Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Desired strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

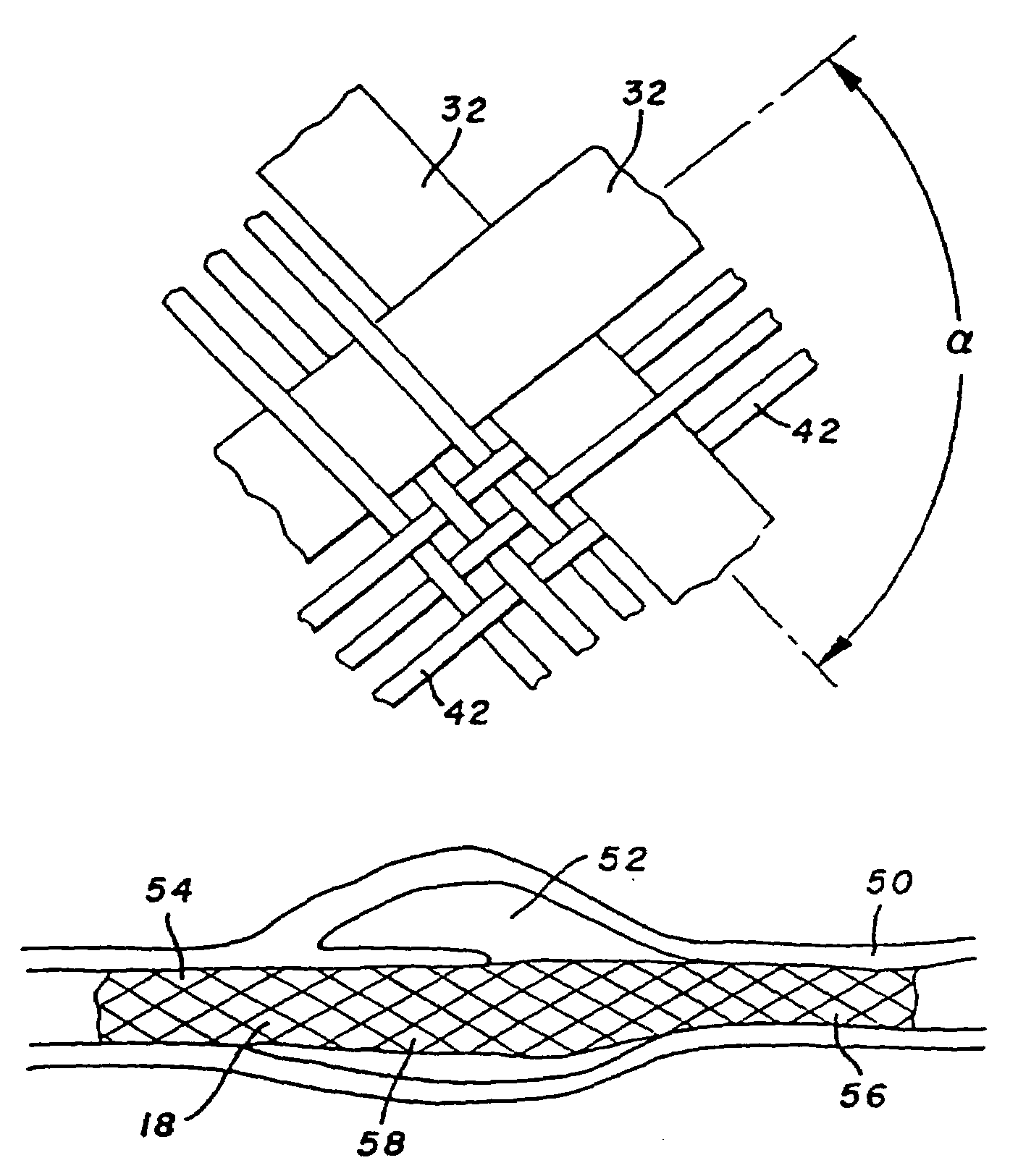

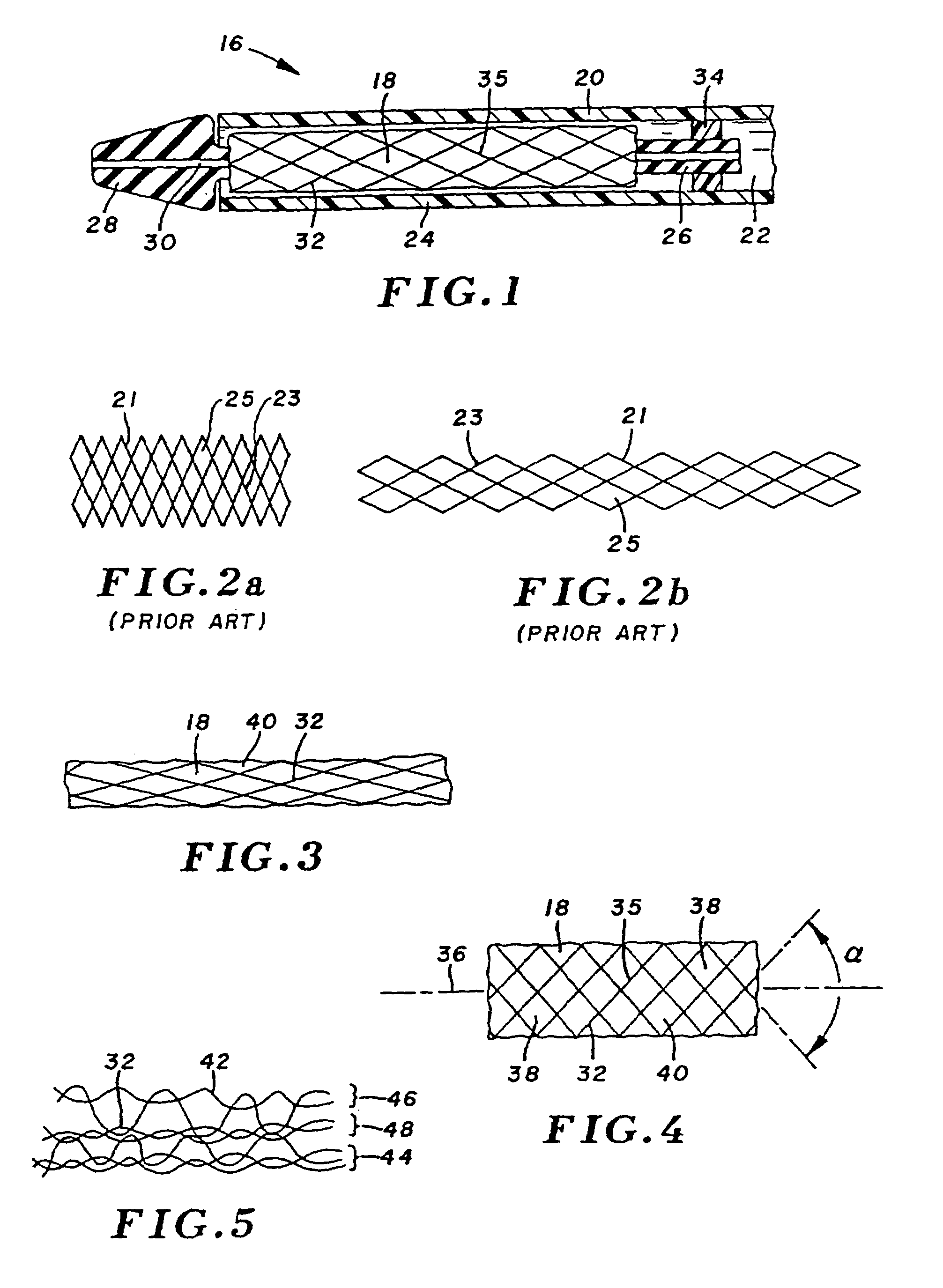

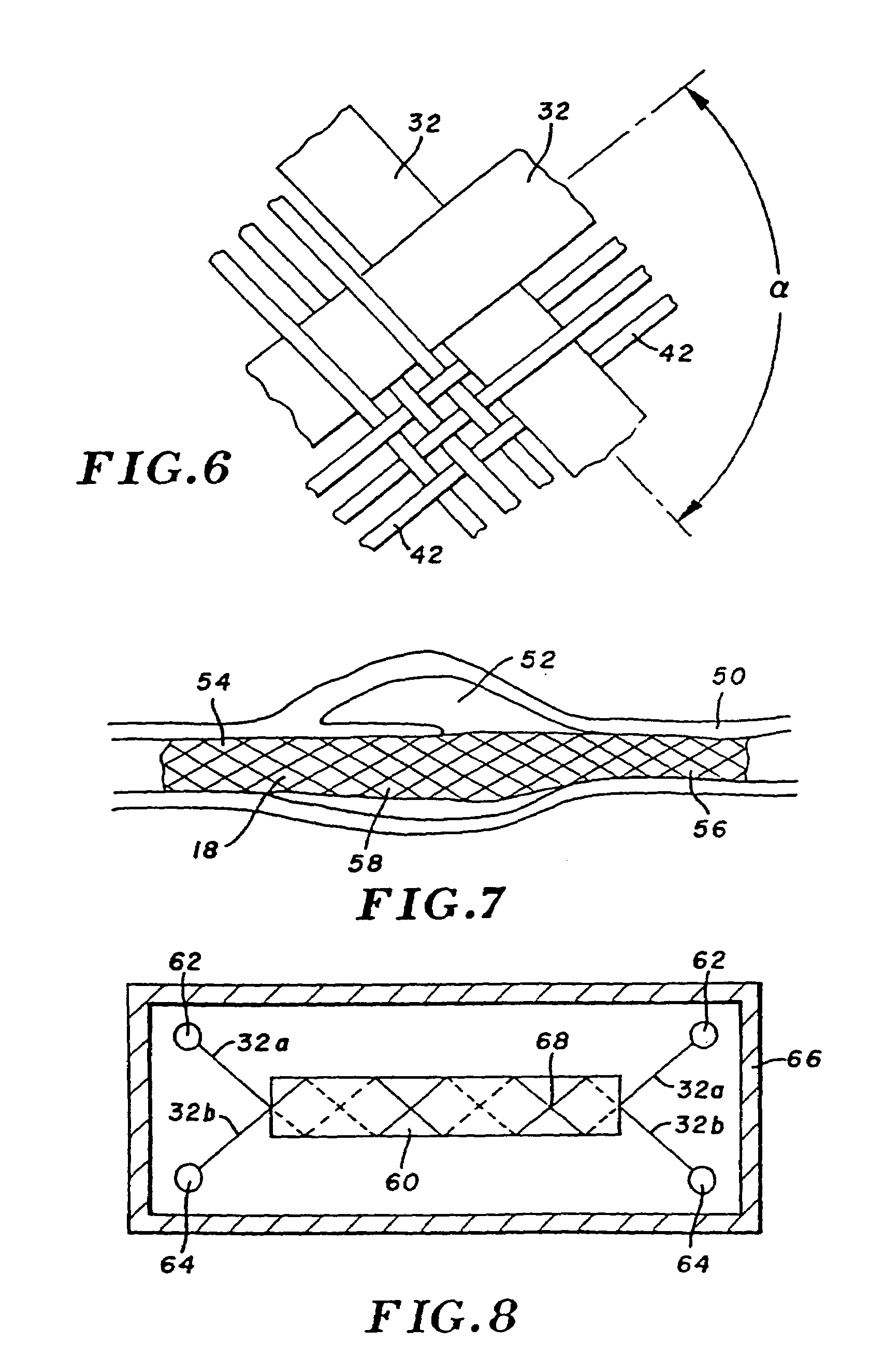

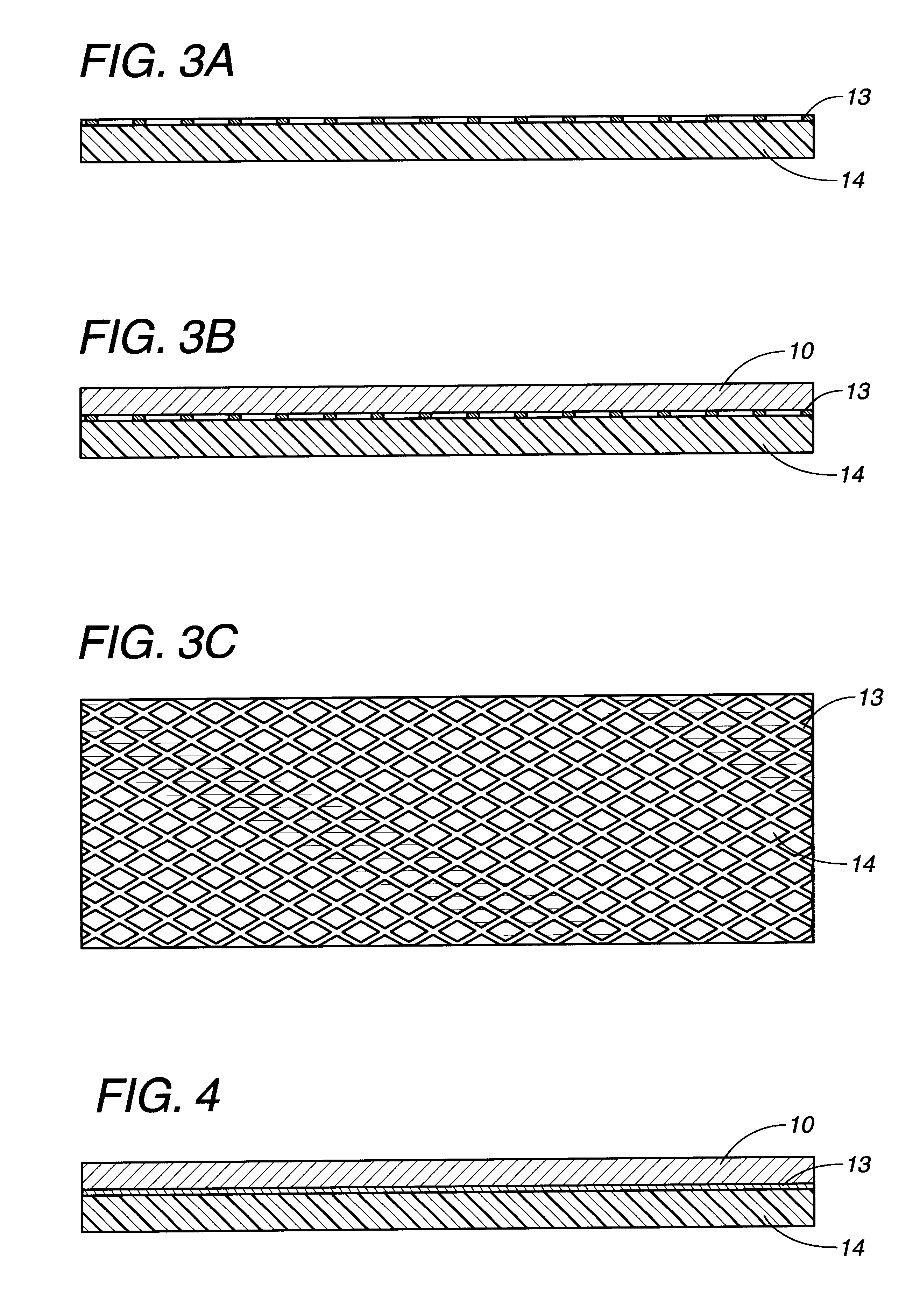

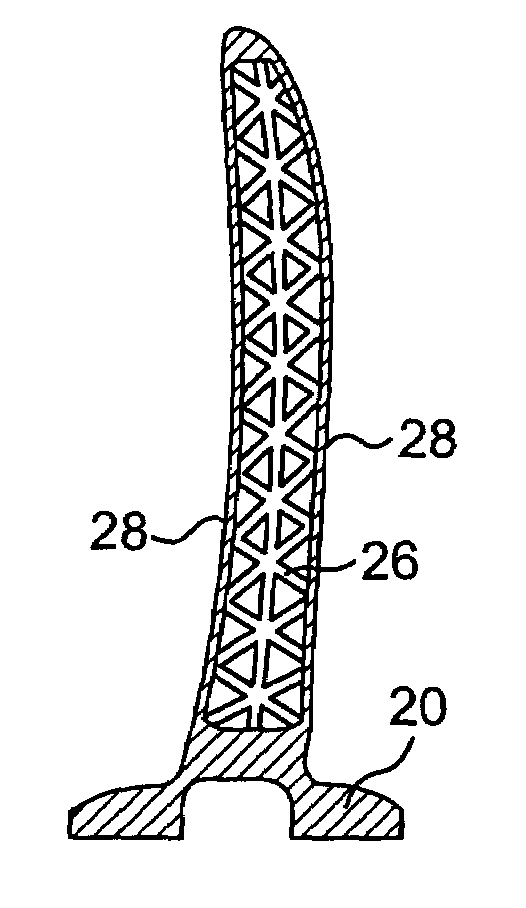

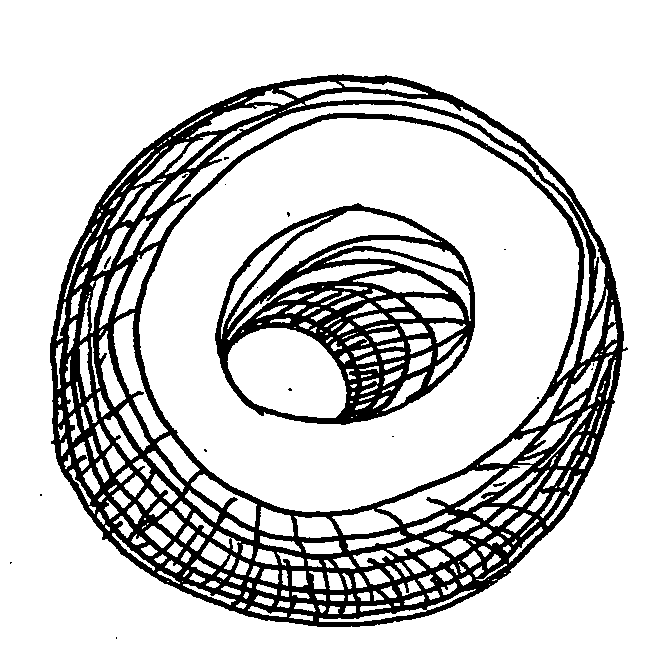

Three-dimensional braided covered stent

InactiveUS7052513B2Reduce manufacturing costSolve the lack of tensionStentsBlood vesselsYarnProsthesis

A prosthesis for transluminal implantation consists of a flexible tubular three-dimensionally braided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide one or more layers of sheeting that reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold working, then three-dimensionally braided to form the prosthesis.

Owner:LIFESHIELD SCI

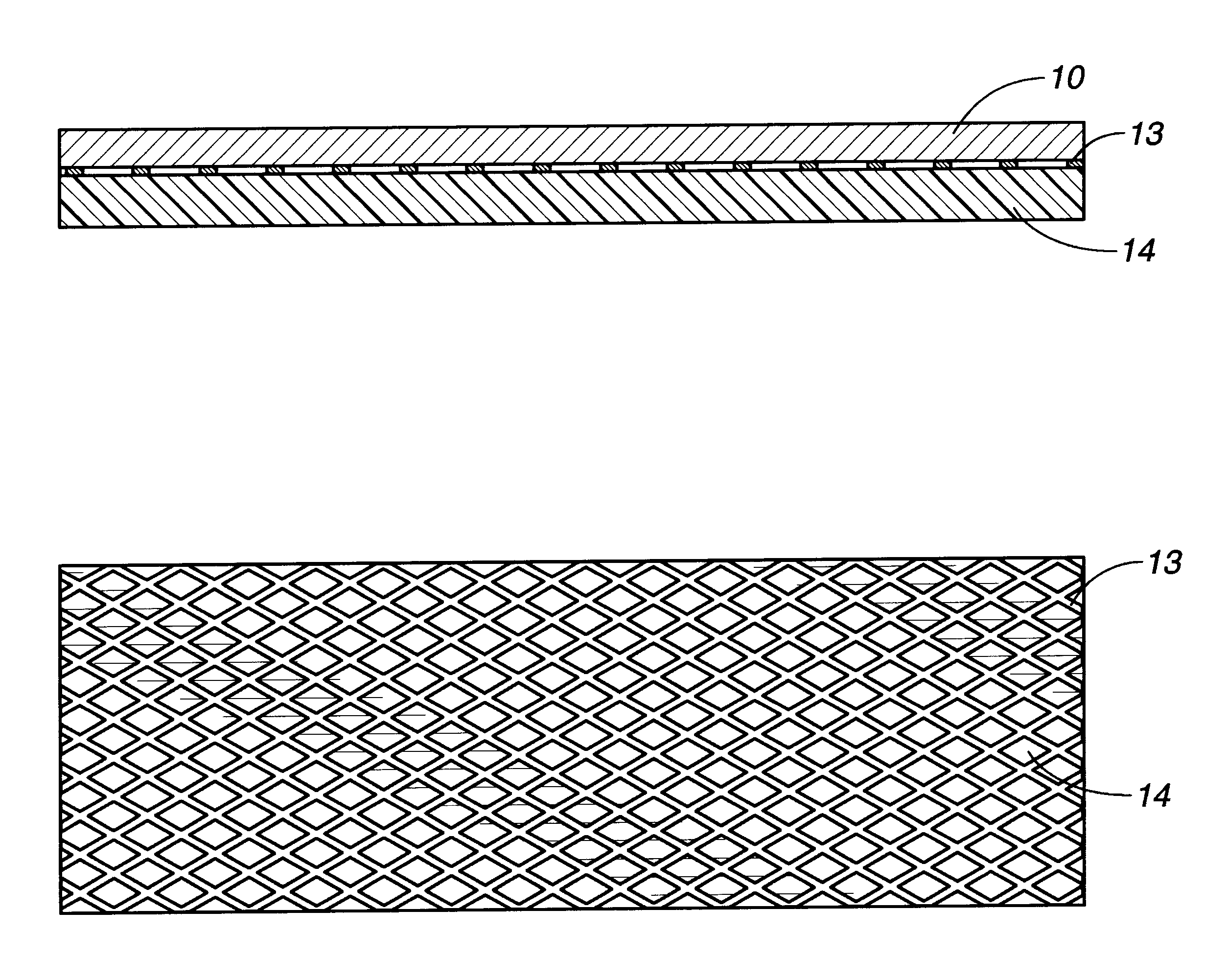

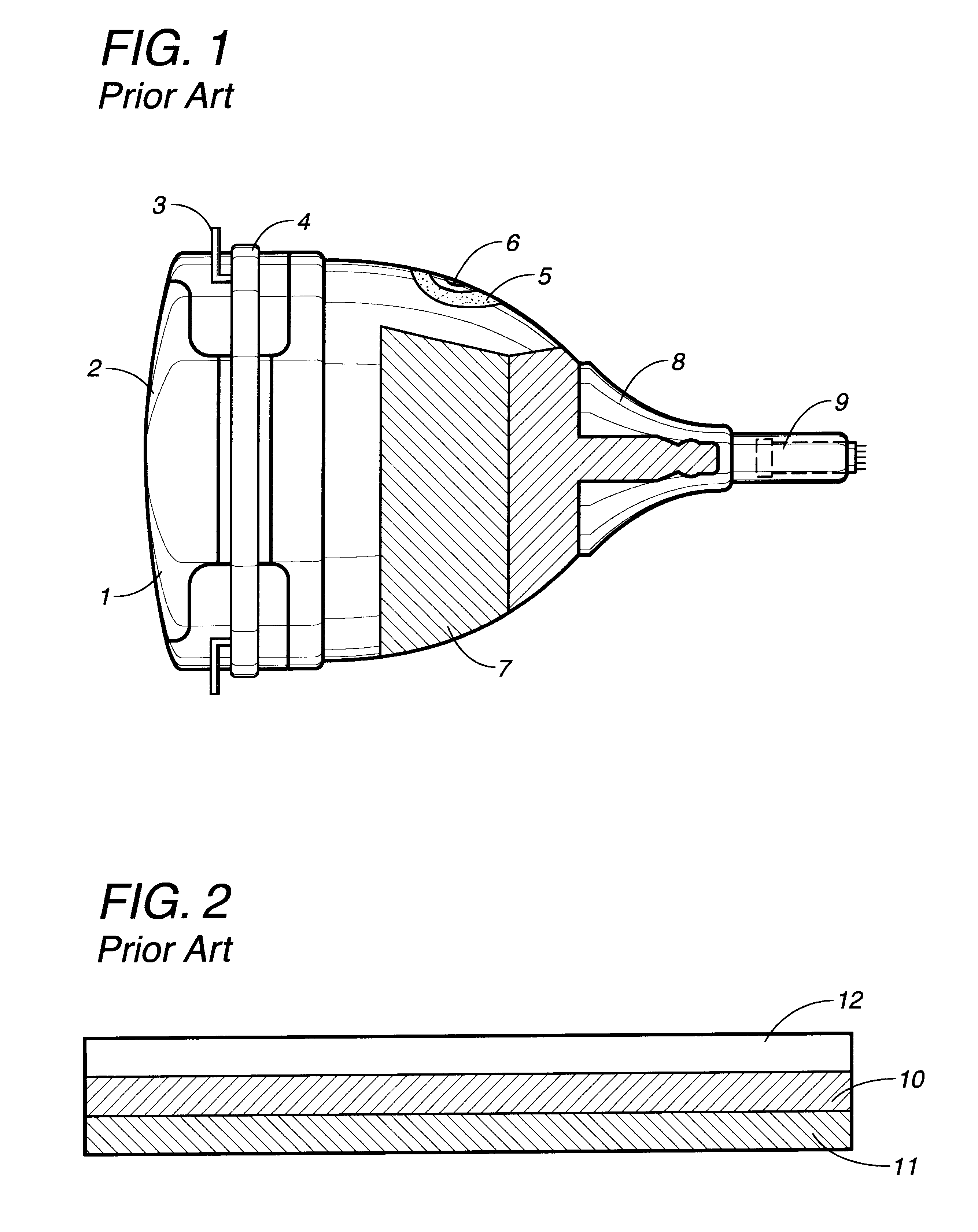

Electrically conductive adhesive tape

InactiveUS6235385B1Avoid accumulationSmall thicknessConductive layers on insulating-supportsElectrostatic discharge protectionUltimate tensile strengthElectron

An electrically conductive adhesive tape used for electrical and electronic products to bond or fix an element to a support while maintaining an electrical conductibility between the element and support. The conductive adhesive tape has a structure including a resin film, a metal layer formed over one surface of the resin film by depositing a conductive metal over the surface of the resin film, and a conductive adhesive layer coated over the metal layer. The metal layer has a net-shaped structure. In some cases, the metal layer may have a planar structure. The conductive adhesive tape has a very small thickness by virtue of its metal layer deposited to a very small thickness. Accordingly, the conductive adhesive tape maintains a desired strength while exhibiting a high flexibility and a high bondability, thereby exhibiting a superior conductibility. In the case in which the metal layer has a net-shaped structure, the tape has a structure having spaces where the metal layer does not exist. Where the tape is applied to a Braun tube, accordingly, there is no influence on an electron beam emitted from a deflection yoke while a desired conductibility is maintained. The manufacture of the tape is simple. By virtue of the conductibility, the tape of the present invention also has an elecromagnetic wave shielding function.

Owner:SHIN WHA INTERTEK

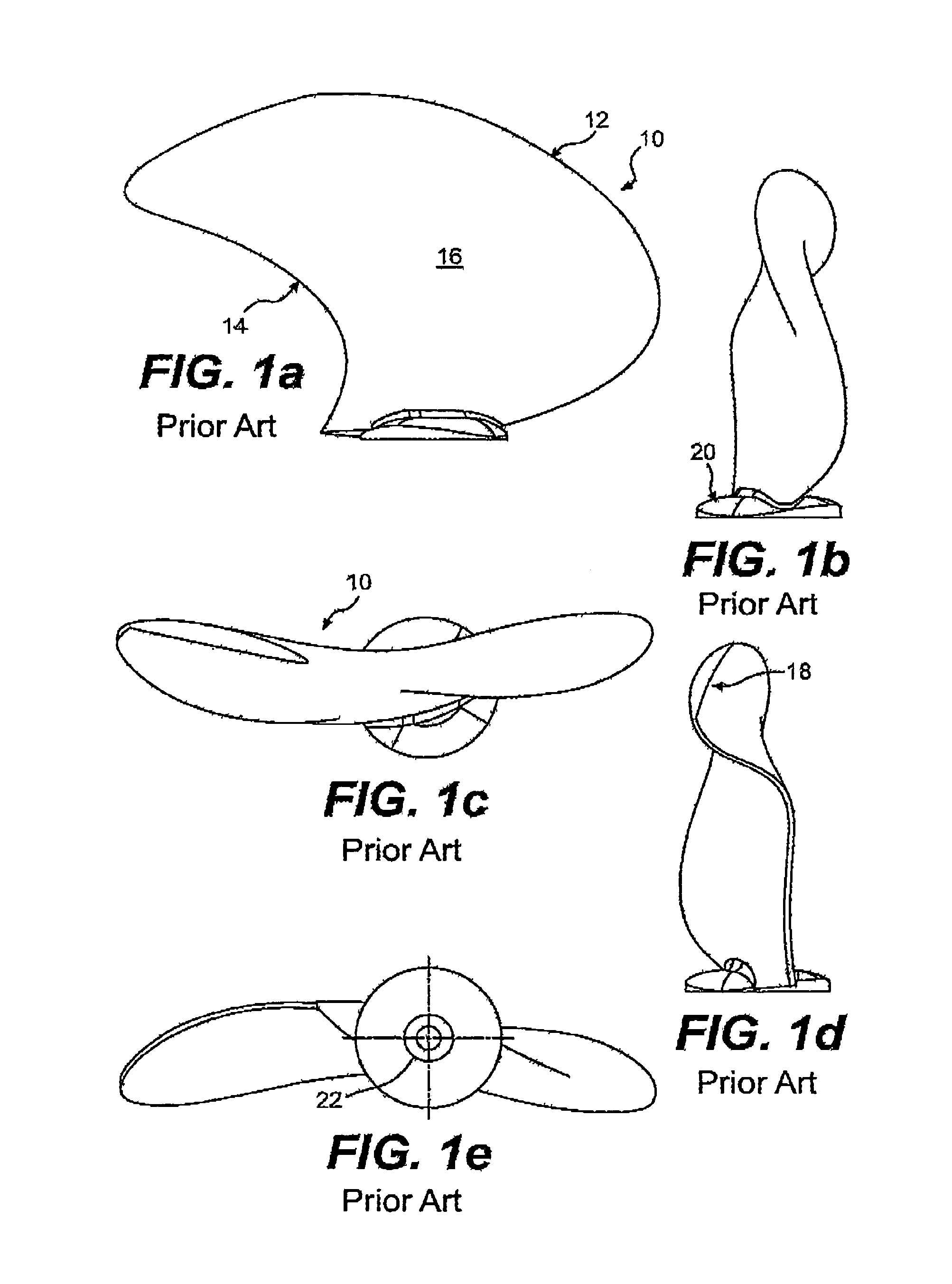

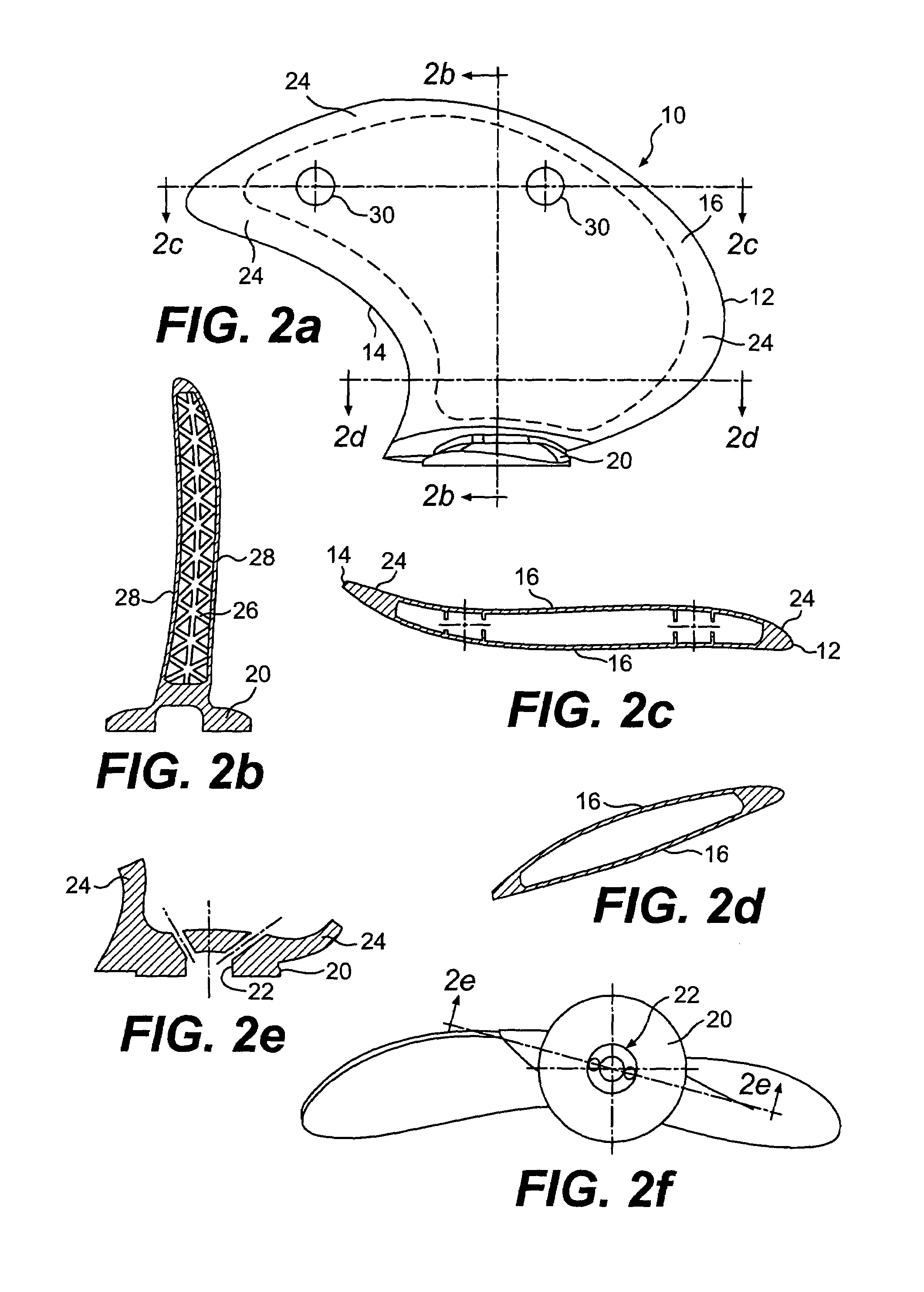

Propeller

InactiveUS7144222B2Desired strengthRelieve pressurePropellersRotary propellersPropellerMechanical engineering

A propeller or propeller blade is manufactured using lattice block material to provide a structure which is generally hollow but for a three-dimensional lattice of support spars. The propeller or propeller blade, being predominately hollow, is substantially lighter than a solid cast propeller or propeller blade while retaining the desired strength due to the three-dimensional lattice of support spars.

