Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Excellent SSC resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seamless steel pipe for line pipe and method for producing the same

ActiveUS20160161028A1Excellent SSC resistanceHigh hardnessFurnace typesRigid pipesChemical compositionLine tubing

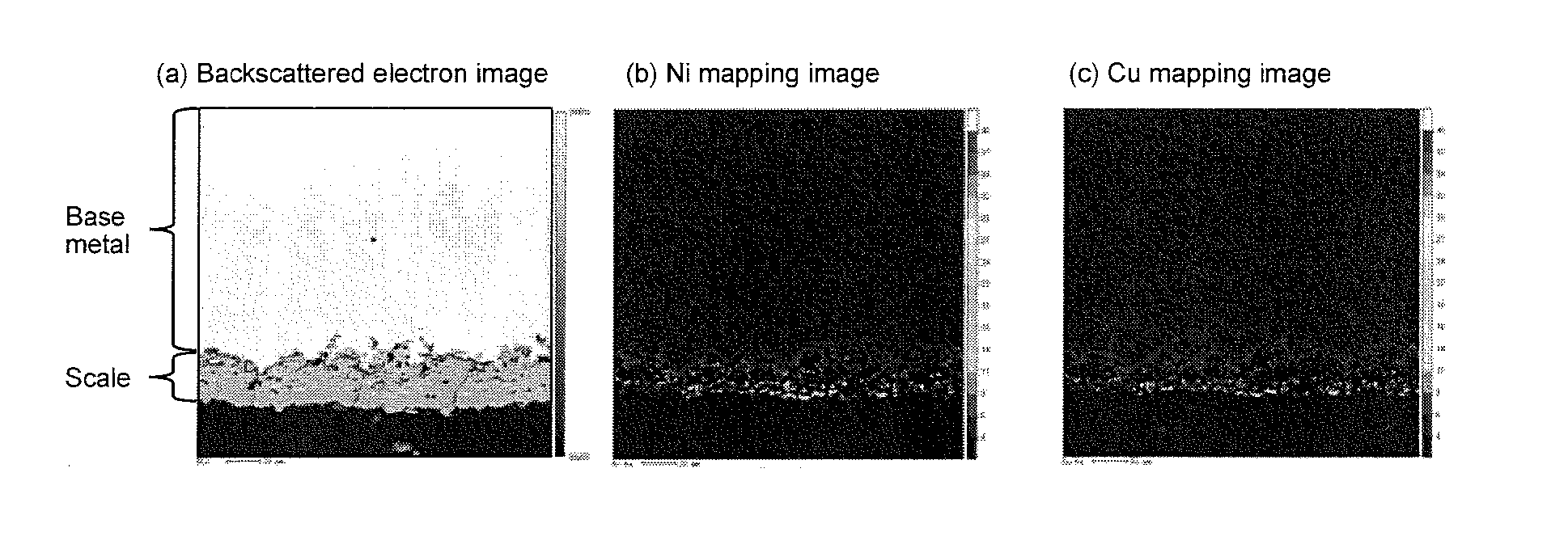

There is provided a seamless steel pipe for line pipe, wherein a chemical composition consists, by mass percent, of C: 0.03-0.10%, Si: ≦0.50%, Mn: 1.0-2.0%, P: ≦0.050%, S: ≦0.005%, Cr: 0.05-1.0%, Mo: 0.01-0.30%, Al: 0.001-0.10%, N: ≦0.01%, Ni: 0.04-2.0%, Ca: 0.0005-0.0050%, Cu: 0-2.0%, Ti: 0-0.05%, Nb: 0-0.05%, V: 0-0.10%, the balance: Fe and impurities, and satisfies the conditions of Cu+Ni: ≧0.10%, and Mo+V: ≦0.30%, wherein in a scale formed on the surface of the steel pipe, metal particles consisting mainly of Ni or Cu having an average circle-equivalent diameter of 0.1-5 μm exist, and a distance from a boundary between the base metal of the steel pipe and the scale to a region in which the metal particles do not exist is 20 μm or longer.

Owner:NIPPON STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same (as amended)

ActiveUS20170349964A1Low costHigh yield strengthFurnace typesHeat treatment furnacesAustenite grainNitride

A high-strength seamless steel pipe for oil country tubular goods comprising, by mass %, C: 0.20% to 0.50%, Si: 0.05% to 0.40%, Mn: more than 0.6% to 1.5% or less, P: 0.015% or less, S: 0.005% or less, Al: 0.005% to 0.1%, N: 0.006% or less, Mo: more than 1.0% to 3.0% or less, V: 0.05% to 0.3%, Nb: 0.001% to 0.020%, B: 0.0003% to 0.0030%, O: 0.0030% or less, and Ti: 0.003% to 0.025%, and wherein Ti / N: 2.0 to 5.0 is satisfied, a volume fraction of a tempered martensitic is 95% or more, prior austenite grains have a grain size number of 8.5 or more, and in a cross-section perpendicular to a rolling direction, the number of nitride-based inclusions having a grain size of 4 m or more is 100 or less per 100 mm2, the number of nitride-based inclusions having a grain size of less than 4 μm is 1000 or less per 100 mm2, the number of oxide-based inclusions having a grain size of 4 μm or more is 40 or less per 100 mm2, and the number of oxide-based inclusions having a grain size of less than 4 μm is 400 or less per 100 mm2, and methods of producing the same.

Owner:JFE STEEL CORP

Steel for oil well pipe excellent in sulfide stress cracking resistance and method for producing seamless steel pipe for oil well

ActiveUS20080017284A1High strengthExcellent SSC resistanceFurnace typesHeat treatment furnacesNitrogenOxygen

A steel for an oil well pipe, having high strength and excellent SSC resistance, consists of, by mass %, C: 0.30 to 0.60%, Si: 0.05 to 0.5%, Mn: 0.05 to 1.0%, Al: 0.005 to 0.10%, Cr+Mo: 1.5 to 3.0%, wherein Mo is 0.5% or more, V: 0.05 to 0.3%, Nb: 0 to 0.1%, Ti: 0 to 0.1%, Zr: 0 to 0.1%, N (nitrogen): 0 to 0.03%, Ca: 0 to 0.01%, and the balance Fe and impurities; P 0.025% or less, S 0.01% or less, B 0.0010% or less and O (oxygen) 0.01% or less. The method involves heating the steel at 1150° C. or more; producing a seamless steel pipe by hot working; water-cooling the pipe to a temperature in a range of 400 to 600° C. immediately after finishing the working; and subjecting the pipe to a heat treatment for bainite isothermal transformation in a range of 400 to 600° C.

Owner:NIPPON STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same (as amended)

ActiveUS20170275715A1Low costExcellent sulfide stress corrosion cracking resistanceFurnace typesHeat treatment furnacesAustenite grainCrystallite

Provided is a high-strength seamless steel pipe having the composition which contains, by mass %, 0.20 to 0.50% C, 0.05 to 0.40% Si, 0.3 to 0.9% Mn, 0.015% or less P, 0.005% or less S, 0.005 to 0.1% Al, 0.008% or less N, 0.6 to 1.7% Cr, 0.4 to 1.0% Mo, 0.01 to 0.30% V, 0.01 to 0.06% Nb, 0.0003 to 0.0030% B, and 0.0030% or less O (oxygen). The high-strength seamless steel pipe has the microstructure where a volume fraction of a tempered martensitic phase is 95% or more, and prior austenitic grains have a grain size number of 8.5 or more, and a segregation degree index Ps which is defined by a formula Ps=8.1 (XSi+XMn+XMo)+1.2XP relating to XM which is a ratio between a segregated portion content and an average content is set to less than 65.

