Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Sulfide stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

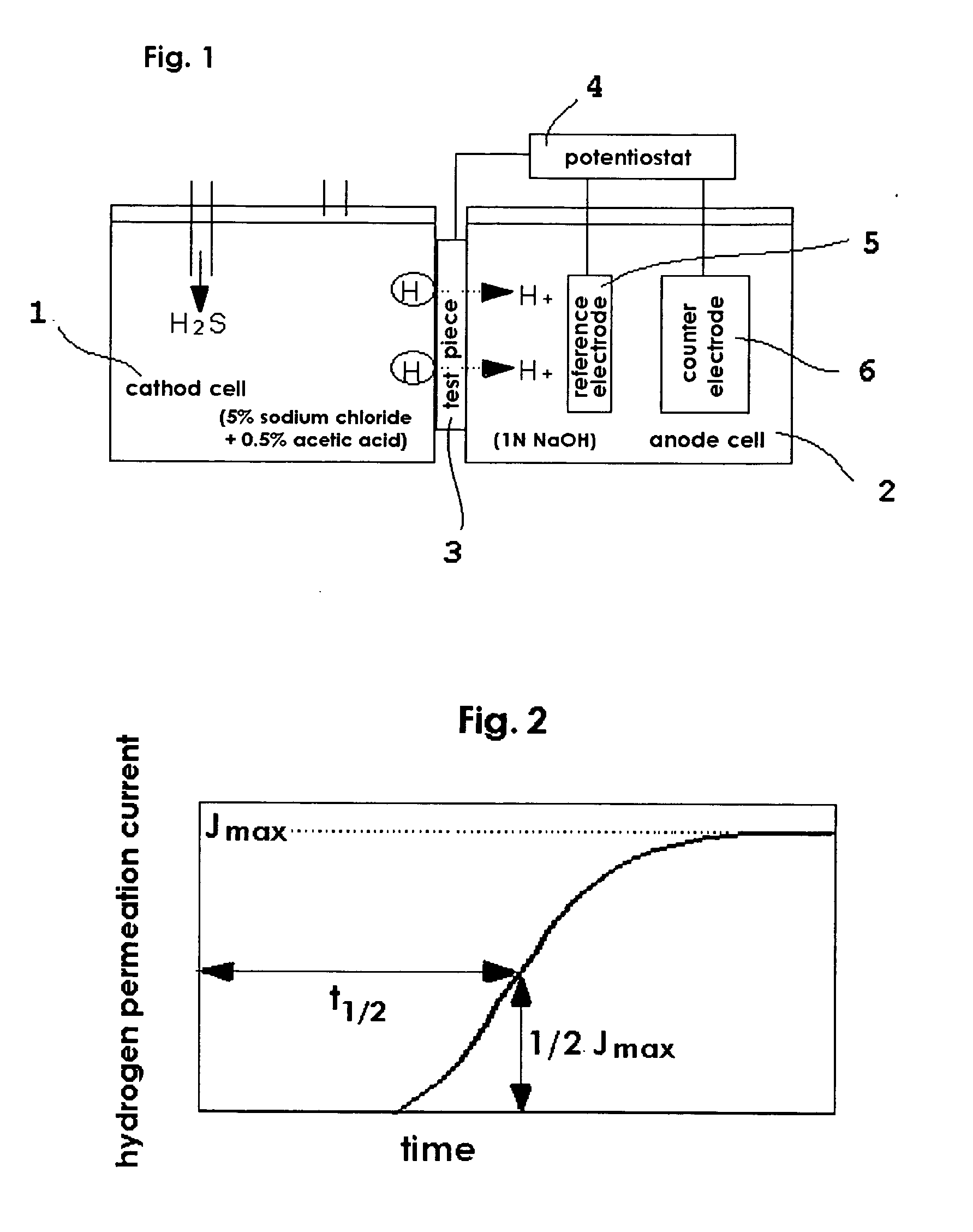

Sulfide stress cracking (SSC) is a form of hydrogen embrittlement which is a cathodic cracking mechanism. It should not be confused with the term stress corrosion cracking which is an anodic cracking mechanism. Susceptible alloys, especially steels, react with hydrogen sulfide, forming metal sulfides and atomic hydrogen as corrosion byproducts. Atomic hydrogen either combines to form H₂ at the metal surface or diffuses into the metal matrix. Since sulfur is a hydrogen recombination poison, the amount of atomic hydrogen which recombines to form H₂ on the surface is greatly reduced, thereby increasing the amount of diffusion of atomic hydrogen into the metal matrix. This aspect is what makes wet H₂S environments so severe.

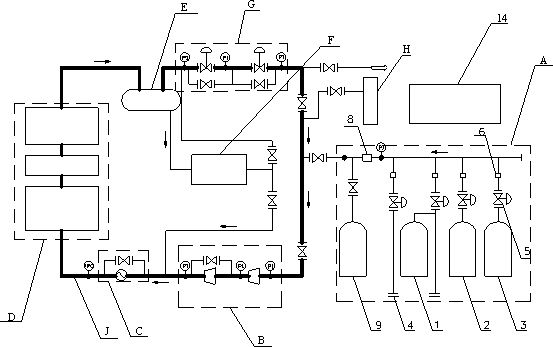

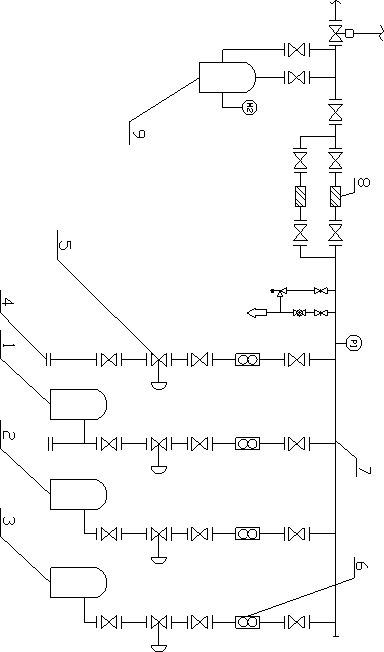

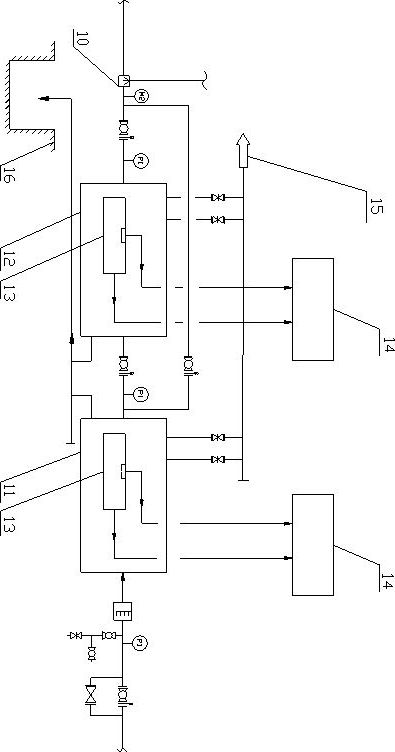

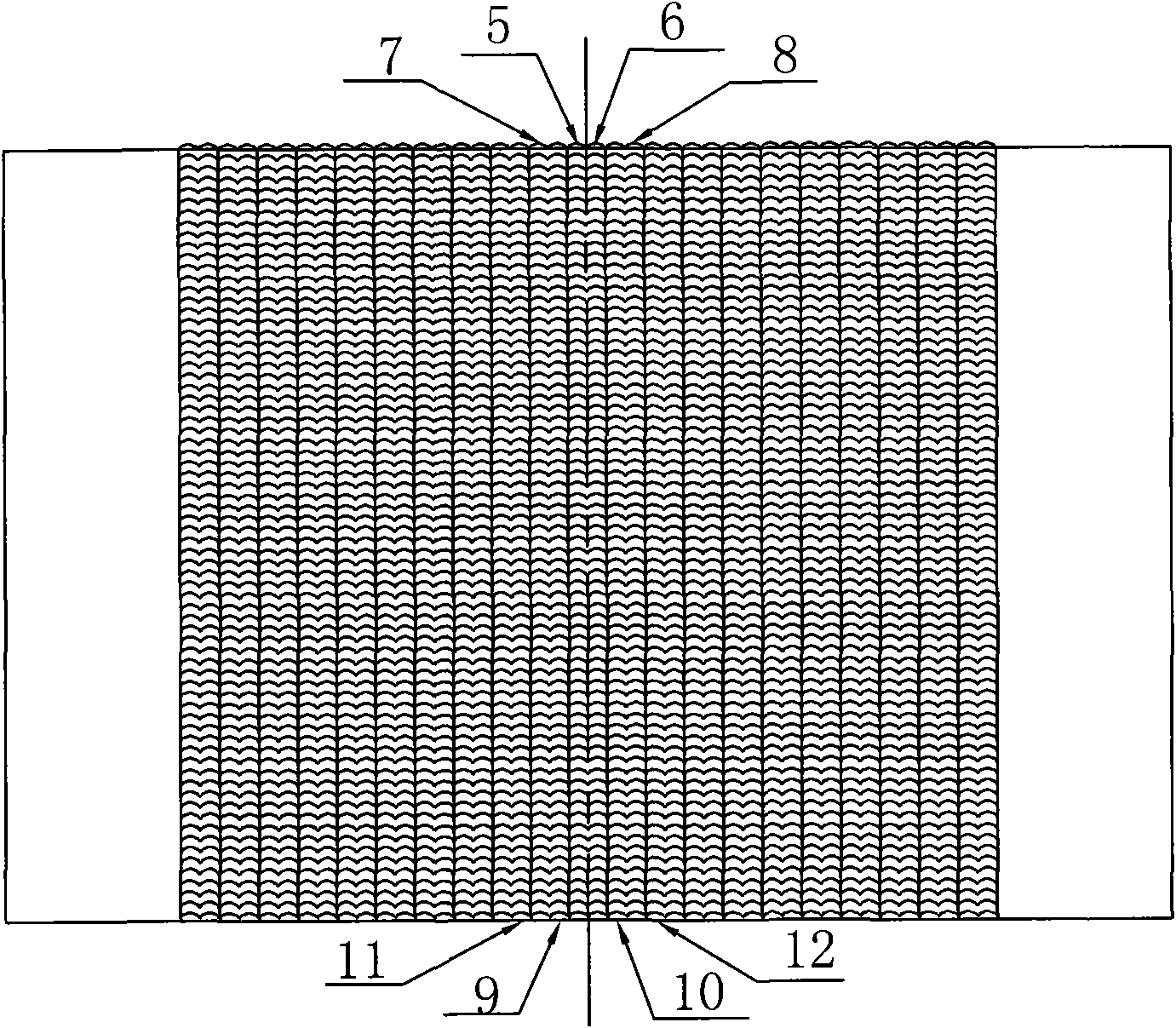

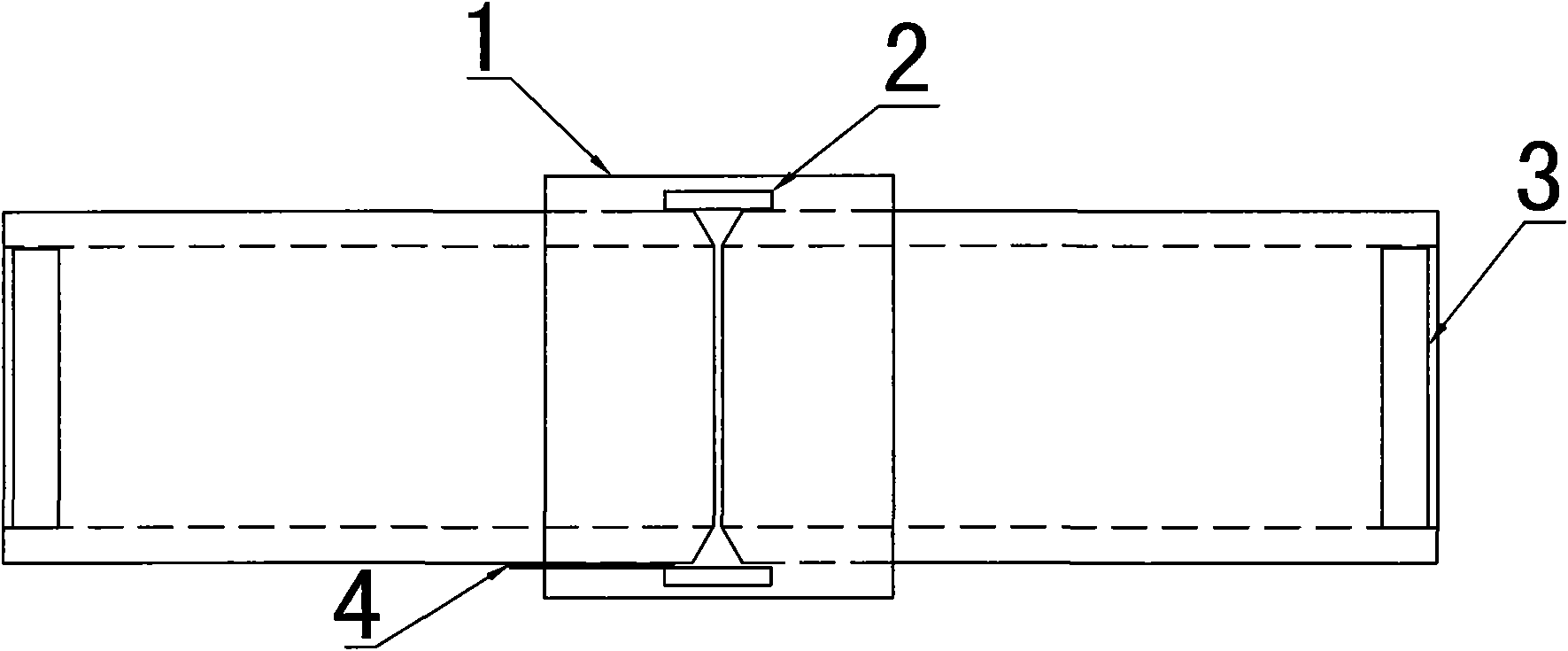

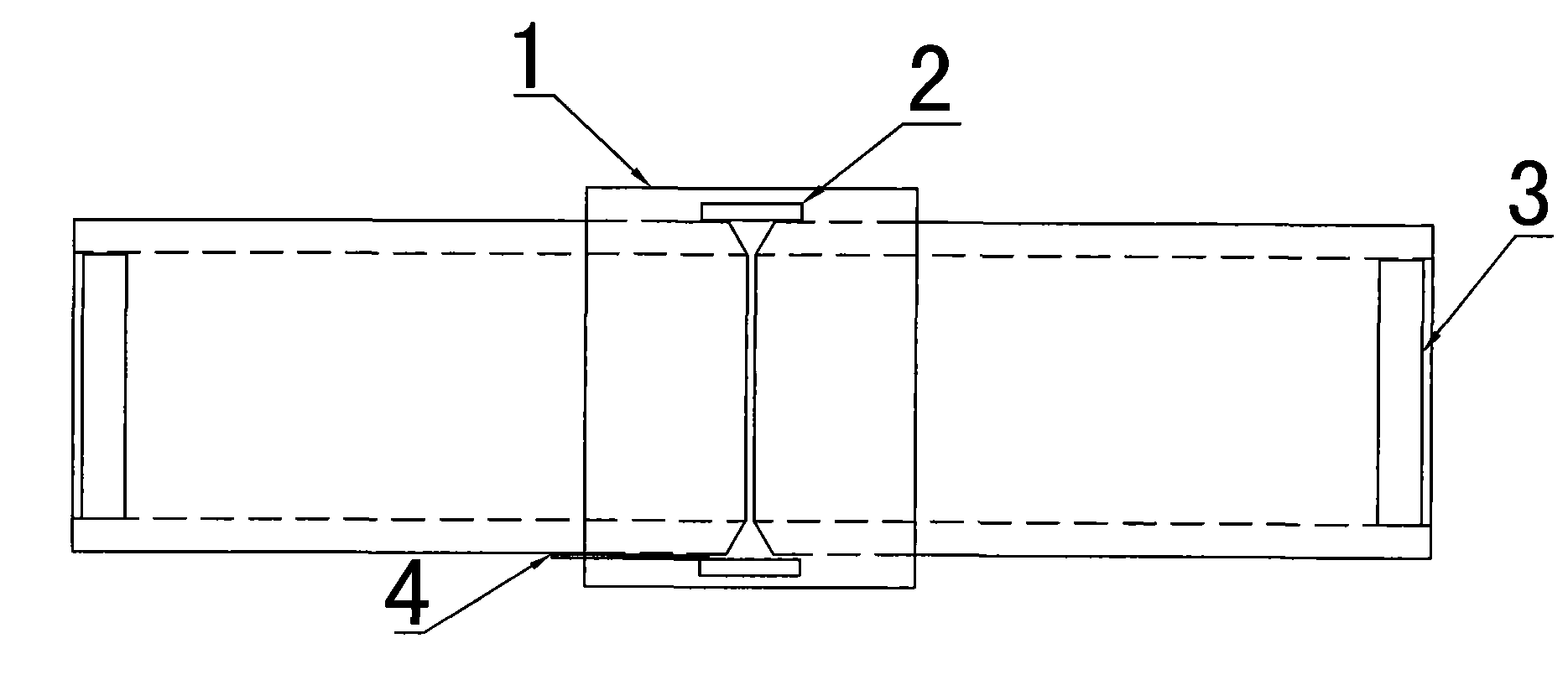

Acid medium transmission pipeline welded joint and parent metal corrosion simulation testing device and method

InactiveCN102305761AIn line with the actual situationWide range of working conditionsWeather/light/corrosion resistanceWashoutStimulation tests

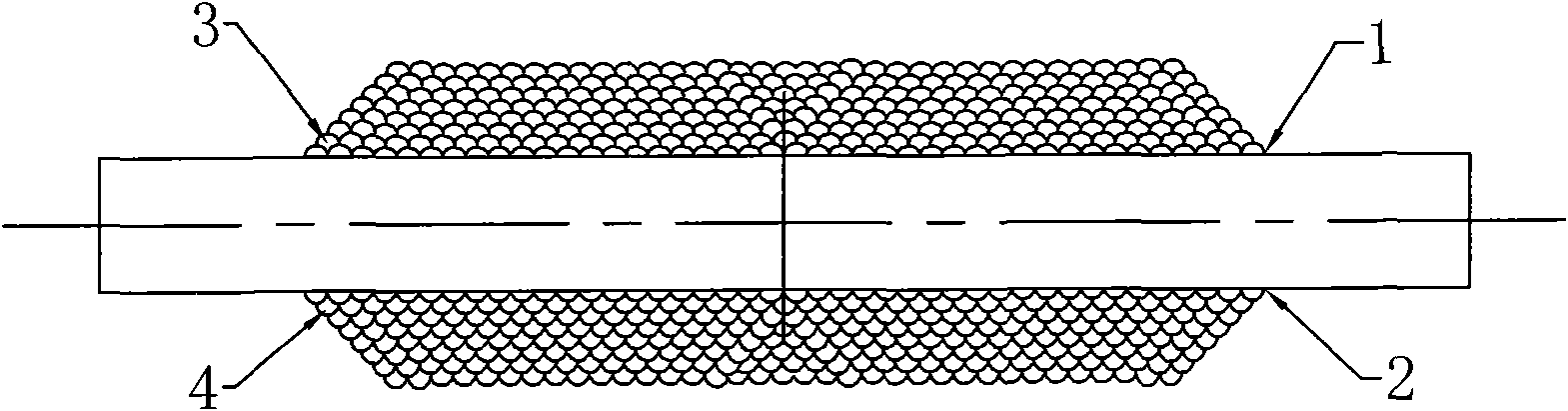

The invention provides a large-scale multifunctional corrosion stimulation test rack taking a test circular road as a main part, which is used for simulating the corrosion condition of high acid natural gas containing H2S, CO2 and Cl on a pipeline parent metal and a welded joint under the pipeline transmission condition. The device and the method provided by the invention can be applied to pipeline parent bodies with different pipe diameters, materials, steel grades and wall thicknesses, or a welded joint corrosion test; and test functions such as test on corrosion of the pipe section parent metal and the welded joint, sulfide stress cracking (SSC), hydrogen induced cracking (HIC), washout, corrosion inhibitor effect, welding process evaluation, corrosion monitoring method comparison, pipeline-corrosion-preventing process optimization and the like are integrated into a whole; and the test functions, such as preference of the corrosion process in the pipeline are integrated into a whole, thus reasonable material selection and safe welding quality are guaranteed, and the corrosion condition of the corresponding corrosion condition on the welded joint and the parent metal is known.

Owner:SOUTHWEST PETROLEUM UNIV

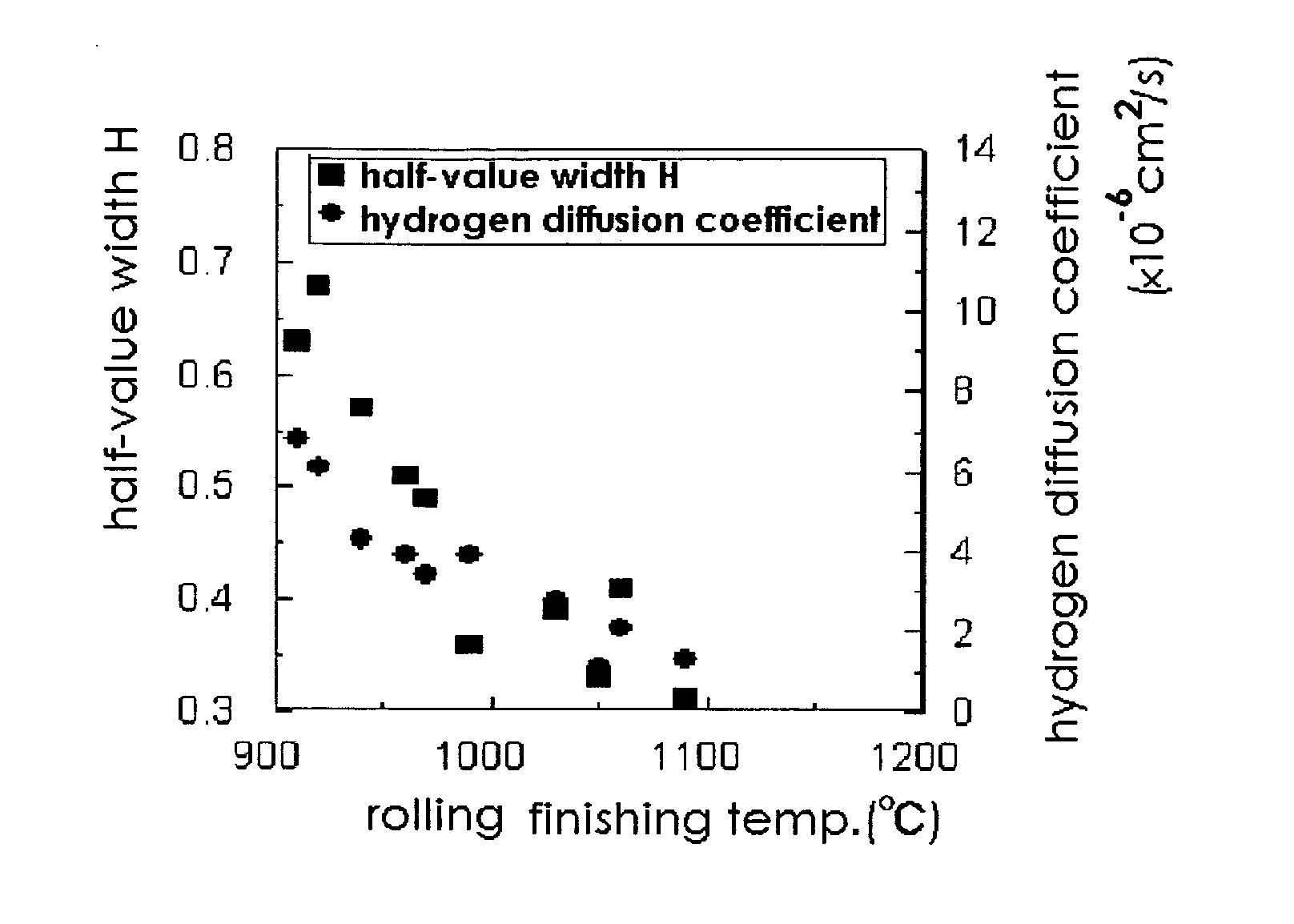

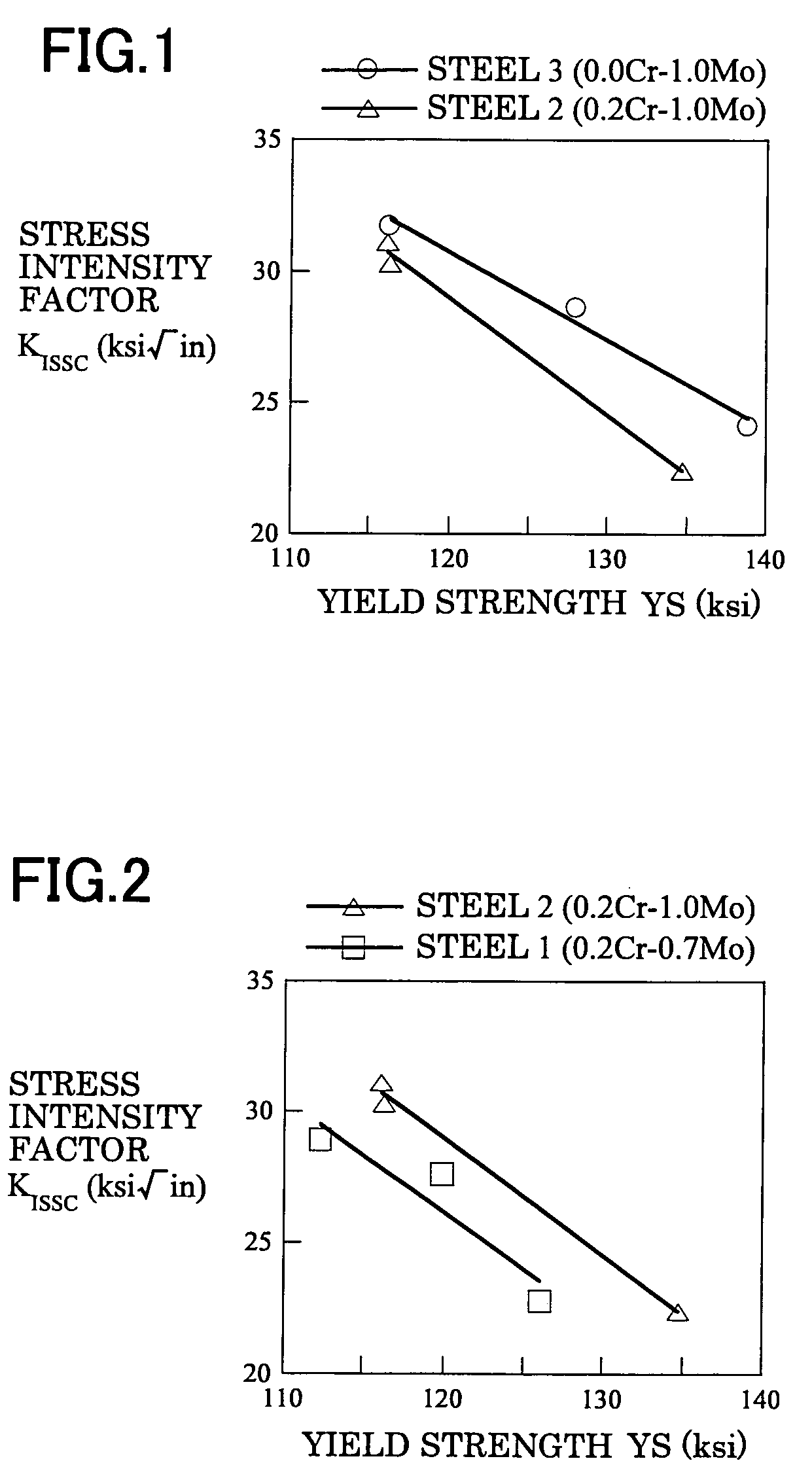

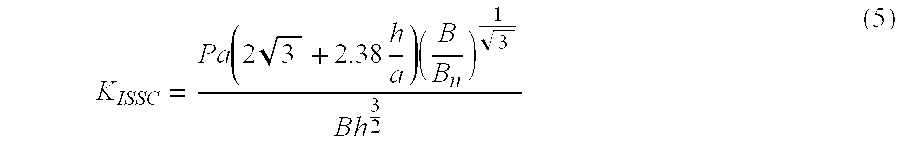

Low alloy steel for oil well pipes having excellent sulfide stress cracking resistance