Owner:MEDTRONIC INC

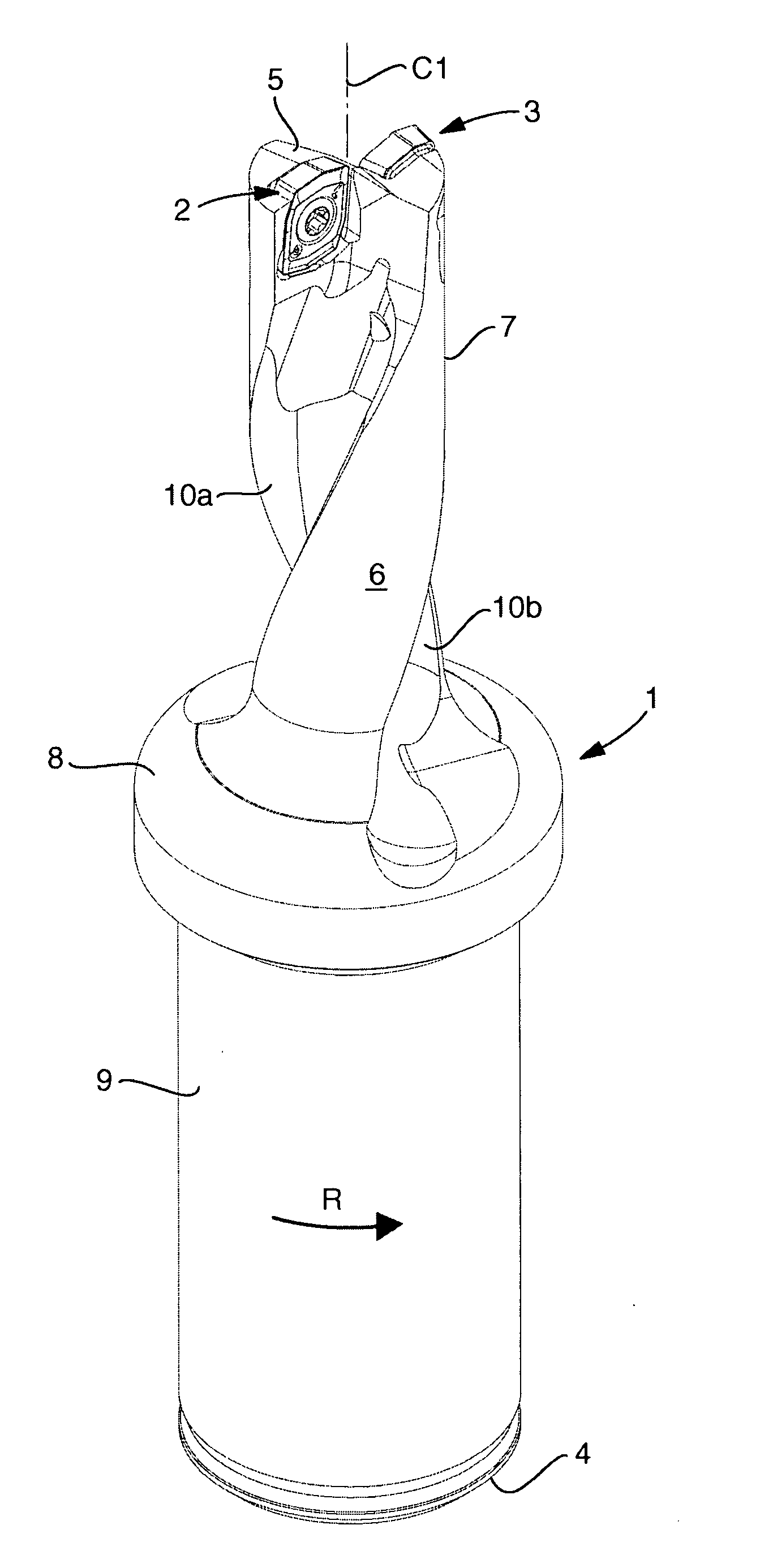

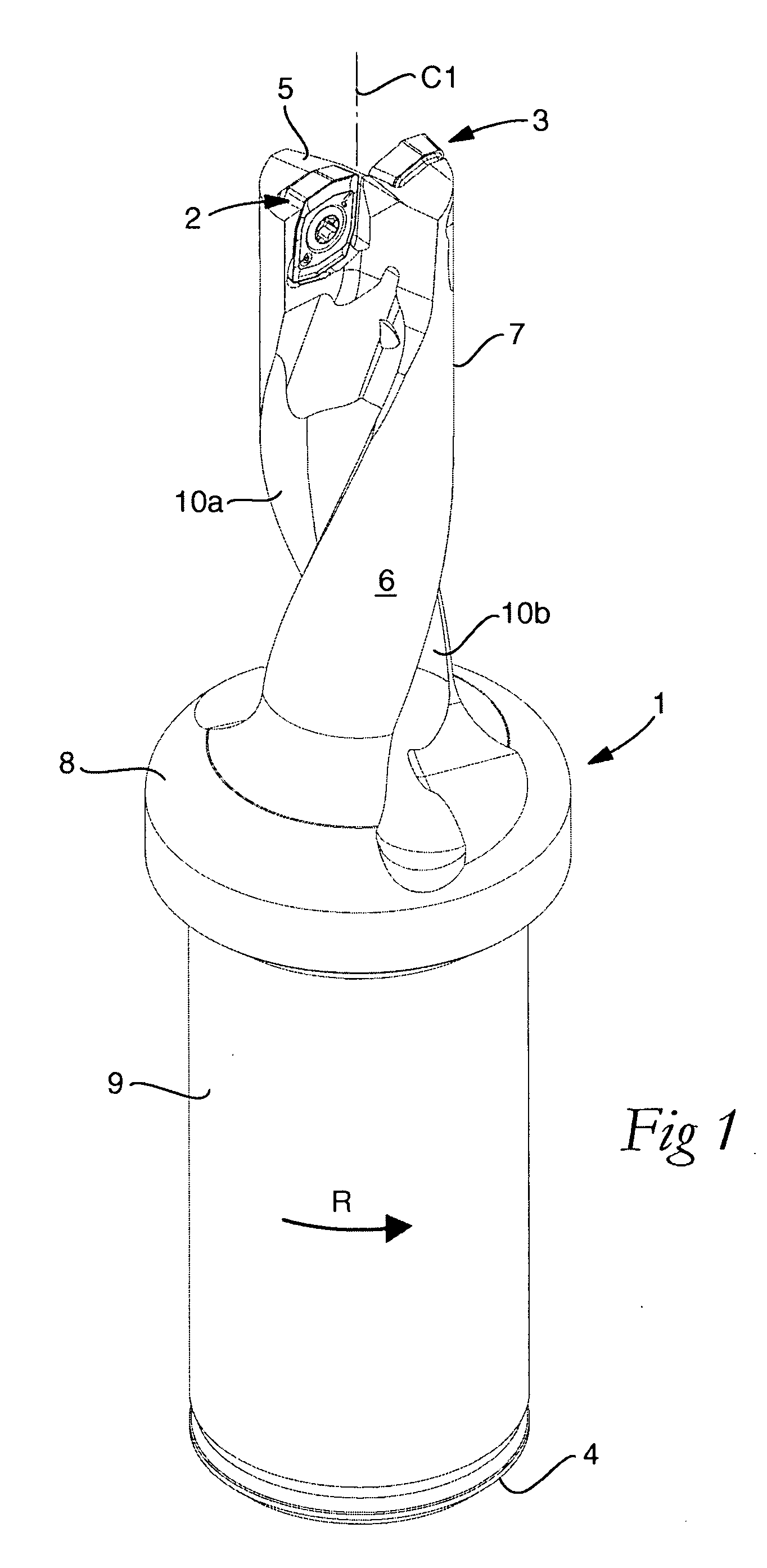

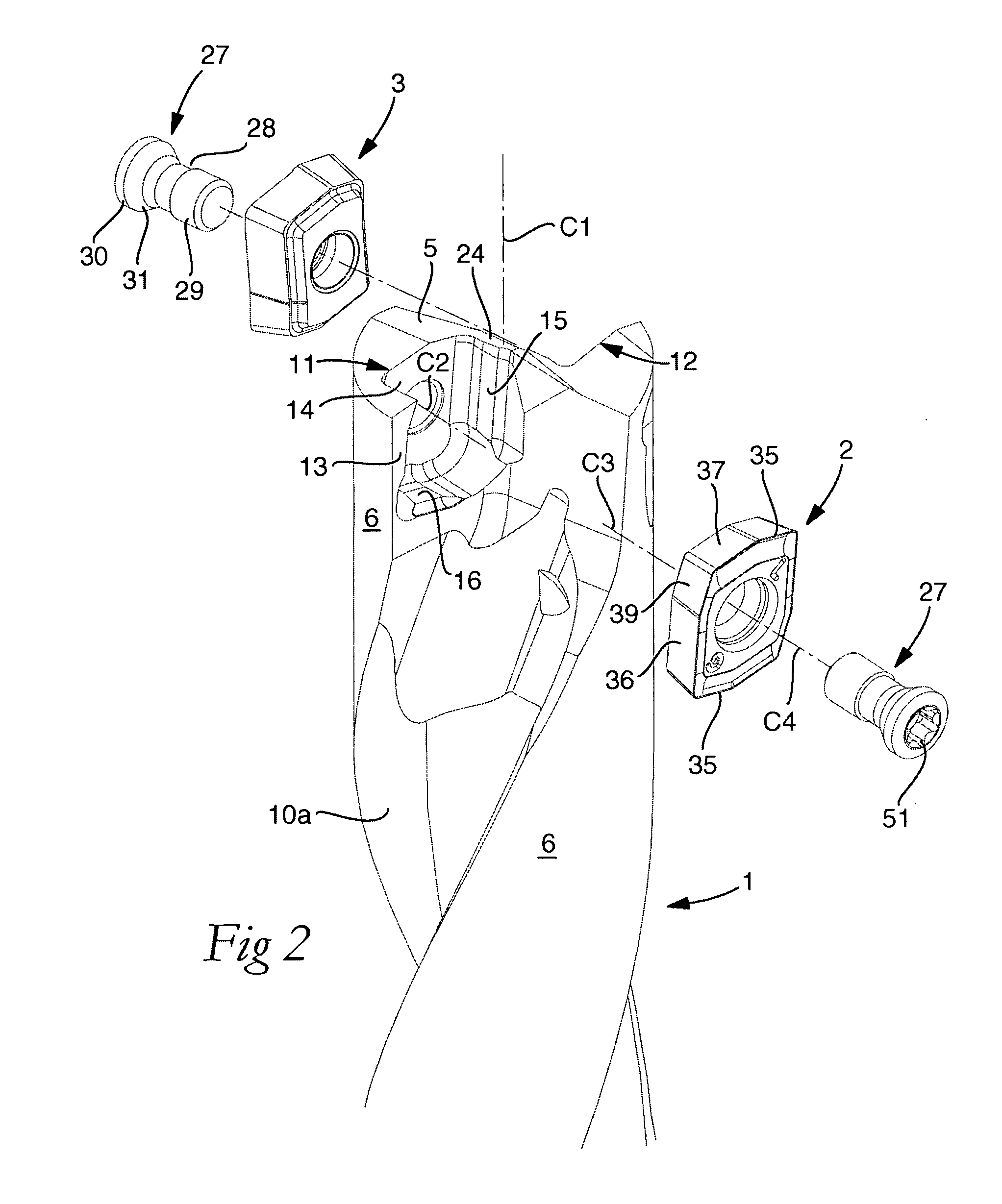

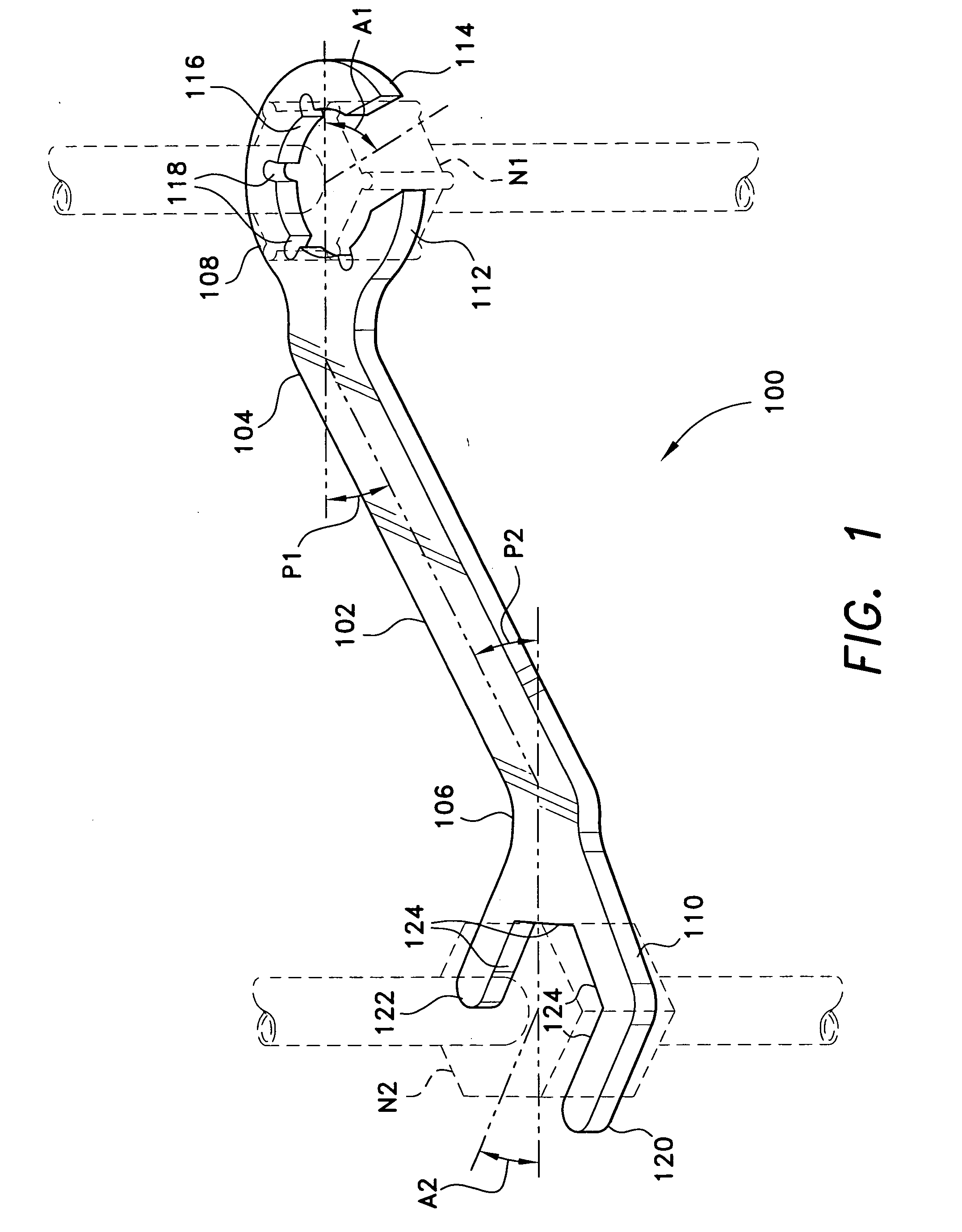

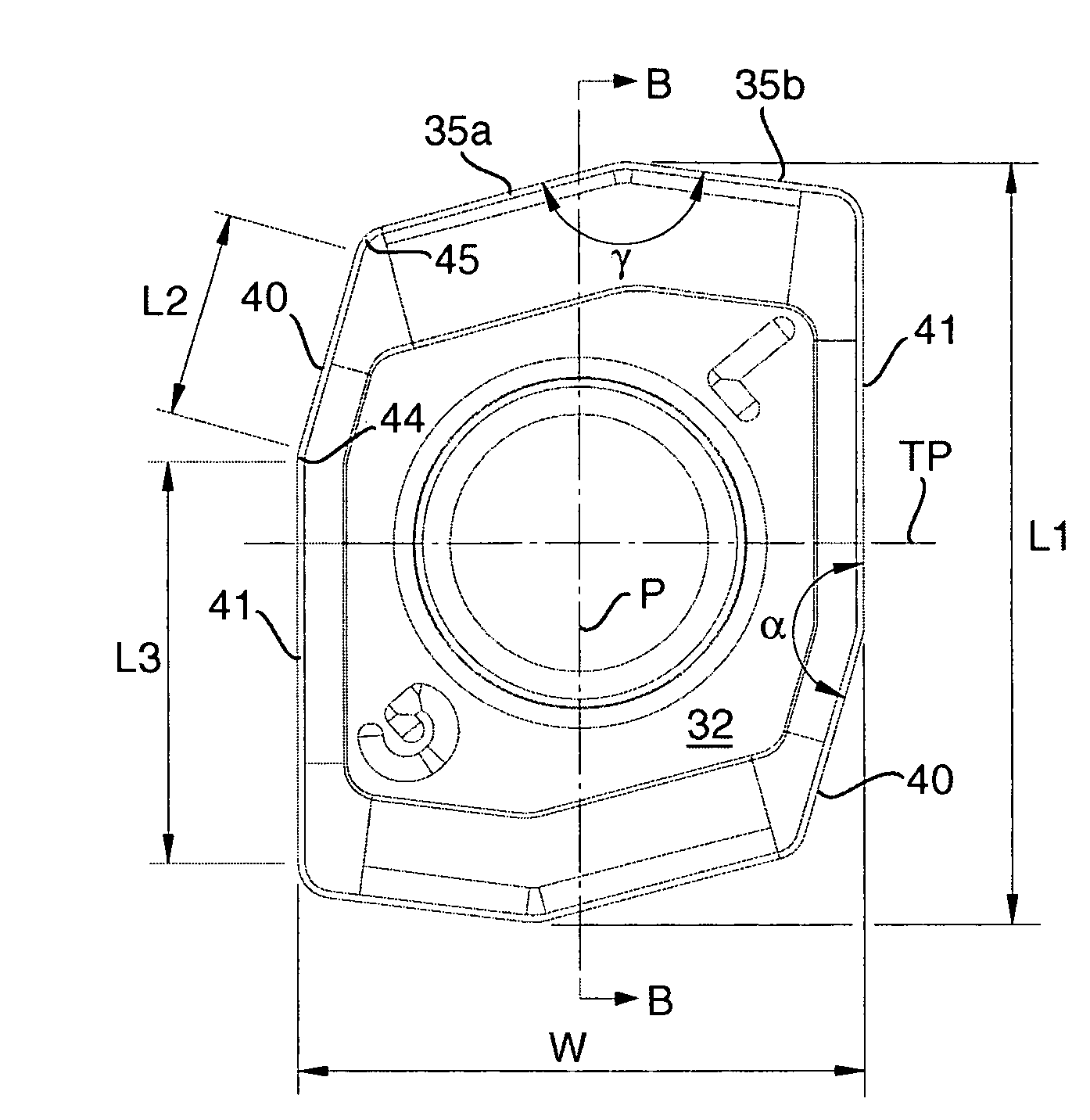

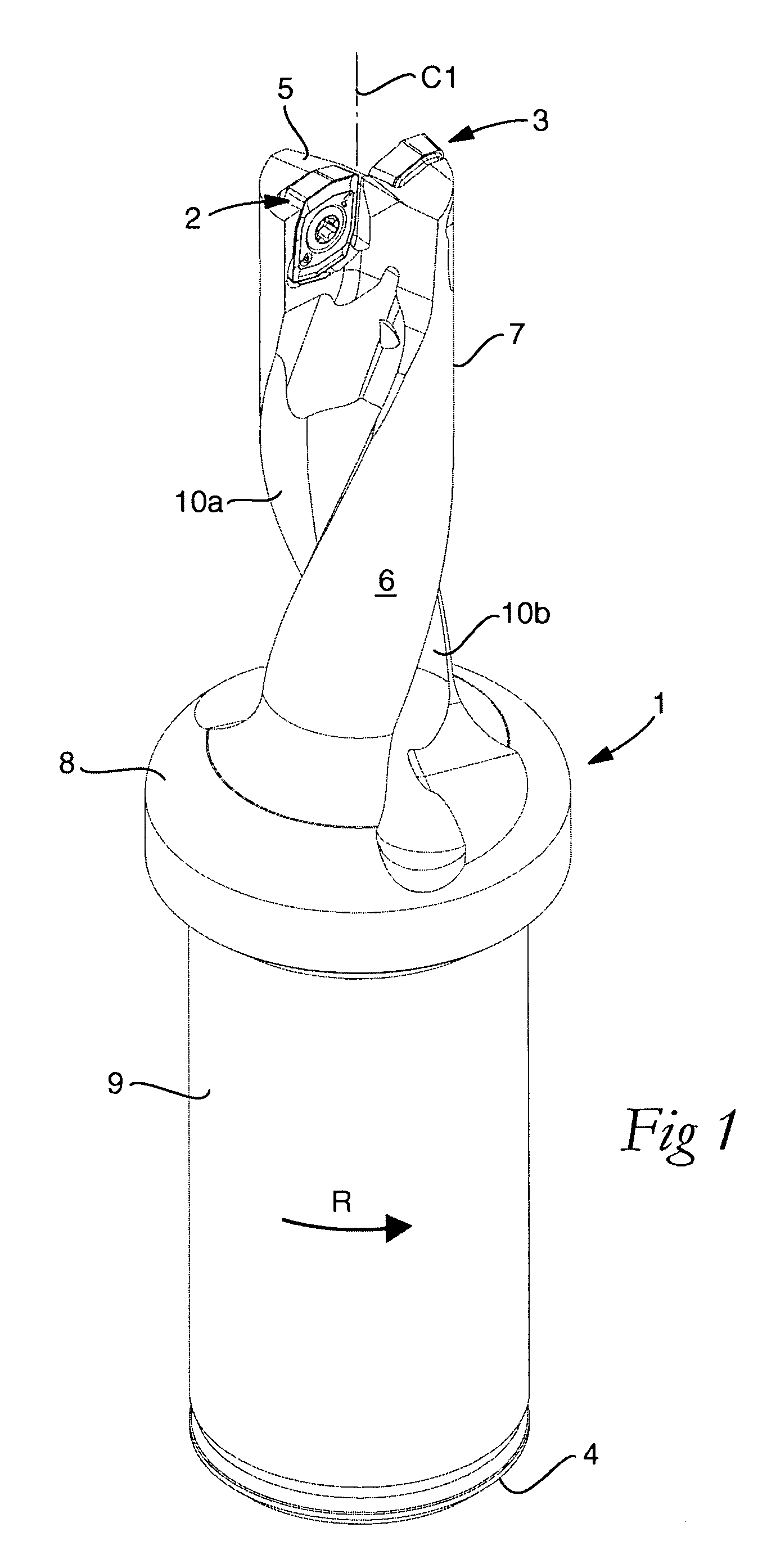

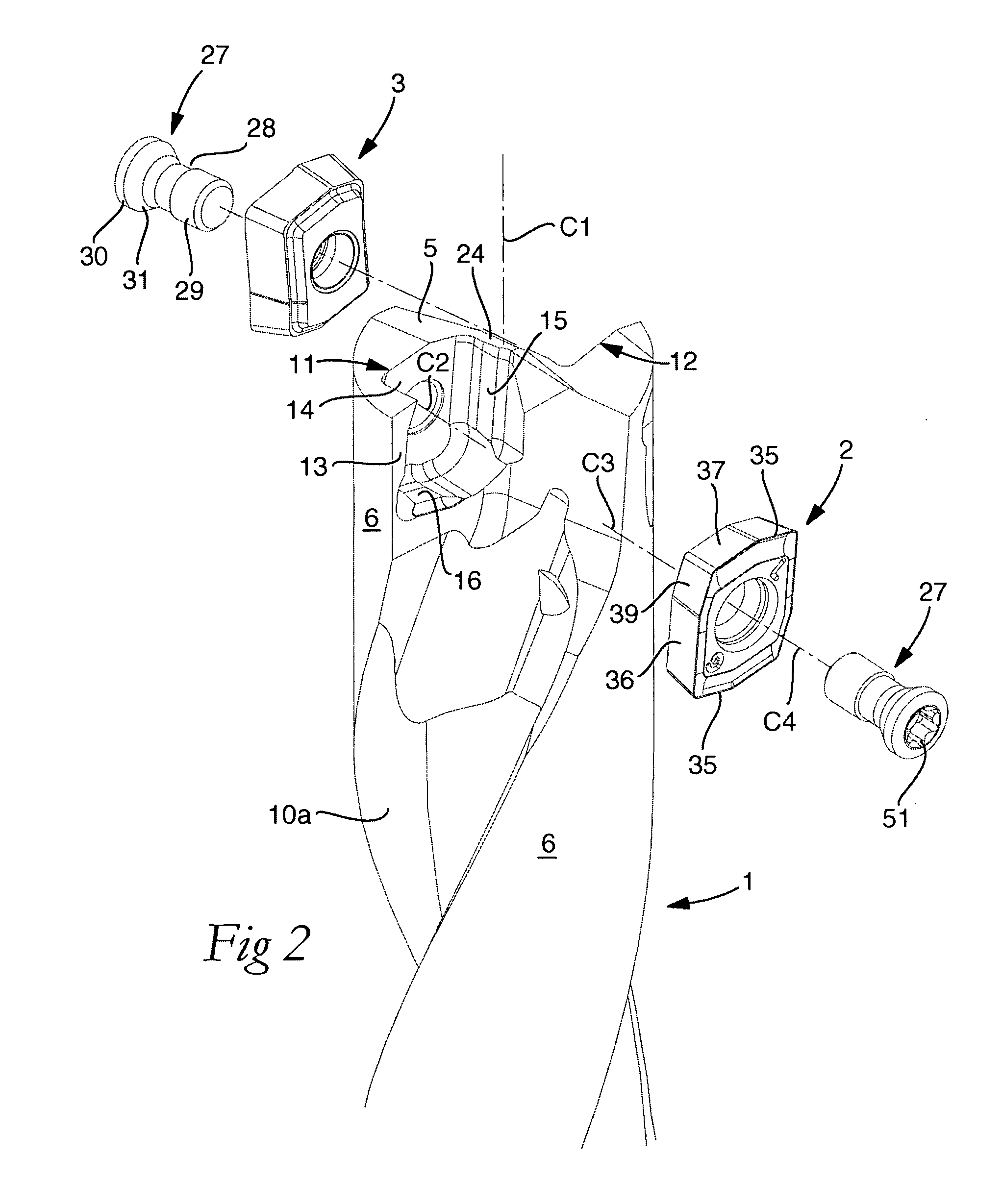

Indexable insert drill and a center insert therefore

ActiveUS20080181737A1Desired strengthDesired widthThread cutting toolsWood turning toolsAcute angleEngineering

A drill for chip removing machining, including a drill body that rotates around a center axis (C1) and has a rear end, and a front end from which there extends rearward an envelope surface in which two chip flutes each having an insert pocket are countersunk, and two replaceable cutting inserts, including a peripheral cutting insert mounted in a peripheral pocket, and a center insert, which is indexable and mounted in a center pocket that opens in the front end of the drill body and is delimited by a bottom surface, a rear end support surface, a side support surface of a partition wall, and an inside of a border adjacent to the envelope surface. The center insert includes an upperside and an underside between which a through hole for a tightening screw extends, and has an elongate basic shape that is mirror-symmetrical in relation to an imaginary, longitudinal central plane (P) with which a center axis (C3) of the hole coincides. One of two opposite, longitudinal side contact surfaces of the cutting insert which run parallel to each other and to the central plane (P), are urged against the side support surface of the center pocket. One of the two opposite end surfaces which are formed adjacent to chip-removing cutting edges at the short ends of the center insert, are urged against the rear end support surface of the center pocket. The side support surface of the center pocket is inclined in relation to the center axis (C1) of the drill body at an acute angle (ε) within the range of 3-8°. At each one of two diagonally opposite corners of the center insert, an intermediate surface is formed between the side contact surface and an end surface. The intermediate surface is shorter than the side contact surface and forms an obtuse angle (α) with the side contact surface. One of the intermediate surfaces is located in an area of a clearance space between the side support surface of the center pocket and the end support surface of the center pocket.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

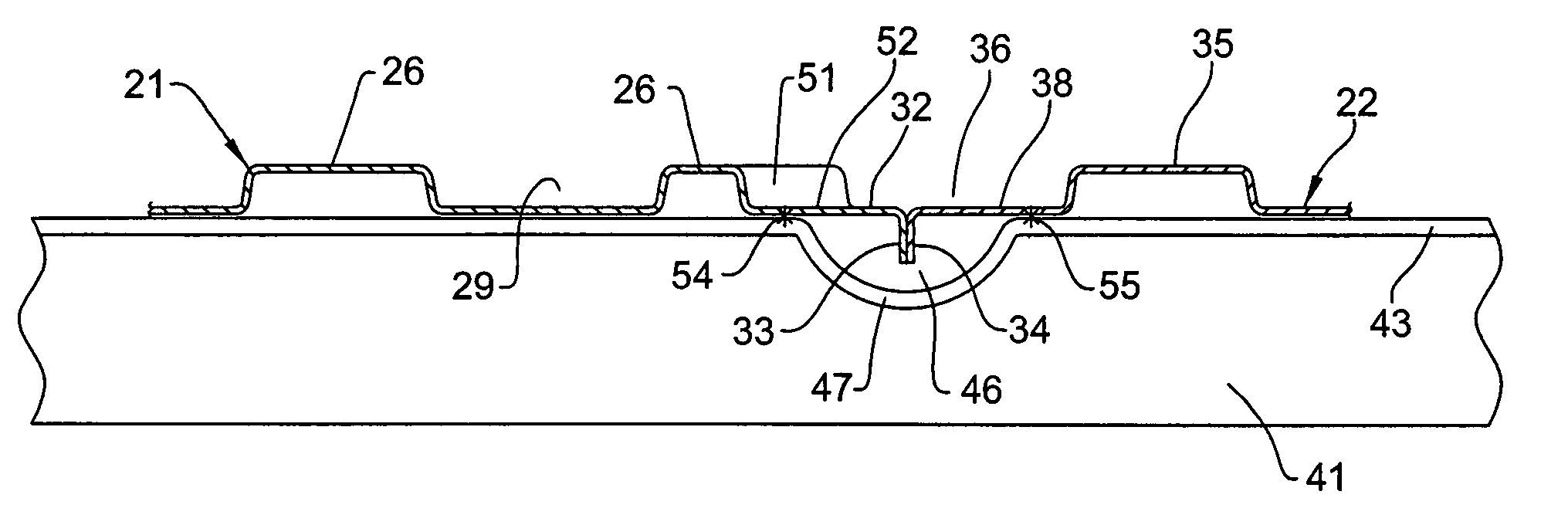

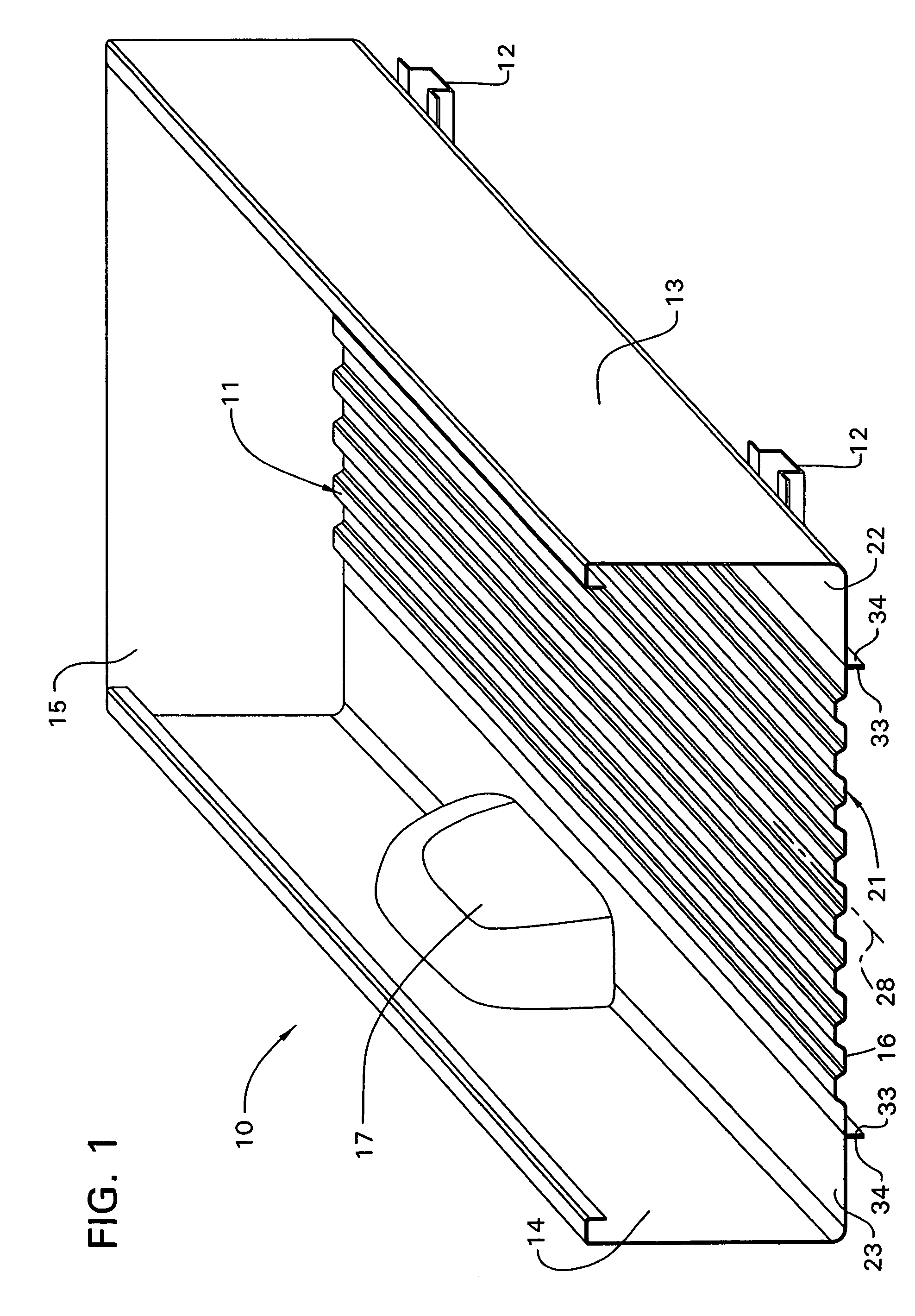

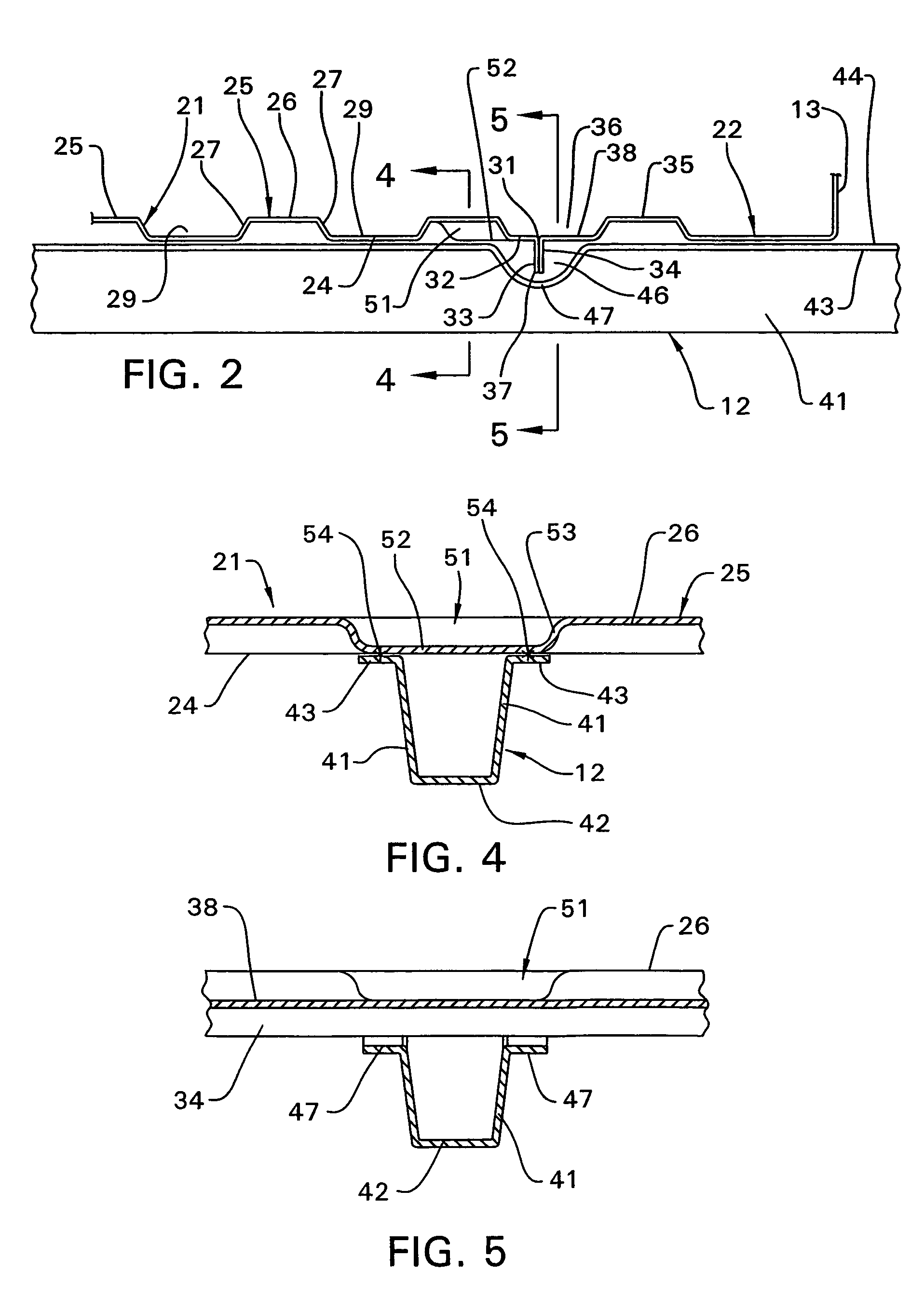

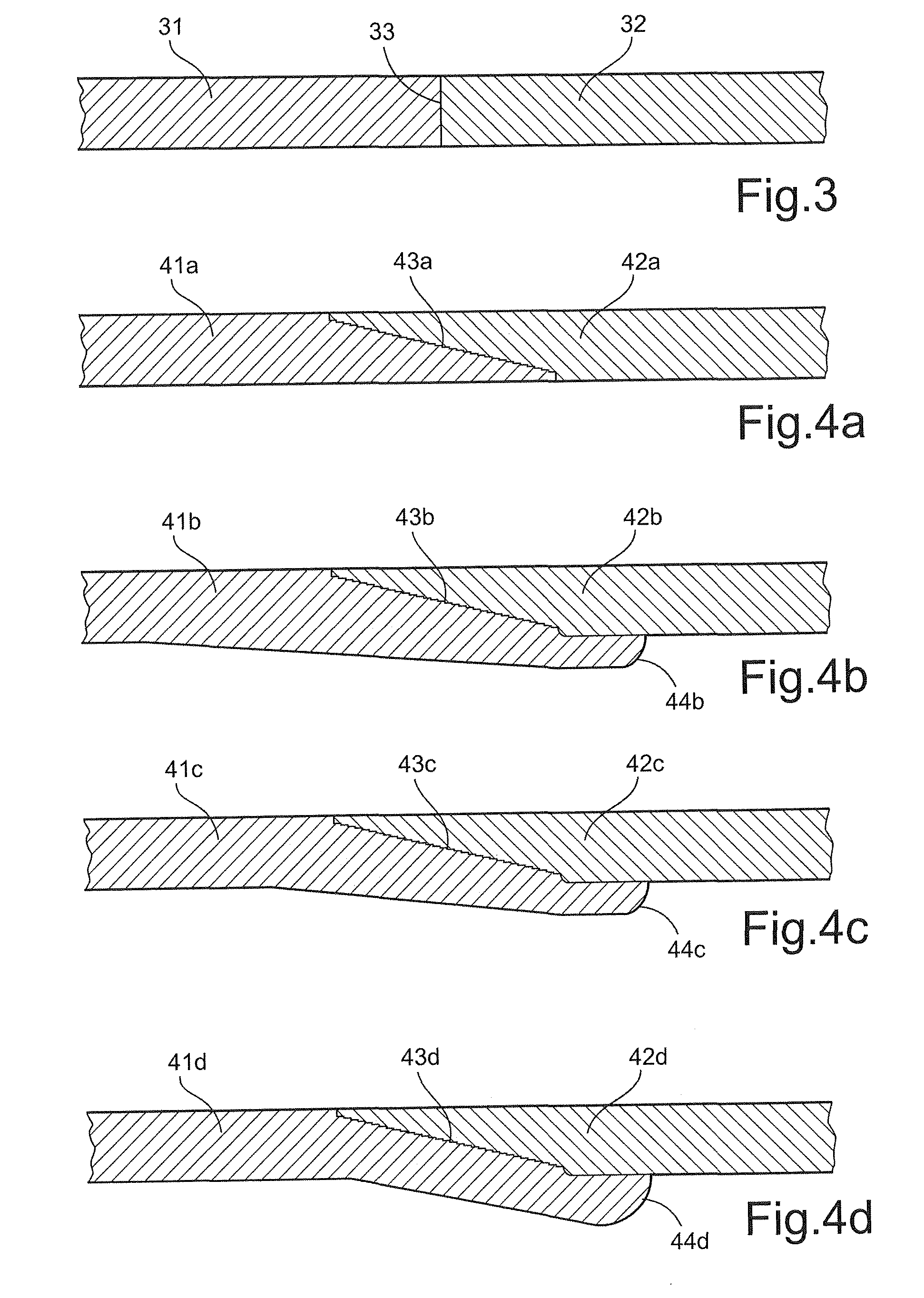

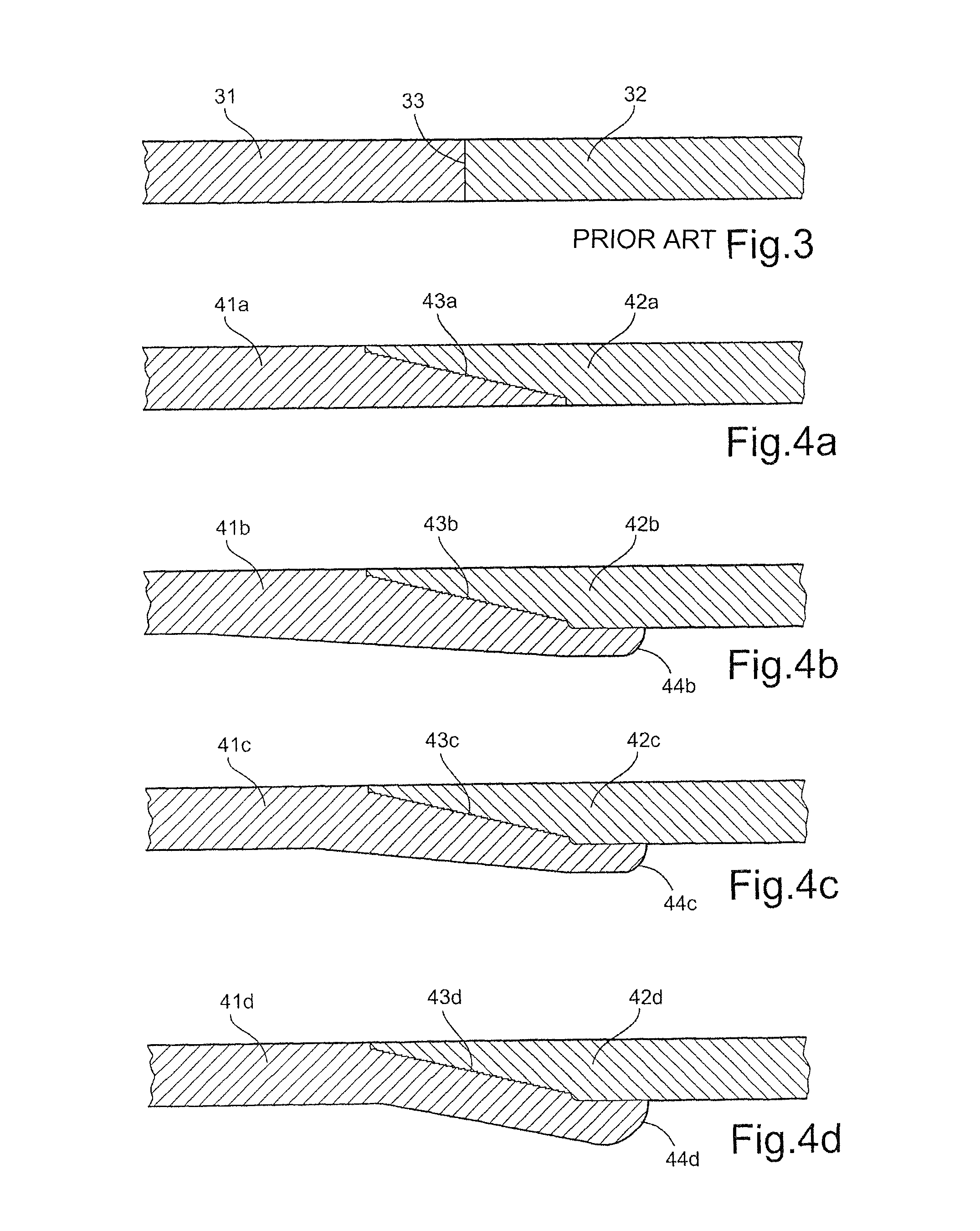

Vehicle bed and cross rail attachment

InactiveUS7152911B1Depth is minimizedMinimizes of depressionVehicle seatsSuperstructure subunitsThin metalCantilever