Owner:JFE STEEL CORP

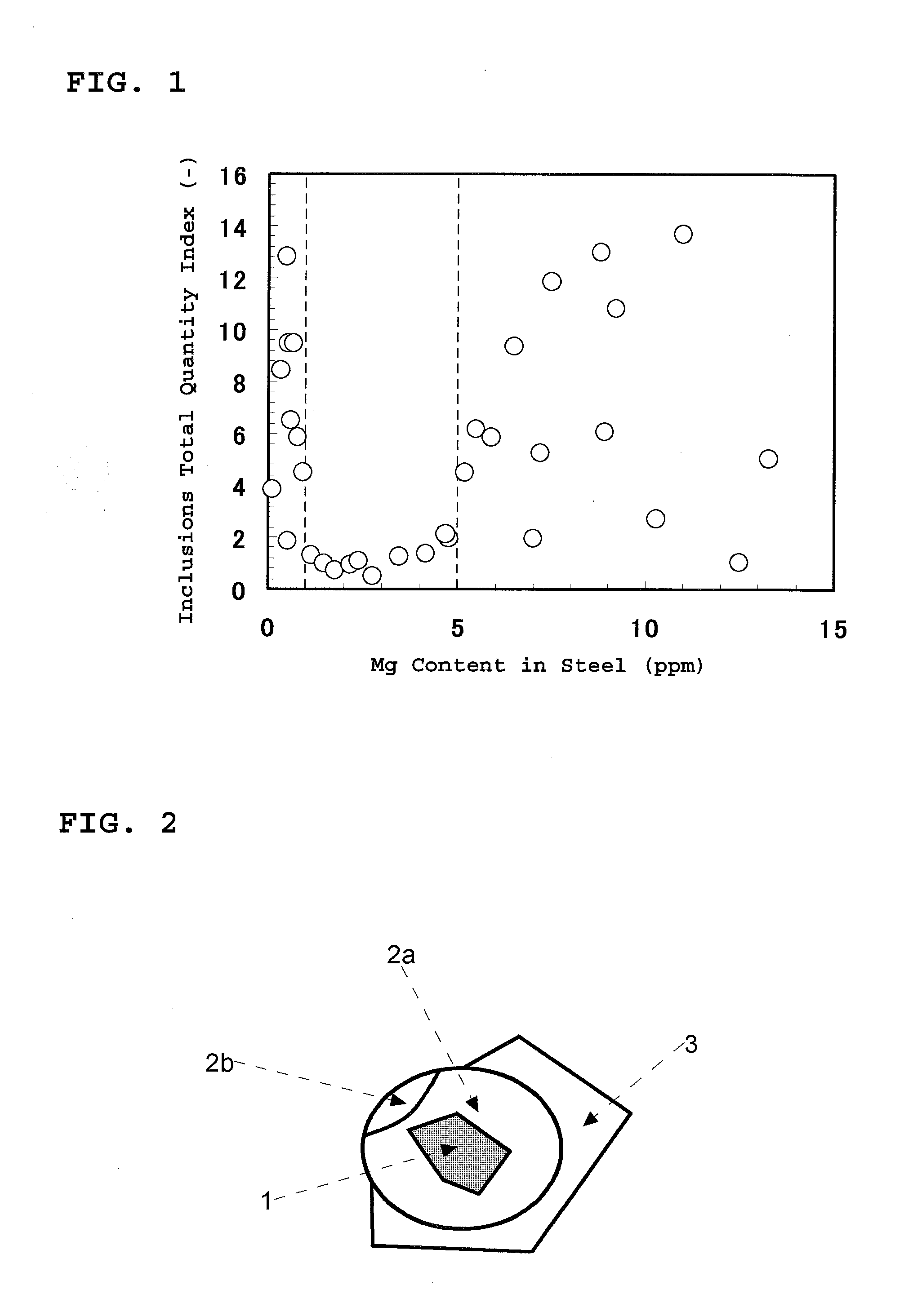

Steel for steel tube with excellent sulfide stress cracking resistance

The present invention provides a steel which simultaneously satisfies a plurality of characteristics, specifically, a steel for tubes with excellent sulfide stress cracking resistance, including, C: 0.2 to 0.7%; Si: 0.01 to 0.8%; Mn: 0.1 to 1.5%; S: not more than 0.005%; P: not more than 0.03%; Al: 0.0005 to 0.1%; Ti: 0.005 to 0.05%; Ca: 0.0004 to 0.005%; N: not more than 0.007%; Cr: 0. 1 to 1.5%; and Mo: 0.2 to 1.0%; the balance being Fe, Mg and impurities, being characterized in that: the content of Mg is not less than 1.0 ppm and not more than 5.0 ppm; and inclusions of not less than 50% of the total number of those in steel have such a morphology that Mg—Al—O-based oxides exist at the central part of the inclusion, Ca—Al-based oxides enclose the Mg—Al—O-based oxides, and Ti-containing-carbonitrides further exist on a periphery of the Ca—Al-based oxides.

Owner:NIPPON STEEL CORP

Martensitic stainless steel for oil well and its producing method

InactiveCN1861832AExcellent SSC resistanceImprove low temperature toughnessFurnace typesHeat treatment process controlMartensitic stainless steelOil well

The present invention provides a martensitic stainless steel for oil wells that has good SSC resistance and excellent low-temperature toughness under the coexistence of Cl-, wet CO2 and a small amount of H2S. The steel material contains, by mass %, C: 0.16-0.22%, Si: 0.1-0.8%, Mn: 0.25-1.00%, P: 0.025% or less, S: 0.010% or less, Cr: 12.0-13.5%, Al: 0.010% or less, Ni: 0-0.2%, Cu: 0-0.10%, Mo: 0-0.20%, Ti: 0-0.050%, N: 0.01-0.1%, and the balance is composed of Fe and impurities. It may also contain predetermined amounts of one or more of Nb and V and / or predetermined amounts of one or more of Ca, Mg, La, and Ce.

Owner:SUMITOMO METAL IND LTD

Low alloy oil well steel pipe and method for manufacturing same

ActiveUS20160160307A1Excellent SSC resistanceStablyFurnace typesIncreasing energy efficiencyAustenite grainCrystal orientation

Low-alloy oil-well steel pipe includes a composition consisting, in mass %, of C: 0.40 to 0.65%, Si: 0.05 to 0.50%, Mn: 0.10 to 1.00%, P: 0.020% or less, S: 0.0020% or less, Cu: 0.15% or less, Cr: 0.40 to 1.50%, Mo: 0.50 to 2.50%, V: 0.05 to 0.25%, Ti: 0 to less than 0.01%, Nb: 0.01 to 0.2%, sol.Al: 0.010 to 0.100%, N: 0.006% or less, B: 0 to 0.0015%, and Ca: 0 to 0.003%, the balance being Fe and impurities. The structure has tempered martensite and 0 to less than 2% volume ratio of retained austenite. A grain size number of prior-austenite grain in the structure is 9.0 or more. An equivalent circular diameter of a sub-structure surrounded by a boundary having a crystal orientation difference of 15° or more from a packet boundary, a block boundary and a lath boundary is 3 μm or less for the tempered martensite.

Owner:NIPPON STEEL CORP

Oil well steel pipe for embedding-expanding

ActiveUS20060073352A1Improve corrosion resistanceReduce contentPig casting plantsIngot casting plantsMetallurgyOil well

An oil well steel pipe for embedding-expanding excellent in the SSC resistance after expanding. The pipe is made of a steel consisting of, by mass %, C: 0.05 to 0.45%, Si: 0.1 to 1.5%, Mn: 0.1 to 3.0%, P: 0.03% or less, S: 0.01% or less, sol.Al: 0.05% or less, and the balance being Fe and impurities, with a soluble N content of 40 ppm or less. The steel can comprise one or more selected from V, Ti, Nb, B, Cr, Mo, Ni, Cu and Ca.

Owner:NIPPON STEEL CORP

Steel for steel tube with excellent sulfide stress cracking resistance

The present invention provides a steel which simultaneously satisfies a plurality of characteristics, specifically, a steel for tubes with excellent sulfide stress cracking resistance, including, C: 0.2 to 0.7%; Si: 0.01 to 0.8%; Mn: 0.1 to 1.5%; S: not more than 0.005%; P: not more than 0.03%; Al: 0.0005 to 0.1%; Ti: 0.005 to 0.05%; Ca: 0.0004 to 0.005%; N: not more than 0.007%; Cr: 0.1 to 1.5%; and Mo: 0.2 to 1.0%; the balance being Fe, Mg and impurities, being characterized in that: the content of Mg is not less than 1.0 ppm and not more than 5.0 ppm; and inclusions of not less than 50% of the total number of those in steel have such a morphology that Mg—Al—O-based oxides exist at the central part of the inclusion, Ca—Al-based oxides enclose the Mg—Al—O-based oxides, and Ti-containing-carbonitrides further exist on a periphery of the Ca—Al-based oxides.