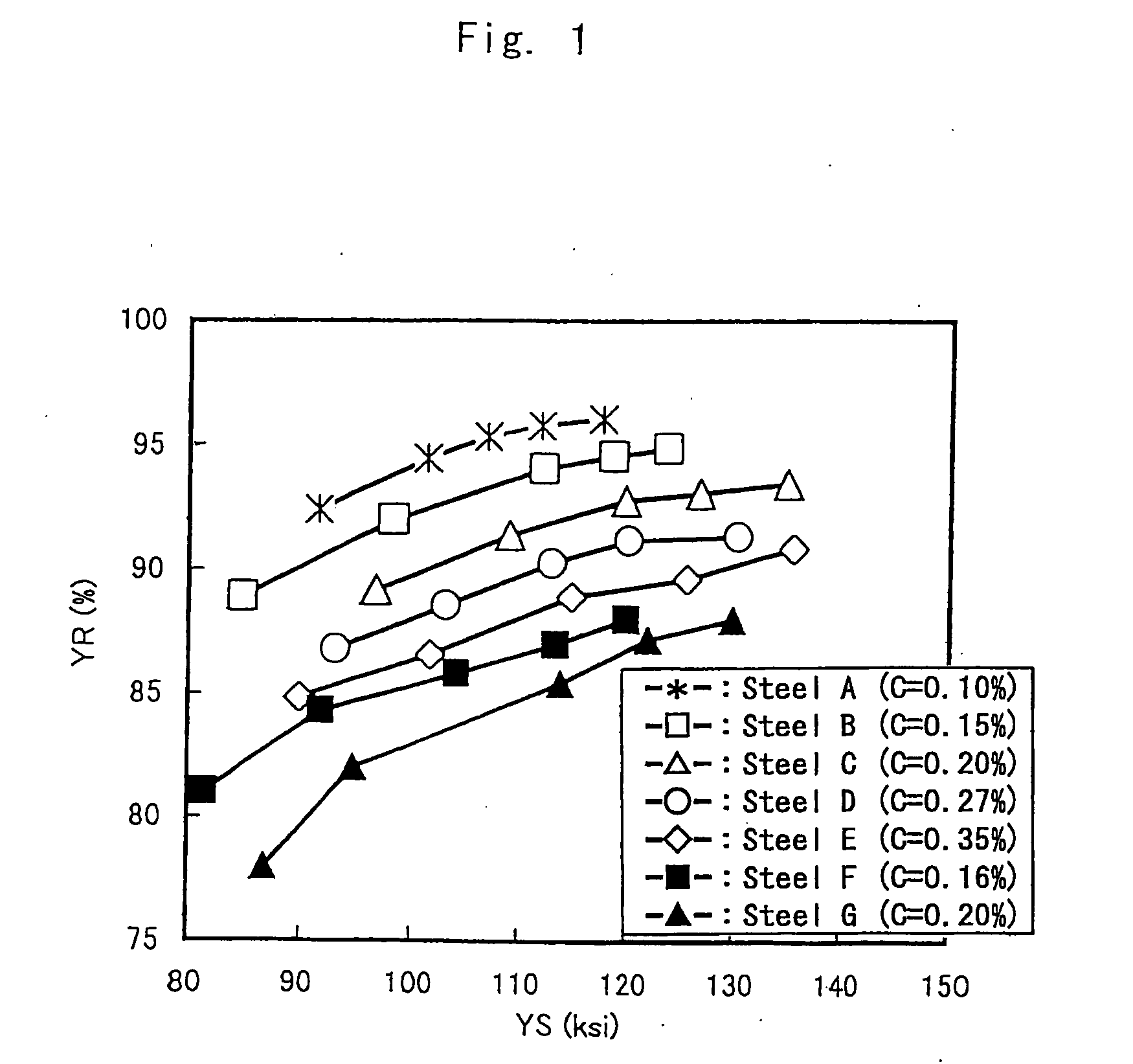

ActiveUS20070137736A1Excellent SSC resistanceProvide stableFurnace typesIncreasing energy efficiencyHydrogenMetallurgy

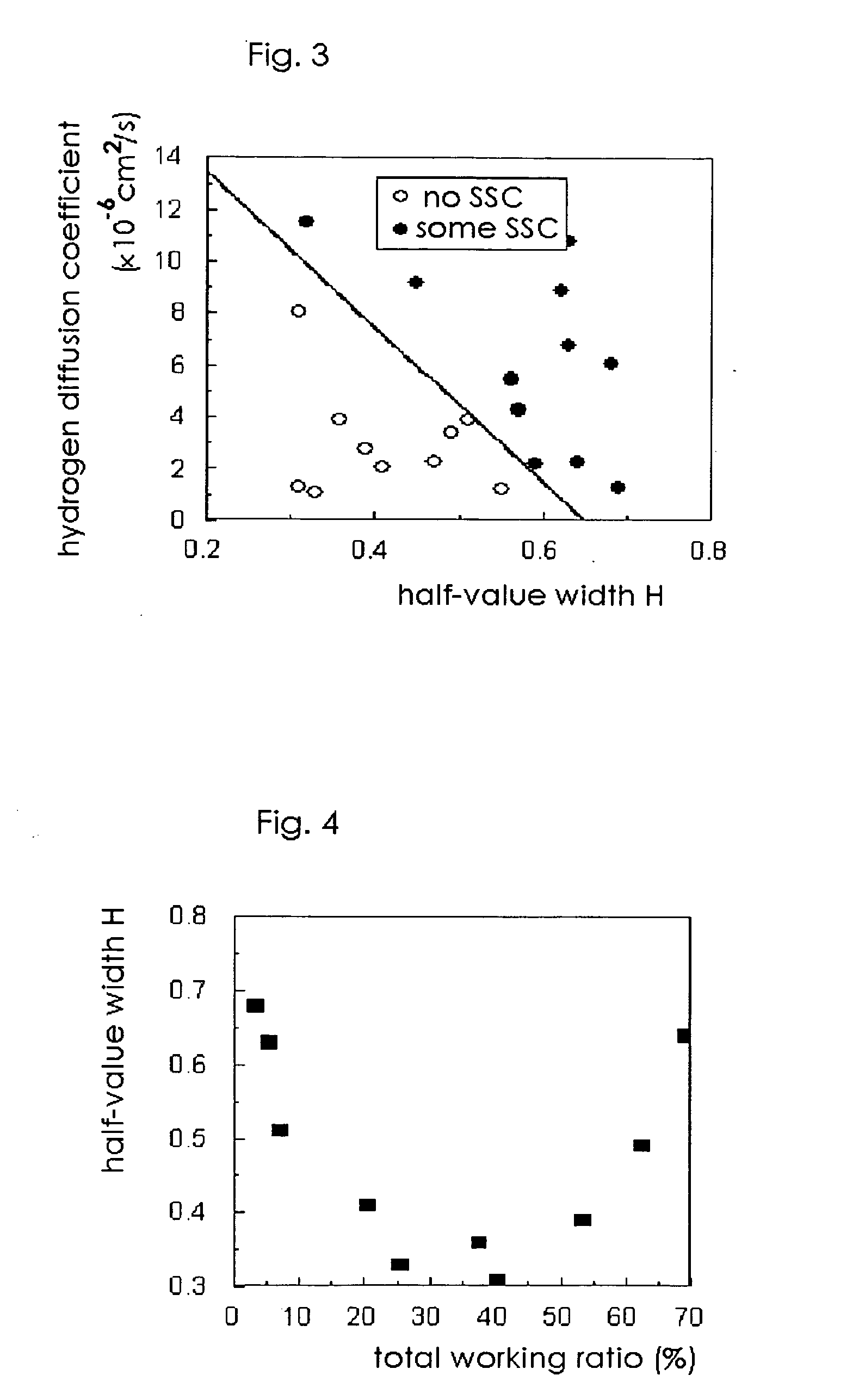

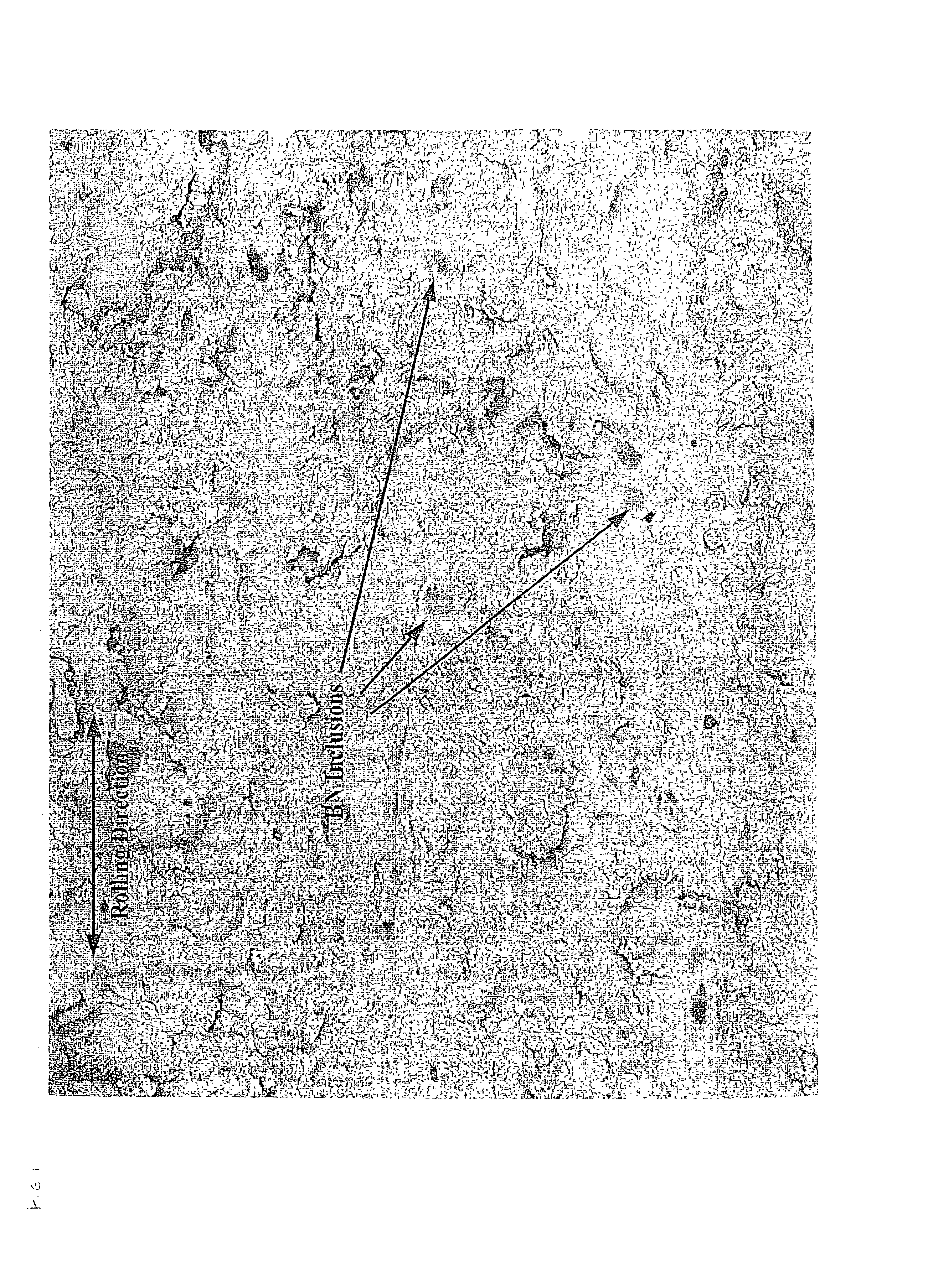

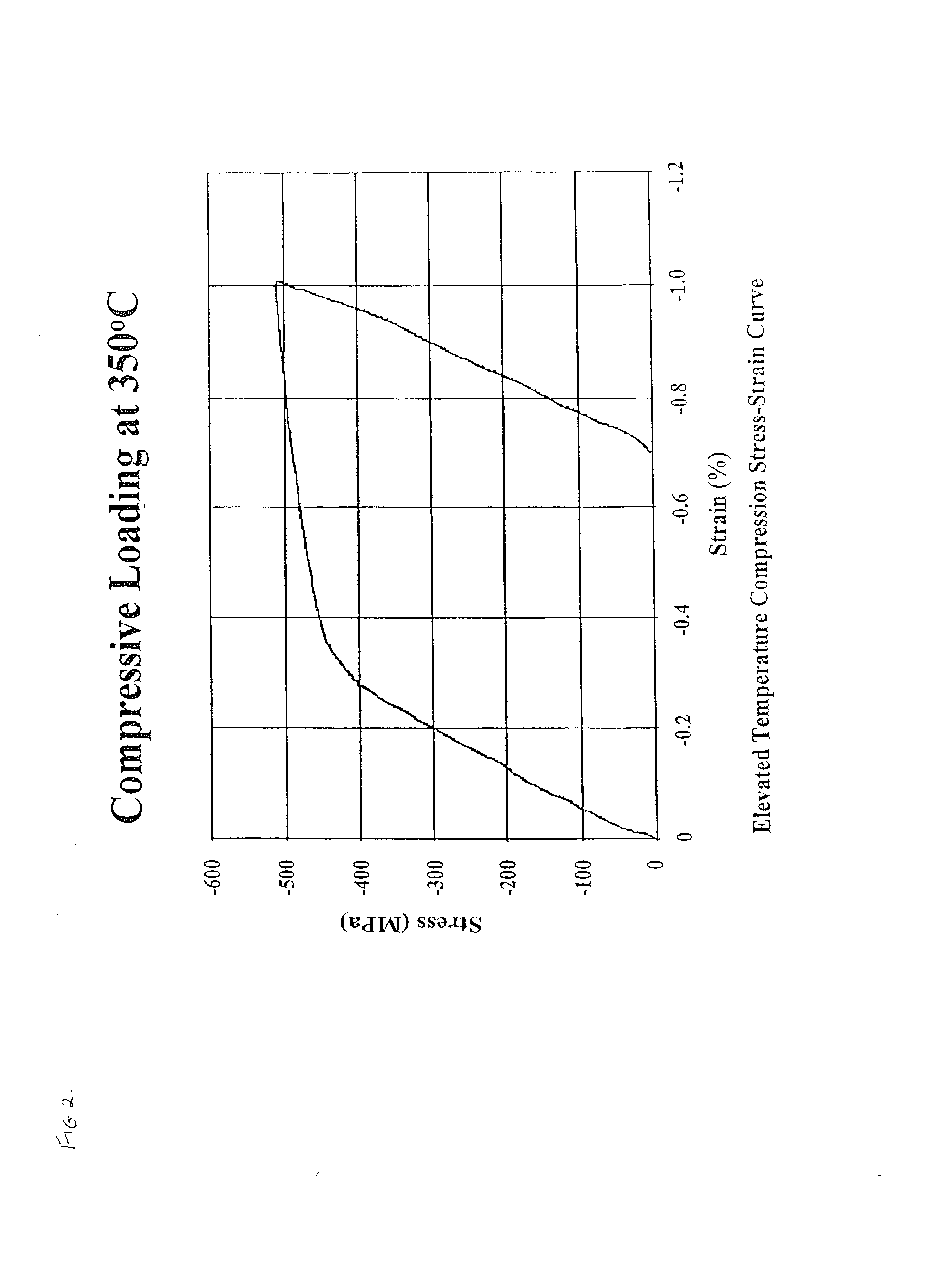

Disclosed is a low alloy steel for oil well pipes which has excellent sulfide stress cracking resistance and is suitable for casing and tubing for oil wells or gas wells. Specifically disclosed is a low alloy steel for oil well pipes containing, in mass %, 0.2-0.35% of C, 0.05-0.5% of Si, 0.05-1.0% of Mn, not more than 0.025% of P,. not more than 0.01% of S, 0.005-0.10% of Al, 0.1-1.0% of Cr, 0.5-1.0% of Mo, 0.002-0.05% of Ti, 0.05-0.3% of V, 0.0001-0.005% of B, not more than 0.01% of N, not more than 0.01% of O (oxygen), 0-0.1% of Nb, 0-0.01% of Ca, 0-0.01% of Mg and 0-0.1% of Zr, and having a half-value breadth (H) and a hydrogen diffusion coefficient (D) (10−6 cm2 / s) satisfying the following formula (1): 30H+D≦19.5 (1).

Owner:NIPPON STEEL CORP

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

The invention relates to a quench-and-temper steel alloy for use in casing for oil and gas wells wherein such casing is exposed to low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, and a sulphur range by weight of less than 0.002%. The steel alloy has a quench-and-temper micro-structure and features precipitated spheroidal molybdenum carbides in manganese- and carbon-rich bands. The steel alloy also has, by weight, a chromium range of less than 0.50%, an aluminum range of less than or equal to 0.08% and a calcium range of less than or equal to 0.0045%.

Owner:IPSCO ENTERPRISES

Low alloy steel for the pipe for oil well use and seamless steel pipe

Owner:NIPPON STEEL CORP

Method for producing high-strength steel material excellent in sulfide stress cracking resistance

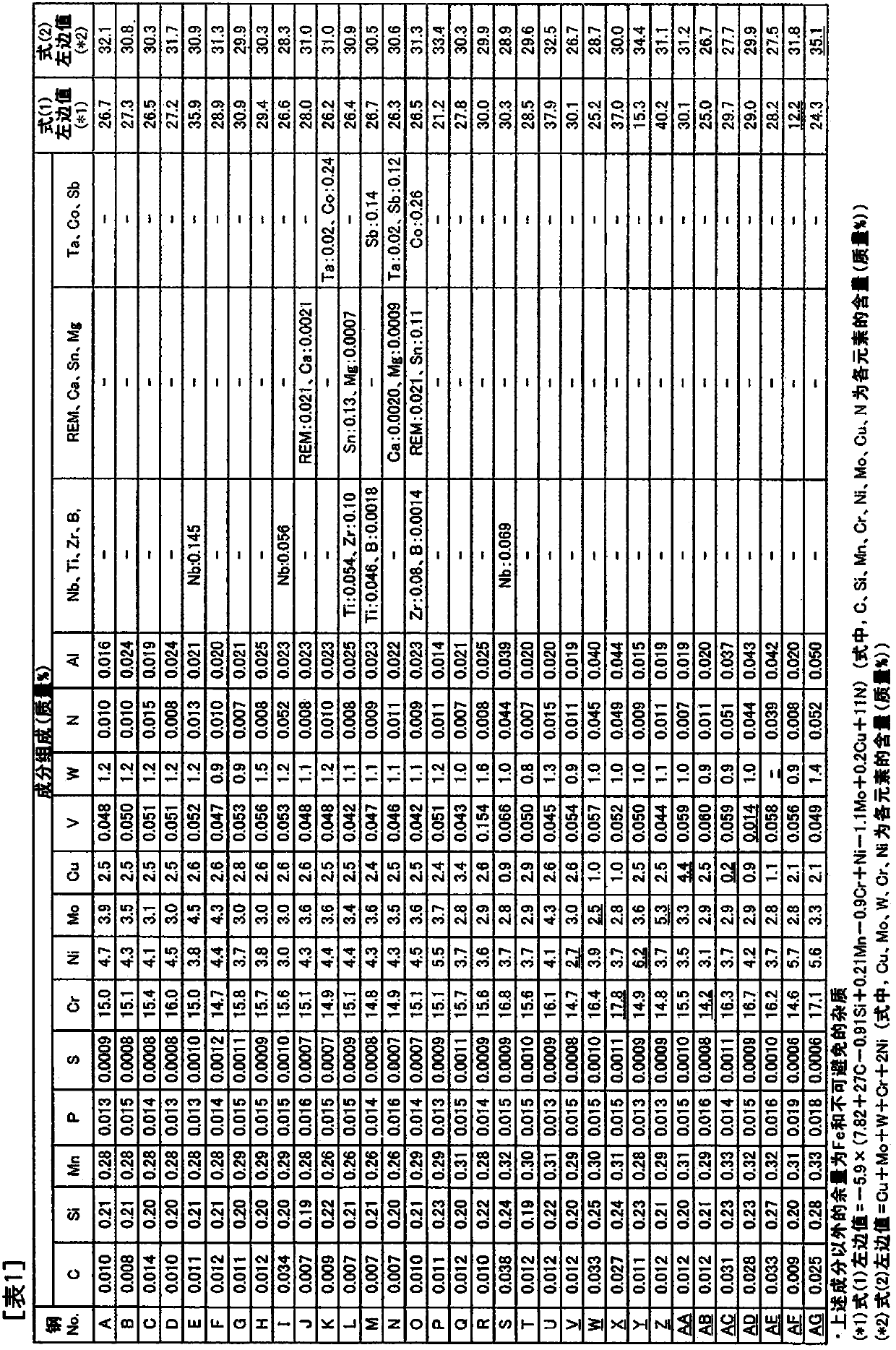

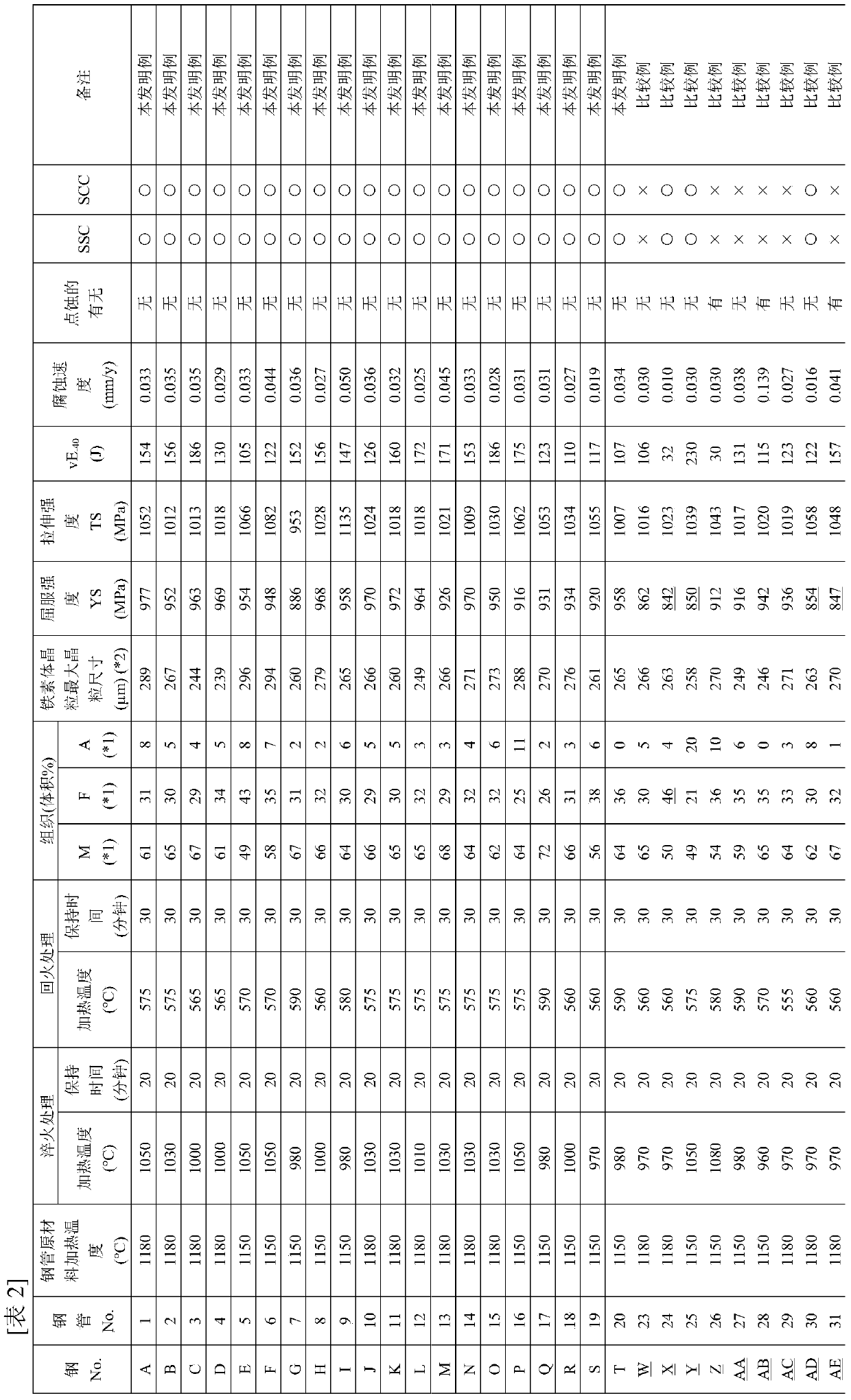

ActiveUS20150041030A1Low costImprove toughnessFurnace typesHeat treatment furnacesChemical compositionHot work