A bed arrangement for a vehicle including a horizontally large floor member defined by a thin metal sheet having a plurality of raised stiffening ribs extending lengthwise thereof. The floor member has a cantilevered edge flange extending along a lengthwise side edge thereof, which edge flange protrudes downwardly below a bottom surface of the floor member. A hat-shaped cross rail is disposed transversely under said floor member, and has a pair of top flanges which supportingly engages the bottom surface of the floor member. The cross rail, where it crosses the edge flange, has a depression formed therein to provide clearance for the edge flange. The top flanges having flange sections which are deformed downwardly to define the profile of the depression while maintaining the continuity of the top flanges as they extend lengthwise of the cross rail.

Owner:NOBLE ADVANCED TECH

Water-Soluble, Quick-Dissolve Flavor Tablets

InactiveUS20080187628A1Easily consumeReadily dissolveMilk preparationButtermilkChemistryWater soluble

The invention is directed to quick-dissolve flavor tablets for use by consumers in flavoring beverages, such as water, and methods for flavoring such beverages. The tablet comprises a flavor component and a quick-dissolve carrier component which disintegrates rapidly upon placement into the beverage container with minimal residue.

Owner:CHAMPION MELINDA L

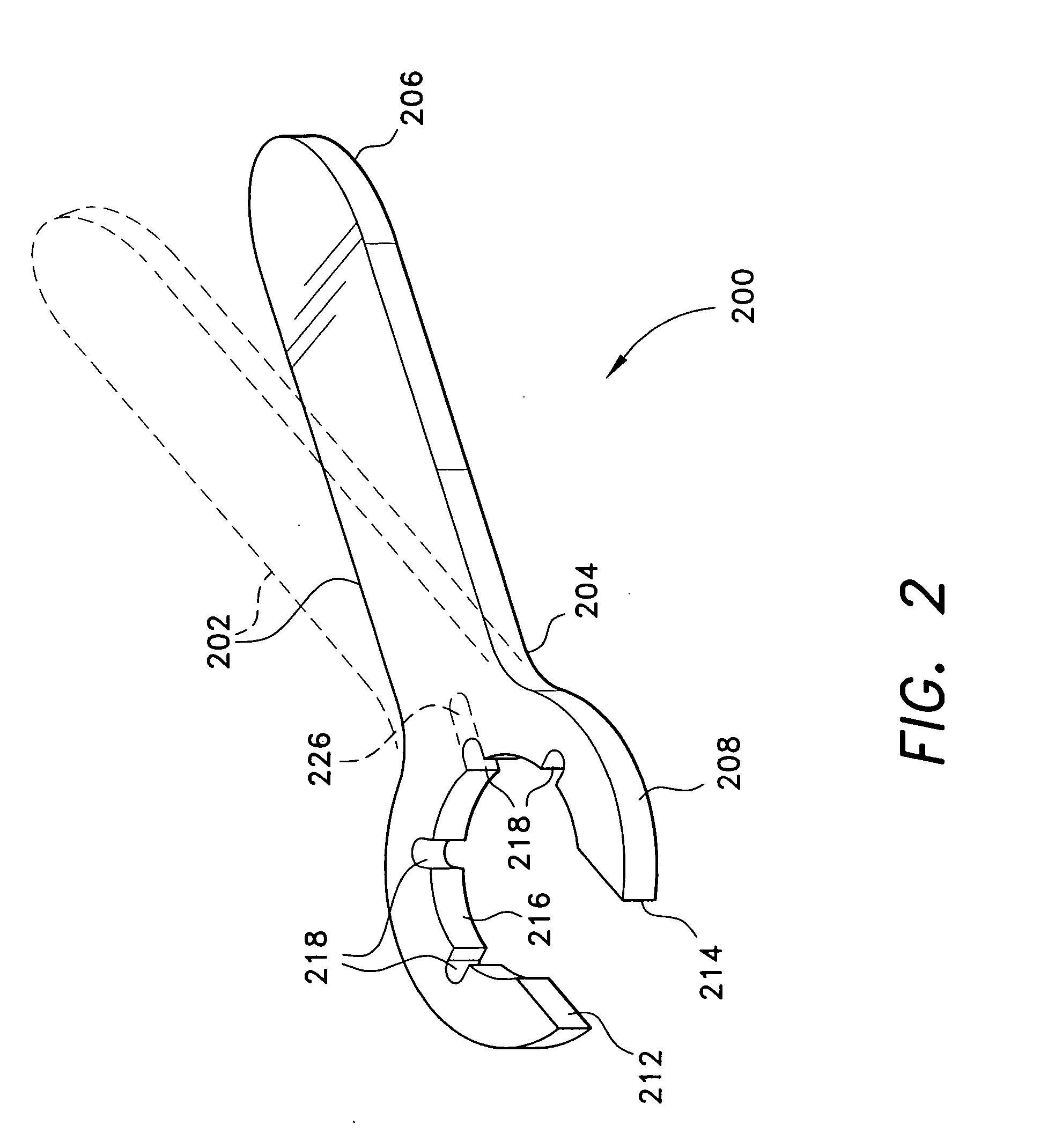

Toilet ballcock valve wrench

The present invention comprises a series of embodiments of a toilet ballcock valve wrench, configured for use on at least one of the retainer nuts and / or supply line nuts used conventionally in a toilet tank ballcock valve installation. The present wrench may be single or double ended, with double ended embodiments including heads adapted for use on the ballcock valve retainer nut and smaller supply line nut, or on different configurations of the retainer nut. The ends may have axial and / or planar offset, or may be straight, as desired. The present wrench in any of its embodiments may be formed as a flat metal stamping or otherwise formed (stamped, forged, etc.) of metal, or may be cast or otherwise formed of a plastic material for lighter duty work and / or limited use, if so desired. The plastic embodiments each include a series of ribs and central webs, for sufficient strength.

Owner:RUSSELL LYNN R

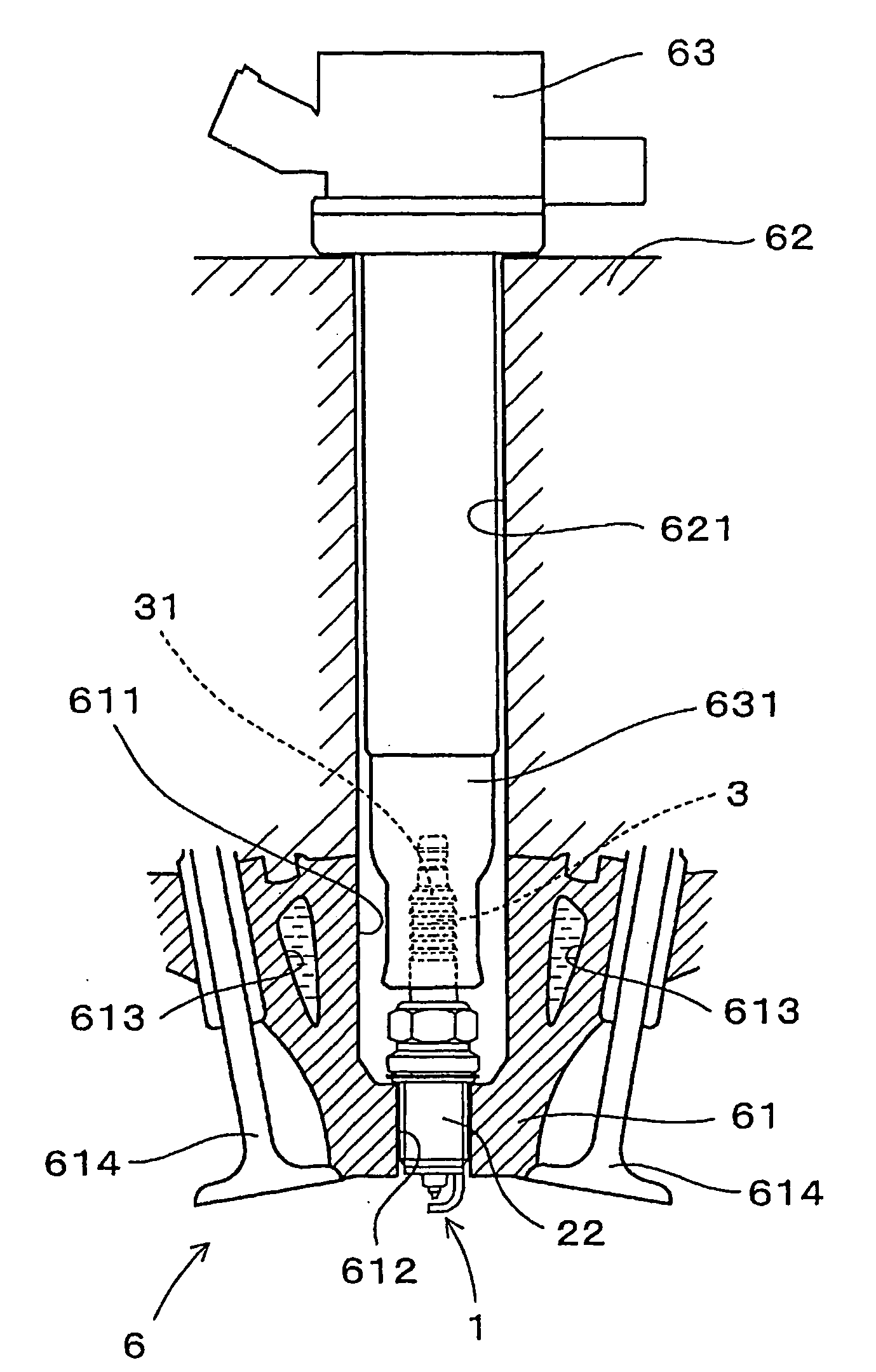

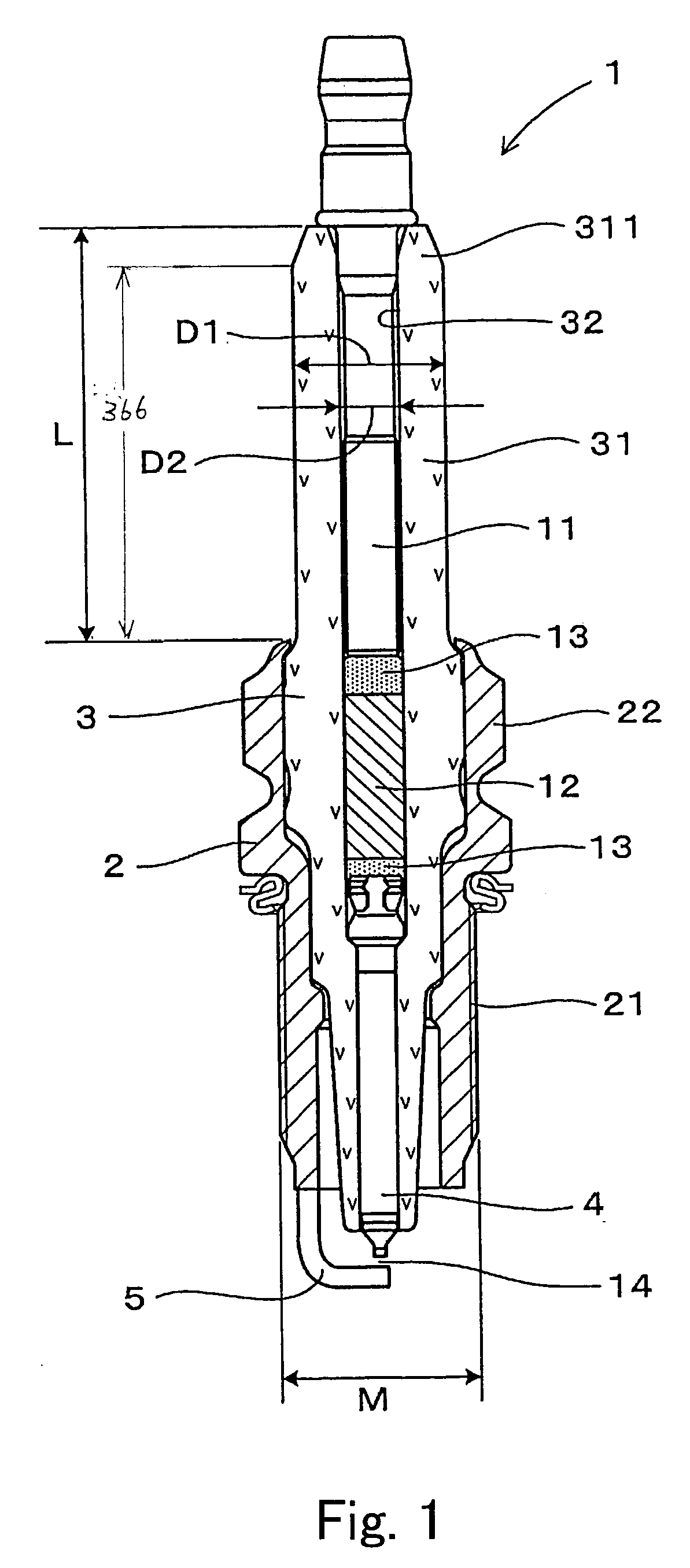

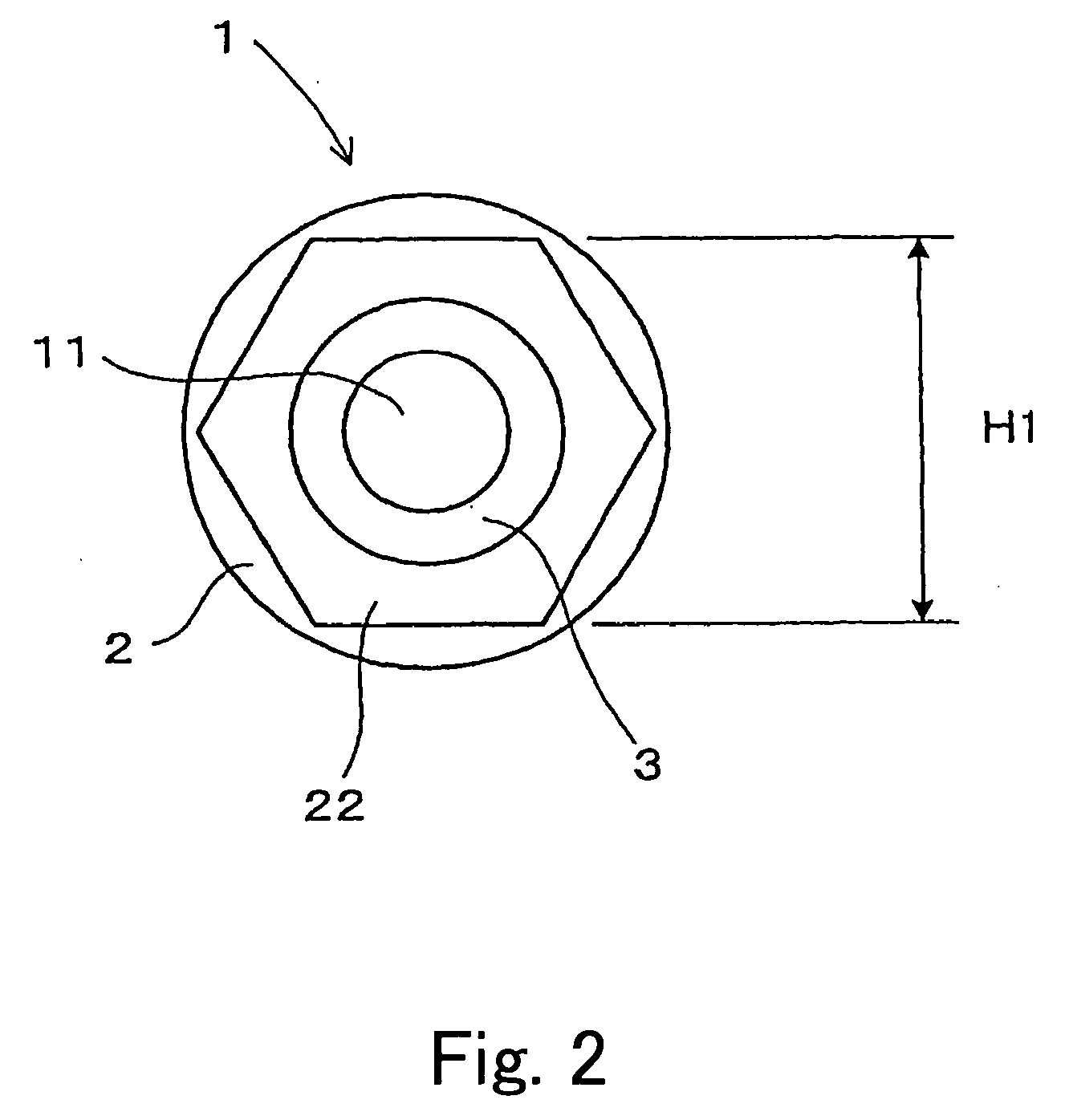

Spark plug with increased durability

InactiveUS20060042610A1Desired strengthSmall sizeSparking plugsMachines/enginesEndurabilityEngineering

A spark plug is provided which is designed to be compact without sacrificing a mechanical strength of a porcelain insulator. The spark plug includes a metal shell having a base end and a top end. The porcelain insulator is made of a hollow cylinder which includes a body and an insulator head. The body is retained within the metal shell. The insulator head extends from the base end of the metal shell in a lengthwise direction of the porcelain insulator and has a length made up of a major body leading to the body of the porcelain insulator and an end portion lying far away from the body. The major body has an outer diameter D1, an inner diameter D2, and a section modulus Z at a smallest-outer diameter portion thereof which meet relations of 7.1 mm≦D1≦8.8 mm, D2≧2.8 mm, and Z≧33 mm3.

