Method for welding MCS anti-sulfur carbon steel pipeline for high sulfur-containing gas field

A welding method, high sulfur technology, used in pipeline systems, welding equipment, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. L360MCS anti-sulfur carbon steel pipe, specification Φ508×22.2mm, cutting and beveling adopt cold working, single-side beveling angle is 35°.

[0048] 2. The pair gap is 2.5mm. The pipe error is less than 1mm.

[0049] 3. Use the formal welding process for spot welding. There are 8 spot-welding spots.

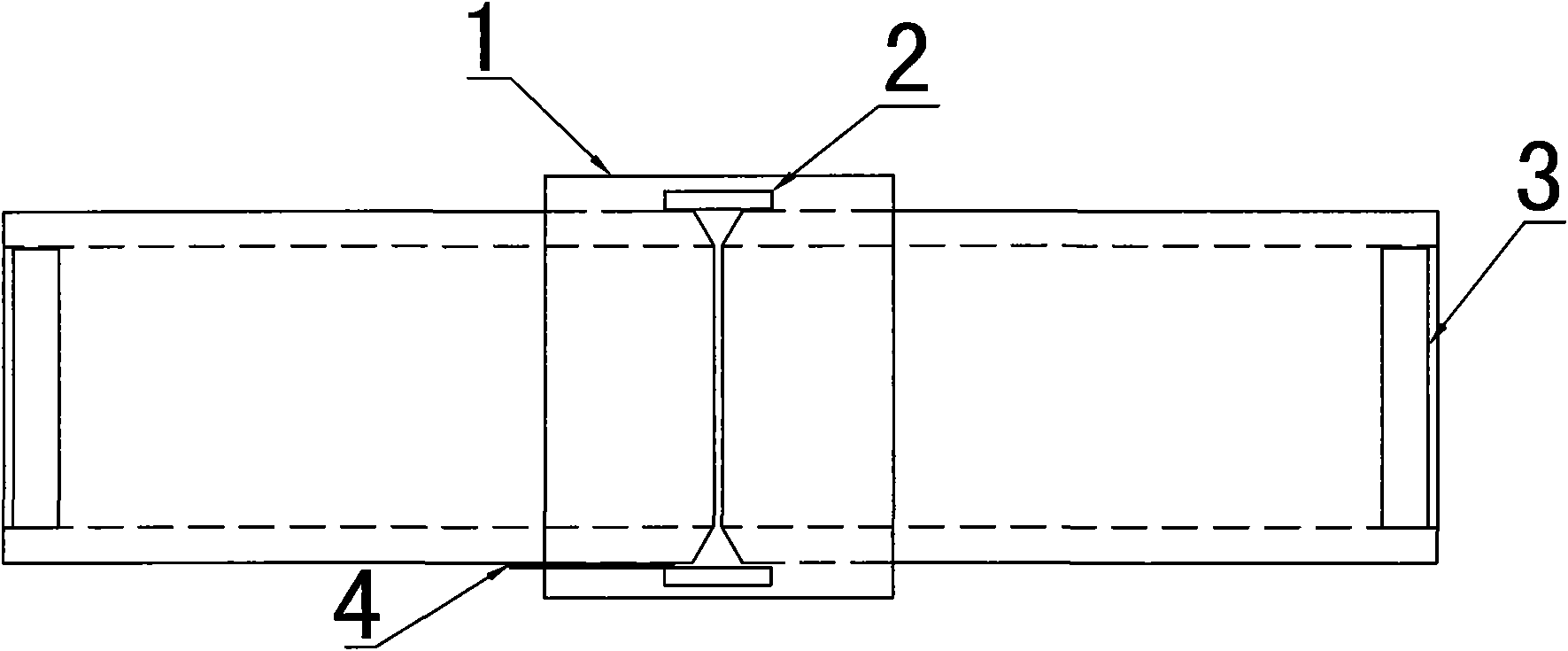

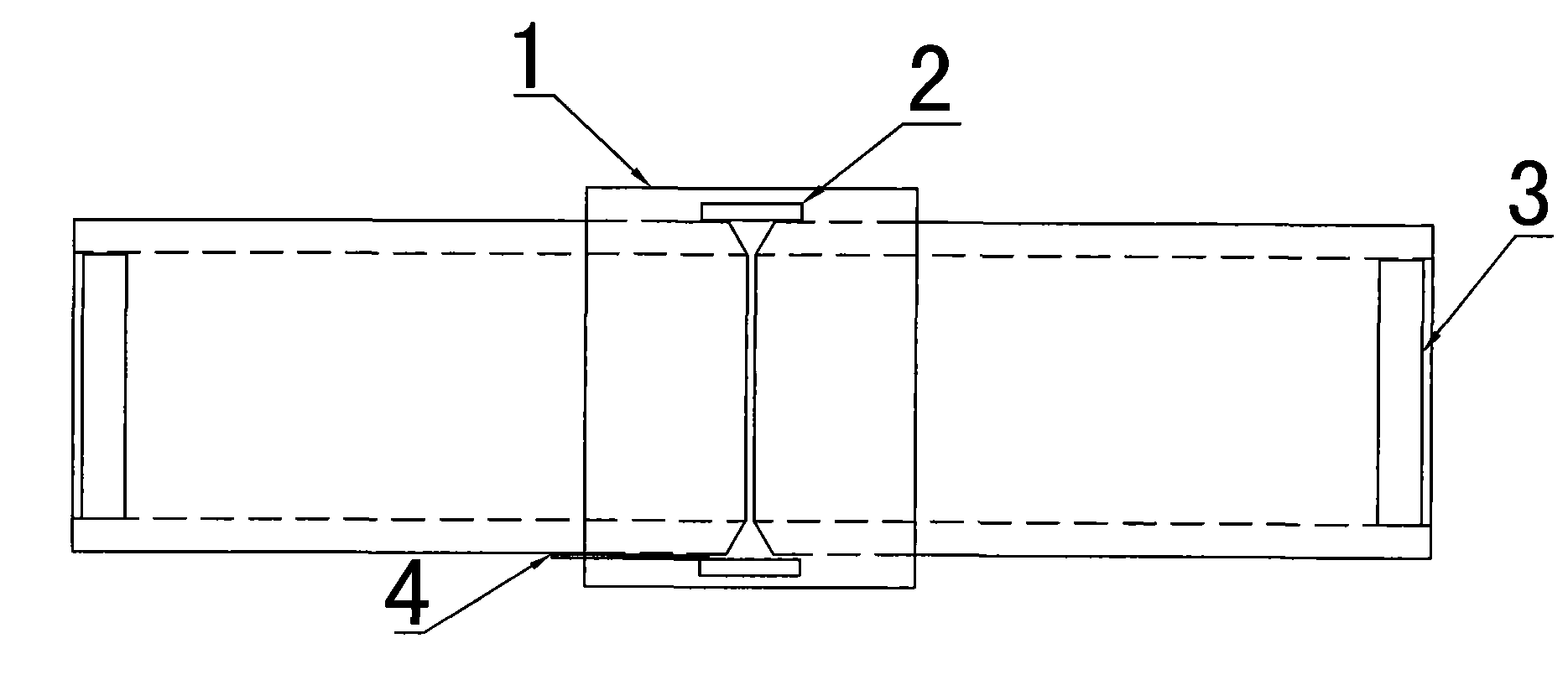

[0050] 4. Before welding, use the electric heating sheet 2 of the crawler electric heater to preheat the pipes within 150mm on both sides of the groove, and the preheating temperature is 100°C. Preheat using as figure 1 The electric track heater shown.

[0051] 5. Use metal powder cored wire for semi-automatic bottom welding. During the welding process, it is necessary to strictly control the formation of the back of the weld and control the hardness value of the welded joint. Use low-hydrogen electrode arc welding for filling and cover welding. The welding process During the process, the welding line energy is strictly controlled, and the interlayer temperature ...

Embodiment 2

[0059] 1. L360MCS anti-sulfur carbon steel pipe, specification Φ508×22.2mm, cutting and beveling adopt cold working, single-side beveling angle is 30°.

[0060] 2. The pair gap is 3.0mm. The misalignment of the pipeline is less than 1mm.

[0061] 3. Use the formal welding process for spot welding. There are 10 spot welding spots.