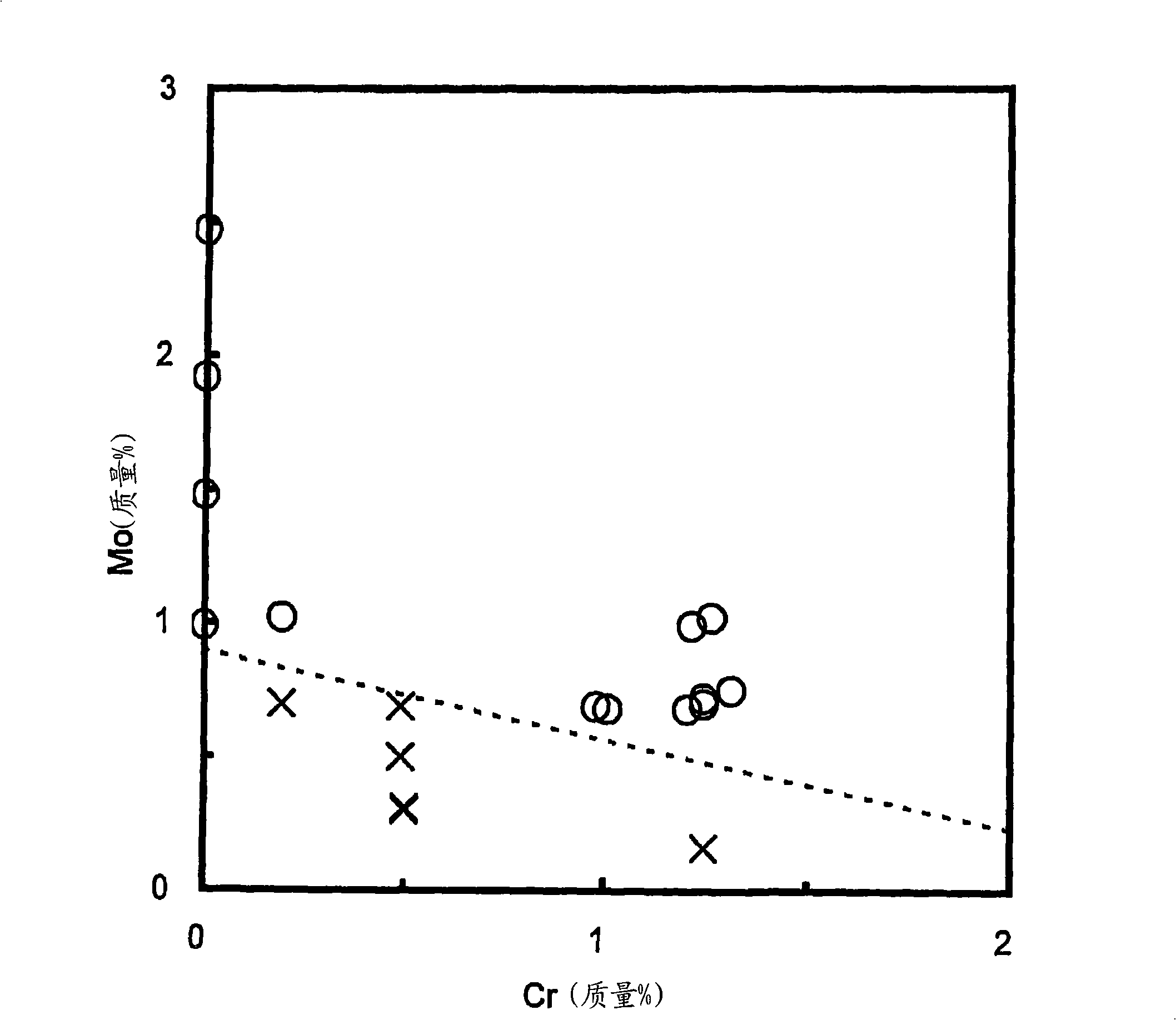

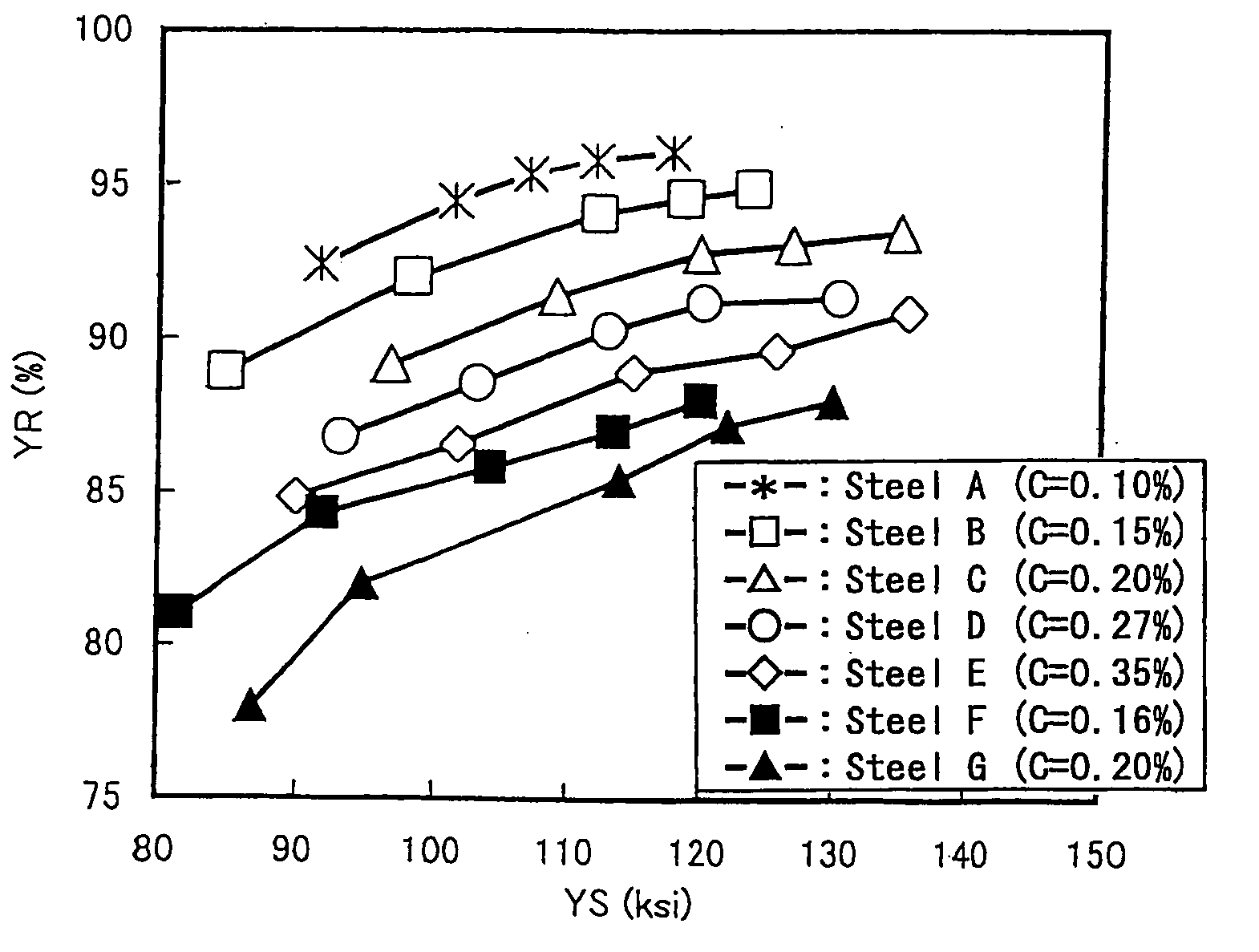

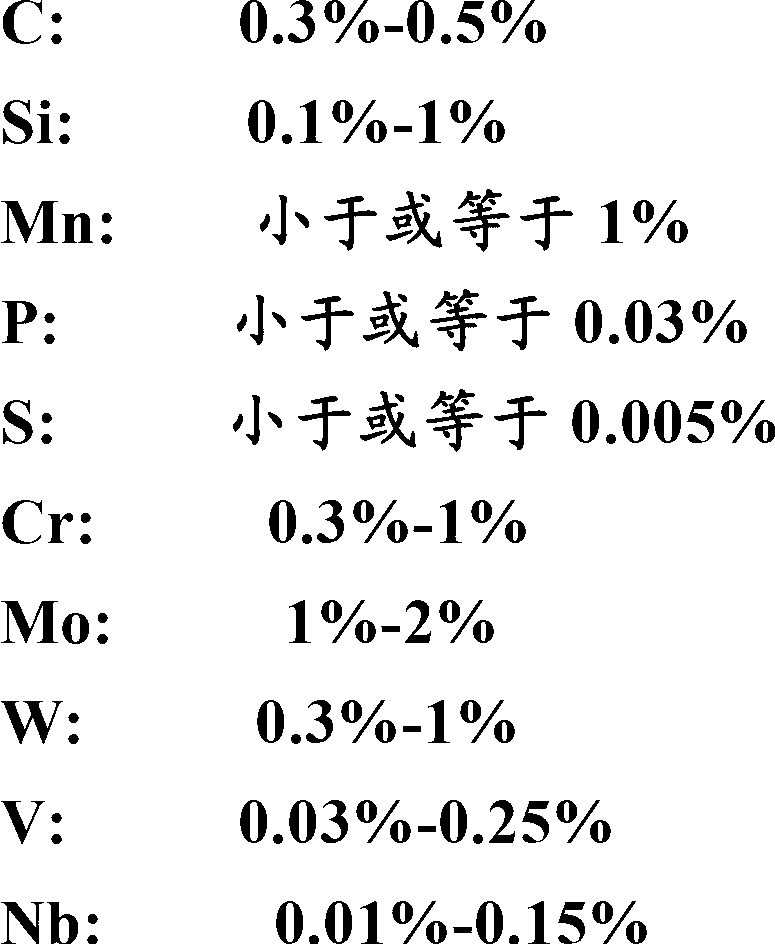

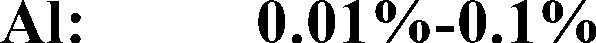

A steel has a chemical composition consisting of, by mass percent, C: 0.15-0.65%, Si: 0.05-0.5%, Mn: 0.1-1.5%, Cr: 0.2-1.5%, Mo: 0.1-2.5%, Ti: 0.005-0.50%, Al: 0.001-0.50%, and optionally at least one element selected from Nb: ≦0.4%, V: ≦0.5%, and B: ≦0.01%, Ca: ≦0.005° A, Mg: ≦0.005%, and REM: ≦0.005%, and the balance of Fe and impurities, wherein Ni, P, S, N and O as impurities are Ni: ≦0.1%, P: ≦0.04%, S: ≦0.01%, N: ≦0.01%, and O: ≦0.01%. The steel is hot-worked into a shape and then sequentially subjected to heating the steel to a temperature exceeding the Ac1 transformation point and lower than the Ac3 transformation point and cooling. Then, a step of reheating the steel to a temperature not lower than the Ac3 transformation point and quenching the steel by rapid cooling, and a step of tempering the steel at a temperature not higher than the Ac1 transformation point are performed.

Owner:NIPPON STEEL CORP

Low alloy steel for oil country tubular goods and seamless steel pipe

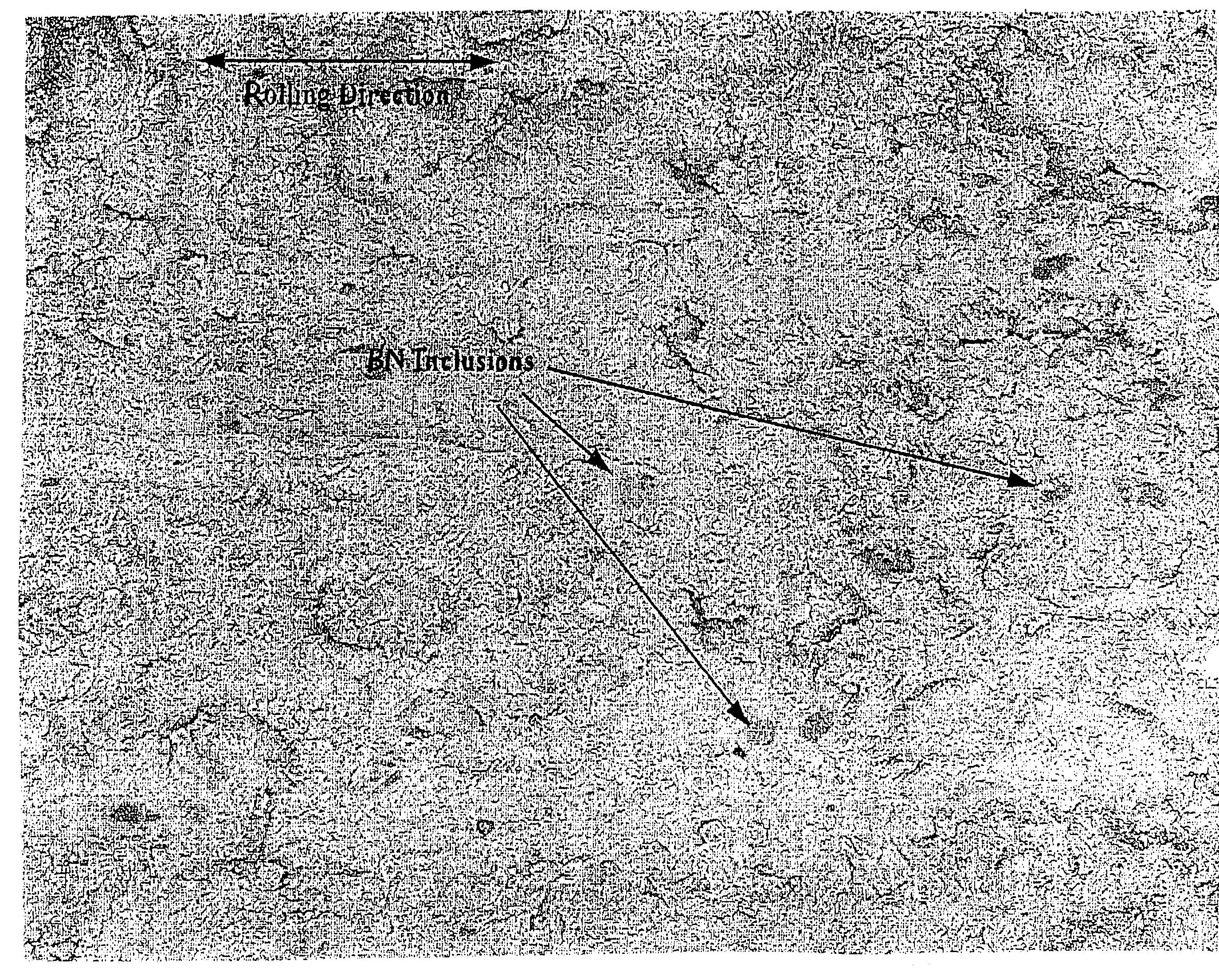

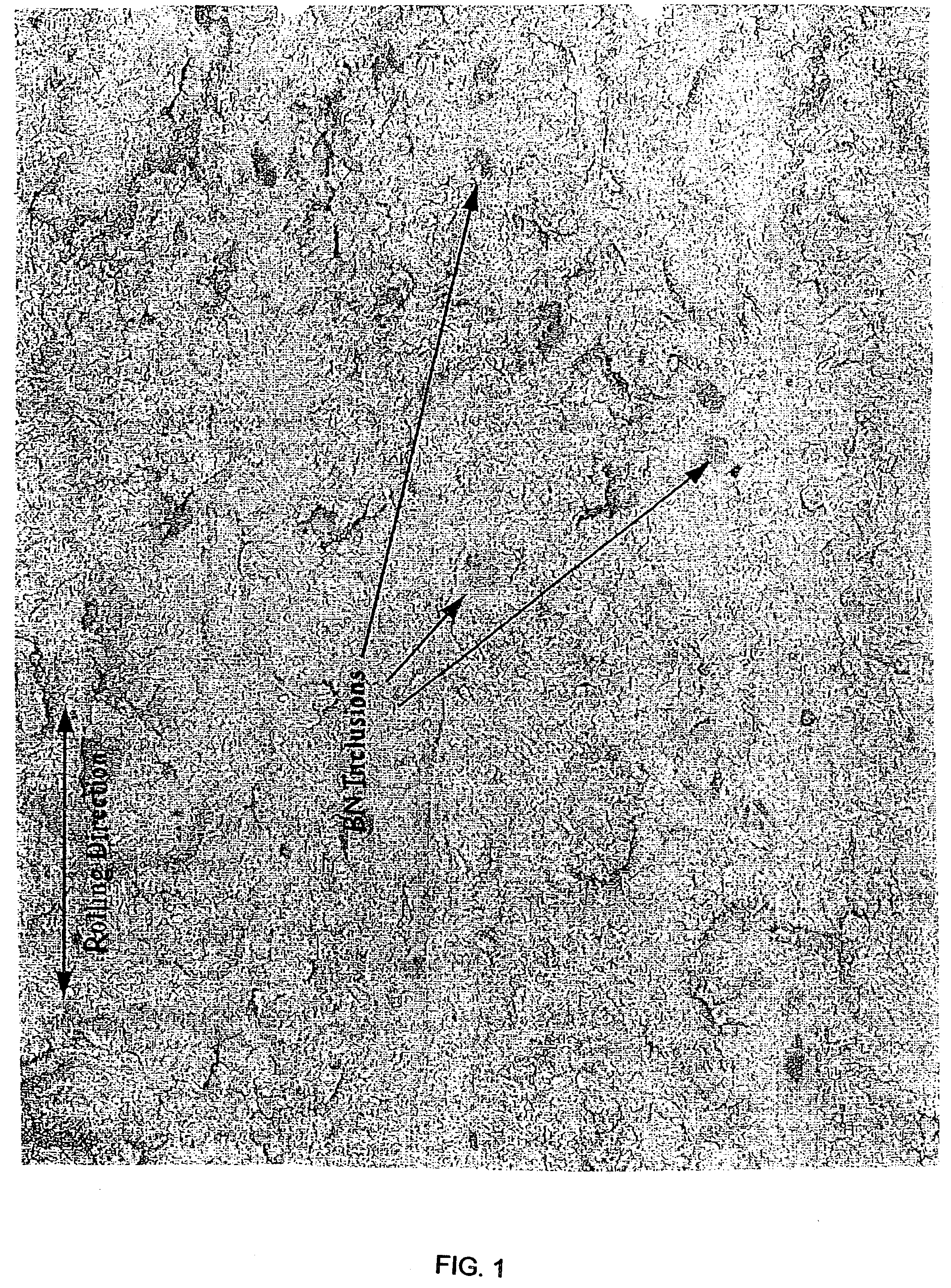

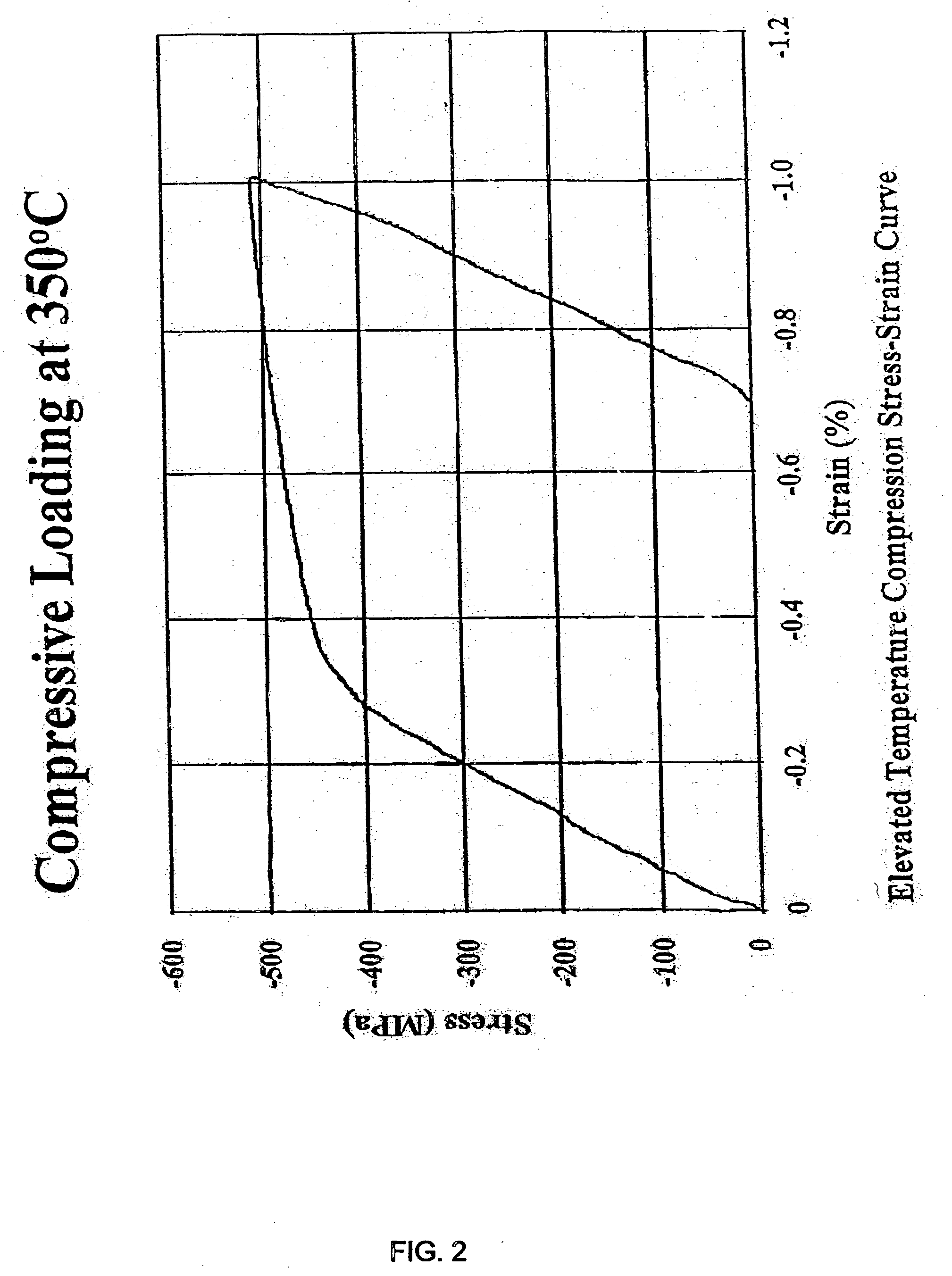

InactiveUS20090098403A1Improve the immunityLayered productsBlade accessoriesSquare MillimeterNon-metallic inclusions

A low alloy steel is provided for oil country tubular goods with a yield strength between 654 MPa and 757 MPa, and possessing excellent resistance to HIC and SSC in high-pressure hydrogen sulfides environment, and comprising, by mass %: 0.10 to 0.60% C; 0.05 to 0.5% Si; 0.05 to 3.0% Mn; 0.025% or less P; 0.010% or less S; 0.005 to 0.10% Al; 0.01% or less O (oxygen); 3.0% or less Cr; and 3.0% or less Mo, wherein the amount of Cr and Mo content is 1.2% or more, with the balance being Fe and impurities, and the number of nonmetallic inclusions whose major axis is 10 μm or more is 10 per square millimeter in the inspected cross section. The present invention provides a low alloy steel for oil country tubular goods possessing excellent resistance to sulfide stress cracking, and a seamless steel pipe.