Owner:NIPPON STEEL CORP

Martensitic stainless steel seamless pipe for oil country tubular goods, and method for manufacturing same

PendingUS20200283866A1High strengthExcellent sulfide stress corrosion cracking resistanceFurnace typesHeat treatment furnacesMartensitic stainless steelStress corrosion cracking

The invention provides a martensitic stainless steel seamless pipe for oil country tubular goods having high strength, and excellent sulfide stress corrosion cracking resistance and a method for manufacturing the same. The martensitic stainless steel seamless pipe for oil country tubular goods has a yield stress of 655 to 758 MPa, and has a composition containing, in mass %, C: 0.10% or less, Si: 0.5% or less, Mn: 0.05 to 2.0%, P: 0.030% or less, S: 0.005% or less, Ni: 4.0 to 8.0%, Cu: 0.02% or more and less than 1.0%, Cr: 10.0 to 14.0%, Mo: 1.0 to 3.5%, V: 0.003 to 0.2%, Co: 0.02% or more and less than 1.0%, Al: 0.1% or less, N: 0.1% or less, Ti: 0.50% or less, and the balance Fe and incidental impurities, wherein C, Mn, Cr, Cu, Co, Ni, Mo, W, Nb, N, and Ti satisfy the predetermined relations.

Owner:JFE STEEL CORP

High-strength steel material for oil wells, and oil well pipe

InactiveCN106795603AExcellent SSC resistanceHigh yield strengthFurnace typesHeat treatment furnacesChemical compositionNumber density

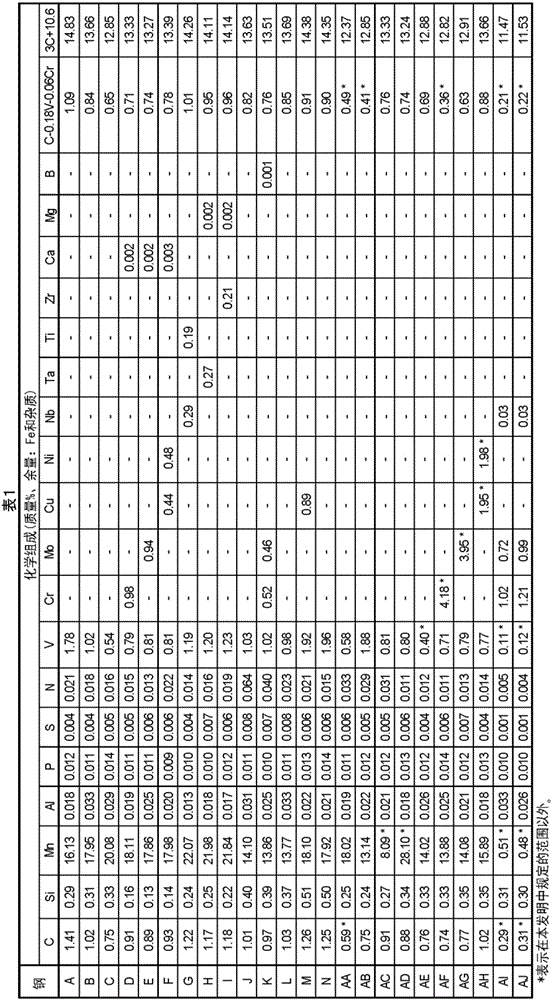

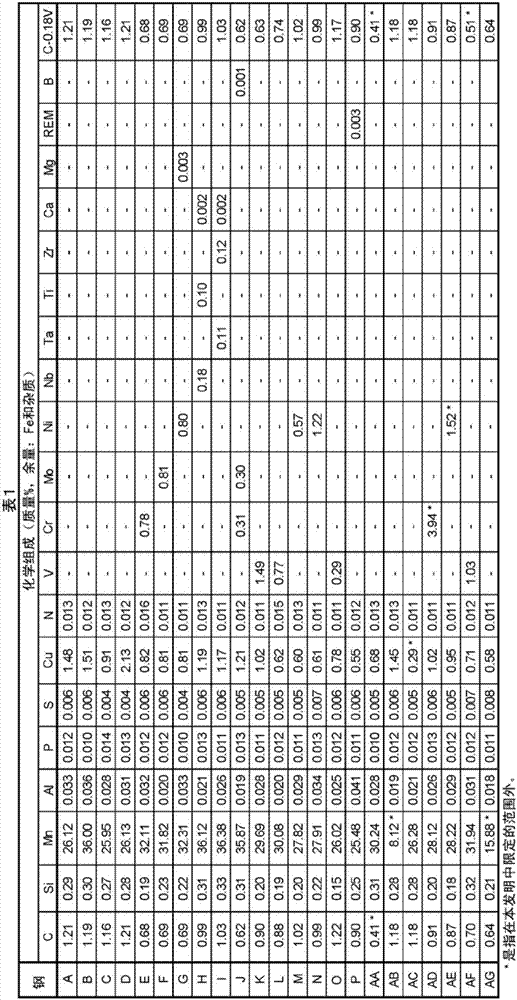

This high-strength steel material for oil wells has a chemical composition which includes, in mass%, 0.70-1.8% of C, 0.05-1.00% of Si, 12.0-25.0% of Mn, 0.003-0.06% of Al, not more than 0.03% of P, not more than 0.03% of S, not more than 0.10% of N, over 0.5% but not more than 2.0% of V, 0-2.0% of Cr, 0-3.0% of Mo, 0-1.5% of Cu, 0-1.5% of Ni, 0-0.5% of Nb, 0-0.5% of Ta, 0-0.5% of Ti, 0-0.5% of Zr, 0-0.005% of Ca, 0-0.005% of Mg, and 0-0.015% of B, the remainder comprising Fe and impurities, and which satisfies [0.6< / =C-0.18V-0.06Cr<1.44]. The metallographic structure substantially comprises an austenite single phase. V carbides having a circle-equivalent diameter of 5-100 nm are present in a number density of at least 20 / [mu]m2. The yield strength is at least 654 MPa.

Owner:NIPPON STEEL CORP

Oil well steel pipe for embedding-expanding

ActiveUS7082992B2Reduce contentExcellent SSC resistancePig casting plantsIngot casting plantsMetallurgyOil well

An oil well steel pipe for embedding-expanding excellent in the SSC resistance after expanding. The pipe is made of a steel consisting of, by mass %, C: 0.05 to 0.45%, Si: 0.1 to 1.5%, Mn: 0.1 to 3.0%, P: 0.03% or less, S: 0.01% or less, sol.Al: 0.05% or less, and the balance being Fe and impurities, with a soluble N content of 40 ppm or less. The steel can comprise one or more selected from V, Ti, Nb, B, Cr, Mo, Ni, Cu and Ca.

Owner:NIPPON STEEL CORP

Martensitic stainless steel seamless pipe for oil country tubular goods, and method for producing same

InactiveUS20190241989A1High strengthExcellent sulfide stress corrosion cracking resistanceFurnace typesHeat treatment furnacesMartensitic stainless steelSulfide

Provided herein is a martensitic stainless steel seamless pipe, intended for oil country tubular goods, having high strength, and excellent sulfide stress corrosion cracking resistance. A method for producing such a martensitic stainless steel seamless pipe is also provided. The martensitic stainless steel seamless pipe for oil country tubular goods has a composition that contains, in mass %, C: 0.035% or less, Si: 0.5% or less, Mn: 0.05 to 0.5%, P: 0.03% or less, S: 0.005% or less, Cu: 2.6% or less, Ni: 5.3 to 7.3%, Cr: 11.8 to 14.5%, Al: 0.1% or less, Mo: 1.8 to 3.0%, V: 0.2% or less, N: 0.1% or less, and the balance Fe and unavoidable impurities, and in which C, Mn, Cr, Cu, Ni, Mo, W, Nb, N, and Ti satisfy the predetermined relations.

Owner:JFE STEEL CORP

Low alloy oil-well steel pipe

ActiveUS20170306461A1Excellent SSC resistanceFurnace typesHeat treatment furnacesChemical compositionEquivalent weight

Provided is a low alloy oil-well steel pipe having a yield strength of 793 MPa or more, and an excellent SSC resistance. A low alloy oil-well steel pipe according to the present invention includes a chemical composition consisting of: in mass%, C: 0.25 to 0.35%; Si: 0.05 to 0.50%; Mn: 0.10 to 1.50%; Cr: 0.40 to 1.50%; Mo: 0.40 to 2.00%; V: 0.05 to 0.25%; Nb: 0.010 to 0.040%; Ti: 0.002 to 0.050%; sol. Al: 0.005 to 0.10%; N: 0.007% or less; B: 0.0001 to 0.0035%; and Ca: 0 to 0.005%; and a balance being Fe and impurities. In a microstructure of the low alloy oil-well steel pipe, a number of cementite particles each of which has an equivalent circle diameter of 200 nm or more is 100 particles / 100 μm2 or more. The above low alloy oil-well steel pipe has a yield strength of 793 MPa or more.

