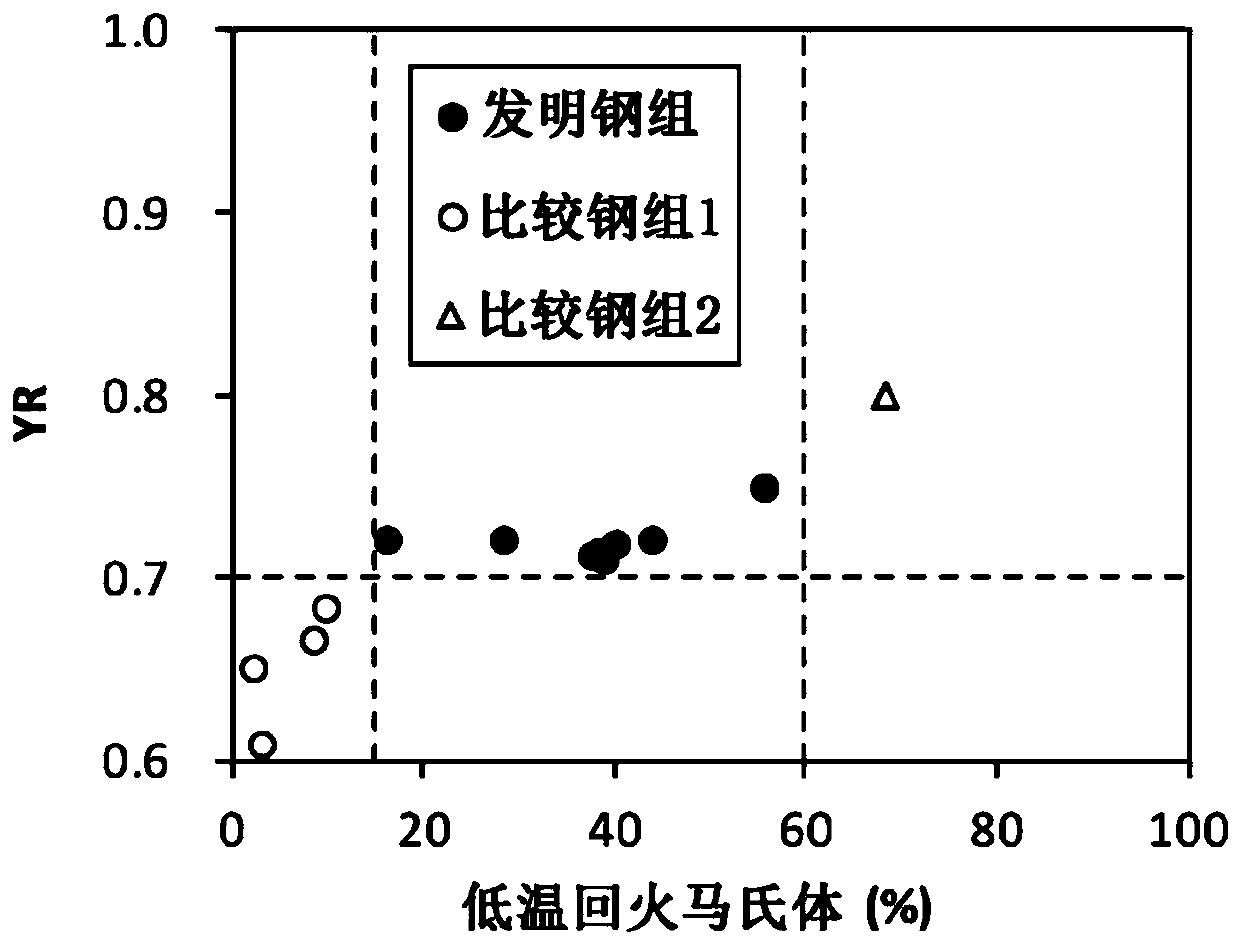

[0223] A test material was taken from the obtained cold-rolled steel sheet, the test material was heated to the highest annealing temperature shown in Tables 2 and 3, and anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com