Owner:SUMITOMO METAL IND LTD

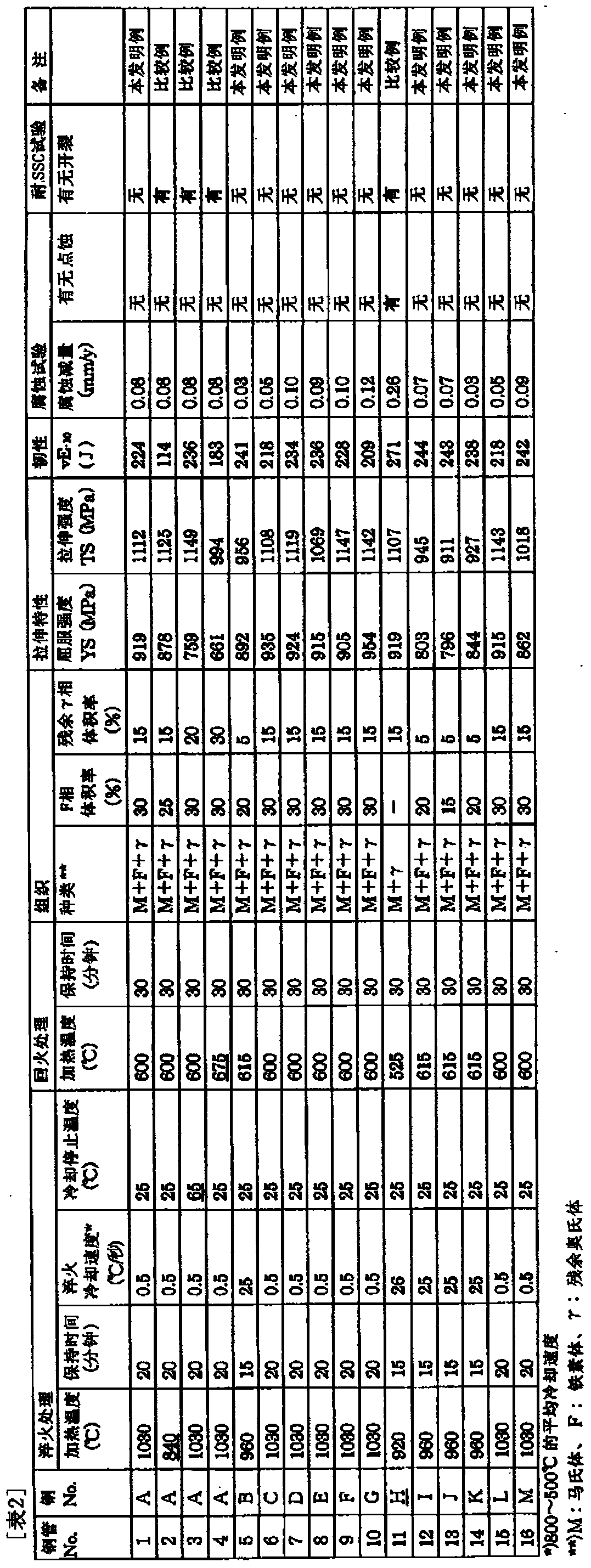

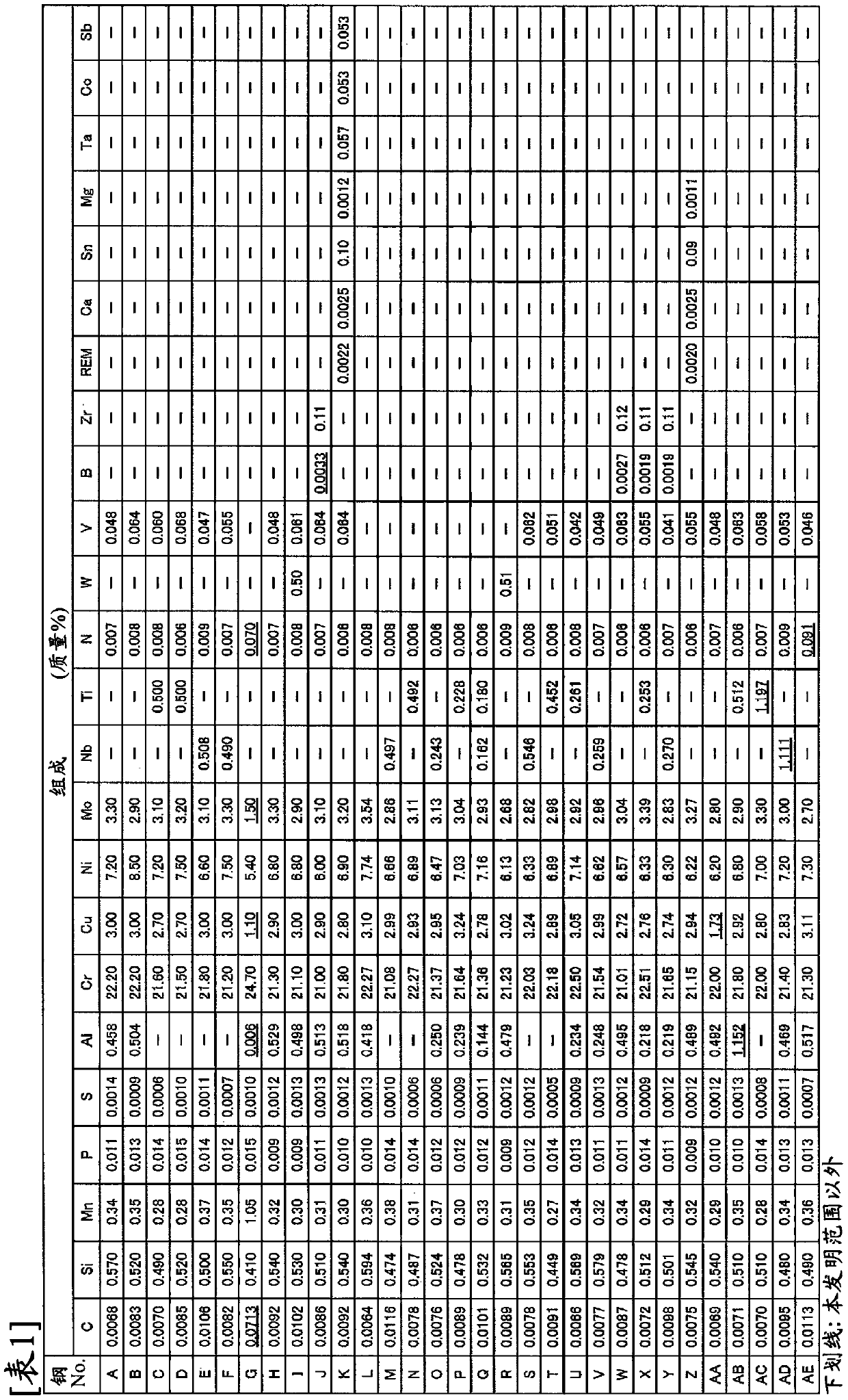

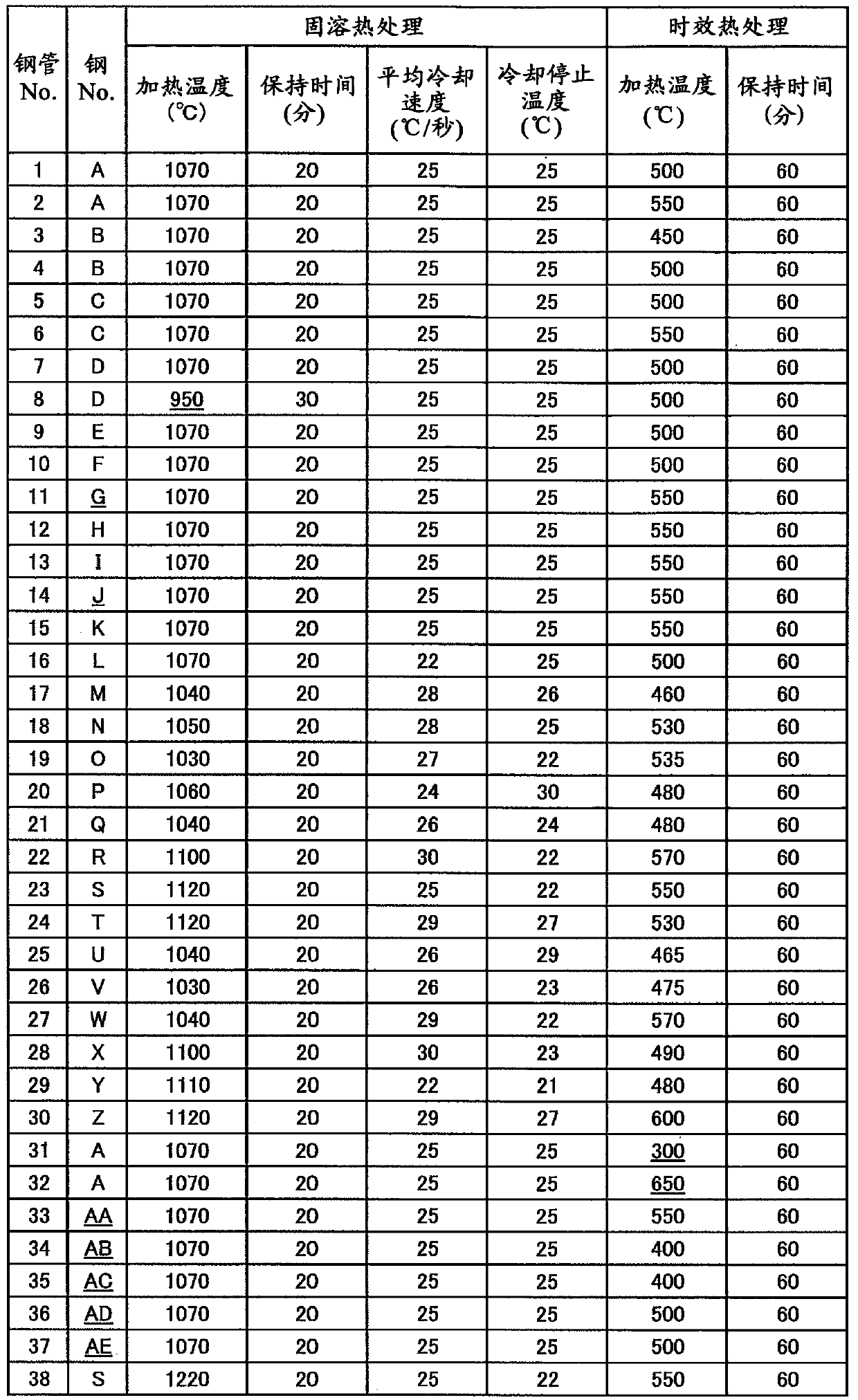

High strength seamless stainless steel pipe for oil wells and production method therefor

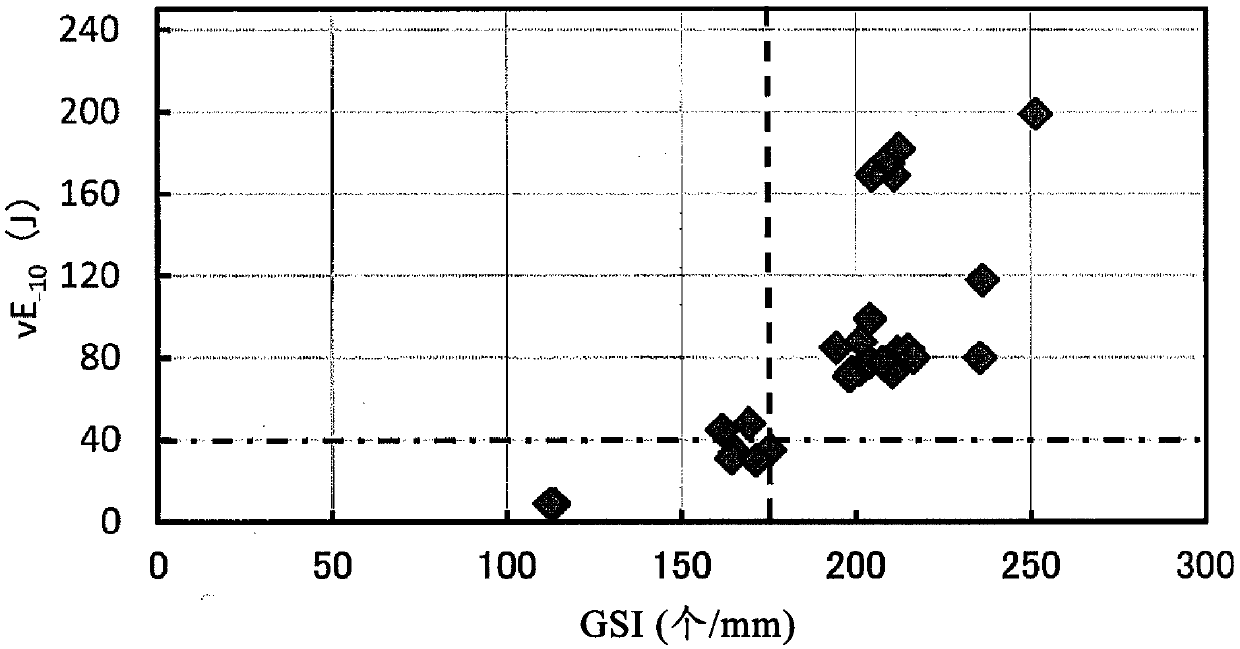

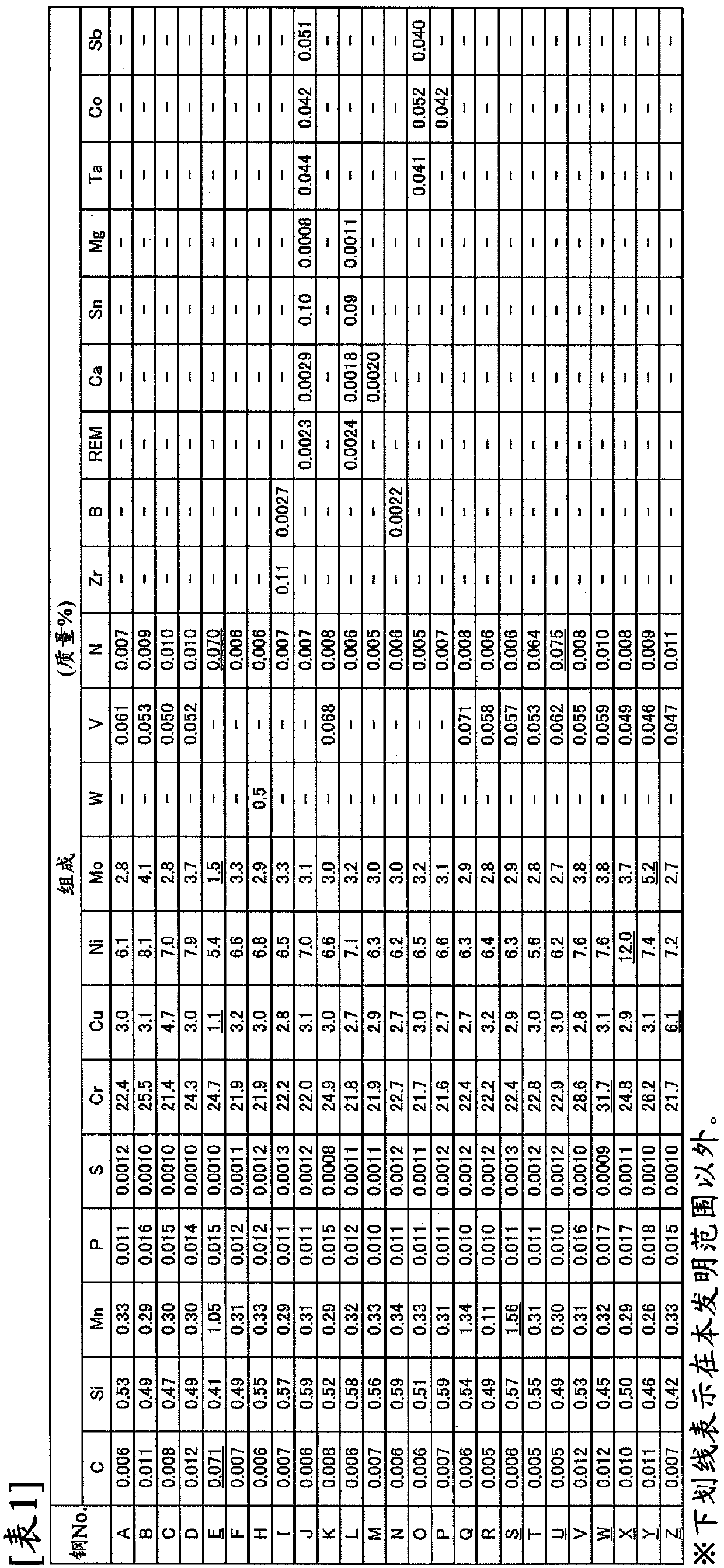

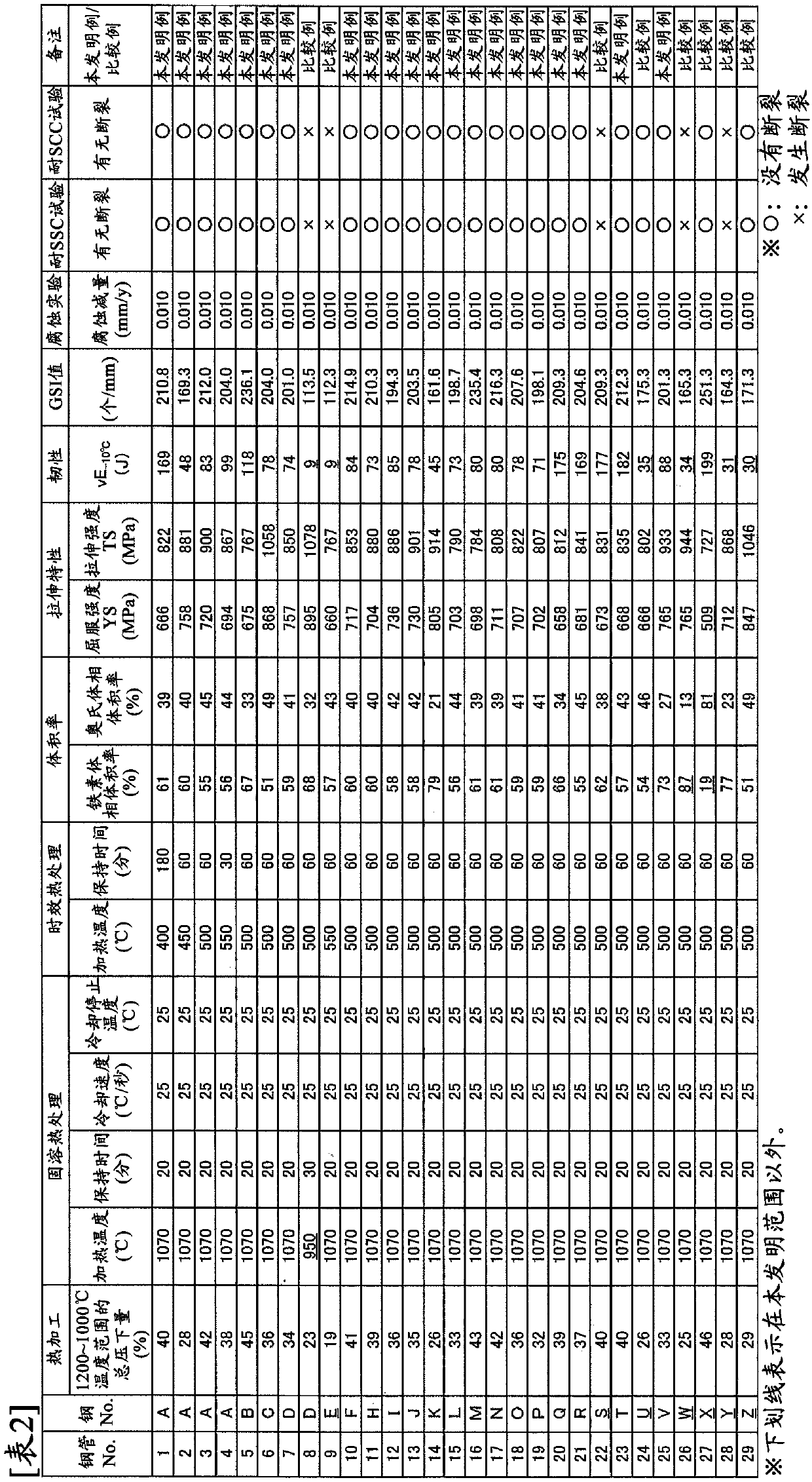

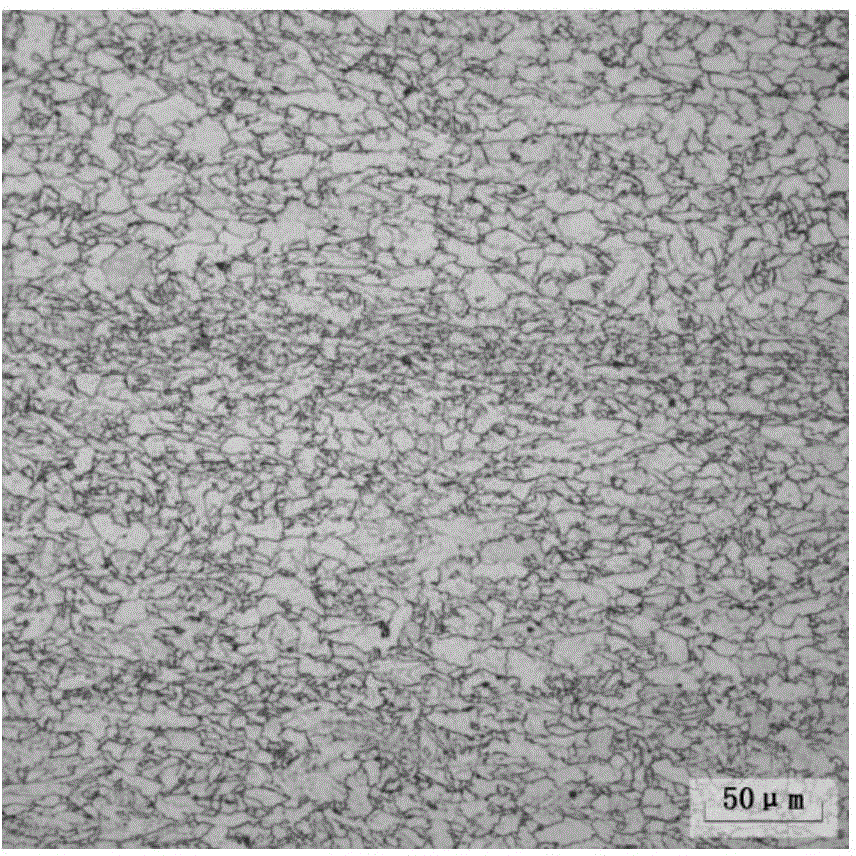

InactiveCN109563581AHigh strengthExcellent stress corrosion cracking resistanceFurnace typesHeat treatment furnacesCarbon dioxide corrosionSS - Stainless steel