Owner:NIPPON STEEL CORP

Method for producing seamless steel pipe

ActiveUS20080121318A1High strengthImprove toughnessFurnace typesHeat treatment furnacesChemical compositionHigh intensity

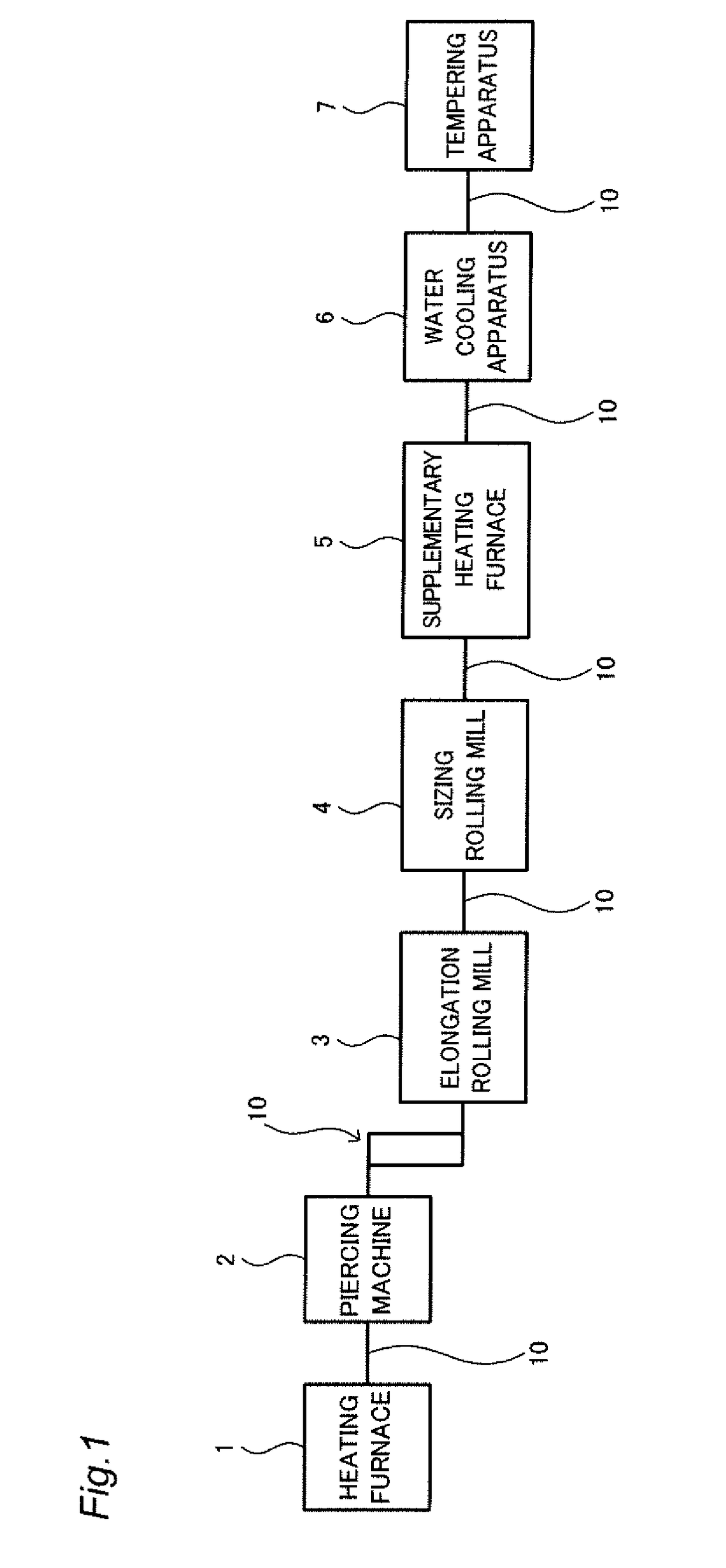

A seamless steel pipe produced by heating a steel billet, which has a chemical composition C: 0.15 to 0.20%, Si: not less than 0.01% to less than 0.15%, Mn: 0.05 to 1.0%, Cr: 0.05 to 1.5%, Mo: 0.05 to 1.0%, Al≦0.10%, V: 0.01 to 0.2%, Ti: 0.002 to 0.03%, B: 0.0003 to 0.005% and N: 0.002 to 0.01%, further optionally one or more of Ca, Mg and REM in a specific amount, under the provision that the conditions “C+(Mn / 6)+(Cr / 5)+(Mo / 3)≧0.43” and “Ti×N<0.0002−0.0006×Si” are satisfied, with the balance being Fe and impurities, wherein P≦0.025%, S≦0.010% and Nb<0.005% among the impurities, to a temperature of 1000 to 1250° C. followed by pipe-making rolling at a final rolling temperature 900 to 1050° C., and then quenching the resulting steel pipe directly from a temperature not lower than the Ar3 transformation point followed by tempering at a temperature range from 600° C. to the Ac1 transformation point, or instead of the above after the said pipe-making rolling, complementarily heating the resulting steel pipe in a temperature range from the Ac3 transformation point to 1000° C. in-line, and then quenching it from a temperature not lower than the Ar3 transformation point followed by tempering at a temperature range from 600° C. to the Ac1 transformation point, has high strength and excellent toughness and at the same time has a high yield ratio and is excellent in SSC resistance as well.

Owner:SUMITOMO METAL IND LTD

Seamless steel pipe for line pipe and method for producing the same

ActiveUS20170067129A1High hardnessExcellent SSC resistanceFurnace typesRigid pipesMicro structureMetal particle

A seamless steel pipe for line pipe has a chemical composition consisting, by mass percent, of C: 0.03-0.15%, Si: ≦0.50%, Mn: 1.0-2.0%, P: ≦0.050%, S: ≦0.005%, Cr: 0.1-1.0%, Al: 0.001-0.10%, N: ≦0.01%, Ni: 0.05-2.0%, B: 0.0003-0.0015%, Ca: 0.0002-0.0050%, Mo: 0.10-0.50%, Ti: 0.001-0.05%, Cu: 0-2.0%, Nb: 0-0.05%, V: 0-0.10%, the balance: Fe and impurities, and satisfying the conditions of 2Nb+4V+Mo≦0.50, wherein a metal micro-structure of the steel pipe contains 50% or more of bainite, in an area fraction, a wall thickness of the steel pipe is 25 mm or larger, and in a scale formed on the surface of the steel pipe, metal particles consisting mainly of Ni or Cu having an average circle-equivalent diameter of 0.1-5 mm exist. A distance from a boundary between the base metal of the steel pipe and the scale to a region in which the metal particles do not exist is 20 mm or longer.

Owner:NIPPON STEEL CORP

Steel and oil well steel pipe

InactiveCN109642293AHigh strengthExcellent SSC resistanceCorrosion preventionFurnace typesPipeSteel tube

Provided are a steel and an oil well steel pipe which have excellent SSC resistance, even in a high pressure H2S environment. This steel contains 0.15-0.45% of C, 0.10-1.0% of Si, 0.10-0.8% of Mn, atmost 0.050 of P, at most 0.010% of S, 0.01-0.1% of Al, at most 0.010% of N, 0.1-2.5% of Cr, 0.35-3.0% of Mo, 0.05-2.0% of Co, 0.003-0.040% of Ti, 0.003-0.050% of Nb, 0.01-0.50% of Cu, and 0.01-0.50% of Ni, and satisfies the equation below. In the microstructure, the grain size of prior-austenite is less than 5 microns, and the block size is less than 2 microns. The steel contains at least 90 vol%total of tempered martensite and tempered bainite. C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15-Co / 6+ alpha>=0.70 (1), (3C+Mo+3Co) / (3Mn+Cr)>=1.0 (2).