Owner:DENSO CORP

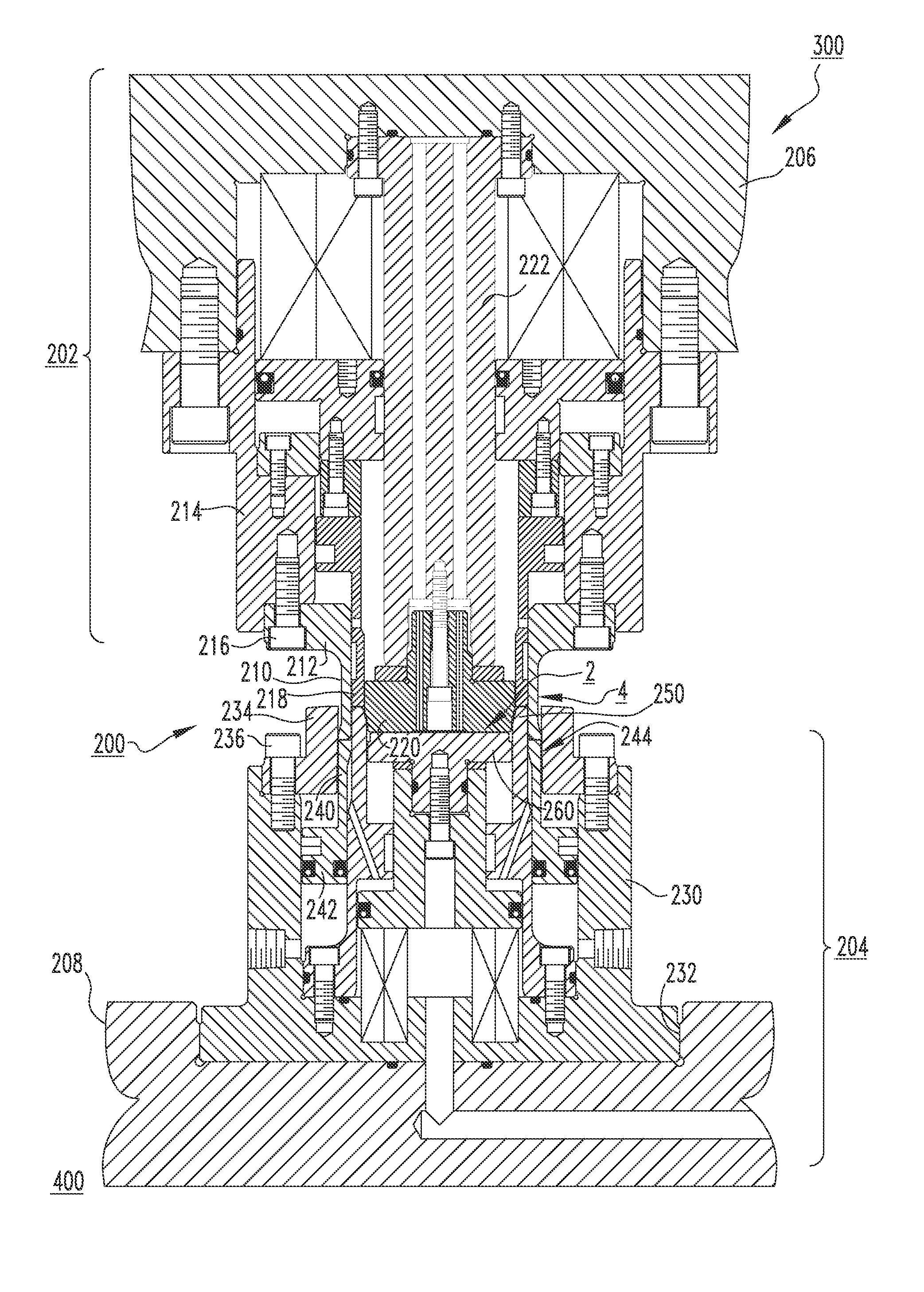

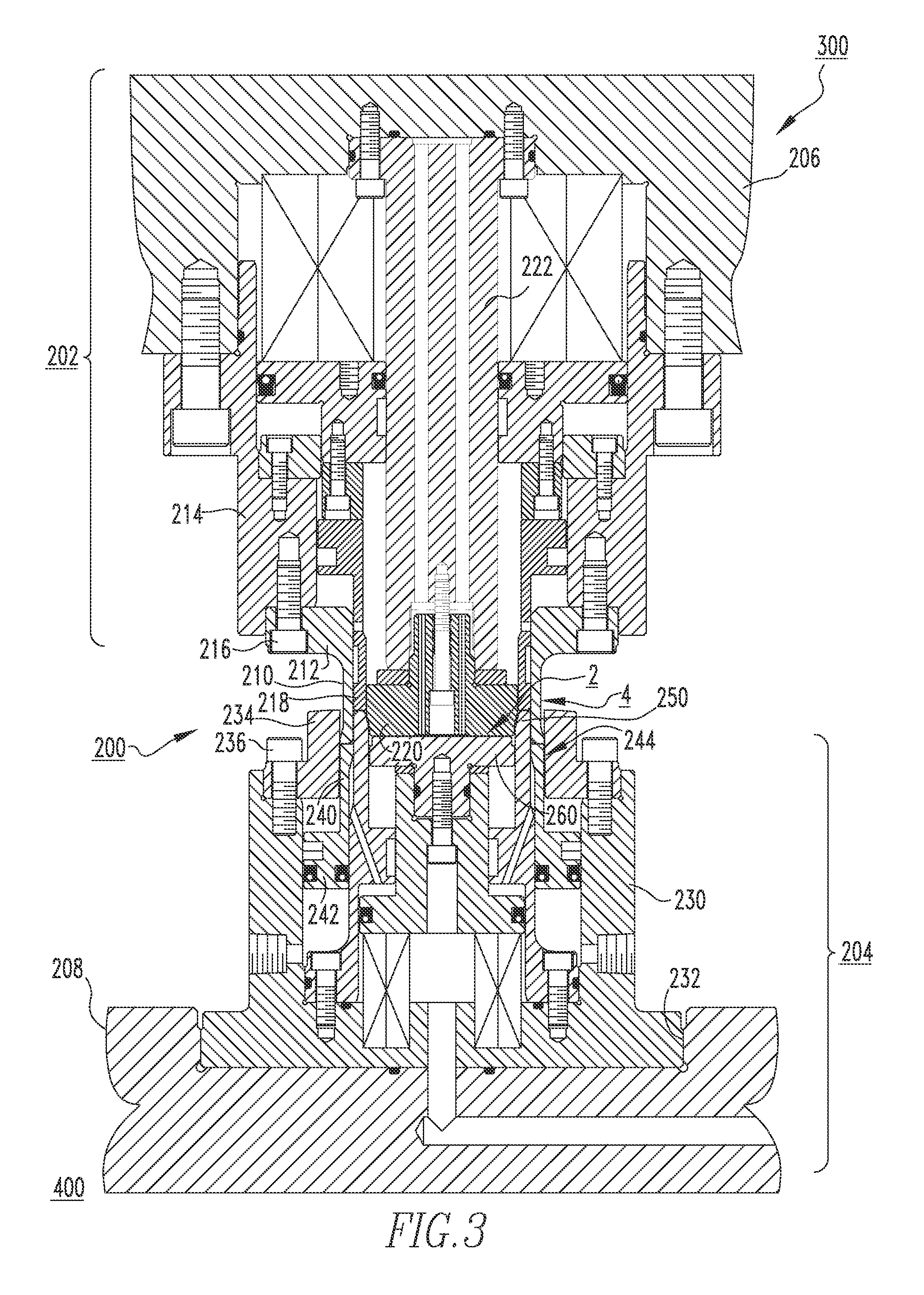

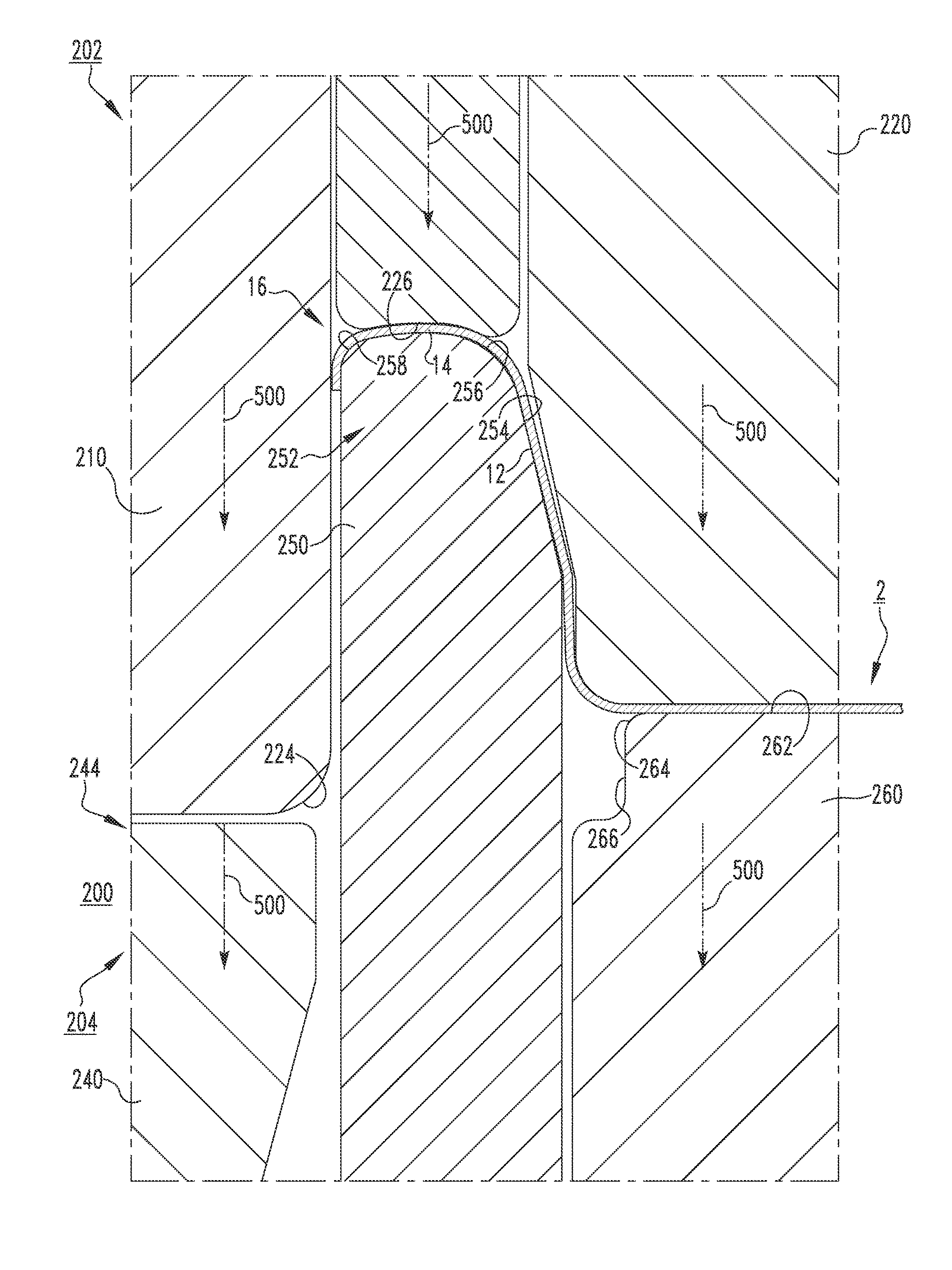

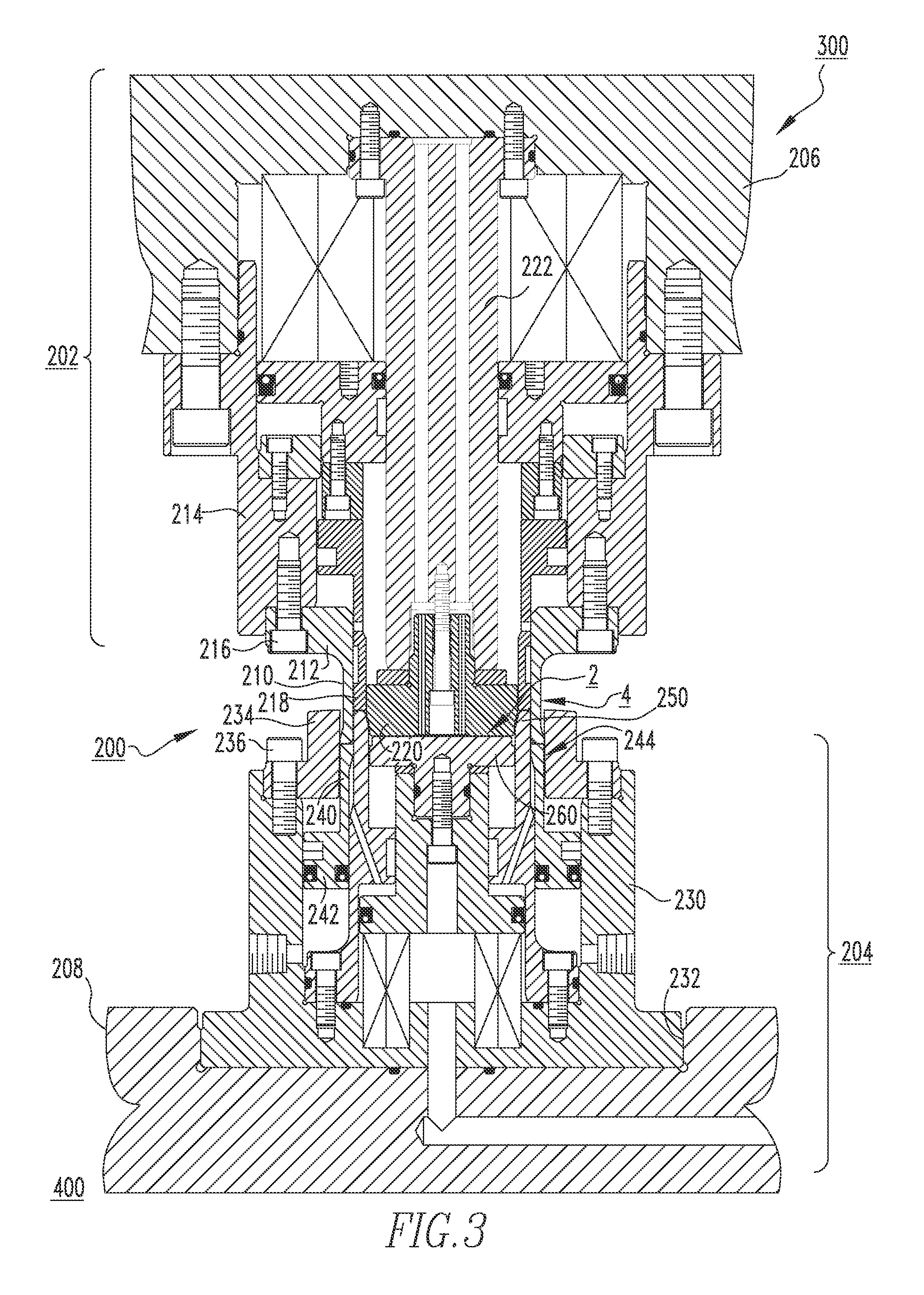

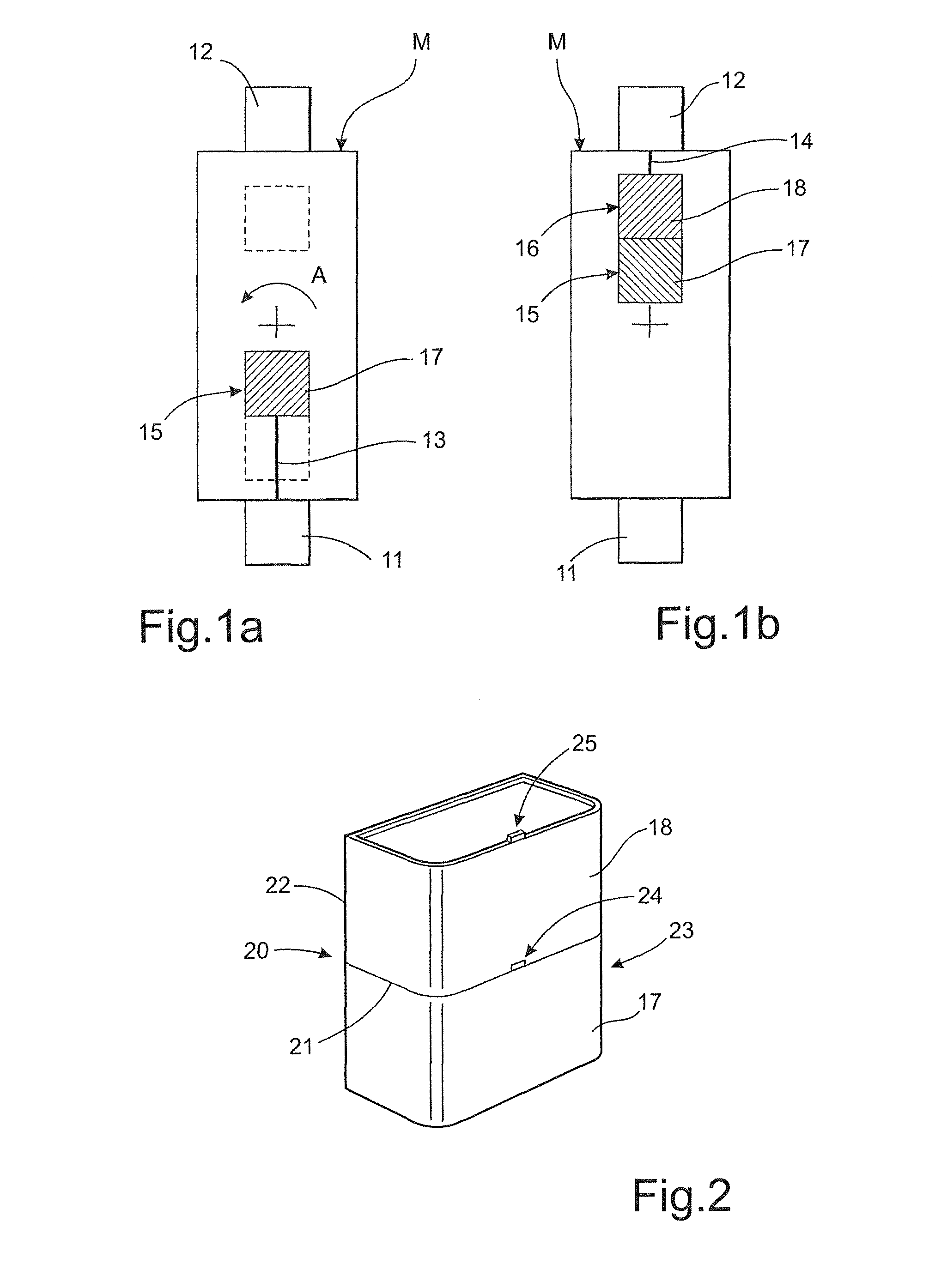

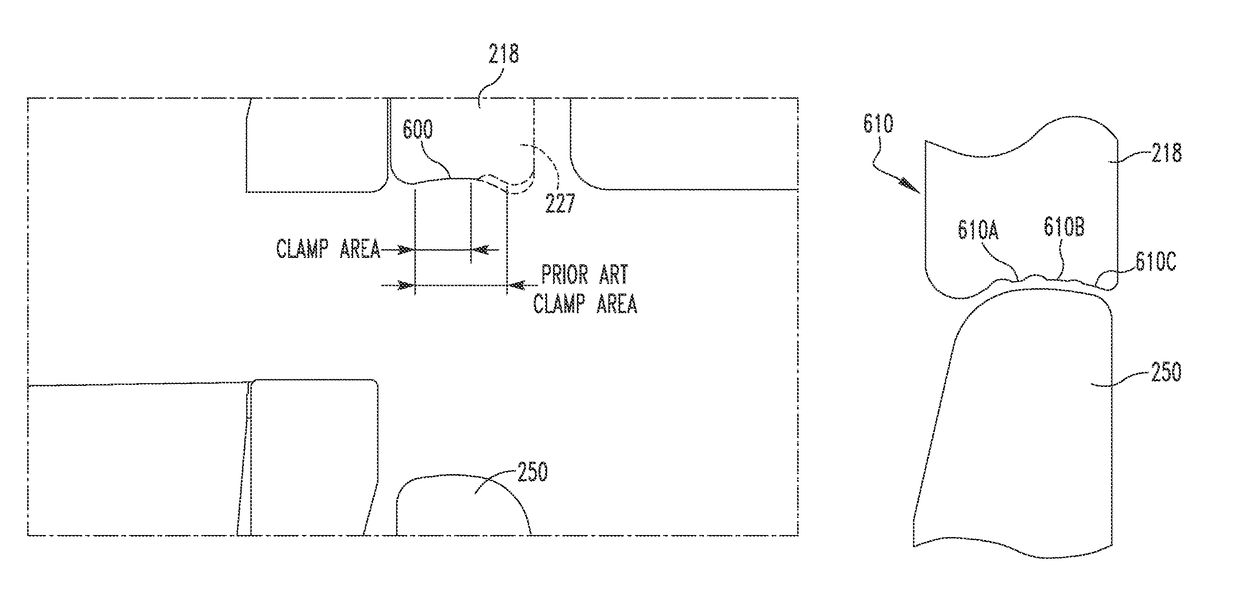

Container, and selectively formed shell, and tooling and associated method for providing same

ActiveUS20130309043A1Reduce the amount requiredDesired strengthShaping toolsMetal-working feeding devicesEngineeringCountersink

A shell, a container employing the shell, and tooling and associated methods for forming the shell are provided. The shell includes a center panel, a circumferential chuck wall, an annular countersink between the center panel and the circumferential chuck wall, and a curl extending radially outwardly from the chuck wall. The material of at least one predetermined portion of the shell is selectively stretched relative to at least one other portion of the shell, thereby providing a corresponding thinned portion.

Owner:STOLLE MACHINERY

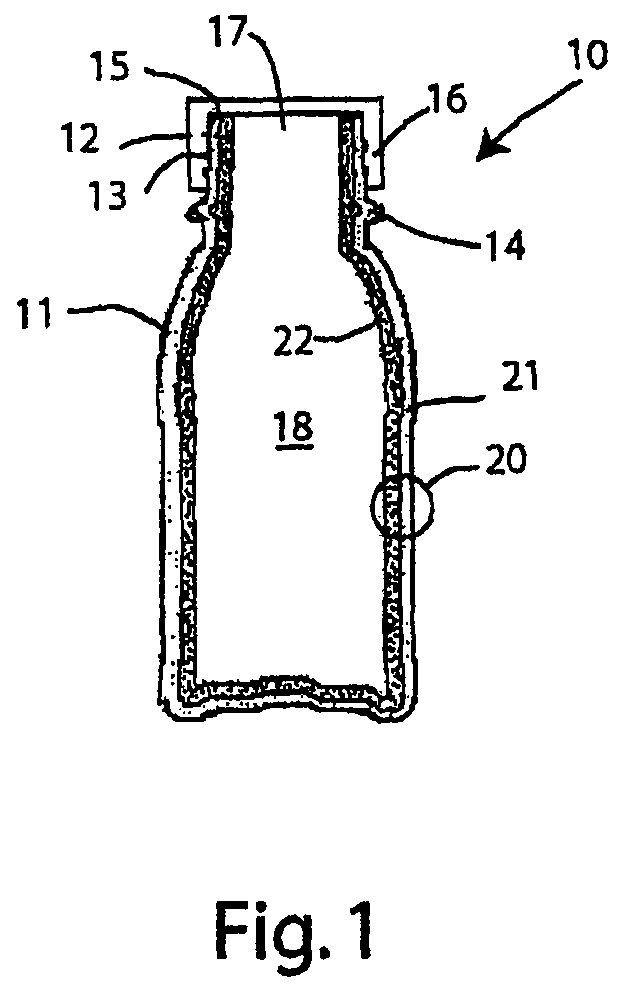

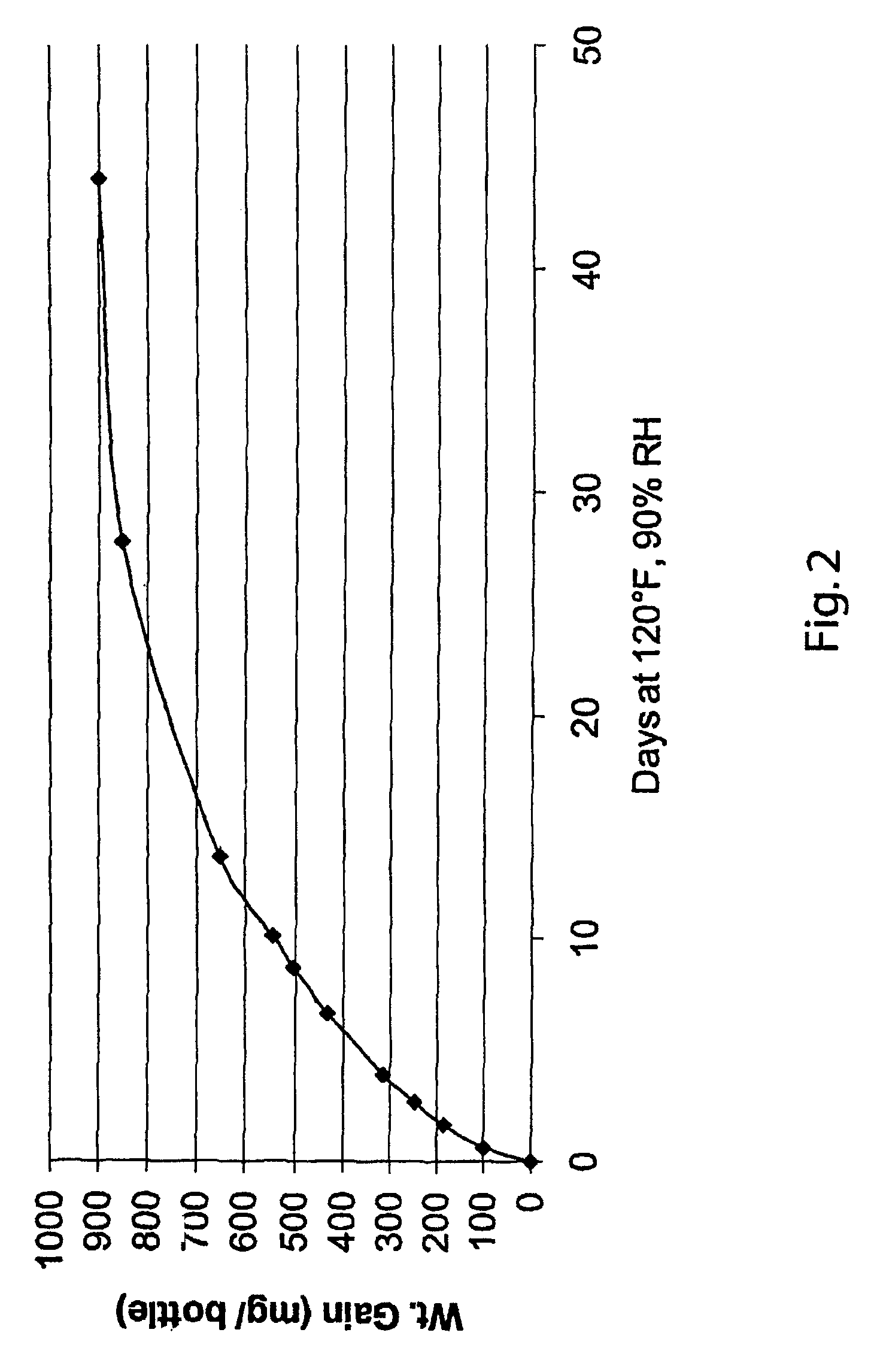

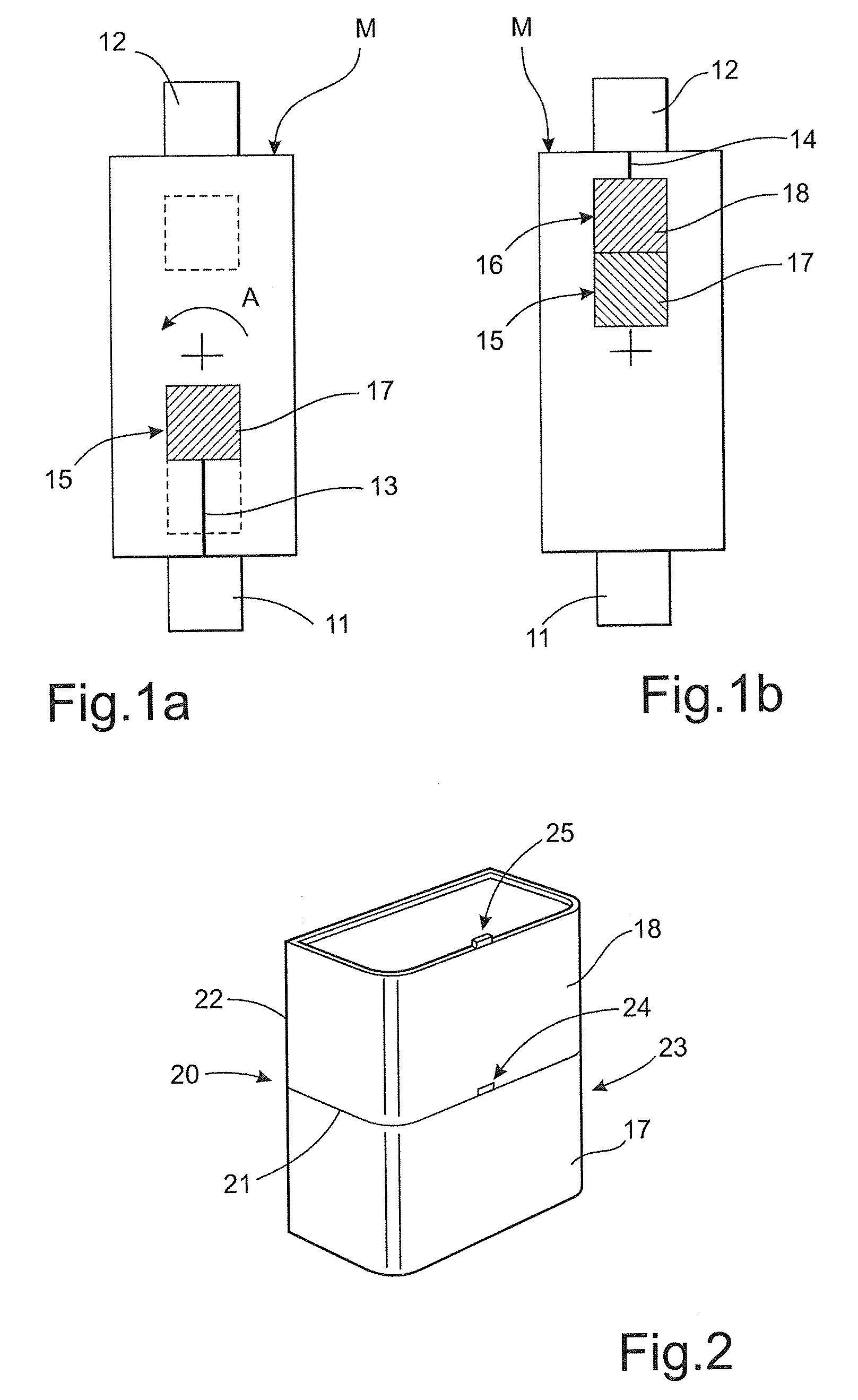

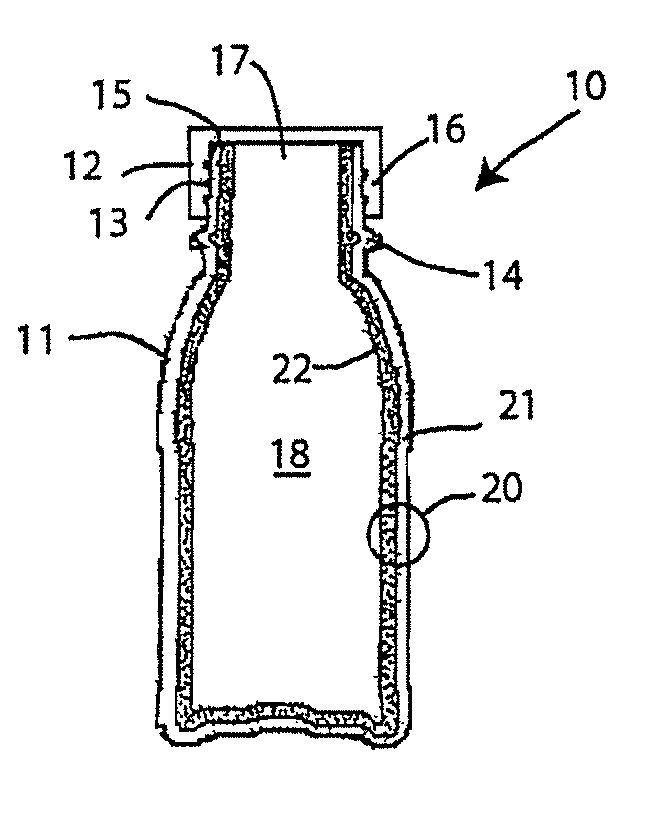

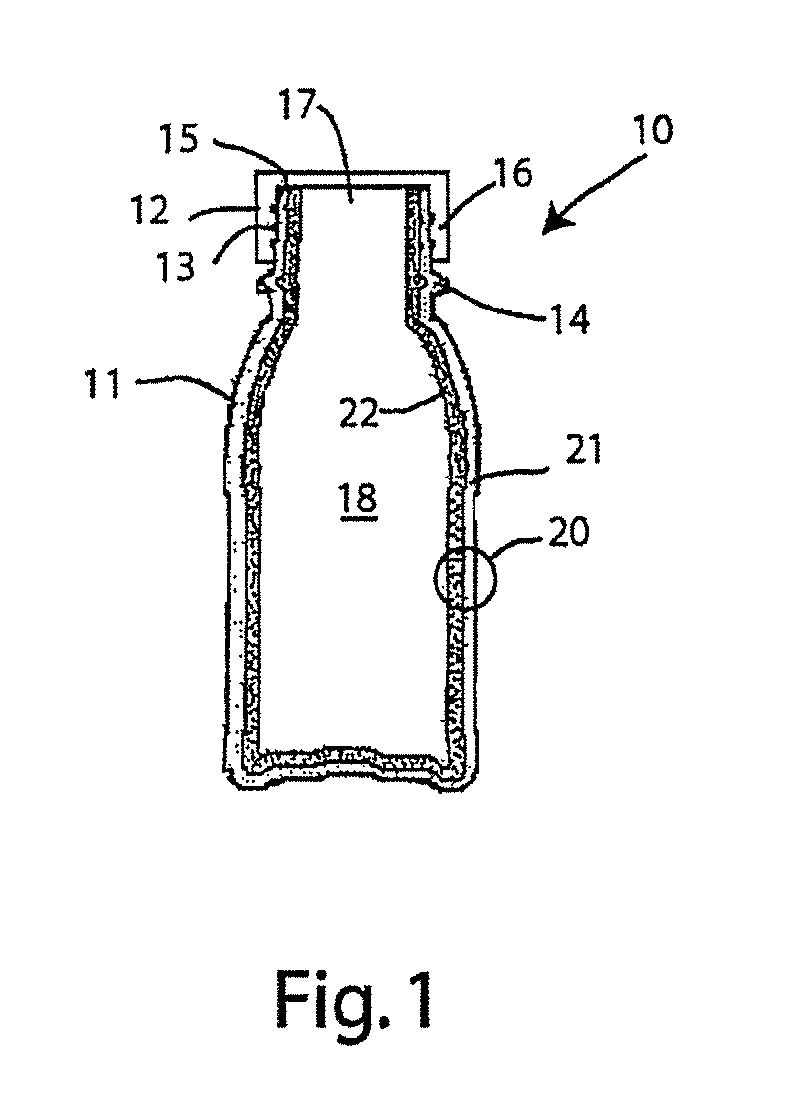

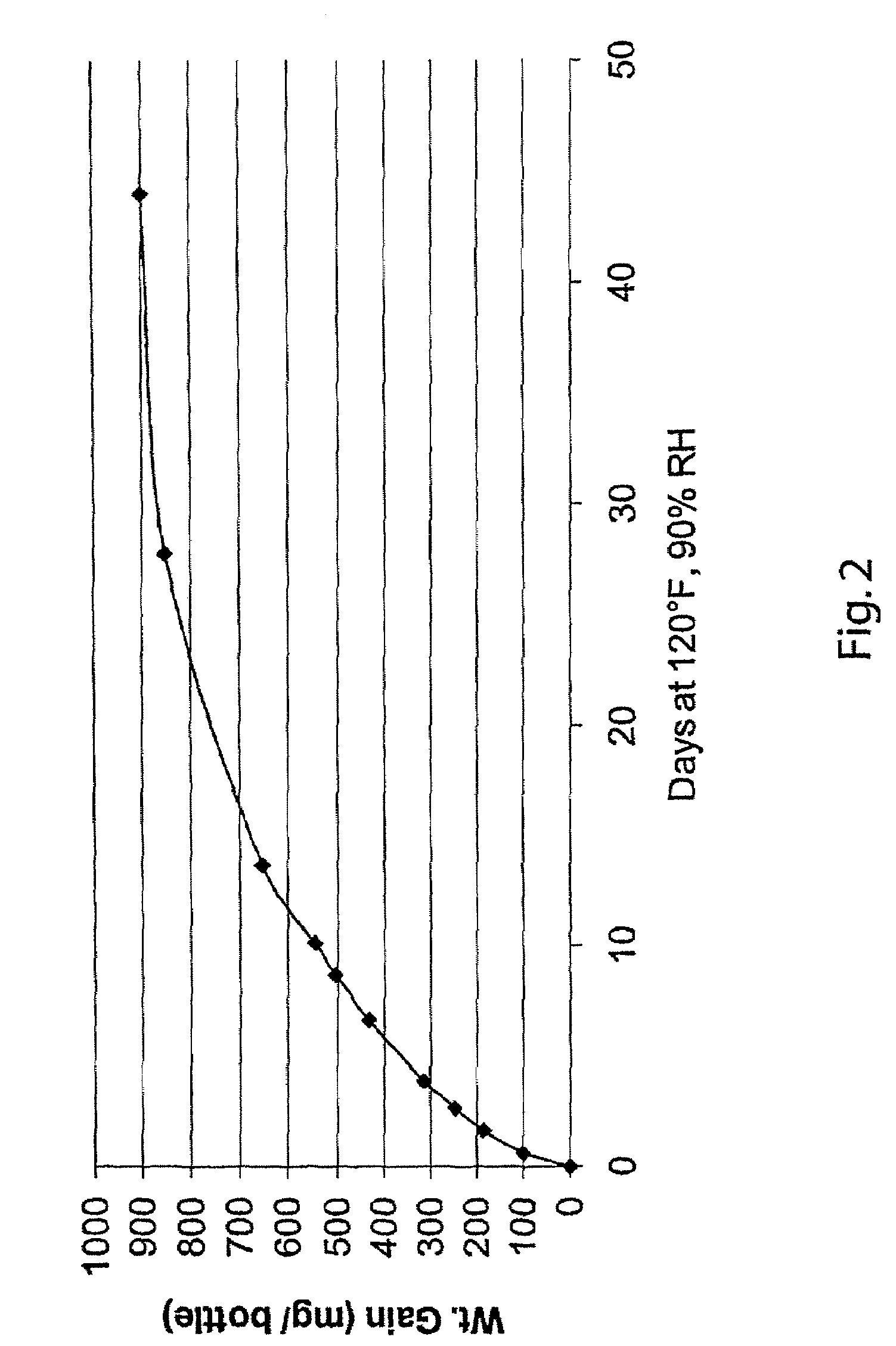

Containers intended for moisture-sensitive products

InactiveUS7871558B2Desired rigidityDesired strengthSynthetic resin layered productsDomestic containersDesiccantEngineering

Owner:ALCAN GLOBAL PHARMA PACKAGING

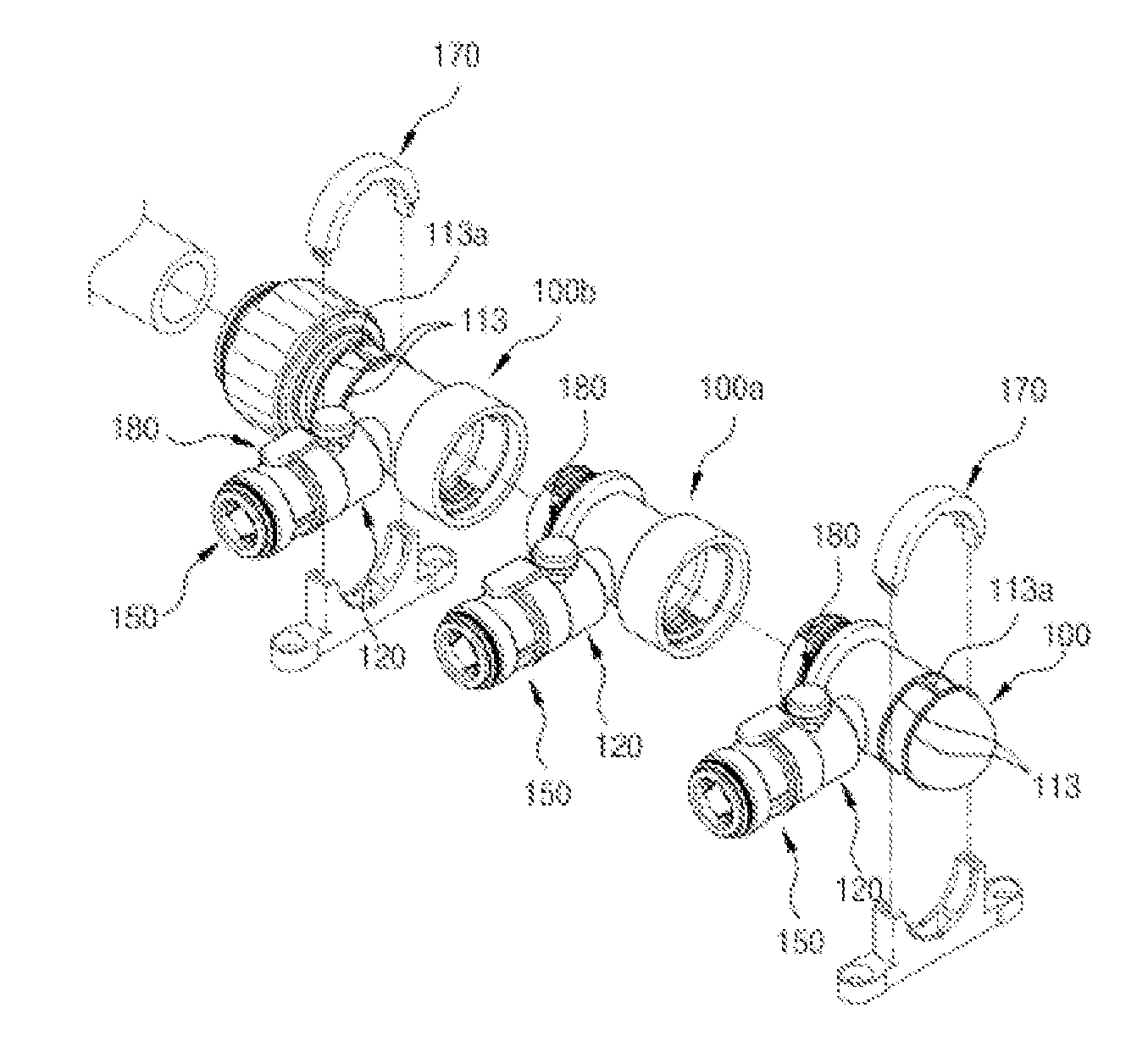

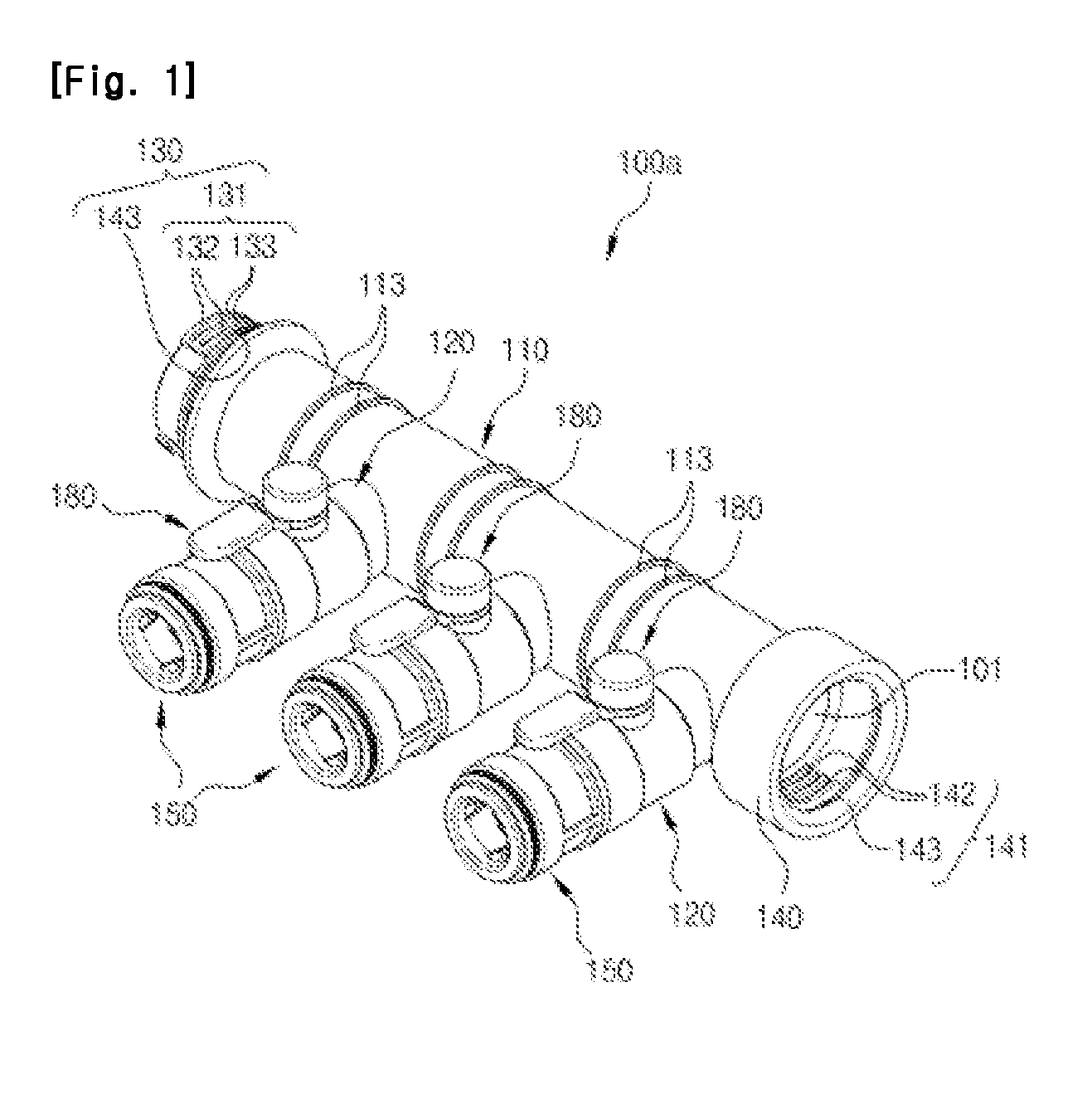

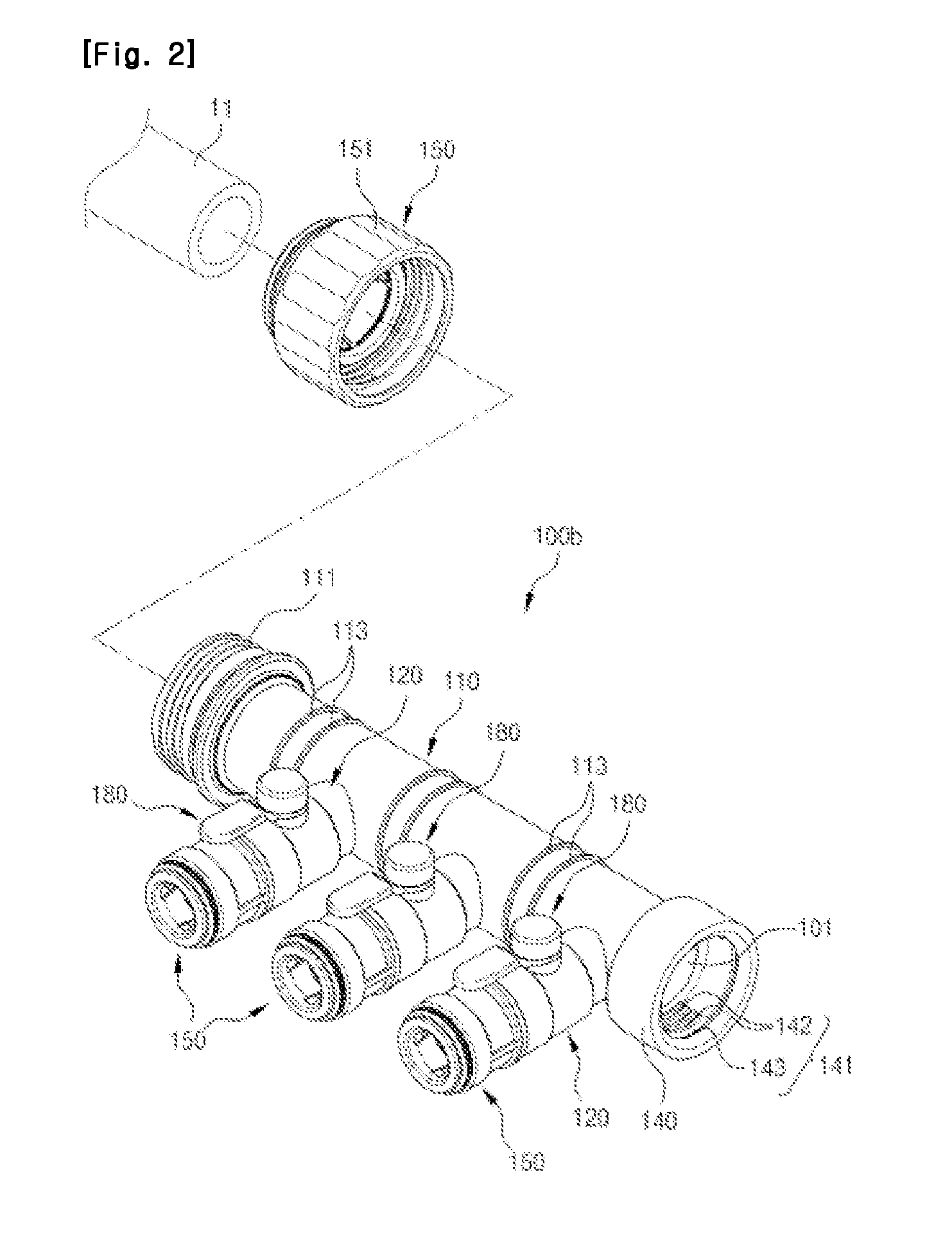

Branch pipe

ActiveUS20120312404A1Enhanced couplingAvoid couplingPipe supportsLighting and heating apparatusEngineering

The manifold type pipe structure according to the present invention is characterized in that at least branch pipe is formed at a pipe passage having a flow hole through which fluid flows, and an input valve is formed at an end portion of the pipe passage, and a joint coupler forming an output valve at the other end portion is prepared, and an output valve of a joint coupler of the other places is joint-connected with a limited rotation angle at an input valve of at least one joint coupler.