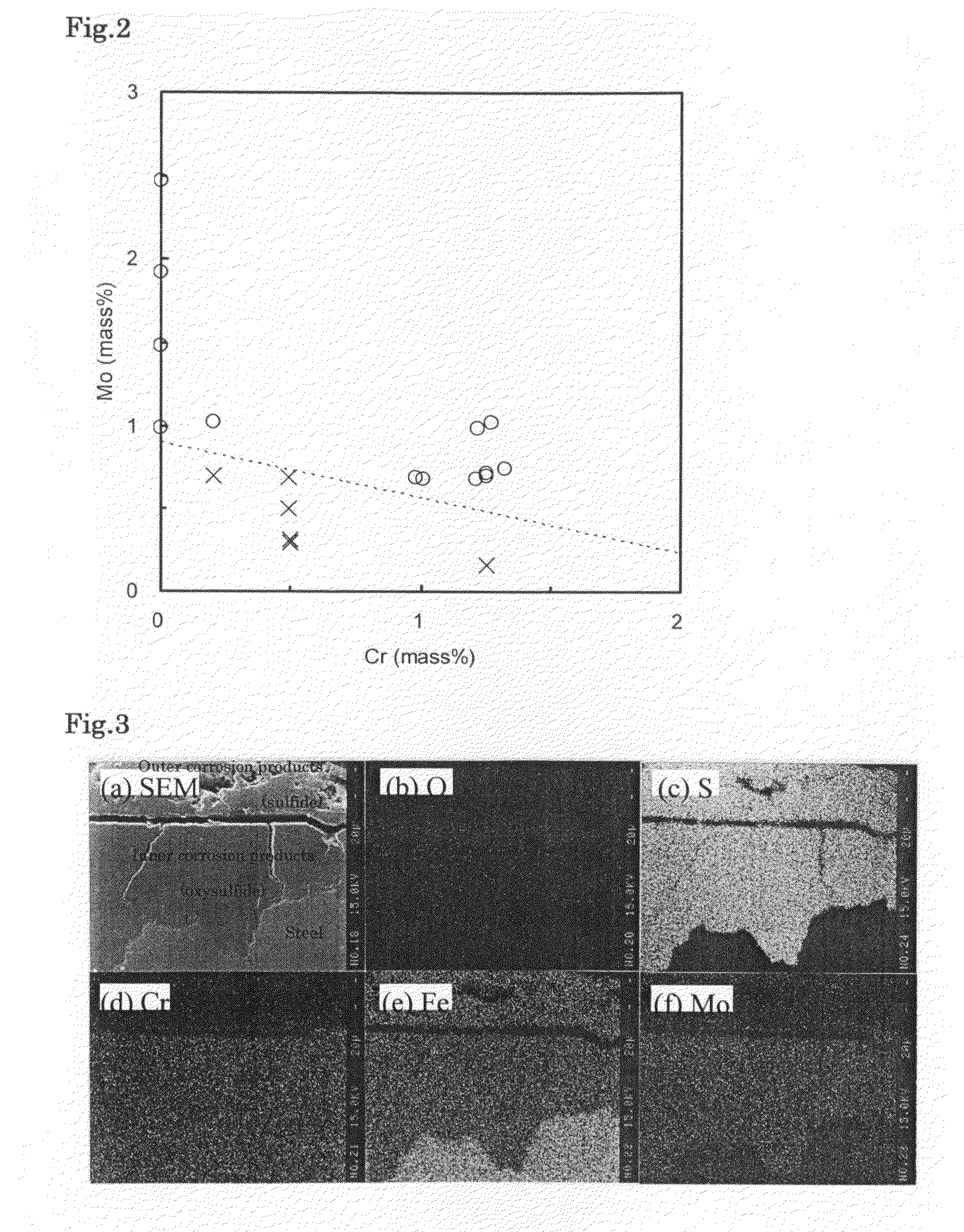

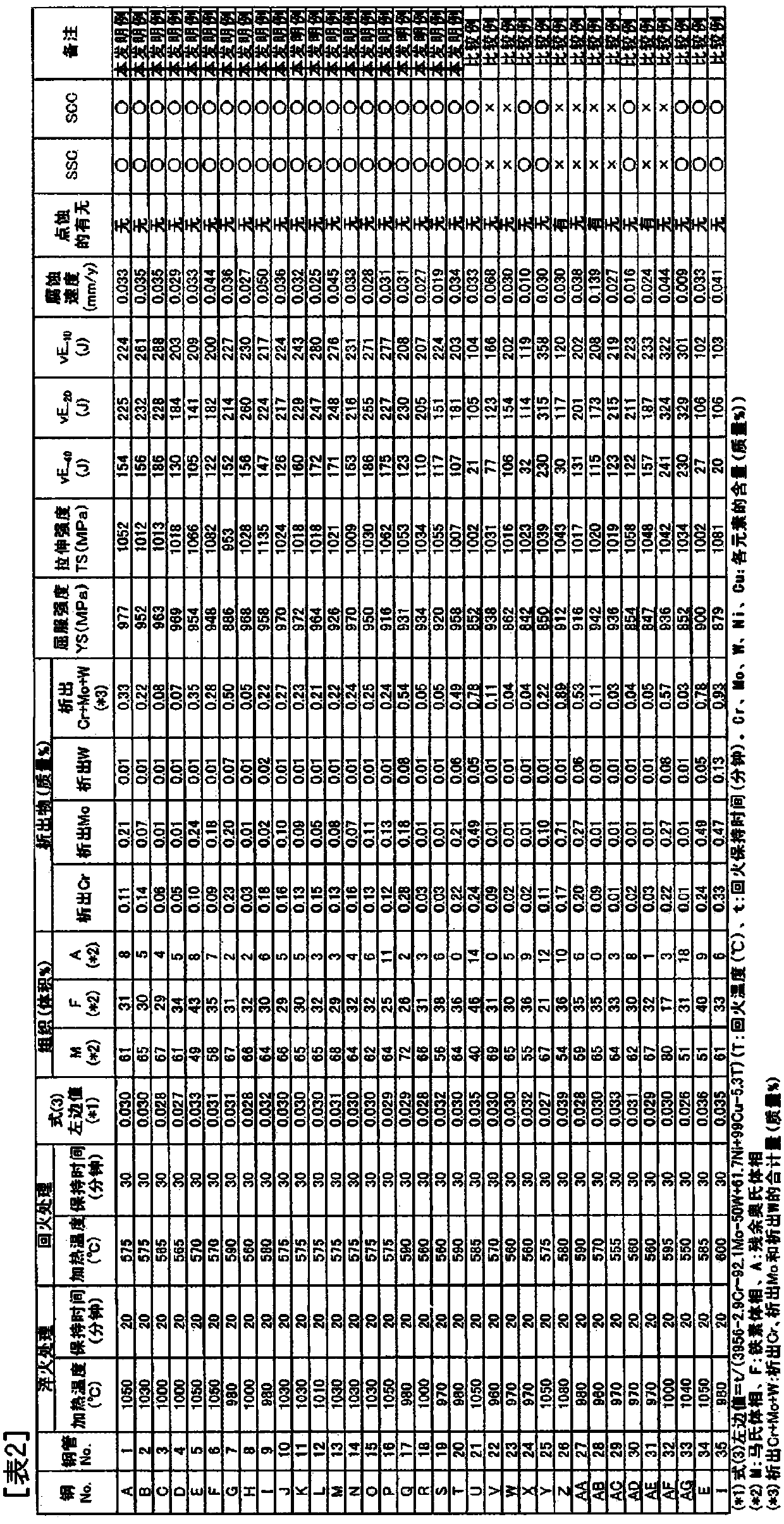

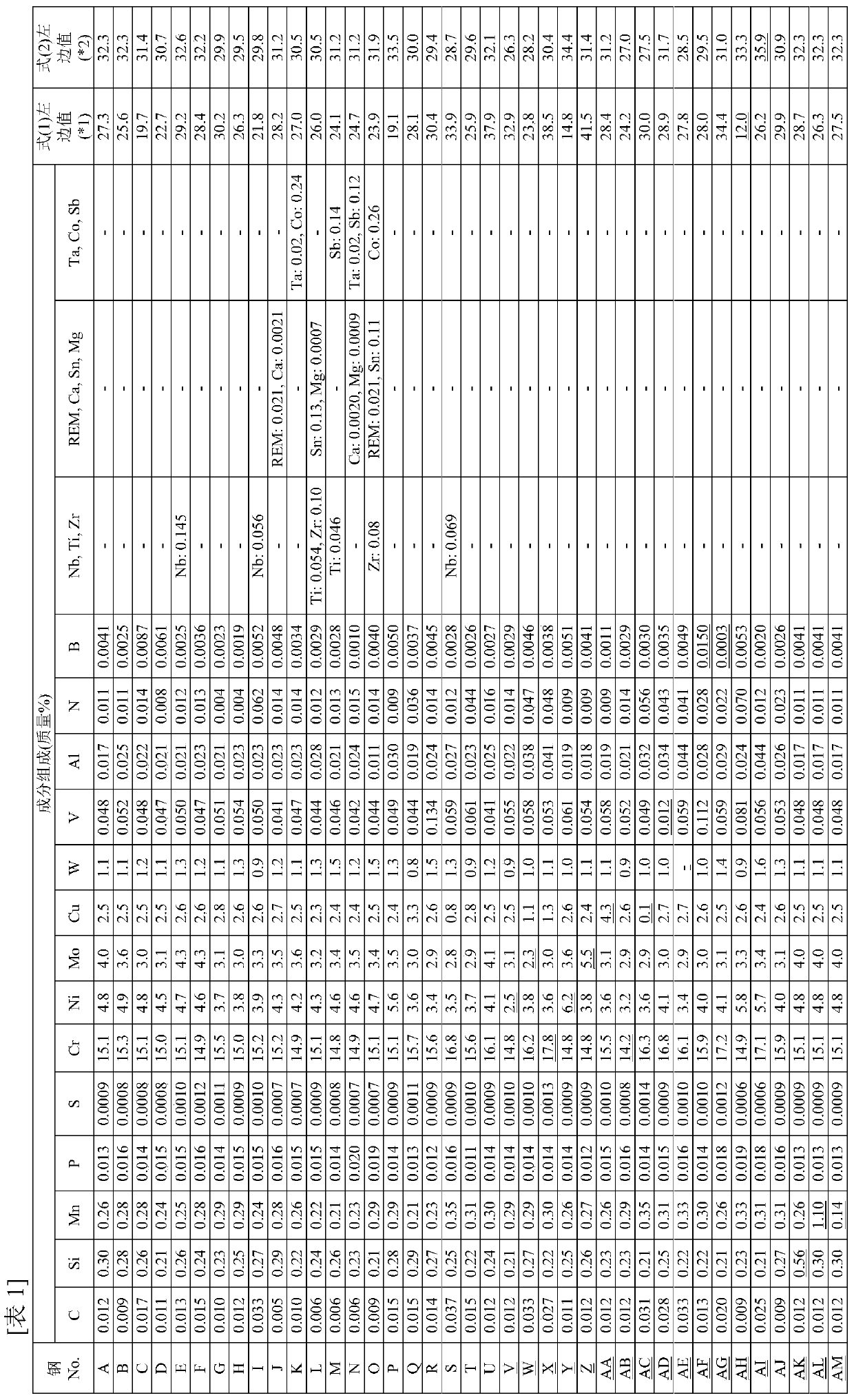

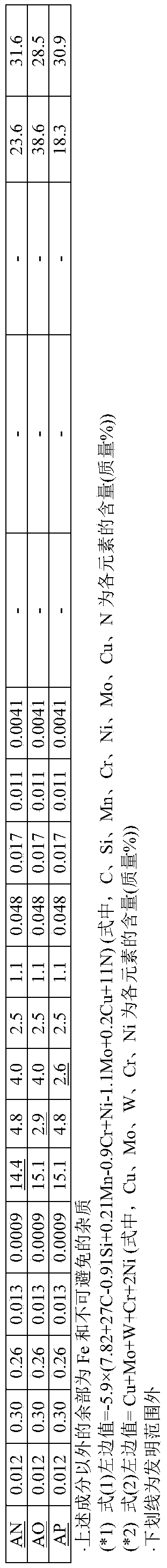

Provided is a high strength seamless stainless steel pipe for oil wells with excellent low temperature toughness, carbon dioxide gas corrosion resistance, sulfide stress corrosion cracking resistance,and sulfide stress cracking resistance. The steel pipe contains, in mass%, C: 0.05% or less, Si: 0.5% or less, Mn: 0.15-1.0%, P: 0.030% or less, S: 0.005% or less, Cr: 14.5-17.5%, Ni: 3.0-6.0%, Mo: 2.7-5.0%, Cu: 0.3-4.0%, W: 0.1-2.5%, V: 0.02-0.20%, Al: 0.10% or less, and N: 0.15% or less, wherein C, Si, Mn, Cr, Ni, Mo, Cu and N satisfy a specified expression and Cu, Mo, W, Cr and Ni satisfy another specified expression, and the balance is made of Fe and unavoidable impurities. The steel pipe comprises martensite phase: greater than 45%, ferrite phase: 10-45%, and retained austenite phase: 30% or less. The total amount of deposited Cr, deposited Mo and deposited W is not more than 0.75 mass% and yield strength is at least 862 MPa.

Owner:JFE STEEL CORP

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

A steel alloy, for use in casing for oil and gas wells in low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, a calcium range by weight of 0.0045% and a sulfur range by weight of less than 0.002%. The steel alloy also has, by weight, a chromium range of less than 0.50%, and an aluminum range of 0.010% to 0.080%.

Owner:OHARA RANDY D +4

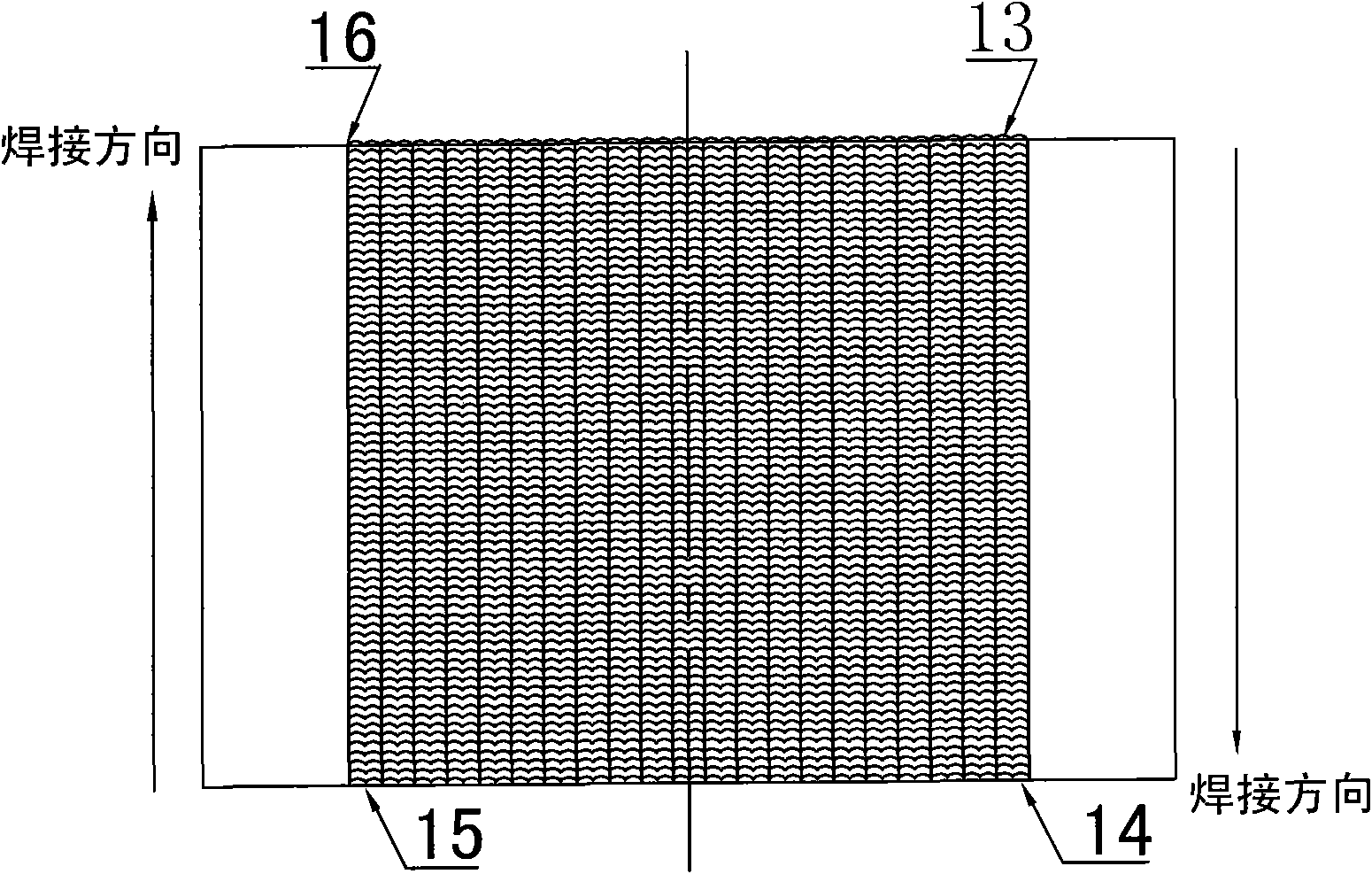

Method for manufacturing test piece of hgdrogen induced cracking (HIC) and sulfide stress cracking (SSC) of welding material melting laid metal

ActiveCN102053024AWeather/light/corrosion resistancePreparing sample for investigationSteel platesSulfide stress cracking

The invention relates to a method for manufacturing a test piece of hgdrogen induced cracking (HIC) and sulfide stress cracking (SSC) of welding material melting laid metal, belonging to the fields of preparation and property evaluation of a sulfur resistant welding material corrosion resistance detection test piece for a high-sulphur-content (hydrogen sulfide) gas field. The method comprises the following steps of: selecting a low-alloy steel plate with a certain thickness as an overlaying test plate; thoroughly cleaning the surface of the steel plate before welding; preheating the steel plate to 100-150 DEG C; overlaying on the steel plate by adopting a symmetrical welding method, wherein 8-12 layers of welding beads are needed to be welded on each side of the test plate, the welding directions of the welding beads on the same layer are consistent, the welding directions of the welding beads on the upper layer are opposite to those on the lower layer, and the thickness of the melting laid metal is 20-22mm; cleaning a melting laid metal surface layer with higher impurity content on the surface of the melting laid metal; and cutting and sampling according to the same standard. In the invention, through detecting and analyzing the test piece, the method can be used for accurately and objectively judging whether the welded material can adapt to the welding of a pipeline in a high sulphur content state or not.

Owner:SINOPEC TENTH CONSTR

Steel for oil well pipe excellent in sulfide stress cracking resistance and method for producing seamless steel pipe for oil well

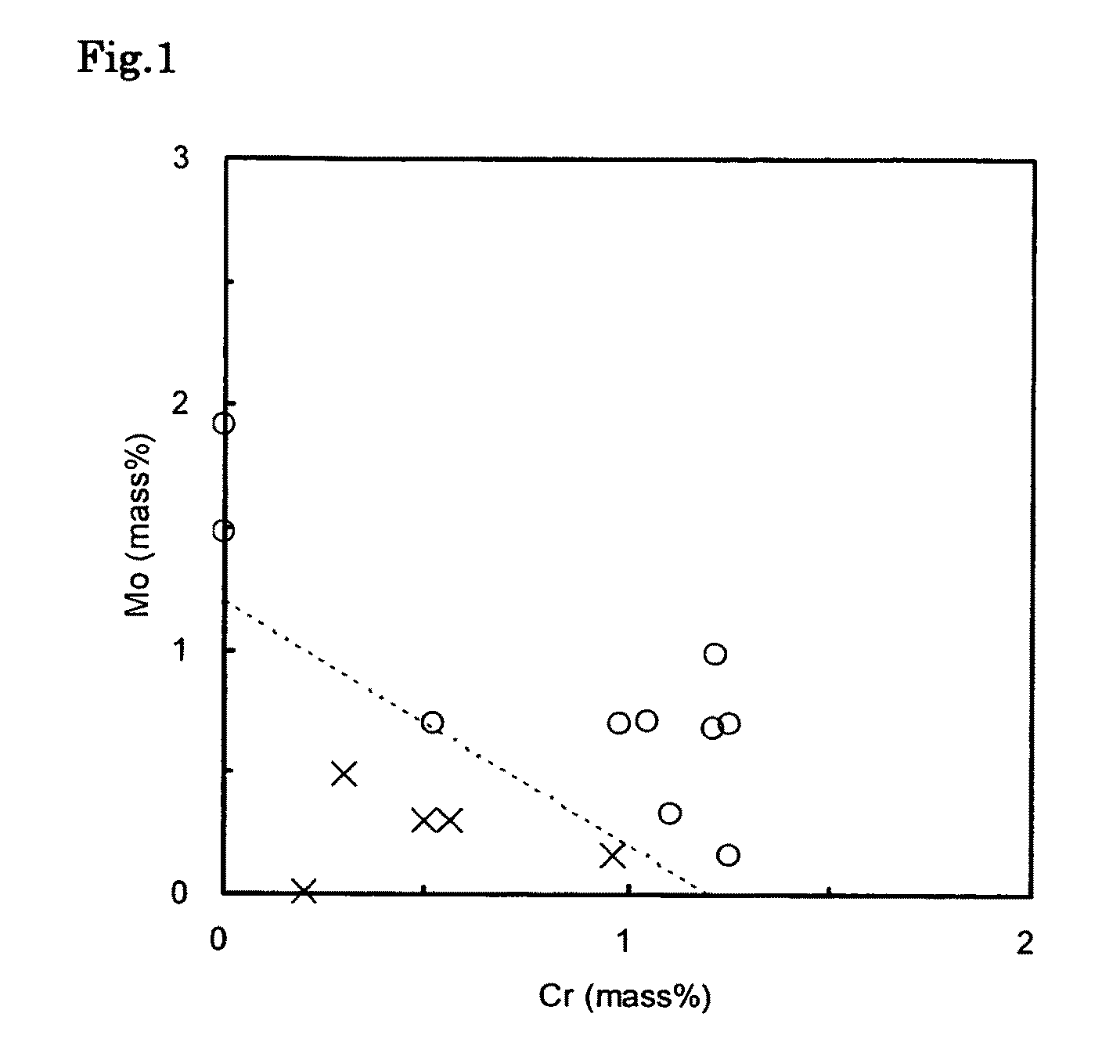

ActiveUS20080017284A1High strengthExcellent SSC resistanceFurnace typesHeat treatment furnacesNitrogenOxygen

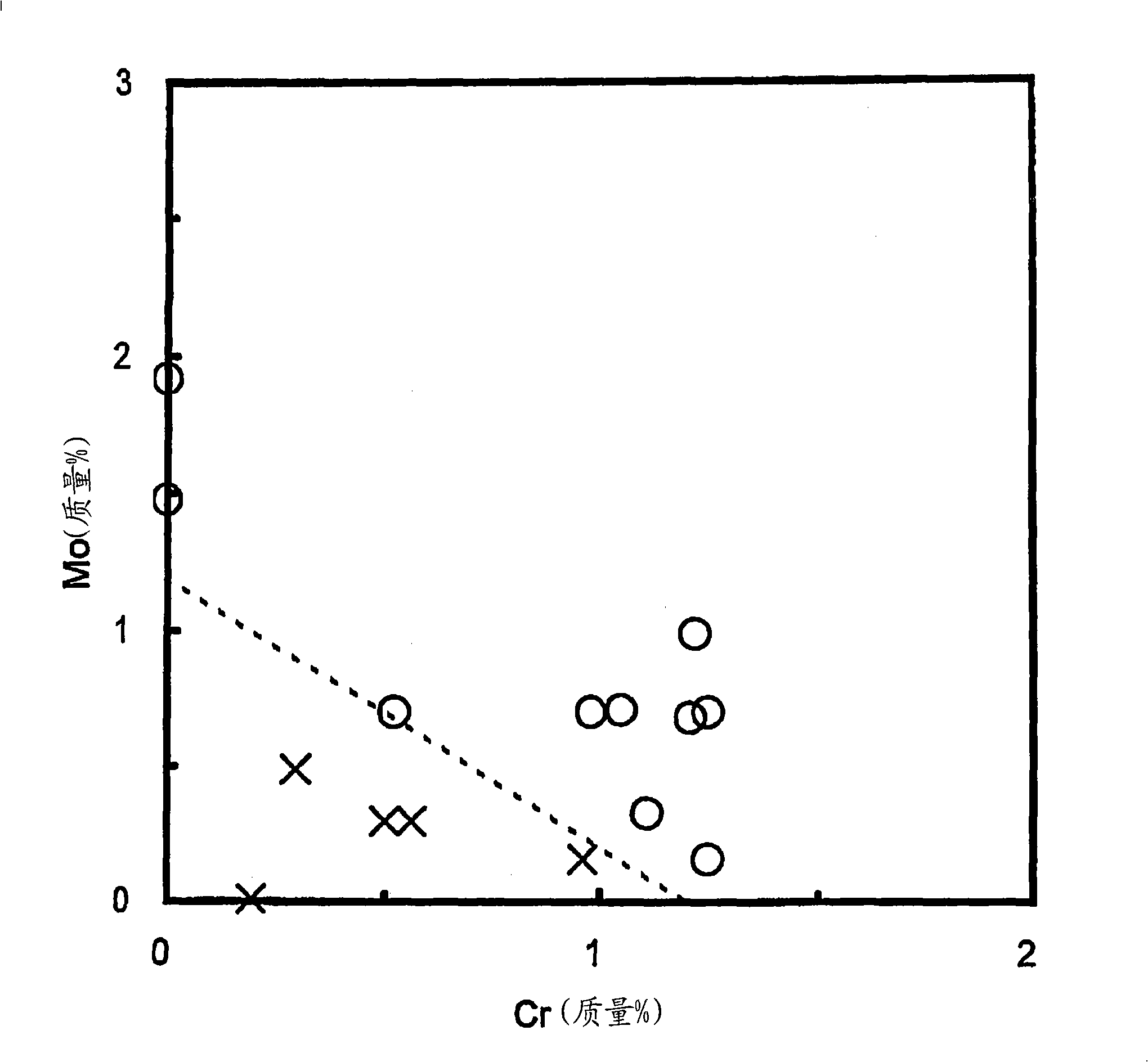

A steel for an oil well pipe, having high strength and excellent SSC resistance, consists of, by mass %, C: 0.30 to 0.60%, Si: 0.05 to 0.5%, Mn: 0.05 to 1.0%, Al: 0.005 to 0.10%, Cr+Mo: 1.5 to 3.0%, wherein Mo is 0.5% or more, V: 0.05 to 0.3%, Nb: 0 to 0.1%, Ti: 0 to 0.1%, Zr: 0 to 0.1%, N (nitrogen): 0 to 0.03%, Ca: 0 to 0.01%, and the balance Fe and impurities; P 0.025% or less, S 0.01% or less, B 0.0010% or less and O (oxygen) 0.01% or less. The method involves heating the steel at 1150° C. or more; producing a seamless steel pipe by hot working; water-cooling the pipe to a temperature in a range of 400 to 600° C. immediately after finishing the working; and subjecting the pipe to a heat treatment for bainite isothermal transformation in a range of 400 to 600° C.