Owner:NIPPON STEEL CORP

Steel material and oil-well steel pipe

A steel material for oil country tubular goods that has a high strength and excellent SSC resistance is provided. The steel material according to this invention contains, in mass %, C: more than 0.45 to 0.65%, Si: 0.10 to 1.0%, Mn: 0.1 to 1.0%, P: 0.050% or less, S: 0.010% or less, Al: 0.01 to 0.1%, N: 0.01% or less, Cr: 0.1 to 2.5%, Mo: 0.25 to 5.0%, and Co: 0.05 to 5.0%, and satisfies expressions (1) and (2), and contains 90% or more of tempered martensite by volume ratio:C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15−Co / 6+α≥0.70 (1)(3C+Mo+3Co) / (3Mn+Cr)≥1.0 (2)Effective B=B−11(N−Ti / 3.4) / 14 (3)where, α in expression (1) is 0.250 when effective B (mass %) defined by expression (3) is 0.0003% or more, and is 0 when effective B is less than 0.0003%.

Owner:NIPPON STEEL CORP

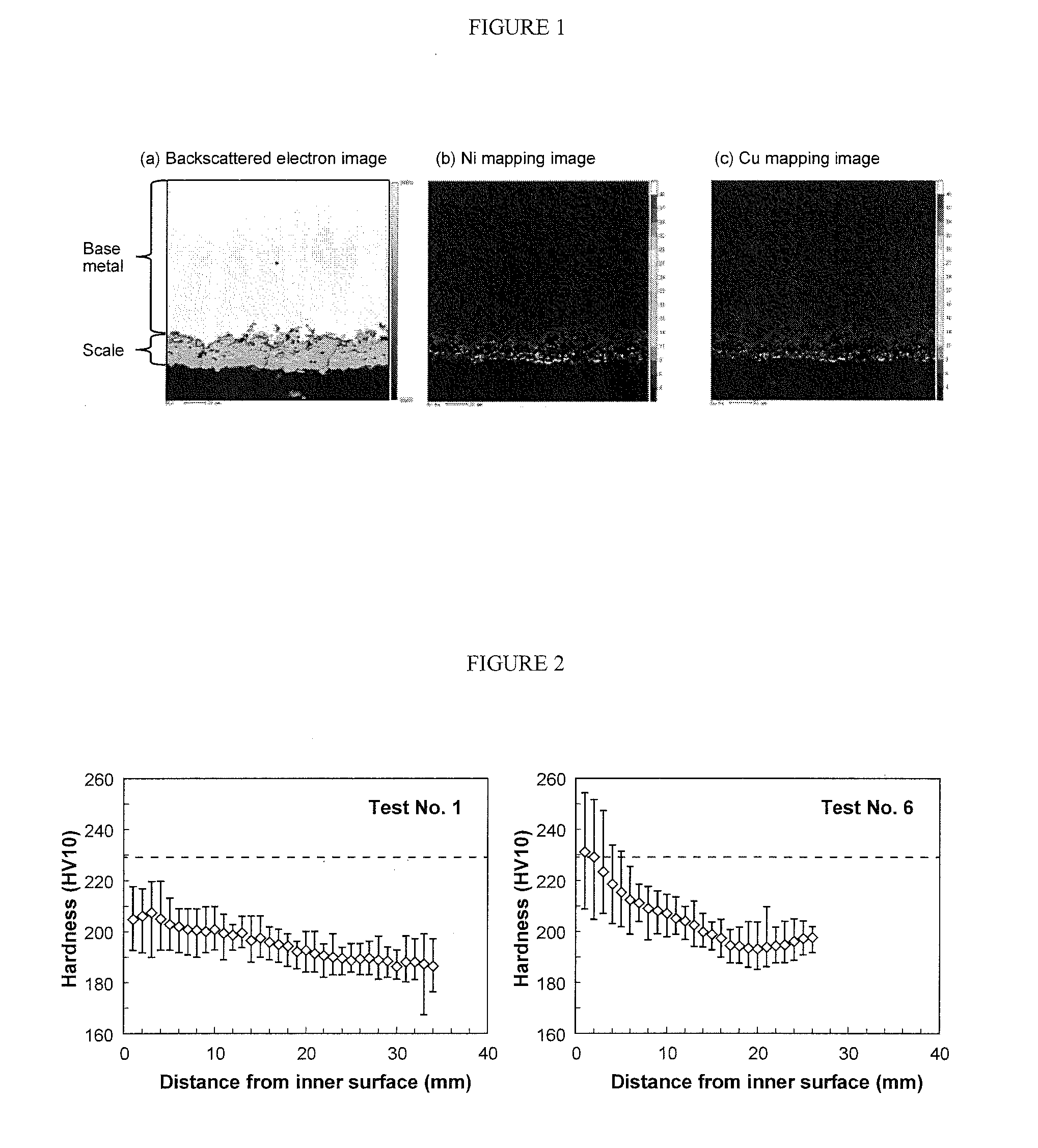

Seamless steel pipe and method of manufacturing the same

InactiveUS20180355451A1High strengthImprove toughnessFurnace typesHeat treatment furnacesAustenite grainBainite

A seamless steel pipe contains, (mass %), C: 0.02 to 0.15%; Si: 0.05 to 0.5%; Mn: 0.30 to 2.5%; Al: 0.01 to 0.10%; Ti: 0.001 to 0.010%; N: up to 0.007%; Cr: 0.05 to 1.0%; Mo: not less than 0.02% and less than 0.5%; Ni: 0.03 to 1.0%; Cu: 0.02 to 1.0%; V: 0.020 to 0.20%; Ca: 0.0005 to 0.005%; and Nb: 0 to 0.05%, where carbon equivalent is not less than 0.430% and less than 0.500%, the microstructure main phase from the surface to an in-the-wall portion is tempered martensite or tempered bainite, prior austenite grain size is lower than 6.0, a portion between 1 mm from the inner surface and 1 mm from the outer surface has Vickers hardness of 250 Hv or lower, and yield strength is 555 MPa or higher.

Owner:NIPPON STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same

ActiveUS10472690B2Low costExcellent sulfide stress corrosion cracking resistanceFurnace typesHeat treatment furnacesAustenite grainManganese

Provided is a high-strength seamless steel pipe having the composition which contains, by mass %, 0.20 to 0.50% C, 0.05 to 0.40% Si, 0.3 to 0.9% Mn, 0.015% or less P, 0.005% or less S, 0.005 to 0.1% Al, 0.008% or less N, 0.6 to 1.7% Cr, 0.4 to 1.0% Mo, 0.01 to 0.30% V, 0.01 to 0.06% Nb, 0.0003 to 0.0030% B, and 0.0030% or less O (oxygen). The high-strength seamless steel pipe has the microstructure where a volume fraction of a tempered martensitic phase is 95% or more, and prior austenitic grains have a grain size number of 8.5 or more, and a segregation degree index Ps which is defined by a formula Ps=8.1 (XSi+XMn+XMo)+1.2XP relating to XM which is a ratio between a segregated portion content and an average content is set to less than 65.

Owner:JFE STEEL CORP

Seamless Steel Pipe and Method for Producing the Seamless Steel Pipe

ActiveUS20190300979A1High yield strengthExcellent SSC resistanceFurnace typesRigid pipesAustenite grainMetallurgy

The seamless steel pipe of the present embodiment consists of in mass %, C: 0.21 to 0.35%, Si: 0.10 to 0.50%, Mn: 0.05 to 1.00%, P: 0.025% or less, S: 0.010% or less, Al: 0.005 to 0.100%, N: 0.010% or less, Cr: 0.05 to 1.50%, Mo: 0.10 to 1.50%, Nb: 0.010 to 0.050%, B: 0.0003 to 0.0050%, and Ti: 0.002 to 0.050%, the balance being Fe and impurities. In a main body region of the seamless steel pipe, a grain size number of prior-austenite grain conforming to ASTM E112 is 7.0 or more, a difference between a maximum value and a minimum value of the grain size number is 1.0 or less, yield strength is 655 to less than 862 MPa, and a difference between a maximum value and a minimum value of tensile strength is 27.6 MPa or less.

