Floor panel

a technology for flooring and panels, applied in the field of floor panels, can solve the problem of insufficient rigidity of concrete itself, and achieve the effect of excellent design and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

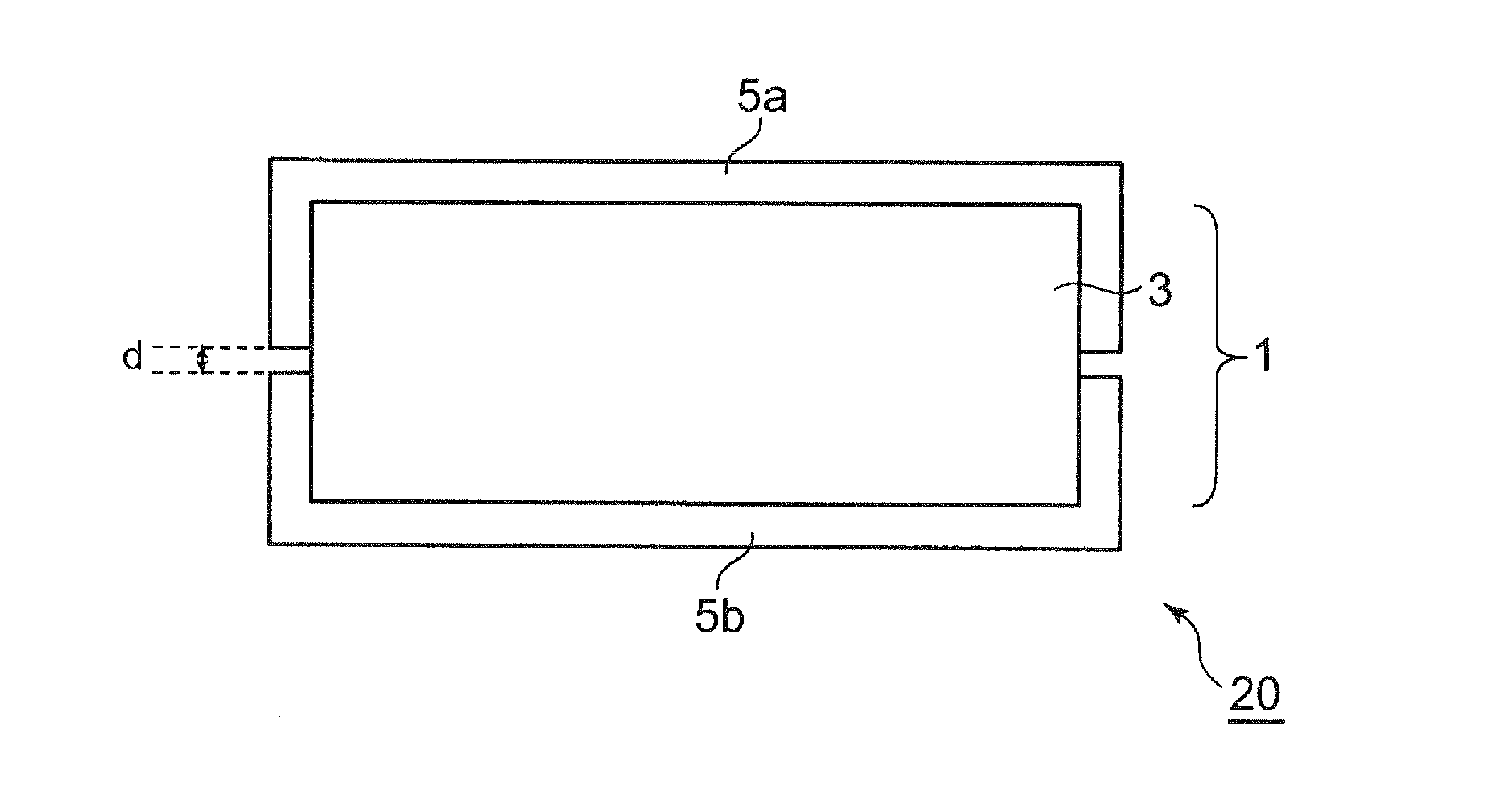

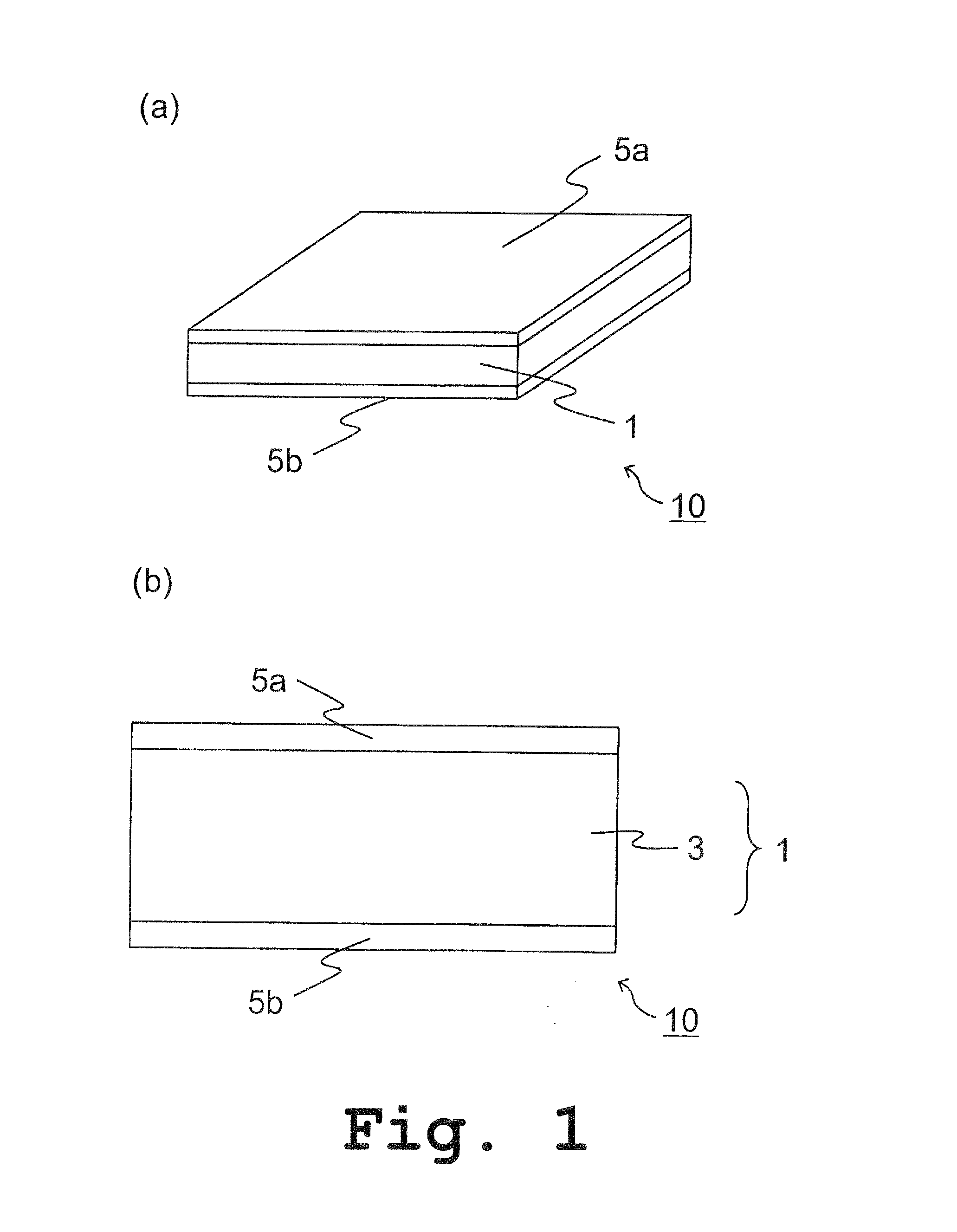

[0051]As shown in FIG. 1, a floor panel 10 as one embodiment according to the present invention comprises a foamed cement board 1; a top plate 5a attached to an upper surface the foamed cement board 1; and a bottom plate 5b attached to a lower surface of the foamed cement board 1. The floor panel 10 can be used such that the top plate 5a is located as a front surface (or a flooring surface) of the floor panel, and that the bottom plate 5b is located as a back surface of the floor panel.

[0052]In this embodiment, the foamed cement board 1 is comprised of a foamed cement layer 3. Herein, the top plate 5a and the bottom plate 5b are attached to an upper surface and a lower surface of the foamed cement layer 3, respectively. However, as long as the foamed cement board 1 comprises at least one foamed cement layer, the foamed cement board 1 may comprise other constituting part(s) (see, for example, Embodiment 2).

[0053]The foamed cement layer 3 is comprised of a material comprising at least...