[0062] 4. Before welding, use the electric heating sheet 2 to preheat the pipe within 180mm on both sides of the groove, and the preheating temperature is 120°C. Preheating uses crawler electric heaters.

[0063] 5. Use metal powder cored wire for semi-automatic bottom welding. During the welding process, it is necessary to strictly control the formation of the back of the weld and control the hardness value of the welded joint. Use low-hydrogen electrode arc welding for filling and cover welding. The welding process During the process, the welding line energy is strictly controlled, and the interlayer temperature of the weld seam does not excee...

Embodiment 3

[0072] 1. L360MCS anti-sulfur carbon steel pipe, specification Φ508×22.2mm, cutting and beveling adopt cold working, single-side beveling angle is 30°.

[0073] 2. The pair gap is 3.5mm. The pipe error is less than 1mm.

[0074] 3. Use the formal welding process for spot welding. There are 6 spot welding spots.

[0075] 4. Before welding, use the electric heating sheet 2 to preheat the pipe within 200mm on both sides of the weld groove, and the preheating temperature is 150°C. Preheating uses crawler electric heaters.

[0076] 5. Use metal powder cored wire for semi-automatic bottom welding. During the welding process, it is necessary to strictly control the formation of the back of the weld and control the hardness value of the welded joint. Use low-hydrogen electrode arc welding for filling and cover welding. The welding process During the process, the welding line energy is strictly controlled, and the interlayer temperature of the weld seam does not exceed 250°C during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com