Owner:NIPPON STEEL CORP

Low alloy steel for oil well pipes having excellent sulfide stress cracking resistance

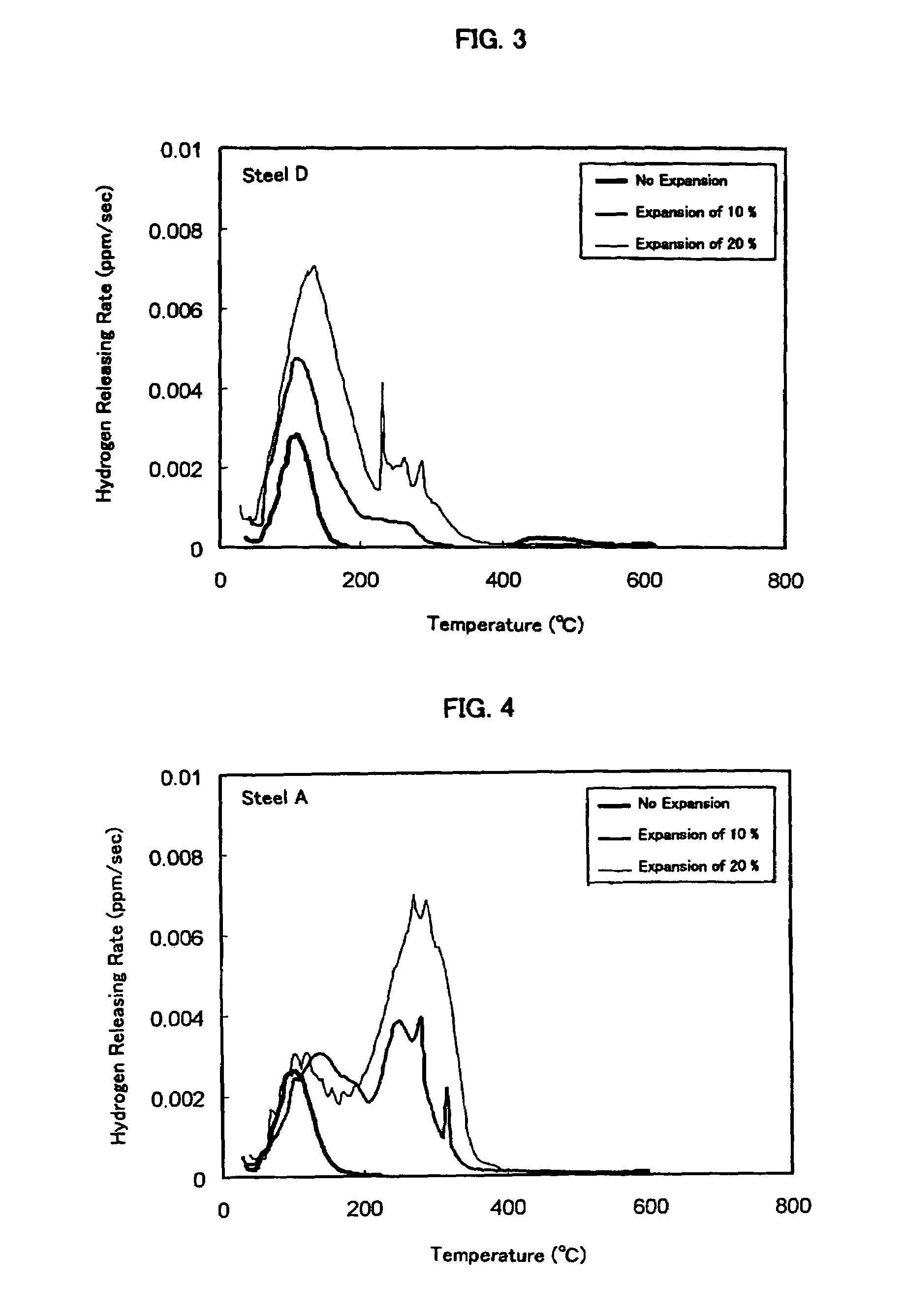

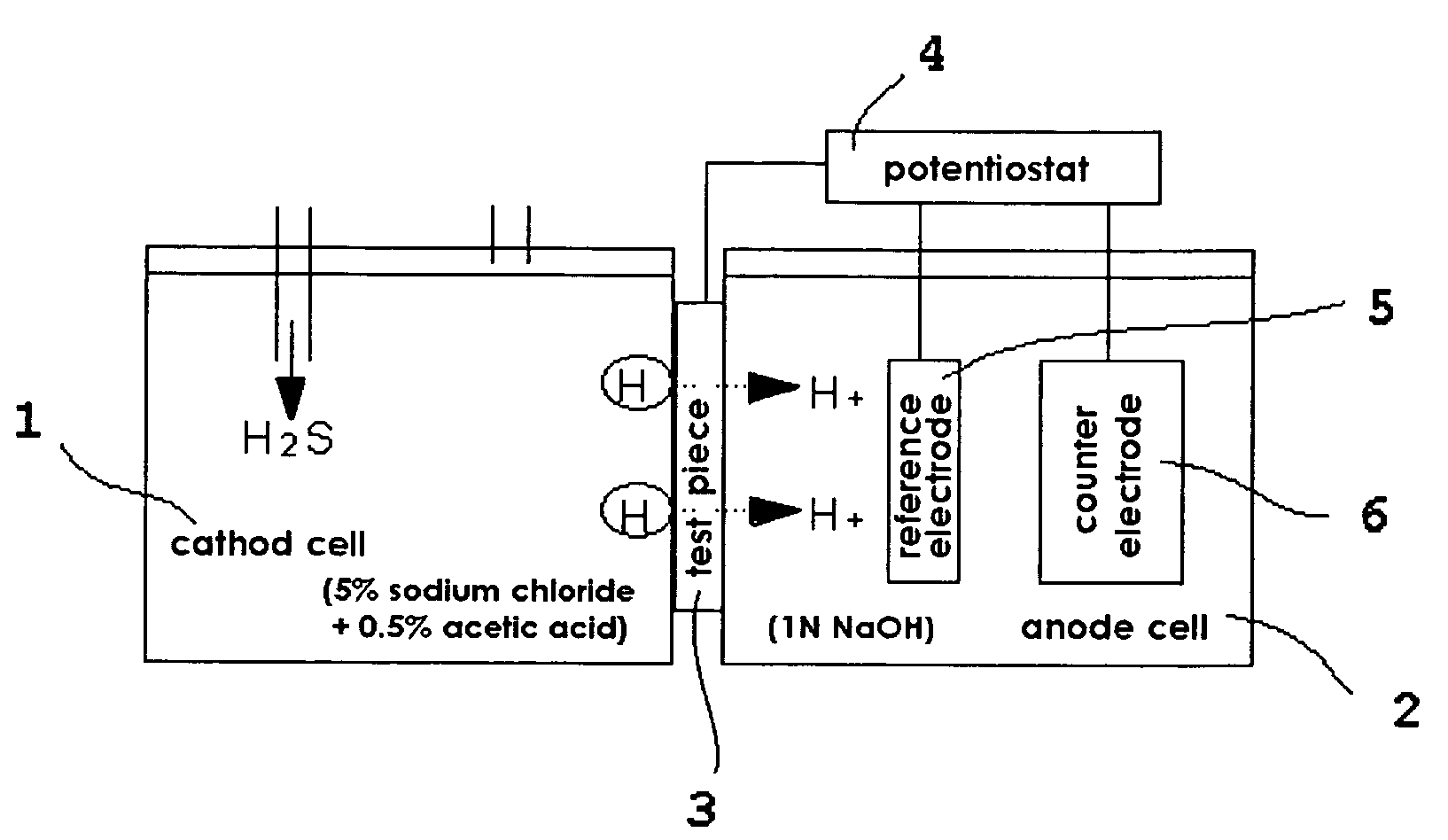

ActiveUS8168010B2Excellent SSC resistanceProvide stableFurnace typesIncreasing energy efficiencyHydrogenMetallurgy

Disclosed is a low alloy steel for oil well pipes which has excellent sulfide stress cracking resistance and is suitable for casing and tubing for oil wells or gas wells. Specifically disclosed is a low alloy steel for oil well pipes containing, in mass %, 0.2-0.35% of C, 0.05-0.5% of Si, 0.05-1.0% of Mn, not more than 0.025% of P, not more than 0.01% of S, 0.005-0.10% of Al, 0.1-1.0% of Cr, 0.5-1.0% of Mo, 0.002-0.05% of Ti, 0.05-0.3% of V, 0.0001-0.005% of B, not more than 0.01% of N, not more than 0.01% of O (oxygen), 0-0.1% of Nb, 0-0.01% of Ca, 0-0.01% of Mg and 0-0.1% of Zr, and having a half-value breadth (H) and a hydrogen diffusion coefficient (D) (10−6 cm2 / s) satisfying the following formula (1):30H+D≦19.5 (1).