Owner:CHOI YUK NAM

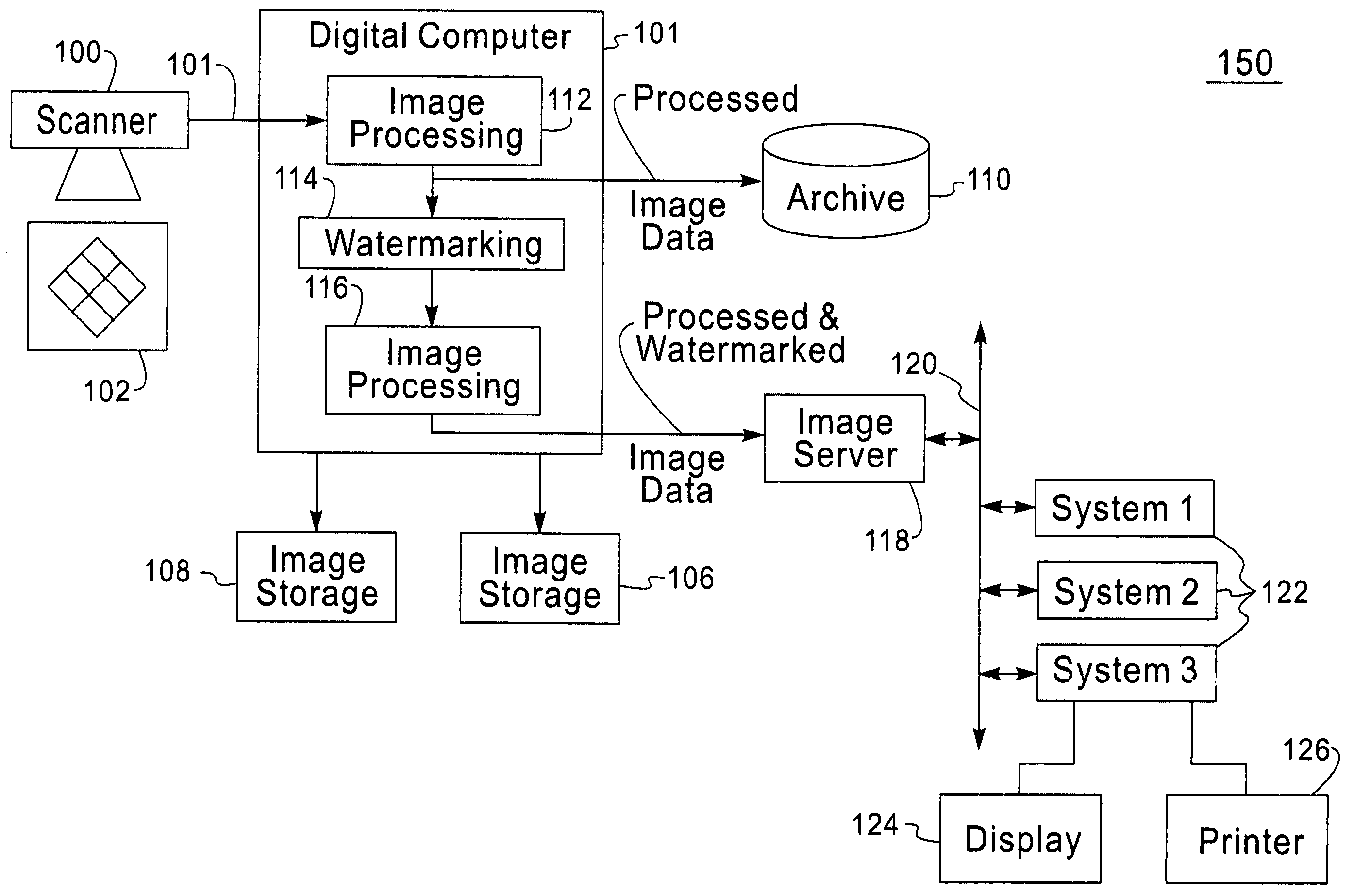

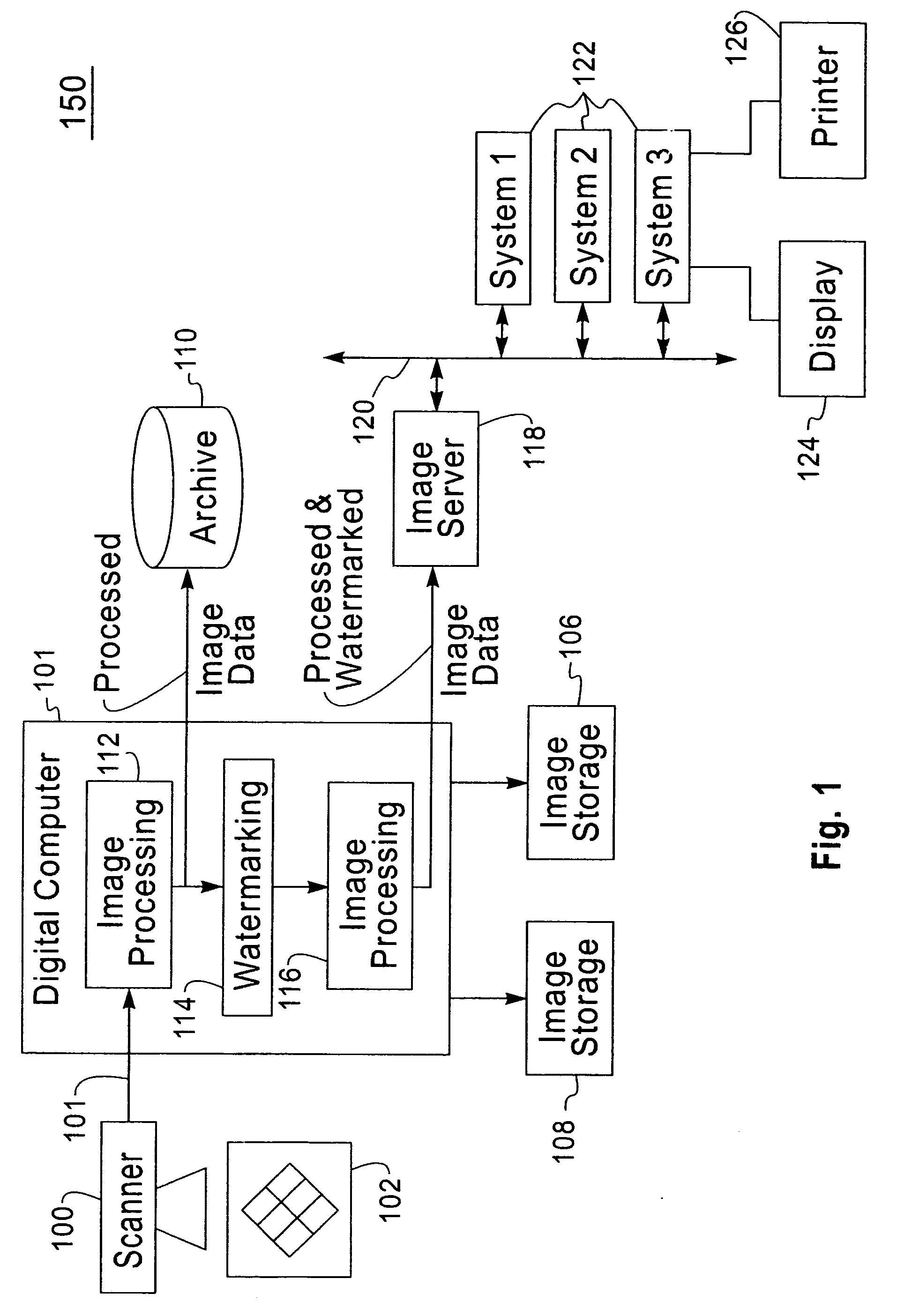

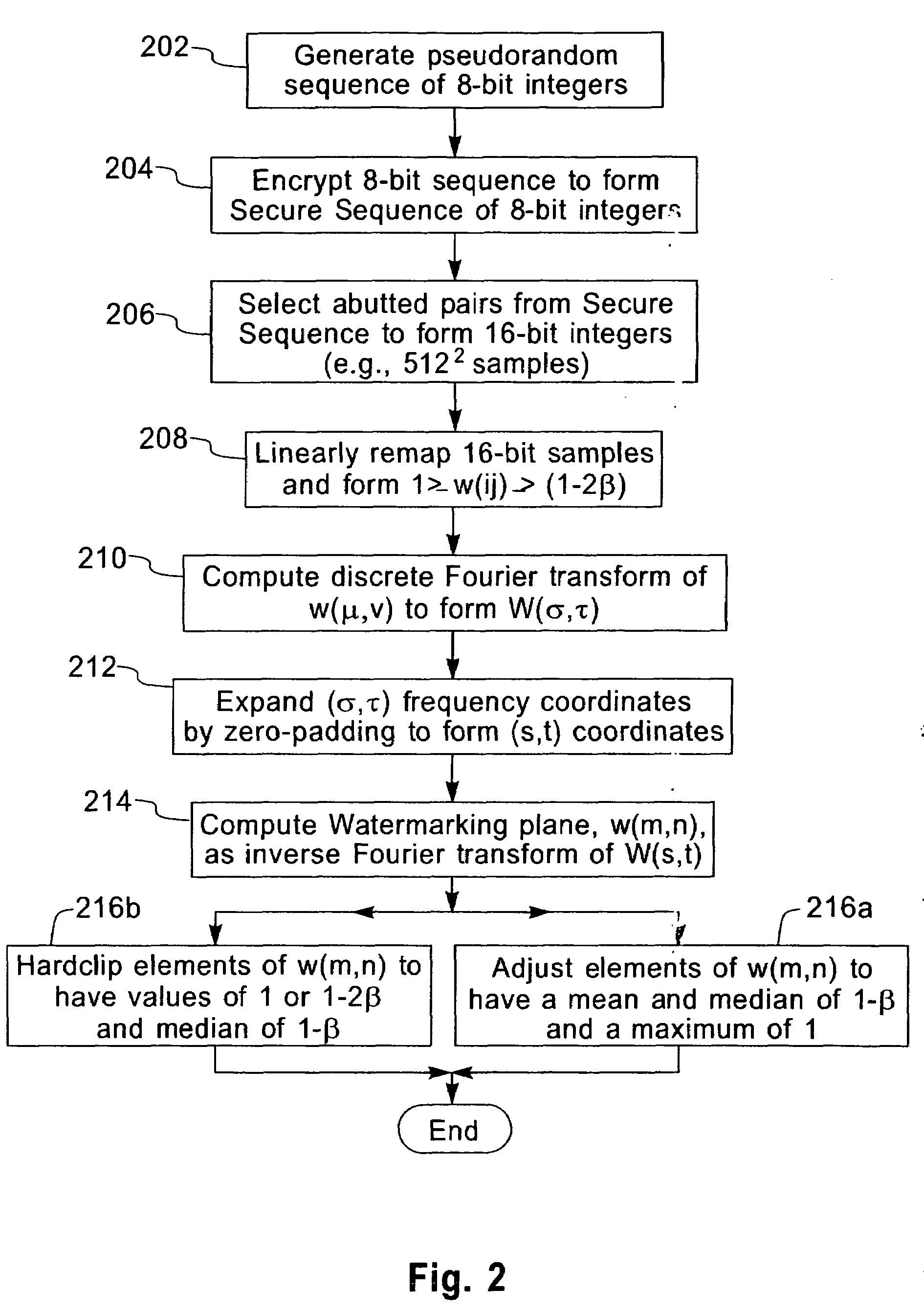

Protecting images with an image watermark

InactiveUS20080212824A1Desired strengthCharacter and pattern recognitionImage watermarkingComputer graphics (images)Pixel brightness

A robust means of watermarking a digitized image with a highly random sequence of pixel brightness multipliers is presented. The random sequence is formed from ‘robust-watermarking-parameters’ selected and known only by the marker and / or the marking entity. A watermarking plane is generated which has an element array with one-to-one element correspondence to the pixels of the digitized image being marked. Each element of the watermarking plane is assigned a random value dependent upon a robust random sequence and a specified brightness modulation strength. The so generated watermarking plane is imparted onto the digitized image by multiplying the brightness value or values of each pixel by its corresponding element value in the watermarking plane. The resulting modified brightness values impart the random and relatively invisible watermark onto the digitized image. Brightness alteration is the essence of watermark imparting. Detection of an imparted watermark requires knowing the watermarking plane with which the watermark was imparted. Regeneration of the watermarking plane requires knowledge of the robust-marking-parameters used in its formulation. This is generally only known to the marker and / or marking entity. Once regenerated the watermarking plane is used together with a verifying image located in a ‘visualizer’ to demonstrate the existence of the watermark.

Owner:IBM CORP

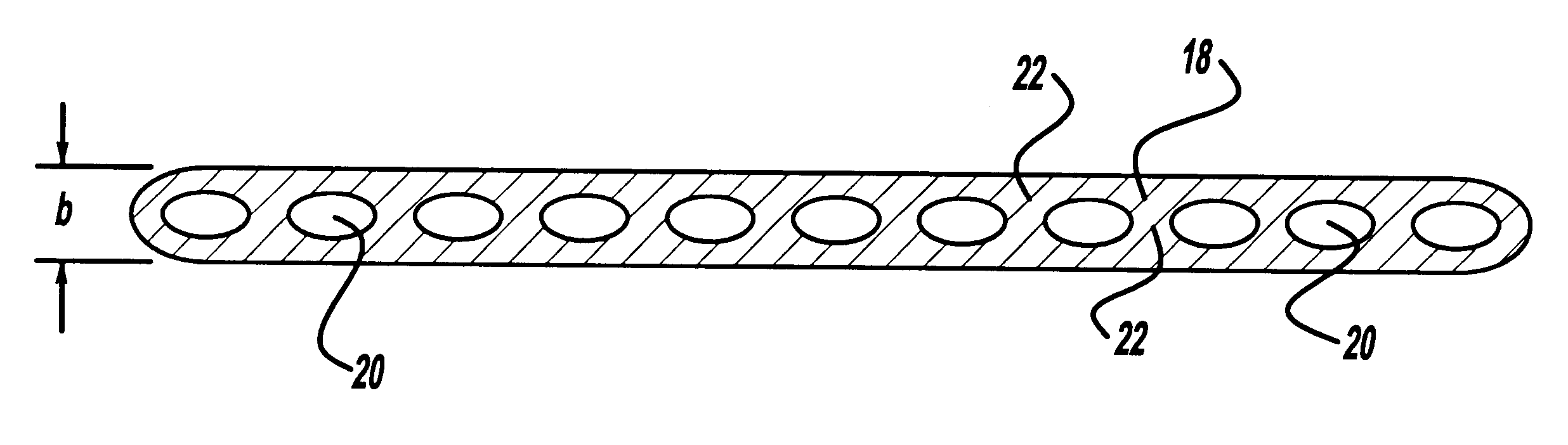

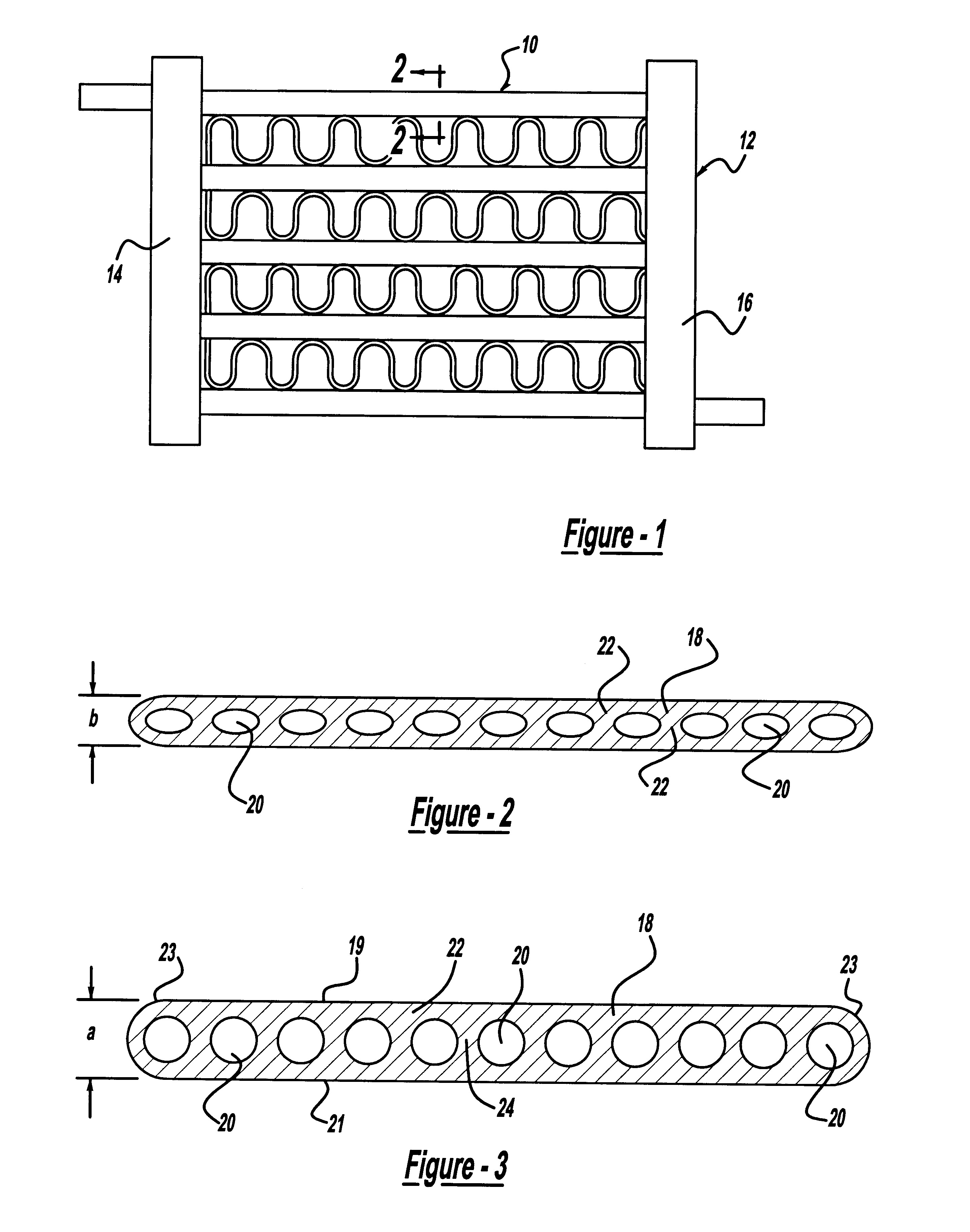

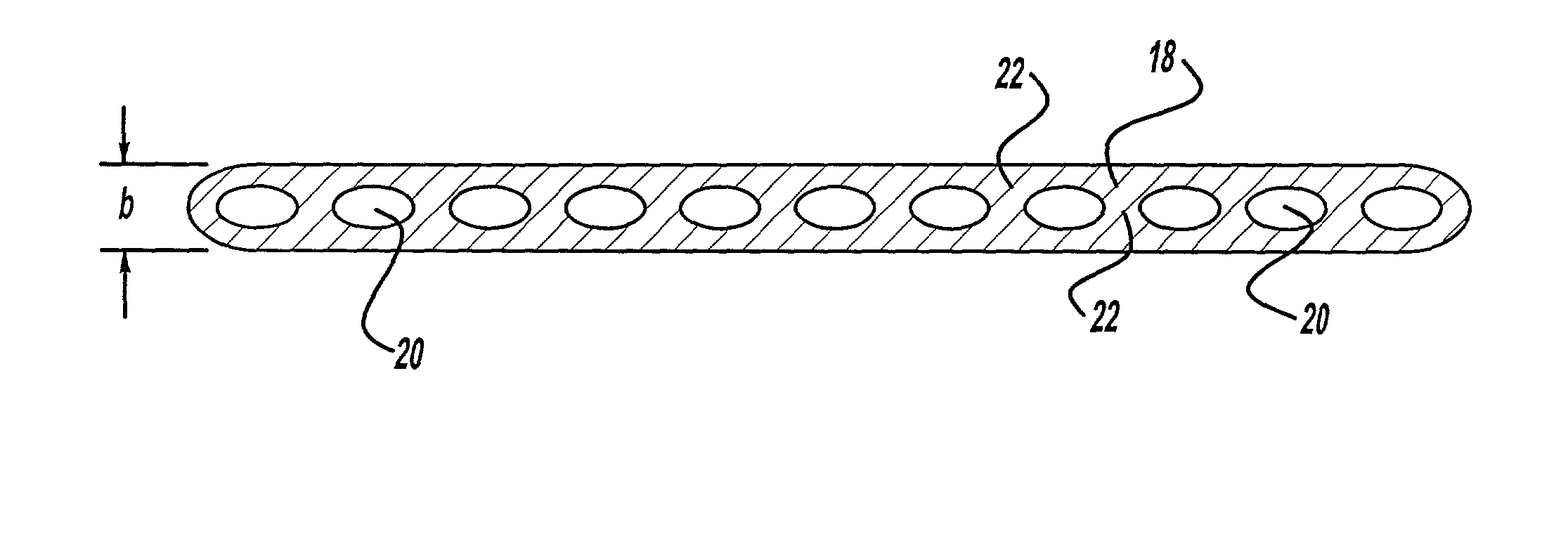

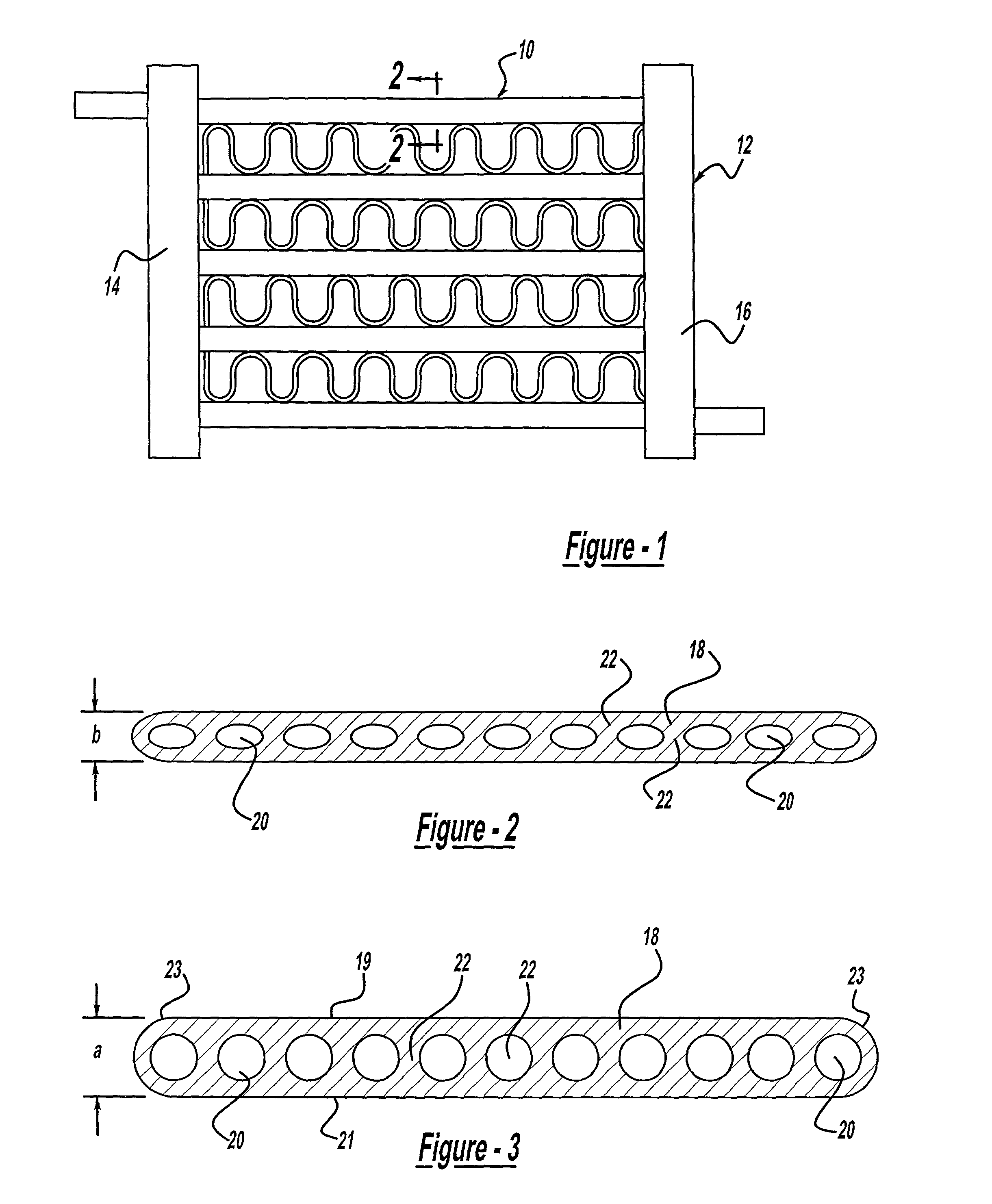

Multivoid heat exchanger tubing with ultra small voids and method for making the tubing

InactiveUS6536255B2Improves grain size and metallurgical strengthDesired strengthStationary conduit assembliesTubular elementsUltimate tensile strengthGrain growth

This invention is a process for making micro-multiport tubing for use in heat exchangers. The tubing is a flat body with a row of side-by-side passageways, which are separated by upright webs. Processing of this tubing involves extrusion, a straightening and cutting operation, a rolling step to reduce the thickness of the flat body and to obtain ultra small voids, assembly and furnace brazing of the heat exchanger. This invention improves the grain size of the metal in the tubing and also improves the metallurgical strength of the tubing. There is at least 10 percent change in material thickness. The strain is concentrated at the center of the web and results in at least enough cold work to produce fine recrystallized grains during the brazing thermal cycle. The amount of grain growth is controlled and the improvement in the metallurgical strength is achieved.

Owner:BRAZEWAY

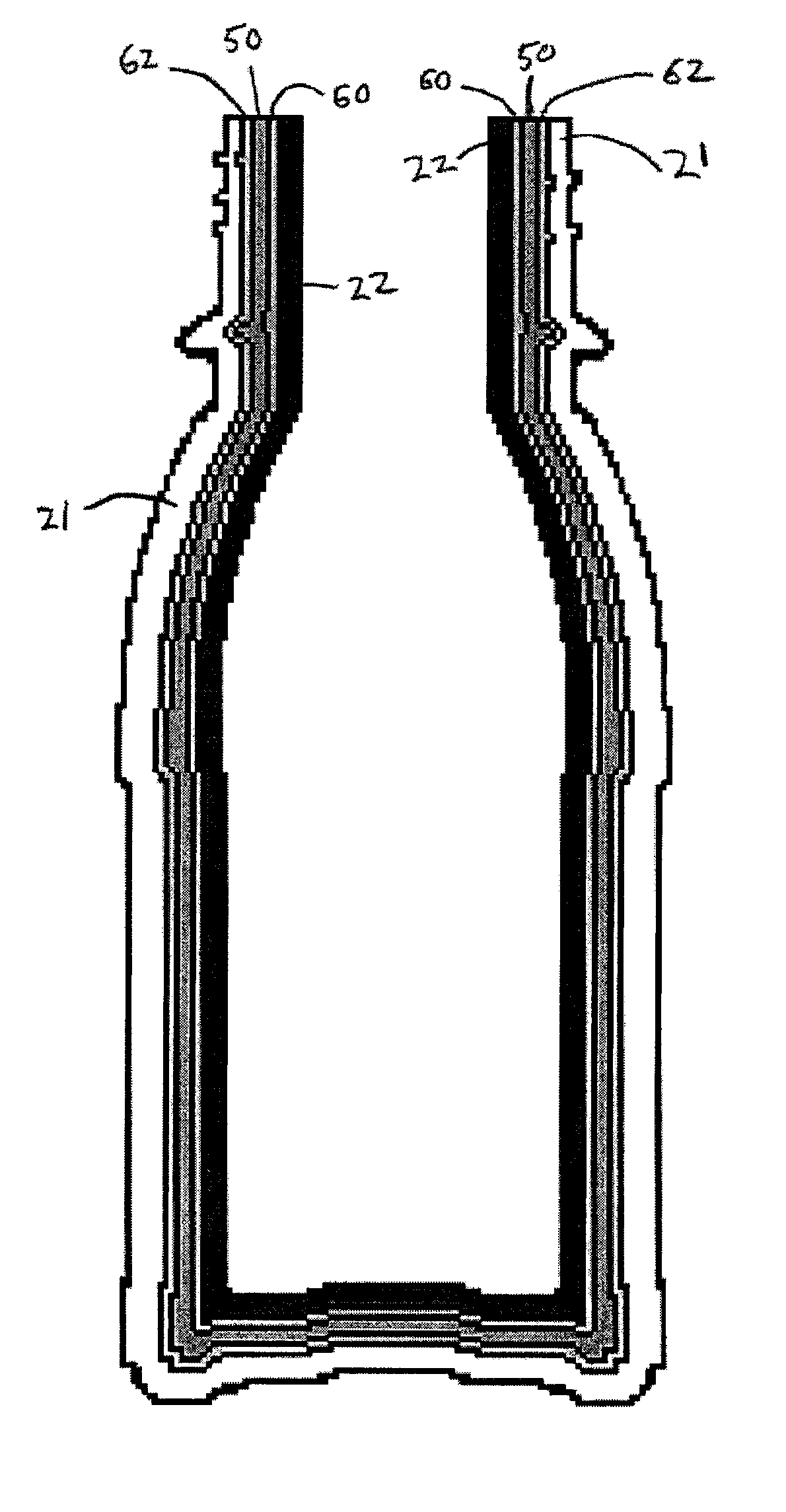

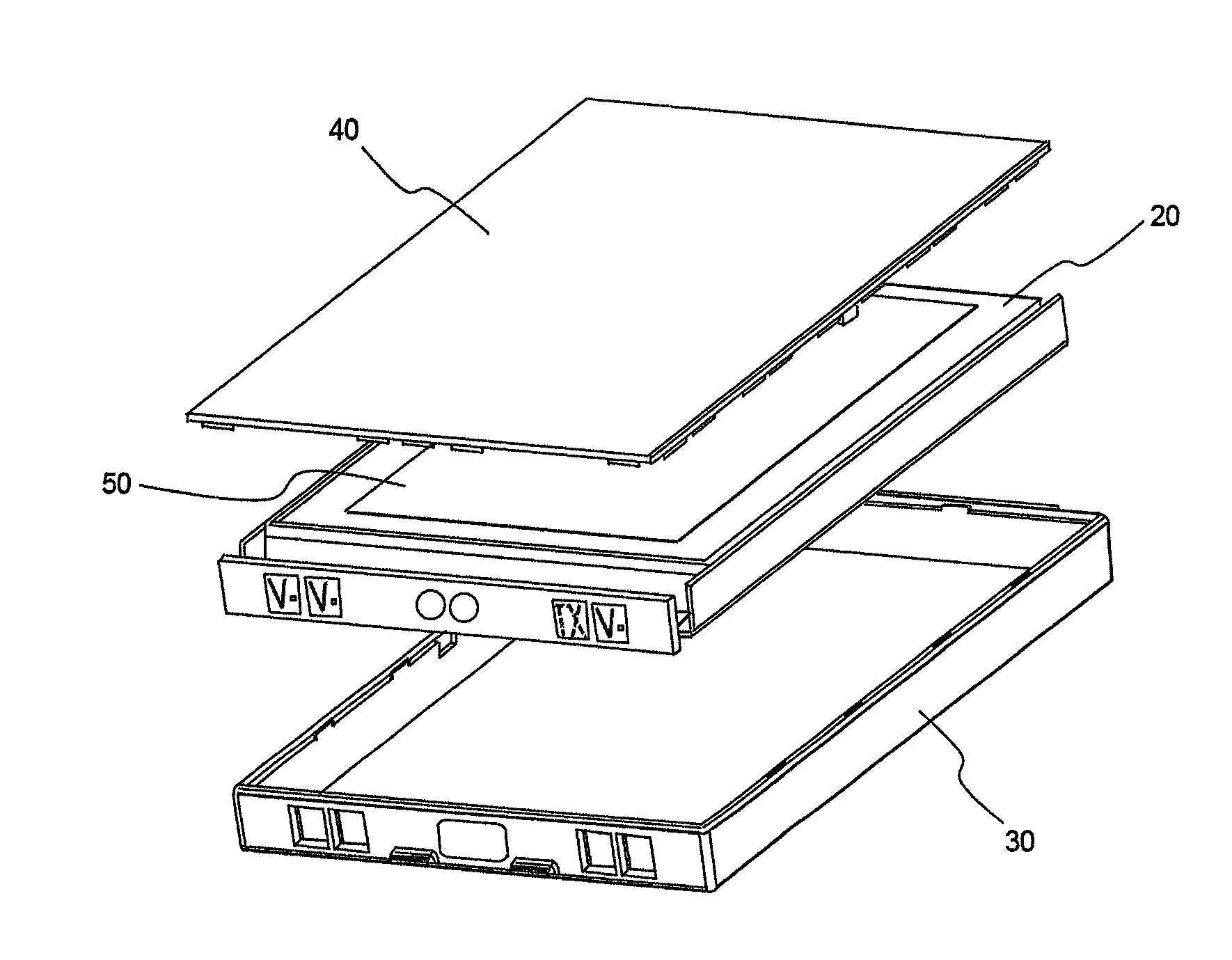

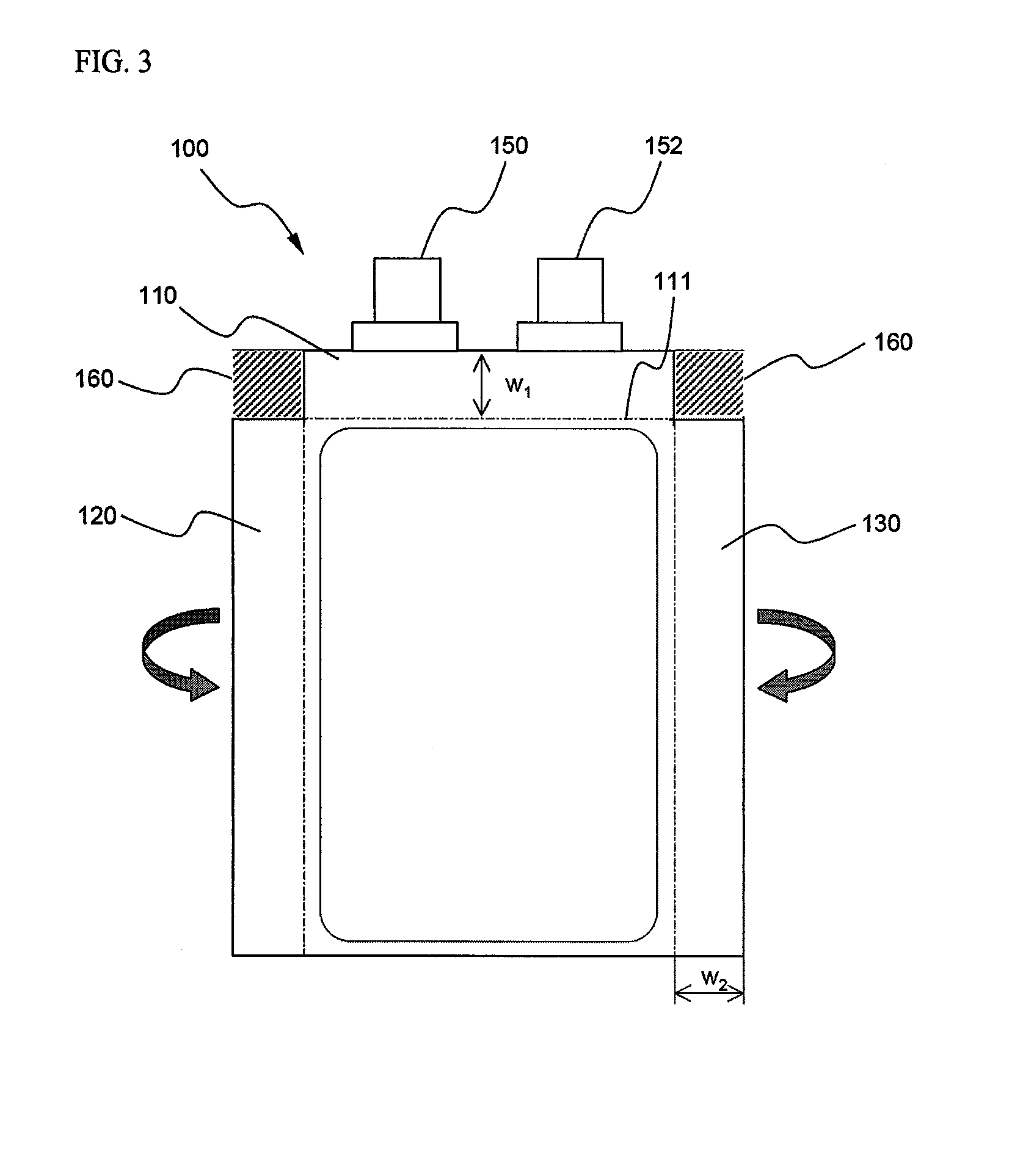

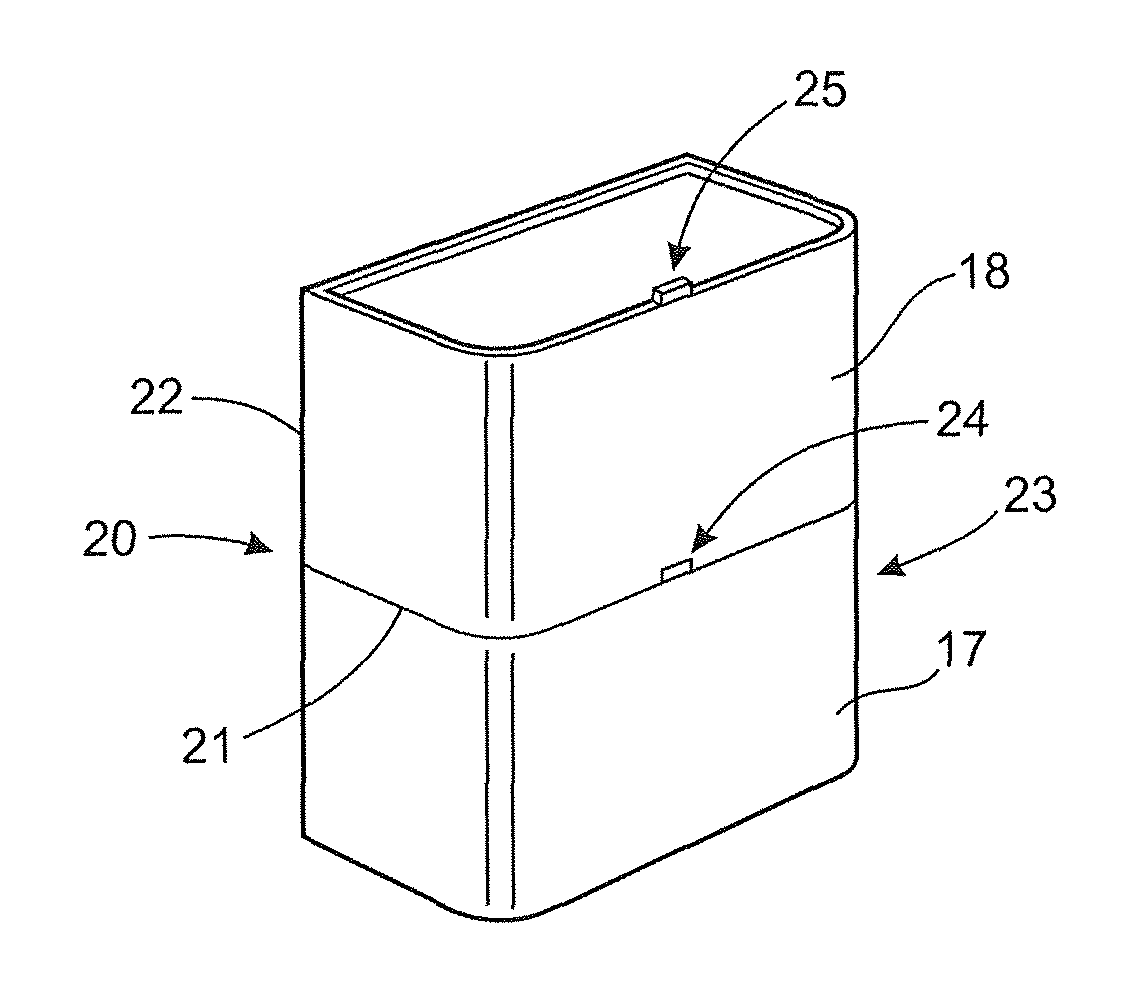

Battery pack of large capacity

ActiveUS20100209768A1Large capacityDesired strengthSmall-sized cells cases/jacketsJackets/cases materialsEngineeringBattery cell

Disclosed herein is a battery pack including a battery cell, having an electrode assembly mounted in a pouch-shaped battery case made of a laminate sheet including a metal layer and a resin layer and is sealed by thermal welding, mounted in a pack case, wherein the pack case includes a frame member constructed in a structure in which a receiving part for receiving the battery cell is open, opposite side sealing portions of the battery cell are mounted to the frame member such that the opposite side sealing portions cover the opposite sides of the frame member, and a sheathing film is applied to the outer surface of the frame member, to which the battery cell is mounted.