embodiment 2

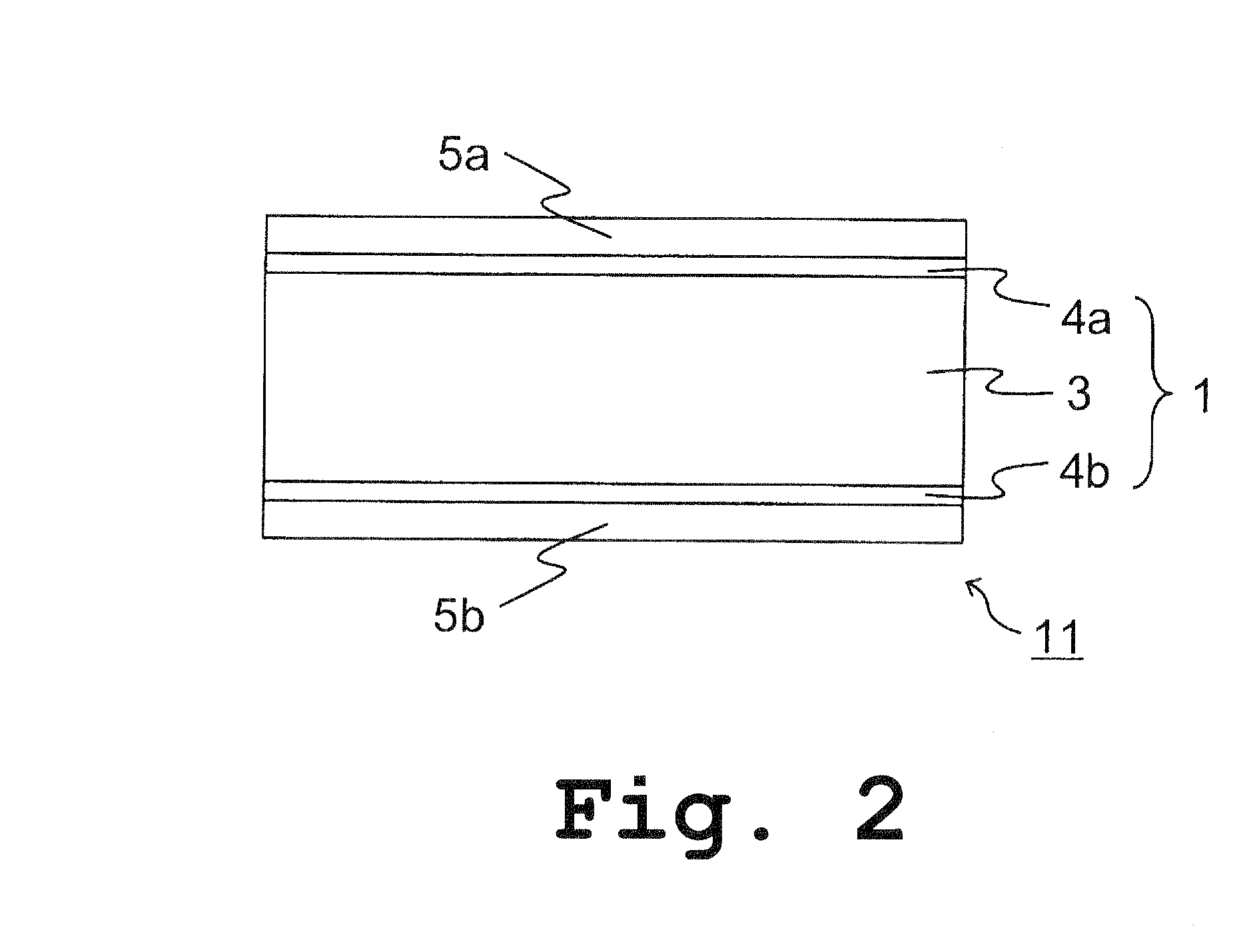

[0101]As shown in FIG. 2, the floor panel 11 according to this embodiment, which is same or similar to the floor panel 10 as Embodiment 1, comprises a foamed cement board 1; a top plate 5a attached to an upper surface of the foamed cement board 1; and a bottom plate 5b attached to a lower surface of the foamed cement board 1. The floor panel 11 may be used so that the top plate 5a is located as a front surface (or a flooring surface) of the floor panel and so that the bottom plate 5b is located as a back surface of the floor panel.

[0102]However, in this embodiment, the foamed cement board further comprises a fiber reinforced resin layers 4a formed on one side of the foamed cement layer 3 and a fiber reinforced resin layer 4b formed on the other side of the foamed cement layer 3, and the top plate 5a is attached to the fiber reinforced resin layer 4a and the bottom plate 5b is attached to the fiber reinforced resin layer 4b. These features are different from those of the floor panel ...

modification 1

[0119]The floor panel according to the present invention, more specifically, the floor panel as Embodiment 1 or 2 may have a planar configuration having a general square shape, for example, as a floor panel 13 illustrated in FIG. 3. The floor panel may have a configuration provided with cut-outs 7a on the four corners of the foamed cement board 1 (hereinafter, each of which may be referred to as a “corner-processed part 7a” or simply referred to as a “processed part 7a”).

[0120]In the case that a plurality of the floor panels are applied over a floor to constitute a free access flooring, it is to be considered that a single floor panel is one unit. The units form a grid constituted by the edges of the units (panels). A single supporting leg can be located at each lattice point of the grid. It is preferable that the planar configuration of the single floor panel as one unit has a square shape. In this case, at a single lattice point of the grid constituted by the edges of these units,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com