Owner:NIPPON STEEL CORP

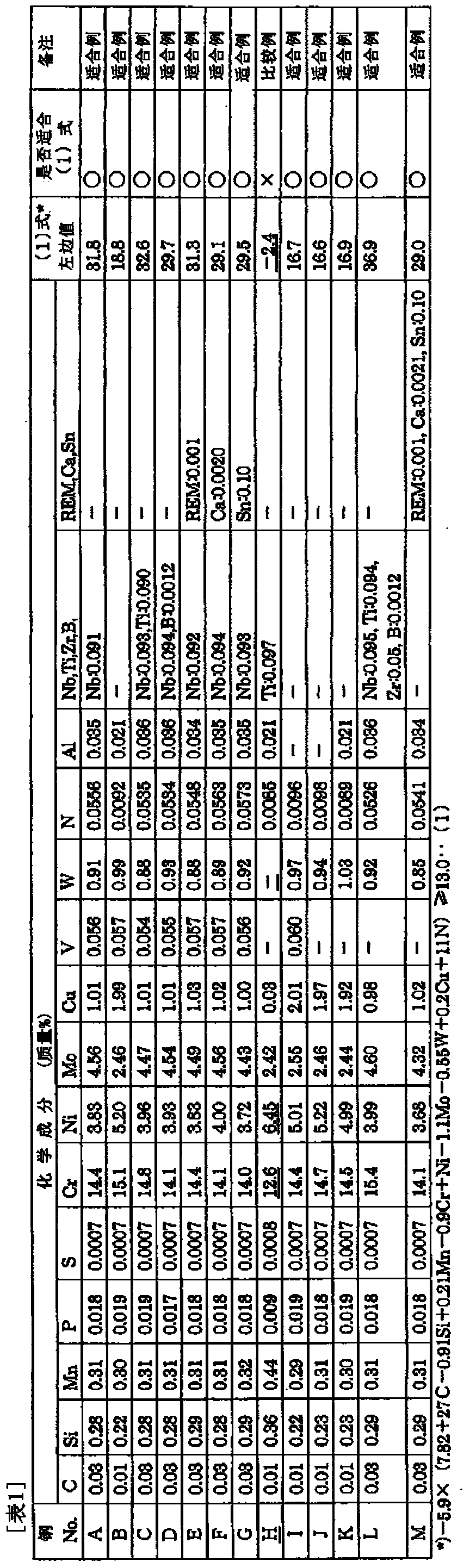

High-strength stainless steel seamless pipe having excellent corrosion resistance for oil well, and method for manufacturing same

ActiveCN104411852AExcellent resistance to sulfide stress crackingCheap manufacturingFurnace typesHeat treatment furnacesMaterials scienceSulfide stress cracking

This stainless steel seamless pipe contains, in terms of mass%, C: 0.05% or less, Si: 0.5% or less, Mn: 0.15 to 1.0%, Cr: 13.5 to 15.4%, Ni: 3.5 to 6.0%, Mo: 1.5 to 5.0%, Cu: 2.5% or less, W: 2.5% or less, and N: 0.15% or less so as to satisfy the formula -5.9 × (7.82 + 27C - 0.91Si + 0.21Mn - 0.9Cr + Ni - 1.1Mo - 0.55W + 0.2Cu + 11N) >= 13.0. A high-strength seamless steel pipe having sulfide stress cracking resistance equivalent to composite steel containing about 17% Cr can be manufactured, even using a composition containing a relatively low amount of Cr of about 15%. It is furthermore possible to include one or more elements selected from V: 0.02 to 0.12%, and / or Al: 0.05% or less, and / or Nb: 0.02 to 0.50%, Ti: 0.02 to 0.16%, Zr: 0.50% or less, and B: 0.0030% or less; and / or one or more elements selected from REM: 0.005% or less, Ca: 0.005% or less, and Sn: 0.20% or less.

Owner:JFE STEEL CORP

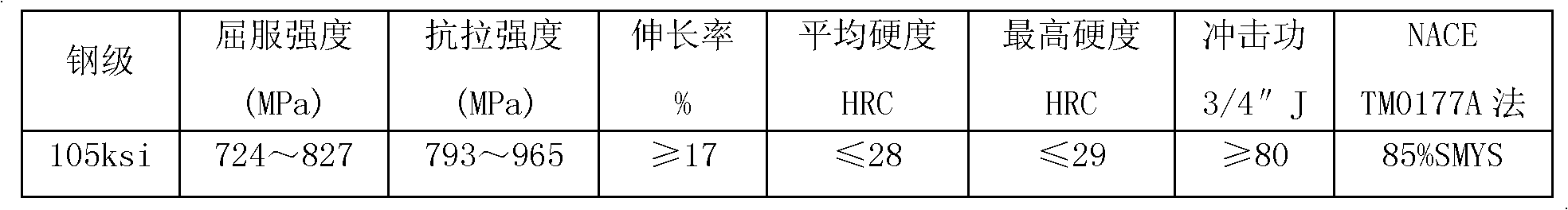

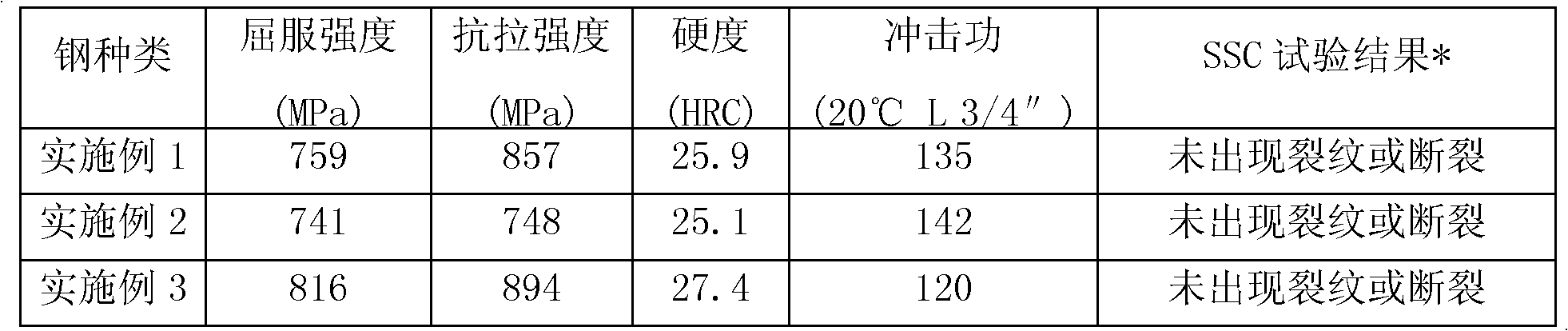

Method for manufacturing 105ksi steel grade sulfide stress corrosion resistant drill rod material

The invention provides a method for manufacturing a 105ksi steel grade sulfide stress corrosion resistant drill rod material. The method comprises the following steps of: smelting waste steel, sponge iron and (or) blast furnace molten iron serving as raw materials through an arc furnace, forming slag and removing phosphorus, performing ladle external refining, deoxidation, desulfuration and inclusion removal, adjusting and controlling chemical components, performing vacuum degassing, performing modification treatment on a calcium silk feeding inclusion, and performing continuous casting to form round billets; feeding the round billets into an annular furnace, and performing high-temperature heating, perforation and precise controlled continuous casting to prepare seamless steel tubes; andperforming tube end upsetting, tempering, thermal treatment and thermal straightening on the seamless steel tubes, cooling to room temperature, and performing flaw detection, mechanical property testand sulfide stress cracking (SSC) test. The manufacturing method has the advantages of low alloy content, low production cost, simple process and easiness in operation; based on the metallurgical clean steel, trace alloy components are added, so that the full hardening performance of the steel is improved; and the thermally treated tempered martensite tissues in which fine carbide granules are uniformly distributed have good SSC resistance.

Owner:TIANJIN PIPE GROUP CORP

High-strength stainless steel pipe excellent in sulfide stress cracking resistance and high-temperature carbonic-acid gas corrosion resistance

ActiveUS20110226378A1High strengthImprove corrosion resistanceRigid pipesMicro structureMetal microstructure

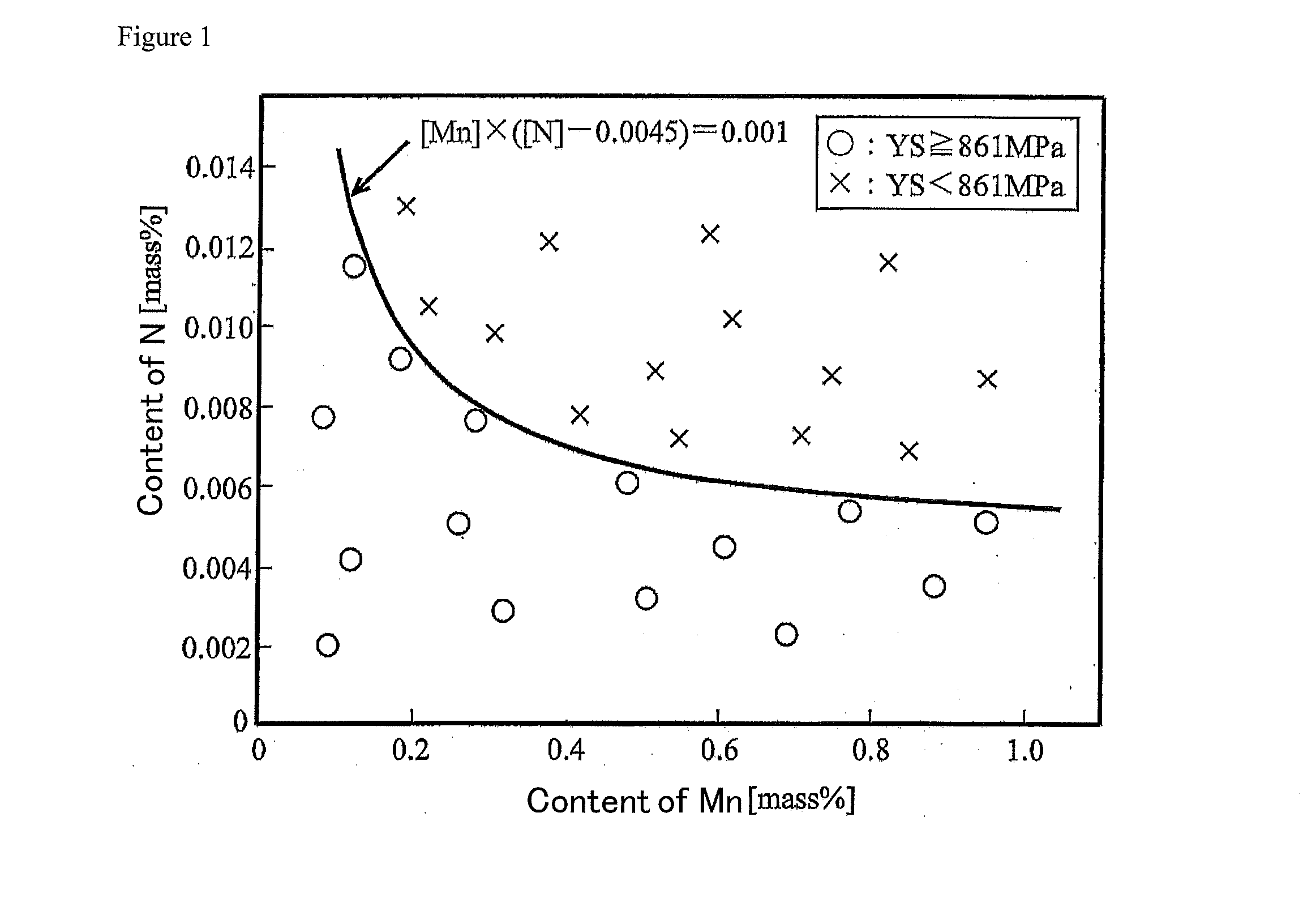

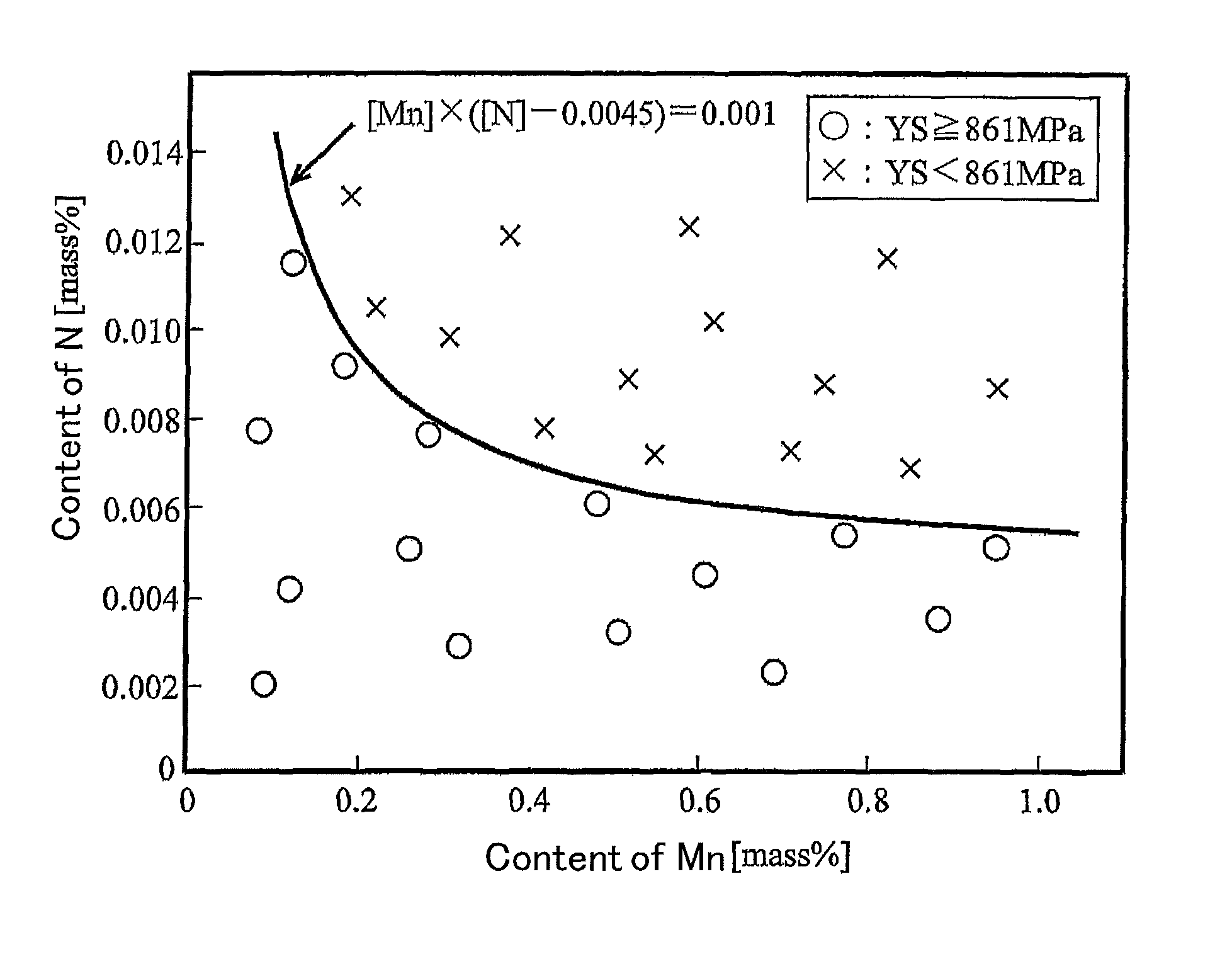

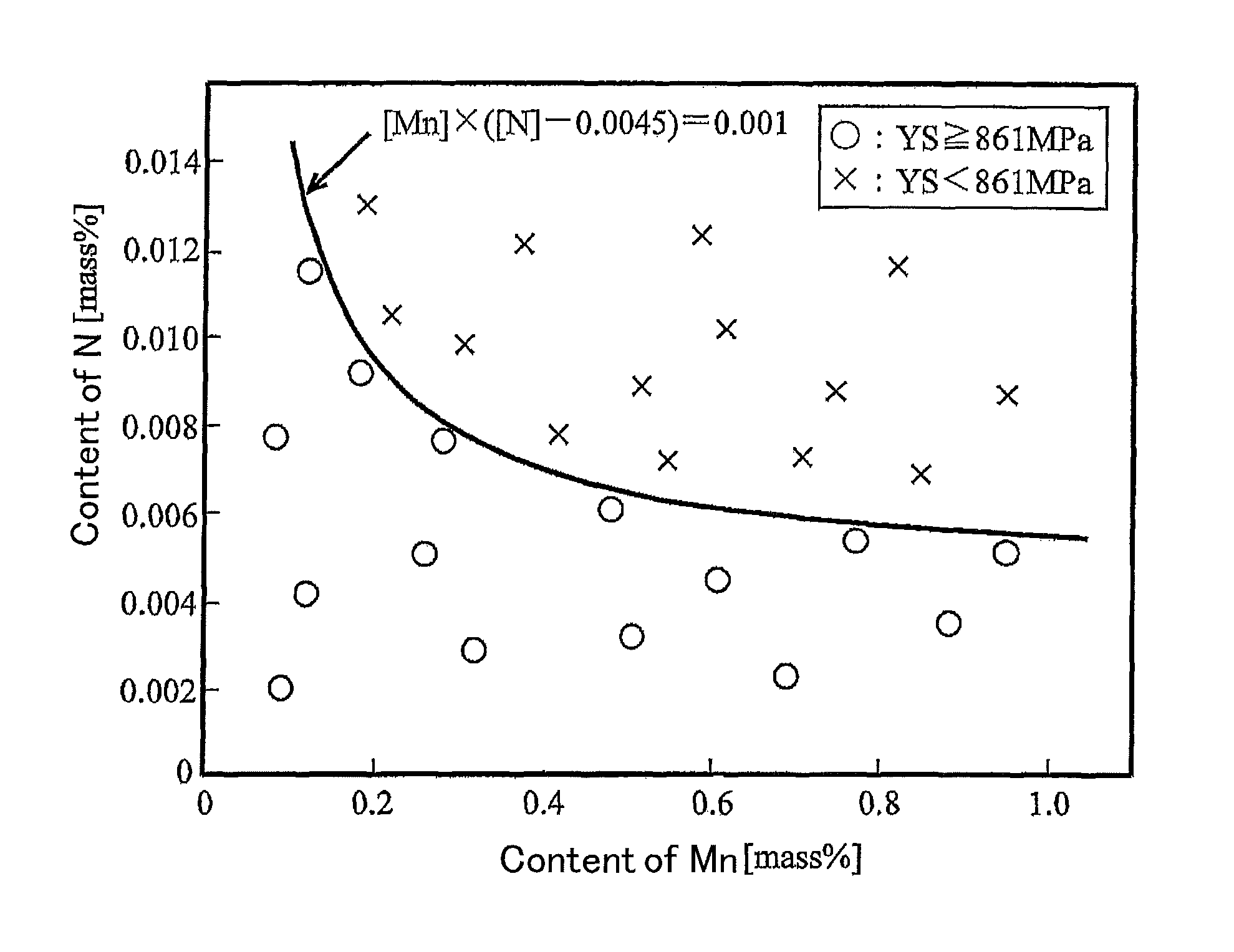

The problem to be solved is the provision of a high-strength stainless steel pipe having a sufficient corrosion resistance in a high-temperature carbonic acid gas environment and having an excellent sulfide stress cracking resistance at normal temperature.A high-strength stainless steel pipe consist of by mass %, C: 0.05% or less, Si: 1.0% or less, P: 0.05% or less, S: less than 0.002%, Cr: more than 16% and 18% or less, Mo: more than 2% and 3% or less, Cu: 1% to 3.5%, Ni: 3% or more and less than 5%, Al: 0.001% to 0.1% and O: 0.01% or less, Mn: 1% or less and N: 0.05% or less, and Mn and N in the above ranges satisfy formula (1), and the balance being Fe and impurities; and the metal micro-structure of the stainless steel pipe mainly includes a martensitic phase and comprises 10 to 40% of a ferritic phase by volume fraction and 10% or less of a retained γ-phase by volume fraction.[Mn]×([N]−0.0045)≦0.001 (1)wherein the symbols of elements in formula (1) respectively represent the contents (unit: mass %) of the elements in the steel.

Owner:NIPPON STEEL CORP

Seamless steel pipe for oil wells excellent in sulfide stress cracking resistance and method for producing the same

InactiveUS20060266448A1High strengthExcellent sulfide stress cracking resistanceFurnace typesHeat treatment furnacesImpurityOil well

A high-strength seamless steel pipe for oil wells excellent in sulfide stress cracking resistance which comprises, on the percent by mass basis, C: 0.1 to 0.20%, Si: 0.05 to 1.0%, Mn: 0.05 to 1.0%, Cr: 0.05 to 1.5%, Mo: 0.05 to 1.0%, Al: 0.10% or less, Ti: 0.002 to 0.05% and B: 0.0003 to 0.005%, with a value of equation “C+(Mn / 6)+(Cr / 5)+(Mo / 3)” of 0.43 or more, with the balance being Fe and impurities, and in the impurities P: 0.025% or less, S: 0.010% or less and N: 0.007% or less. The seamless steel pipe may contain a specified amount of one or more element(s) of V and Nb, and / or a specified amount of one or more element(s) of Ca, Mg and REM. The seamless steel pipe can be produced at a low cost by adapting an in-line tube making and heat treatment process having a high production efficiency since a reheating treatment for refinement of grains is not required.