Owner:LG ENERGY SOLUTION LTD

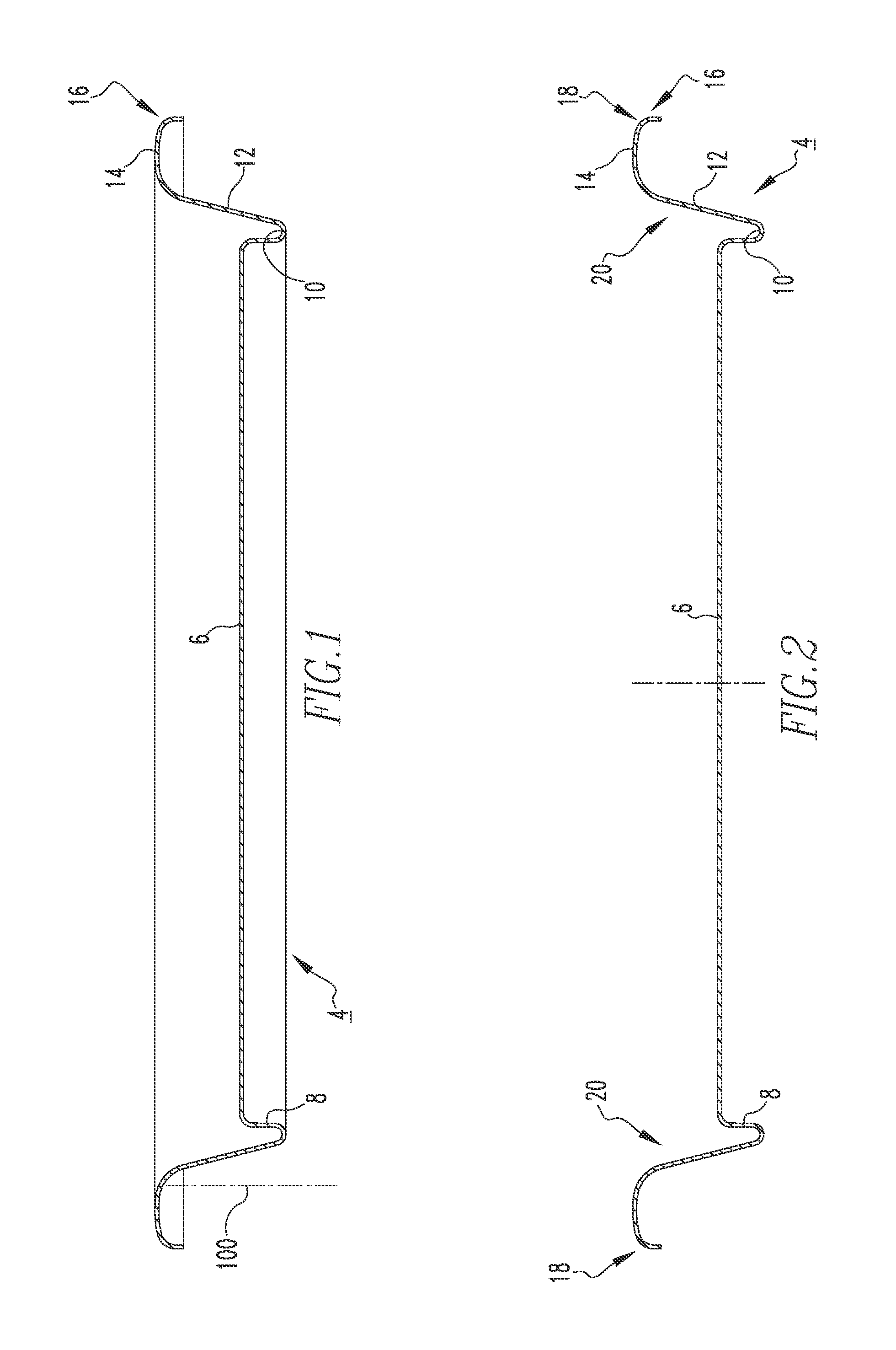

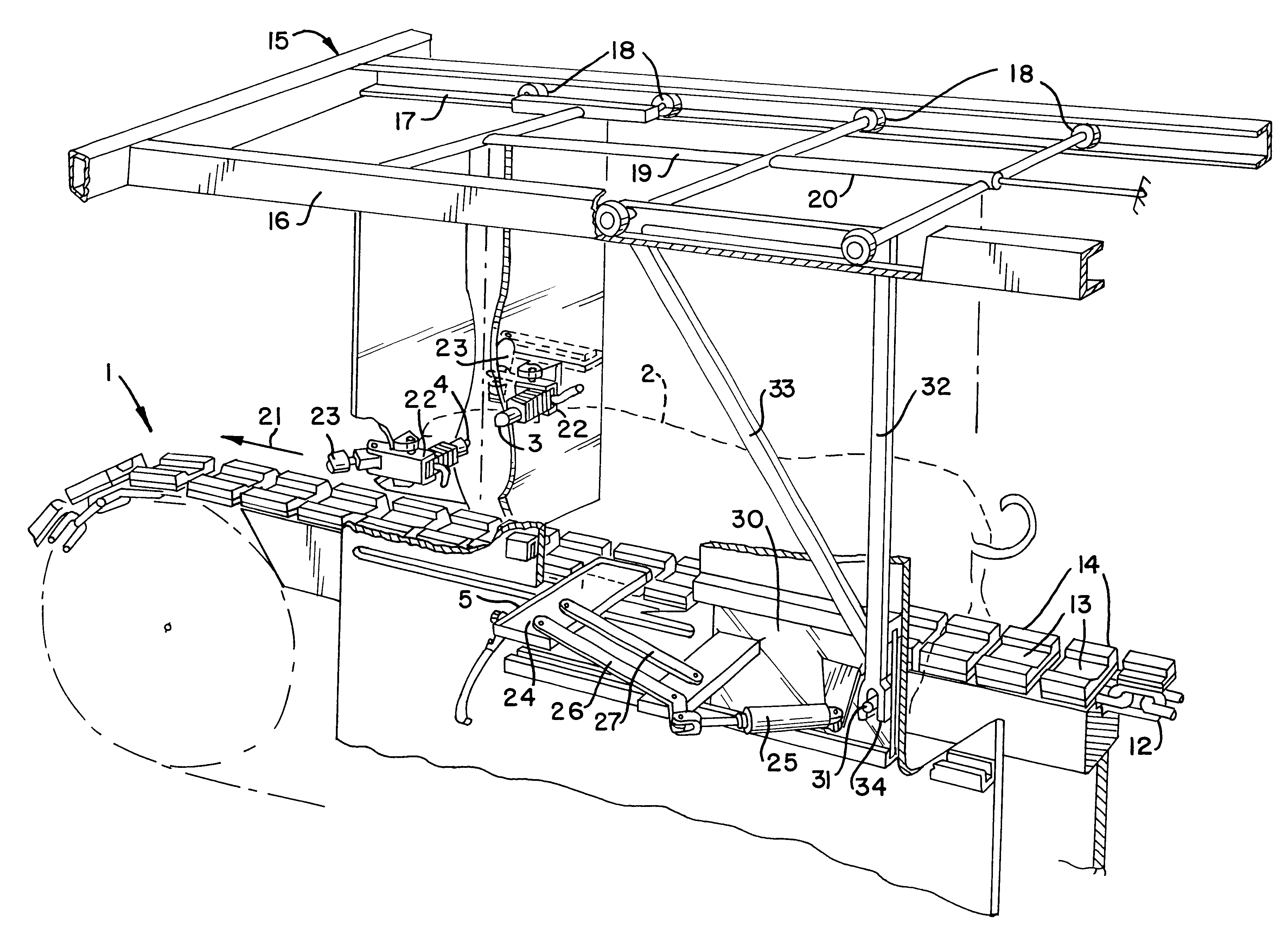

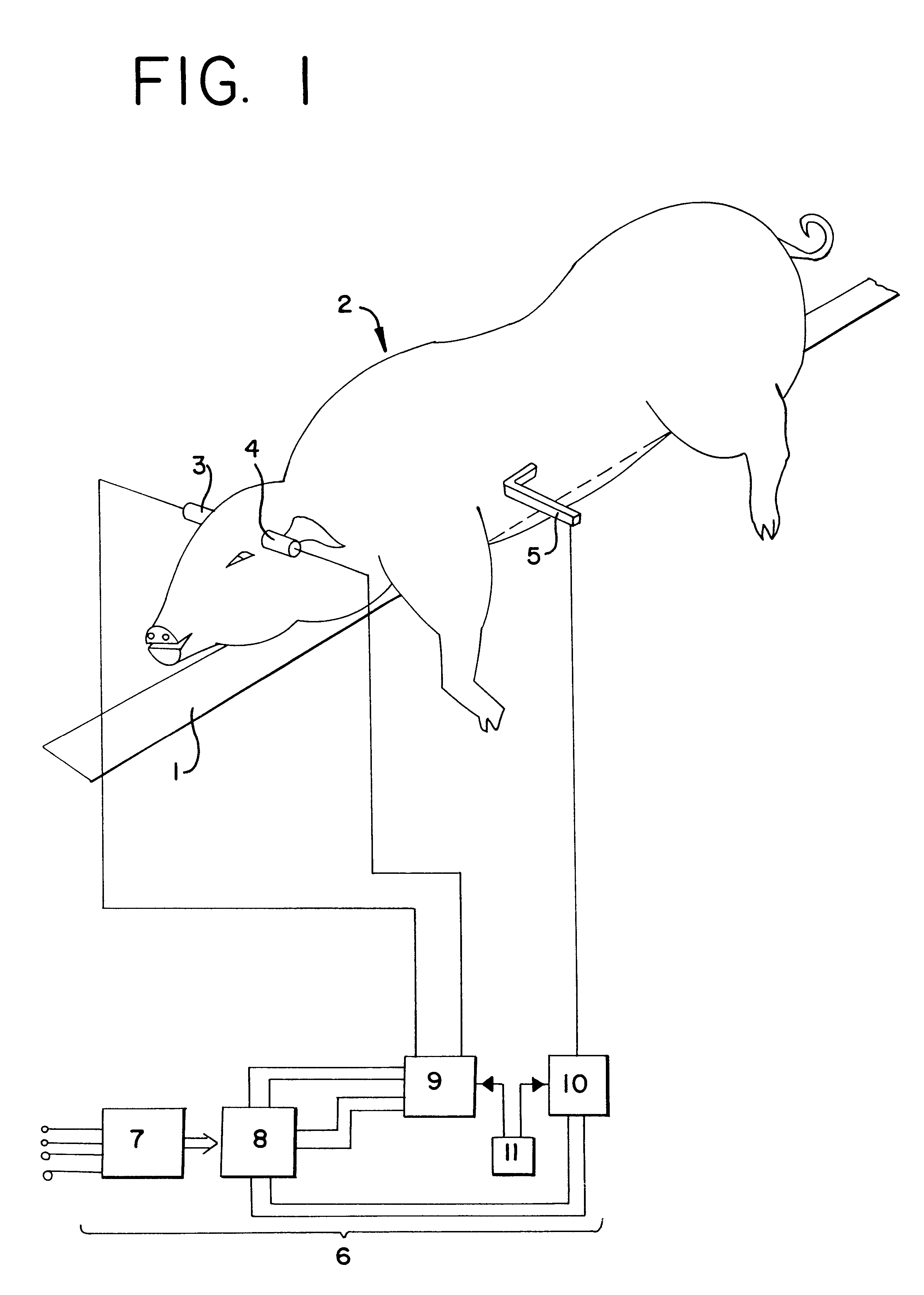

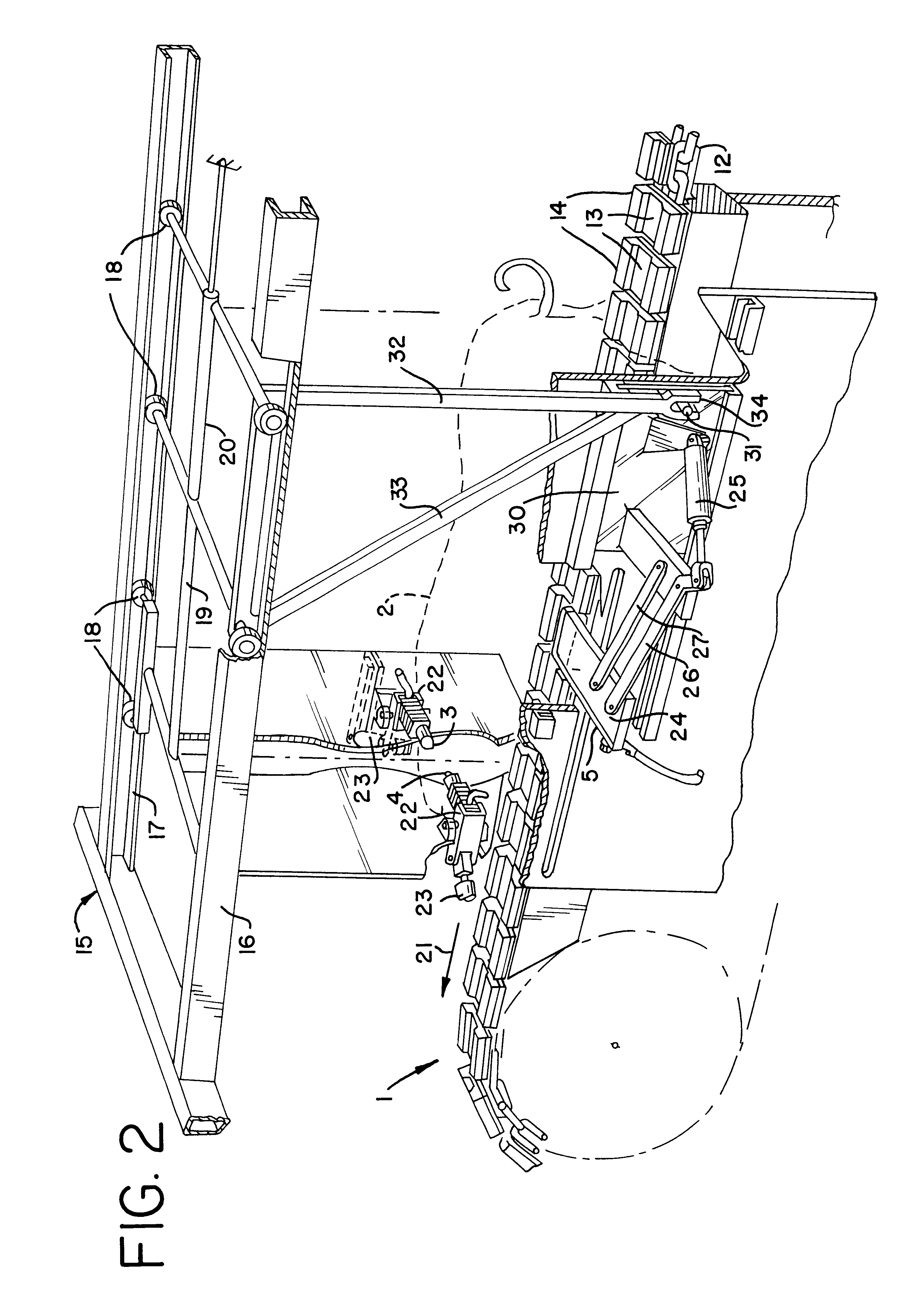

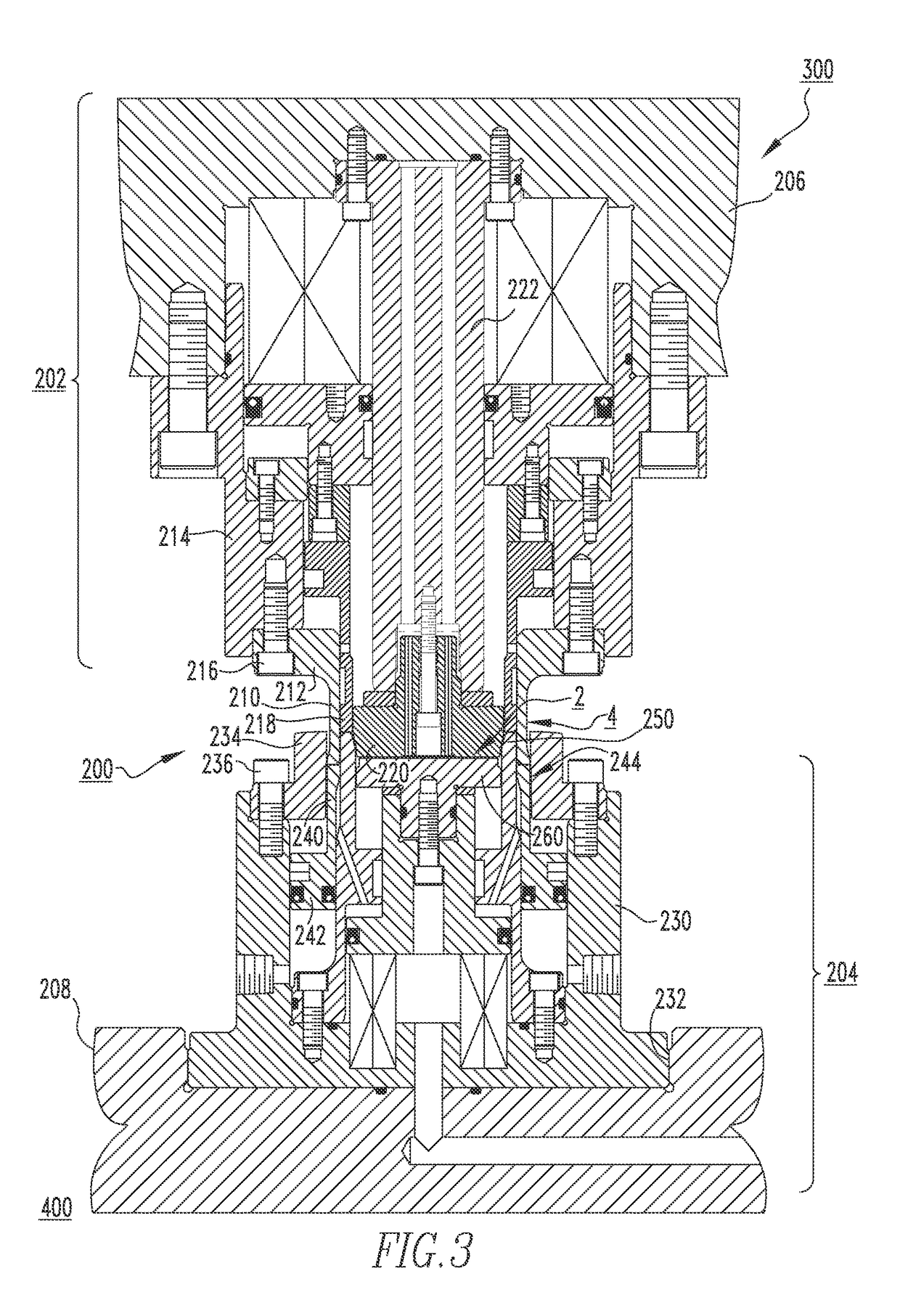

Method and device for stunning an animal for slaughter

InactiveUSRE37266E1Simple yet effectiveSuffering is preventedElectric current slaughtering/stunningCardiorespiratory arrestPower flow

A method of stunning an animal for slaughter includes the steps of providing the animal for slaughter; conveying the animal using conveying means; while conveying, causing a first current pulse having a maximum duration of 10 seconds to flow through the head and / or neck region of the animal to stun the animal; and, while conveying, causing a second current pulse to flow through the body of the animal to cause a cardiac arrest. The first and second current pulses may be applied successively or may be overlapping or partly overlapping.

Owner:STORK RMS BV

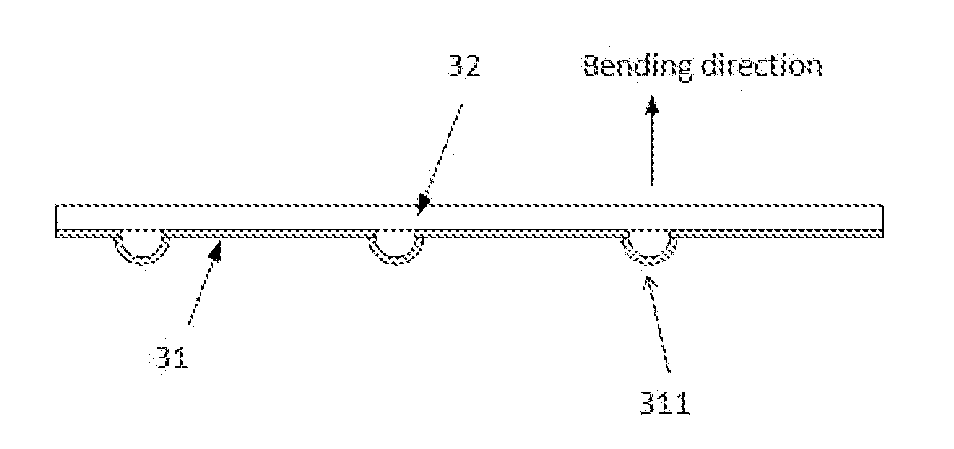

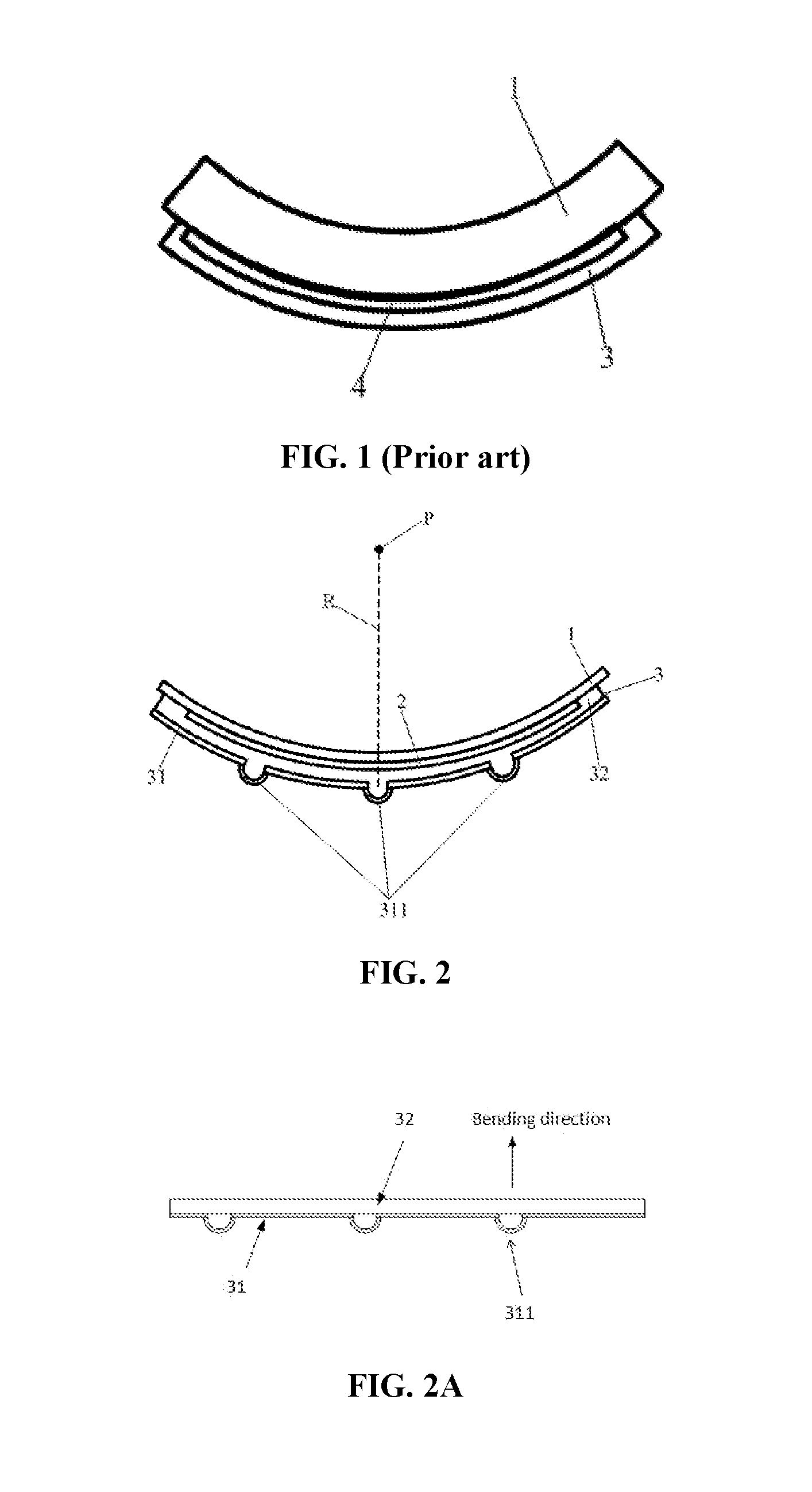

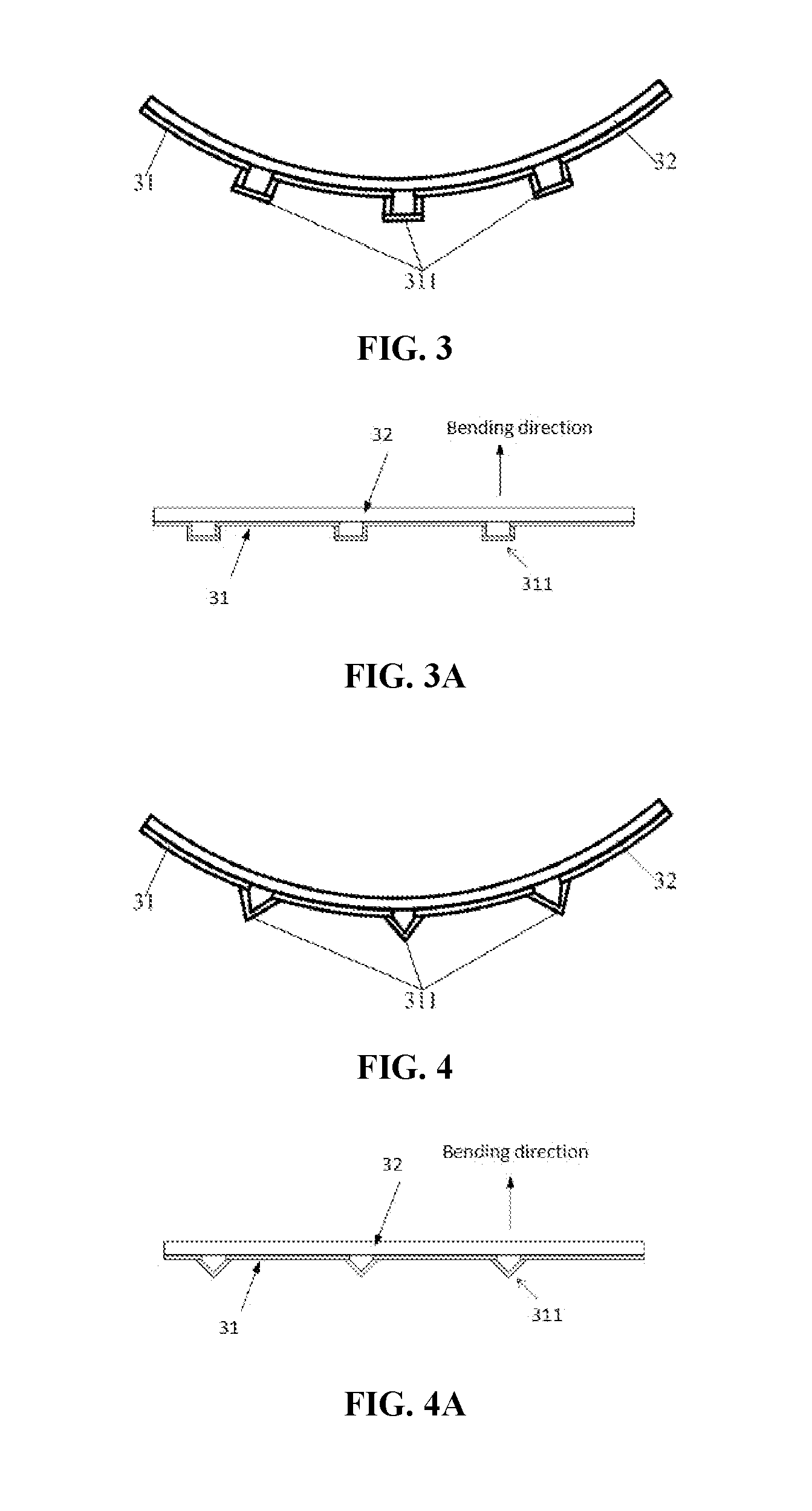

Cover plate, and curved display apparatus

ActiveUS20160359132A1Reduce radial stress and tangential stressReduce stressSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTangential stress

A cover plate for packaging a curved display apparatus is provided. The cover plate includes a plate body having a plurality of grooves configured to assist to bend the plate body to cause the cover plate have a bending tendency for reducing a radial stress and tangential stress of the curved display apparatus.

Owner:BOE TECH GRP CO LTD

Peg-containing fragranced pastille for laundry application

InactiveUS20180100124A1Desired strengthImproved visual appearanceOrganic detergent compounding agentsDetergent mixture composition preparationLaundryBiomedical engineering

Owner:HENKEL IP & HOLDING GMBH

Flexible unbonded pipe

InactiveUS20140076450A1Reduce weightDesired strengthDrilling rodsFlexible pipesMechanical engineeringPolymer

The invention relates to a flexible unbonded pipe for sub sea fluid transfer. The pipe comprises an inner sealing sheath defining a bore and a centre axis. Inside the inner sealing sheath the pipe comprises a carcass. The pipe further comprises a pair of reinforcement layers consisting essentially of helically wound elongate armoring elements of fiber reinforced polymer material. The elongate armoring elements of the innermost of the pair of reinforcement layers are wound in a first winding direction with an angle α to the centre axis, and the elongate armoring elements of the outermost of the pair of reinforcement layers are wound in a second winding direction with an angle β to the centre axis, wherein α≧βfπ / 2, α is about 65° or less. The pipe preferably comprises an anti-creep layer placed between the inner sealing sheath and the innermost of the pair of reinforcement layers.

Owner:NAT OILWELL VARCO DENMARK

Indexable insert drill and a center insert therefore

ActiveUS8192113B2Desired strengthDesired widthWood turning toolsTransportation and packagingAcute angleEngineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

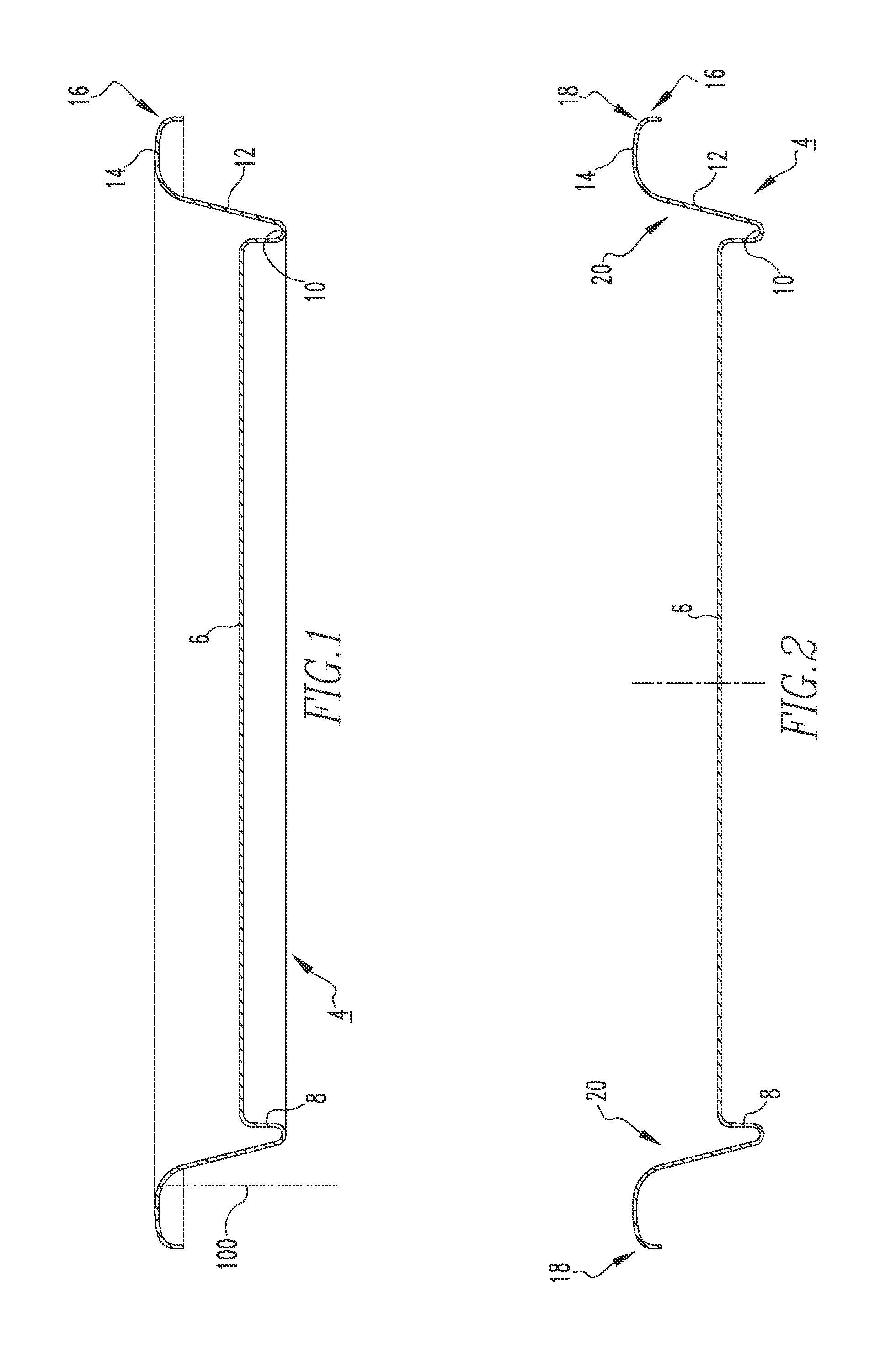

Dispenser part

ActiveUS8609216B2Promote meltingDesired strengthLayered productsThin material handlingEngineeringInjection molding machine

Owner:ESSITY HYGIENE & HEALTH AB

Container, and selectively formed shell, and tooling and associated method for providing same

ActiveUS9573183B2Reduce the amount requiredDesired strengthShaping toolsThin material handlingEngineeringCountersink

A shell, a container employing the shell, and tooling and associated methods for forming the shell are provided. The shell includes a center panel, a circumferential chuck wall, an annular countersink between the center panel and the circumferential chuck wall, and a curl extending radially outwardly from the chuck wall. The material of at least one predetermined portion of the shell is selectively stretched relative to at least one other portion of the shell, thereby providing a corresponding thinned portion.

