Sulfide stress cracking resistance tubing and casing, and production method thereof

A stress cracking, anti-sulfide technology, used in casing, drill pipe, earthwork drilling, etc., can solve the problems of inability to guarantee oil casing, low total alloying elements, inability to guarantee impact toughness and good SSC resistance

Active Publication Date: 2014-08-06

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are two defects of this technology: one is that there is no grain refinement element, and the C content is too high, and C is easy to form coarse grained M with Cr. 23 C 6 Type carbide, can not guarantee good impact toughness and good SSC resistance

Second, the total amount of alloying elements is low, and the final product cannot guarantee a high content of tempered martensitic structure, so it cannot be guaranteed that the steel grade of the oil casing pipe reaches 125ksi or above

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

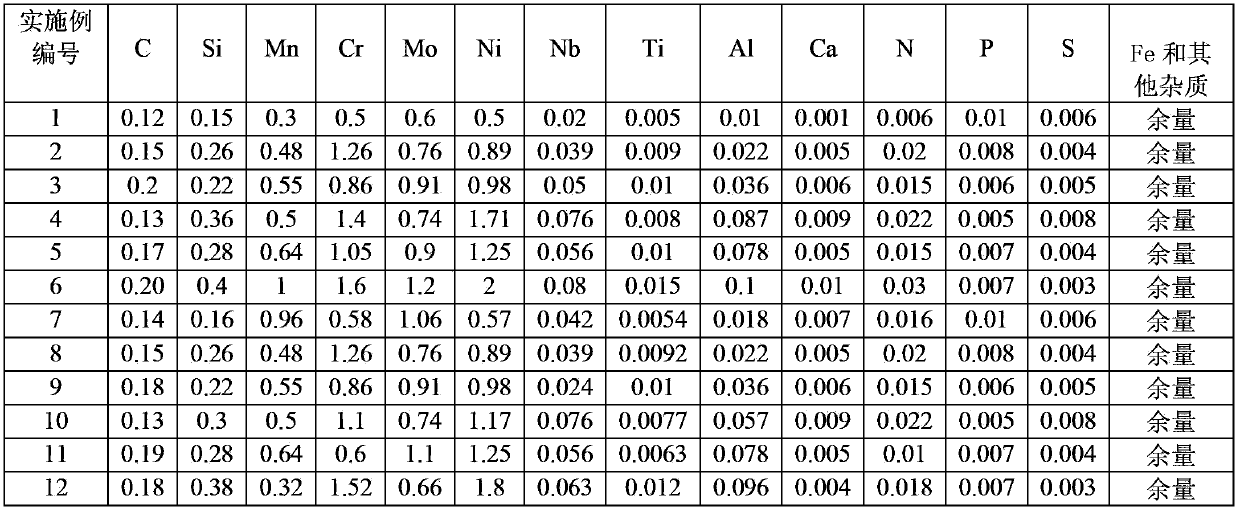

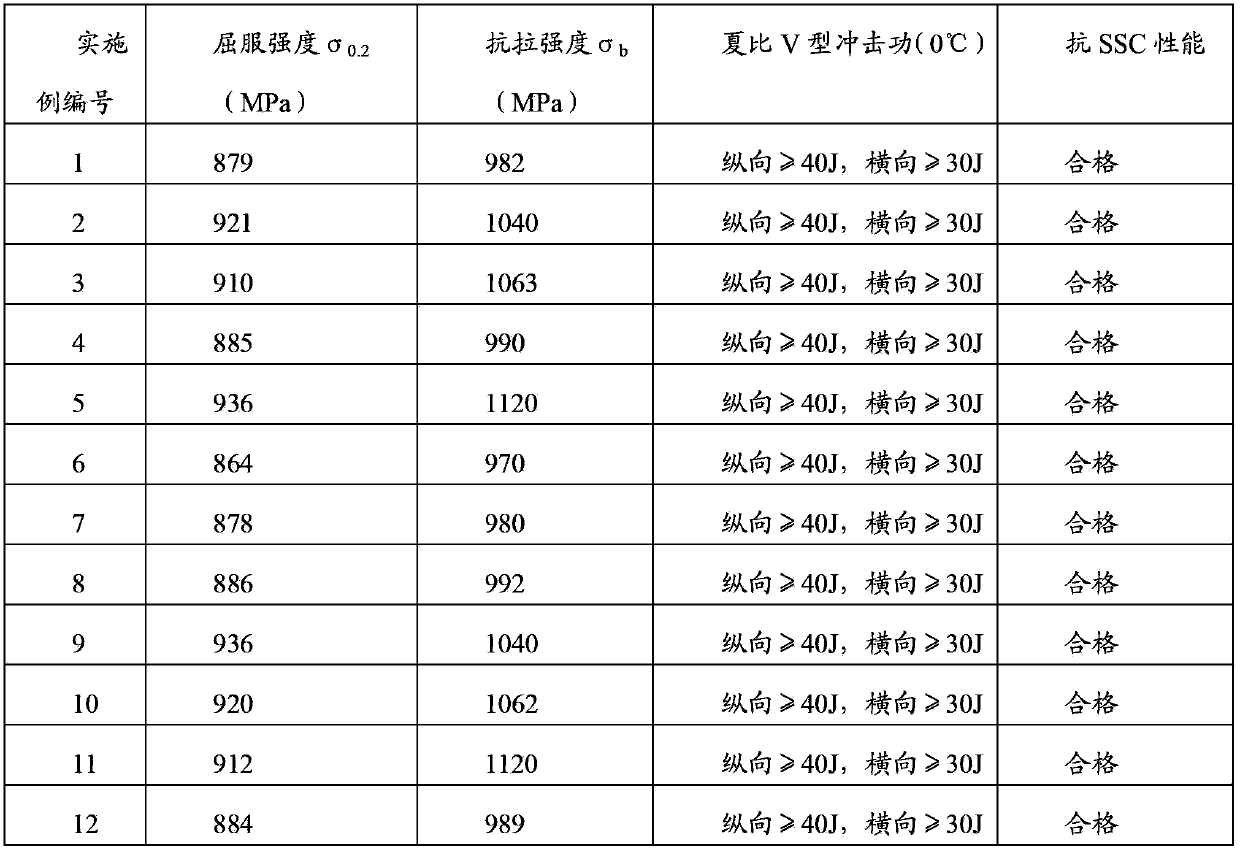

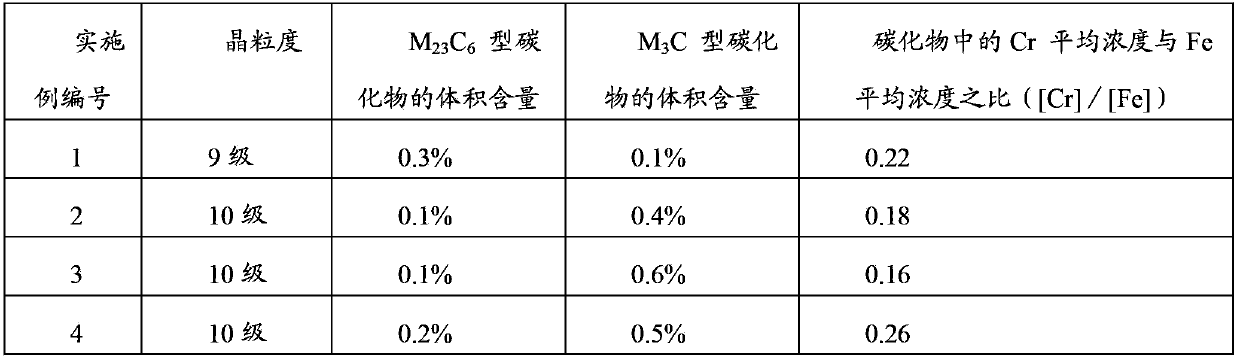

[0081] The present invention provides 12 groups of examples, namely examples 1 to 12. The components of each example are shown in Table 1. In each example, the tubing and casing are manufactured according to the above-mentioned manufacturing method.

[0082] The composition mass percentage data table of the tubing and casing provided by Table 1 Examples 1-12

[0083]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The present invention discloses a sulfide stress cracking resistance tubing and casing, and a production method thereof, and belongs to the field of tubing and casing. The components of the tubing and casing comprise, by mass, 0.12-0.20% of C, 0.15-0.40% of Si, 0.30-1.0% of Mn, 0.50-1.60% of Cr, 0.60-1.20% of Mo, 0.50-2.0% of Ni, 0.02-0.08% of Nb, 0.005-0.015% of Ti, 0.01-0.10% of Al, 0.001-0.01% of Ca, 0.005-0.03% of