Owner:SUMITOMO METAL IND LTD

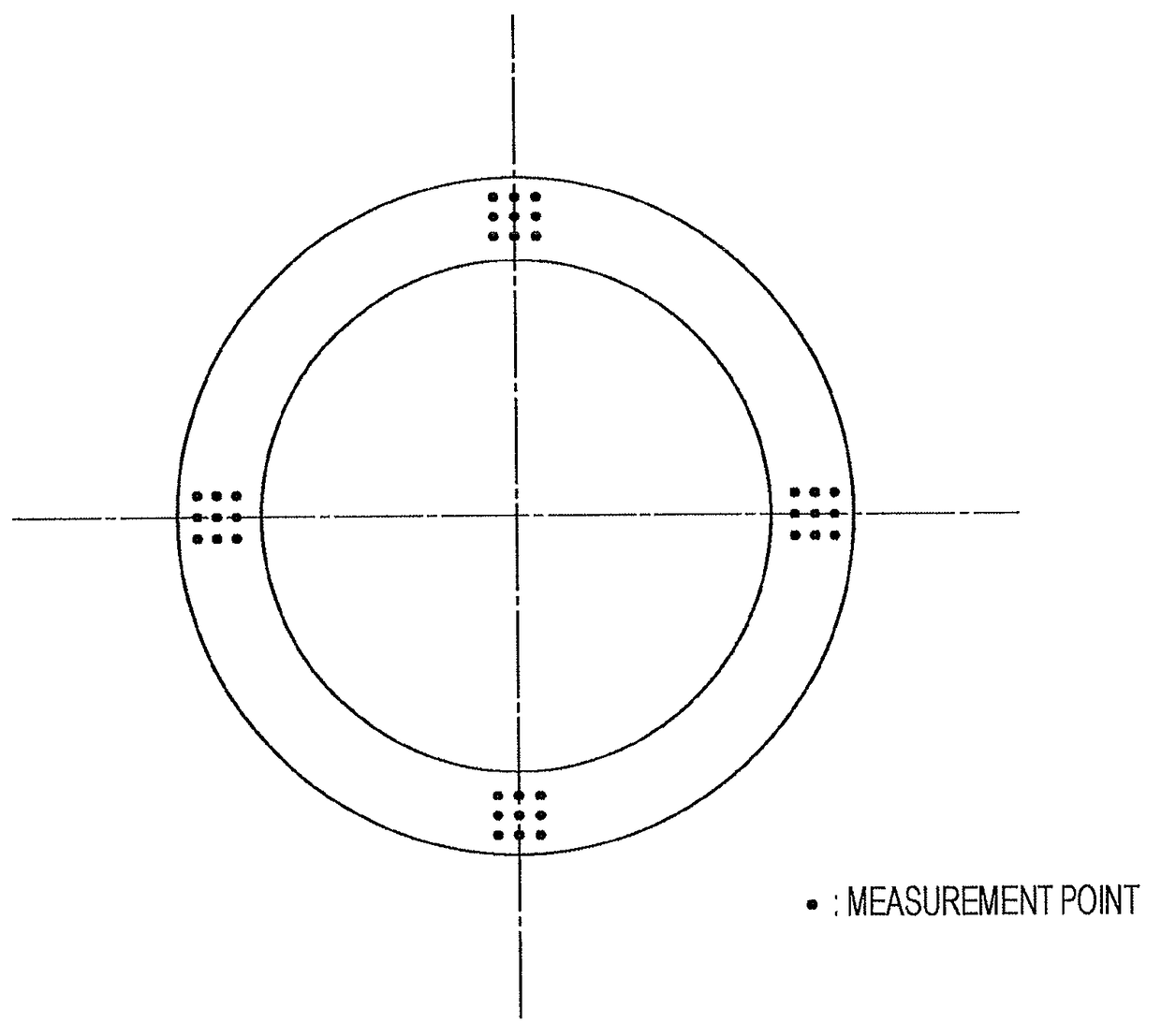

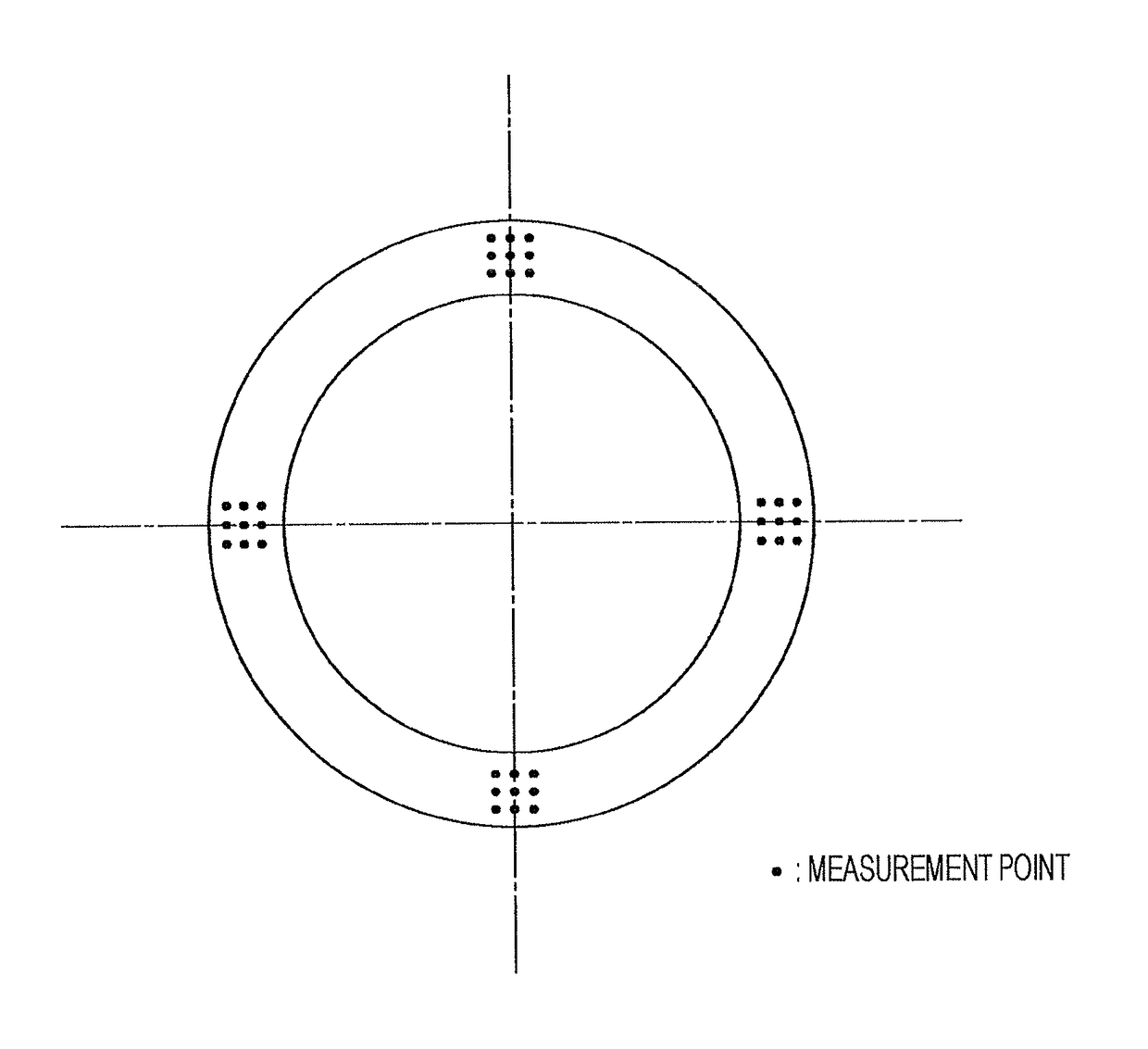

High-strength seamless steel pipe for oil well use having excellent resistance to sulfide stress cracking

A seamless steel pipe has a composition containing, by mass %, C: 0.15 to 0.50%, Si: 0.1 to 1.0%, Mn: 0.3 to 1.0%, P: 0.015% or less, S: 0.005% or less, Al: 0.01 to 0.1%, N: 0.01% or less, Cr: 0.1 to 1.7%, Mo: 0.40 to 1.1%, V: 0.01 to 0.12%, Nb: 0.01 to 0.08%, Ti: 0.03% or less, and B: 0.0005 to 0.003%, a structure composed of a tempered martensite phase as a main phase with a prior austenite grain size of 8.5 or more, and a hardness distribution in which in four portions 90° apart from each other in the circumferential direction, hardness is 295 HV10 or less in any one of an inner surface-side region at 2.54 to 3.81 mm from the inner surface of the pipe, an outer surface side-region at the same distance from the outer surface of the pipe, and a center of the thickness.

Owner:JFE STEEL CORP

Steel for steel tube with excellent sulfide stress cracking resistance

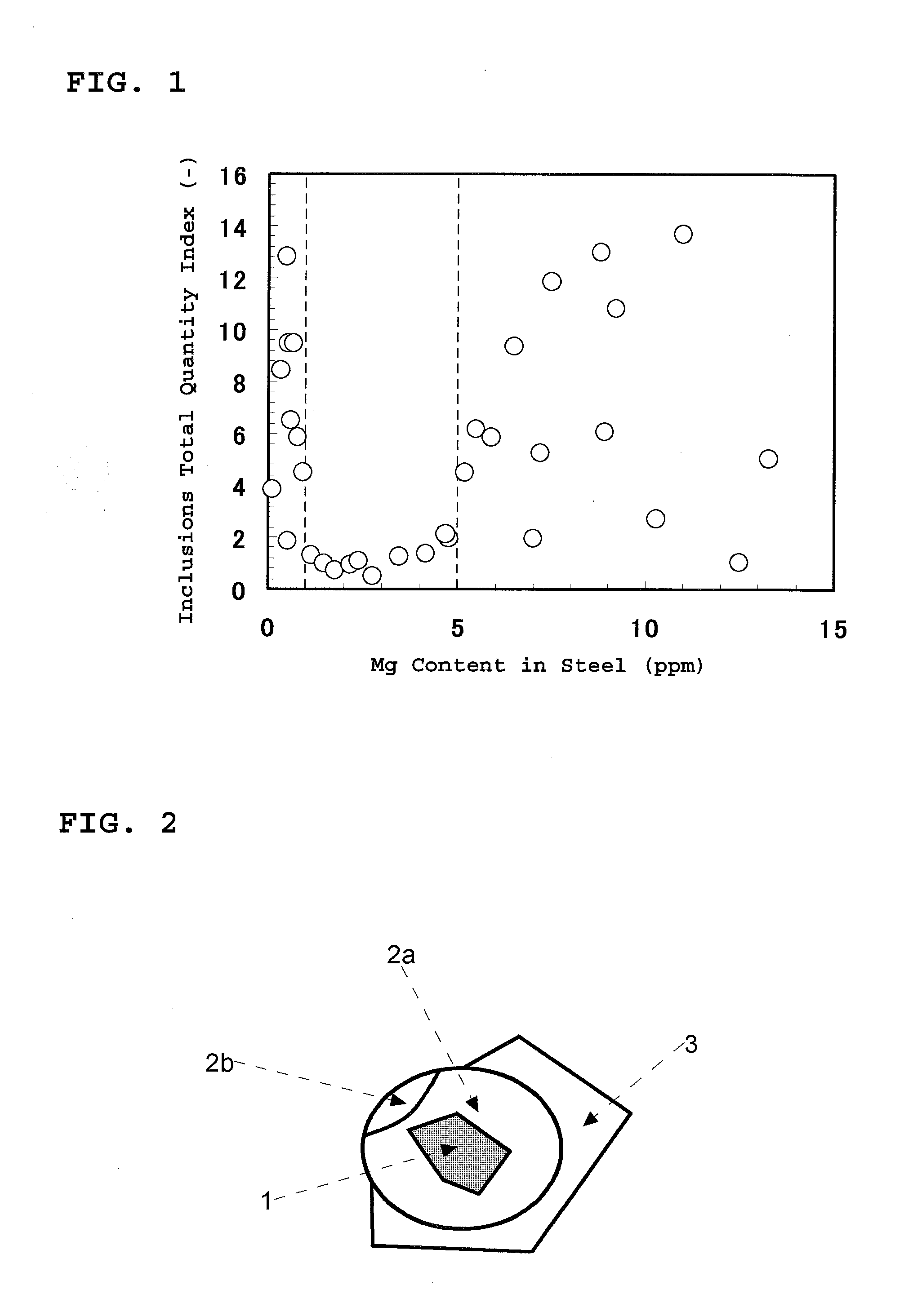

The present invention provides a steel which simultaneously satisfies a plurality of characteristics, specifically, a steel for tubes with excellent sulfide stress cracking resistance, including, C: 0.2 to 0.7%; Si: 0.01 to 0.8%; Mn: 0.1 to 1.5%; S: not more than 0.005%; P: not more than 0.03%; Al: 0.0005 to 0.1%; Ti: 0.005 to 0.05%; Ca: 0.0004 to 0.005%; N: not more than 0.007%; Cr: 0. 1 to 1.5%; and Mo: 0.2 to 1.0%; the balance being Fe, Mg and impurities, being characterized in that: the content of Mg is not less than 1.0 ppm and not more than 5.0 ppm; and inclusions of not less than 50% of the total number of those in steel have such a morphology that Mg—Al—O-based oxides exist at the central part of the inclusion, Ca—Al-based oxides enclose the Mg—Al—O-based oxides, and Ti-containing-carbonitrides further exist on a periphery of the Ca—Al-based oxides.

Owner:NIPPON STEEL CORP

Duplex stainless steel and method for manufacturing same

ActiveCN109642282AHighly corrosiveImprove corrosion resistanceFurnace typesHeat treatment furnacesCarbon dioxide corrosionSS - Stainless steel

Provided is a duplex stainless steel having excellent corrosion resistance, in which excellent carbon dioxide corrosion resistance, excellent sulfide stress corrosion cracking resistance, and excellent sulfide stress cracking resistance are provided at the same time. The present invention has a composition containing, in terms of mass%, 0.03% or less of C, 1.0% or less of Si, 0.10-1.5% Mn, 0.030%or less of P, 0.005% or less of S, 20.0-30.0% Cr, 5.0-10.0% Ni, 2.0-5.0% Mo, 2.0-6.0% Cu, and less than 0.07% of N, the remainder comprising Fe and unavoidable impurities, and the metallographic structure of the present invention has an austenitic phase that is 20-70% by volume ratio and a ferritic phase that is 30-80% by volume ratio.

Owner:JFE STEEL CORP

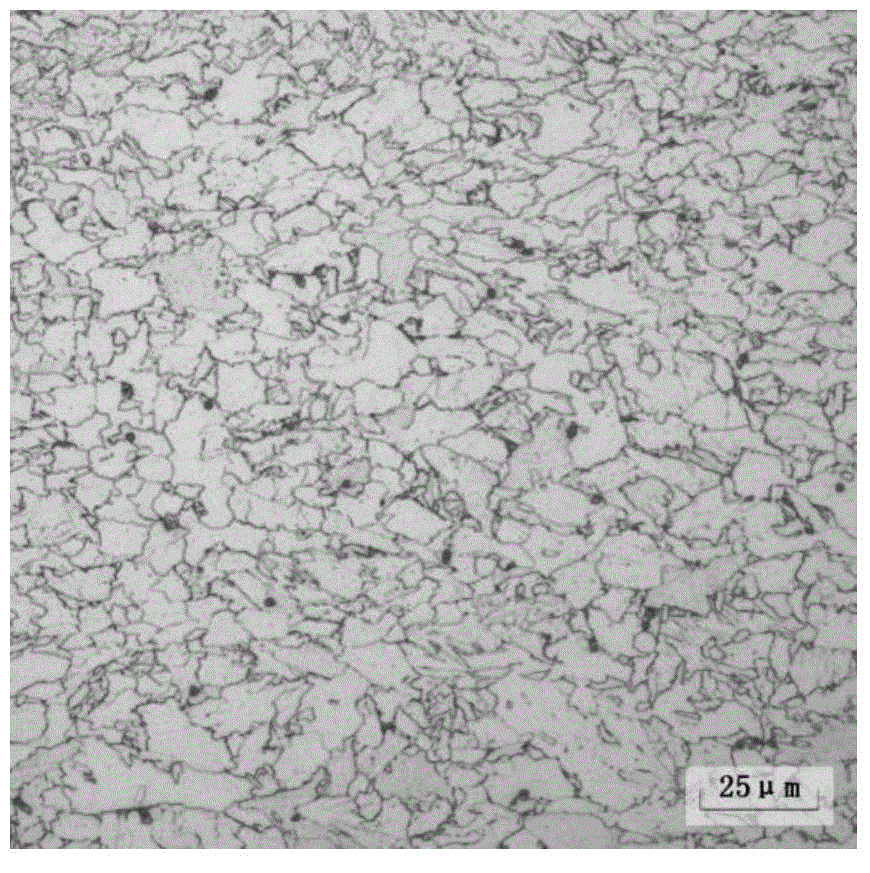

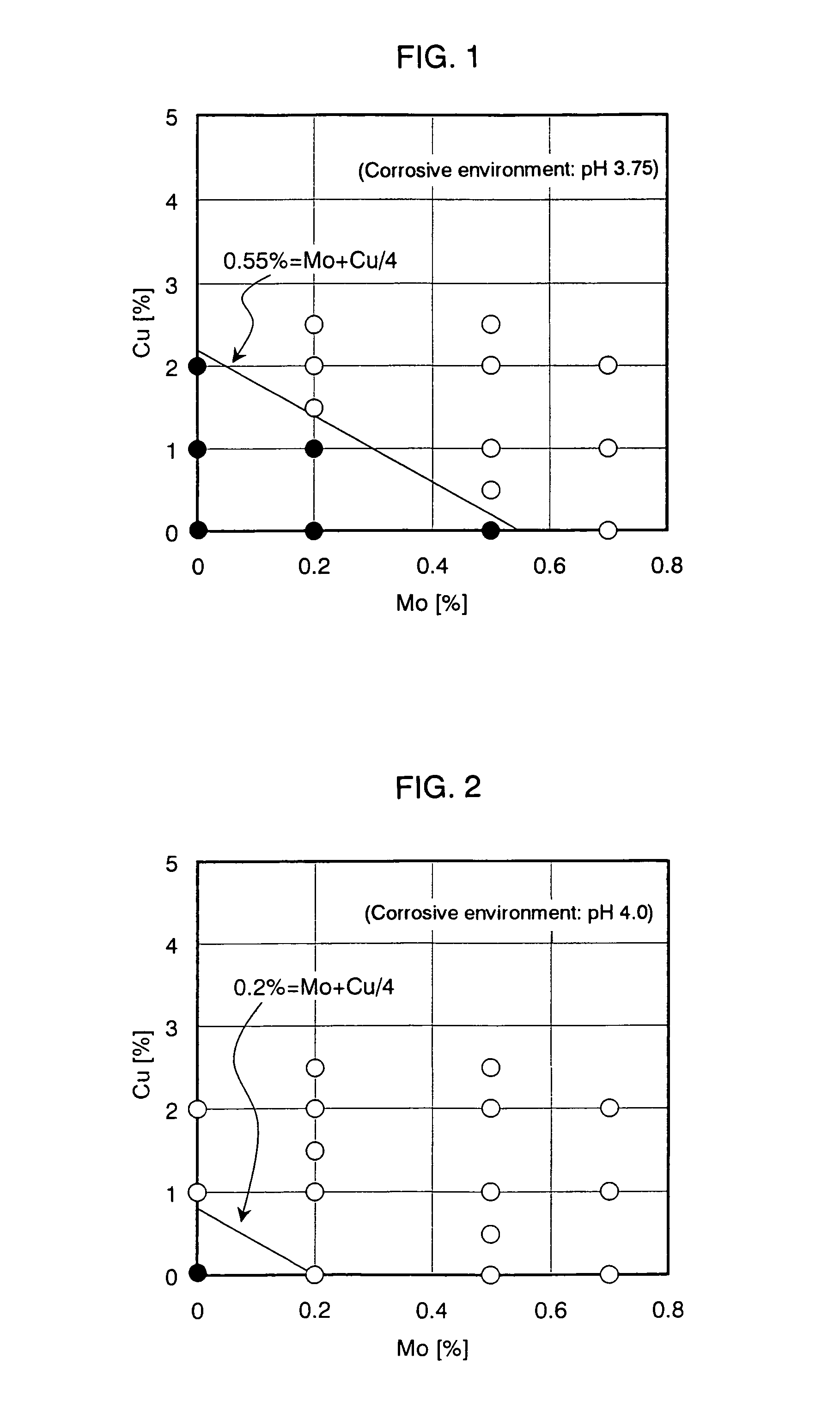

Quenched and tempered state HIC (Hydrogen Induce Crack)-resistant and SSC (Sulfide Stress Cracking)-resistant wide and thick plate and preparation method thereof

The invention provides a quenched and tempered state HIC (Hydrogen Induce Crack)-resistant and SSC (Sulfide Stress Cracking)-resistant wide and thick plate and a preparation method thereof, which belong to the technical field of low-carbon microalloyed steel production. The preparation method mainly comprises the processes of smelting and casting of a plate blank, heating of the plate blank, rolling and heat treatment of a steel plate, and the like. The preparation method has the advantages that the steel plate has good mechanical performance and excellent HIC-resistant and SSC-resistant performance through a reasonable composition system, ultraclean steel smelting, optimum rolling process and advanced heat treatment technology; and Mo-free and low-Ni alloy production is adopted, so that consumption of precious alloy is reduced, and the production cost is relatively low.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Martensitic stainless steel

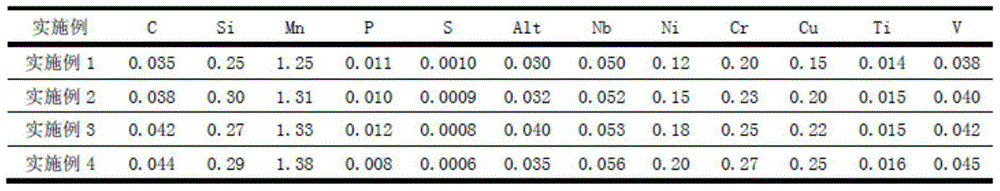

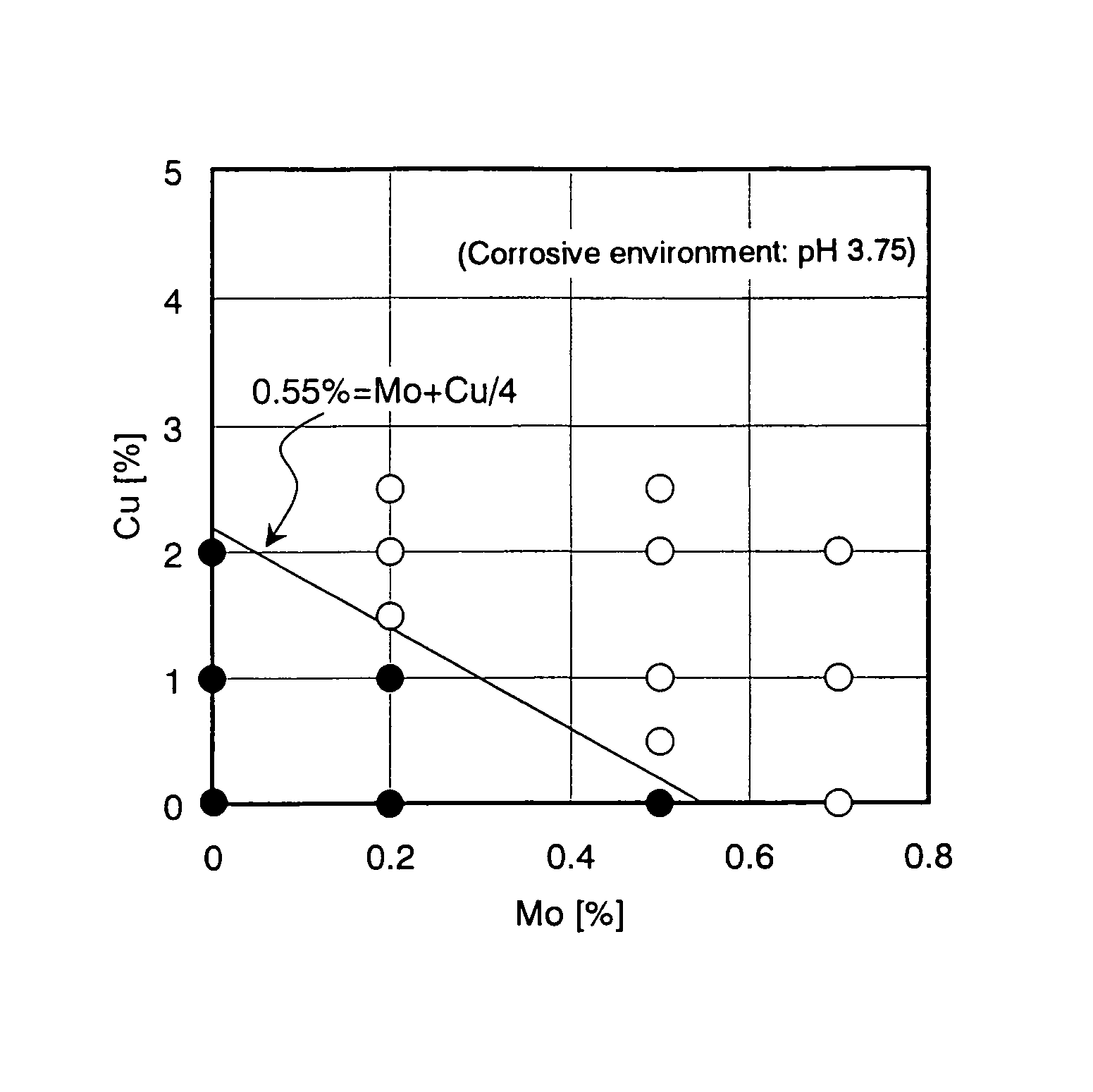

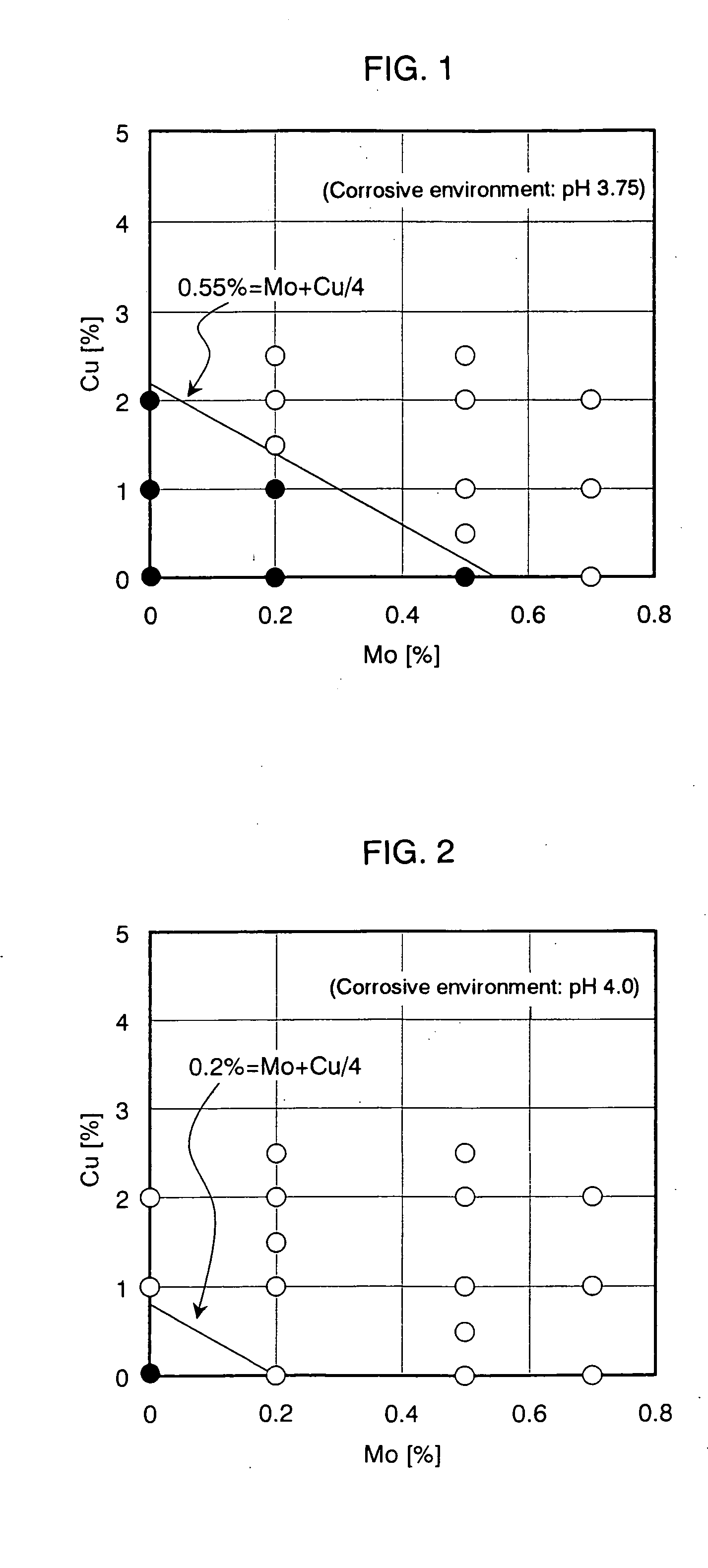

A martensitic stainless steel comprising C: 0.01-0.10%, Si: 0.05-1.0%, Mn: 0.05-1.5%, P: not more than 0.03%, S: not more than 0.01%, Cr: 9-15%, Ni: 0.1-4.5%, Al: not more than 0.05% and N: not more than 0.1% in mass %, and further comprising at least one of Cu: 0.05-5% and Mo: 0.05-5%, the residual being Fe and impurities, is provided, wherein the contents of Cu and Mo satisfy the following formula (a) or (b),0.2%≦Mo+Cu / 4≦5% (a)0.55%≦Mo+Cu / 4≦5% (b)and wherein the hardness is 30-45 in HRC and the carbide amount in grain boundaries of the prior austenite is not more than 0.5 volume %. The marensitic stainless steel has excellent properties regarding the sulfide stress cracking resistance, the resistance to corrosive wear and the localized corrosion.