Owner:STOLLE MACHINERY

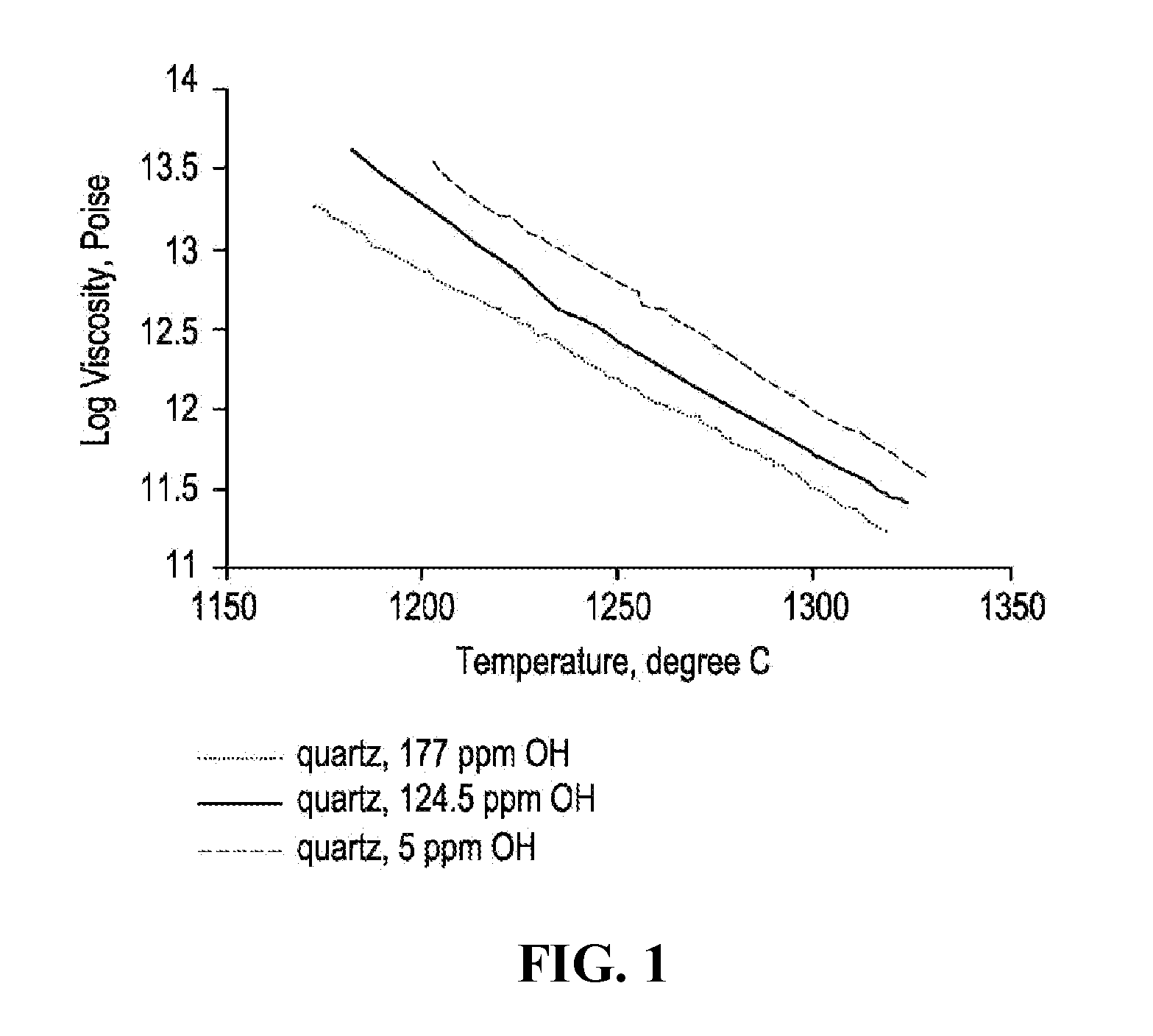

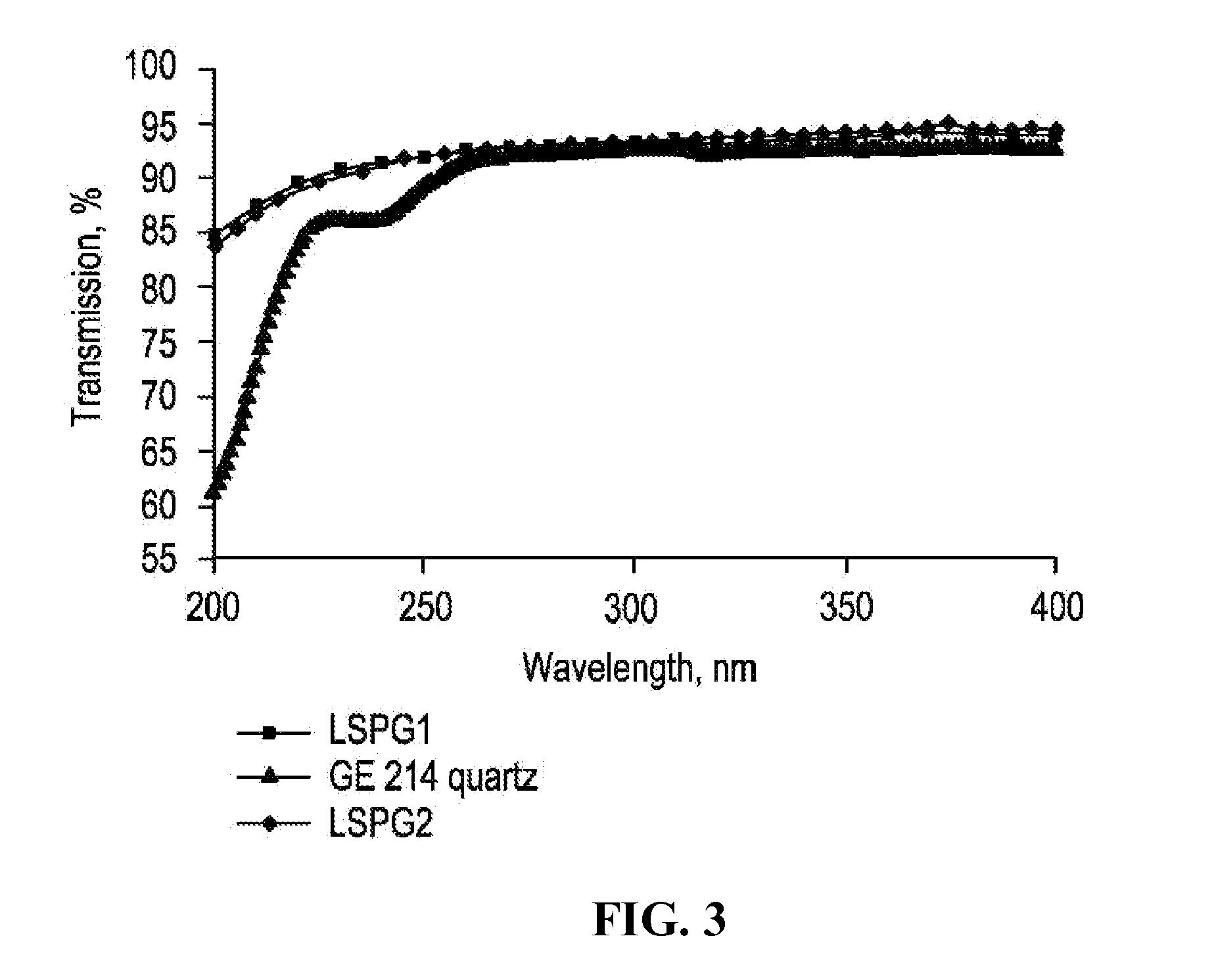

Silica glass having improved properties

The invention relates to a silica glass compound having improved physical and chemical properties. In one embodiment, the present invention relates to a silica glass having a desirable brittleness in combination with a desirable density while still yielding a glass composition having a desired hardness and desired strength relative to other glasses. In another embodiment, the present invention relates to a silica glass composition that contains at least about 85 mole percent silicon dioxide and up to about 15 mole percent of one or more dopants selected from F, B, N, Al, Ge, one or more alkali metals (e.g., Li, Na, K, etc.), one or more alkaline earth metals (e.g., Mg, Ca, Sr, Ba, etc.), one or more transition metals (e.g., Ti, Zn, Y, Zr, Hf, etc.), one or more lanthanides (e.g., Ce, etc.), or combinations of any two or more thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

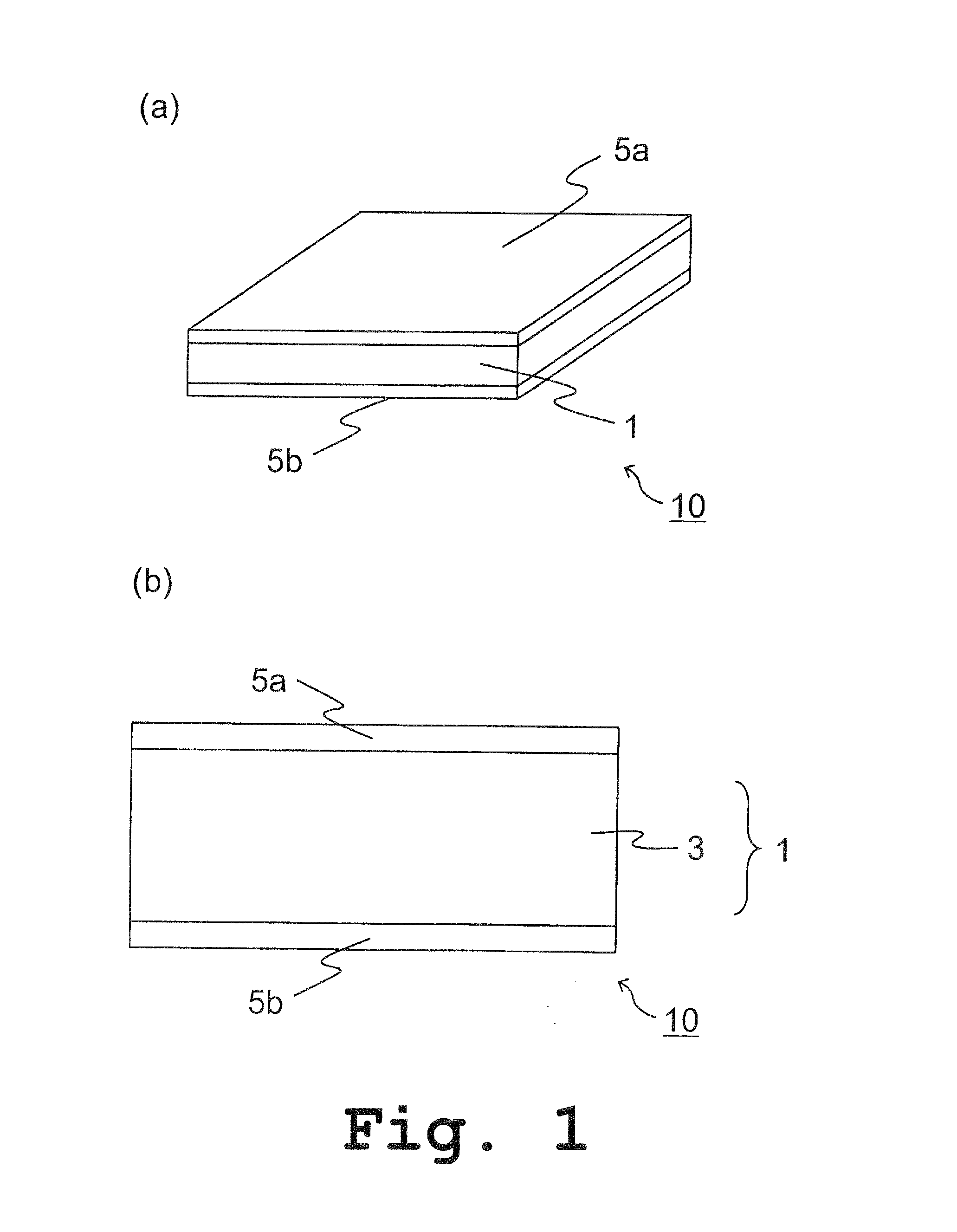

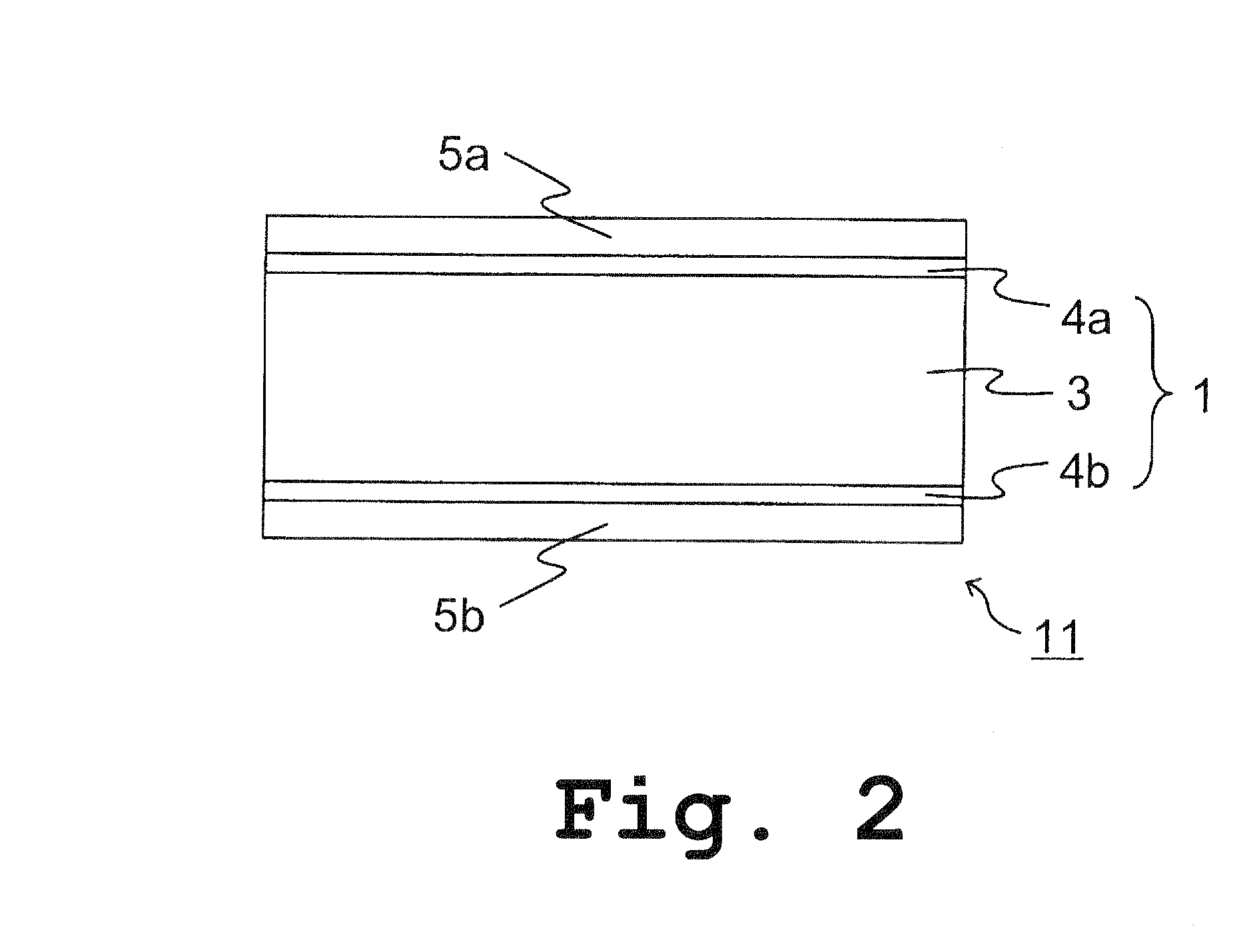

Floor panel

ActiveUS9944050B2Easy to produceDesired strengthSynthetic resin layered productsConstructions elementsCement boardUltimate tensile strength

Owner:KANA FURETSUKUSU KOOHOREESHON

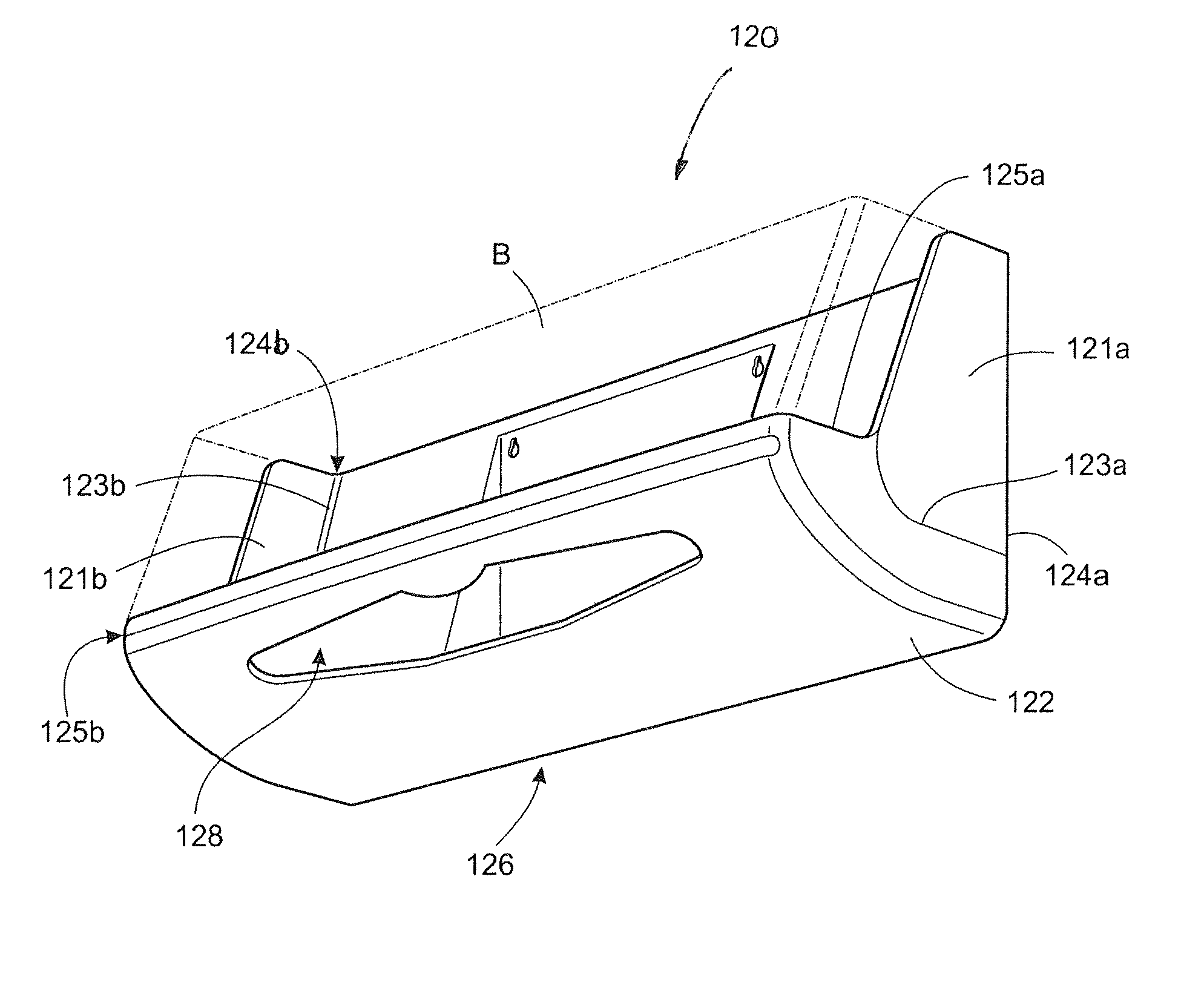

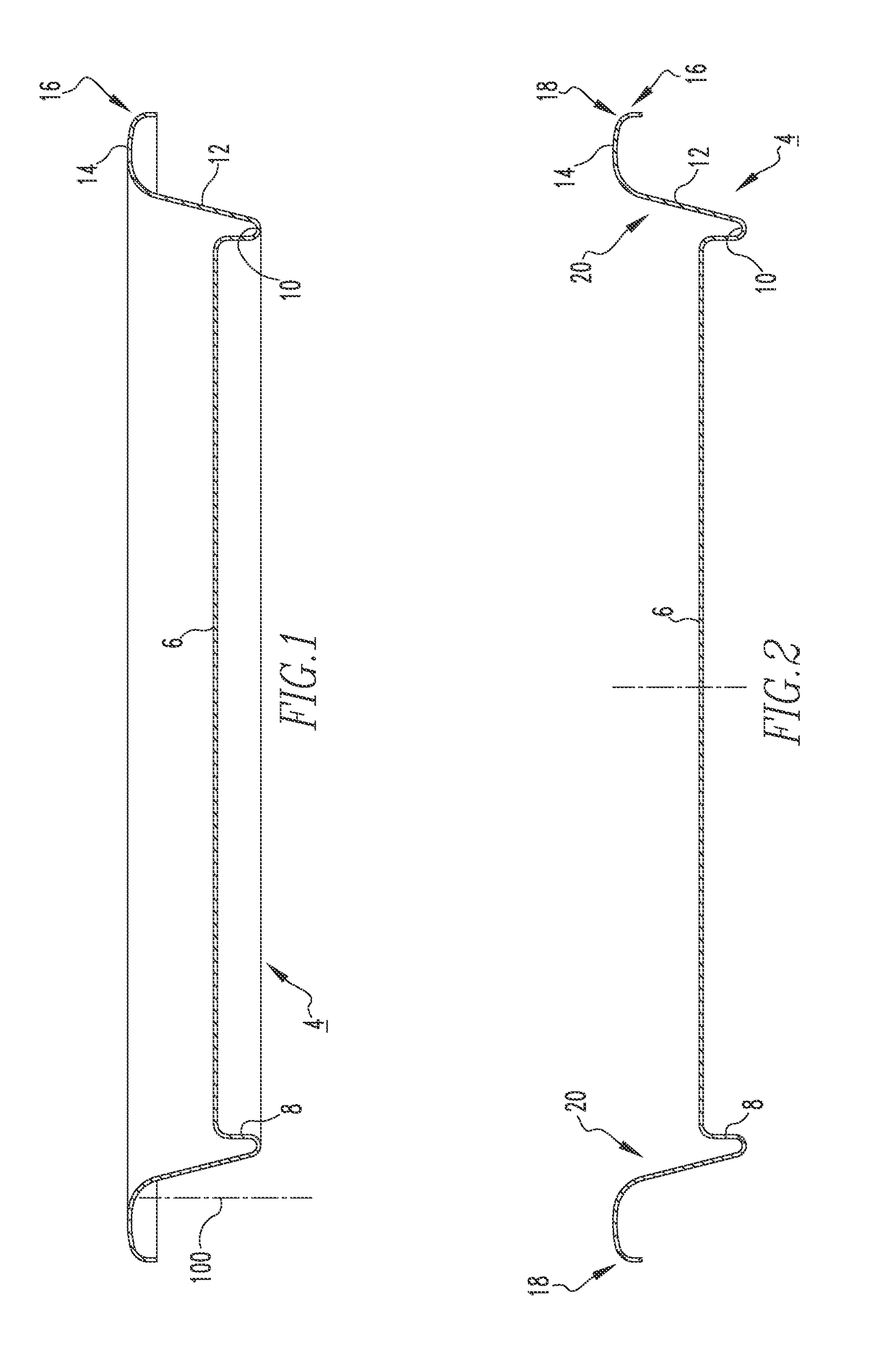

Injection molded dispenser part with a seam

ActiveUS8733571B2Promote meltingDesired strengthHolders and dispensersNon-disconnectible pipe-jointsEngineeringInjection moulding

A dispenser part, includes a first injection molded plastic component part with an associated first mating surface; a second injection molded plastic component part having an associated second mating surface; a seam formed by the first mating surface and the second mating surface during injection molding for joining the first component part and the second component part to define a dispenser part, and component part including a front surface, a first and a second side surface each having an edge facing away from the front surface. The resulting seam extends from the edge associated with the first side surface to the edge associated with the second side surface.

Owner:ESSITY HYGIENE & HEALTH AB

Container, and selectively formed shell, and tooling and associated method for providing same

ActiveUS9975164B2Reduce the amount requiredDesired strengthShaping toolsThin material handlingEngineeringCountersink

Owner:STOLLE MACHINERY CO LLC

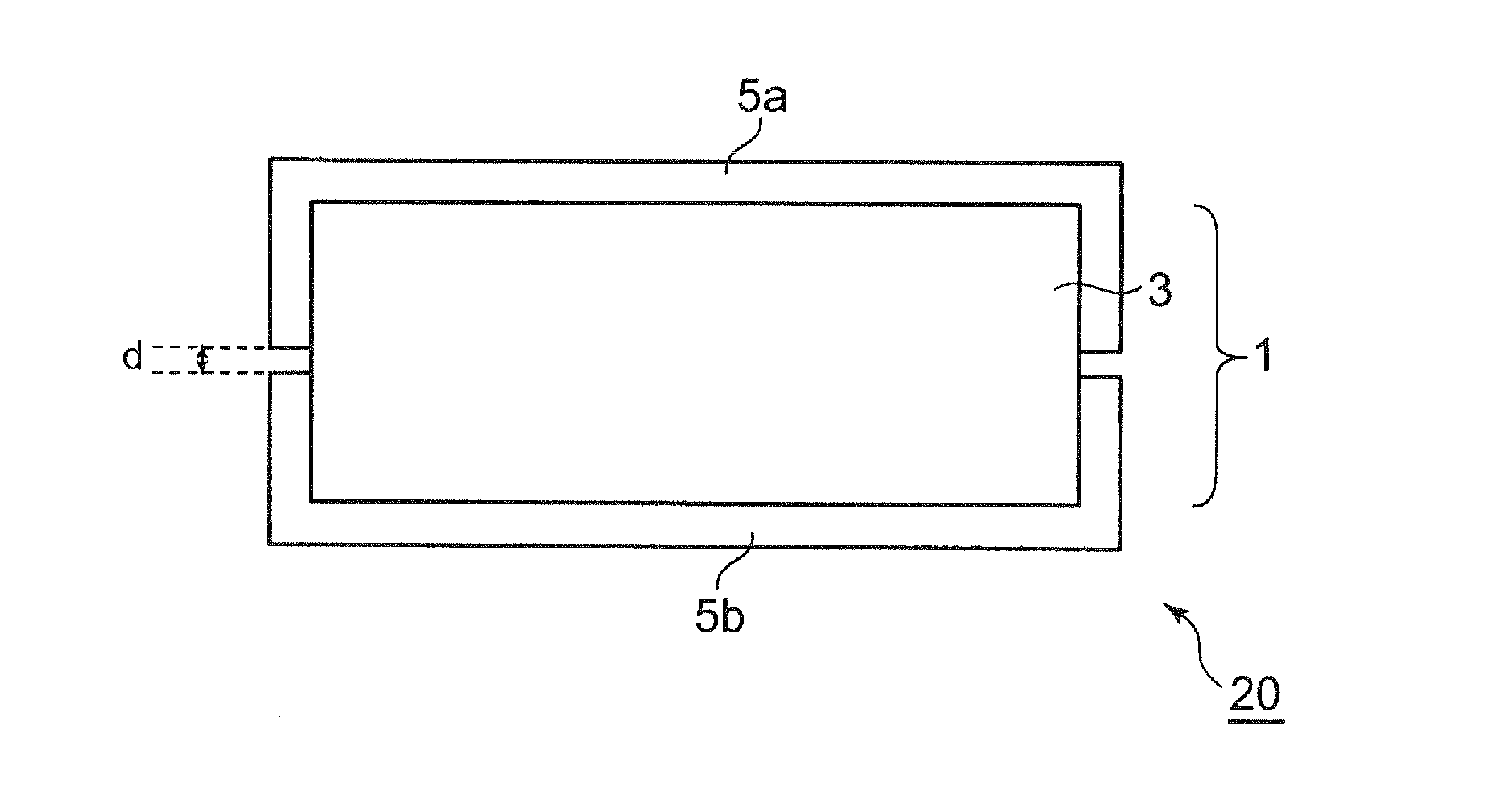

Floor panel

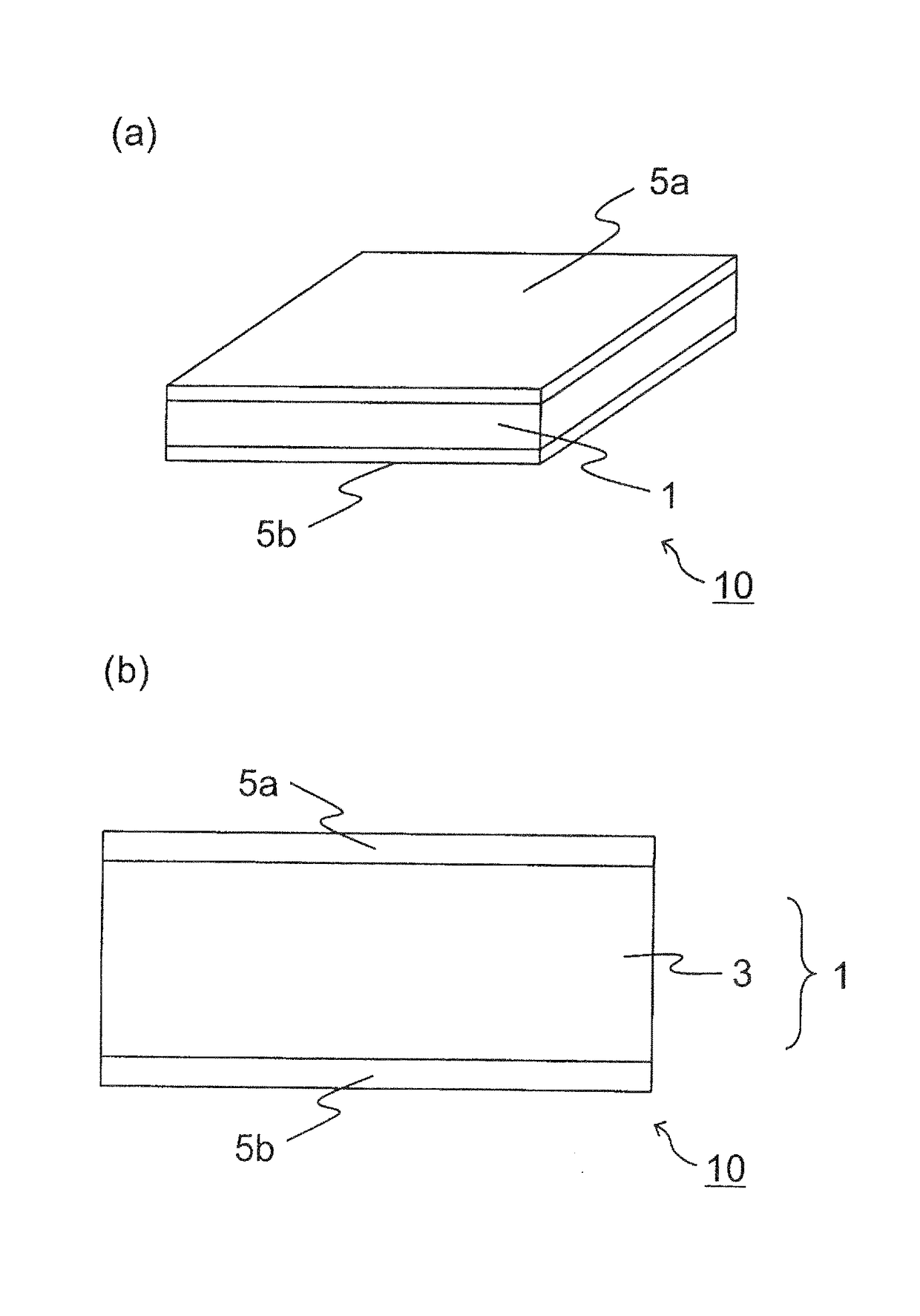

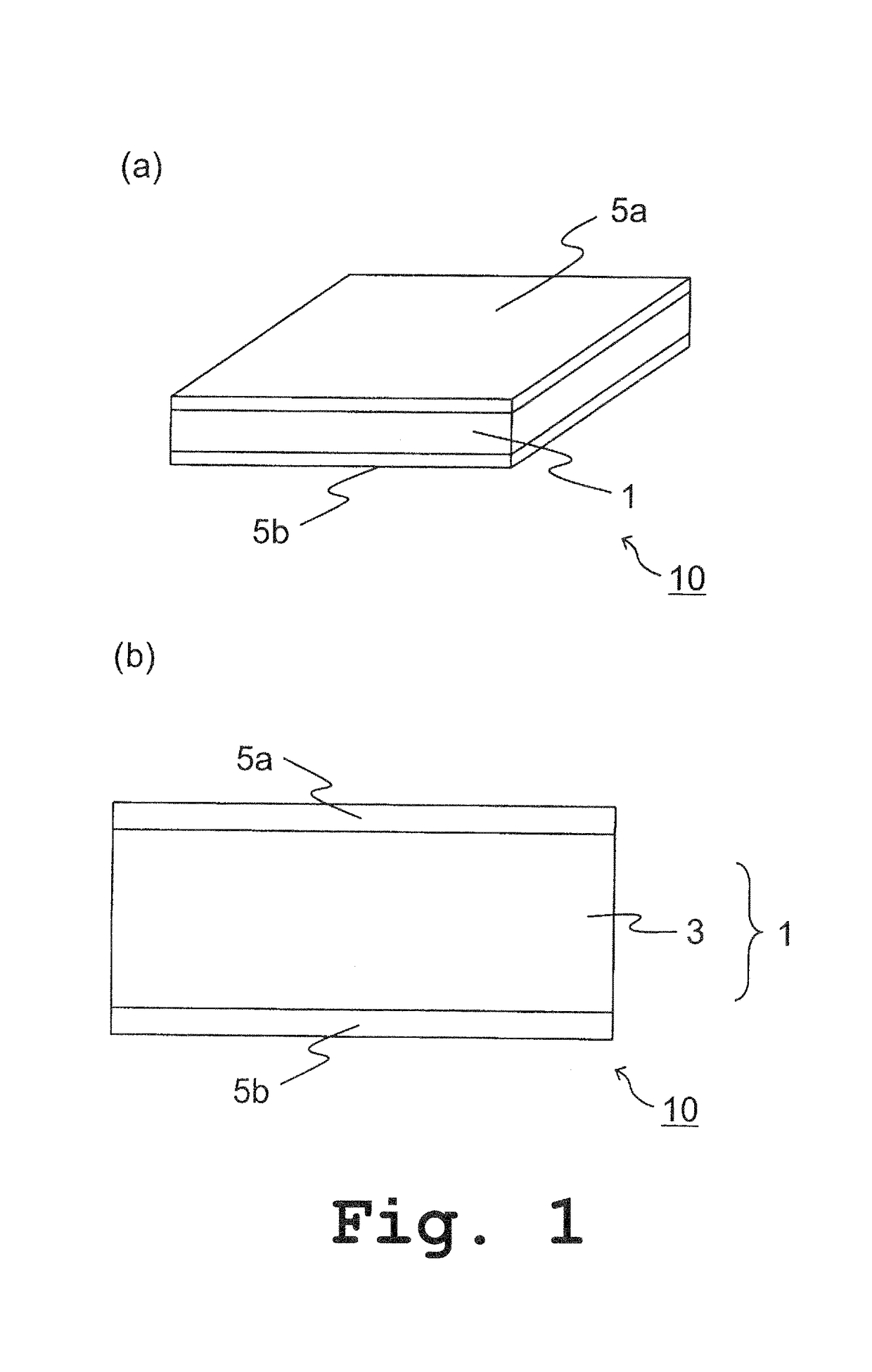

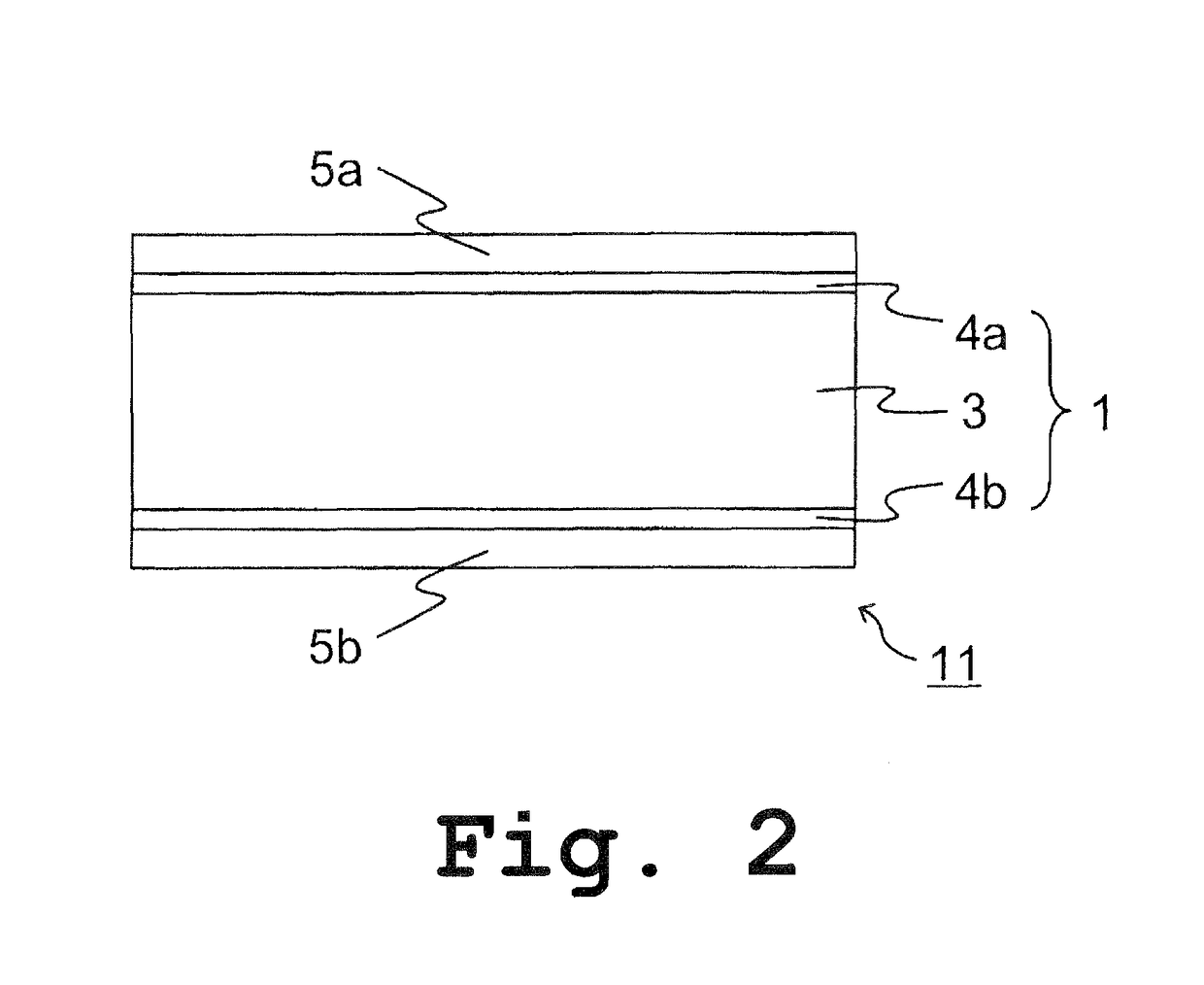

ActiveUS20150360443A1Easy to produceAvoid damageSynthetic resin layered productsConstructions elementsPanellingCement board