N, less than 0.015% of P, less than 0.01% of S, less than 0.001% of B, and the balance of Fe and other unavoidable impurities. According to the present invention, the contents of Cr, Mo, Ni and Nb are optimized, and the C content is reduced so as to control the ratio of the average Cr concentration to the average Fe concentration in the M23C6 type carbide, the M3C type carbide and the carbide in the tempering martensite structure within a certain range, such that the tubing and casing with the fine and uniform tempering martensite structure is obtained, it is ensured that the steel grade achieves 125 ksi or above, and the tubing and casing concurrently has characteristics of high strength, SSC resistance and high toughness.

Description

technical field [0001] The invention relates to the field of oil pipes and casings, in particular to a 125ksi steel-grade low-alloy oil pipe and casing with high resistance to sulfide stress cracking and a manufacturing method thereof. Background technique [0002] containing H 2 S, CO 2 and Cl - During the development of highly acidic oil and gas fields with corrosive media, tubing and casing (referred to as tubing and casing) will not only experience weightless corrosion and localized corrosion with a high corrosion rate, but also sulfide stress cracking (sulfide stress cracking for short SSC) . The coexistence of multiple forms of severe corrosion poses a huge challenge to the anti-corrosion technology of tubing and casing. [0003] At present, there are usually two protective measures for the corrosion of tubing and casing in high acid gas fields: the first is to use super 13Cr, 22Cr stainless steel or nickel-based alloys and other pipes; the second is to use carbon ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/50C22C33/04C21D8/10E21B17/00

Inventor 魏斌秦长毅李发根韩燕冯耀荣

Owner BC P INC CHINA NAT PETROLEUM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com