Owner:NIPPON STEEL CORP

Ultrahigh-strength steel having excellent cold workability and ssc resistance, and manufacturing method therefor

ActiveCN113166897AImproved cold working propertiesExcellent SSC resistanceFurnace typesHeat treatment furnacesNiobiumManganese

One embodiment of the present invention provides an ultrahigh-strength steel having excellent cold workability and SSC resistance, comprising, by wt%, carbon (C) in an amount of more than 0.08% and equal to or less than 0.2%, 0.05-0.5% of silicon (Si), 0.5-2% of manganese (Mn), 0.005-0.1% of aluminum (Al), 0.01% or less of phosphorus (P), 0.0015% or less of sulfur (S), 0.001-0.03% of niobium (Nb), 0.001-0.03% of vanadium (V), 0.001-0.03% of titanium (Ti), 0.01-1% of chromium (Cr), 0.01-0.15% of molybdenum (Mo), 0.01-0.5% of copper (Cu), 0.05-4% of nickel (Ni), 0.0005-0.004% of calcium (Ca), and the balance of Fe and other inevitable impurities, wherein the microstructure of a surface layer part, which is the region from the surface to 10% of the total thickness, comprises 90 area% or more of polygonal ferrite, the microstructure of the region excluding the surface layer part comprises 90 area% or more of tempered martensite or 90 area% or more of a mixed structure of tempered martensite and tempered bainite, and the dislocation density of the surface layer part is 3*10 14 / m 2 or less.

Owner:浦项股份有限公司

Thick-wall oil-well steel pipe and production method thereof

ActiveUS20170292177A1Excellent SSC resistanceHigh strengthFurnace typesHeat treatment furnacesCarbideThick wall

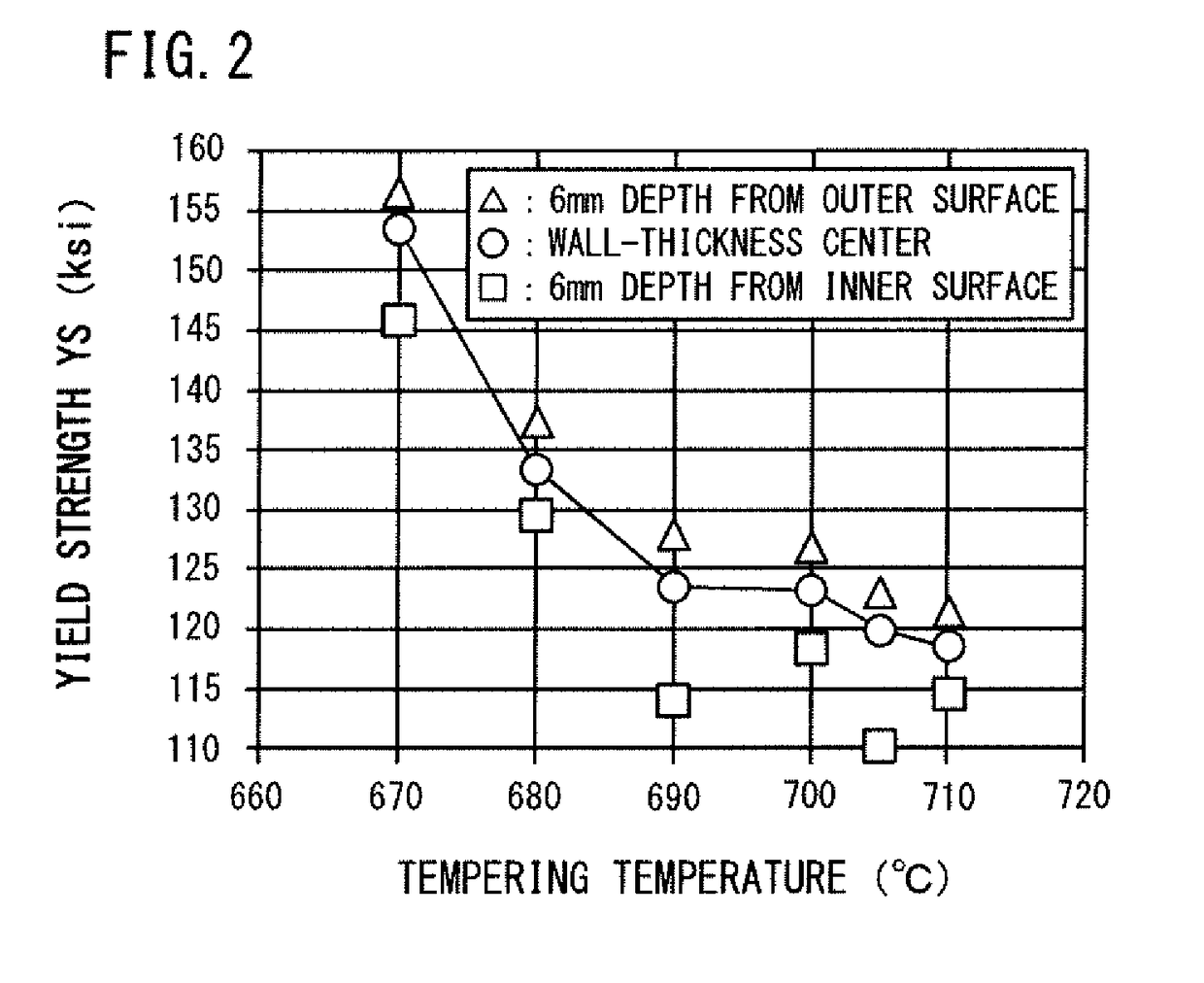

A thick-wall oil-well steel pipe has a wall thickness of 40 mm or more, excellent SSC resistance and high strength. The thick-wall oil-well steel pipe has a composition containing, in mass %, C: 0.40 to 0.65%, Si: 0.05 to 0.50%, Mn: 0.10 to 1.0%, P: 0.020% or less, S: 0.0020% or less, sol. Al: 0.005 to 0.10%, Cr more than 0.40 to 2.0%, Mo: more than 1.15 to 5.0%, Cu: 0.50% or less, Ni: 0.50% or less, N: 0.007% or less, and O: 0.005% or less. The number of carbide which has a circle equivalent diameter of 100 nm or more and contains 20 mass % or more of Mo is 2 or less per 100 mm2. The thick-wall oil-well steel pipe has yield strength of 827 MPa or more. A difference between a maximum value and a minimum value of the yield strength in the wall-thickness direction is 45 MPa or less.

Owner:NIPPON STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same

ActiveUS10876182B2Increase resistanceSuperior sulfide stress cracking resistanceFurnace typesHeat treatment furnacesAustenite grainPipe

A high-strength seamless steel pipe for oil country tubular goods comprising, by mass %, C: 0.20% to 0.50%, Si: 0.05% to 0.40%, Mn: 0.3% to 0.9%, P: 0.015% or less, S: 0.005% or less, Al: 0.005% to 0.1%, N: 0.006% or less, Mo: more than 1.0% to 3.0% or less, V: 0.01% to less than 0.05%, Nb: 0.001% to less than 0.01%, B: 0.0003% to 0.0030%, O: 0.0030% or less, and Ti: 0.003% to 0.025%, and wherein Ti / N: 2.0 to 5.0 is satisfied, a volume fraction of a tempered martensitic is 95% or more, prior austenite grains have a grain size number of 8.5 or more, and in a cross-section perpendicular to a rolling direction, the number of nitride-based inclusions having a grain size of 4 μm or more is 100 or less per 100 mm2, the number of nitride-based inclusions having a grain size of less than 4 μm is 1000 or less per 100 mm2, the number of oxide-based inclusions having a grain size of 4 μm or more is 40 or less per 100 mm2, and the number of oxide-based inclusions having a grain size of less than 4 μm is 400 or less per 100 mm2.