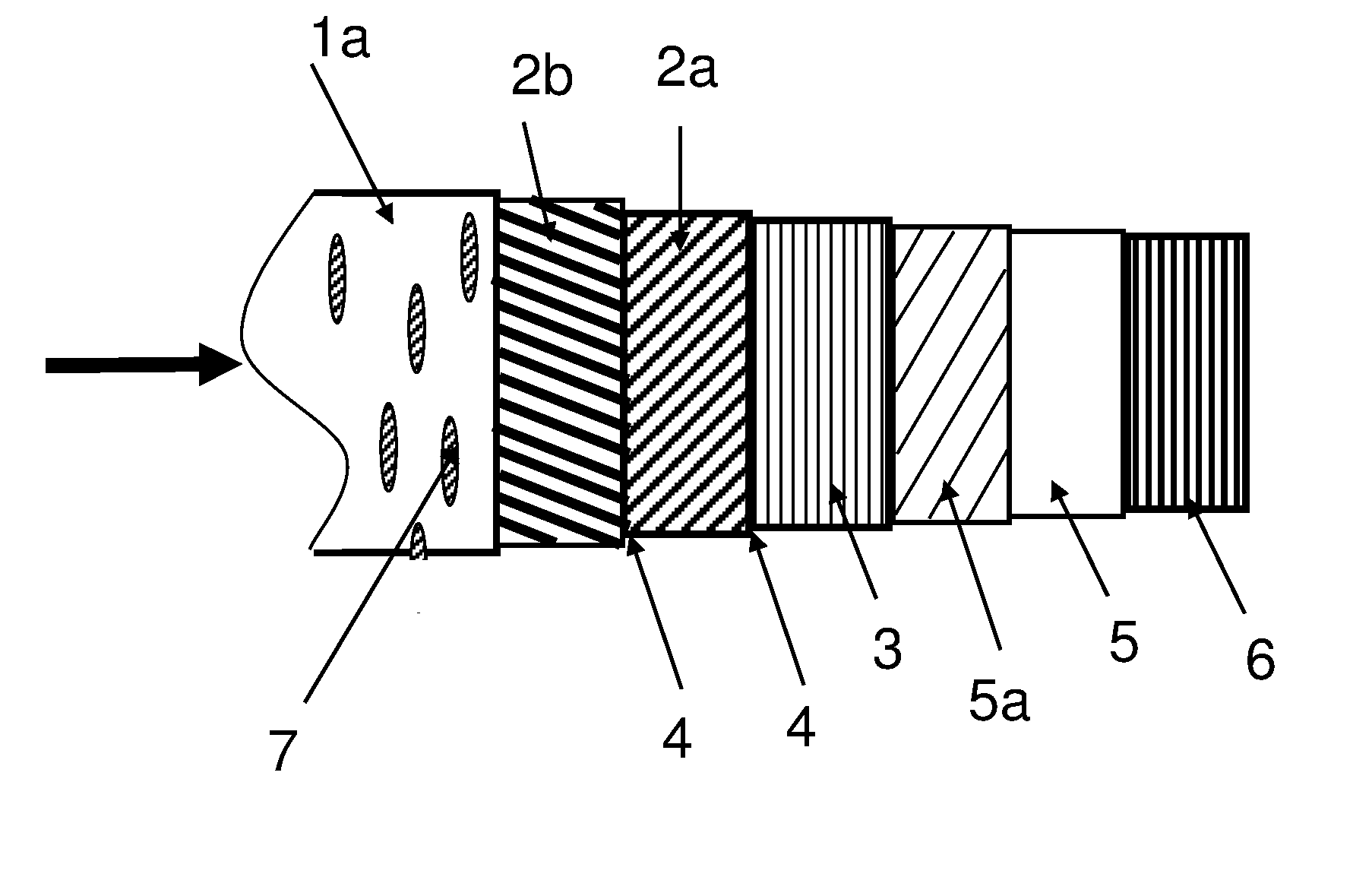

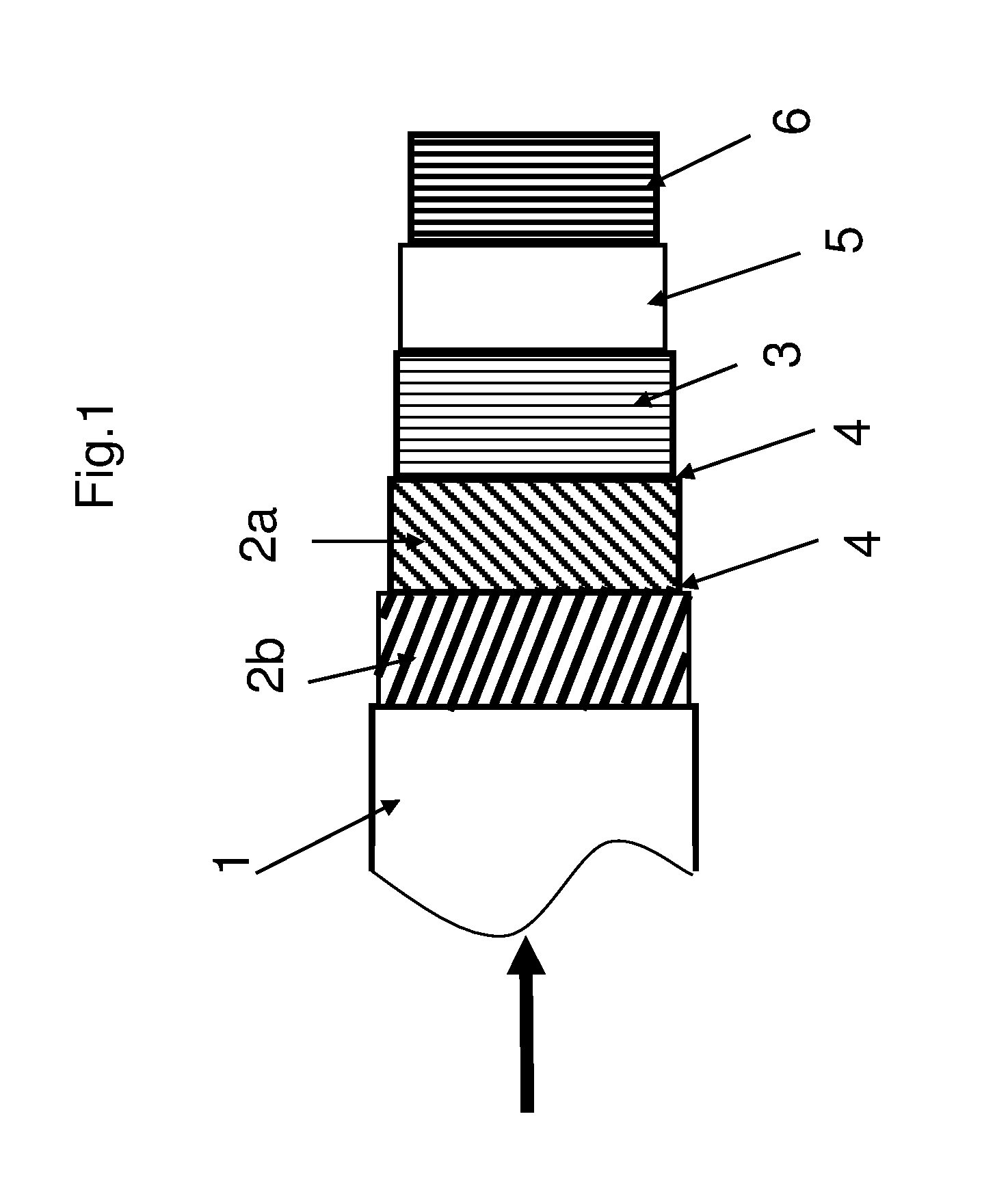

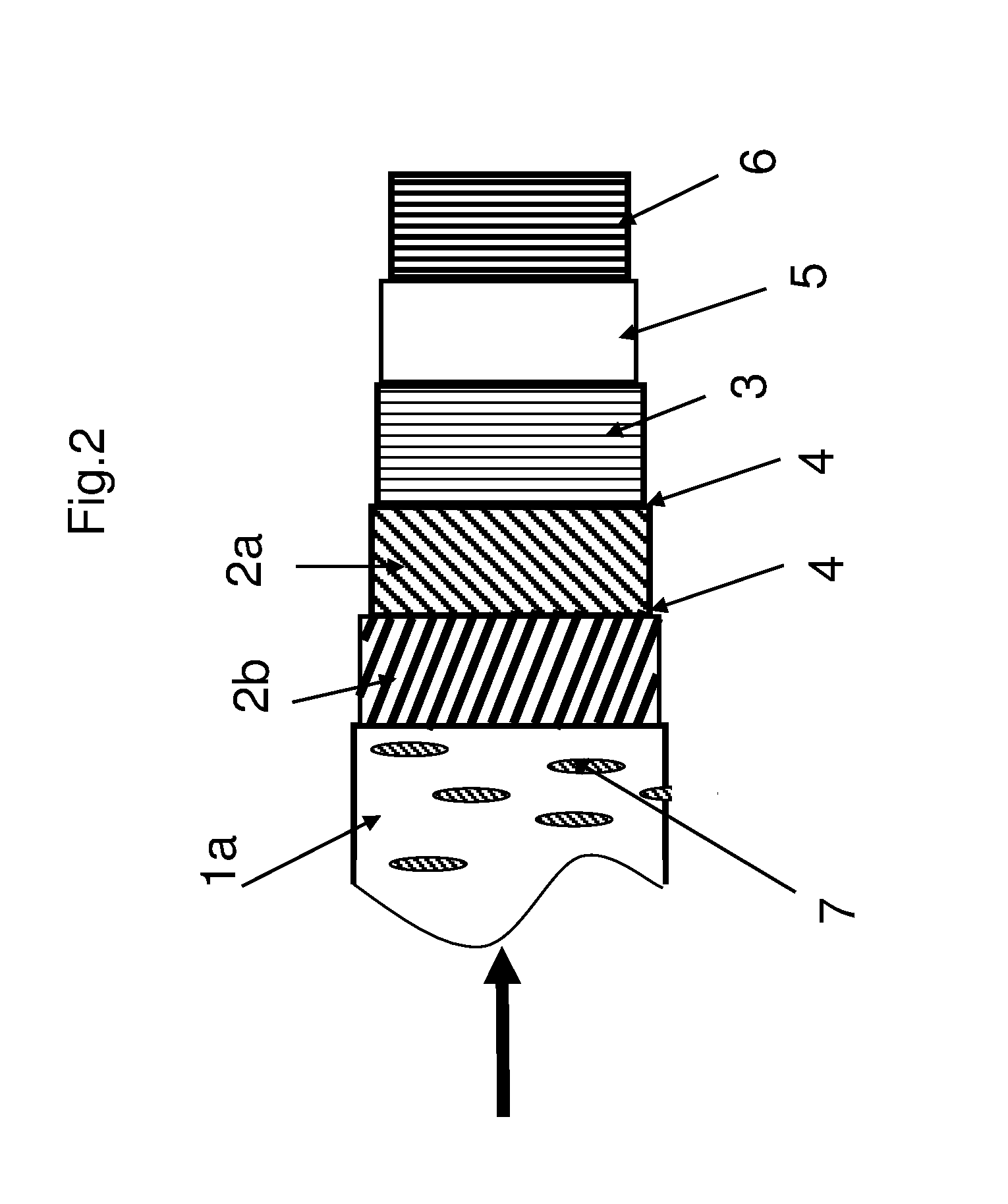

In a floor panel (10) comprising a foamed cement board (1) comprising at least a foamed cement layer (3), a top plate (5a) attached to an upper surface of the foamed cement board (1), and a bottom plate (5b) attached to a lower surface of the foamed cement board (1), the foamed cement layer (3) is configured so that the layer (3) comprises a porous hardened cement phase and a fiber dispersed in the phase, and that the layer (3) has a thickness within a range from 12 to 30 mm and a specific gravity within a range from 0.8 to 1.5. Thereby, the floor panel can be light-weighted while desired strengths for the floor panel are established. Such floor panel can be readily produced without any complicated processes.

Owner:KANA FURETSUKUSU KOOHOREESHON

Multivoid heat exchanger tubing with ultra small voids and method for making the tubing

InactiveUS20020070012A1Improves grain size and metallurgical strengthDesired strengthStationary conduit assembliesTubular elementsUltimate tensile strengthGrain growth

This invention is a process for making micro-multiport tubing for use in heat exchangers. The tubing is a flat body with a row of side-by-side passageways, which are separated by upright webs. Processing of this tubing involves extrusion, a straightening and cutting operation, a rolling step to reduce the thickness of the flat body and to obtain ultra small voids, assembly and furnace brazing of the heat exchanger. This invention improves the grain size of the metal in the tubing and also improves the metallurgical strength of the tubing. There is at least 10 percent change in material thickness. The strain is concentrated at the center of the web and results in at least enough cold work to produce fine recrystallized grains during the brazing thermal cycle. The amount of grain growth is controlled and the improvement in the metallurgical strength is achieved.

Owner:BRAZEWAY

Containers intended for moisture-sensitive products

ActiveUS8110260B2Desired rigidityDesired strengthBoxes/cartons making machineryContainer/bottle contructionDesiccantEngineering

A container for a moisture-sensitive product. The container has an openable container body defining an interior volume for holding the product. More specifically, a rigid container defining an interior volume for holding a moisture-sensitive product, and comprising at least an inner layer and an outer layer, the inner and outer layers being coextruded layers, the inner layer comprising a polymeric material and a desiccant material, the outer layer comprising a moisture-barrier material.

Owner:MERICAL RICK +2

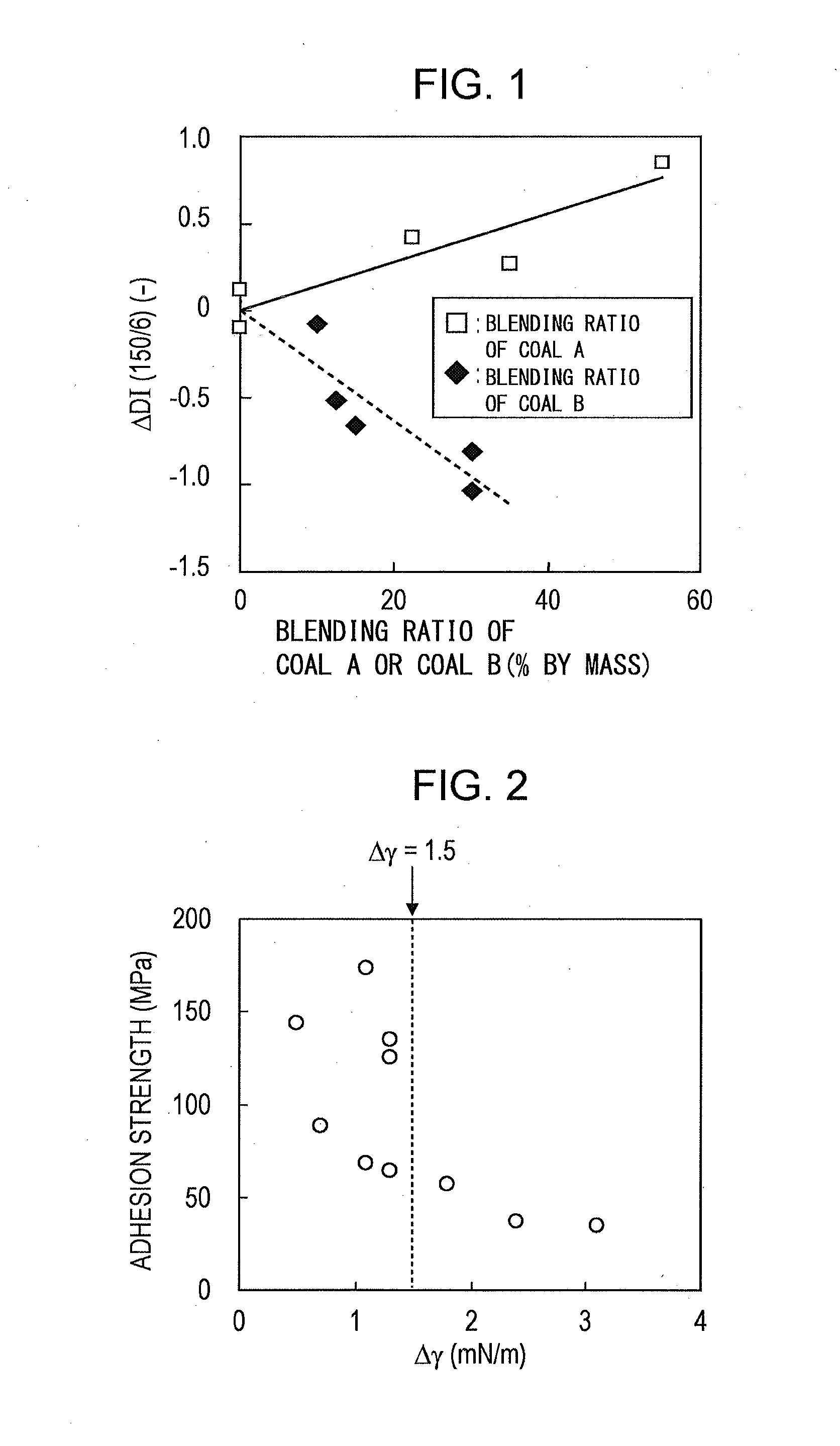

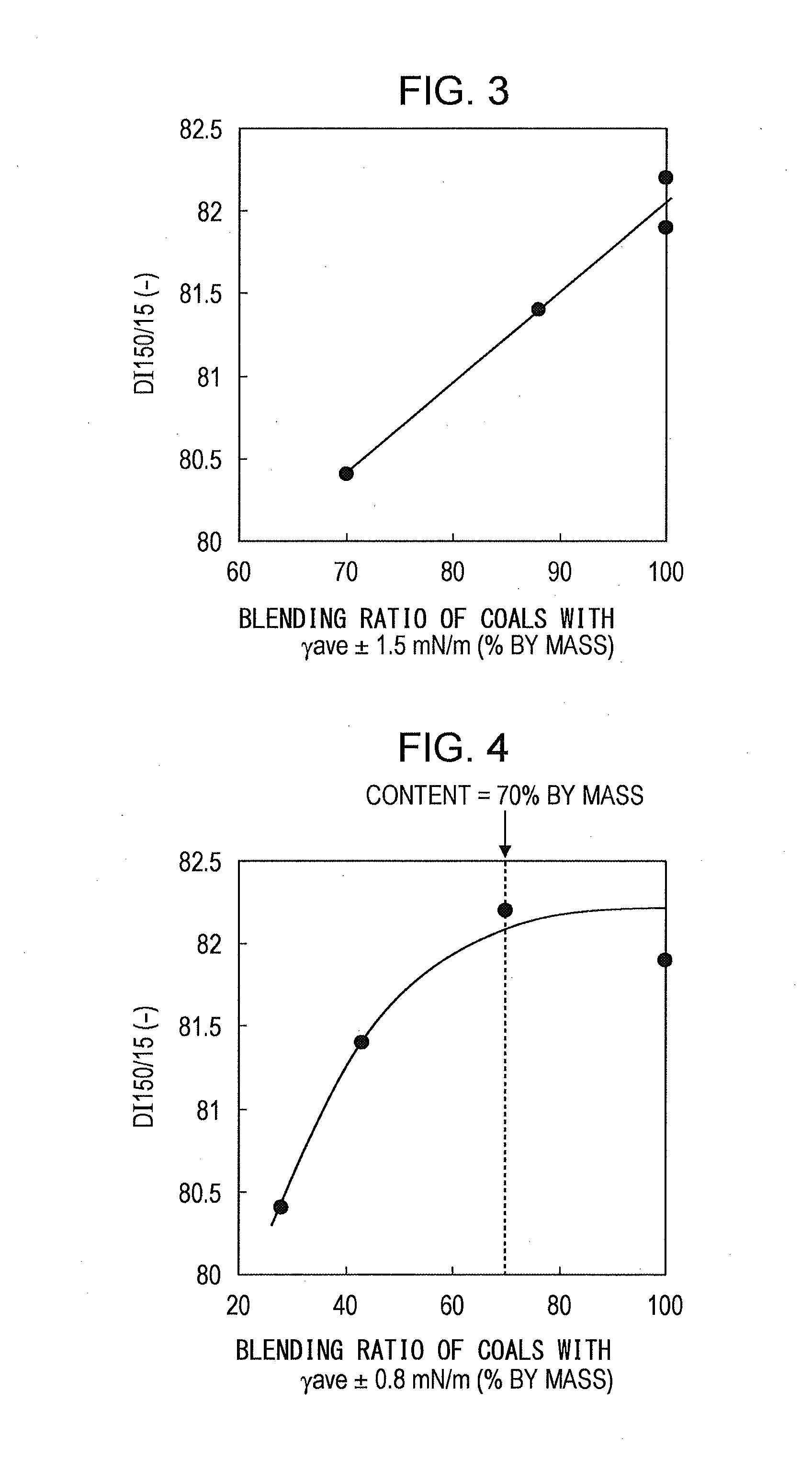

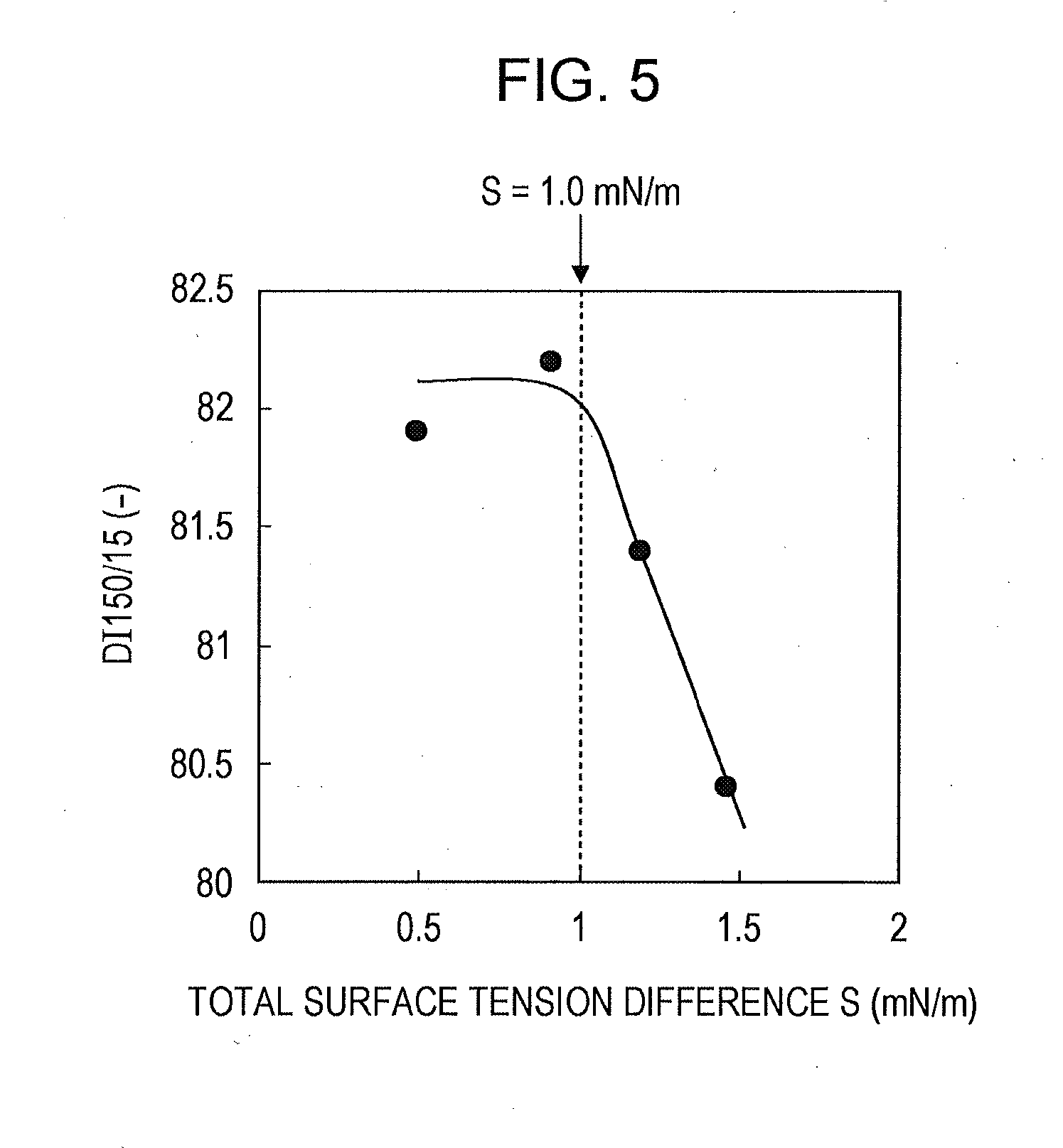

Method for blending coals for cokemaking and method for producing coke

ActiveUS20150075962A1Accurate predictionHigh strengthElectrical coke oven heatingDirect heating destructive distillationCoalProcess engineering

Provided is a technique by which the compatibility between coals for cokemaking can be quantitatively determined to estimate the coke strength taking into account the compatibility and to select and blend coals based on the coke strength estimated taking into account the compatibility, thereby allowing the production of a coke with the desired strength. A method for blending coals for cokemaking includes predicting the strength of a coke to be produced from a blend of a plurality of coals based on a difference between the surface tensions of the plurality of coals after heat treatment and determining the types and proportions of the coals to be blended.

Owner:JFE STEEL CORP

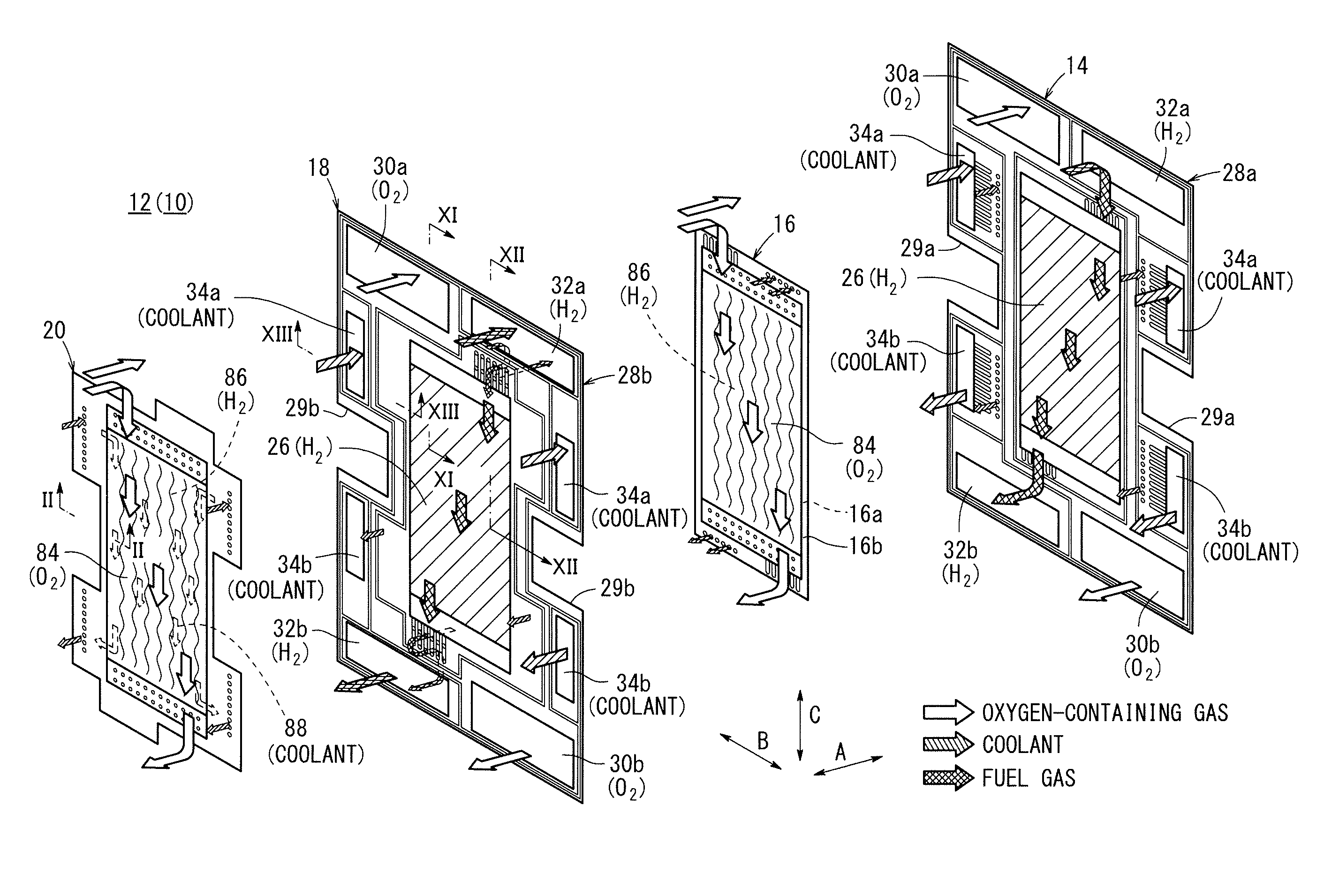

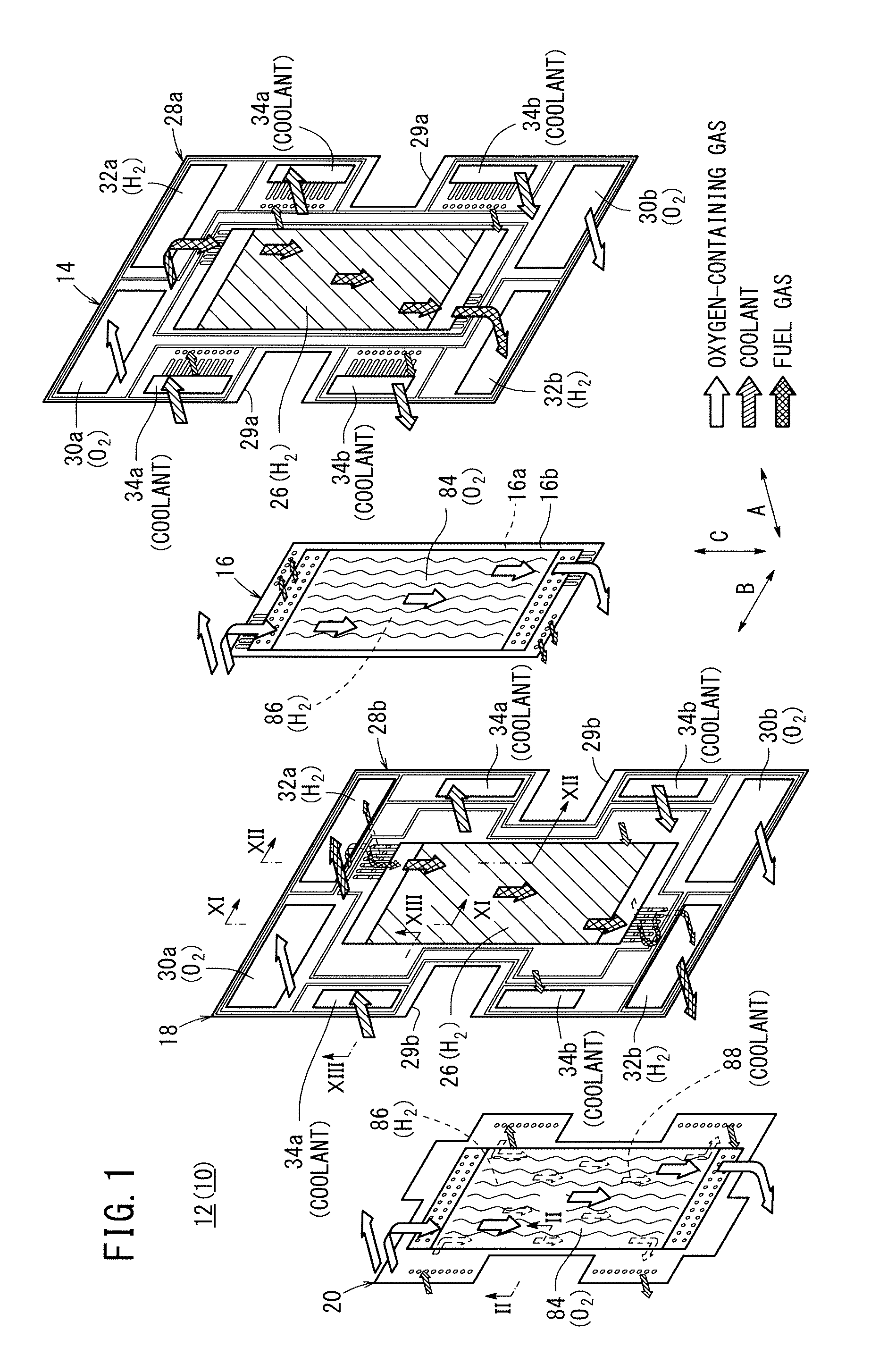

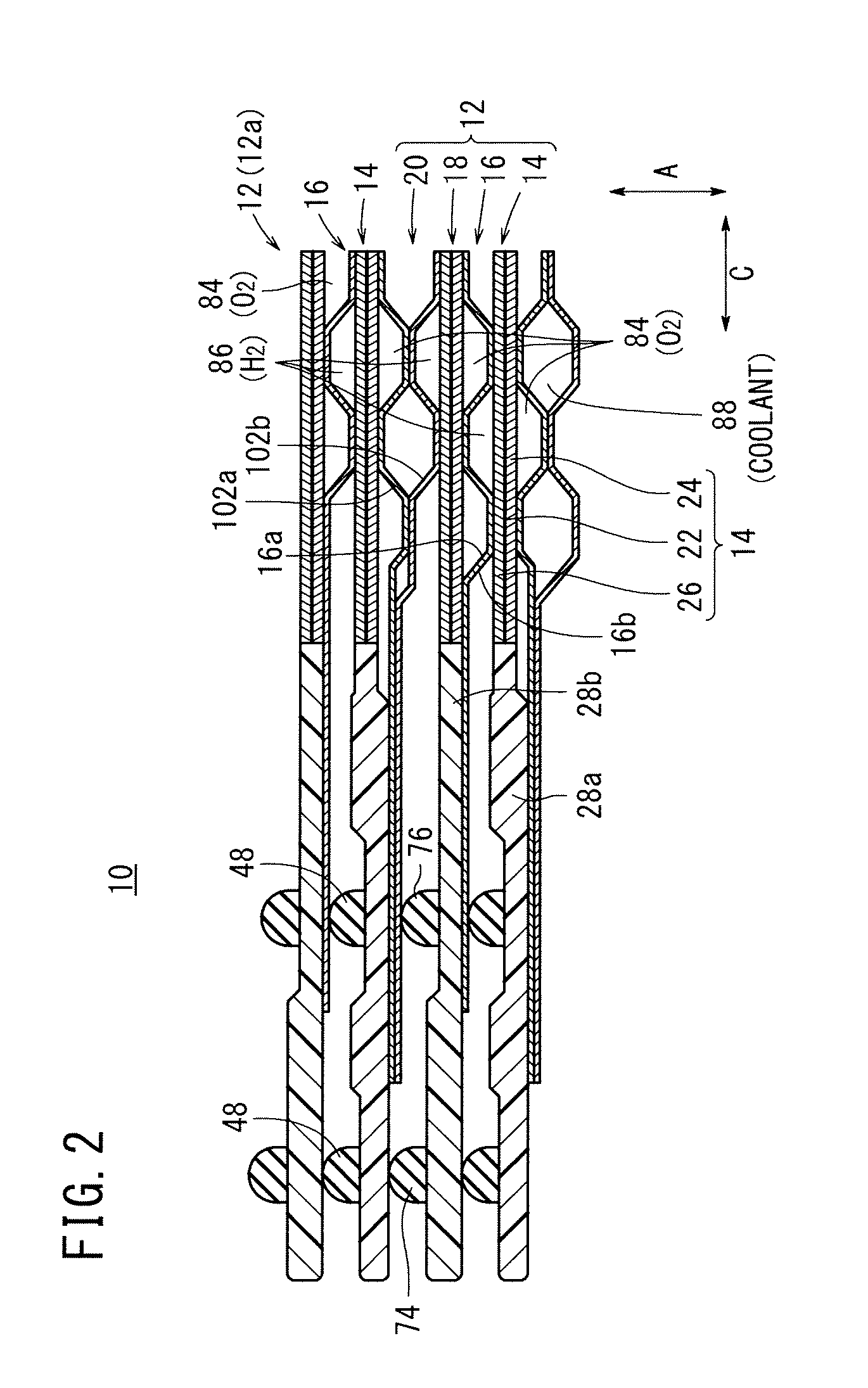

Fuel cell

ActiveUS20120295177A1Easily damagedIncreasing the thicknessFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A cell unit of a fuel cell includes a first membrane electrode assembly, a first metal separator, a second membrane electrode assembly, and a second metal separator. Resin frame members are provided at the outer ends of the first and second membrane electrode assemblies. Coolant connection channels including a plurality of grooves is formed in each of the resin frame members. The grooves of the coolant connection channels of the cell unit and grooves of coolant connection channels of a cell unit that is adjacent to the cell unit in the stacking direction are offset from each other, and are not overlapped with each other in the stacking direction.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com