Owner:NIPPON STEEL CORP

Method for welding MCS anti-sulfur carbon steel pipeline for high sulfur-containing gas field

The invention discloses a method for welding an MCS anti-sulfur carbon steel pipeline for a high sulfur-containing gas field, and belongs to the technical field of pipeline welding. The welding joint of the MCS anti-sulfur carbon steel pipeline is subjected to drawing, bending, impacting, notch groove hammering, metallographic component analysis, standard liquid hydrogen induced cracking (HIC) and sulfide stress cracking (SSC) experiments, so that the welding technical problem of the L360MCS anti-sulfur carbon steel pipeline of gas conveying pipelines of a gathering and delivery project of the high sulfur-containing gas field is solved, and the method can be comprehensively applied to welding of the L360MCS anti-sulfur carbon steel pipeline of the high sulfur-containing gas field.

Owner:SINOPEC TENTH CONSTR

Low alloy steel for oil country tubular goods having high sulfide stress cracking resistance

Low alloy steel for oil country tubular goods contains, in percentage by mass, 0.20% to 0.35% C, 0.05% to 0.5% Si, 0.05% to 0.6% Mn, at most 0.025% P, at most 0.01% S, 0.005% to 0.100% Al, 0.8% to 3.0% Mo, 0.05% to 0.25% V, 0.0001% to 0.005% B, at most 0.01% N, and at most 0.01% O, the balance comprising Fe and impurities, the steel satisfying Expression (1): 12V+1−Mo≧0 (1) where the symbols of elements represent the contents of the elements in percentage by mass. In this way, the steel according to the present invention has high SSC resistance.

Owner:NIPPON STEEL CORP

Technology for solving hydrogen sulphide corrosion of pipe drilling tool and pump during oil gas dislodging

InactiveCN101012557ASave processing costReduce shipping costsLiquid/solution decomposition chemical coatingHydrogenSodium Hypophosphite Monohydrate

The invention discloses an alloy plating liquid on the metal piece, which comprises the following parts: pure water, tin chloride, nickel sulphate, sodium hypophosphite, boric acid, saccharin sodium and lead ion with molar rate at 90:3:3:2:1.9:0.3:0.02, wherein the plating liquid is heat to 50-80 deg.c with plating time affirmed according to the needed thickness.

Owner:李天忠

Martensitic stainless steel

A martensitic stainless steel comprising C: 0.01-0.10%, Si: 0.05-1.0%, Mn: 0.05-1.5%, P: not more than 0.03%, S: not more than 0.01%, Cr: 9-15%, Ni: 0.1-4.5%, Al: not more than 0.05% and N: not more than 0.1% in mass %, and further comprising at least one of Cu: 0.05-5% and Mo: 0.05-5%, the residual being Fe and impurities, is provided, wherein the contents of Cu and Mo satisfy the following formula (a) or (b), 0.2%≦Mo+Cu / 4≦5% (a) 0.55%≦Mo+Cu / 4≦5% (b) and wherein the hardness is 30-45 in HRC and the carbide amount in grain boundaries of the prior austenite is not more than 0.5 volume %. The marensitic stainless steel has excellent properties regarding the sulfide stress cracking resistance, the resistance to corrosive wear and the localized corrosion.

Owner:NIPPON STEEL CORP

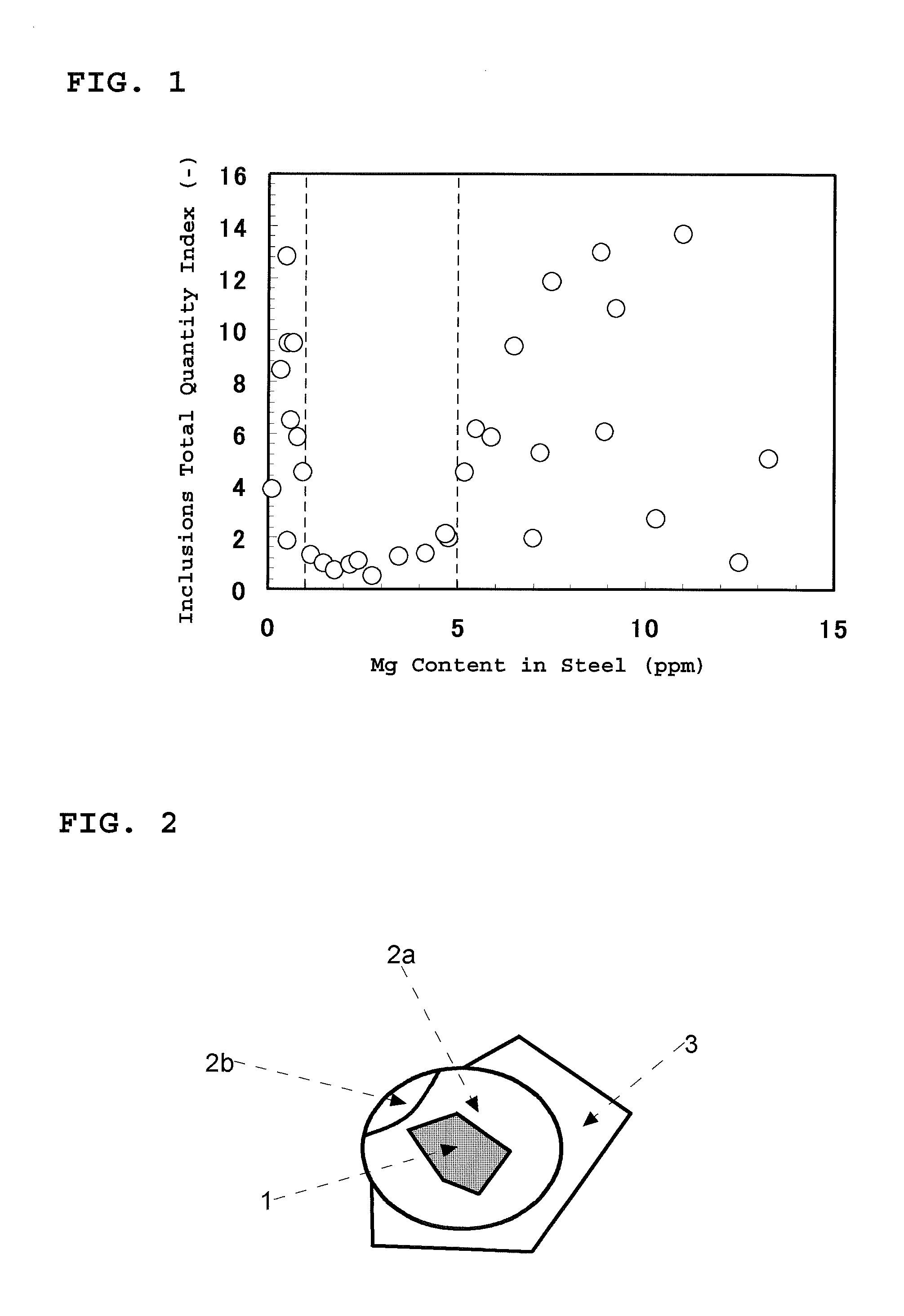

Steel for steel tube with excellent sulfide stress cracking resistance

The present invention provides a steel which simultaneously satisfies a plurality of characteristics, specifically, a steel for tubes with excellent sulfide stress cracking resistance, including, C: 0.2 to 0.7%; Si: 0.01 to 0.8%; Mn: 0.1 to 1.5%; S: not more than 0.005%; P: not more than 0.03%; Al: 0.0005 to 0.1%; Ti: 0.005 to 0.05%; Ca: 0.0004 to 0.005%; N: not more than 0.007%; Cr: 0.1 to 1.5%; and Mo: 0.2 to 1.0%; the balance being Fe, Mg and impurities, being characterized in that: the content of Mg is not less than 1.0 ppm and not more than 5.0 ppm; and inclusions of not less than 50% of the total number of those in steel have such a morphology that Mg—Al—O-based oxides exist at the central part of the inclusion, Ca—Al-based oxides enclose the Mg—Al—O-based oxides, and Ti-containing-carbonitrides further exist on a periphery of the Ca—Al-based oxides.

Owner:NIPPON STEEL CORP

Duplex stainless steel and method for producing same

ActiveCN110168124AHighly corrosiveExcellent stress corrosion cracking resistanceFurnace typesHeat treatment furnacesMetallurgySS - Stainless steel

The present invention provides a duplex stainless steel having excellent corrosion resistance, which has excellent carbon dioxide gas corrosion resistance, excellent sulfide stress corrosion crackingresistance and excellent sulfide stress cracking resistance at the same time. This duplex stainless steel has a composition which contains, in mass%, 0.03% or less of C, 1.0% or less of Si, 0.10-1.5%of Mn, 0.030% or less of P, 0.005% or less of S, 20.0-30.0% of Cr, 5.0-10.0% of Ni, 2.0-5.0% of Mo, 2.0-6.0% of Cu, less than 0.07% of N, and one or more elements selected from among 0.05-1.0% of Al,0.02-1.0% of Ti and 0.02-1.0% of Nb, with the balance made up of Fe and unavoidable impurities. This duplex stainless steel has a structure that comprises, in volume percentage, 20-70% of an austenitephase and 30-80% of a ferrite phase.

Owner:JFE STEEL CORP

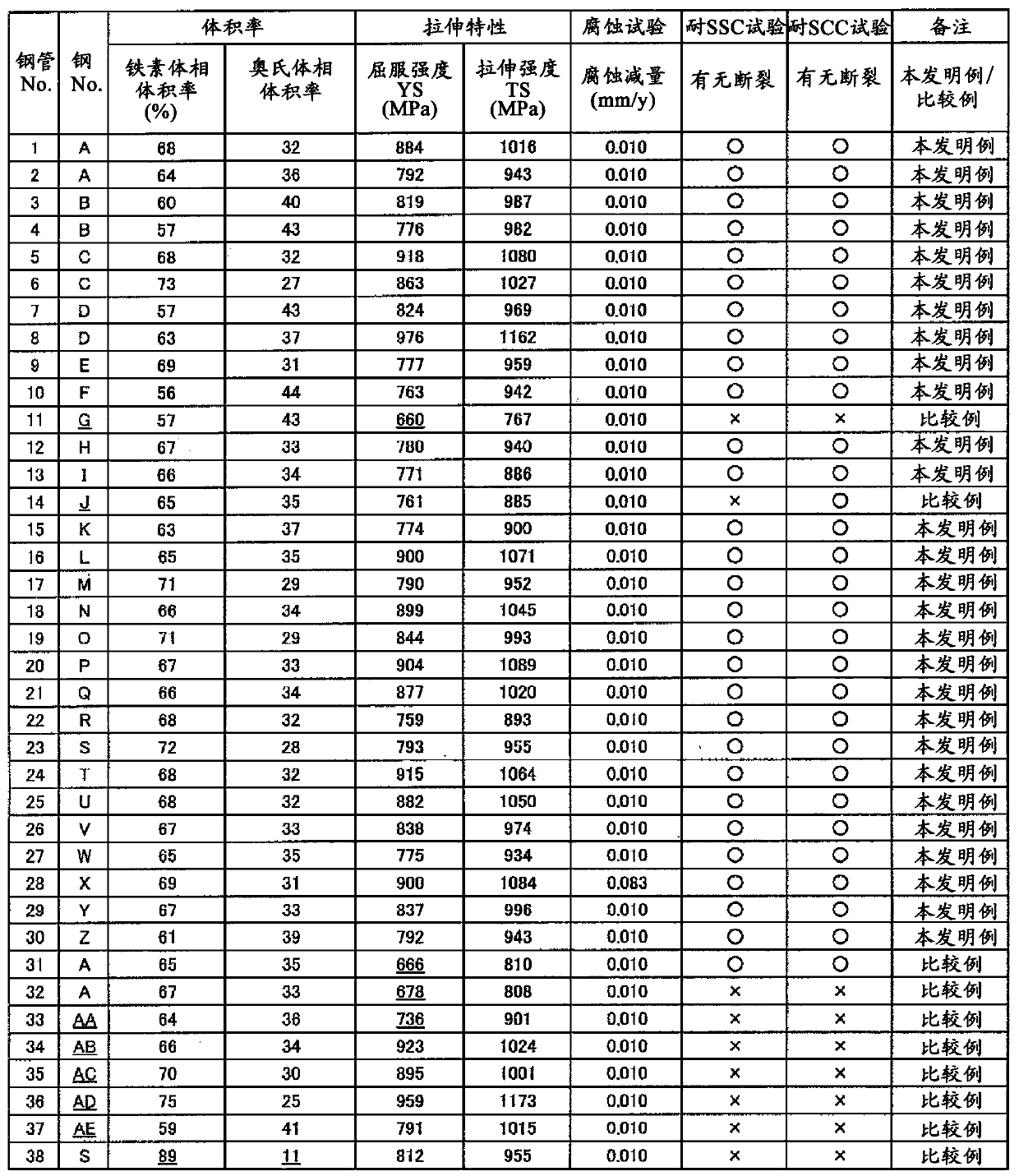

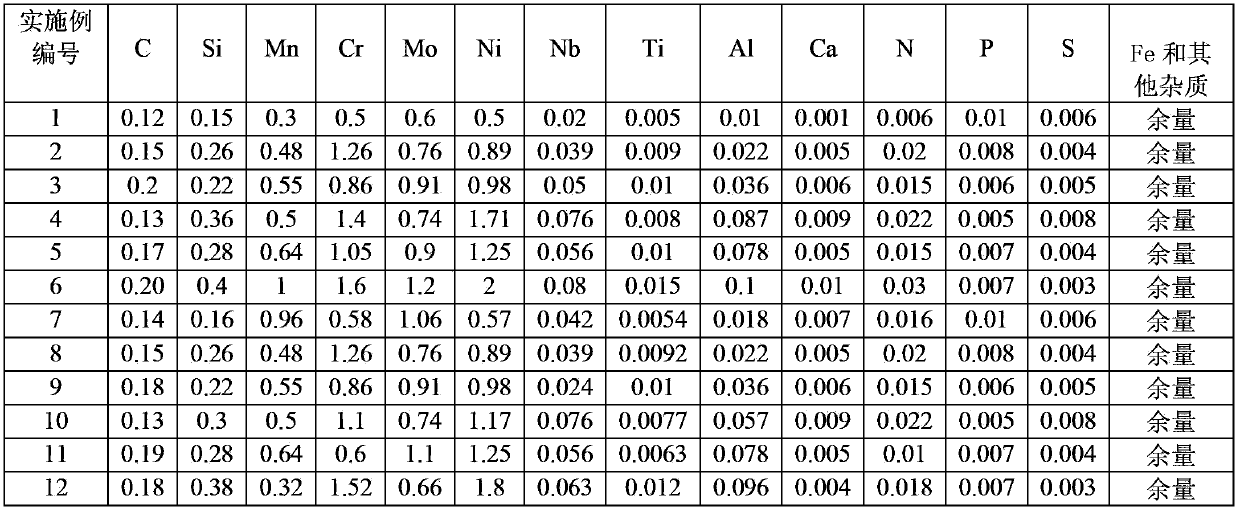

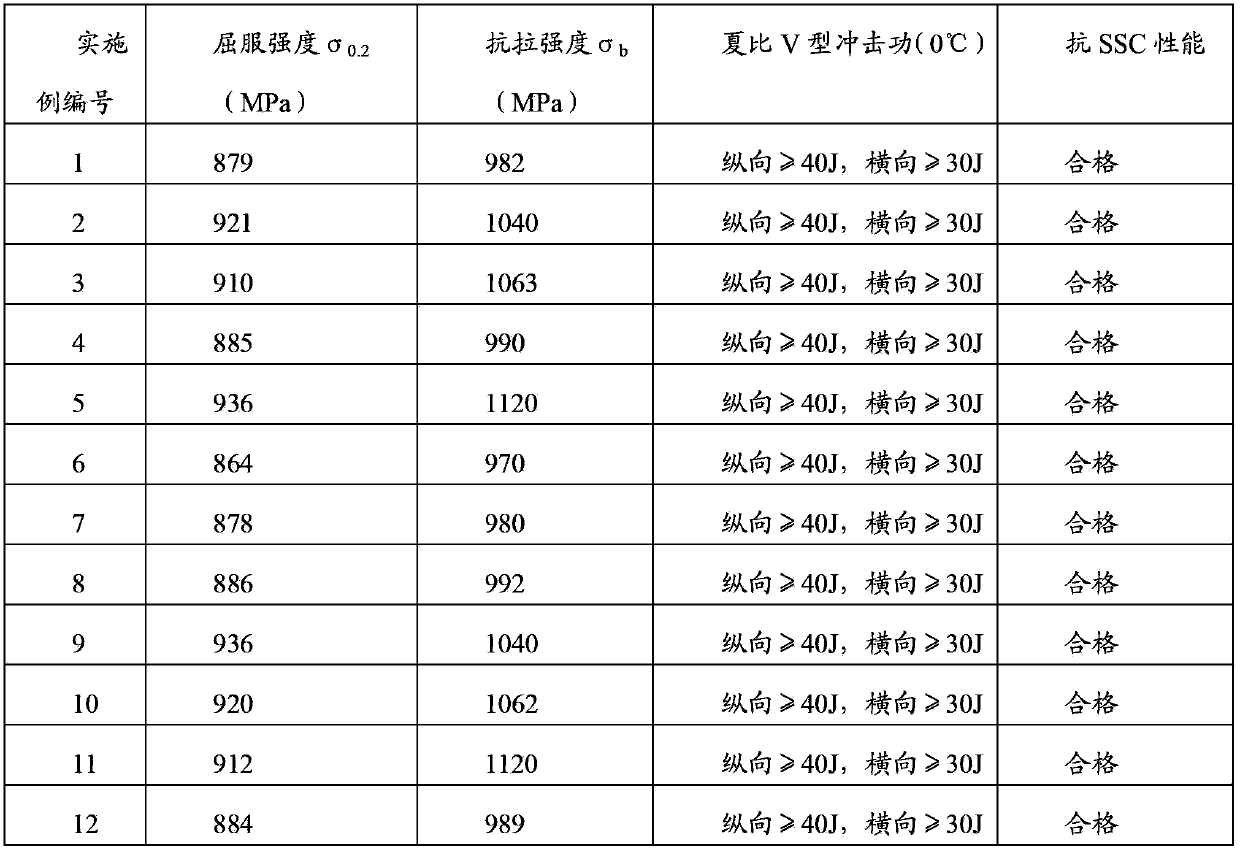

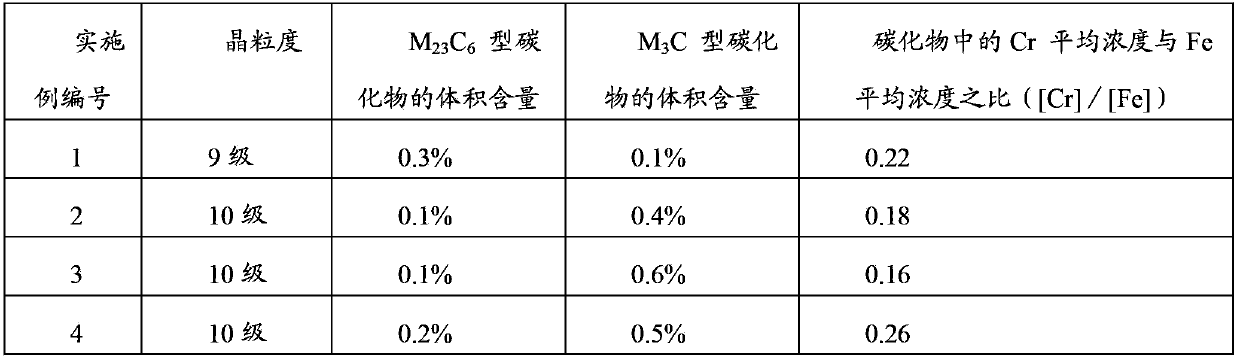

Sulfide stress cracking resistance tubing and casing, and production method thereof

ActiveCN103966524AHigh strengthImprove toughnessDrilling rodsDrilling casingsSulfide stress crackingMaterials science

The present invention discloses a sulfide stress cracking resistance tubing and casing, and a production method thereof, and belongs to the field of tubing and casing. The components of the tubing and casing comprise, by mass, 0.12-0.20% of C, 0.15-0.40% of Si, 0.30-1.0% of Mn, 0.50-1.60% of Cr, 0.60-1.20% of Mo, 0.50-2.0% of Ni, 0.02-0.08% of Nb, 0.005-0.015% of Ti, 0.01-0.10% of Al, 0.001-0.01% of Ca, 0.005-0.03% of N, less than 0.015% of P, less than 0.01% of S, less than 0.001% of B, and the balance of Fe and other unavoidable impurities. According to the present invention, the contents of Cr, Mo, Ni and Nb are optimized, and the C content is reduced so as to control the ratio of the average Cr concentration to the average Fe concentration in the M23C6 type carbide, the M3C type carbide and the carbide in the tempering martensite structure within a certain range, such that the tubing and casing with the fine and uniform tempering martensite structure is obtained, it is ensured that the steel grade achieves 125 ksi or above, and the tubing and casing concurrently has characteristics of high strength, SSC resistance and high toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-strength stainless steel pipe excellent in sulfide stress cracking resistance and high-temperature carbonic-acid gas corrosion resistance

The problem to be solved is the provision of a high-strength stainless steel pipe having a sufficient corrosion resistance in a high-temperature carbonic acid gas environment and having an excellent sulfide stress cracking resistance at normal temperature. A high-strength stainless steel pipe consist of, by mass %, C: 0.05% or less, Si: 1.0% or less, P: 0.05% or less, S: less than 0.002%, Cr: more than 16% and 18% or less, Mo: more than 2% and 3% or less, Cu: 1% to 3.5%, Ni: 3% or more and less than 5%, Al: 0.001% to 0.1% and O: 0.01% or less, Mn: 1% or less and N: 0.05% or less, and Mn and N in the above ranges satisfy formula (1), and the balance being Fe and impurities; and the metal micro-structure of the stainless steel pipe mainly includes a martensitic phase and comprises 10 to 40% of a ferritic phase by volume fraction and 10% or less of a retained γ-phase by volume fraction.[Mn]×([N]−0.0045)≦0.001 (1)wherein the symbols of elements in formula (1) respectively represent the contents (unit: mass %) of the elements in the steel.

Owner:NIPPON STEEL CORP

High strength seamless stainless steel pipe for oil well and production method therefor

PendingCN110312816AHigh strengthExcellent stress corrosion cracking resistanceFurnace typesHeat treatment furnacesCarbon dioxide corrosionCrystal orientation

Owner:JFE STEEL CORP

High grade corrosion resistant raw material pipe blank for offshore oil platform

The invention relates to a production technology of steel pipes, particularly to a high grade corrosion resistant raw material pipe blank for an offshore oil platform. The raw material pipe blank comprises the following ingredients: 0.25-0.33 wt% of C, 0.15-0.35 wt% of Si, 0.40-0.60 wt% of Mn, no larger than 0.015 wt% of P, no larger than 0.010 wt% of Si, 0.90-1.10 wt% of Cr, 0.15-0.25 wt% of Mo, no larger than 0.20 wt% of Ni, no larger than 0.20 wt% of Cu, 0.002-0.08 wt% of N, and the balance consisting of Fe. The invention can fundamentally solve the defects of common steel pipes in prior art, resist H2S corrosion, improve the capabilities of resisting uniform corrosion and local corrosion, prevent sulphide stress crack and H-induced crack, and completely adapt to offshore high temperature, high press and high content of H2S and CO2 and other strong corrosion environments, thus the invention can prevent the occurrences of accidents of underground pipeline fracture and leakage of gas collection trunk in oil and gas fields.

Owner:江苏诚德钢管股份有限公司

Low-alloy steel having a high yield strength and a high sulphide-induced stress cracking resistance

InactiveCN102939400AReduce manufacturing costImprove forgeabilityCrack resistanceChemical composition

Owner:VALLOUREC OIL & GAS FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com