Owner:JFE STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same

ActiveUS10640856B2Low costExcellent sulfide stress corrosion cracking resistanceFurnace typesRigid pipesAustenite grainPipe

Provided is a high-strength seamless steel pipe having the composition which contains, by mass %, 0.20 to 0.50% C, 0.05 to 0.40% Si, 0.3 to 0.9% Mn, 0.015% or less P, 0.005% or less S, 0.005 to 0.1% Al, 0.008% or less N, more than 0.6% and 1.7% or less Cr, more than 1.0% and 3.0% or less Mo, 0.01 to 0.30% V, 0.001% or more and less than 0.01% Nb, 0.0003 to 0.0030% B, and 0.0030% or less O (oxygen). The high-strength seamless steel pipe has the microstructure where a volume fraction of a tempered martensitic phase is 95% or more, and prior austenitic grains have a grain size number of 8.5 or more, and a segregation degree index Ps which is defined by a formula Ps=8.1 (XSi+XMn+XMo)+1.2XP is set to less than 65.

Owner:JFE STEEL CORP

Steel for oil well pipe excellent in sulfide stress cracking resistance

ActiveUS8617462B2High strengthExcellent SSC resistanceFurnace typesHeat treatment furnacesHot workingWater cooling

Owner:NIPPON STEEL CORP

High-strength seamless steel pipe for oil country tubular goods and method of producing the same

ActiveUS20170283918A1Low costExcellent sulfide stress corrosion cracking resistanceFurnace typesRigid pipesAustenite grainCrystallite

Provided is a high-strength seamless steel pipe having the composition which contains, by mass %, 0.20 to 0.50% C, 0.05 to 0.40% Si, 0.3 to 0.9% Mn, 0.015% or less P, 0.005% or less S, 0.005 to 0.1% Al, 0.008% or less N, more than 0.6% and 1.7% or less Cr, more than 1.0% and 3.0% or less Mo, 0.01 to 0.30% V, 0.001% or more and less than 0.01% Nb, 0.0003 to 0.0030% B, and 0.0030% or less O (oxygen). The high-strength seamless steel pipe has the microstructure where a volume fraction of a tempered martensitic phase is 95% or more, and prior austenitic grains have a grain size number of 8.5 or more, and a segregation degree index Ps which is defined by a formula Ps=8.1 (XSi+XMn+XMo)+1.2XP is set to less than 65.

Owner:JFE STEEL CORP

Steel material, and oil-well steel pipe for expansion

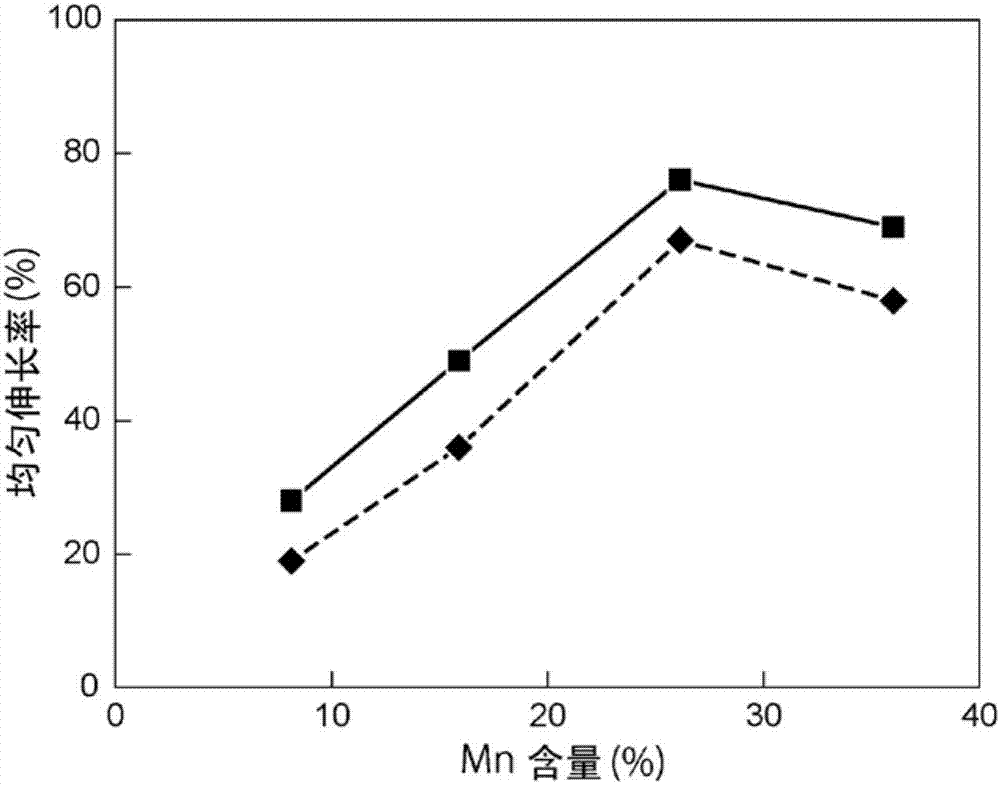

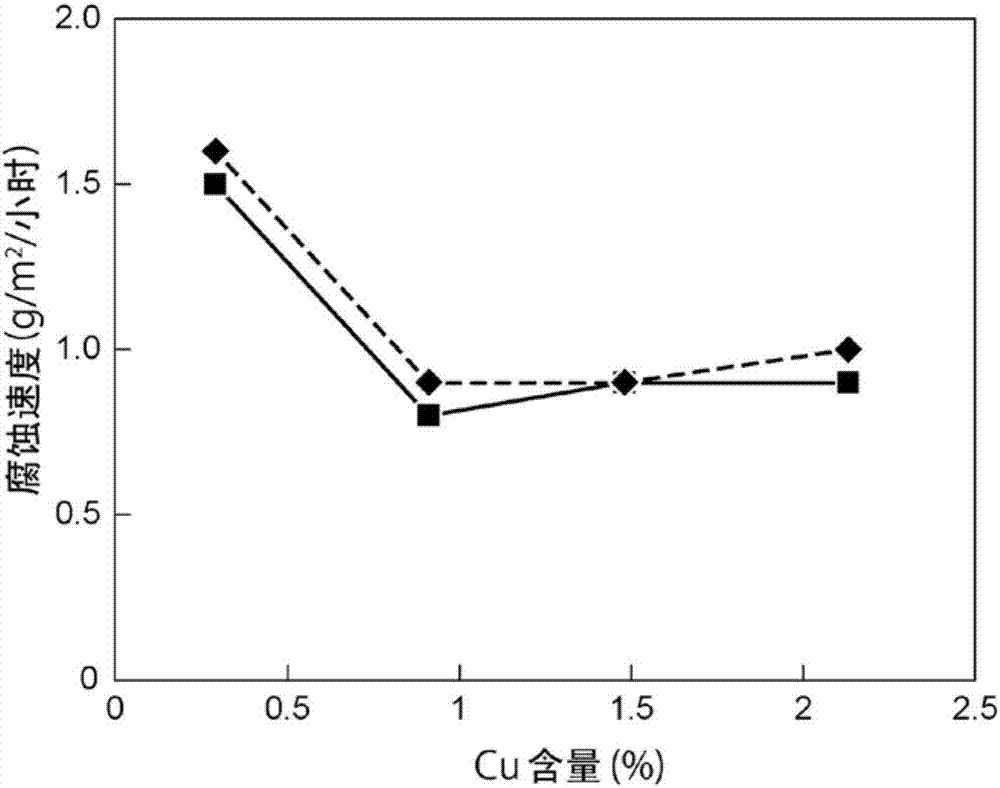

InactiveCN107075634AExcellent SSC resistanceUniform elongationFurnace typesHeat treatment furnacesChemical compositionPipe

Owner:NIPPON STEEL CORP

Low-alloy steel pipe for an oil well

ActiveUS10233520B2Good and stable SSC resistanceIncrease resistanceFurnace typesHeat treatment furnacesCarbideImpurity

A low-alloy steel pipe includes C: 0.15% to less than 0.30%, Si: 0.05 to 1.00%, Mn: 0.05 to 1.00%, P: at most 0.030%, S: at most 0.0050%, Al: 0.005 to 0.100%, O: at most 0.005%, N: at most 0.007%, Cr: 0.10% to less than 1.00%, Mo: 1.0% to not more than 2.5%, V: 0.01 to 0.30%, Ti: 0.002 to 0.009%. Nb: 0 to 0.050%, B: 0 to 0.0050%, Ca: 0 to 0.0050%, Mo / Cr≥2.0, and the balance being Fe and impurities. The pipe has a crystal grain size number of 7.0 or more, 50 or more particles of cementite based on equivalent circle diameter and area of the matrix, M2C-based alloy carbide in a number density of not less than 25 / μm2, and a yield strength of 758 MPa or more.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com